Assessing the Feasibility of Biorefineries for a Sustainable Citrus Waste Management in Korea

Abstract

1. Introduction

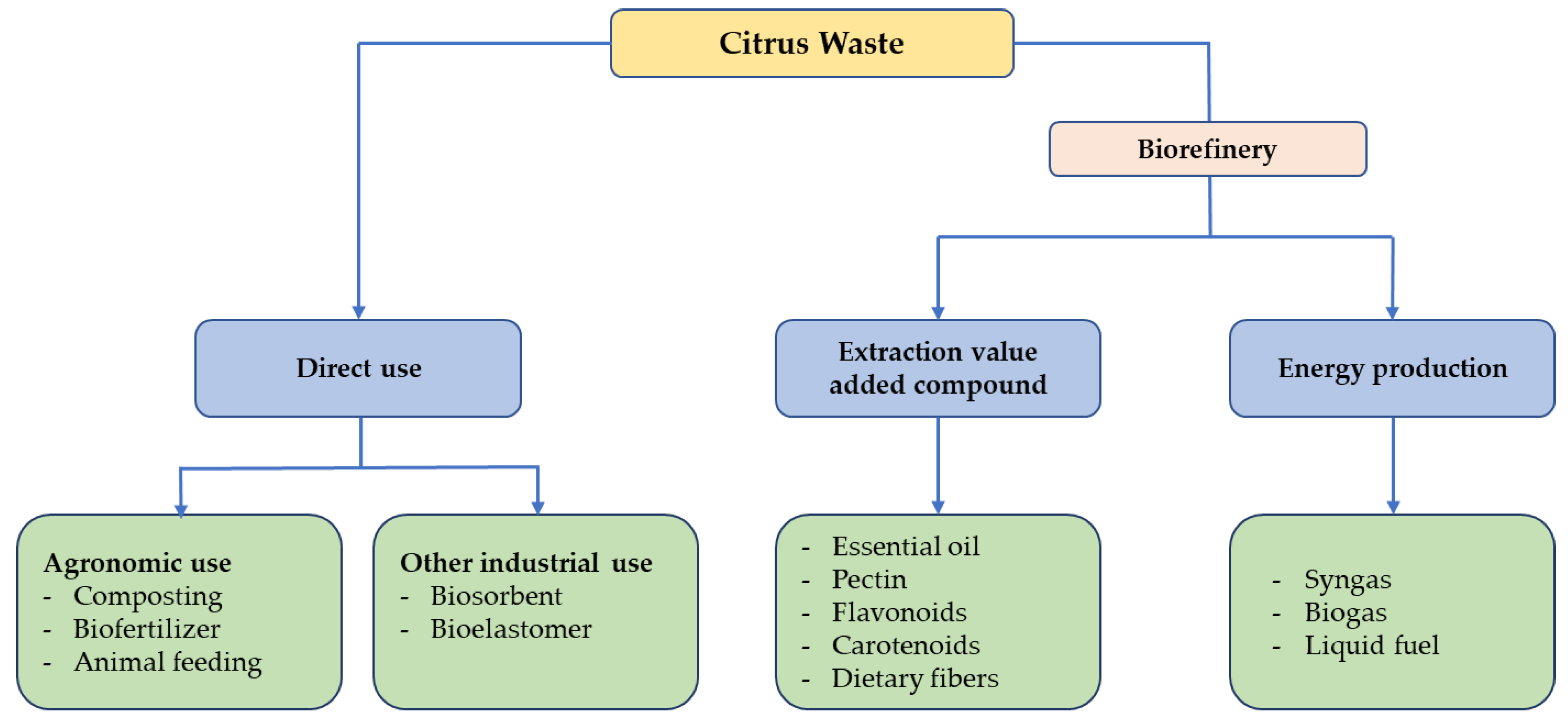

2. Environmental Issues Related to Citrus Production and Its By-Products in Korea

3. Current Status of Citrus Waste Biorefining Efforts

3.1. Direct Use

3.1.1. Agronomic Utilization

3.1.2. Other Industrial Uses

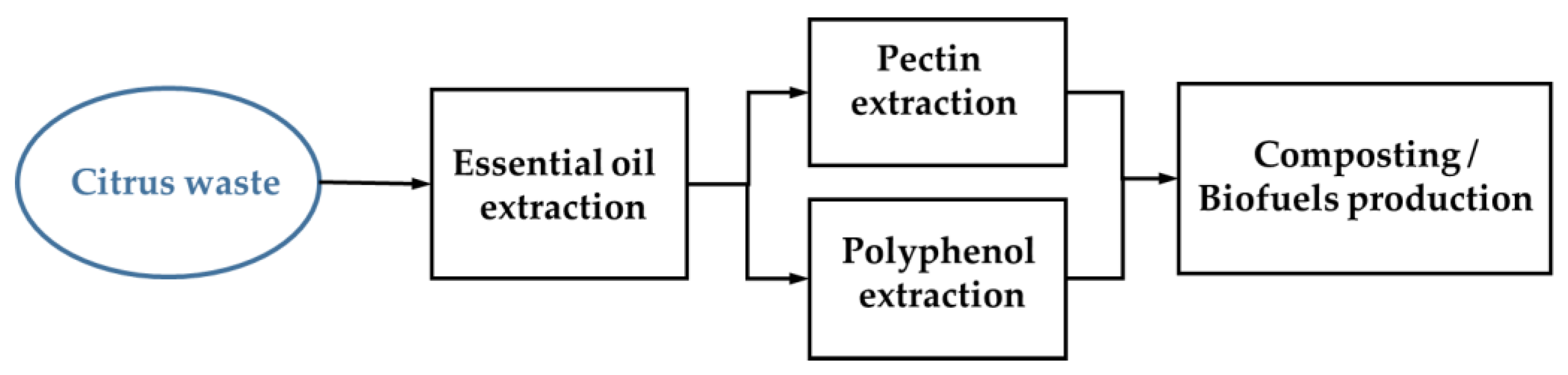

3.2. Value-Added Compound Production

3.2.1. Essential Oils

3.2.2. Pectin

3.2.3. Flavonoids

3.3. Energy Production

4. Challenges and Technical Limitations for Biorefinery Implementation

5. Perspectives and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ravindran, R.; Jaiswal, A.K. Exploitation of food industry waste for high-value products. Trends Biotechnol. 2016, 34, 58–69. [Google Scholar] [CrossRef]

- Matharu, A.S.; de Melo, E.M.; Houghton, J.A. Opportunity for high value-added chemicals from food supply chain wastes. Bioresour. Technol. 2016, 215, 123–130. [Google Scholar] [CrossRef] [PubMed]

- Alzate, C.A.C.; Toro, J.C.S.; Peña, Á.G. Fermentation, thermochemical and catalytic processes in the transformation of biomass through efficient biorefineries. Catal. Today 2018, 302, 61–72. [Google Scholar] [CrossRef]

