Inkjet Printing of High-Color-Purity Blue Organic Light-Emitting Diodes with Host-Free Inks

Abstract

1. Introduction

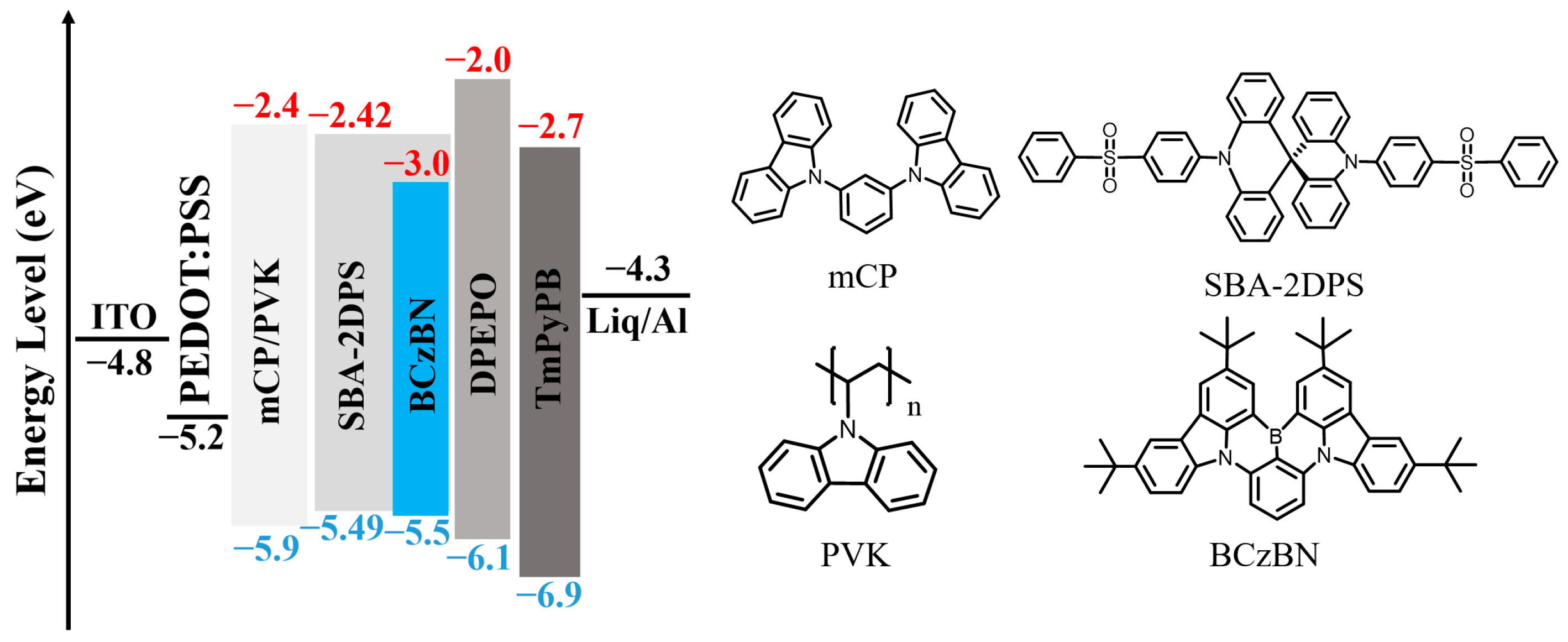

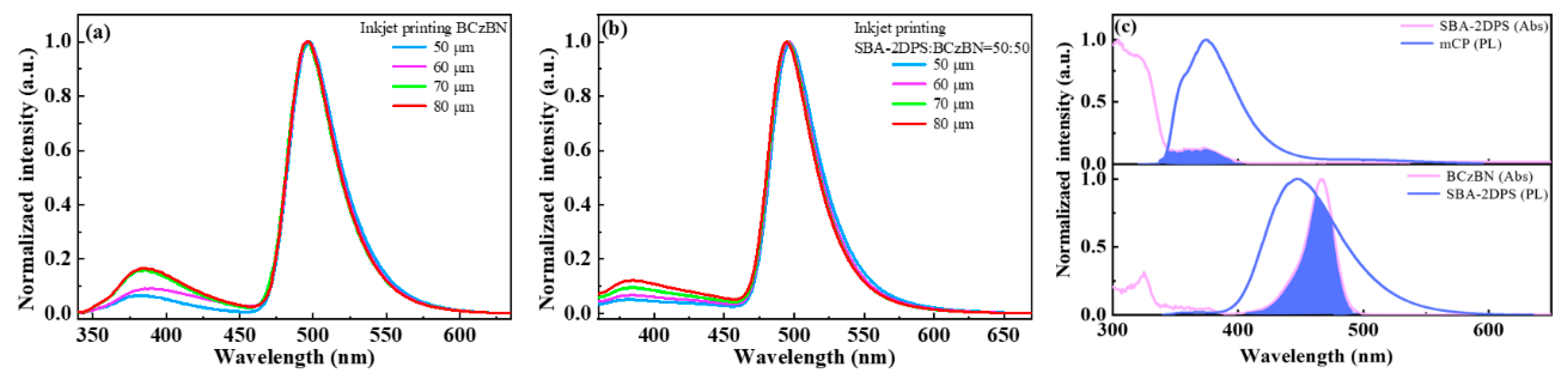

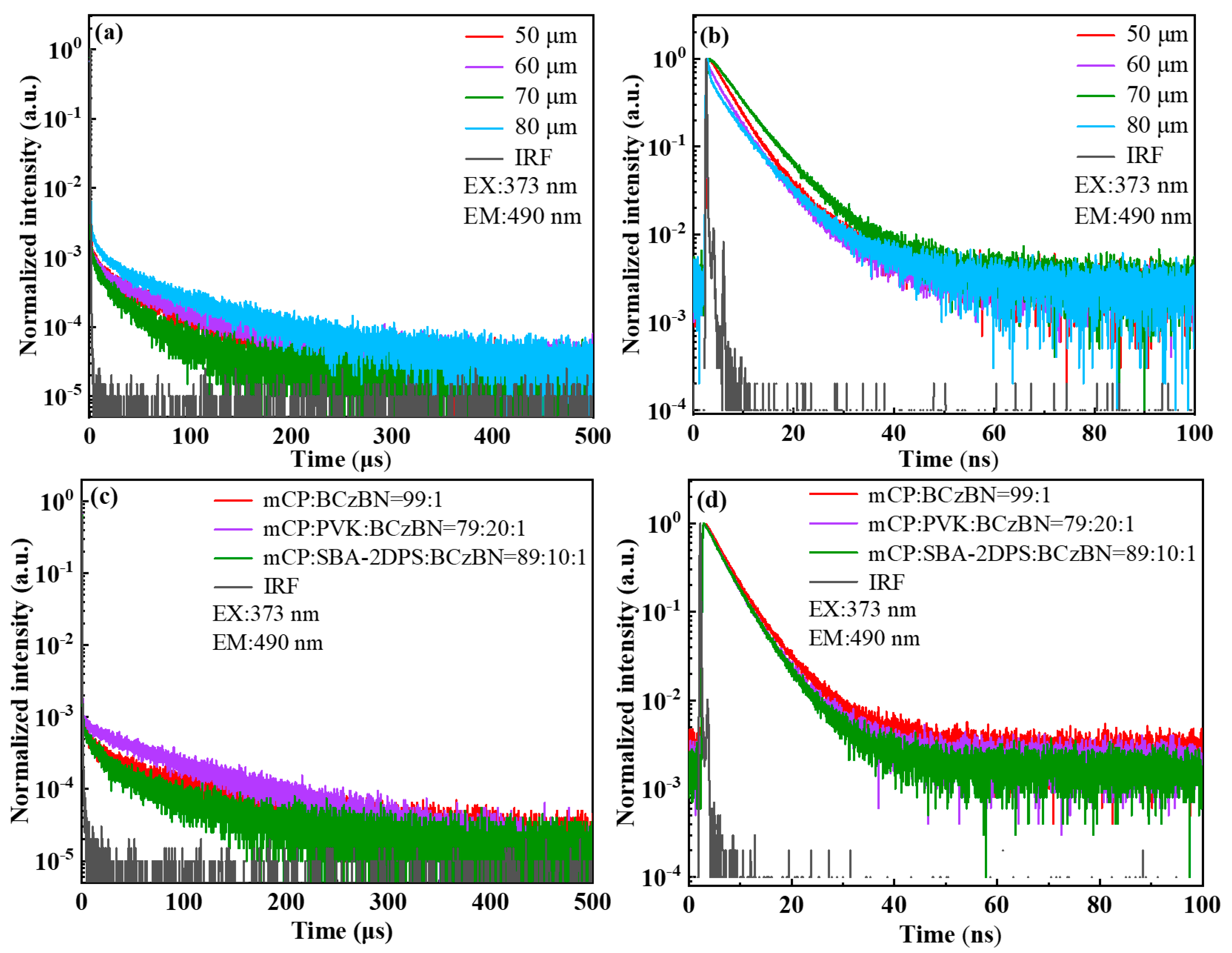

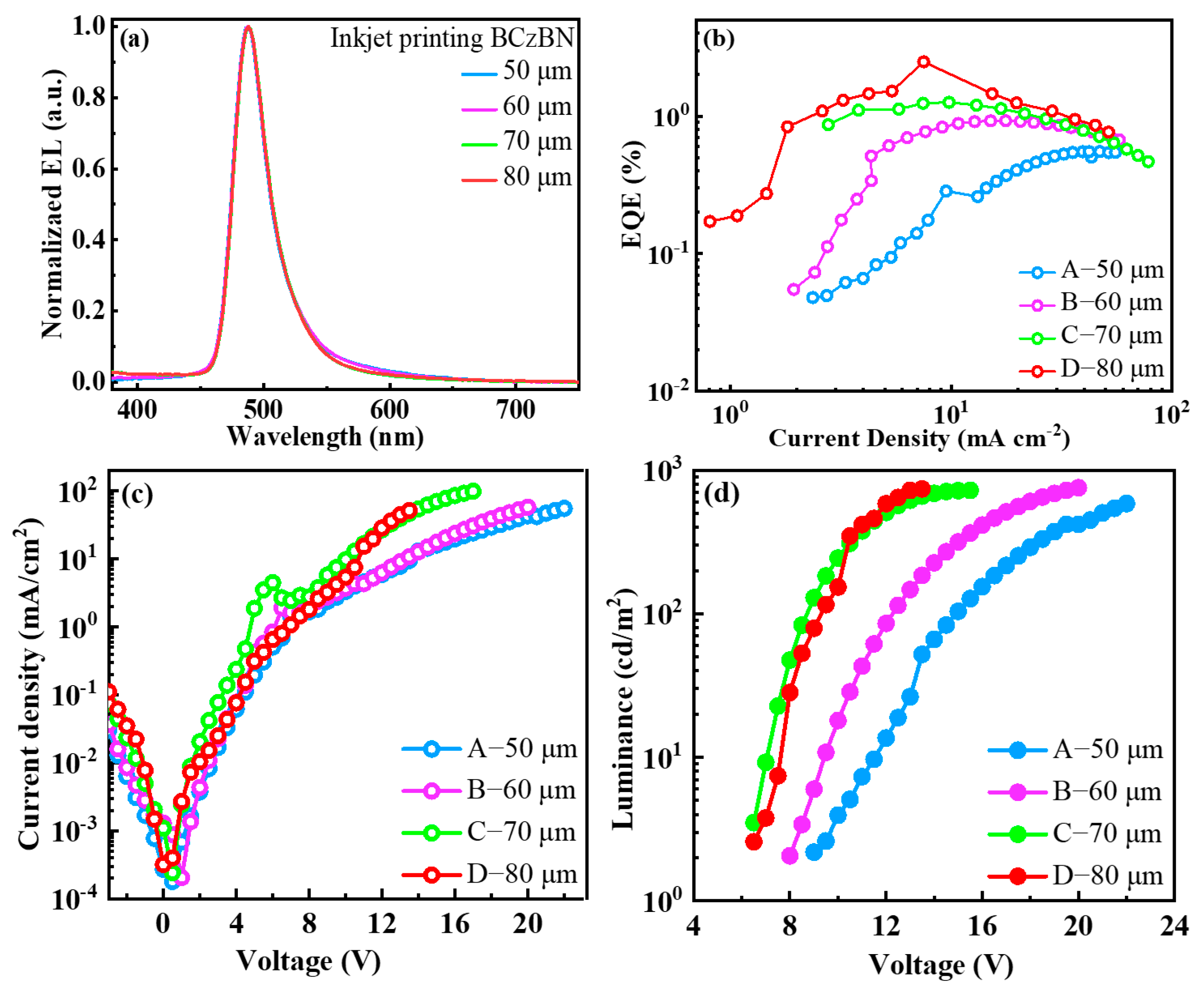

2. Results and Discussion

3. Experimental Section

3.1. OLED Fabrication and Characterization

3.2. Inkjet Printing of the Emitting Layer

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Meng, Q.-Y.; Wang, R.; Wang, Y.-L.; Guo, X.-W.; Liu, Y.-Q.; Wen, X.-L.; Yao, C.-Y.; Qiao, J. Longevity gene responsible for robust blue organic materials employing thermally activated delayed fluorescence. Nat. Commun. 2023, 14, 3927. