Abstract

Three-dimensional printing, particularly Fused Deposition Modeling (FDM), has revolutionized dermatological drug delivery by offering the ability to create personalized and precise drug formulations. This technology enables the design of customized drug delivery systems using a variety of polymers, such as Polylactic Acid (PLA), Polyvinyl Alcohol (PVA), Polyethylene Glycol (PEG), and Polycaprolactone (PCL), each with unique properties that enhance drug release, patient compliance, and treatment efficacy. This review analyzes these polymers in terms of their advantages, limitations, and suitability for dermatological applications. The ability to tailor these materials offers significant potential in overcoming treatment regimens. Additionally, the customization of three-dimensional-printed drug delivery systems provides a platform for creating patient-specific solutions that are more effective and adaptable to individual needs. Despite challenges such as moisture sensitivity and mechanical brittleness, the potential of FDM technology to improve dermatological treatments remains promising. The future of three-dimensional printing in dermatology lies in the integration of optimized materials and advanced printing techniques, which could further enhance patient-specific care and broaden the clinical applicability of these technologies in the pharmaceutical and biomedical sectors. By addressing these limitations and expanding material choices, FDM-based drug delivery systems have the potential to revolutionize the management of dermatological conditions, offering improved therapeutic outcomes and quality of life for patients.

1. Background

The integration of 3D printing technology, particularly Fused Deposition Modeling (FDM), has revolutionized the field of dermatological drug delivery. This advancement offers unparalleled potential for the customization of drug delivery systems, addressing specific patient needs while optimizing therapeutic outcomes. Dermatological conditions, affecting a significant portion of the global population, present diverse challenges ranging from treatment adherence to drug delivery efficiency. Traditional topical therapies are limited by the skin’s barrier properties, requiring novel solutions for improved drug penetration and sustained release.

Existing literature underscores the potential of 3D printing in healthcare, with FDM emerging as a versatile technique for creating drug-loaded devices [1]. Polymers such as PLA, PVA, PCL, and chitosan have been explored for their unique properties in fabricating dermatological preparations. However, there remains a gap in systematically evaluating the suitability of various FDM-compatible polymers for dermatological applications, particularly in overcoming limitations such as moisture sensitivity, mechanical brittleness, and drug delivery efficiency.

This review aims to bridge this gap by providing a comprehensive analysis of filaments used in FDM for dermatological preparations by examining the properties, drug-loading capacities, and practical applications of these materials. The insights gained here are poised to support the broader adoption of FDM technology in dermatology, fostering innovation and improving patient outcomes.

2. Introduction

Three-dimensional printing technology has revolutionized the healthcare fields including pharmaceutical science, offering innovative solutions for personalized medicine [2]. In dermatology, 3D printing enables the creation of customized drug delivery systems that can be tailored to disease conditions and individual patient requirements. A study demonstrated that 3D-printed microneedle arrays enhance transdermal drug delivery by improving skin penetration and controlled drug release, while personalized wound dressings fabricated via 3D printing provide optimized hydration and drug release profiles for enhanced healing [1]. This review focuses on the filaments used in 3D printing for topical drug delivery systems by the Fused Deposition Modeling Method, examining their properties, drug-loading capacities, and their applications.

2.1. The Impact of Dermatological Diseases and Disorders

Dermatological disorders represent a substantial portion of the global burden of disease, affecting individuals across various age groups and demographics. These conditions range from common ailments like acne and eczema to more severe disorders such as psoriasis. The prevalence of skin diseases is widespread and continues to increase worldwide, creating profound implications for physical health, quality of life, and healthcare systems [3].

A comprehensive report from the Global Burden of Disease Study (GBD) indicated that approximately 1.9 billion individuals, or nearly 25% of the global population, are affected by at least one skin disease at any given time [4]. Acne vulgaris, which predominantly affects adolescents, has been identified as one of the most prevalent dermatological conditions, with a global incidence rate of approximately 9.4% [5]. Eczema (atopic dermatitis) affects 15–20% of children and 1–3% of adults worldwide, making it another major concern in dermatology [6]. Psoriasis, a chronic autoimmune disorder, affects around 2–4% of the global population, equating to more than 125 million individuals [7]. Melanoma of the skin accounted for approximately 287,723 new cases and 60,712 deaths worldwide in 2018, making it the 19th most commonly diagnosed cancer globally [8]. In developing countries, infectious skin diseases such as scabies and impetigo remain highly prevalent, often driven by poor hygiene and overcrowded living conditions. For instance, the World Health Organization (WHO) estimates that over 200 million people globally suffer from scabies annually, with the majority residing in tropical and subtropical regions.

The widespread prevalence of dermatological disorders has significant ramifications across multiple facets of society. The impact on physical health is often compounded by severe psychological distress, as many skin conditions, such as psoriasis and eczema, are highly visible, leading to stigmatization, low self-esteem, and mental health issues, including anxiety and depression. Nearly 60% of individuals with psoriasis report that the disease poses a substantial problem in their daily lives while approximately one-third of people living with psoriasis experience depression. These statistics underscore the profound impact of psoriasis on both physical and psychological well-being [9].

Economically, skin diseases impose a considerable financial burden on healthcare systems and patients. In the United States alone, the direct medical costs associated with treating skin diseases are estimated to be over USD 75 billion annually [10]. Indirect costs, including lost productivity and absenteeism, further exacerbate the economic impact. For instance, individuals suffering from severe eczema may need to take time off work to manage flare-ups or attend medical appointments, leading to significant productivity losses [11]. In developing countries, the burden is amplified by limited access to dermatological care, resulting in inadequate treatment and prolonged suffering, particularly for preventable conditions like scabies and fungal infections [12].

2.2. Background on Topical Drug Delivery Systems

Topical drug therapy remains one of the most common and effective approaches to treating dermatological disorders. It has several advantages, including targeted delivery, reduced systemic side effects, and ease of application, making them an essential part of dermatological management. Various classes of topical agents are used depending on the type and severity of the condition, ranging from corticosteroids and antibiotics to immunomodulators and retinoids [13,14,15].

Topical drug delivery systems have traditionally relied on formulations such as creams and gels, designed for localized treatment of conditions like skin infections, inflammation, and pain [13,16]. These formulations are widely used due to their non-invasive nature and convenience. The stratum corneum, the outermost layer of the skin, serves as a substantial barrier, limiting the effectiveness of many topical therapies. Studies have shown that drug delivery through the skin is influenced by multiple factors, including formulation type, the presence of permeation enhancers, and the physicochemical properties of the drug [17]. As a result, achieving therapeutic drug concentrations in target tissues often requires high drug loading, which may increase the risk of side effects [18]. Furthermore, the variability in skin permeability between patients and different application sites makes it difficult to achieve consistent therapeutic outcomes [19].

In recent years, advancements in topical drug formulations have led to the development of new delivery systems, such as nanocarriers and 3D-printed transdermal patches, which enhance drug penetration and provide more consistent release profiles. Such innovations are particularly promising for the treatment of chronic conditions like psoriasis, where effective drug delivery to deeper skin layers is often challenging.

2.3. Emergence of Three-Dimensional (3D) Printing in Pharmaceuticals

Three-dimensional printing dates to 1984, when Charles W. Hull filed the first patent for stereolithography, a process to produce three-dimensional objects by layering materials based on Computer-Aided Design (CAD) models [20]. Initially, this technology served industrial purposes, facilitating rapid prototyping due to its speed, precision, and capability to produce highly customized models efficiently. Over the subsequent decades, 3D printing expanded significantly, transitioning from exclusively industrial use to broader applications across various sectors, driven by declining costs and enhanced accessibility to consumers and hobbyists [20].

In healthcare, 3D printing had significant advancements beginning in the early 2000s. Early trials at Boston Children’s Hospital, Harvard Medical School, involved manually constructing urinary bladders using scaffolds and patient cells, highlighting the potential for tissue engineering. This manual process prompted further automation, leading Anthony Atala to establish the Wake Forest Institute for Regenerative Medicine in 2004, where foundational research on bioprinting commenced using modified inkjet printers to fabricate customized organ scaffolds [20]. The medical field rapidly adopted 3D printing, utilizing it for surgical models, custom implants, and prosthetics, drastically enhancing precision in clinical outcomes. Landmark successes include titanium facial implants, customized hip replacements, jawbones, and even skull implants [20].

Contemporary developments have progressed towards bioprinting actual tissues and organs, demonstrating groundbreaking innovations like Organovo’s fully cellular 3D bioprinted liver tissues in 2013, paving the way for future transplantable organs [20]. Although fully functioning bioprinted organs remain an aspiration, the ongoing research and clinical trials underscore the transformative and expanding role of 3D printing in modern healthcare [20].

Today, 3D printing has transformed healthcare, including pharmaceuticals. Initially developed for rapid prototyping, it now enables precise fabrication of medical devices, implants, and personalized drug delivery systems [21]. The key benefit of 3D printing in pharmaceuticals is its ability to produce customized drug products tailored to individual needs, ensuring precise drug release [22]. It also allows for complex drug formulations that control release rates, improve bioavailability, and enhance patient compliance [23].

