Synthesis of 0.75Pb(Zr0.52Ti0.48)O3-0.25BiFeO3 Thin Film Capacitors with Excellent Efficiency and Thermal Stability

Abstract

1. Introduction

2. Results and Discussion

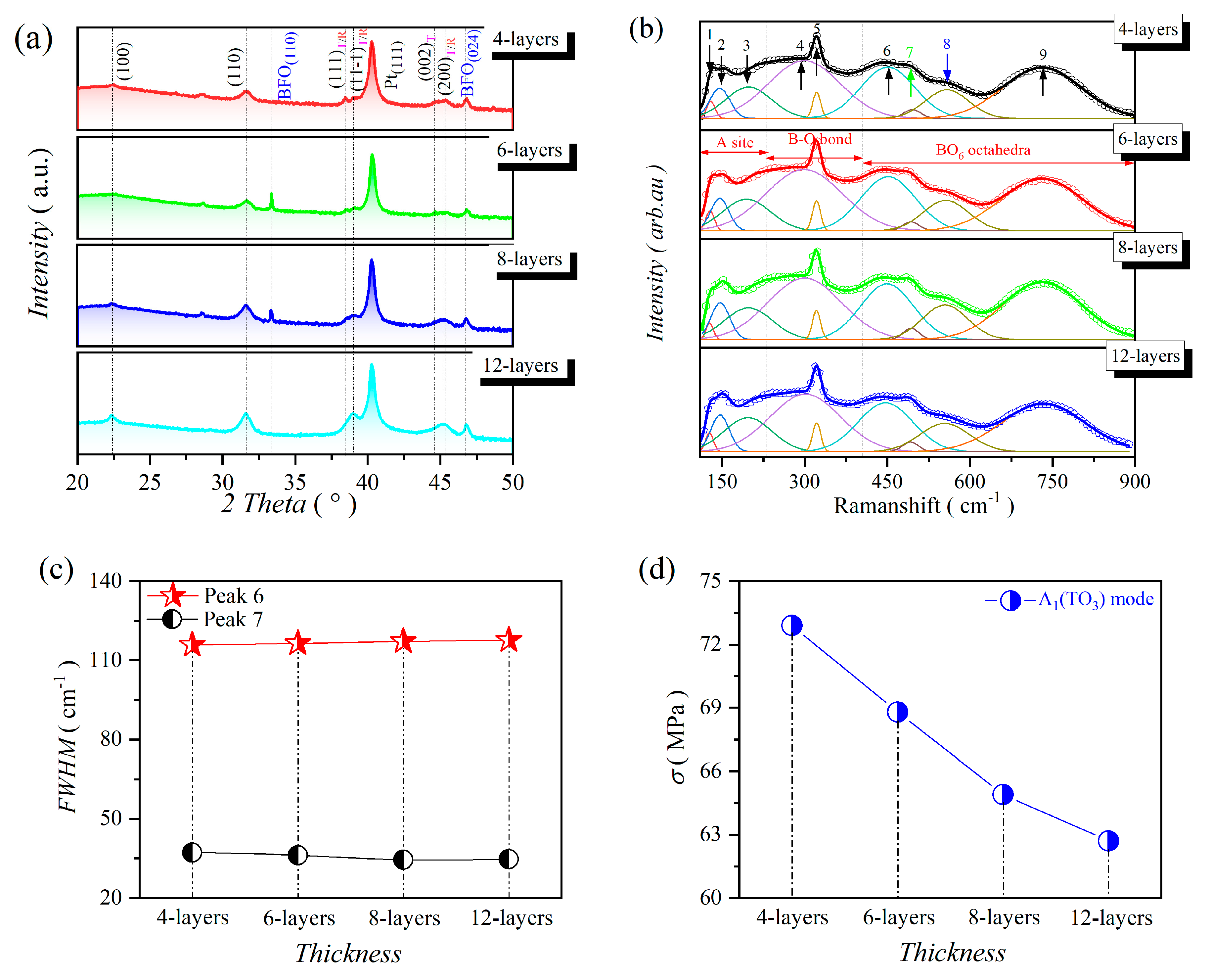

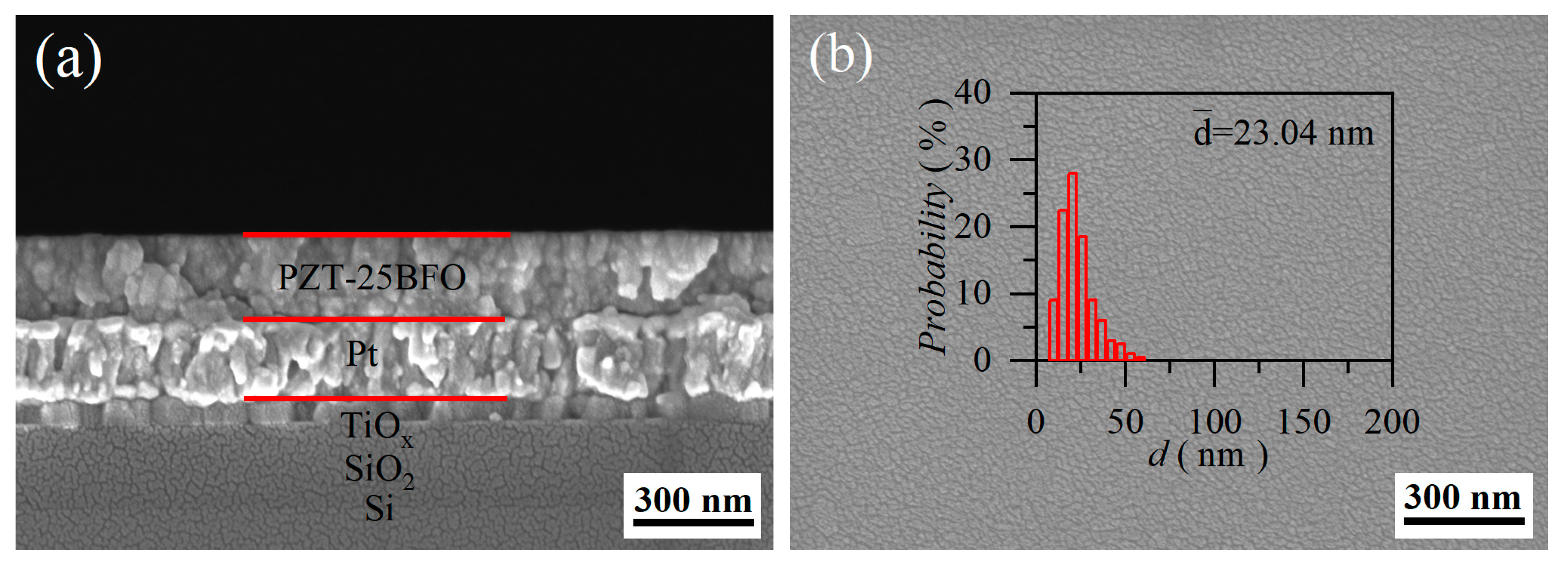

2.1. Structure

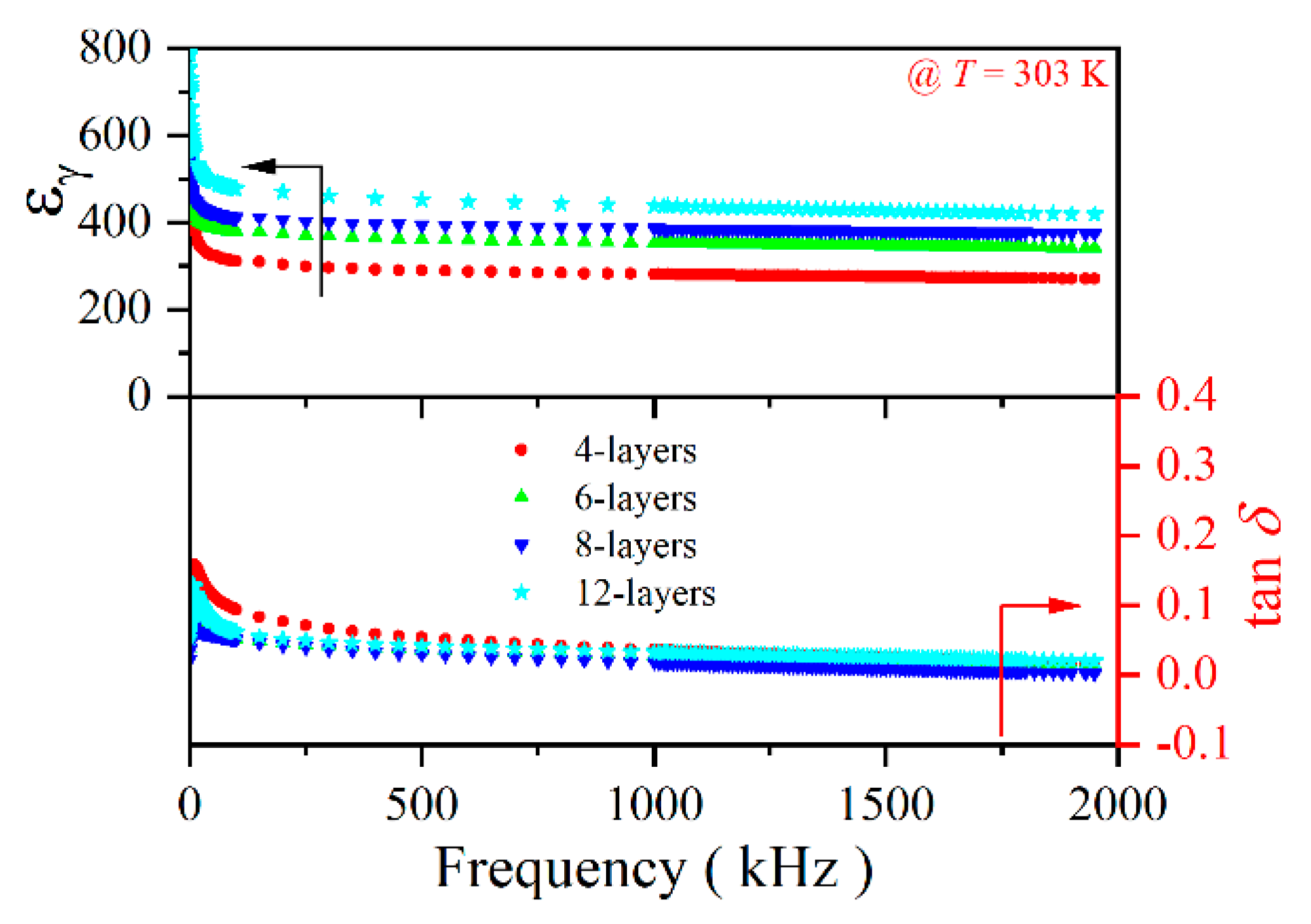

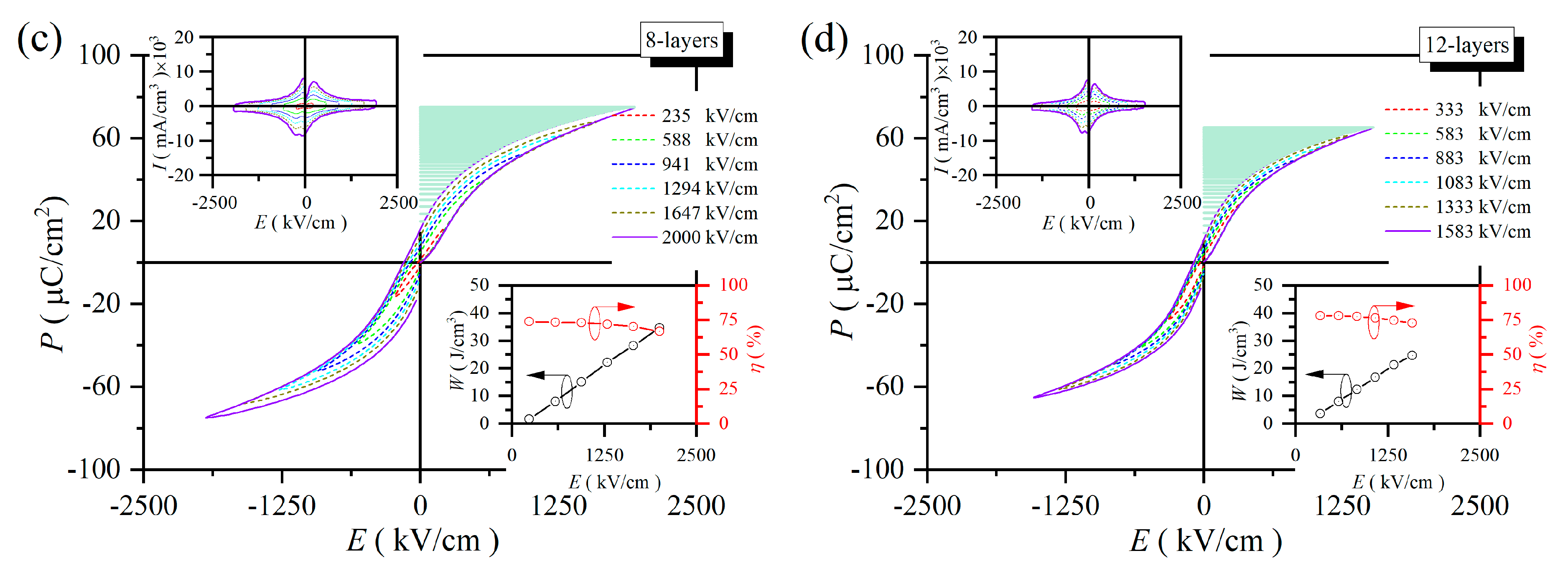

2.2. Energy Storage Density

3. Characterization

4. Materials and Methods

Preparation of PZT-25BFO Thin Films

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Peng, B.L.; Zhang, Q.; Li, X.; Sun, T.Y.; Fan, H.Q.; Ke, S.M.; Ye, M.; Wang, Y.; Lu, W.; Niu, H.B.; et al. Large Energy Storage Density and High Thermal Stability in a Highly Textured (111)-Oriented Pb0.8Ba0.2ZrO3 Relaxor Thin Film with the Coexistence of Antiferroelectric and Ferroelectric Phases. ACS Appl. Mater. Interfaces 2015, 27, 13512–13517. [Google Scholar] [CrossRef] [PubMed]