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Zhang, C.; Yan, H.; Chai, Y.; Zhou, D. A simple strategy for obtaining aggregation-induced delayed fluorescence material achieving nearly 20% external quantum efficiency for non-doped solution-processed OLEDs. Chem. Eng. J. 2023, 476, 146675. [Google Scholar] [CrossRef]

- Liao, C.; Chen, B.; Xie, Q.; Li, X.; Liu, H.; Wang, S. A Breakthrough in Solution-Processed Ultra-Deep-Blue HLCT OLEDs: A Record External Quantum Efficiency Exceeding 10% Based on Novel V-Shaped Emitters. Adv. Mater. 2023, 35, e2305310. [Google Scholar] [CrossRef]

- Zhou, L.; Yang, L.; Yu, M.; Jiang, Y.; Liu, C.-F.; Lai, W.-Y.; Huang, W. Inkjet-Printed Small-Molecule Organic Light-Emitting Diodes: Halogen-Free Inks, Printing Optimization, and Large-Area Patterning. ACS Appl. Mater. Interfaces 2017, 9, 40533–40540. [Google Scholar] [CrossRef]

- Cai, X.; Pan, Y.; Song, X.; Li, C.; Pu, Y.; Zhuang, X.; Bi, H.; Wang, Y. Precisely Regulation of Peripheral Decoration of Multi-Resonance Molecules and Construction of Highly Efficient Solution-Processed Orange–Red OLEDs with External Quantum Efficiency Approaching 20%. Adv. Opt. Mater. 2023, 2023, 2302811. [Google Scholar] [CrossRef]

- Wong, M.Y.; Zysman-Colman, E. Purely Organic Thermally Activated Delayed Fluorescence Materials for Organic Light-Emitting Diodes. Adv. Mater. 2017, 29, 1605444. [Google Scholar] [CrossRef]

- Data, P.; Pander, P.; Okazaki, M.; Takeda, Y.; Minakata, S.; Monkman, A.P. Dibenzo[a,j]phenazine-Cored Donor–Acceptor–Donor Compounds as Green-to-Red/NIR Thermally Activated Delayed Fluorescence Organic Light Emitters. Angew. Chem. 2016, 128, 5833–5838. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, J.; Wang, L.; Huang, T.; Meng, G.; Wang, X.; Zeng, X.; Du, M.; Fan, T.; Yin, C.; et al. Multiple Fusion Strategy for High-Performance Yellow OLEDs with Full Width at Half Maximums Down to 23 nm and External Quantum Efficiencies up to 37.4%. Adv. Mater. 2023, 35, e2209396. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, D.; Huang, T.; Gillett, A.J.; Liu, Y.; Hu, D.; Cui, L.; Bin, Z.; Li, G.; Wei, J.; et al. Multi-Resonance Deep-Red Emitters with Shallow Potential-Energy Surfaces to Surpass Energy-Gap Law*. Angew. Chem. Int. Ed. Engl. 2021, 60, 20498–20503. [Google Scholar] [CrossRef]