In dermatology, 3D printing revolutionizes drug delivery by enabling personalized and precise treatments. In contrast to conventional systems limited by mass production, 3D printing allows for custom formulations, addressing varied dosing needs and improving adherence [23]. It also enables intricate designs, beneficial for microneedle patches, transdermal systems, and wound dressings, improving targeted delivery [24]. Fused Deposition Modeling (FDM) provides a simple method to produce patient-specific drug devices. Another study showed that FDM-created custom drug patches to enhance treatment by ensuring precise application to the affected areas [24].

Conventional topical therapies struggle with limited skin penetration due to the stratum corneum, the skin’s natural barrier. Many APIs fail to reach therapeutic concentrations in deeper layers [16]. Three-dimensional-printed microneedle arrays, made using SLA or other methods, bypass this barrier, allowing for better drug penetration and bioavailability [25]. Moreover, 3D printing ensures controlled drug release. By designing complex geometries and multilayer structures, multiple APIs with different release profiles can be incorporated into a single device [26]. This enables immediate and sustained release, eliminating the need for frequent application.

Patient adherence is a major challenge in dermatology, especially with frequent application of topical treatments. Three-dimensional-printed devices provide a convenient, user-friendly alternative, requiring less frequent use [23]. Printed hydrogels and transdermal patches release drugs over extended periods, reducing reapplication and improving compliance [27]. Additionally, customized device designs ensure better fit and comfort, further enhancing patient experience.

Three-dimensional printing also allows for precise dosing and targeted delivery, minimizing drug waste and reducing side effects from systemic absorption [28]. On-demand manufacturing eliminates large-scale production and inventory costs, potentially lowering healthcare expenses [29].

Furthermore, 3D printing optimizes drug release by controlling the microstructure of materials, ensuring immediate, sustained, or controlled release as needed [30]. This ability to tailor release profiles improves treatment outcomes, particularly for localized and sustained therapies.

Beyond dermatological applications, 3D printing has revolutionized various biomedical fields, including prosthetics, organ modeling, and pharmaceutical manufacturing by enabling precise customization, improved patient-specific solutions, and efficient production workflows [31]. In prosthetics, 3D printing allows for the fabrication of highly customized, lightweight, and cost-effective prosthetic limbs tailored to individual patient needs, significantly improving comfort and functionality compared to traditional prosthetic fabrication methods. For organ modeling, 3D-printed anatomical structures are used for pre-surgical planning, medical training, and patient-specific implants, facilitating better surgical outcomes and reducing intraoperative risks [28].

In pharmaceutical manufacturing, 3D printing has paved the way for the development of personalized drug formulations, enabling the fabrication of dosage forms with controlled drug release profiles, complex geometries, and the ability to combine multiple active ingredients into a single unit [32]. Technologies such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) have been extensively explored for creating oral tablets, transdermal patches, and implantable drug delivery systems with enhanced therapeutic efficiency [33]. The introduction of patient-specific 3D-printed medications, such as the FDA-approved Spritam® (levetiracetam), exemplifies how this technology can enhance drug bioavailability and patient adherence [34].

The ability to fabricate personalized implants and customized drug release systems underscores the versatility of 3D printing in modern healthcare, reducing manufacturing costs, minimizing waste, and enhancing treatment efficacy through precision medicine [28]. As research advances, the integration of bioinks, bioprinting techniques, and smart materials into 3D printing is expected to further expand its applications, particularly in tissue engineering and regenerative medicine. The potential of 3D printing also extends to pediatric and geriatric medicine, where customized doses, flavors, and dosage forms can improve patient acceptability and compliance [26]. The table below (Table 1) illustrates the milestones of 3D printing up until year 2024.

Table 1.

Milestones of 3D printing.

2.4. Overview of Three-Dimensional (3D) Printing Methods for Dermatological Applications

- Fused Deposition Modeling (FDM):

- ▪

- Extrusion of thermoplastic polymers through a heated nozzle to build layers.

- ▪

- Commonly used for creating drug-loaded patches and transdermal systems.

- ▪

- Advantages: Cost-effective, versatile, and suitable for heat-sensitive APIs with low processing temperatures.

- Stereolithography (SLA):

- ▪

- Utilizes UV lasers to cure photosensitive resins layer by layer.

- ▪

- Ideal for high-resolution applications like microneedle arrays.

- ▪

- Advantages: Produces intricate designs with sharp details and smooth surfaces.

- Selective Laser Sintering (SLS):

- ▪

- Fuses powdered material using a laser to form layers.

- ▪

- Useful for creating porous structures, enhancing drug loading and release.

- ▪

- Advantages: No need for support structures, good for transdermal patches and wound dressings.

- Direct Ink Writing (DIW):

- ▪

- Deposits droplets of drug solution onto a substrate to create thin films.

- ▪

- Non-thermal, suitable for heat-sensitive drugs.

- ▪

- Advantages: Precise control of drug loading and film thickness.

- Semi-Solid Extrusion (SSE):

- ▪

- Extrudes paste-like materials for soft and flexible drug delivery devices.

- ▪

- Advantages: Suitable for formulations that require room-temperature processing.

2.5. Fused Deposition Modeling (FDM)

FDM has gained considerable attention in pharmaceutical applications due to its simplicity, cost-effectiveness, and ability to process a wide range of thermoplastic polymers. FDM works by extruding a drug-loaded thermoplastic filament through a heated nozzle, which melts the material and deposits it layer by layer to form the desired object [24,35]. This method is particularly suitable for drug delivery systems, including patches and microneedles, as it allows for the incorporation of API directly into the filament during extrusion, resulting in uniform drug distribution [36]. Furthermore, the relatively low operational temperatures of FDM make it compatible with heat-sensitive APIs, which is critical in the formulation of many dermatological products [37].

FDM is used for fabricating personalized drug delivery systems using thermoplastic polymers such as Polylactic Acid (PLA), Polyvinyl Alcohol (PVA), and Polycaprolactone (PCL). A notable example is the fabrication of extended-release tablets loaded with ibuprofen, where the drug was incorporated into a polymeric filament, enabling precise control over the drug release profile [32]. Additionally, FDM has been employed in personalized transdermal patches, where hydrogel-based formulations are extruded to create layered structures that optimize drug diffusion through the skin. This technology has also been successfully applied in the development of buccal films designed for rapid drug absorption, particularly beneficial for pediatric and geriatric patients requiring non-invasive delivery routes [31].

FDM is cost-effective, making it ideal for small-scale production and research [26,38]. It enables rapid prototyping and customization, allowing for personalized patches and transdermal systems tailored to patients [24,35]. The ability to design complex geometries and control internal structures supports drug delivery systems with immediate or sustained release [36]. However, FDM has lower resolution than SLA, limiting its use in high-precision applications [39]. Additionally, it is restricted to thermoplastic polymers, which may not be suitable for all drug formulations [29].

FDM enhances yield and productivity in dermatological drug delivery by enabling rapid prototyping and tailored treatments. Its affordability and flexibility make it suitable for research and personalized applications [26]. For instance, FDM-printed transdermal patches conform to the patient’s skin, improving adhesion and localized drug delivery [24]. Additionally, FDM enables devices with controlled drug release, ensuring consistent therapeutic dosing [36].

The choice of filaments is crucial in FDM for dermatology. PLA, PVA, and PCL are preferred due to biocompatibility, strength, and low melting points, preventing API degradation [40,41]. PLA offers biodegradability and durability but is hydrophobic, limiting compatibility with hydrophilic drugs. PVA, being water-soluble, supports controlled drug release, while the flexibility and slow degradation of PCL make it ideal for wound dressings [30].

Conversely, some polymers are unsuitable for FDM. Chitosan lacks a melting point and thermally degrades, making it incompatible with high extrusion temperatures [42]. Similarly, the high viscosity and moisture sensitivity of PEO cause extrusion issues and inconsistent print quality, limiting its use [28]. These challenges highlight the importance of material selection to ensure efficient and reliable FDM-based dermatological devices.

While FDM improves productivity, customization, and drug delivery performance, careful filament selection is key to optimizing its application in dermatology. Balancing material properties and limitations ensures effective patient-specific treatments.

2.6. Stereolithography (SLA)

Stereolithography (SLA) is a 3D printing technique that uses a UV laser to cure a photosensitive resin layer by layer. SLA is known for its high-resolution capabilities, making it ideal for applications requiring intricate designs, such as microneedle arrays for drug delivery [23]. These microneedles, fabricated with photopolymerizable resins loaded with Active Pharmaceutical Ingredients (APIs), penetrate the stratum corneum, facilitating efficient drug absorption while eliminating the need for hypodermic injections [34].

