Pyrolysis of Rice Husk for the Production of Bioactive Compounds with Potential in Green Chemistry and Sustainable Agriculture

Abstract

1. Introduction

2. Results and Discussion

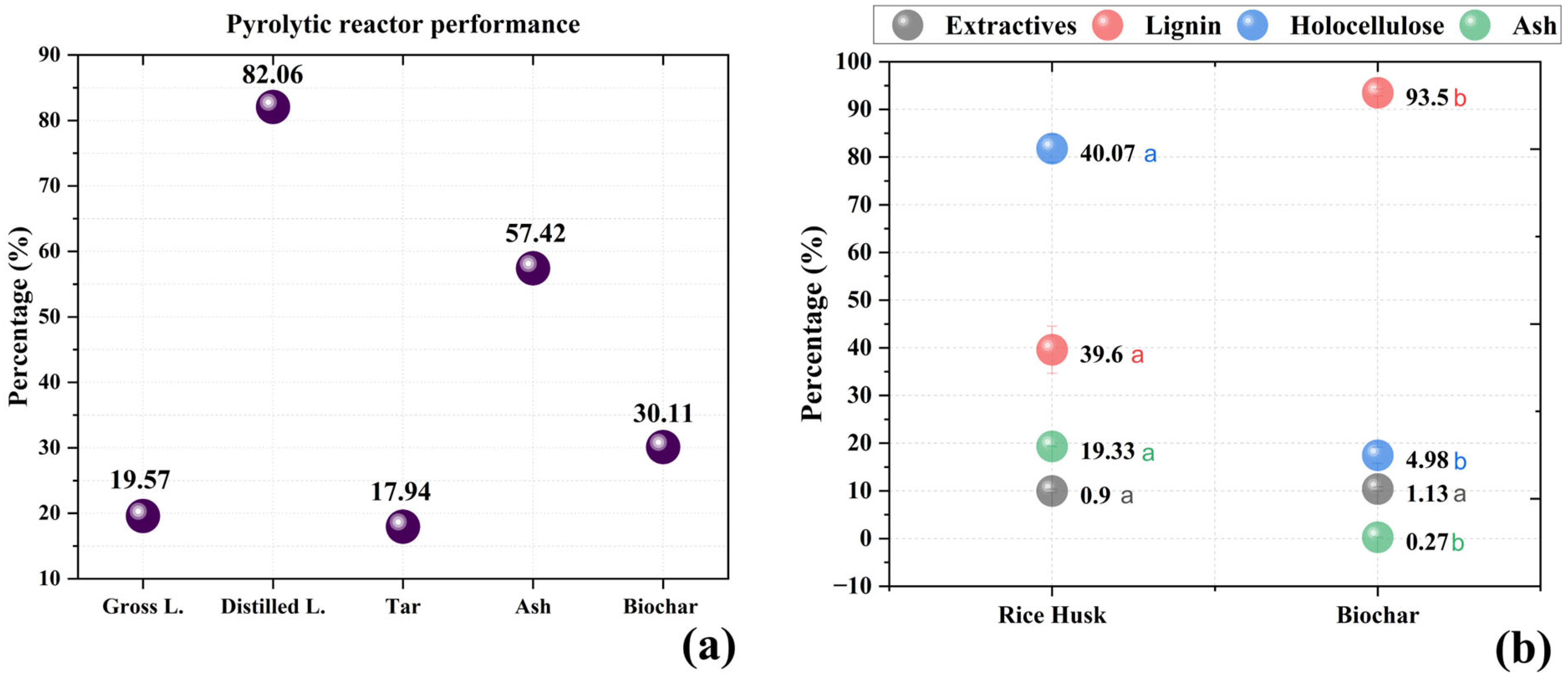

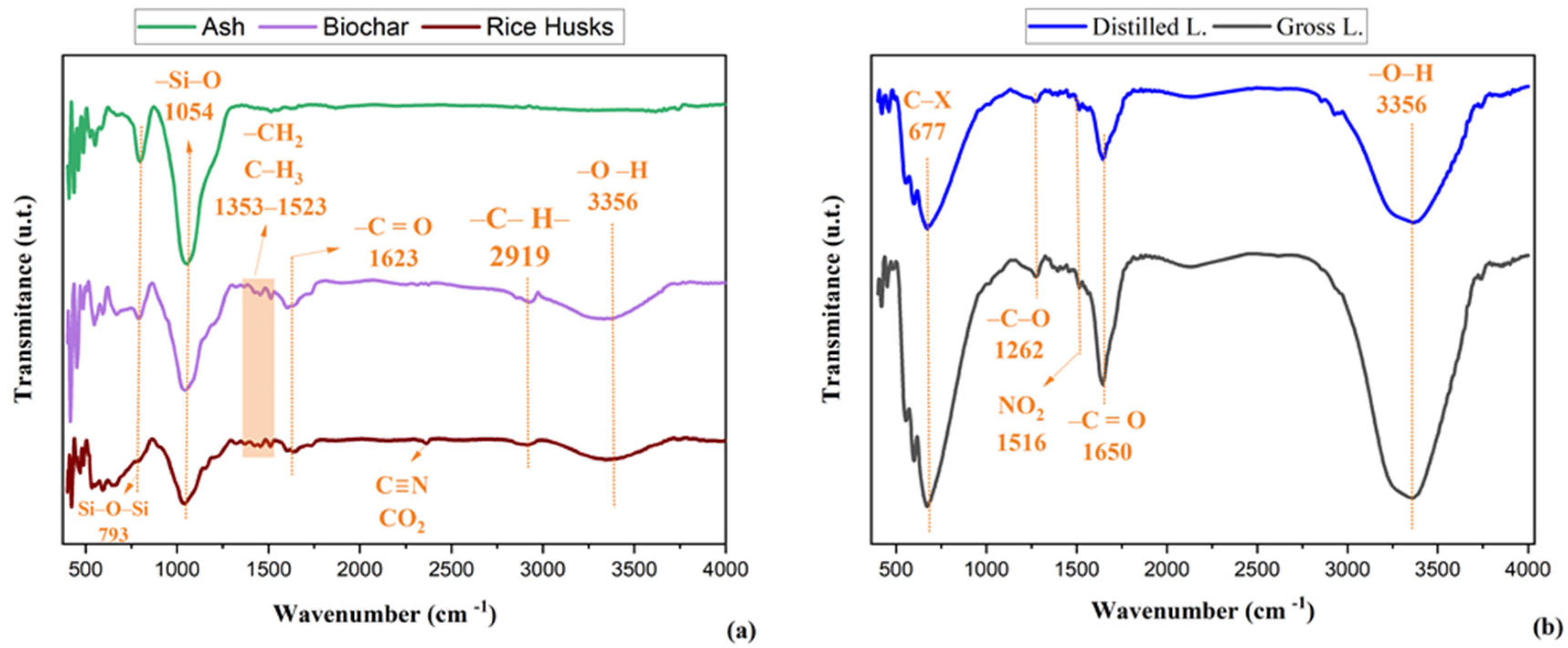

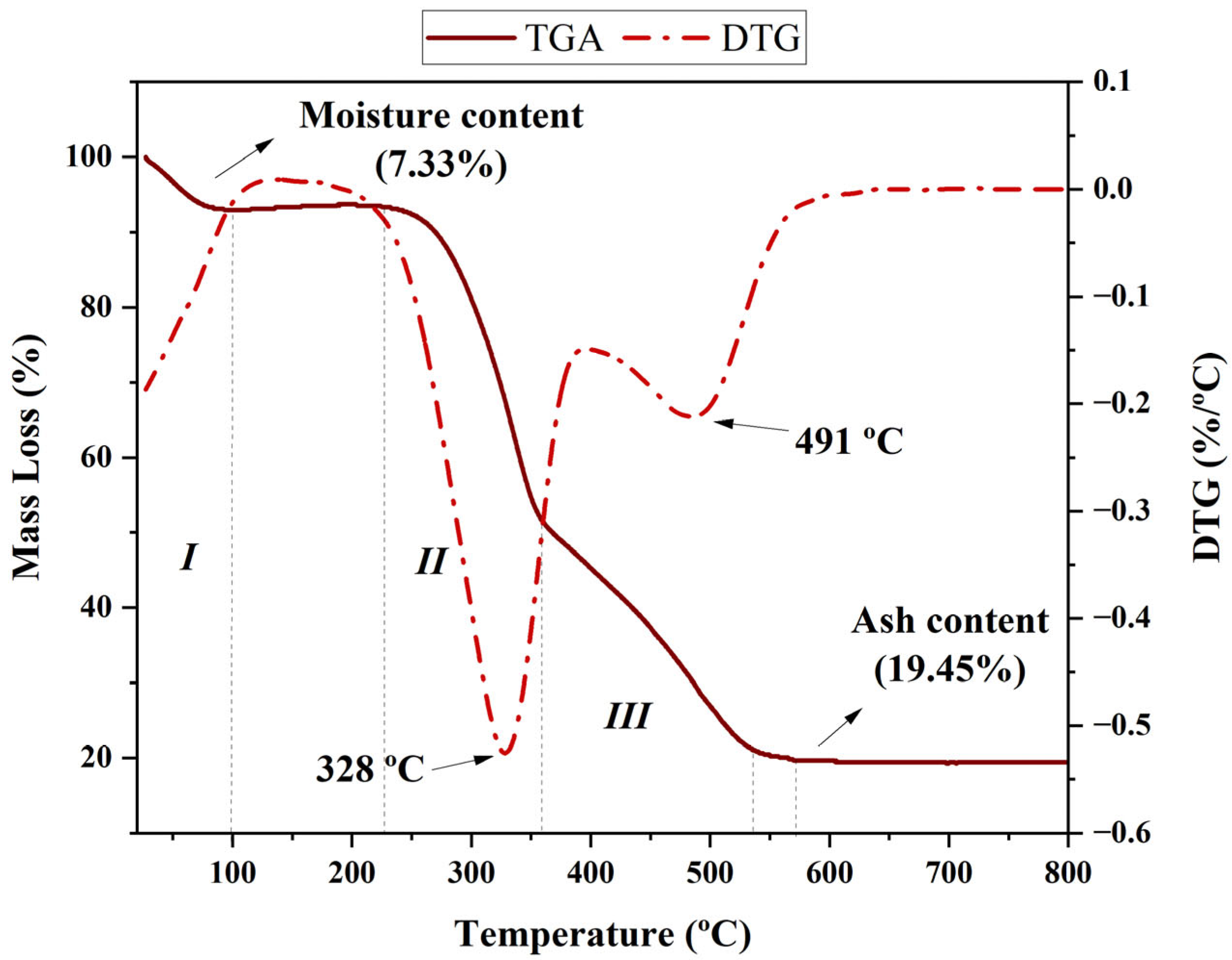

2.1. Slow Pyrolysis Process and Characterization

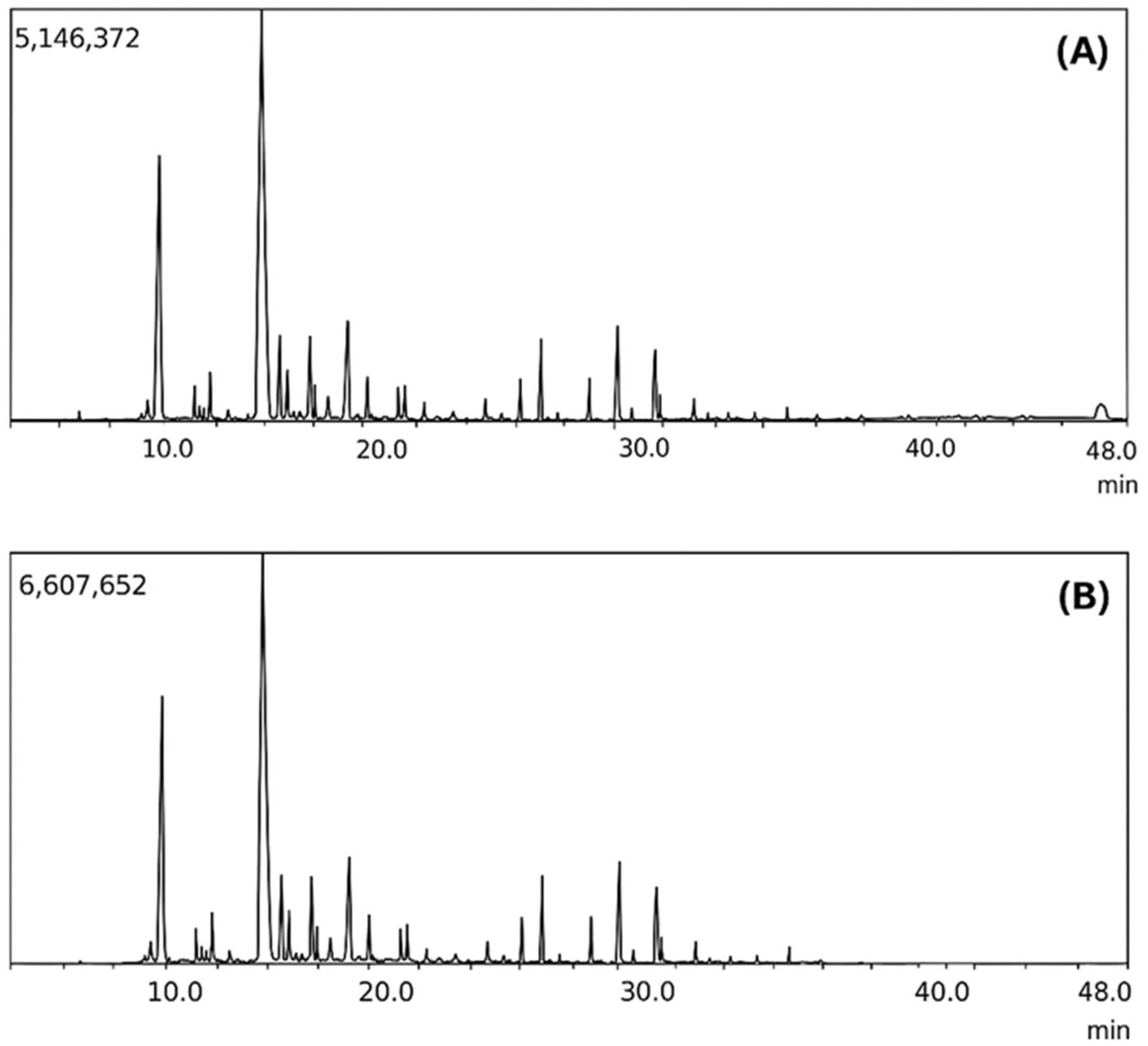

2.2. Liquid Fraction Analysis

2.3. Antioxidant Activity of the Liquid Fractions

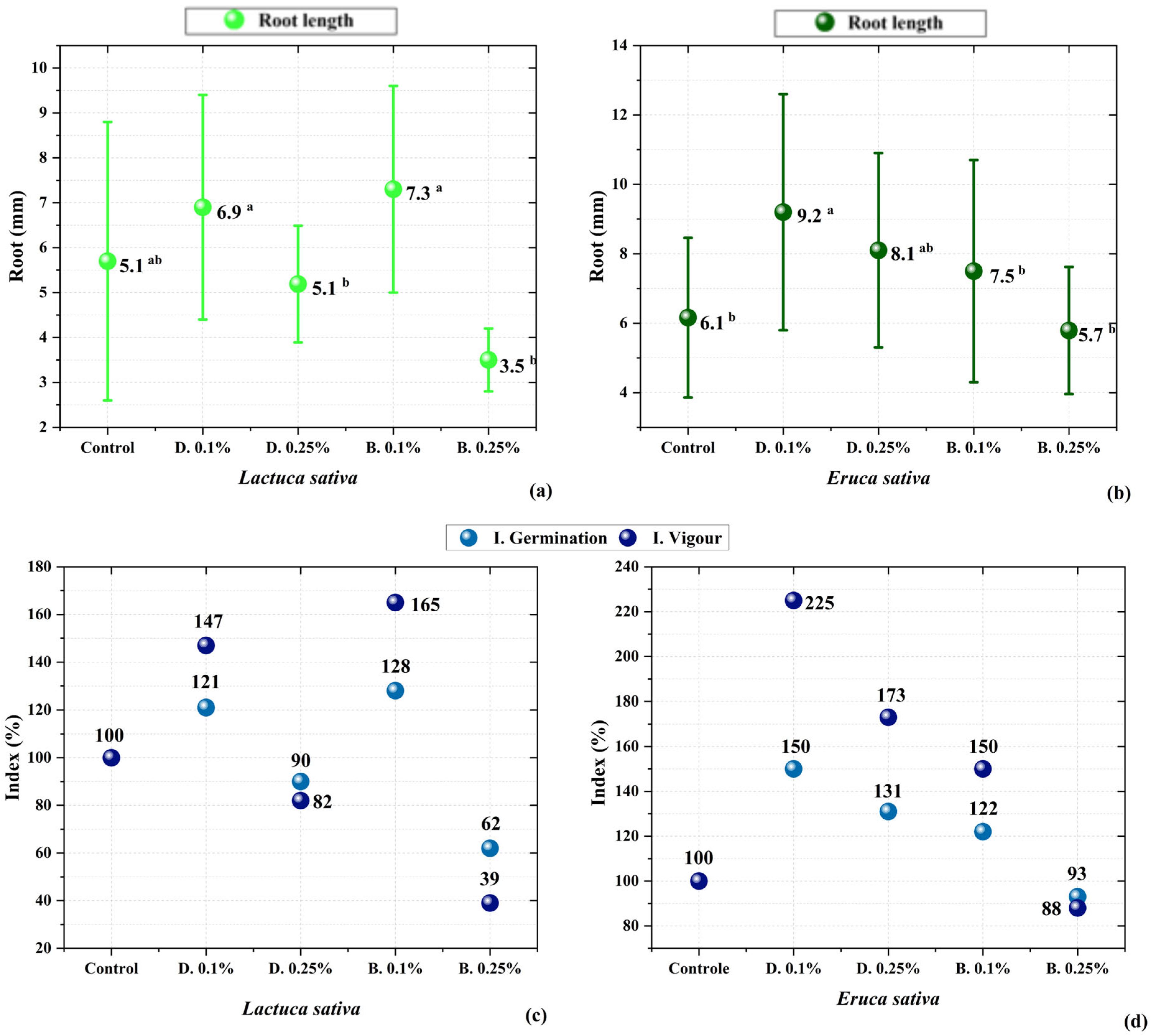

2.4. Evaluation of Plant Growth Stimulation

3. Materials and Methods

3.1. Raw Materials

3.2. Slow Pyrolysis Process

3.3. Chemical Characterisation of Rice Husk

3.4. Fourier-Transform Infrared Spectroscopy (FTIR)

3.5. Thermal Characterisation

3.6. Distillation of Pyroligneous

3.7. Chemical Analysis of Liquid Fractions

3.8. Antioxidant Activity of Liquid Fractions

3.8.1. Determination of Antioxidant Activity by the DPPH Method

3.8.2. Determination of Antioxidant Capacity by the FRAP Method

3.8.3. Quantification of Total Phenolic Compounds by the Folin–Ciocalteu Method

3.9. Bioactivity Assay

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DPPH | 2,2-Diphenyl-1-picrylhydrazyl |