- Park, M.H.; Kim, H.J.; Kim, Y.J.; Moon, T.; Kim, K.D.; Hwang, C.S. Thin HfxZr1−xO2 Films: A New Lead-Free System for Electrostatic Supercapacitors with Large Energy Storage Density and Robust Thermal Stability. Adv. Energy Mater. 2014, 4, 1400610. [Google Scholar] [CrossRef]

- Hu, Q.; Wang, T.; Zhao, L.; Jin, L.; Xu, Z.; Wei, X. Dielectric and energy storage properties of BaTiO3-Bi(Mg1/2Ti1/2)O3 ceramic: Influence of glass addition and biasing electric field. Ceram. Int. 2017, 43, 35–39. [Google Scholar] [CrossRef]

- Li, F.; Zhai, J.; Shen, B.; Liu, X.; Yang, K.; Zhang, Y.; Li, P.; Liu, B.H.; Zheng, H.R. Influence of structural evolution on energy storage properties in Bi0.5Na0.5TiO3-SrTiO3-NaNbO3 lead-free ferroelectric ceramics. J. Appl. Phys. 2017, 121, 054103. [Google Scholar] [CrossRef]

- Qi, P. Dielectric tunability properties of the Pb[(Mg1/3Nb2/3)1−xZrx]O3 ceramics. J. Alloys Compd. 2013, 549, 283–287. [Google Scholar]

- Luo, N.N.; Han, K.; Zhuo, F.P.; Chao, X.; Zhang, G.Z.; Liu, L.J.; Chen, X.Y.; Hu, C.Z.; Zhou, H.F.; Wei, Y.Z. Aliovalent A-site engineered AgNbO3 lead-free antiferroelectric ceramics toward superior energy storage density. J. Mater. Chem. A 2019, 7, 14118–14128. [Google Scholar] [CrossRef]

- Luo, N.N.; Han, K.; Zhuo, F.P.; Liu, L.J.; Chen, X.Y.; Peng, B.L.; Wang, X.P.; Feng, Q.; Wei, Y.Z. Design for high energy storage density and temperature-insensitive lead-free antiferroelectric ceramics. J. Mater. Chem. C 2019, 7, 4999–5008. [Google Scholar] [CrossRef]

- Panda, P.K.; Sahoo, B. PZT to Lead Free Piezo Ceramics: A Review. Ferroelectrics 2015, 474, 128–143. [Google Scholar] [CrossRef]

