Control of Pore Sizes in Epoxy Monoliths and Applications as Sheet-Type Adhesives in Combination with Conventional Epoxy and Acrylic Adhesives

Abstract

1. Introduction

2. Experimental Method

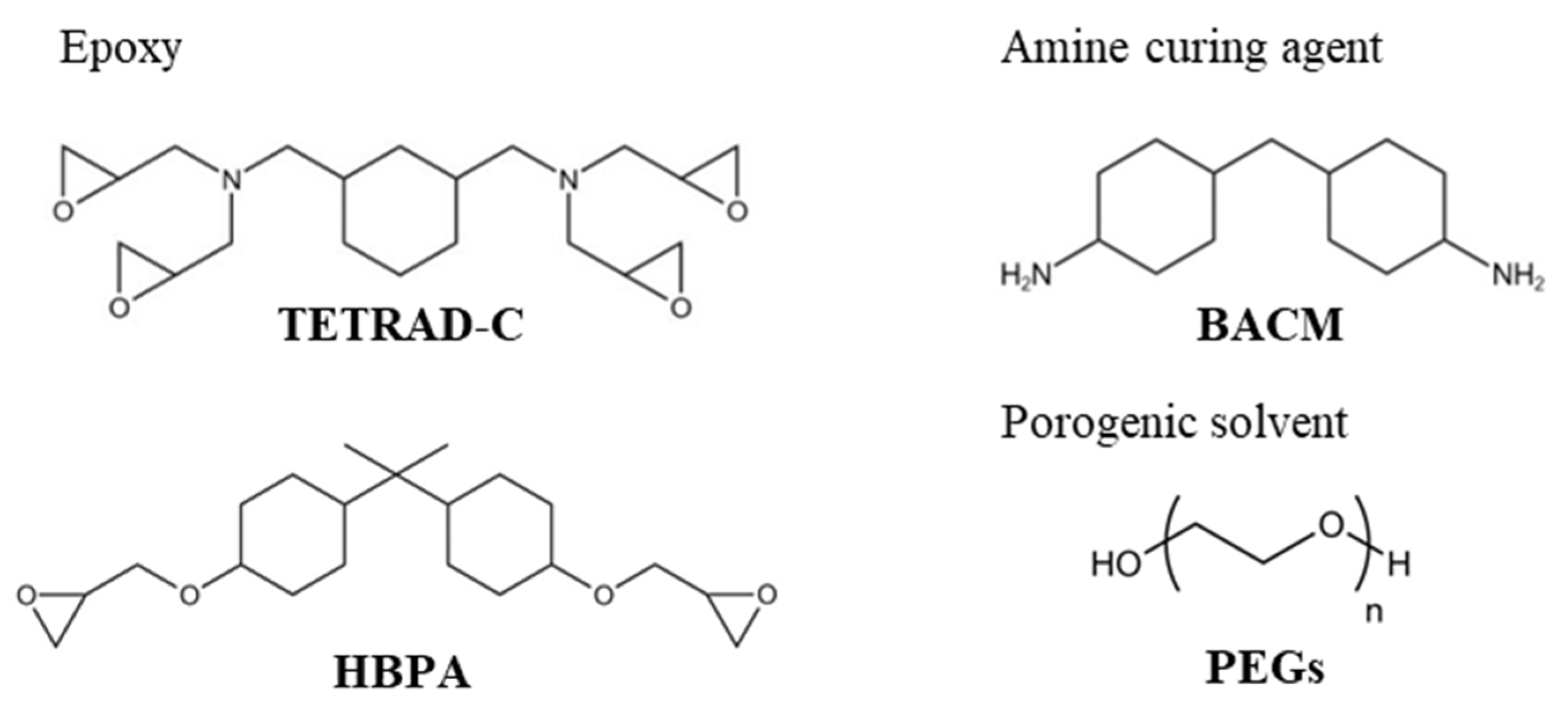

2.1. Fabrication of Epoxy Monoliths