| EC50 | Half Maximal Effective Concentration |

| EAG | Gallic Acid Equivalent |

| FRAP | Ferric Reducing Antioxidant Power |

| LD | Distilled Pyroligneous Liquid |

| LB | Crude Pyroligneous Liquid |

| TG | Thermogravimetric Analysis |

| Fe2+ | Ferrous Ion |

References

- Leung, D.Y.C.; Koo, B.C.P.; Guo, Y. Degradation of Biodiesel under Different Storage Conditions. Bioresour. Technol. 2006, 97, 250–256. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Chen, B.; Wang, J. Biochar and Its Impact on Soil Fertility and Plant Growth. J. Environ. Sci. 2011, 30, 45–57. [Google Scholar]

- Nishimura, H.; Saito, A.; Yamamoto, M. Effects of Phenolic Compounds on Root Development. J. Plant Biochem. 2017, 35, 214–227. [Google Scholar]

- Fiorio, M.S.; Butzge, J.C.; Apel, M.A. Chemical Composition, Production, Biological Properties, and Patent Registrations of Eucalyptus Spp. Pyroligneous Extract: A Systematic Review. J. Anal. Appl. Pyrolysis 2025, 190, 107155. [Google Scholar] [CrossRef]

- Huang, P.Q.; Boren, B.C.; Hegde, S.G.; Liu, H.; Unni, A.K.; Abraham, S.; Hopkins, C.D.; Paliwal, S.; Samatar, A.A.; Li, J.; et al. Discovery of ZN-C3, a Highly Potent and Selective Wee1 Inhibitor Undergoing Evaluation in Clinical Trials for the Treatment of Cancer. J. Med. Chem. 2021, 64, 13004–13024. [Google Scholar] [CrossRef]