- Park, K.I.; Son, J.H.; Hwang, G.T.; Jeong, C.K.; Ryu, J.; Koo, M.; Choi, I.; Lee, S.H.; Byun, M.; Wang, Z.L. Highly-Efficient, Flexible Piezoelectric PZT Thin Film Nanogenerator on Plastic Substrates. Adv Mater. 2014, 26, 2514–2520. [Google Scholar] [CrossRef]

- Ang, C.; Yu, Z. dc electric-field dependence of the dielectric constant in polar dielectrics: Multiploidization mechanism model. Phys. Rev. B 2004, 69, 219904. [Google Scholar] [CrossRef]

- Choi, S.G.; Palmstrøm, C.J.; Kim, Y.D.; Cooper, S.L.; Aspens, D.E. Dielectric functions of AlxGa1-xSb (0.00 ≤ x ≤ 0.39) alloys from 1.5 to 6.0 eV. J. Appl. Phys. 2005, 98, 5821. [Google Scholar] [CrossRef]

- Zhang, T.D.; Li, W.L.; Cao, W.P.; Hou, Y.; Yu, Y.; Fei, W.L. Giant electrocaloric effect in PZT bilayer thin films by utilizing the electric field engineering. Appl. Phys. Lett. 2016, 108, 162902. [Google Scholar] [CrossRef]

- Li, M.J.; Xu, L.P.; Shi, K. Interband electronic transitions and phase diagram of PbZr1-xTixO3 (0.05 ≤ x ≤ 0.70) ceramics: Ellipsometric experiment and first-principles theory. J. Phy. D Appl. Phys. 2016, 49, 275305. [Google Scholar] [CrossRef]

- Mukherjee, D.; Hyde, R.; Hordagoda, M. Challenges in the stoichiometric growth of polycrystalline and epitaxial PbZr0.52Ti0.48O3/La0.7Sr0.3MnO3 multiferroic heterostructures using pulsed laser deposition. J. Appl. Phys. 2012, 112, 064101. [Google Scholar] [CrossRef]

- Aggarwal, S.; Madhukar, S.; Nagaraj, B. Can lead nonstoichiometry influence ferroelectric properties of Pb(Zr,Ti)O3 thin films. Appl. Phys. Lett. 1999, 75, 716–718. [Google Scholar] [CrossRef]

- Wu, Y.J.; Wan, J.G.; Huang, C.F.; Weng, Y.Y.; Zhao, S.F.; Liu, J.M.; Wang, G.H. Strong magnetoelectric coupling in multiferroic BiFeO3-Pb(Zr0.52Ti0.48)O3 composite films derived from electrophoretic deposition. Appl. Phys. Lett. 2008, 93, 192915. [Google Scholar] [CrossRef]

- Li, Y.; Gao, H.; Liu, Y.; Zhang, L.; Hao, X. The coexisting negative and positive electrocaloric effect in (Pb0.97La0.02)(Zr,Sn,Ti)O3 antiferroelectric thick films optimized via phase transition procedure. J. Mater. Sci. Mater. Electron. 2018, 29, 14528–14534. [Google Scholar] [CrossRef]

- Gao, H.; Hao, X.; Zhang, Q.; An, S.; Kong, L.B. Electrocaloric effect and energy-storage performance in grain-size-engineered PBLZT antiferroelectric thick films. J. Mater. Sci. Mater. Electron. 2016, 27, 10309–10319. [Google Scholar] [CrossRef]

- Zhao, Y.; Hao, X.H.; Zhang, Q. A giant electrocaloric effect of a Pb0.97La0.02(Zr0.75Sn0.18Ti0.07)O3 antiferroelectric thick film at room temperature. J. Mater. Chem. C 2015, 3, 1694–1699. [Google Scholar] [CrossRef]

- Ge, J.; Pan, G.; Remiens, D. Effect of electrode materials on the scaling behavior of energy density in Pb(Zr0.96Ti0.03)Nb0.01O3 antiferroelectric films. Appl. Phys. Lett. 2012, 101, 112905. [Google Scholar] [CrossRef]

- Lebeugle, D.; Colson, D.; Forget, A.; Viret, M. Very large spontaneous electric polarization in BiFeO3 single crystals at room temperature and its evolution under cycling fields. Appl. Phys. Lett. 2007, 91, 022907. [Google Scholar] [CrossRef]

- Rödel, J.; Jo, W.; Seifert, K.T.P.; Anton, E.M.; Granzow, T.; Damjanovic, D. Perspective on the Development of Lead-free Piezoceramics. J. Am. Chem. Soc. 2009, 92, 1153–1177. [Google Scholar] [CrossRef]

- Deluca, M.; Fukumura, H.; Tonari, N.; Capiani, C.; Hasuike, N.; Kisoda, K.; Galassi, C.; Harima, H. Raman spectroscopic study of phase transitions in undoped morphotropic PbZr1−xTixO3. J. Raman Spectrosc. 2011, 42, 488–495. [Google Scholar] [CrossRef]

- Smith, R.T.; Achenbach, G.D.; Gerson, R.; James, W.J. Dielectric Properties of Solid Solutions of BiFeO3 with Pb(Ti, Zr)O3 at High Temperature and High Frequency. J. Appl. Phys. 1968, 39, 70–74. [Google Scholar] [CrossRef]

- Sharma, S.; Singh, V.; Kotnala, R.K.; Ranjan, R.; Dwivedi, R.K. Co-existence of tetragonal and monoclinic phases and multiferroic properties for x ≤ 0.30 in the (1−x)Pb(Zr0.52Ti0.48)O3–(x)BiFeO3 system. J. Alloys Compd. 2014, 614, 165–172. [Google Scholar] [CrossRef]

- Lappalainen, J.; Frantti, J.; Lantto, V. Electrical and mechanical properties of ferroelectric thin films laser ablated from a Pb0.97Nd0.02(Zr0.55Ti0.45)O3 target. J. Appl. Phys. 1997, 82, 3469–3477. [Google Scholar] [CrossRef]