2.2. Measurements

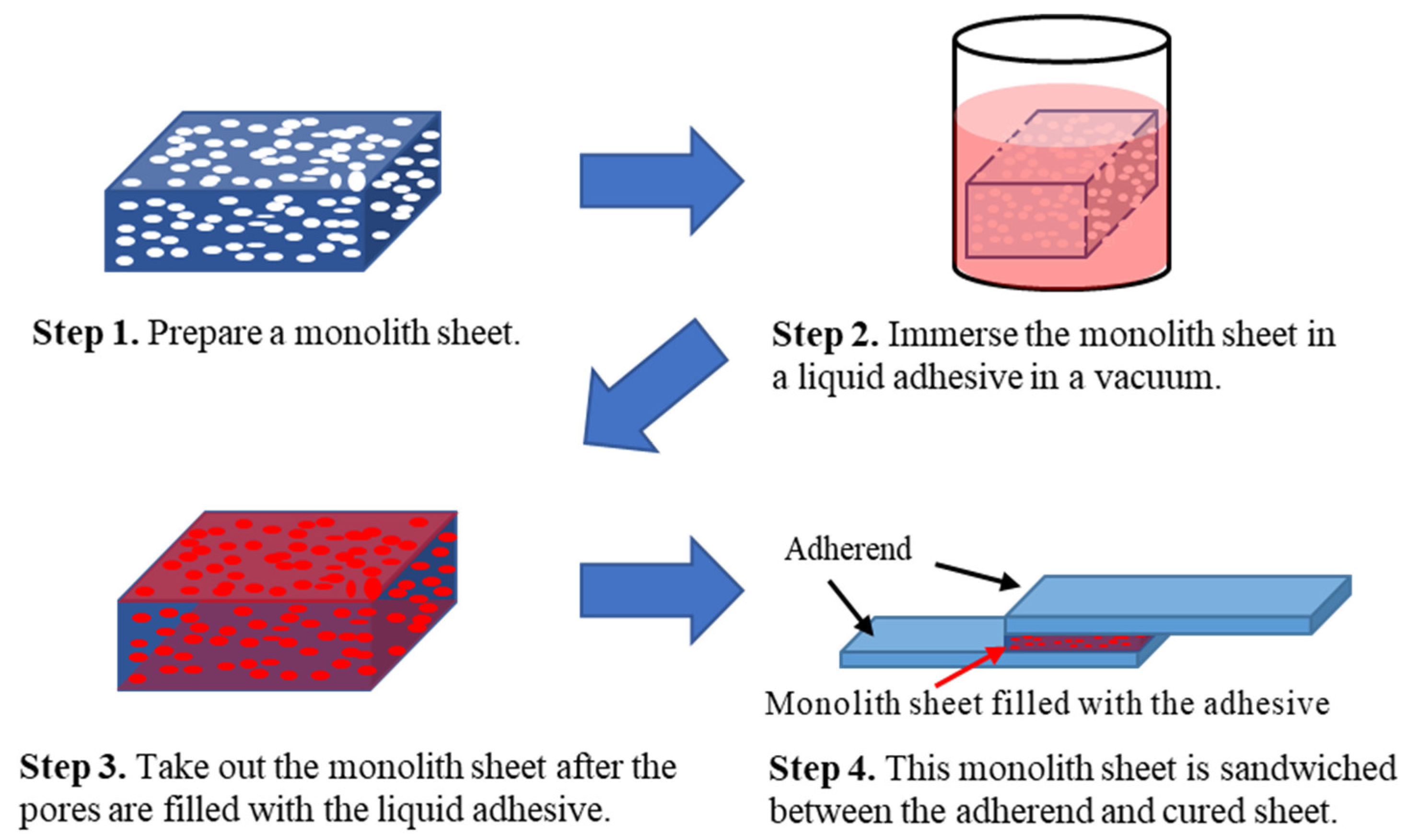

2.3. Adhesion Test

3. Results and Discussion

3.1. DSC Measurement

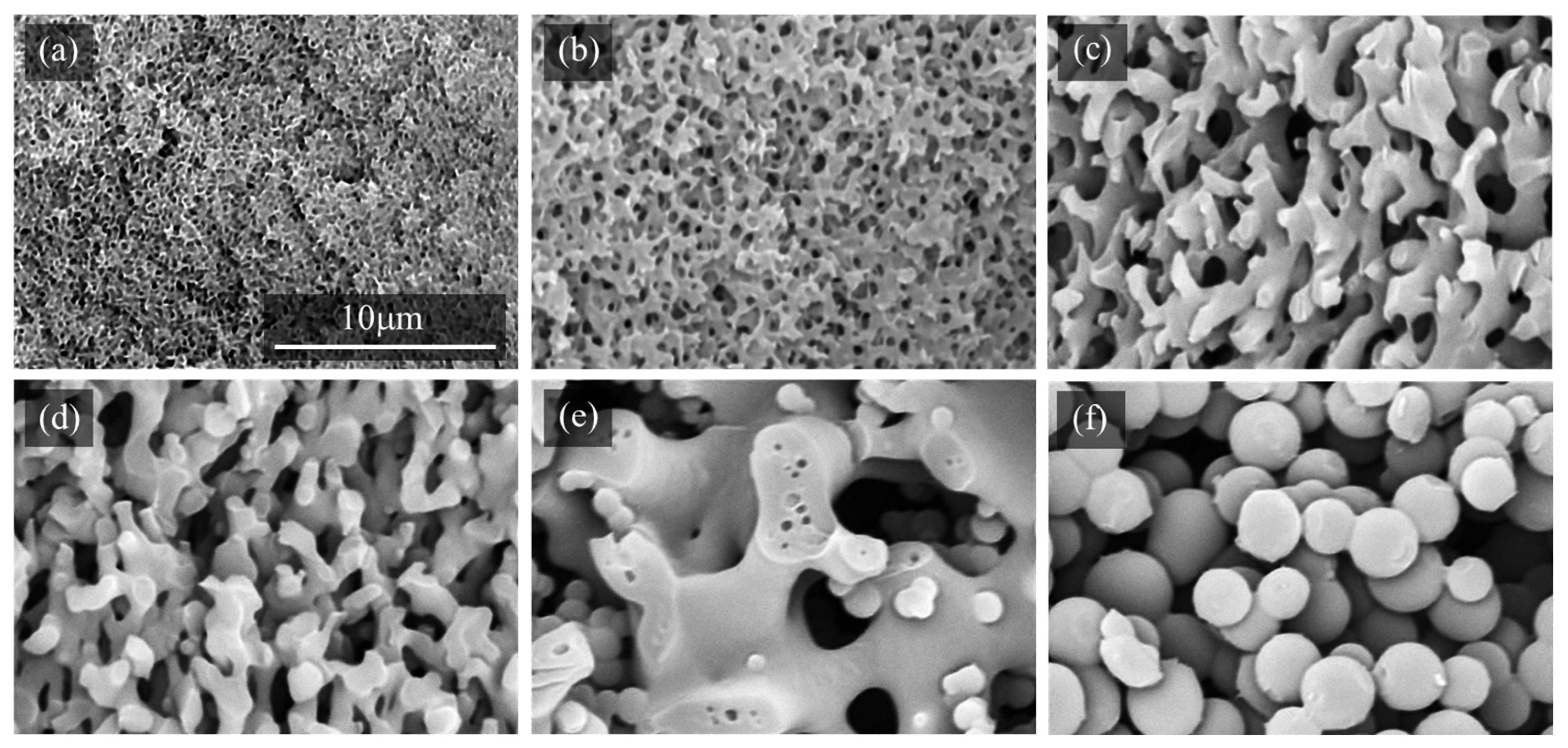

3.2. SEM Observations

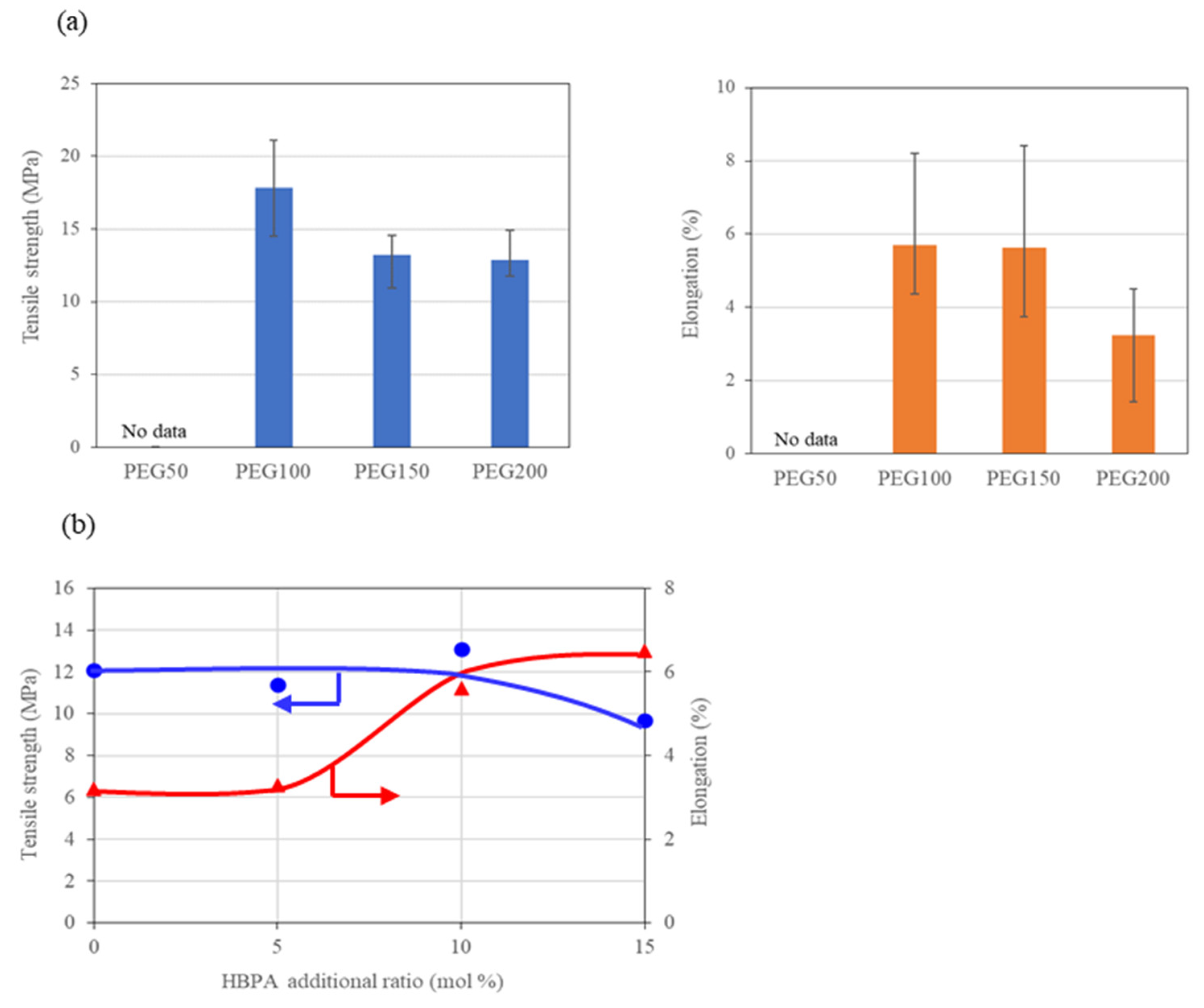

3.3. Mechanical and Physical Properties of the Monolith Sheets

3.4. Adhesive Property

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gajdosik, M.S.; Clifton, J.; Josic, D. Sample displacement chromatography as a method for purification of proteins and peptides from complex mixtures. J. Chromatogr. A 2012, 1239, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Tsujioka, N.; Hira, N.; Aoki, S.; Tanaka, N.; Hosoya, K. A new preparation method for well-controlled 3D skeletal epoxy resin-based polymer monoliths. Macromolecules 2005, 38, 9901–9903. [Google Scholar] [CrossRef]