- Prapagdee, B.; Rodtong, S.; Kuekulvong, C. Influence of Biochar and Wood Vinegar on Plant Growth. Environ. Sci. Biotechnol. 2021, 26, 287–300. [Google Scholar]

- Mathew, S.; Zakaria, Z.A. Pyroligneous Acid—The Smoky Acidic Liquid from Plant Biomass. Appl. Microbiol. Biotechnol. 2015, 99, 611–622. [Google Scholar] [CrossRef]

- Cândido, N.R.; Pasa, V.M.D.; Vilela, A.d.O.; Campos, Â.D.; de Fátima, Â.; Modolo, L.V. Understanding the Multifunctionality of Pyroligneous Acid from Waste Biomass and the Potential Applications in Agriculture. Sci. Total Environ. 2023, 881, 163519. [Google Scholar] [CrossRef]

- Wang, L.; Chen, S.; Xu, J. Chemical Characterization of Biochar from Agricultural Residues. Sustain. Energy Rev. 2019, 103, 503–515. [Google Scholar]

- Mu, J.; Guo, L.; Zhang, X. Evaluation of Pyrolytic Bio-Oils for Plant Growth Stimulation. J. Agric. Chem. 2003, 50, 1024–1030. [Google Scholar]

- Midhun Kumar, M.; Gurrala, L.; Paek, C.; Vinu, R. Selective Production of Guaiacol from Lignin via Catalytic Transfer Hydrogenolysis Using Ru-Cu/Zirconia. Mol. Catal. 2022, 530, 112532. [Google Scholar] [CrossRef]