- Spierings, G.A.C.M.; Dormans, G.J.M.; Moors, W.G.J.; Ulenaers, M.J.E.; Larsen, P.K. Stresses in Pt/Pb(Zr,Ti)O3/Pt thin-film stacks for integrated ferroelectric capacitors. J. Appl. Phys. 1995, 78, 1926–1933. [Google Scholar] [CrossRef]

- Wang, X.J.; Wang, Y.C.; Peng, B.L.; Deng, J.Y.; Yang, Y.; Sun, W.H.; Wang, Z.L. Thickness dependence of PbZr0.52Ti0.48O3 thin film ferroelectric parameters. Nano Energy 2023, 107, 108161. [Google Scholar] [CrossRef]

- Abdessalem, L.B.; Aydi, S.; Aydi, A.; Sassi, Z.; Maalej, A.; Khemakhem, H. X-ray diffraction; dielectric, and Raman spectroscopy studies of BaSrTiO3-NaNbO3 ceramic. Appl. Phys. A 2017, 123, 305. [Google Scholar] [CrossRef]

- Dobal, P.S.; Katiyar, R.S. Studies on ferroelectric perovskites and Bi-layered compounds using micro-Raman spectroscopy. J. Raman Spectrosc. 2002, 33, 405–423. [Google Scholar] [CrossRef]

- Peng, B.L.; Zhang, Q.; Bai, G.; Leighton, J.T.; Glenn, S.; Christopher, M.; Steven, J.; Zou, B.S.; Sun, W.H.; Huang, H.T.; et al. Phase-transition induced giant negative electrocaloric effect in a lead-free relaxor ferroelectric thin film. Energy Environ. Sci. 2019, 12, 1708–1717. [Google Scholar] [CrossRef]

- Xu, W.H.; Lu, D.; Zhang, T.Y. Determination of residual stresses in Pb(Zr0.53Ti0.47)O3 thin films with Raman spectroscopy. Appl. Phys. Lett. 2001, 79, 4112–4114. [Google Scholar] [CrossRef]

- Zhu, J.J.; Jiang, K.; Xu, G.S.; Hu, Z.G.; Li, Y.W.; Zhu, Z.Q.; Chu, J.H. Temperature-dependent Raman scattering and multiple phase coexistence in relaxor ferroelectric Pb(In1/2Nb1/2)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 single crystals. J. Appl. Phys. 2013, 114, 153508. [Google Scholar] [CrossRef]

- Buixaderas, E.; Berta, M.; Kozielski, L. Raman spectroscopy of Pb(Zr1-xZxTix)O3 graded ceramics around the morphotropic phase boundary. Phase Transit. 2011, 84, 528–541. [Google Scholar] [CrossRef]

- Peng, B.L.; Tang, S.L.; Lu, L.; Zhang, Q.; Huang, H.T.; Bai, G.; Miao, L.; Zhou, B.S.; Liu, L.J.; Sun, W.H.; et al. Low-temperature-poling awakened high dielectric breakdown strength and outstanding improvement of discharge energy density of (Pb, La)(Zr, Sn, Ti)O3 relaxor thin film. Nano Energy 2020, 77, 105132. [Google Scholar] [CrossRef]

- Peng, B.L.; Wang, T.T.; Liu, L.J.; Chen, X.; Li, J.F.; Zhang, Q.; Yang, R.S.; Sun, W.H.; Wang, Z.L. P-GaN-substrate sprouted giant pure negative electrocaloric effect in Mn-doped Pb(Zr0.3Ti0.7)O3 thin film with a super-broad operational temperature range. Nano Energy 2021, 86, 106059. [Google Scholar] [CrossRef]

- Chaves, A.; Katiyar, R.S.; Porto, S. Coupled modes with A1 symmetry in tetragonal BaTiO3. Phys. Rev. B. 1974, 10, 3522–3533. [Google Scholar] [CrossRef]

- Lee, J.H.; Hwang, K.S.; Kim, T.S. Microstress relaxation effect of Pb(Zr0.52Ti0.48)O3 films with thicknesses for micro/nano piezoelectric device. Appl. Phys. Lett. 2010, 96, 092904. [Google Scholar] [CrossRef]

- Rodrigues, S.; Rolo, A.G.; Khodorov, A.; Pereira, M.; Gomes, M. Determination of residual stress in PZT films produced by laser ablation with X-ray diffraction and Raman spectroscopy. J. Eur. Chem. Soc. 2010, 30, 521–524. [Google Scholar] [CrossRef]

- Rouquette, J.; Haines, J.; Bornand, V.; Pintard, M.; Papet, P.; Bonnet, B.; Gorelli, F.A. P-T phase diagram of PbZr0.52Ti0.48O3 (PZT). Solid State Sci. 2003, 5, 451–457. [Google Scholar] [CrossRef]

- Beshenkov, V.G.; Znamenskii, A.G.; Irzhak, A.V.; Marchenko, V.A. Method of phase composition diagnostics of lead zirconate titanate films based on Raman spectra. Appl. Surf. Sci. 2021, 562, 149937. [Google Scholar] [CrossRef]

- Begg, B.D.; Finnie, K.S.; Vance, E.R. Raman Study of the Relationship between Room-Temperature Tetragonality and the Curie Point of Bariam Titanate. J. Am. Chem. Soc. 1996, 79, 2666–2672. [Google Scholar]

- Ohno, T.; Matsuda, T.; Ishikawa, K.; Suzuki, H. Thickness Dependence of Residual Stress in Alkoxide-Derived Pb(Zr0.3Ti0.7)O3 Thin Film by Chemical Solution Deposition. Jpn. J. Appl. Phys. 2006, 45, 7265–7269. [Google Scholar] [CrossRef]