- Lv, X.; Zhao, S.; Ning, Z.; Zeng, H.; Shu, Y.; Tao, O.; Xiao, C.; Lu, C.; Liu, Y. Citrus fruits as a treasure trove of active natural metabolites that potentially provide benefits for human health. Chem. Cent. J. 2015, 9, 68. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.; Sharma, V.; Pandey, K.; Ahmed, S.; Kaur, M.; Sidhu, G.S. Horticultural classification of citrus cultivars. Citrus Res. Dev. Biotechnol. 2021, 1–24. [Google Scholar] [CrossRef]

- Mamma, D.; Christakopoulos, P. Biotransformation of citrus by-products into value added products. Waste Biomass Valorization 2014, 5, 529–549. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, Q.; Quan, J.; Zheng, Q.; Xi, W. Determination of sugars, organic acids, aroma components, and carotenoids in grapefruit pulps. Food Chem. 2016, 205, 112–121. [Google Scholar] [CrossRef] [PubMed]

- Satari, B.; Karimi, K. Citrus processing wastes: Environmental impacts, recent advances, and future perspectives in total valorization. Resour. Conserv. Recycl. 2018, 129, 153–167. [Google Scholar] [CrossRef]

- Sharma, K.; Mahato, N.; Cho, M.H.; Lee, Y.R. Converting citrus wastes into value-added products: Economic and environmently friendly approaches. Nutrition 2017, 34, 29–46. [Google Scholar] [CrossRef]