- Song, X.; Shen, S.; Zou, S.; Guo, F.; Gao, S.; Wang, Y.; Zhang, Y. Asymmetric strategy based on 5H-benzofuro[3,2-c]carbazole enables efficient narrowband multi-resonance thermally activated delayed fluorescence emitters. J. Mater. Chem. C 2023, 11, 16928–16932. [Google Scholar] [CrossRef]

- Monkman, A. Why Do We Still Need a Stable Long Lifetime Deep Blue OLED Emitter? ACS Appl. Mater. Interfaces 2022, 14, 20463–20467. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Zhang, L.; Wang, J.; Kumar Gupta, A.; Samuel, I.D.W.; Zysman-Colman, E. Merging Boron and Carbonyl based MR-TADF Emitter Designs to Achieve High Performance Pure Blue OLEDs. Angew. Chem. Int. Ed. Engl. 2023, 62, e202305182. [Google Scholar] [CrossRef] [PubMed]

- Mubarok, H.; Amin, A.; Lee, T.; Jung, J.; Lee, J.H.; Lee, M.H. Triptycene-Fused Sterically Shielded Multi-Resonance TADF Emitter Enables High-Efficiency Deep Blue OLEDs with Reduced Dexter Energy Transfer. Angew. Chem. Int. Ed. Engl. 2023, 62, e202306879. [Google Scholar] [CrossRef] [PubMed]

- Liang, L.; Qu, C.; Fan, X.; Ye, K.; Zhang, Y.; Zhang, Z.; Duan, L.; Wang, Y. Carbonyl- and Nitrogen-Embedded Multi-Resonance Emitter with Ultra-Pure Green Emission and High Electroluminescence Efficiencies. Angew. Chem. Int. Ed. Engl. 2023, 63, e202316710. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Chen, Z.; Zhou, C.; Ni, F.; Huang, Z.; Cao, X.; Yang, C. Versatile Host Materials for Both D-A-Type and Multi-Resonance TADF Emitters toward Solution-Processed OLEDs with Nearly 30% EQE. Adv. Mater. 2023, 35, e2300510. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Xing, R.; Peng, Z.; Lin, Y.; Du, Z.; Ding, J.; Wang, L.; Han, Y. To inhibit coffee ring effect in inkjet printing of light-emitting polymer films by decreasing capillary force. Chin. Chem. Lett. 2019, 30, 135–138. [Google Scholar] [CrossRef]

- Wei, C.; Su, W.; Li, J.; Xu, B.; Shan, Q.; Wu, Y.; Zhang, F.; Luo, M.; Xiang, H.; Cui, Z.; et al. A Universal Ternary-Solvent-Ink Strategy toward Efficient Inkjet-Printed Perovskite Quantum Dot Light-Emitting Diodes. Adv. Mater. 2022, 34, e2107798. [Google Scholar] [CrossRef] [PubMed]

- C, A.; Szymanski, M.Z.; Luszczynska, B.; Ulanski, J. Inkjet Printing of Super Yellow: Ink Formulation, Film Optimization, OLEDs Fabrication, and Transient Electroluminescence. Sci. Rep. 2019, 9, 8493. [Google Scholar] [CrossRef] [PubMed]

- Yang, P.; Zhang, L.; Kang, D.J.; Strahl, R.; Kraus, T. High-Resolution Inkjet Printing of Quantum Dot Light-Emitting Microdiode Arrays. Adv. Opt. Mater. 2019, 8, 1901429. [Google Scholar] [CrossRef]

- Liu, L.; Chen, D.; Xie, J.; Piao, J.; Liu, Y.; Wang, W.; Cao, K.; Chen, S. Universally applicable small-molecule co-host ink formulation for inkjet printing red, green, and blue phosphorescent organic light-emitting diodes. Org. Electron. 2021, 96, 106247. [Google Scholar] [CrossRef]

- Chen, M.; Xie, L.; Wei, C.; Yi, Y.-Q.-Q.; Chen, X.; Yang, J.; Zhuang, J.; Li, F.; Su, W.; Cui, Z. High performance inkjet-printed QLEDs with 18.3% EQE: Improving interfacial contact by novel halogen-free binary solvent system. Nano Res. 2021, 14, 4125–4131. [Google Scholar] [CrossRef]