SLA enhances resolution, precision, and structural integrity in 3D-printed dermatological devices. Its high resolution enables intricate designs, such as microneedle arrays, which improve drug penetration by bypassing the stratum corneum, enhancing therapeutic efficacy [25]. The SLA precision ensures consistent device geometry and optimized surfaces, leading to uniform drug release and effective skin contact. Additionally, its smooth surface finish minimizes discomfort, making it ideal for wearable drug delivery systems [29].

SLA efficiently produces high-quality prototypes and customized drug delivery devices, including personalized wound dressings. However, post-processing steps like resin cleaning and curing lower yield and extend manufacturing time, making it less suitable for large-scale production compared to FDM [39]. Despite this, its ability to create detailed, patient-friendly devices makes it invaluable for precision-driven dermatological applications.

The suitability of SLA resins in dermatology depends on biocompatibility and curing properties. PEGDA and polyurethane-based resins are preferred for their non-toxic nature, flexibility, and durability. The PEGDA hydrophilicity supports controlled drug release, making it ideal for skin-contact applications [23]. In contrast, rigid or low-biocompatibility resins can cause skin irritation and reduce flexibility, limiting their use in wearable patches or microneedles. Additionally, poorly curing photosensitive resins can lead to incomplete polymerization, compromising mechanical properties and safety.

Thus, the SLA high precision and smooth finishes enhance dermatological 3D-printed devices. However, resin selection and post-processing considerations are crucial to optimizing performance while addressing its limitations.

2.7. Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a 3D printing method that uses a laser to fuse powdered material layer by layer. SLS is known for its ability to create porous structures, which can be advantageous for drug delivery devices that require a high surface area for drug loading [26]. This method has been explored for orodispersible tablets containing poorly water-soluble drugs, enhancing their bioavailability through porous structures that facilitate rapid dissolution in saliva [28]. Additionally, SLS has been applied in implantable drug delivery devices, such as biodegradable scaffolds loaded with antibiotics, providing localized drug release for post-surgical infection prevention [31].

SLS offers the benefit of producing porous structures that enhance drug loading and release, making it useful for transdermal patches and wound dressings [28]. Another advantage of SLS is that it does not require support structures during printing, which simplifies the manufacturing process [23]. However, the cost of SLS printers and materials is relatively high, making it less feasible for routine pharmaceutical applications [29]. Furthermore, the need for extensive post-processing to remove excess powder can be time-consuming and may affect the final product’s quality [26].

Materials suitable for SLS in dermatological applications include thermoplastic polymers such as Polycaprolactone (PCL) and Thermoplastic Polyurethanes (TPUs). These materials exhibit excellent flexibility, biocompatibility, and durability, essential for wearable and conformable devices. For instance, the PCL slow degradation rate makes it ideal for long-term applications like wound healing scaffolds, while the TPU elasticity allows to produce comfortable patches [41]. Conversely, materials with high brittleness or poor thermal stability, such as chitosan or some rigid resins, are less suitable due to challenges in maintaining structural integrity during the sintering process or in the final product [42]. The choice of material greatly influences both the yield and functional effectiveness of SLS-printed dermatological devices, necessitating careful selection to optimize performance.

2.8. Direct Ink Writing (DIW)

Direct Ink Writing (DIW) is another technique used in pharmaceutical applications, particularly for creating thin films and drug-loaded patches. It involves depositing droplets of drug solution onto a substrate to form a film [43]. It has gained attention for its ability to deposit precise microdoses of drugs, making it highly suitable for personalized medicine and multidrug combination therapies. This technique has been successfully used to create layered polypill formulations, where multiple APIs with different release kinetics are printed in a single tablet, allowing for controlled and sequential drug release [33].

Direct Ink Writing (DIW) influences the uniformity and precision of drug delivery devices, particularly for dermatological preparations requiring controlled dosing and thin-film applications. By allowing for the precise deposition of drug solutions, this method enhances the accuracy of drug distribution within patches, ensuring consistent therapeutic outcomes. For instance, personalized patches for localized treatment of skin conditions can be produced with minimal wastage of active pharmaceutical ingredients [43]. Additionally, the ability to integrate multiple drugs into a single layer opens avenues for combination therapies tailored to complex dermatological conditions [29].

The method is most suitable for low-viscosity liquid formulations that can flow smoothly through nozzles, such as solutions or emulsions containing hydrophilic polymers like Polyvinyl Alcohol (PVA). These materials enable the creation of uniform and stable films with excellent adhesion to substrates. However, inkjet printing is not ideal for high-viscosity or particulate-laden formulations, as they may clog the nozzle or produce inconsistent layers [23]. This limitation underscores the need to optimize formulation properties for effective use in inkjet-based dermatological applications. The precision and adaptability of inkjet printing make it a valuable tool for creating advanced, patient-specific treatments in dermatology.

2.9. Why Fused Deposition Modeling (FDM) Stands out for Dermatological Applications

Fused Deposition Modeling stands out as a preferred method for printing dermatological preparations due to its versatility, cost-effectiveness, and ability to process biocompatible polymers suitable for drug delivery. In contrast to SLA and SLS, which require expensive equipment and post-processing, FDM offers a simpler and more economical solution for fabricating drug-loaded patches. Additionally, the FDM compatibility with a wide range of thermoplastic polymers allows for the development of customized drug delivery systems tailored to specific patient needs [24].

The ability to incorporate APIs directly into the filament during extrusion is a key advantage of FDM over other methods, as it ensures homogeneous drug distribution and reduces the risk of dose variability [36]. Furthermore, the low operational temperatures of FDM make it suitable for processing heat-sensitive drugs, which is a limitation for many other 3D printing methods [37]. Overall, the FDM combination of flexibility, accessibility, and compatibility with pharmaceutical-grade materials makes it an ideal choice for advancing dermatological therapies.

2.10. Post-Processing in Three-Dimensional (3D) Printing

Post-processing is a crucial step to refine the mechanical, structural, and biological properties of 3D-printed materials, ensuring their suitability for medical use. Various post-processing techniques are employed across different 3D printing methods, including Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and inkjet printing, to enhance surface finish, improve drug release profiles, and optimize mechanical strength.

In FDM, the layer-by-layer deposition process results in rough surfaces and potential interlayer delamination, which can affect drug release kinetics and mechanical stability. Solvent vapor smoothing is a key post-processing method used to improve surface uniformity by partially dissolving polymer layers, creating a smoother finish and enhancing the controlled release of Active Pharmaceutical Ingredients (APIs) [1]. Annealing is another approach, where the printed structure is heated to below its melting point, reducing residual stresses and increasing mechanical integrity [44].

SLA-printed objects require extensive post-curing using UV light to achieve complete polymerization and enhance crosslinking, improving mechanical strength and drug stability [31]. Additionally, chemical post-processing techniques, such as ethanol or isopropanol rinsing, are employed to remove residual uncured resin, which can be cytotoxic if not properly eliminated [44]. These post-processing steps are essential to ensure SLA-printed materials are safe and effective for biomedical applications.

SLS utilizes a laser to sinter powdered polymers layer by layer, resulting in porous structures that can be advantageous for implantable drug delivery devices. However, the powder-based process requires extensive post-processing to remove unsintered particles, which may impact the overall drug content and uniformity. Heat treatment is often applied to enhance the mechanical properties of sintered structures, reducing brittleness and ensuring long-term durability [44]. Furthermore, surface coating with biocompatible polymers can be utilized to modify drug release kinetics and improve biocompatibility [31].

Inkjet-based 3D printing is primarily used for fabricating personalized drug formulations, offering precise control over dosage and drug layering. However, inkjet-printed structures often require thermal post-processing to stabilize drug-polymer matrices, preventing degradation during storage. Additionally, drying and solvent evaporation techniques help improve mechanical stability and prevent drug crystallization, ensuring consistent drug release profiles [34].

Post-processing plays a vital role in optimizing the performance and safety of 3D-printed biomedical devices. Techniques such as solvent vapor smoothing, UV curing, heat treatment, and chemical post-processing are essential for enhancing mechanical properties, drug release profiles, and biocompatibility. As 3D printing continues to evolve, integrating advanced post-processing strategies will be crucial in overcoming current limitations and expanding the applications of personalized drug delivery and tissue engineering [1].

2.11. Comparison of Fused Deposition Modeling (FDM) with Other Three-Dimensional (3D) Printing Technologies

Fused Deposition Modeling (FDM) offers distinct advantages in dermatological drug delivery, primarily due to its affordability, simplicity, and compatibility with various thermoplastic polymers such as PLA, PVA, and PCL [24]. It allows for the straightforward and cost-effective production of customized drug-loaded devices, ideal for personalized patches and transdermal systems. However, FDM typically provides lower resolution compared to other techniques, restricting its suitability for applications requiring precise features, such as microneedles [39].

In comparison, Stereolithography (SLA) delivers superior resolution and surface quality, making it suitable for intricate applications, including microneedle arrays and detailed skin patches [25]. However, the SLA necessity for UV-curable resins limits material choices and increases production complexity due to additional post-curing processes. These factors may affect drug stability and bioactivity due to prolonged exposure to UV light [23].