- Zhu, T.; Row, K.H. Preparation and Applications of Hybrid Organic-Inorganic Monoliths: A Review. J. Sep. Sci. 2012, 35, 1294–1302. [Google Scholar] [CrossRef] [PubMed]

- Zajickova, Z. Advances in the Development and Applications of Organic-Silica Hybrid Monoliths. J. Sep. Sci. 2017, 40, 25–48. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, A.M.; Irgum, K. Epoxy-based Monoliths. A Novel Hydrophilic Separation Material for Liquid Chromatography of Biomolecules. Chem. Mater. 2006, 18, 6308–6315. [Google Scholar] [CrossRef]

- Hasegawa, G.; Kanamori, K.; Ishizuka, N.; Nakanishi, K. New Monolithic Capillary Columns with Well-Defined Macropores Based on Poly(styrene-co-divinylbenzene). ACS Appl. Mater. Interfaces 2012, 4, 2343–2347. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Aggarwal, P.; Lawson, J.S.; Tolley, H.D.; Lee, M.L. Organic monoliths for highperformance reversed-phase liquid chromatography. J. Sep. Sci. 2013, 36, 2767–2781. [Google Scholar] [CrossRef] [PubMed]

- Jandera, P. Advances in the development of organic polymer monolithic columns and their applications in food analysis—A review. J. Chromatogr. A 2013, 1313, 37–53. [Google Scholar] [CrossRef] [PubMed]

- Svec, F.; Lv, Y. Advances and recent trends in the field of monolithic columns for chromatography. Anal. Chem. 2015, 87, 250–273. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, J.; Liu, Z.; Zhang, Y.; Mi, Y. Preparation of Porous Epoxy Resin Materials by Reaction-Induced Phase Separation Regulated Using Fumed Silica. ACS Appl. Polym. Mater. 2023, 5, 2859–2866. [Google Scholar] [CrossRef]

- Okada, K.; Nandi, M.; Maruyama, J.; Oka, T.; Tsujimoto, T.; Kondoh, K.; Uyama, H. Fabrication of mesoporous polymer monolith: A template-free approach. Chem. Commun. 2011, 47, 7422–7424. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Diao, J.; Wang, Q.; Gu, S.; Chen, T.; Miao, C.; Yang, W.; Su, D. A nanodiamond/CNT–SiC monolith as a novel metal free catalyst for ethylbenzene direct dehydrogenation to styrene. Chem. Commun. 2014, 50, 7810–7812. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Li, X.; Jiang, X.; Dong, P.; Liu, H.; Bai, L.; Yan, H. Preparation of a poly(styrene-co-DPHA-co-EDMA) monolith and its application for the separation of small molecules and biomacromolecules by HPLC. Talanta 2017, 165, 339–345. [Google Scholar] [CrossRef] [PubMed]

- Hara, A.; Inoue, R.; Takahashi, N.; Nishida, K.; Kanaya, T. Trajectory of Critical Point in Polymerization-Induced Phase Separation of Epoxy/Oligoethylene Glycol Solutions. Macromolecules 2014, 47, 4453–4459. [Google Scholar] [CrossRef]

- Bonyadi, S.; Chung, T.S.; Krantz, W.B. Investigation of Corrugation Phenomenon in the Inner Contour of Hollow Fibers during the Non-Solvent Induced Phase-Separation Process. J. Membr. Sci. 2007, 299, 200–210. [Google Scholar] [CrossRef]

- Xin, Y.; Fujimoto, T.; Uyama, H. Facile Fabrication of Polycarbonate Monolith by Non-Solvent Induced Phase Separation Method. Polymer 2012, 53, 2847–2853. [Google Scholar] [CrossRef]

- Lloyd, D.R.; Kinzer, K.E.; Tseng, H.S. Microporous Membrane Formation via Thermally Induced Phase Separation 1. Solid Liquid-Phase Separation. J. Membr. Sci. 1990, 52, 239–261. [Google Scholar] [CrossRef]