- Corsino, S.F.; Di Trapani, D.; Torregrossa, M.; Viviani, G. Aerobic granular sludge treating high strength citrus wastewater: Analysis of pH and organic loading rate effect on kinetics, performance and stability. J. Environ. Manag. 2018, 214, 23–35. [Google Scholar] [CrossRef]

- Wei, Y.; Li, J.; Shi, D.; Liu, G.; Zhao, Y.; Shimaoka, T. Environmental challenges impeding the composting of biodegradable municipal solid waste: A critical review. Resour. Conserv. Recycl. 2017, 122, 51–65. [Google Scholar] [CrossRef]

- Calabrò, P.S.; Pontoni, L.; Porqueddu, I.; Greco, R.; Pirozzi, F.; Malpei, F. Effect of the concentration of essential oil on orange peel waste biomethanization: Preliminary batch results. Waste Manag. 2016, 48, 440–447. [Google Scholar] [CrossRef]

- Tripodo, M.M.; Lanuzza, F.; Micali, G.; Coppolino, R.; Nucita, F. Citrus waste recovery: A new environmentally friendly procedure to obtain animal feed. Bioresour. Technol. 2004, 91, 111–115. [Google Scholar] [CrossRef]

- Wang, F.; Chen, L.; Chen, H.; Chen, S.; Liu, Y. Analysis of flavonoid metabolites in citrus peels (Citrus reticulata “Dahongpao”) using UPLC-ESI-MS/MS. Molecules 2019, 24, 2680. [Google Scholar] [CrossRef]

- Wang, L.; He, F.; Huang, Y.; He, J.; Yang, S.; Zeng, J.; Deng, C.; Jiang, X.; Fang, Y.; Wen, S. Genome of wild mandarin and domestication history of mandarin. Mol. Plant 2018, 11, 1024–1037. [Google Scholar] [CrossRef]

- Putnik, P.; Barba, F.J.; Lorenzo, J.M.; Gabrić, D.; Shpigelman, A.; Cravotto, G.; Bursać Kovačević, D. An integrated approach to mandarin processing: Food safety and nutritional quality, consumer preference, and nutrient bioaccessibility. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1345–1358. [Google Scholar] [CrossRef]

- Tietel, Z.; Srivastava, S.; Fait, A.; Tel-Zur, N.; Carmi, N.; Raveh, E. Impact of scion/rootstock reciprocal effects on metabolomics of fruit juice and phloem sap in grafted Citrus reticulata. PLoS ONE 2020, 15, e0227192. [Google Scholar] [CrossRef]

- USDA-FAS: Foreign Agricultural Service. Citrus: World Markets and Trade; USDA Foreign Agricultural Service: Washington, DC, USA, 2020.

- Lado, J.; Gambetta, G.; Zacarias, L. Key determinants of citrus fruit quality: Metabolites and main changes during maturation. Sci. Hortic. 2018, 233, 238–248. [Google Scholar] [CrossRef]

- Saini, M.K.; Capalash, N.; Kaur, C.; Singh, S.P. Targeted metabolic profiling indicates differences in primary and secondary metabolites in Kinnow mandarin (C. nobilis × C. deliciosa) from different climatic conditions. J. Food Compos. Anal. 2019, 83, 103278. [Google Scholar] [CrossRef]

- Xi, W.; Zhang, Y.; Sun, Y.; Shen, Y.; Ye, X.; Zhou, Z. Phenolic composition of Chinese wild mandarin (Citrus reticulata Blanco) pulps and their antioxidant properties. Ind. Crops Prod. 2014, 52, 466–474. [Google Scholar] [CrossRef]

- Cho, E.J.; Lee, Y.G.; Chang, J.; Bae, H.-J. A high-yield process for production of biosugars and hesperidin from Mandarin peel wastes. Molecules 2020, 25, 4286. [Google Scholar] [CrossRef] [PubMed]

- Çalıskan Eleren, S.; Öziş, A.S.; Altınçekiç, E. Biofuel potential of fruit juice industry waste. J. Hazard. Toxic Radioact. Waste 2018, 22, 05018002. [Google Scholar] [CrossRef]

- Ruiz, B.; Flotats, X. Citrus essential oils and their influence on the anaerobic digestion process: An overview. Waste Manag. 2014, 34, 2063–2079. [Google Scholar] [CrossRef] [PubMed]