- Wu, Z.; Zhou, J.; Chen, W.; Shen, J.; Lv, C. Effects of residual stress on the electrical properties in PbZr0.52Ti0.48O3 thin films. J. Sol-Gel Sci. Technol. 2015, 75, 551–556. [Google Scholar] [CrossRef]

- Berfield, T.A.; Ong, R.J.; Payne, D.A.; Sottos, N.R. Residual stress effects on piezoelectric response of sol-gel derived lead zirconate titanate thin films. J. Appl. Phys. 2007, 101, 024102. [Google Scholar] [CrossRef]

- Hao, X.; Wang, P.; Zhang, X.; Xu, J. Microstructure and energystorage performance of PbO–B2O3–SiO2–ZnO glass added (Pb0.97La0.02)(Zr0.97Ti0.03)O3 antiferroelectric thick films. Mater. Res. Bull. 2013, 48, 84–88. [Google Scholar] [CrossRef]

- Li, P.; Zhai, J.W.; Zeng, H.R.; Zhao, K.Y.; Shen, B.; Chen, H. Effects of LaNiO3 seeding layers on the crystal structure and electrical properties in 0.94(Bi0.5Na0.5)TiO3–0.06BaTiO3 thin films. Ceram. Int. 2015, 41, 12980–12987. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Li, W.L.; Cao, W.P.; Yu, F.; Qiao, Y.L.; Zhang, T.D.; Fei, W.D. Mn doping to enhance energy storage performance of lead-free 0.7NBT-0.3ST thin films with weak oxygen vacancies. Appl. Phys. Lett. 2017, 110, 243901. [Google Scholar] [CrossRef]

- Wang, X.L.; Zhang, L.W.; Hao, X.H.; An, S.L.; Song, B. Dielectric properties and energy-storage performances of (1-x)Pb(Mg1/3Nb2/3)O3-xPbTiO3 relaxor ferroelectric thin films. J. Mater. Sci. Mater. Electron. 2015, 26, 9583–9590. [Google Scholar] [CrossRef]

- Xu, Z.; Hao, X.H.; An, S.L. Dielectric propertie and energy-storage performance of (Na0.5Bi0.5)TiO3-SrTiO3 thick films derived from polyvinylpyrrolidone-modified chemical solution. J. Alloys Compd. 2015, 639, 387–392. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, H.; Hao, X.H.; Zhang, Q. Orientation-dependent energy-storage performance and electrocaloric effect in PLZST antiferroelectric thick films. Mater. Res. Bull. 2016, 84, 177–184. [Google Scholar] [CrossRef]

- Xie, Z.K.; Yue, Z.X.; Ruehl, G.; Peng, B.L.; Zhang, J.; Qi, Y.; Zhang, X.H.; Li, L.T. Bi(Ni1/2Zr1/2)O3-PbTiO3 relaxor-ferroelectric films for piezoelectric energy harvesting and electrostatic storage. Appl. Phys. Lett. 2014, 104, 243902. [Google Scholar] [CrossRef]

- Cao, W.P.; Li, W.L.; Feng, Y.; Bai, T.; Qiao, Y.L.; Hou, Y.F.; Zhang, T.D.; Yu, F.; Fei, W.D. Defect dipole induced large recoverable strain and high energy-storage density in leadfree Na0.5Bi0.5TiO3-based systems. Appl. Phys. Lett. 2016, 108, 202902. [Google Scholar] [CrossRef]

- Zhao, L.; Gao, J.; Liu, Q.; Zhang, S.; Li, J.F. Silver Niobate Lead-Free Antiferroelectric Ceramics: Enhancing Energy Storage Density by B-Site Doping. ACS Appl. Mater. Interfaces 2018, 10, 819–826. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Shen, Y.; Zhang, S.H.; Zhang, Q.M.; Clarke, D.R. Polymer-based dielectrics with high energy storage density. Annu. Rev. Mater. Res. 2015, 45, 433–458. [Google Scholar] [CrossRef]

- Müller, J.; Böscke, T.S.; Schröder, U.; Mueller, S.; Bräuhaus, D.; Böttger, U.; Frey, L.; Mikolajick, T. Ferroelectricity in Simple Binary ZrO2 and HfO2. Nano Lett. 2012, 12, 4318–4323. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.X.; Peng, B.L.; Zhu, J.G.; Liu, L.J.; Sun, W.H.; Leighton, G.; Shaw, C.; Lou, N.N.; Zhang, Q. Enhanced energy storage performance of (1-x)(BCT-BMT)-xBFO lead-free relaxor ferroelectric ceramics in a broad temperature range. J. Alloys Compd. 2019, 789, 303–312. [Google Scholar] [CrossRef]

- He, S.K.; Peng, B.L.; Leighton, G.; Shaw, C.; Wang, N.Z.; Sun, W.H.; Liu, L.J.; Zhang, Q. High-performance La-doped BCZT thin film capacitors on LaNiO3/Pt composite bottom electrodes with ultra-high efficiency and high thermal stability. Ceram. Int. 2019, 45, 11749–11755. [Google Scholar] [CrossRef]

- Li, L.C.; Xu, M.X.; Zhang, Q.; Chen, P.; Wang, N.Z.; Xiong, D.K.; Peng, B.L.; Liu, L.J. Electrocaloric effect in La-doped BNT-6BT relaxor ferroelectric ceramics. Ceram. Int. 2018, 44, 343–350. [Google Scholar] [CrossRef]