- Yoneda, S.; Han, W.; Hasegawa, U.; Uyama, H. Facile Fabrication of Poly(methyl methacrylate) Monolith via Thermally Induced Phase Separation by Utilizing Unique Cosolvency. Polymer 2014, 55, 3212–3216. [Google Scholar] [CrossRef]

- Tsujioka, N.; Ishizuka, N.; Tanaka, N.; Kubo, T.; Hosoya, K. Well-Controlled 3D Skeletal Epoxy-Based Monoliths Obtained by Polymerization Induced Phase Separation. J. Polym. Sci. Part A Polym. Chem. 2008, 46, 3272–3281. [Google Scholar] [CrossRef]

- Plieva, F.M.; Andersson, J.; Galaev, I.Y.; Mattiasson, B. Characterization of polyacrylamide based monolithic columns. J. Sep. Sci. 2004, 27, 828–836. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, C.; Du, Z.; Xiang, A.; Li, H. Formation of porous epoxy monolith via concentrated emulsion polymerization. J. Colloid Interface Sci. 2008, 325, 453–458. [Google Scholar] [CrossRef] [PubMed]

- Sakai, M.; Kato, T.; Ishizuka, N.; Isobe, T.; Nakajima, A.; Fujishima, A. Bio-inspired highly hydrophobic surface with ecdysis behavior using an organic monolithic resin and titanium dioxide photocatalyst. J. Sol-Gel Sci. Technol. 2016, 77, 257–265. [Google Scholar] [CrossRef]

- Kubo, T.; Tsujioka, N.; Tanaka, N.; Hosoya, K. Co-continuous monolithic titania prepared by organic polymer monolith as pore template. Mater. Lett. 2010, 64, 177–180. [Google Scholar] [CrossRef]

- Shimizu, Y.; Sakakibara, K.; Yasuda, S.; Tsujii, Y. Lubrication Characteristics of Epoxy Resin-Based Monolithic Thin Films with a Well-Defined Porous Morphology. Adv. Eng. Mater. 2019, 21, 1900683. [Google Scholar] [CrossRef]

- Tominaga, R.; Nishimura, Y.; Suzuki, Y.; Takeda, Y.; Kotera, M.; Matsumoto, A. Co-continuous network polymers using epoxy monolith for the design of tough materials. Sci. Rep. 2021, 11, 1431–1441. [Google Scholar] [CrossRef] [PubMed]

- Tominaga, R.; Takeda, Y.; Kotera, M.; Suzuki, Y.; Matsumoto, A. Non-destructive observation of internal structures of epoxy monolith and co-continuous network polymer using X-ray CT imaging for elucidation of their unique mechanical features and fracture mechanism. Polymer 2022, 263, 125433. [Google Scholar] [CrossRef]

- Sugimoto, Y.; Nishimura, Y.; Uehara, F.; Matsumoto, A. Dissimilar Materials Bonding Using Epoxy Monolith. ACS Omega 2018, 3, 7532–7541. [Google Scholar] [CrossRef] [PubMed]

- Sakata, N.; Takeda, Y.; Kotera, M.; Suzuki, Y.; Matsumoto, A. Interfacial Structure Control and Three-Dimensional X-ray Imaging of an Epoxy Monolith Bonding System with Surface Modification. Langmuir 2020, 36, 10923–10932. [Google Scholar] [CrossRef]

- Capricho, J.C.; Fox, B.; Hameed, N. Multifunctionality in epoxy resins. Polym. Rev. 2020, 60, 1–41. [Google Scholar] [CrossRef]

- Mustata, F.; Bicu, I. Multifunctional Epoxy Resins: Synthesis and Characterization. Sci. Appl. Polym. Sci. 2000, 77, 2430–2436. [Google Scholar] [CrossRef]

- Liu, X.; Xiao, Y.; Luo, X.; Liu, B.; Guo, D.; Chen, L.; Wang, Y. Flame-Retardant multifunctional epoxy resin with high performances. Chem. Eng. J. 2022, 427, 132031. [Google Scholar] [CrossRef]