- Mirhosseini, H.; Tan, C.; Hamid, N.; Yusof, S. Effect of Arabic Gum, Xanthan Gum and Orange Oil on Flavor Release from Diluted Orange Beverage Emulsion. Food Chem. 2007, 107, 1161–1172. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Sarsaiya, S.; Patel, A.; Juneja, A.; Singh, R.P.; Yan, B.; Awasthi, S.K.; Jain, A.; Liu, T.; Duan, Y.; et al. Refining Biomass Residues for Sustainable Energy and Bio-Products: An Assessment of Technology, Its Importance, and Strategic Applications in Circular Bio-Economy. Renew. Sustain. Energy Rev. 2020, 127, 109876. [Google Scholar] [CrossRef]

- Giraldo, L.; Moreno-Piraján, J.C. Exploring the Use of Rachis of Chicken Feathers for Hydrogen Storage. J. Anal. Appl. Pyrolysis 2013, 104, 243–248. [Google Scholar] [CrossRef]

- Cao, Y.; Chen, S.S.; Zhang, S.; Ok, Y.S.; Matsagar, B.M.; Wu, K.C.-W.; Tsang, D.C.W. Advances in Lignin Valorization towards Bio-Based Chemicals and Fuels: Lignin Biorefinery. Bioresour. Technol. 2019, 291, 121878. [Google Scholar] [CrossRef]

- Wang, Y.; Li, H.; Li, Y.; Guo, H.; Zhou, J.; Wang, T. Metagenomic Analysis Revealed Sources, Transmission, and Health Risk of Antibiotic Resistance Genes in Confluence of Fenhe, Weihe, and Yellow Rivers. Sci. Total Environ. 2023, 858, 159913. [Google Scholar] [CrossRef]