Selective Laser Sintering (SLS) stands out due to its powder-based approach, offering design freedom and eliminating the need for supports. Additionally, it is advantageous for fabricating porous drug delivery systems and complex internal structures [29]. However, the post-processing required to remove excess powder can be cumbersome, affecting drug yield and process efficiency. Additionally, the thermal conditions involved in SLS may limit its suitability for thermolabile Active Pharmaceutical Ingredients (APIs).

Direct Ink Writing (DIW) differs from FDM by allowing for the use of viscous, paste-like materials and bio-inks, enabling the fabrication of highly porous and bioactive structures that are suitable for regenerative applications such as wound dressings and tissue scaffolds [34]. Nonetheless, the relatively slower printing speed and complexity of DIW in formulation adjustments restrict its practicality for large-scale or rapid prototyping scenarios.

In conclusion, while FDM is highly beneficial for cost-effective, customizable, and straightforward dermatological applications, each 3D printing technology offers unique strengths and limitations. The table below (Table 2) illustrates the comparison of various 3D printing technologies. Selecting the appropriate method thus requires careful consideration of the specific dermatological application, desired resolution, material properties, and production scalability.

Table 2.

Comparison of various 3D printing technologies.

3. Problem Statement

There is currently a lack of comprehensive review articles focused specifically on the selection of filaments for Fused Deposition Modeling (FDM) 3D printing in dermatological preparations leading to challenges in choosing the appropriate filament causing increased trial-and-error, wasted resources, and potential failures in developing effective drug delivery systems. Hence, this review aims to bridge this gap by providing a detailed analysis of the available filaments, their properties, and suitability for 3D printing of preparations for dermatological applications.

4. Polymers Used for Three-Dimensional (3D) Printing Fused Deposition Modeling (FDM)

4.1. List of Polymers

- Polyethylene Glycol (PEG)

- Kolliphor P188 (Poloxamer 188)

- Polyvinylpyrrolidone (Kollidon 12PF)

- Vinylpyrrolidone vinyl acetate copolymer (Kollidon VA64)

- Polylactic Acid (PLA)

- Polyvinyl Alcohol (PVA)

- Chitosan

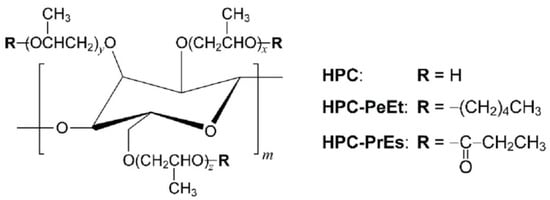

- Hydroxypropyl Cellulose (HPC)

- Polycaprolactone (PCL)

- Thermoplastic Polyurethanes (TPUs)

- Eudragit (methyl prop-2-enoate;2-methylprop-2-enoic acid)

- Ethylene Vinyl Acetate (EVA)

4.2. Filaments Specific to Dermatological Preparations

PVA and PEG: Ideal for creating drug delivery devices requiring controlled dissolution and flexibility.

PCL and TPU: Used for wound dressings and wearable patches due to their flexibility and prolonged degradation properties.

Eudragit: Suitable for pH-sensitive and sustained release systems for localized drug delivery.

EVA: Employed in transdermal systems for its sustained drug release capability.

HPC and Kollidon: Preferred for their biocompatibility and excellent drug release properties.

4.3. Properties of Polymers

4.3.1. Polyethylene Glycol (PEG)

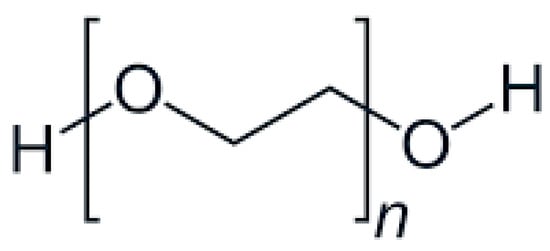

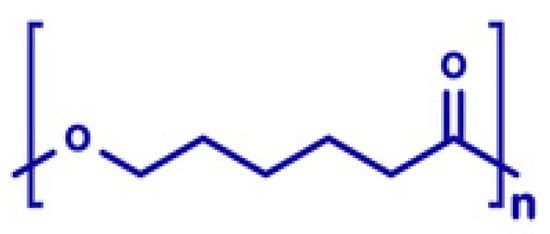

PEG is commonly used as a plasticizer in FDM due to its excellent hydrophilicity and flexibility-enhancing properties. Its structure, characterized by repeating ethylene oxide units [45], significantly lowers extrusion temperatures and improves filament flexibility, as illustrated in Figure 1.

Figure 1.

Chemical structure of PEG.

- General formula: HO-(CH2CH2O)n-H

- Functional Groups:

Ether Groups (-O-):

Provide hydrophilicity through hydrogen bonding with water molecules, enhancing solubility.

Offer chemical inertness, allowing for compatibility with APIs.

Terminal Hydroxyl Groups (-OH):

Increase hydrophilicity by forming hydrogen bonds.

Enable conjugation with APIs, improving solubility and stability [46].

- Physical Description:

- Low molecular weight PEGs: Colorless, viscous liquids.

- High molecular weight PEGs: White, waxy solids [46,47].

- Odorless [46,47].

- Solubility: Highly soluble in water; soluble in organic solvents such as acetone, ethanol, and chloroform [46].

- Impact on Stratum Corneum Permeation:

- PEG increases hydration of the stratum corneum and interacts with skin lipids, facilitating the delivery of hydrophilic APIs.

Properties of Polyethylene Glycol (PEG)

In Fused Deposition Modeling (FDM), PEG is often employed as a plasticizer to improve filament flexibility and reduce extrusion temperatures [48]. Different molecular weights of PEG (e.g., 4000, 6000) are used to modify the mechanical properties of the filaments. The crystallinity and molecular configuration (helix or trans planar zigzag) of PEO greatly influence its properties and application [49]. In this study carried out by Azizoğlu & Özer [27], PEG was added to polymer blends to reduce the extrusion temperature and improve the flexibility of the filaments, which helped make the resulting filaments more flexible and easier to handle during 3D printing.

PEG has good biocompatibility, which makes it a preferred choice in biomedical and pharmaceutical applications [50,51,52]. Its non-toxic nature ensures safety in dermatological preparations, making PEG particularly valuable for use in 3D-printed drug delivery systems, such as transdermal patches and wound dressings.

PEG is a hydrophilic polymer with high solubility in water and various organic solvents. The hydrophilicity of PEG can pose challenges in FDM, as it may absorb moisture during printing, which can lead to filament degradation, bubbling, or poor layer adhesion during the extrusion process [53].

The melting point of PEG depends on its molecular weight. For example, PEG 4000 and PEG 6000 have melting points in the range of 50–60 °C [27]. These relatively low melting points can be beneficial in FDM, as they reduce the extrusion temperature required, making PEG ideal for blending with other polymers to create composite filaments. The reduced extrusion temperature also allows for the incorporation of heat-sensitive APIs without significant thermal degradation [27].

The PEG viscosity varies based on its molecular weight, impacting the ease of extrusion during 3D printing. Low molecular weight PEGs, such as PEG 4000, exhibit lower viscosity, which can enhance flow properties and facilitate smoother extrusion. High viscosity PEGs, such as PEG 8000 on the other hand, can lead to nozzle clogging or inconsistent extrusion, posing challenges in the printing process [54]. Spreadability, which influences how well the material layers adhere to one another, is also affected by viscosity. The PEG ability to act as a plasticizer improves the spreadability of the filament, resulting in better layer adhesion and a more uniform surface finish.

Advantages and Disadvantages of Polyethylene Glycol (PEG) in Fused Deposition Modeling (FDM)

PEG offers several benefits when used in FDM. One of its primary advantages is its plasticizing effect, which improves the flexibility of FDM filaments, reduces brittleness, and lowers extrusion temperatures. This makes PEG particularly useful for enhancing the printability of rigid polymers such as PLA and PCL, making them more suitable for drug delivery applications that require pliable materials [27]. Additionally, the PEG biocompatibility ensures that it is safe for use in dermatological applications where prolonged skin contact is necessary. The relatively low extrusion temperatures of PEG-containing filaments make it compatible with various heat-sensitive APIs, ensuring that the therapeutic efficacy of the drug is not compromised during printing [55].

However, there are also significant drawbacks to using PEG in FDM. One major limitation is its moisture sensitivity. PEG is highly hygroscopic, meaning it readily absorbs moisture from the environment which can lead to issues during the printing process, such as filament swelling, bubbling, and poor adhesion between layers, ultimately affecting the quality of the printed object. Additionally, PEG-based filaments may lack the mechanical strength required for certain applications. Pure PEG or high PEG content blends tend to be softer and less durable, which may limit their use in structural components of drug delivery devices [28].