- Sakakibara, K.; Kagata, H.; Ishizuka, N.; Sato, T.; Tsujii, Y. Fabrication of surface skinless membranes of epoxy resin-based mesoporous monoliths toward advanced separators for lithium ion batteries. J. Mater. Chem. A 2017, 5, 6866–6873. [Google Scholar] [CrossRef]

- Aragishi, K.; Takeda, Y.; Suzuki, Y.; Matsumoto, A. Study on the Deformation and Fracture of Epoxy Monoliths through Mechanical Tensile and Compressive Tests and X-ray CT Imaging. Polym. J. 2024, 56, 529–540. [Google Scholar] [CrossRef]

- Jojibabu, P.; Zhang, Y.X.; Prusty, B.G. A review of research advances in epoxy-based nanocomposites as adhesive materials. Int. J. Adhes. Adhes. 2020, 96, 102454. [Google Scholar] [CrossRef]

- Wagle, P.G.; Tamboli, S.S.; More, A.P. Peelable coatings: A review. Prog. Org. Coat. 2021, 150, 106005. [Google Scholar] [CrossRef]

- Yang, S.; Liu, C.; Sun, Z.; Xu, M.; Feng, Y. Effects of resin pre-coating treatment and fibre reinforcement on adhesive bonding between CFRP sheet and concrete. Compos. Struct. 2022, 292, 115610. [Google Scholar] [CrossRef]

- Zhu, Z.; Tu, Y.; Ye, M.; Zeng, Q.; Rao, J.; Chen, N. A formaldehyde-free bio-composite sheet used as adhesive with excellent water-wet bonding performance. Ind. Crops Prod. 2023, 198, 116680. [Google Scholar] [CrossRef]

- Fedors, R.F. A method for estimating both the solubility parameters and molar volumes of liquids. Polym. Eng. Sci. 1974, 14, 147–154. [Google Scholar] [CrossRef]

- ISO 4587:2003; Adhesives Determination of Tensile Lap-Shear Strength of Rigid-to-Rigid Bonded Assemblies. International Organization for Standardization: Geneva, Switzerland, 2003.

- Smith, I.T. The mechanism of the crosslinking of epoxide resins by amines. Polymer 1961, 2, 95–108. [Google Scholar] [CrossRef]

- Shundo, A.; Yamamoto, S.; Tanaka, K. Network formation and physical properties of epoxy resins for future practical applications. JACS Au 2022, 2, 1522–1542. [Google Scholar] [CrossRef]

- Kinloch, A.J. Mechanics and mechanisms of fracture of thermosetting epoxy polymers. Adv. Polym. Sci. 1985, 72, 45–67. [Google Scholar]

- Ratna, D.; Simon, G.P. Thermomechanical properties and morphology of blends of a hydroxy-functionalized hyperbranched polymer and epoxy resin. Polymer 2001, 42, 8833–8839. [Google Scholar] [CrossRef]

- Xing, A.; Sun, Q.; Meng, Y.; Zhang, Y.; Li, X.; Han, B. A hydroxyl-containing hyperbranched polymer as a multi-purpose modifier for a dental epoxy. React. Funct. Polym. 2020, 149, 104505. [Google Scholar] [CrossRef]

- Choi, S.; Janisse, A.P.; Liu, C.; Douglas, E.P. Effect of Water Addition on the Cure Kinetics of an Epoxy-Amine Thermoset. Polym. Chem. 2011, 49, 4650–4659. [Google Scholar] [CrossRef]

- Ehlers, J.; Rondan, N.G.; Huynh, L.K.; Pham, H.; Marks, M.; Truong, T.N. Theoretical Study on Mechanisms of the Epoxy-Amine Curing Reaction. Macromolecules 2007, 40, 4370–4377. [Google Scholar] [CrossRef]

- Wei, J.; Ma, S.; Yue, H.; Wang, S.; Zhu, J. Comparison of Hydrogenated Bisphenol A and Bisphenol A Epoxies: Curing Behavior, Thermal and Mechanical Properties, Shape Memory Properties. Macromol. Res. 2018, 26, 529–538. [Google Scholar] [CrossRef]