- Kuo, W.-P.; Kitamura, Y.; Hara, Y.; Hsieh, C.-C.; Lin, Y.-H.; Chen, C.-P. Pyroligneous Acid Produced by Rice Husk Using the Charcoal Processing System with Internal Combustion Furnace. Agric. Res. Technol. 2019, 23, 00344. [Google Scholar] [CrossRef]

- Al-Khalaf, M.N.; Yousif, H.A. Use of Rice Husk Ash in Concrete. Int. J. Cem. Compos. Lightweight Concr. 1984, 6, 241–248. [Google Scholar] [CrossRef]

- Ozturk, E.; Ince, C.; Derogar, S.; Ball, R. Factors Affecting the CO2 Emissions, Cost Efficiency and Eco-Strength Efficiency of Concrete Containing Rice Husk Ash: A Database Study. Constr. Build. Mater. 2022, 326, 126905. [Google Scholar] [CrossRef]

- Hayashi, K.; Ono, K.; Kajiura, M.; Sudo, S.; Yonemura, S.; Fushimi, A.; Saitoh, K.; Fujitani, Y.; Tanabe, K. Trace Gas and Particle Emissions from Open Burning of Three Cereal Crop Residues: Increase in Residue Moistness Enhances Emissions of Carbon Monoxide, Methane, and Particulate Organic Carbon. Atmos. Environ. 2014, 95, 36–44. [Google Scholar] [CrossRef]

- Ferrari, V.; Nazari, M.T.; da Silva, N.F.; Crestani, L.; Raymundo, L.M.; Dotto, G.L.; Piccin, J.S.; Oliveira, L.F.S.; Bernardes, A.M. Pyrolysis: A Promising Technology for Agricultural Waste Conversion into Value-Added Products. Environ. Dev. Sustain. 2024. [Google Scholar] [CrossRef]

- Schmidt, H.; Anca-Couce, A.; Hagemann, N.; Werner, C.; Gerten, D.; Lucht, W.; Kammann, C. Pyrogenic Carbon Capture and Storage. GCB Bioenergy 2019, 11, 573–591. [Google Scholar] [CrossRef]

- Fedeli, R.; Zhatkanbayeva, Z.; Loppi, S. Soil Amendment with Biochar from Slaughterhouse Waste Bones Enhances Soil Quality and Promotes the Growth of Crop Plants. Plant Biosyst.-Int. J. Deal. All Asp. Plant Biol. 2025, 159, 378–386. [Google Scholar] [CrossRef]

- Joshi, G.; Chaudhuri, S. Biopesticides from Agricultural and Forest Biomass. In Agricultural and Forest Biomass Waste for Biorefineries; Royal Society of Chemistry: London, UK, 2025; pp. 316–356. [Google Scholar]

- Organização Das Nações Unidas (ONU) Objetivos de Desenvolvimento Sustentável (ODS). Available online: https://brasil.un.org/pt-br/sdgs (accessed on 6 June 2025).

- Pimenta, A.; Fasciotti, M.; Monteiro, T.; Lima, K. Chemical Composition of Pyroligneous Acid Obtained from Eucalyptus GG100 Clone. Molecules 2018, 23, 426. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Ibáñez, S.; Sirvent, A.; Yus, M.; Foubelo, F. Stereoselective Synthesis of 1-Substituted Homotropanones, Including Natural Alkaloid (−)-Adaline. Molecules 2023, 28, 2414. [Google Scholar] [CrossRef]

- Mati, A.; Buffi, M.; Dell’Orco, S.; Lombardi, G.; Ruiz Ramiro, P.; Kersten, S.; Chiaramonti, D. Fractional Condensation of Fast Pyrolysis Bio-Oil to Improve Biocrude Quality towards Alternative Fuels Production. Appl. Sci. 2022, 12, 4822. [Google Scholar] [CrossRef]

- Yang, J.-F.; Yang, C.-H.; Liang, M.-T.; Gao, Z.-J.; Wu, Y.-W.; Chuang, L.-Y. Chemical Composition, Antioxidant, and Antibacterial Activity of Wood Vinegar from Litchi Chinensis. Molecules 2016, 21, 1150. [Google Scholar] [CrossRef]

- Loo, A.Y.; Jain, K.; Darah, I. Antioxidant Activity of Compounds Isolated from the Pyroligneous Acid, Rhizophora apiculata. Food Chem. 2008, 107, 1151–1160. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of Hemicellulose, Cellulose and Lignin Pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Springer, N. Chemical and Spectral Analysis of Biochar from Biomass Pyrolysis. J. Anal. Chem. 2023, 55, 342–356. [Google Scholar]

- Mavroulidou, M.; Hughes, S.J.; Hellawell, E.E. Developing the Interaction Matrix Technique as a Tool Assessing the Impact of Traffic on Air Quality. J. Environ. Manag. 2007, 84, 513–522. [Google Scholar] [CrossRef] [PubMed]

- Mashuni, M.; Kadidae, L.O.; Jahiding, M.; Hamid, F.H.; Kadir, W.A.; Khaeri, A.M.N. Chemical Characterization and Antibacterial Activities of Bio-oil from Durian Shell Pyrolysis. J. Kim. Val. 2024, 10, 86–96. [Google Scholar] [CrossRef]

- Sun, Y.; Gao, B.; Yao, Y.; Fang, J.; Zhang, M.; Zhou, Y.; Chen, H.; Yang, L. Effects of Feedstock Type, Production Method, and Pyrolysis Temperature on Biochar and Hydrochar Properties. Chem. Eng. J. 2014, 240, 574–578. [Google Scholar] [CrossRef]

- Lin, H.; Xu, J.; Sun, W.; Hu, W.; Gao, H.; Hu, K.; Qiu, J.; Huang, B.; Zhang, L. Efficient 1-Hydroxy-2-Butanone Production from 1,2-Butanediol by Whole Cells of Engineered E. coli. Catalysts 2021, 11, 1184. [Google Scholar] [CrossRef]

- Mujtaba, G.; Hayat, R.; Hussain, Q.; Ahmed, M. Physio-Chemical Characterization of Biochar, Compost and Co-Composted Biochar Derived from Green Waste. Sustainability 2021, 13, 4628. [Google Scholar] [CrossRef]