- Ren, P.R.; Liu, Z.C.; Wang, Q.; Peng, B.L.; Ke, S.M.; Fan, H.Q.; Zhao, G.Y. Large nonlinear dielectric behavior in BaTi(1-x)SnxO3. Sci. Rep. 2017, 7, 6693. [Google Scholar]

- Wang, J.; Sun, N.; Li, Y.; Zhang, Q.; Hao, X.; Chou, X. Effects of Mn doping on dielectric properties and energy-storage performance of Na0.5Bi0.5TiO3 thick films. Ceram. Int. 2017, 43, 7804–7809. [Google Scholar] [CrossRef]

- Liu, X.H.; Li, Y.; Hao, X.H. Ultra-high energy-storage density and fast discharge speed of (Pb0.98−xLa0.02Srx)(Zr0.9Sn0.1)0.995O3 antiferroelectric ceramics prepared via tape-casting method. J. Mater. Chem. A 2019, 19, 11858–11866. [Google Scholar] [CrossRef]

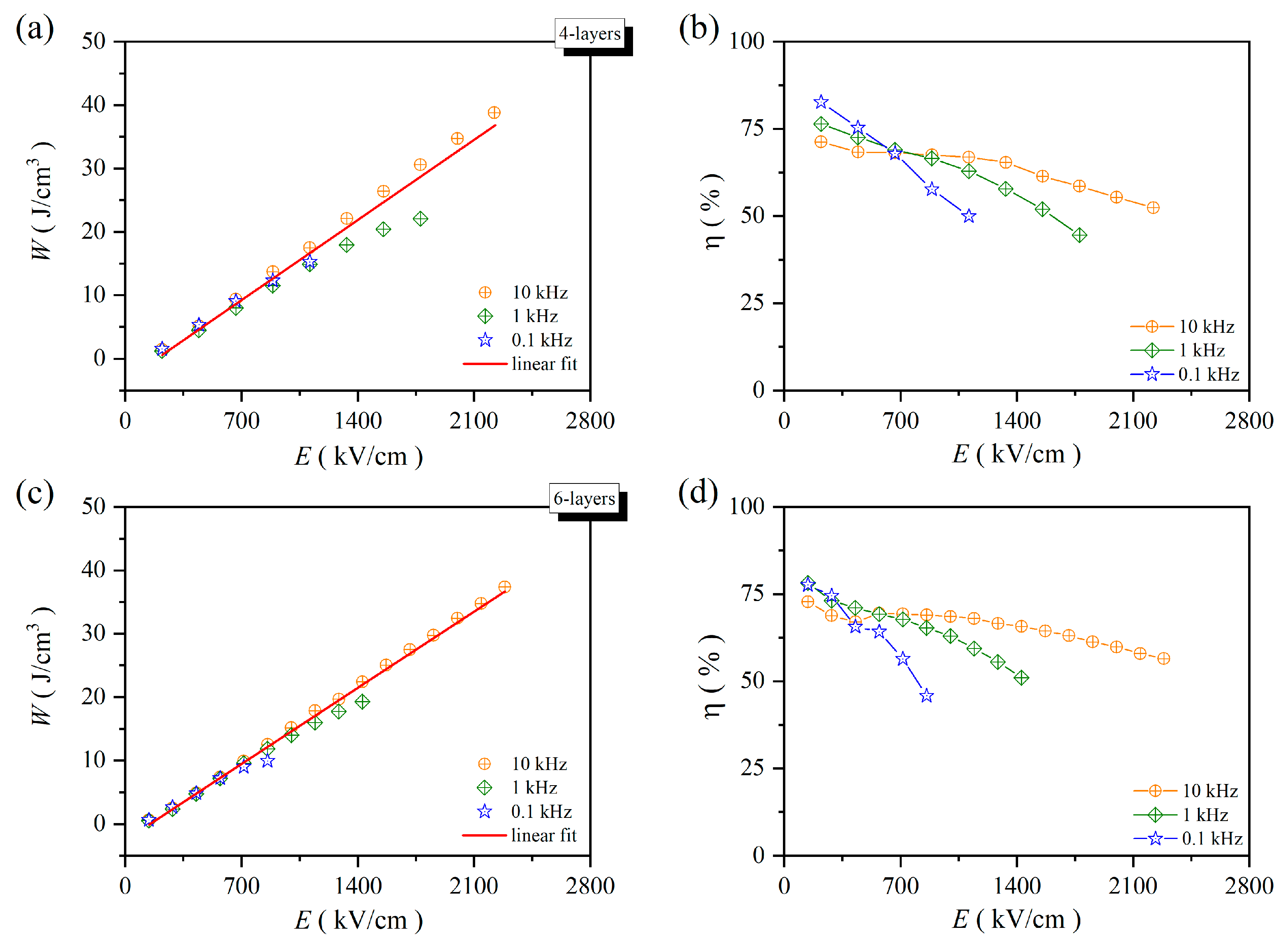

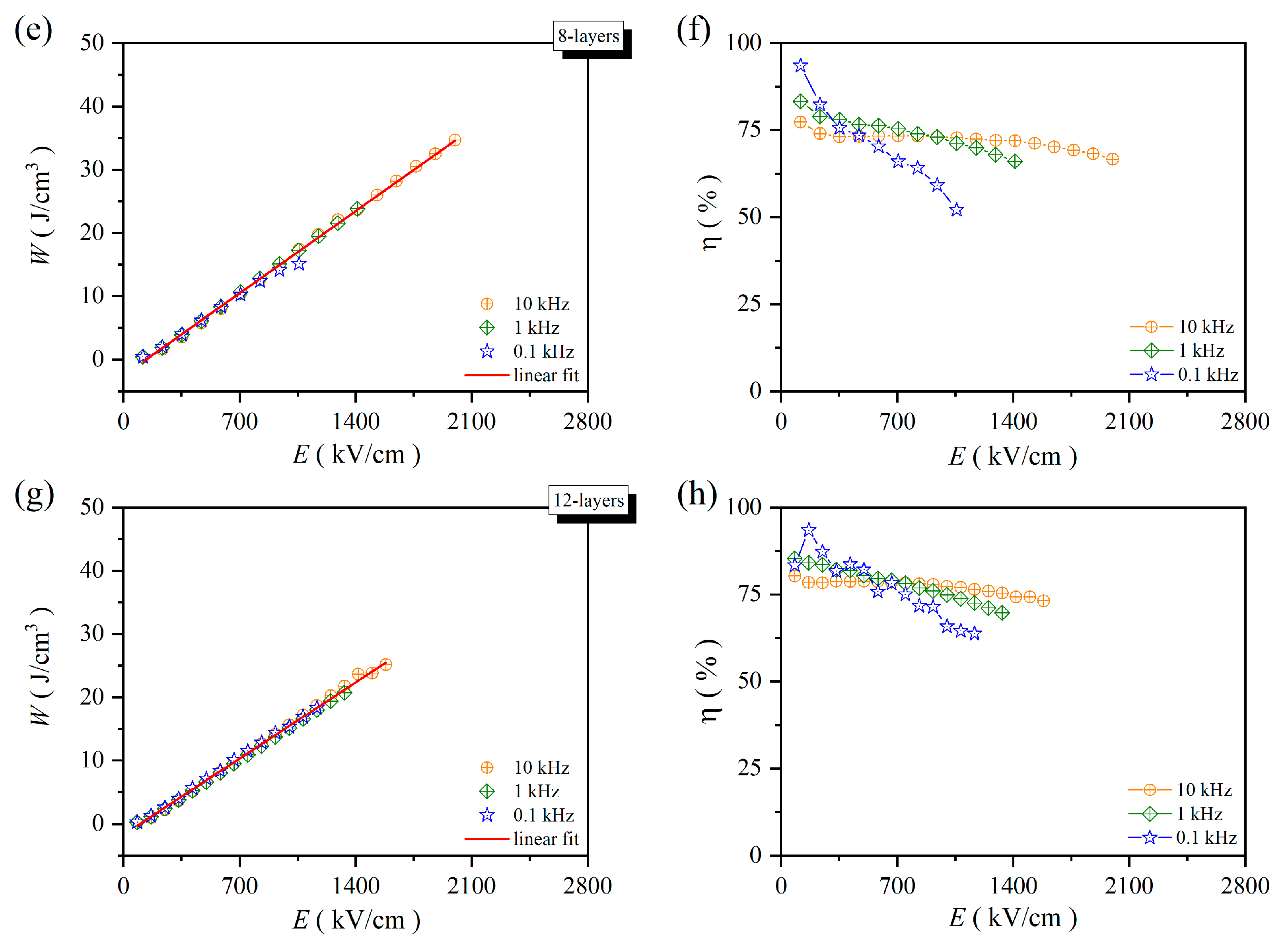

| Materials | Wmax (J/cm3) | η (%) | E (kV/cm) | References |

|---|---|---|---|---|

| 4-layers | 39.76 | 53.78 | 2157 | This work |

| 6-layers | 37.37 | 56.47 | 2285 | This work |

| 8-layers | 34.67 | 66.67 | 2000 | This work |

| 12-layers | 24.61 | 72.74 | 1584 | This work |

| 0.8PMN-0.2PT | 31 | 64 | 2000 | [49] |

| BNT-ST | 36.1 | 40.8 | 1965 | [50] |

| PLZST | 13.5 | 73 | 900 | [51] |

| 0.7NBT-0.3ST | 27 | 45.2 | 1903 | [48] |

| 0.4BNZ-0.6PT | 39.8 | 56.5 | 2167 | [52] |

| Samples | Pmax − Pr (μC/cm2) | Pr (μC/cm2) | W (J/cm3) | η (%) |