- Kant, C.; Mahmood, S.; Katiyar, M. Large-Area Inkjet-Printed OLEDs Patterns and Tiles Using Small Molecule Phosphorescent Dopant. Adv. Mater. Technol. 2022, 8, 2201514. [Google Scholar] [CrossRef]

- Wei, H.; Yi, Y.-Q.-Q.; Song, Y.; Xie, L.; Liu, Y.; Wei, Z.; Dai, Q.; Meng, X.; Su, W.; Cui, Z. Molecularly engineered host materials for high performance inkjet-printed thermally activated delayed fluorescence organic light-emitting diodes. J. Mater. Chem. C 2023, 11, 4342–4350. [Google Scholar] [CrossRef]

- Chen, S.; Wang, W.; Zhang, Z.; Li, Z.; Fan, K.; Zhang, Z.; Liu, L.; Chen, S. Ink formulation of phosphorescent emitter with mixed host and its application in inkjet-printed organic light-emitting devices. Org. Electron. 2023, 122, 106880. [Google Scholar] [CrossRef]

- Jung, S.-H.; Kim, J.-J.; Kim, H.-J. High performance inkjet printed phosphorescent organic light emitting diodes based on small molecules commonly used in vacuum processes. Thin Solid Film. 2012, 520, 6954–6958. [Google Scholar] [CrossRef]

- Feng, C.; Zheng, X.; Xu, R.; Zhou, Y.; Hu, H.; Guo, T.; Ding, J.; Ying, L.; Li, F. Highly efficient inkjet printed flexible organic light-emitting diodes with hybrid hole injection layer. Organic Electronics 2020, 85, 105822. [Google Scholar] [CrossRef]

- Pan, Y.; Liu, H.; Wang, S.; Han, X.; Li, X. Inkjet-printed alloy-like cross-linked hole-transport layer for high-performance solution-processed green phosphorescent OLEDs. J. Mater. Chem. C 2021, 9, 12712–12719. [Google Scholar] [CrossRef]

| Device | λmax a (nm) | FWHM b (nm) | Von c (V) | CEmax d (cd/A) | EQEmax e (%) | CIE(x,y) f |

|---|---|---|---|---|---|---|

| A | 488 | 32 | 11.5 | 1.1 | 0.6 | (0.14, 0.38) |

| B | 488 | 32 | 9.5 | 2.1 | 0.9 | (0.14, 0.38) |

| C | 488 | 32 | 7.3 | 2.5 | 1.3 | (0.14, 0.39) |

| D | 488 | 32 | 7.5 | 4.6 | 2.5 | (0.12, 0.38) |

| Device | λmax a (nm) | FWHM b (nm) | Von c (V) | CEmax d (cd/A) | EQEmax e (%) | CIE(x,y) f |