- Rehrah, D.; Reddy, M.R.; Novak, J.M.; Bansode, R.R.; Schimmel, K.A.; Yu, J.; Watts, D.W.; Ahmedna, M. Production and Characterization of Biochars from Agricultural By-Products for Use in Soil Quality Enhancement. J. Anal. Appl. Pyrolysis 2014, 108, 301–309. [Google Scholar] [CrossRef]

- Blenis, N.; Hue, N.; Maaz, T.M.; Kantar, M. Biochar Production, Modification, and Its Uses in Soil Remediation: A Review. Sustainability 2023, 15, 3442. [Google Scholar] [CrossRef]

- Tan, Z.; Li, Y.; Chen, F.; Liu, J.; Zhong, J.; Guo, L.; Zhang, R.; Chen, R. Challenges and Perspectives of the Conversion of Lignin Waste to High-Value Chemicals by Pyrolysis. Processes 2024, 12, 589. [Google Scholar] [CrossRef]

- Keiluweit, M.; Nico, P.S.; Johnson, M.; Kleber, M. Dynamic Molecular Structure of Plant Biomass-Derived Black Carbon (Biochar). Environ. Sci. Technol. 2010, 44, 1247–1253. [Google Scholar] [CrossRef]

- Gai, X.; Wang, H.; Liu, J.; Zhai, L.; Liu, S.; Ren, T.; Liu, H. Effects of Feedstock and Pyrolysis Temperature on Biochar Adsorption of Ammonium and Nitrate. PLoS ONE 2014, 9, e113888. [Google Scholar] [CrossRef] [PubMed]

- Wu, H. Surface Properties of Biochar from Rice Husk Pyrolysis. BioResources 2018, 13, 5460–5477. [Google Scholar]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar Physicochemical Properties: Pyrolysis Temperature and Feedstock Kind Effects. Rev. Environ. Sci. Biotechnol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Singh, B.; Fang, Y.; Cowie, B.C.C.; Thomsen, L. NEXAFS and XPS Characterisation of Carbon Functional Groups of Fresh and Aged Biochars. Org. Geochem. 2014, 77, 1–10. [Google Scholar] [CrossRef]

- Severo, F.F.; da Silva, L.S.; Moscôso, J.S.C.; Sarfaraz, Q.; Rodrigues Júnior, L.F.; Lopes, A.F.; Marzari, L.B.; Molin, G.D. Chemical and Physical Characterization of Rice Husk Biochar and Ashes and Their Iron Adsorption Capacity. SN Appl. Sci. 2020, 2, 1286. [Google Scholar] [CrossRef]

- Drugkar, K.; Rathod, W.; Sharma, T.; Sharma, A.; Joshi, J.; Pareek, V.K.; Ledwani, L.; Diwekar, U. Advanced Separation Strategies for Up-Gradation of Bio-Oil into Value-Added Chemicals: A Comprehensive Review. Sep. Purif. Technol. 2022, 283, 120149. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, L.; Chen, G.; Wu, L.; Liu, B.; Li, Y.; Sun, S.; Zhang, H.; Zhang, Z.; Wang, Z. A New Method for Comprehensive Utilization of Wood Vinegar by Distillation and Liquid−liquid Extraction. Process Biochem. 2018, 75, 194–201. [Google Scholar] [CrossRef]

- Forbes, S.L.; Pradhan, S.; Savage, P.E. Thermal Stability of Fractionated Bio-Oil from Fast Pyrolysis. Energy Fuels 2016, 30, 1234–1242. [Google Scholar] [CrossRef]

- Duan, Y.; Duan, L.; Wang, J.; Anthony, E.J. Observation of Simultaneously Low CO, NOx and SO2 Emission during Oxy-Coal Combustion in a Pressurized Fluidized Bed. Fuel 2019, 242, 374–381. [Google Scholar] [CrossRef]

- Ameloot, N.; Graber, E.R.; Verheijen, F.; De Neve, S. Effect of Biochar on Abiotic and Biotic Degradation of Halogenated Organic Compounds in Soil. Environ. Int. 2022, 160, 107–118. [Google Scholar]

- Ye, Z.; Liu, L.; Tan, Z.; Zhang, L.; Huang, Q. Effects of Pyrolysis Conditions on Migration and Distribution of Biochar Nitrogen in the Soil-Plant-Atmosphere System. Sci. Total Environ. 2020, 723, 138006. [Google Scholar] [CrossRef]

- Rambo, M.K.D.; Barin, J.S.; Souza, I.G. Estudo de Análise Termogravimétrica de Diferentes Biomassas Lignocelulósicas Utilizando a Análise Por Componentes Principais. Ciênc. Nat. 2015, 37, 862–868. [Google Scholar] [CrossRef]

- Santos, N.A.d. Análise Termogravimétrica da Biomassa e Seus Compostos (Celulose, Hemicelulose e Lignina). Master’s Thesis, University Federal São Carlos, São Carlos, Brazil, 2021. [Google Scholar]

- Brebu, M.; Vasile, C. Thermal Degradation of Lignin—A Review. Cellul. Chem. Technol. 2010, 44, 353–363. [Google Scholar]

- Kumar, A.; Singh, B.; Mishra, S. Effect of Pyrolysis Temperature on Chemical Composition of Biochar from Rice Straw and Its Influence on Silica Enrichment. J. Chem. Eng. Process Technol. 2020, 7, 1–6. [Google Scholar]

- López-González, D.; Fernández-Llorente, M.J.; Valverde, J.L.; Sánchez-Silva, L. Pyrolysis of Two Agricultural Resi-Dues: Chemical Composition and Kinetic Behavior. Anal. Appl. Pyrolysis 2013, 104, 207–213. [Google Scholar]

- Bridgwater, A.V. Review of Fast Pyrolysis of Biomass and Product Upgrading. Biomass Bioenergy 2021, 38, 68–94. [Google Scholar] [CrossRef]

- Demirbas, A. Pyrolysis of Biomass for Fuels and Chemicals. Energy Convers. Manag. 2020, 210, 112321. [Google Scholar] [CrossRef]

- Shafizadeh, F.; Chin, P.P.S.; Zaman, J. Thermal Degradation of 2-Hydroxypropanone and Related Carbonyl Compounds. J. Anal. Appl. Pyrolysis 2019, 138, 143–150. [Google Scholar] [CrossRef]