- Boukroufa, M.; Boutekedjiret, C.; Petigny, L.; Rakotomanomana, N.; Chemat, F. Bio-refinery of orange peels waste: A new concept based on integrated green and solvent free extraction processes using ultrasound and microwave techniques to obtain essential oil, polyphenols and pectin. Ultrason. Sonochem. 2015, 24, 72–79. [Google Scholar] [CrossRef]

- Ángel Siles López, J.; Li, Q.; Thompson, I.P. Biorefinery of waste orange peel. Crit. Rev. Biotechnol. 2010, 30, 63–69. [Google Scholar] [CrossRef]

- Karadeniz, F. Main organic acid distribution of authentic citrus juices in Turkey. Turk. J. Agric. For. 2004, 28, 267–271. [Google Scholar]

- Koppar, A.; Pullammanappallil, P. Anaerobic digestion of peel waste and wastewater for on-site energy generation in a citrus processing facility. Energy 2013, 60, 62–68. [Google Scholar] [CrossRef]

- Yadav, V.; Sarker, A.; Yadav, A.; Miftah, A.O.; Bilal, M.; Iqbal, H.M. Integrated biorefinery approach to valorize citrus waste: A sustainable solution for resource recovery and environmental management. Chemosphere 2022, 293, 133459. [Google Scholar] [CrossRef] [PubMed]

- Mahato, N.; Sharma, K.; Sinha, M.; Cho, M.H. Citrus waste derived nutra-/pharmaceuticals for health benefits: Current trends and future perspectives. J. Funct. Foods 2018, 40, 307–316. [Google Scholar] [CrossRef]

- Oikeh, E.; Oriakhi, K.; Omoregie, E. Proximate analysis and phytochemical screening of Citrus sinensis fruit wastes. Biosci. J. 2013, 1, 164–170. [Google Scholar]

- Singh, B.; Singh, J.P.; Kaur, A.; Singh, N. Phenolic composition, antioxidant potential and health benefits of citrus peel. Food Res. Int. 2020, 132, 109114. [Google Scholar] [CrossRef] [PubMed]

- Figuerola, F.; Hurtado, M.L.; Estévez, A.M.; Chiffelle, I.; Asenjo, F. Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chem. 2005, 91, 395–401. [Google Scholar] [CrossRef]

- Rafiq, S.; Kaul, R.; Sofi, S.; Bashir, N.; Nazir, F.; Nayik, G.A. Citrus peel as a source of functional ingredient: A review. J. Saudi Soc. Agric. Sci. 2018, 17, 351–358. [Google Scholar] [CrossRef]

- Hosseini, S.S.; Khodaiyan, F.; Yarmand, M.S. Aqueous extraction of pectin from sour orange peel and its preliminary physicochemical properties. Int. J. Biol. Macromol. 2016, 82, 920–926. [Google Scholar] [CrossRef]

- Anticona, M.; Blesa, J.; Frigola, A.; Esteve, M.J. High biological value compounds extraction from citrus waste with non-conventional methods. Foods 2020, 9, 811. [Google Scholar] [CrossRef] [PubMed]

- Jung, I.-C.; Moon, Y.-H.; Yang, S.-J. Quality of Jeju island’s indigenous pork fed with dried citrus byproducts. J. Korean Soc. Food Sci. Nutr. 2007, 36, 228–232. [Google Scholar] [CrossRef]

- Cerisuelo, A.; Castelló, L.; Moset, V.; Martínez, M.; Hernández, P.; Piquer, O.; Gómez, E.; Gasa, J.; Lainez, M. The inclusion of ensiled citrus pulp in diets for growing pigs: Effects on voluntary intake, growth performance, gut microbiology and meat quality. Livest. Sci. 2010, 134, 180–182. [Google Scholar] [CrossRef]

- Panwar, D.; Panesar, P.S.; Chopra, H.K. Recent trends on the valorization strategies for the management of citrus by-products. Food Rev. Int. 2021, 37, 91–120. [Google Scholar] [CrossRef]

- Bernal-Vicente, A.; Ros, M.; Tittarelli, F.; Intrigliolo, F.; Pascual, J. Citrus compost and its water extract for cultivation of melon plants in greenhouse nurseries. Evaluation of nutriactive and biocontrol effects. Bioresour. Technol. 2008, 99, 8722–8728. [Google Scholar] [CrossRef]