|---|---|---|---|---|---|---|

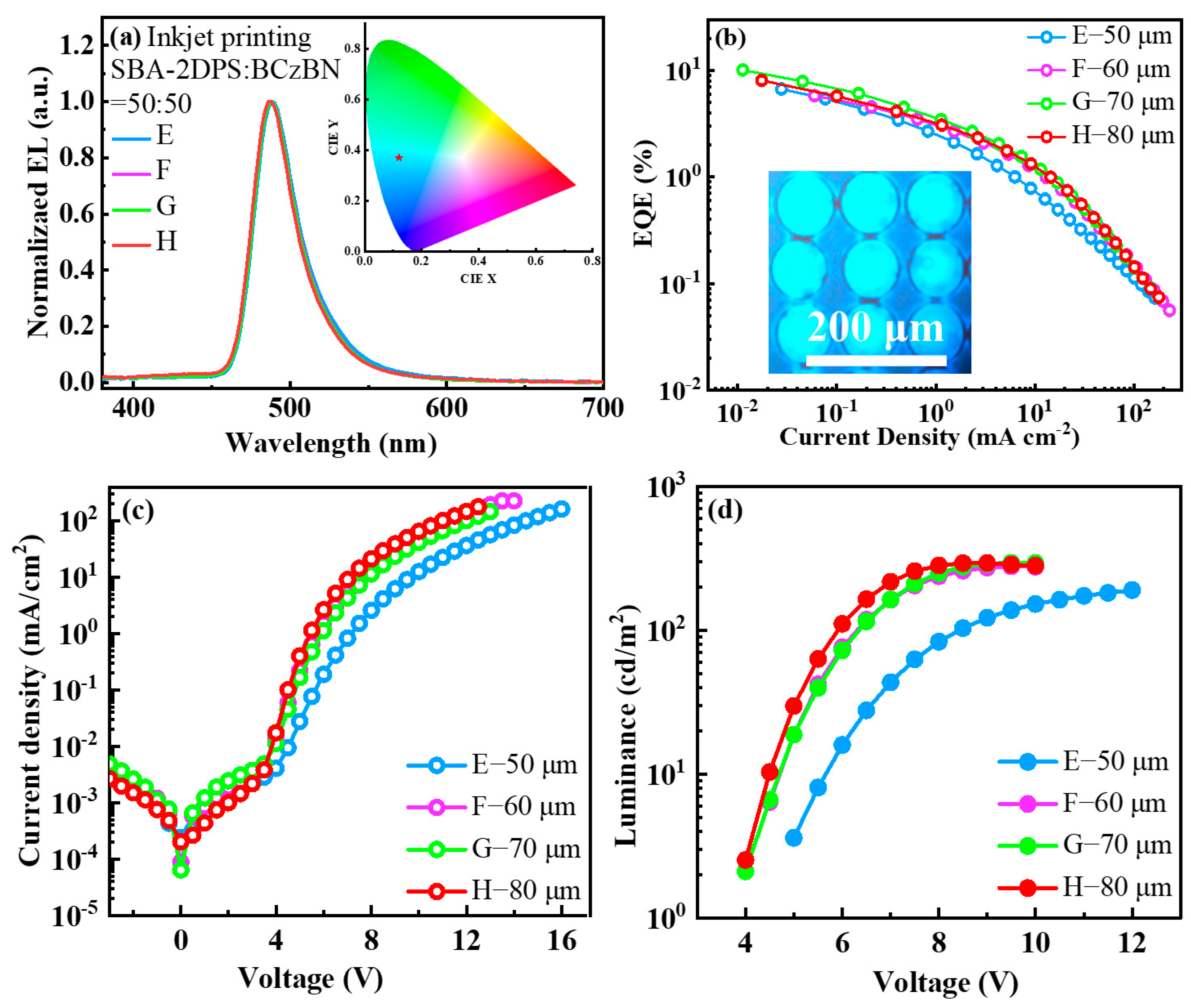

| E | 488 | 32 | 5.6 | 8.7 | 4.5 | (0.13, 0.39) |

| F | 488 | 32 | 4.6 | 10.7 | 5.8 | (0.13, 0.37) |

| G | 488 | 32 | 4.6 | 18.7 | 10.1 | (0.12, 0.37) |

| H | 488 | 32 | 4.5 | 14.4 | 8.1 | (0.12, 0.35) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, H.; Li, J.; Gong, S.; Lin, J.; Xie, G. Inkjet Printing of High-Color-Purity Blue Organic Light-Emitting Diodes with Host-Free Inks. Molecules 2024, 29, 2147. https://doi.org/10.3390/molecules29092147

Fang H, Li J, Gong S, Lin J, Xie G. Inkjet Printing of High-Color-Purity Blue Organic Light-Emitting Diodes with Host-Free Inks. Molecules. 2024; 29(9):2147. https://doi.org/10.3390/molecules29092147

Chicago/Turabian StyleFang, Hui, Jiale Li, Shaolong Gong, Jinliang Lin, and Guohua Xie. 2024. "Inkjet Printing of High-Color-Purity Blue Organic Light-Emitting Diodes with Host-Free Inks" Molecules 29, no. 9: 2147. https://doi.org/10.3390/molecules29092147

APA StyleFang, H., Li, J., Gong, S., Lin, J., & Xie, G. (2024). Inkjet Printing of High-Color-Purity Blue Organic Light-Emitting Diodes with Host-Free Inks. Molecules, 29(9), 2147. https://doi.org/10.3390/molecules29092147