While PEG has several properties that make it attractive for FDM, including its plasticizing effect and biocompatibility, it is not ideally suited for use as a primary polymer in FDM. The hygroscopic nature of PEG poses significant challenges during the printing process, as moisture absorption can lead to poor print quality and inconsistent mechanical properties. Additionally, the PEG lack of mechanical strength limits its applicability in creating robust structures that are required for certain drug delivery devices.

Instead, PEG is better suited as an additive or plasticizer in combination with other polymers to enhance their flexibility and reduce extrusion temperatures. For instance, PEG can be blended with PLA or PCL to improve the overall flexibility and printability of the filament, making it more suitable for applications that require soft and conformable drug delivery systems [27].

4.3.2. Kolliphor P188 (Poloxamer 188)

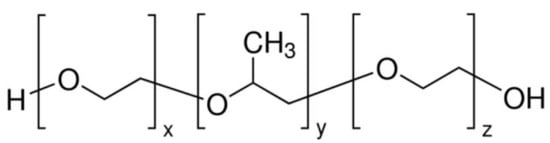

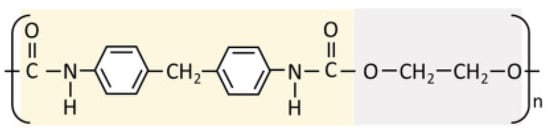

Kolliphor P188 is an amphiphilic polymer known for enhancing drug permeation and filament flexibility in topical drug delivery systems. Its unique molecular structure supports better integration with hydrophobic and hydrophilic drug compounds, as depicted in Figure 2.

Figure 2.

Chemical structure of Kolliphor P188.

- General Formula: HO–(C2H4O)n–(C3H6O)m–(C2H4O)n–H

Functional Groups:

Polyoxyethylene (PEO) Chains: Hydrophilic segments that enhance water solubility.

Polyoxypropylene (PPO) Chains: Hydrophobic segments that facilitate interaction with hydrophobic drug molecules.

Physical Description:

Appearance: Solid, white to slightly yellowish, coarse-grained powder with a waxy consistency. [56,57]

Odor: Faint, characteristic odor.

- Melting Point: Approximately 52 °C (125 °F). [56]

- Boiling Point: N/A (decomposes before boiling).

- Solubility: Freely soluble in water and ethanol; insoluble in diethyl ether, paraffin, and fatty oils. [58]

- Impact on Stratum Corneum Permeation:

- The amphiphilic nature of Kolliphor P188 allows it to interact with both hydrophilic and hydrophobic regions of the stratum corneum, enhancing the permeation of Active Pharmaceutical Ingredients (APIs) through the skin.

Properties of Kolliphor P188

Kolliphor P188 is well-known for its excellent biocompatibility, which makes it suitable for use in a wide range of pharmaceutical and biomedical applications. This polymer is non-toxic and non-irritant, making it particularly suitable for topical applications where direct contact with the skin is necessary. Its biocompatibility ensures that formulations containing Kolliphor P188 can be used safely for dermatological treatments, minimizing the risk of skin irritation or adverse reactions.

Kolliphor P188 is highly soluble in water, which is advantageous for applications requiring the homogeneous distribution of active ingredients. However, its high solubility also means that it can absorb moisture from the environment, potentially leading to issues such as poor adhesion between layers during the FDM process, which may affect the mechanical properties of the printed object.

The melting point of Kolliphor P188 is relatively low, ranging from 52 °C to 57 °C, which is beneficial for FDM as it allows for lower extrusion temperatures [27]. This lower melting point is particularly useful for incorporating heat-sensitive APIs without causing thermal degradation. However, at certain concentrations and temperatures, Kolliphor P188 may lead to brittleness or fluidity issues, which can limit its application in filament formulations [27]. Careful optimization of the polymer concentration is needed to avoid these issues and to maintain suitable mechanical properties for FDM.

Kolliphor P188 exhibits relatively low viscosity compared to other polymers, which contributes to its ability to reduce the extrusion temperature during FDM. The low viscosity ensures that the material can be extruded smoothly, reducing the likelihood of nozzle clogging. However, the low viscosity can also result in reduced mechanical strength of the printed parts, which may limit their suitability for certain applications requiring robust structures. The spreadability of Kolliphor P188 also influences the quality of the printed layers, as its plasticizing effect improves the layer adhesion and surface uniformity, leading to better-quality 3D-printed products.

Advantages and Disadvantages of Using Kolliphor P188 in Fused Deposition Modeling (FDM)

Kolliphor P188 provides several advantages in FDM-based drug delivery systems. Its plasticizing effect enhances flexibility and reduces brittleness in rigid polymers, making it ideal for stable, flexible filaments [27]. Its low melting point allows for lower extrusion temperatures, benefiting heat-sensitive APIs. Additionally, its biocompatibility minimizes the risk of skin irritation, making it a safe option for dermatological formulations [55].

However, Kolliphor P188 has limitations. Its high solubility and hygroscopic nature can lead to moisture absorption, causing poor adhesion and reduced mechanical strength in printed objects. At certain concentrations, it can result in brittleness or excessive fluidity, requiring careful polymer optimization for ideal mechanical and printing properties [27].

Compared to PLA, PEG, and PEO, Kolliphor P188 has distinct advantages and challenges. PLA, widely used for biomedical applications, often requires plasticizers to improve flexibility. Blending Kolliphor P188 with PLA enhances flexibility and reduces brittleness, making PLA-based filaments more suitable for dermatological use [27]. Similarly, while PEG serves as a plasticizer in FDM, the lower melting point of Kolliphor P188 makes it preferable for heat-sensitive APIs, though moisture sensitivity remains a drawback.

Due to its hygroscopic nature and brittleness at certain concentrations, Kolliphor P188 is best used as a plasticizer rather than a primary polymer. Blending it with PLA or PCL improves printability and mechanical properties, making it ideal for dermatological drug delivery applications [27].

Given the limitations of Kolliphor P188 in FDM, other 3D printing methods may be more suitable for this polymer. Inkjet printing and Stereolithography (SLA) are potentially better options for Kolliphor P188-based formulations. Inkjet printing is a non-thermal process, which makes it ideal for heat-sensitive polymers like Kolliphor P188 [43]. SLA, which uses photopolymerizable resins, can also be adapted to incorporate Kolliphor P188 as part of a resin mixture, allowing for the creation of hydrogel-based structures with high precision and controlled drug release [23].

4.3.3. Polyvinylpyrrolidone (Kollidon 12PF)

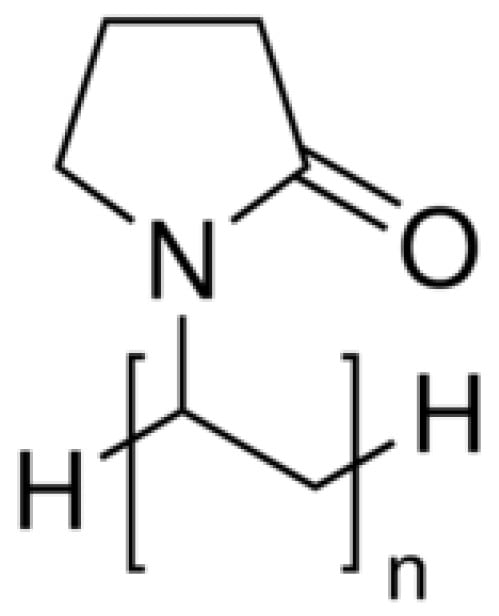

Kollidon 12PF, a polyvinylpyrrolidone-based polymer, is widely valued for its biocompatibility and strong drug-dispersing capabilities. The polymer’s molecular architecture, highlighted in Figure 3, promotes uniform drug distribution within printed formulations.

Figure 3.

Chemical structure of Kollidon 12PF.

- General/Molecular Formula: (C6H9NO)n

- Functional Groups:

- Lactam Group (-C=O and -NH):

- ▪

- Contributes to hydrophilicity by forming hydrogen bonds with water and APIs.

- ▪

- Aids in API solubilization and stabilization.

- Hydrocarbon Backbone:

- ▪

- Provides moderate hydrophobicity, aiding in the interaction with non-polar APIs.

- Physical Description:

- Appearance: White, spray-dried powder.

- Odor: Faint, characteristic odor.

- Boiling Point: N/A (Decomposes before boiling).

- Solubility: Highly soluble in water and a variety of organic solvents, including ethanol, glycerin, and methanol. Insoluble in non-polar solvents like cyclohexane and toluene [59].

- Impact on Stratum Corneum Permeation:

- The hydrophilic lactam groups facilitate hydration of the stratum corneum, increasing permeability.

- Enhances the compatibility and stability of APIs for topical and transdermal applications.