- Golueke, C.G. Bacteriology of composting. Biocycle 1992, 33, 55–57. [Google Scholar]

- Shakoor, M.B.; Niazi, N.K.; Bibi, I.; Murtaza, G.; Kunhikrishnan, A.; Seshadri, B.; Shahid, M.; Ali, S.; Bolan, N.S.; Ok, Y.S. Remediation of arsenic-contaminated water using agricultural wastes as biosorbents. Crit. Rev. Environ. Sci. Technol. 2016, 46, 467–499. [Google Scholar] [CrossRef]

- Khaskheli, M.I.; Memon, S.Q.; Siyal, A.N.; Khuhawar, M. Use of orange peel waste for arsenic remediation of drinking water. Waste Biomass Valorization 2011, 2, 423–433. [Google Scholar] [CrossRef]

- Romero-Cano, L.A.; González-Gutiérrez, L.V.; Baldenegro-Pérez, L.A.; Carrasco-Marín, F. Grapefruit peels as biosorbent: Characterization and use in batch and fixed bed column for Cu(II) uptake from wastewater. J. Chem. Technol. Biotechnol. 2017, 92, 1650–1658. [Google Scholar] [CrossRef]

- Balu, A.M.; Budarin, V.; Shuttleworth, P.S.; Pfaltzgraff, L.A.; Waldron, K.; Luque, R.; Clark, J.H. Valorisation of orange peel residues: Waste to biochemicals and nanoporous materials. ChemSusChem 2012, 5, 1694–1697. [Google Scholar] [CrossRef]

- Mariño, M.; Lopes da Silva, L.; Durán, N.; Tasic, L. Enhanced materials from nature: Nanocellulose from citrus waste. Molecules 2015, 20, 5908–5923. [Google Scholar] [CrossRef]

- Hiasa, S.; Iwamoto, S.; Endo, T.; Edashige, Y. Isolation of cellulose nanofibrils from mandarin (Citrus unshiu) peel waste. Ind. Crops Prod. 2014, 62, 280–285. [Google Scholar] [CrossRef]

- Zhang, W.; Zhou, Z. Citrus pectin-derived carbon microspheres with superior adsorption ability for methylene blue. Nanomaterials 2017, 7, 161. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; Gao, Y.; He, W.; Hu, H.; Tian, M.; Wang, K.; Pan, S. Production of nano bacterial cellulose from beverage industrial waste of citrus peel and pomace using Komagataeibacter xylinus. Carbohydr. Polym. 2016, 151, 1068–1072. [Google Scholar] [CrossRef]

- Lee, K.H.; Chun, Y.; Lee, J.H.; Lee, J.U.; Lee, T.; Yoo, H.Y. Sustainable Utilization Strategy of Organic Waste via Fabrication of Bioelastomer with Antibacterial and Antioxidant Activities Using Mandarin Peel Extracts. Agriculture 2023, 13, 161. [Google Scholar] [CrossRef]

- Sharma, K.; Mahato, N.; Lee, Y.R. Extraction, characterization and biological activity of citrus flavonoids. Rev. Chem. Eng. 2019, 35, 265–284. [Google Scholar] [CrossRef]

- Braddock, R.; Temelli, F.; Cadwallader, K. Citrus essential oils-a dossier for material safety data sheets. Food Technol. 1986, 40, 114–116. [Google Scholar]

- Mahato, N.; Sharma, K.; Koteswararao, R.; Sinha, M.; Baral, E.; Cho, M.H. Citrus essential oils: Extraction, authentication and application in food preservation. Crit. Rev. Food Sci. Nutr. 2019, 59, 611–625. [Google Scholar] [CrossRef]

- Arce, A.; Marchiaro, A.; Martínez-Ageitos, J.M.; Soto, A. Citrus essential oil deterpenation by liquid-liquid extraction. Can. J. Chem. Eng. 2005, 83, 366–370. [Google Scholar] [CrossRef]

- Tao, N.-G.; Liu, Y.; Zhang, J.-H.; Zeng, H.; Tang, Y.-F.; Zhang, M. Chemical composition of essential oil from the peel of Satsuma mandarin. Afr. J. Biotechnol. 2008, 7, 1261–1264. [Google Scholar]