- Mungkunkamchao, T. Furfural Effects on Plant Growth and Stress Resistance. J. Plant Sci. 2013, 30, 84–95. [Google Scholar]

- Scitotenv, J. Characterization and Application of Biochar for Soil Amendments. Sci. Total Environ. 2023, 859, 159913. [Google Scholar]

- Hidayati, N.; Mahajoeno, E.; Saragih, B. Role of Organic Acids in Root Development under Stress Conditions. Plant Physiol. Biochem. 2016, 104, 42–50. [Google Scholar] [CrossRef]

- Fabiyi, O.A. Application of Furfural in Sugarcane Nematode Pest Management. Pak. J. Nematol. 2021, 39, 68–159. [Google Scholar] [CrossRef]

- Crops, J. Effects of Biochar on Soil Properties and Plant Growth. J. Agric. Sci. 2024, 32, 102–115. [Google Scholar]

- Metabo, L. Chemical Characterization of Bioactive Compounds in Plant-Derived Extracts. Metabolomics J. 2023, 19, 145–160. [Google Scholar]

- Horticulturae, A. Characterization of Wood Vinegar Fractions Using FTIR and Their Correlation with Bioactivity. Acta Hortic. 2023, 1379, 211–220. [Google Scholar]

- Sciappl, L. Applications of Pyrolytic Biochar in Sustainable Agriculture. Sci. Appl. J. 2024, 12, 122–136. [Google Scholar]

- Bhoi, P.R.; Huhnke, R.L.; Kumar, A.; Patil, K.N.; Whiteley, J.R. Design and Development of a Bench Scale Vegetable Oil Based Wet Packed Bed Scrubbing System for Removing Producer Gas Tar Compounds. Fuel Process. Technol. 2015, 134, 243–250. [Google Scholar] [CrossRef]

- Wei, Q.; Ma, X.; Zhao, Z.; Zhang, S.; Liu, S. Antioxidant Activities and Chemical Profiles of Pyroligneous Acids from Walnut Shell. J. Anal. Appl. Pyrolysis 2010, 88, 149–154. [Google Scholar] [CrossRef]

- Gao, T.; Zhang, Y.; Shi, J.; Mohamed, S.R.; Xu, J.; Liu, X. The Antioxidant Guaiacol Exerts Fungicidal Activity Against Fungal Growth and Deoxynivalenol Production in Fusarium Graminearum. Front. Microbiol. 2021, 12, 762844. [Google Scholar] [CrossRef]

- Yong, K.J.; Wu, T.Y.; Lee, C.B.T.L.; Lee, Z.J.; Liu, Q.; Jahim, J.M.; Zhou, Q.; Zhang, L. Furfural Production from Biomass Residues: Current Technologies, Challenges and Future Prospects. Biomass Bioenergy 2022, 161, 106458. [Google Scholar] [CrossRef]

- Xue, R.; Cui, E.-L.; Hu, G.-Q.; Zhu, M.-Q. The Composition, Physicochemical Properties, Antimicrobial and Antioxidant Activity of Wood Vinegar Prepared by Pyrolysis of Eucommia Ulmoides Oliver Branches under Different Refining Methods and Storage Conditions. Ind. Crops Prod. 2022, 178, 114586. [Google Scholar] [CrossRef]

- Sun, X.; Sarteshnizi, R.A.; Udenigwe, C.C. Recent Advances in Protein–Polyphenol Interactions Focusing on Structural Properties Related to Antioxidant Activities. Curr. Opin. Food Sci. 2022, 45, 100840. [Google Scholar] [CrossRef]

- Lee, J.K.; Park, H.J.; Cha, S.J.; Kwon, S.J.; Park, J.H. Effect of Pyroligneous Acid on Soil Urease, Amidase, and Nitrogen Use Efficiency by Chinese Cabbage (Brassica campestris var. Pekinensis). Environ. Pollut. 2021, 291, 118132. [Google Scholar] [CrossRef]

- Pulido, R.; Bravo, L.; Saura-Calixto, F. Antioxidant Activity of Dietary Polyphenols As Determined by a Modified Ferric Reducing/Antioxidant Power Assay. J. Agric. Food Chem. 2000, 48, 3396–3402. [Google Scholar] [CrossRef] [PubMed]

- Silva, F.T.; Gomes, A.C.; Ramos, L. Bioactive Compounds in Wood Vinegar and Their Effects on Plant Growth. Braz. J. Agric. Sci. 2023, 45, 87–101. [Google Scholar]

- Zhou, H.; Guo, J.; Liu, H.; Wang, J.; Wang, Y. Effects of Biochar Pyrolysis Temperature and Application Rate on Saline Soil Quality and Maize Yield. Agronomy 2024, 14, 1529. [Google Scholar] [CrossRef]

- TAPPI T 257; Sampling and Preparing Wood for Analysis. Technical Association of the Pulp and Paper Industry: Atlanta, GA, USA, 2002.

- TAPPI T 204 Cm-17; Solvent Extractives of Wood and Pulp. Technical Association of the Pulp and Paper Industry: Atlanta, GA, USA, 2017.

- TAPPI T 222 Om-02; Acid-Insoluble Lignin in Wood and Pulp. Technical Association of the Pulp and Paper Industry: Atlanta, GA, USA, 2002.

- TAPPI T 9 Wd-75; Holocellulose in Wood and Pulp. Technical Association of the Pulp and Paper Industry: Atlanta, GA, USA, 1975.

- ASTM D1762-84; Standard Test Method for Chemical Analysis of Wood Charcoal. ASTM International: West Conshohocken, PA, USA, 2007.