Properties of Kollidon 12PF

Kollidon 12PF is a biocompatible polymer, making it suitable for use in pharmaceutical and biomedical applications where direct contact with biological tissues is required. Its non-toxic nature ensures safety for dermatological applications, such as transdermal patches and wound dressings. The biocompatibility of Kollidon 12PF plays an essential role in ensuring that it does not cause any adverse skin reactions, which is a crucial factor in dermatological preparations. This property makes Kollidon 12PF a reliable option for use in drug delivery systems that need to be in direct contact with the skin [55]

Kollidon 12PF is highly soluble in water, which makes it an excellent candidate for formulations requiring controlled release or enhanced drug solubility. The high solubility of Kollidon 12PF allows it to form homogenous mixtures with APIs, which improves drug dispersion and enhances bioavailability. However, this high solubility may also lead to challenges during the printing process, as the hygroscopic nature of Kollidon 12PF can result in moisture absorption, potentially leading to filament degradation and inconsistent printing quality [55].

Kollidon 12PF has a glass transition temperature (Tg) of approximately 90 °C, which means it requires relatively high processing temperatures for extrusion [27]. This high Tg contributes to the structural stability of the printed object, providing good mechanical strength and rigidity. However, the high processing temperatures required to extrude Kollidon 12PF may limit its suitability for temperature-sensitive APIs, as they could degrade during the extrusion process. To overcome this limitation, plasticizers are often added to reduce the extrusion temperature, thereby preserving the integrity of the active compounds [55].

The viscosity of Kollidon 12PF is relatively low, which helps improve its flow properties during extrusion. The polymer’s low viscosity facilitates smoother extrusion, resulting in fewer issues such as nozzle clogging during the 3D printing process. Additionally, the ability of Kollidon 12PF to act as a matrix polymer helps improve the spreadability of the filament, resulting in better adhesion between layers and more consistent print quality [55]. The enhanced spreadability of Kollidon 12PF helps achieve uniform surface finishes in the final printed object, making it ideal for producing drug delivery devices for dermatological applications.

Advantages and Disadvantages of Kollidon 12PF in Fused Deposition Modeling (FDM)

One of the primary advantages of Kollidon 12PF in FDM is its excellent solubility, which allows for the homogeneous distribution of APIs in the filament. This results in improved drug release profiles, making it a suitable choice for creating 3D-printed transdermal patches and other topical drug delivery systems [27]. Another significant advantage is its biocompatibility, which ensures that the printed products are safe for use in contact with the skin. Additionally, the ability of Kollidon 12PF to form solid dispersions with APIs helps improve the bioavailability of poorly soluble drugs, making it a valuable polymer for drug delivery applications [55].

However, there are also limitations to using Kollidon 12PF in FDM. The high glass transition temperature means that the polymer requires high processing temperatures for extrusion, which may not be suitable for temperature-sensitive compounds [55]. While plasticizers can be added to lower the extrusion temperature, they may also compromise the mechanical properties of the printed object, potentially leading to reduced stability. Moreover, the hygroscopic nature of Kollidon 12PF can lead to moisture absorption, which may affect the quality of the filament and the final printed product.

Kollidon 12PF has several properties that make it suitable for use in FDM, including its excellent solubility, biocompatibility, and ability to enhance drug bioavailability. However, its high glass transition temperature and hygroscopic nature present challenges during the printing process. The high processing temperatures required for Kollidon 12PF may limit its use with temperature-sensitive APIs, and its moisture absorption can lead to filament degradation and inconsistent print quality. Therefore, Kollidon 12PF is best used in combination with plasticizers or other polymers to reduce extrusion temperatures and enhance printability [55].

Hot-melt extrusion combined with FDM remains a viable approach for producing drug-loaded filaments, especially when plasticizers are used to lower the extrusion temperature. However, inkjet printing and Stereolithography (SLA) could also be considered for Kollidon 12PF-based formulations. Inkjet printing is a non-thermal process, which makes it ideal for heat-sensitive APIs [43]. SLA, which uses photopolymerizable resins, can also be adapted to incorporate Kollidon 12PF, allowing for high-precision structures with controlled drug release properties [23].

4.3.4. Vinylpyrrolidone Vinyl Acetate Copolymer (Kollidon VA64)

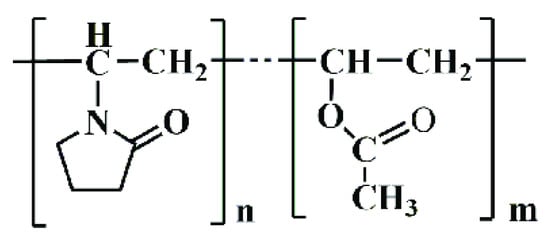

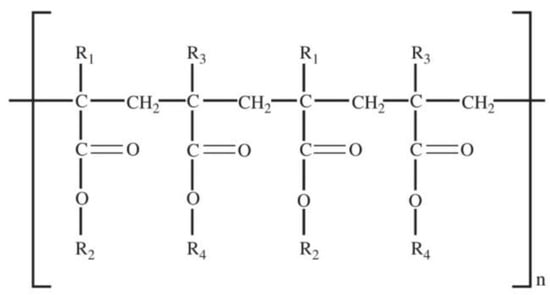

Kollidon VA64 combines hydrophilic and hydrophobic characteristics, enhancing drug solubility and bioavailability in dermatological preparations. Its molecular structure facilitates the formation of stable, flexible films suitable for transdermal drug delivery, as shown in Figure 4.

Figure 4.

Chemical structure of Kollidon VA64.

- General Formula: (C6H9NO)n(C4H6O2)m

- Composition: Approximately 60% N-vinylpyrrolidone and 40% vinyl acetate by weight (BASF, 2022).

- Functional Groups:

- Lactam Group (-C=O and -NH):

- ▪

- Contributes to hydrophilicity and compatibility with APIs.

- ▪

- Forms hydrogen bonds, enhancing solubility and drug dispersion.

- Acetate Ester Group (-COO-):

- ▪

- Adds hydrophobicity, improving the copolymer’s ability to interact with hydrophobic APIs.

- ▪

- Enhances film-forming properties for coatings.

- Physical Description:

- Appearance: White to slightly yellowish spray-dried powder.

- Odor: Faint characteristic odor.

- Melting Point: Amorphous; no defined melting point.

- Glass Transition Temperature: 101 °C.

- Solubility: Soluble in water, alcohols (ethanol, isopropanol), and organic solvents like methylene chloride. Insoluble in non-polar solvents such as cyclohexane (BASF, 2022).

- Impact on Stratum Corneum Permeation:

- Hydrophilic and hydrophobic segments in the copolymer facilitate drug dispersion and enhance permeation through the lipid-rich stratum corneum.

- Forms stable films, improving the controlled release and skin adhesion of dermatological formulations.

Properties of Kollidon VA64

Kollidon VA64 is a biocompatible polymer, which is a crucial property for dermatological preparations where direct contact with the skin is required. The non-toxic nature of Kollidon VA64 ensures that it is safe for use in drug delivery systems, minimizing the risk of skin irritation or adverse reactions. This biocompatibility is especially important for 3D-printed transdermal patches and other dermatological devices that need to be in prolonged contact with the skin.

Kollidon VA64 and Kollidon VA64 Fine are soluble in both water and alcohols, which makes them highly suitable for a range of applications requiring controlled release or enhanced drug solubility. The high solubility of Kollidon VA64 allows it to form homogeneous mixtures with APIs, thereby improving drug dispersion and enhancing bioavailability. This characteristic is particularly beneficial for FDM 3D printing, as it ensures that the active ingredients are uniformly distributed throughout the printed structure. However, the hygroscopic nature of Kollidon VA64 can pose challenges during the printing process, as it may absorb moisture from the environment, potentially leading to filament degradation and inconsistent printing quality [55].

Kollidon VA64 has a Tg of approximately 101 °C, and a high temperature resistance up to 220 °C, which contributes to the structural stability and rigidity of the printed object. This high Tg, however, means that relatively high processing temperatures are required for extrusion, which may limit its use with temperature-sensitive APIs that could degrade during the extrusion process. To address this limitation, plasticizers like PEG are often added to reduce the extrusion temperature, thereby preserving the integrity of the active compounds while maintaining the mechanical properties of the filament [27].

Kollidon VA64 exhibits good viscosity characteristics, which facilitate its smooth extrusion during the FDM process. Its viscosity helps in reducing nozzle clogging, resulting in consistent printing and smooth surface finishes. Solutions of Kollidon VA64 exhibit good flow behavior, enabling easy extrusion with fewer printing defects. Additionally, the excellent film-forming properties of Kollidon VA64 ensure that printed layers adhere well to each other, which is critical for achieving robust and durable printed structures. These attributes make Kollidon VA64 particularly suitable for applications that require uniform drug delivery and reliable mechanical strength [55].

Kollidon VA64 absorbs only about one-third of the amount of water absorbed by povidone, which reduces its hygroscopicity compared to other similar polymers. This property makes Kollidon VA64 less prone to moisture-related issues during storage and processing. However, some level of moisture absorption can still occur, which requires careful handling to prevent adverse effects on filament stability and print quality.