- Feng, S.; Niu, L.; Suh, J.H.; Hung, W.-L.; Wang, Y. Comprehensive metabolomics analysis of mandarins (Citrus reticulata) as a tool for variety, rootstock, and grove discrimination. J. Agric. Food Chem. 2018, 66, 10317–10326. [Google Scholar] [CrossRef] [PubMed]

- Zema, D.; Calabrò, P.; Folino, A.; Tamburino, V.; Zappia, G.; Zimbone, S. Valorisation of citrus processing waste: A review. Waste Manag. 2018, 80, 252–273. [Google Scholar] [CrossRef] [PubMed]

- Dosoky, N.S.; Setzer, W.N. Biological activities and safety of Citrus spp. essential oils. Int. J. Mol. Sci. 2018, 19, 1966. [Google Scholar] [CrossRef]

- Bousbia, N.; Vian, M.A.; Ferhat, M.A.; Meklati, B.Y.; Chemat, F. A new process for extraction of essential oil from Citrus peels: Microwave hydrodiffusion and gravity. J. Food Eng. 2009, 90, 409–413. [Google Scholar] [CrossRef]

- Sahraoui, N.; Vian, M.A.; El Maataoui, M.; Boutekedjiret, C.; Chemat, F. Valorization of citrus by-products using Microwave Steam Distillation (MSD). Innov. Food Sci. Emerg. Technol. 2011, 12, 163–170. [Google Scholar] [CrossRef]

- Bertouche, S.; Tomao, V.; Ruiz, K.; Hellal, A.; Boutekedjiret, C.; Chemat, F. First approach on moisture determination in food products using alpha-pinene as an alternative solvent for Dean–Stark distillation. Food Chem. 2012, 134, 602–605. [Google Scholar] [CrossRef]

- Veillet, S.; Tomao, V.; Ruiz, K.; Chemat, F. Green procedure using limonene in the Dean–Stark apparatus for moisture determination in food products. Anal. Chim. Acta 2010, 674, 49–52. [Google Scholar] [CrossRef] [PubMed]

- M’hiri, N.; Ioannou, I.; Ghoul, M.; Mihoubi Boudhrioua, N. Phytochemical characteristics of citrus peel and effect of conventional and nonconventional processing on phenolic compounds: A review. Food Rev. Int. 2017, 33, 587–619. [Google Scholar] [CrossRef]

- Ciriminna, R.; Chavarría-Hernández, N.; Inés Rodríguez Hernández, A.; Pagliaro, M. Pectin: A new perspective from the biorefinery standpoint. Biofuels Bioprod. Biorefining 2015, 9, 368–377. [Google Scholar] [CrossRef]

- Mohnen, D. Pectin structure and biosynthesis. Curr. Opin. Plant Biol. 2008, 11, 266–277. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Shi, J.; Langrish, T. Water-based extraction of pectin from flavedo and albedo of orange peels. Chem. Eng. J. 2006, 120, 203–209. [Google Scholar] [CrossRef]

- Quoc, L.; Huyen, V.; Hue, L.; Hue, N.; Thuan, N.; Tam, N.; Thuan, N.; Duy, T. Extraction of pectin from pomelo (Citrus maxima) peels with the assistance of microwave and tartaric acid. Int. Food Res. J. 2015, 22, 1637. [Google Scholar]

- Espitia, P.J.P.; Du, W.-X.; de Jesús Avena-Bustillos, R.; Soares, N.d.F.F.; McHugh, T.H. Edible films from pectin: Physical-mechanical and antimicrobial properties—A review. Food Hydrocoll. 2014, 35, 287–296. [Google Scholar] [CrossRef]

- Karboune, S.; Khodaei, N. Structures, isolation and health-promoting properties of pectic polysaccharides from cell wall-rich food by-products: A source of functional ingredients. Curr. Opin. Food Sci. 2016, 8, 50–55. [Google Scholar] [CrossRef]

- Panche, A.N.; Diwan, A.D.; Chandra, S.R. Flavonoids: An overview. J. Nutr. Sci. 2016, 5, e47. [Google Scholar] [CrossRef]

- Goldenberg, L.; Yaniv, Y.; Porat, R.; Carmi, N. Mandarin fruit quality: A review. J. Sci. Food Agric. 2018, 98, 18–26. [Google Scholar] [CrossRef]