|---|---|---|---|---|

| 4-layers | 40.71 | 11.89 | 15.29 | 65.37 |

| 6-layers | 41.83 | 9.50 | 15.43 | 68.20 |

| 8-layers | 44.07 | 8.45 | 15.68 | 71.64 |

| 12-layers | 46.69 | 7.10 | 15.73 | 77.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, L.; Han, F.; Chen, K.; Deng, J.; Liu, L.; Peng, B. Synthesis of 0.75Pb(Zr0.52Ti0.48)O3-0.25BiFeO3 Thin Film Capacitors with Excellent Efficiency and Thermal Stability. Molecules 2025, 30, 8. https://doi.org/10.3390/molecules30010008

Wu L, Han F, Chen K, Deng J, Liu L, Peng B. Synthesis of 0.75Pb(Zr0.52Ti0.48)O3-0.25BiFeO3 Thin Film Capacitors with Excellent Efficiency and Thermal Stability. Molecules. 2025; 30(1):8. https://doi.org/10.3390/molecules30010008

Chicago/Turabian StyleWu, Li, Feifei Han, Kaiyuan Chen, Jianming Deng, Laijun Liu, and Biaolin Peng. 2025. "Synthesis of 0.75Pb(Zr0.52Ti0.48)O3-0.25BiFeO3 Thin Film Capacitors with Excellent Efficiency and Thermal Stability" Molecules 30, no. 1: 8. https://doi.org/10.3390/molecules30010008

APA StyleWu, L., Han, F., Chen, K., Deng, J., Liu, L., & Peng, B. (2025). Synthesis of 0.75Pb(Zr0.52Ti0.48)O3-0.25BiFeO3 Thin Film Capacitors with Excellent Efficiency and Thermal Stability. Molecules, 30(1), 8. https://doi.org/10.3390/molecules30010008