Advantages and Disadvantages of Kollidon VA64 in Fused Deposition Modeling (FDM)

Kollidon VA64 is biocompatible, making it a safe option for dermatological applications, such as transdermal patches and topical formulations [55]. However, its high glass transition temperature (Tg) requires elevated extrusion temperatures, which may not be suitable for temperature-sensitive APIs. While plasticizers can lower extrusion temperatures, they may also alter mechanical stability [60]. Additionally, the hygroscopic nature of Kollidon VA64 makes it prone to moisture absorption, potentially affecting filament quality and print stability if not properly managed [55].

Compared to PLA and PEG, Kollidon VA64 offers better solubility and API compatibility. While PLA is widely used for its biodegradability and mechanical strength, it often requires plasticizers for flexibility. In contrast, Kollidon VA64 provides superior solubility, making it more suitable for drug delivery applications requiring enhanced bioavailability [55].

PEG is often used as a plasticizer in FDM to improve filament flexibility. While Kollidon VA64 also requires plasticizers for lower temperature processing, it offers better structural stability and mechanical strength than PEG and PEO, making it ideal for applications needing rigidity and durability. Blending Kollidon VA64 with plasticizers or other polymers further enhances flexibility, expanding its use in various 3D printing applications.

Despite its advantages, the high Tg and hygroscopic nature of Kollidon VA64 pose challenges in FDM-based formulations. The high extrusion temperature requirement may limit its use with heat-sensitive APIs, while moisture absorption can degrade filament stability. Thus, Kollidon VA64 is best combined with plasticizers or other polymers to reduce extrusion temperatures and enhance printability [55]. While FDM is a viable option for Kollidon VA64, other 3D printing methods may be more suitable in certain scenarios. For example, inkjet printing and Stereolithography (SLA) could also be considered for Kollidon VA64-based formulations. Inkjet printing is a non-thermal process, which makes it ideal for heat-sensitive APIs, while SLA can create high-precision structures using photopolymerizable resins, which can be adapted to incorporate Kollidon VA64 for enhanced drug delivery properties [55].

4.3.5. Polylactic Acid (PLA)

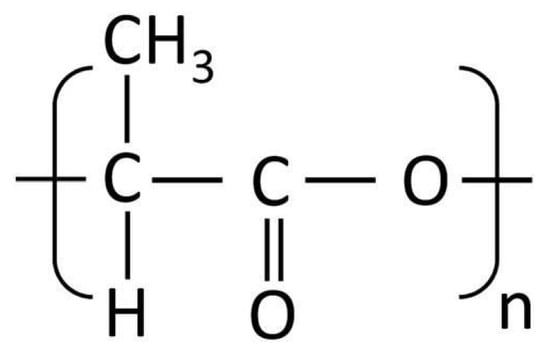

PLA is a biodegradable thermoplastic commonly utilized in FDM due to its mechanical robustness and environmental sustainability. Its molecular structure, consisting of repeating lactic acid units, provides structural integrity, as illustrated in Figure 5. Although rigid, it often requires plasticizers to enhance flexibility for dermatological uses.

Figure 5.

Chemical structure of PLA.

- General Formula: (C3H4O2)n

- Functional Groups:

- Ester Group (-COO-): Provides hydrophobicity, reducing water solubility and enhancing compatibility with hydrophobic APIs [61].

- Hydroxyl Group (-OH, as terminal group): Adds limited hydrophilicity, allowing for minor interaction with hydrophilic APIs.

- Physical Description:

- Appearance: Transparent to opaque, shiny, and brittle.

- Odor: Odorless.

- Melting Point: 140–210 °C, depending on crystallinity. [62,63]

- Glass Transition Temperature: 50–75 °C.

- Solubility: Soluble in organic solvents such as chloroform and benzene; insoluble in water [61,63].

- Impact on Stratum Corneum Permeation:

- The hydrophobic nature of PLA enables controlled release of encapsulated drugs through the lipid-rich stratum corneum.

- Provides structural integrity in formulations, making it suitable for transdermal patches and drug-loaded microneedles [61].

Properties of Polylactic Acid (PLA)

PLA is considered to be biocompatible, which makes it a suitable candidate for drug delivery systems that come into direct contact with the skin. This property is particularly important for dermatological preparations, where polymers must be safe for prolonged contact with human tissues. The degradation products of PLA are lactic acid monomers, which are naturally metabolized by the body, reducing the likelihood of adverse reactions. The biocompatibility of PLA ensures that it can be safely used in a wide range of biomedical applications, including wound healing patches and transdermal drug delivery systems [24].

PLA is hydrophobic, which impacts its ability to incorporate and release hydrophilic drugs effectively. This hydrophobic nature limits the drug-loading capacity for certain types of drugs, particularly those that are water-soluble. This presents a significant challenge for the use of PLA in dermatological preparations that require controlled release of hydrophilic APIs. Strategies to overcome this include the use of plasticizers or blending PLA with other polymers that possess better hydrophilic characteristics. Recent studies have demonstrated the effectiveness of such modifications in improving the drug-loading capacity and release profiles of PLA-based formulations [30].

PLA has a melting point in the range of 150–180 °C and a glass transition temperature (Tg) of about 55 °C, which are well within the range for processing using FDM technology. The moderate melting point of PLA allows for efficient extrusion through the 3D printer nozzle without the need for extremely high temperatures, which could be detrimental to the stability of active pharmaceutical ingredients. However, its relatively low Tg means that PLA parts can deform under elevated temperatures, which can be a limiting factor in the production of structures that need to maintain their form in warm environments [55].

The viscosity and rheological behavior of PLA are suitable for FDM, allowing for consistent extrusion and good layer adhesion during the printing process. The viscosity of PLA is impacted by the molecular weight, which must be carefully controlled to ensure optimal print quality. The good spreadability of PLA facilitates the deposition of smooth, consistent layers during the FDM process, which is crucial for the production of high-quality, functional parts. However, the addition of plasticizers or blending with other polymers can further improve the spreadability and printability of PLA filaments, making them more suitable for intricate drug delivery applications [24].

Advantages and Disadvantages of Using Polylactic Acid (PLA) in Fused Deposition Modeling (FDM)

One of the main advantages of PLA in FDM is its ease of processing. PLA filaments are readily available, and their processing does not require extremely high temperatures, making them user-friendly and suitable for a wide range of 3D printers [64]. Additionally, PLA is biodegradable, which is a significant advantage for dermatological applications where biodegradability can enhance safety and environmental sustainability [55]. The ability of PLA to degrade into lactic acid makes it particularly appealing for short-term use medical devices, such as wound dressings and drug delivery systems.

However, there are also some drawbacks to using PLA for dermatological preparations. The hydrophobic nature of PLA makes it less suitable for loading hydrophilic drugs, which can result in limited drug release from the printed structure. Moreover, the brittleness of PLA can lead to mechanical failure, especially in applications where flexibility is required. Studies have shown that incorporating plasticizers like PEG or blending PLA with more flexible polymers can help to overcome these issues, improving both the mechanical properties and drug delivery characteristics of PLA-based filaments [30].

Compared to other commonly used FDM polymers like Polyethylene Glycol (PEG), Polyvinyl Alcohol (PVA), and Polycaprolactone (PCL), PLA stands out for its ease of printing and biodegradability. PCL, for instance, has better flexibility compared to PLA but requires higher extrusion temperatures and takes longer to degrade. PVA is hydrophilic and water-soluble, making it a good candidate for applications involving hydrophilic drug delivery, whereas the hydrophobicity of PLA limits its compatibility with such APIs. However, the mechanical strength and biocompatibility of PLA make it a better choice for applications where structural integrity and skin safety are essential [24].

PLA is generally well-suited for FDM due to its relatively low melting point, ease of processing, and mechanical strength. Its use in dermatological preparations is feasible when the specific application benefits from its biodegradability and biocompatibility. However, for applications that require the incorporation of hydrophilic drugs, PLA may not be the ideal choice unless modified through the addition of plasticizers or blended with other polymers. Alternative 3D printing methods, such as Semi-Solid Extrusion (SSE) or Stereolithography (SLA), could offer advantages for PLA-based formulations where improved drug loading or more precise structures are required [55].

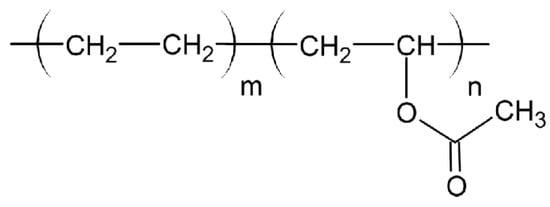

4.3.6. Polyvinyl Alcohol (PVA)

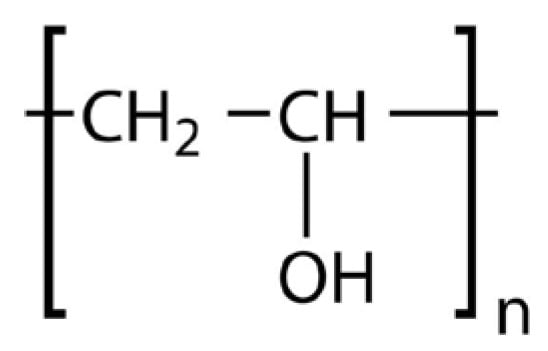

Polyvinyl Alcohol (PVA) is a hydrophilic polymer extensively employed for controlled and sustained drug release due to its water solubility. The hydroxyl groups in its molecular chain, depicted in Figure 6, facilitate controlled drug release but also make it susceptible to moisture absorption, impacting its stability during storage and printing.