- Yamamoto, S.; Kuwahara, R.; Tanaka, K. Dynamic behaviour of water molecules in heterogeneous free space formed in an epoxy resin. Soft Matter 2021, 17, 6073–6080. [Google Scholar] [CrossRef] [PubMed]

- Nunes, S.P.; Inoue, T. Evidence for spinodal decomposition and nucleation and growth mechanisms during membrane formation. J. Mem. Sci. 1996, 111, 93–103. [Google Scholar] [CrossRef]

- Skripov, V.P.; Skripov, A.V. Spinodal decomposition (phase transitions via unstable states). Sov. Phys. Uspekhi 1979, 22, 389–410. [Google Scholar] [CrossRef]

| Category | Materials | Solubility Parameter a (−) |

|---|---|---|

| Epoxy | TETRAD-C | 10.1 |

| HBPA | 9.2 | |

| Amine curing agent | BACM | 9.7 |

| Porogenic agent | PEG50 | 14.1 |

| PEG100 | 12.6 | |

| PEG150 | 12.1 | |

| PEG200 | 11.6 |

| HBPA Content (mol%) | PEG | Onset Temperature (°C) | Peak Temperature (°C) |

|---|---|---|---|

| 0 | PEG50 | 69 | 112 |

| 0 | PEG100 | 74 | 120 |

| 0 | PEG150 | 79 | 133 |

| 0 | PEG200 | 86 | 139 |

| 5 | PEG200 | 72 | 138 |

| 10 | PEG200 | 72 | 138 |

| 15 | PEG200 | 71 | 138 |

| 20 | PEG200 | 70 | 136 |

| 30 | PEG200 | 68 | 136 |

| HBPA (mol%) | PEG | Mean Pore Diameter (μm) | Tensile Test | DMA | ||

|---|---|---|---|---|---|---|

| Strength (MPa) | Elongation (%) | Tg (°C) | Storage Modulus at 25 °C (GPa) | |||

| 0 | PEG50 | 3.80 | - | - | - | - |

| 0 | PEG100 | 1.91 | 17.9 | 5.8 | 175 | 1.01 |

| 0 | PEG150 | 0.63 | 13.3 | 5.6 | 177 | 0.66 |

| 0 | PEG200 | 0.28 | 12.5 | 3.2 | 187 | 0.68 |

| 5 | PEG200 | 0.87 | 11.4 | 3.3 | 172 | 0.56 |

| 10 | PEG200 | 1.21 | 13.2 | 5.6 | 170 | 0.56 |

| 15 | PEG200 | 3.15 | 9.5 | 6.5 | 161 | 0.59 |

| 0 | - | - | - | - | 223 | 1.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamo, Y.; Matsumoto, A. Control of Pore Sizes in Epoxy Monoliths and Applications as Sheet-Type Adhesives in Combination with Conventional Epoxy and Acrylic Adhesives. Molecules 2024, 29, 2059. https://doi.org/10.3390/molecules29092059

Kamo Y, Matsumoto A. Control of Pore Sizes in Epoxy Monoliths and Applications as Sheet-Type Adhesives in Combination with Conventional Epoxy and Acrylic Adhesives. Molecules. 2024; 29(9):2059. https://doi.org/10.3390/molecules29092059

Chicago/Turabian StyleKamo, Yoshiyuki, and Akikazu Matsumoto. 2024. "Control of Pore Sizes in Epoxy Monoliths and Applications as Sheet-Type Adhesives in Combination with Conventional Epoxy and Acrylic Adhesives" Molecules 29, no. 9: 2059. https://doi.org/10.3390/molecules29092059

APA StyleKamo, Y., & Matsumoto, A. (2024). Control of Pore Sizes in Epoxy Monoliths and Applications as Sheet-Type Adhesives in Combination with Conventional Epoxy and Acrylic Adhesives. Molecules, 29(9), 2059. https://doi.org/10.3390/molecules29092059