- Pinheiro Pires, A.P.; Arauzo, J.; Fonts, I.; Domine, M.E.; Fernández Arroyo, A.; Garcia-Perez, M.E.; Montoya, J.; Chejne, F.; Pfromm, P.; Garcia-Perez, M. Challenges and Opportunities for Bio-Oil Refining: A Review. Energy Fuels 2019, 33, 4683–4720. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a Free Radical Method to Evaluate Antioxidant Activity. LWT Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Sánchez-Moreno, C.; Larrauri, J.A.; Saura-Calixto, F. A Procedure to Measure the Antiradical Efficiency of Polyphenols. J. Sci. Food Agric. 1998, 76, 270–276. [Google Scholar] [CrossRef]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of Total Phenols and Other Oxidation Substrates and Antioxidants by Means of Folin-Ciocalteu Reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar] [CrossRef]

| Compound | Formula | Crude (%) | Distilled (%) |

|---|---|---|---|

| Pyridine | C5H5N | 0.42 | – |

| 2-Methylpyridine | C6H7N | 0.08 | – |

| Formamide | CH3NO | 0.06 | – |

| 1,6-Heptadien-4-ol | C7H12O | 0.06 | – |

| Butanoic acid, 2-propenyl ester | C7H12O2 | 0.11 | 0.06 |

| 2-Butanone, 3-hydroxy- | C4H8O2 | 0.46 | 0.75 |

| 2-Propanone, 1-hydroxy- | C3H6O2 | 11.69 | 14.5 |

| Furan, 2-methyl- | C5H6O | 1.09 | 2.09 |

| 2-Cyclopenten-1-one, 2-methyl- | C6H8O | 0.17 | – |

| 1-Hydroxy-2-butanone | C4H8O2 | 1.33 | 51.53 |

| Acetic acid | C2H4O2 | 52.84 | – |

| Furfural | C5H4O2 | 1.37 | 2.92 |

| 2-Propanone, 1-(acetyloxy)- | C5H8O3 | 2.18 | – |

| Formic acid | CH2O2 | 2.85 | 2.97 |

| 2,5-Hexanedione | C6H10O2 | 0.42 | – |

| 2-Cyclopenten-1-one, 3-methyl- | C6H8O | 0.37 | – |

| Propanoic acid | C3H6O2 | 2.49 | 3.96 |

| Butyrolactone | C4H6O2 | 0.79 | 0.36 |

| Butanoic acid | C4H8O2 | 0.69 | – |

| 3-Hexen-2-one, 3-methyl- | C7H12O | 0.11 | 0.27 |

| 2-Furanmethanol | C5H6O2 | 0.31 | – |

| 2(5H)-Furanone, 3-methyl- | C5H6O2 | 0.13 | – |

| 2(5H)-Furanone | C4H4O2 | 0.34 | – |

| Crotonic acid | C4H6O2 | 0.26 | 0.30 |

| 1,2-Cyclopentanedione, 3-methyl- | C6H8O2 | 1.5 | 0.55 |

| Phenol, 2-methoxy- | C7H8O2 | 2.5 | 3.46 |

| 2-Cyclopenten-1-one, 3-ethyl-2-hydroxy- | C7H10O2 | 0.18 | – |

| Phenol, 2-methoxy-4-methyl- | C8H10O2 | 1.4 | 1.4 |

| Carbamic acid, phenyl ester | C7H7NO2 | 2.99 | 3.42 |

| Phenol, 4-ethyl-2-methoxy- | C9H12O2 | 0.28 | – |

| Cyclopropyl carbinol | C4H8O | 2.57 | – |

| Phenol, 2-methyl- | C7H8O | 0.72 | 1.04 |

| 2-Hydroxy-gamma-butyrolactone | C4H6O3 | 0.34 | – |

| 1,6-Anhydro-beta-D-glucopyranose | C6H10O5 | 1.35 | – |

| 4-Pentenal | C5H8O | – | 0.14 |

| Butanal, 3-methyl- | C5H10O | – | 0.14 |

| 1,4-Butanediol, 2,3-bis(methylene)- | C6H10O2 | – | 0.82 |

| 1,2-Epoxy-3-propyl acetate | C5H8O3 | – | 2.09 |

| 1-Octen-3-yl-acetate | C10H18O2 | – | 0.65 |

| 3-Pentanone, 2-methyl- | C6H12O | – | 0.17 |

| Hexanoic acid | C6H12O2 | – | 0.94 |

| N-carbobenzyloxy-l-tyrosyl-l-valine | C22H26N2O6 | – | 0.44 |

| Phenol, 3-ethyl- | C8H10O | 0.53 | 0.76 |

| Method | Crude | Tar | Distillate |

|---|---|---|---|

| DPPH (EC50 µg/mL) | 7.881 ± (3.43) b | 216.78 ± (40.10) a | 10.98 ± (2.30) b |

| FRAP (µM Fe2+/g) | 7.62 ± (3.38) b | 6.08 ± (0.25) b | 23.40 ± (1.14) a |

| Total phenolics (mg/mL) | 713.72 ± (6.17) c | 729.25 ± (7.55) c | 708.38 ± (1.37) c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goularte, M.d.P.; de Sousa, Á.F.; Cholant, C.; Romano, L.; Labidi, J.; Missio, A.L.; Acosta, A.; Gatto, D.A. Pyrolysis of Rice Husk for the Production of Bioactive Compounds with Potential in Green Chemistry and Sustainable Agriculture. Molecules 2025, 30, 2754. https://doi.org/10.3390/molecules30132754

Goularte MdP, de Sousa ÁF, Cholant C, Romano L, Labidi J, Missio AL, Acosta A, Gatto DA. Pyrolysis of Rice Husk for the Production of Bioactive Compounds with Potential in Green Chemistry and Sustainable Agriculture. Molecules. 2025; 30(13):2754. https://doi.org/10.3390/molecules30132754

Chicago/Turabian StyleGoularte, Matheus de Paula, Ávila Ferreira de Sousa, Camila Cholant, Lucas Romano, Jalel Labidi, André Luiz Missio, Andrey Acosta, and Darci Alberto Gatto. 2025. "Pyrolysis of Rice Husk for the Production of Bioactive Compounds with Potential in Green Chemistry and Sustainable Agriculture" Molecules 30, no. 13: 2754. https://doi.org/10.3390/molecules30132754

APA StyleGoularte, M. d. P., de Sousa, Á. F., Cholant, C., Romano, L., Labidi, J., Missio, A. L., Acosta, A., & Gatto, D. A. (2025). Pyrolysis of Rice Husk for the Production of Bioactive Compounds with Potential in Green Chemistry and Sustainable Agriculture. Molecules, 30(13), 2754. https://doi.org/10.3390/molecules30132754