Figure 6.

Chemical structure of PVA.

- General Formula: (C2H4O)n

- Functional Groups:

- Hydroxyl Groups (-OH):

- ▪

- Provide strong hydrophilicity, making PVA water-soluble.

- ▪

- Facilitate interaction with APIs and enhance compatibility.

- Hydrocarbon Backbone (-CH2-):

- ▪

- Contributes to limited hydrophobicity, improving interaction with hydrophobic APIs.

- Physical Description:

- Appearance: White to cream-colored granules or powder. [65]

- Odor: Odorless. [65]

- Melting Point: Decomposes > 200 °C [66].

- Solubility: Fully soluble in water; slightly soluble in ethanol; insoluble in most organic solvents [66].

- Impact on Stratum Corneum Permeation:

- The hydrophilic hydroxyl groups in PVA hydrate the stratum corneum, enhancing drug permeability.

- PVA forms a flexible matrix, making it suitable for drug-loaded films and patches in dermatological applications.

Properties of Polyvinyl Alcohol (PVA)

PVA is a biocompatible polymer, which makes it an ideal material for applications in direct contact with the skin, such as dermatological preparations, hydrogels, and even synthetic articular cartilage [67]. The non-toxic nature of PVA ensures its safety in transdermal drug delivery systems, minimizing the risk of irritation or adverse reactions. This characteristic is especially relevant for creating personalized drug delivery devices like 3D-printed patches, where direct and prolonged skin contact is required. Studies have shown that PVA has minimal irritation properties, making it suitable for use in medical applications [66,68].

The water solubility of PVA is one of its most notable characteristics, allowing it to dissolve easily in water without requiring any organic solvents. This property not only contributes to the polymer’s biodegradability, but also enhances its utility in FDM 3D printing for pharmaceutical applications. The ability of PVA to dissolve in water makes it an ideal choice for printing water-soluble support structures, which can be easily removed post-printing [66,68]. Additionally, its hydrophilic nature enhances drug release properties, making PVA-based 3D-printed formulations effective for sustained drug release. However, the hygroscopic nature of PVA requires careful handling to avoid moisture absorption, which can lead to printing inconsistencies [68].

PVA has a melting point of approximately 163 °C and a Vicat softening temperature of 60.2 °C, making it suitable for FDM 3D printing when processed within specific temperature ranges [66]. The viscosity of PVA influences its printability, with high viscosity ensuring consistent flow through the extruder nozzle, which is crucial for achieving smooth and accurate prints. The viscosity can be optimized by adding plasticizers, such as glycerol or sorbitol, to reduce processing temperatures and facilitate smooth extrusion [68]. This is particularly important for printing flexible transdermal patches or other dermatological devices that require both mechanical strength and flexibility.

The spreadability of PVA is closely related to its ability to form consistent layers during the FDM process. The good film-forming ability of PVA ensures that each printed layer adheres well to the previous one, resulting in structurally stable and robust printed objects. This property is beneficial for producing patches and other drug delivery devices that need to maintain integrity during application to the skin [68].

Advantages and Disadvantages of Using Polyvinyl Alcohol (PVA) in Fused Deposition Modeling (FDM)

PVA offers several advantages in FDM, including biocompatibility, ease of dissolution, and biodegradability. Its water solubility makes it easy to remove as a support material, and its non-toxic nature makes it suitable for use in drug delivery systems intended for prolonged contact with the skin [68]. Additionally, the film-forming properties of PVA and the ability to create hydrogels make it a versatile polymer for creating patches that deliver drugs directly to targeted areas [69].

However, there are also challenges associated with using PVA in FDM. Its hygroscopic nature makes it prone to absorbing moisture, which can lead to filament degradation and printing issues if not properly stored and handled. Additionally, the melting point of PVA requires careful temperature control during printing to avoid decomposition or jamming of the extruder nozzle [66].

The properties of PVA make it suitable for use in FDM 3D printing, particularly for creating personalized drug delivery devices. Its biocompatibility and water solubility are beneficial for transdermal and topical applications, where patient safety and ease of use are critical. However, to ensure optimal printability and structural integrity, PVA should be used in combination with plasticizers and handled carefully to avoid moisture absorption. The FDM method is well-suited for PVA, as it allows for precise control over the printing process, enabling the production of customized patches and drug delivery devices that fit the unique needs of individual patients [66,68].

4.3.7. Chitosan

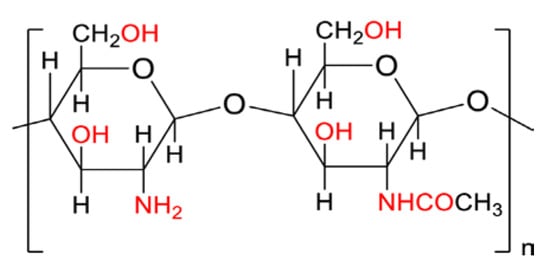

Chitosan is recognized for its remarkable antimicrobial activity, biocompatibility, and bioadhesiveness, making it particularly effective in wound healing applications. The presence of reactive amine groups within its molecular structure, illustrated in Figure 7, supports these therapeutic properties.

Figure 7.

Chemical structure of chitosan.

- General Formula: (C6H11NO4)n

- Functional Groups:

- Amino Groups (-NH2):

- ▪

- Provide hydrophilicity by forming hydrogen bonds with water molecules.

- ▪

- Enhance ionic interactions, improving API compatibility.

- Hydroxyl Groups (-OH):

- ▪

- Contribute to hydrophilicity and solubility in acidic environments.

- ▪

- Allow for modifications to enhance solubility and API inclusion.

- Glycosidic Linkages (-O-):

- ▪

- Provide structural stability but contribute to limited hydrophobicity.

- Physical Description:

- Appearance: Off-white to beige powder [70].

- Odor: Odorless [70].

- Melting Point: Decomposes at approximately 102.5 °C [70].

- Solubility: Soluble in dilute acids (e.g., acetic acid); insoluble in water and organic solvents at neutral pH [71,72,73].

- Impact on Stratum Corneum Permeation:

Hydrophilic amino and hydroxyl groups enhance the hydration of the stratum corneum, improving drug permeation.

Forms a flexible and bio-adhesive matrix, making it suitable for drug delivery systems like films and gels [71].

Properties of Chitosan

Chitosan is a natural polysaccharide derived from chitin, commonly found in the exoskeletons of crustaceans such as crabs and shrimp [74]. Known for its remarkable biocompatibility, biodegradability, and antimicrobial properties, chitosan is widely used in a variety of biomedical applications, including drug delivery systems and wound dressings [1]. Its biocompatibility ensures minimal foreign body reaction and little to no fibrous encapsulation, which is advantageous for dermatological and wound healing applications [75,76]. Additionally, chitosan is biodegradable and can be broken down by enzymes such as lysozyme, a glycosidic hydrolase present in the human body, which hydrolyzes the β (1–4) linkages between N-acetylglucosamine and glucosamine [77,78]. This property makes chitosan particularly appealing for applications that require gradual degradation, such as topical patches or wound healing scaffolds. The controlled biodegradation allows for sustained release of therapeutic agents, reducing the need for patch removal and enhancing patient compliance. As an added benefit, Chitosan exhibits broad-spectrum antimicrobial activity and its effectiveness is influenced by factors such as molecular weight, degree of deacetylation, and pH of the environment [79].

Chitosan is soluble in acidic aqueous solutions due to the protonation of its amino groups, which gives it a positive charge and allows it to interact with negatively charged drugs and biological components. This solubility characteristic is advantageous for creating hydrogels and films for drug delivery. However, the requirement for acidic conditions to dissolve chitosan may present challenges in processing, especially for FDM, which generally operates at neutral pH [42]. The solubility profile of chitosan can impact its ability to be uniformly mixed with Active Pharmaceutical Ingredients (APIs), influencing the homogeneity and drug release characteristics of 3D-printed formulations [80].

Chitosan does not have a well-defined melting point, as it degrades before melting when exposed to high temperatures. This characteristic poses a significant challenge for its use in FDM, which relies on thermoplastic properties for filament extrusion. Instead of melting, chitosan undergoes thermal decomposition at temperatures above 200 °C, which makes it unsuitable for conventional FDM without modifications [42]. To overcome this limitation, chitosan can be blended with thermoplastic polymers or plasticizers to improve its thermal stability and make it more amenable to FDM processing [80].