- Benavente-García, O.; Castillo, J.; Marin, F.R.; Ortuño, A.; Del Río, J.A. Uses and properties of citrus flavonoids. J. Agric. Food Chem. 1997, 45, 4505–4515. [Google Scholar] [CrossRef]

- Victor, M.M.; David, J.M.; Cortez, M.V.; Leite, J.L.; da Silva, G.S. A high-yield process for extraction of hesperidin from orange (Citrus sinensis L. osbeck) peels waste, and its transformation to diosmetin, A valuable and bioactive flavonoid. Waste Biomass Valorization 2021, 12, 313–320. [Google Scholar]

- Zhao, C.; Wang, F.; Lian, Y.; Xiao, H.; Zheng, J. Biosynthesis of citrus flavonoids and their health effects. Crit. Rev. Food Sci. Nutr. 2020, 60, 566–583. [Google Scholar] [CrossRef] [PubMed]

- Martins, L.C.; Monteiro, C.C.; Semedo, P.M.; Sá-Correia, I. Valorisation of pectin-rich agro-industrial residues by yeasts: Potential and challenges. Appl. Microbiol. Biotechnol. 2020, 104, 6527–6547. [Google Scholar] [CrossRef] [PubMed]

- Jeong, D.; Park, H.; Jang, B.-K.; Ju, Y.; Shin, M.H.; Oh, E.J.; Lee, E.J.; Kim, S.R. Recent advances in the biological valorization of citrus peel waste into fuels and chemicals. Bioresour. Technol. 2021, 323, 124603. [Google Scholar] [CrossRef] [PubMed]

- Zema, D.A. Planning the optimal site, size, and feed of biogas plants in agricultural districts. Biofuels Bioprod. Biorefining 2017, 11, 454–471. [Google Scholar] [CrossRef]

- Choi, I.S.; Kim, J.-H.; Wi, S.G.; Kim, K.H.; Bae, H.-J. Bioethanol production from mandarin (Citrus unshiu) peel waste using popping pretreatment. Appl. Energy 2013, 102, 204–210. [Google Scholar] [CrossRef]

- John, I.; Muthukumar, K.; Arunagiri, A. A review on the potential of citrus waste for D-Limonene, pectin, and bioethanol production. Int. J. Green Energy 2017, 14, 599–612. [Google Scholar] [CrossRef]

- Nayak, A.; Bhushan, B. An overview of the recent trends on the waste valorization techniques for food wastes. J. Environ. Manag. 2019, 233, 352–370. [Google Scholar] [CrossRef]

- Bożym, M.; Florczak, I.; Zdanowska, P.; Wojdalski, J.; Klimkiewicz, M. An analysis of metal concentrations in food wastes for biogas production. Renew. Energy 2015, 77, 467–472. [Google Scholar] [CrossRef]

- Calabrò, P.; Paone, E.; Komilis, D. Strategies for the sustainable management of orange peel waste through anaerobic digestion. J. Environ. Manag. 2018, 212, 462–468. [Google Scholar] [CrossRef]

- Gunaseelan, V.N. Biochemical methane potential of fruits and vegetable solid waste feedstocks. Biomass Bioenergy 2004, 26, 389–399. [Google Scholar] [CrossRef]

- Plochl, M.; Heiermann, M. Biogas farming in central and northern Europe: A strategy for developing countries? Agric. Eng. Int. CIGR Ej. 2006, 8, 1–15. [Google Scholar]

- Zema, D.A.; Andiloro, S.; Bombino, G.; Caridi, A.; Sidari, R.; Tamburino, V. Comparing different schemes of agricultural wastewater lagooning: Depuration performance and microbiological characteristics. Water Air Soil Pollut. 2016, 227, 1–9. [Google Scholar] [CrossRef]

- Alibardi, L.; Astrup, T.F.; Asunis, F.; Clarke, W.P.; De Gioannis, G.; Dessì, P.; Lens, P.N.; Lavagnolo, M.C.; Lombardi, L.; Muntoni, A. Organic waste biorefineries: Looking towards implementation. Waste Manag. 2020, 114, 274–286. [Google Scholar] [CrossRef]

- Lee, J.-K.; Patel, S.K.S.; Sung, B.H.; Kalia, V.C. Biomolecules from municipal and food industry wastes: An overview. Bioresour. Technol. 2020, 298, 122346. [Google Scholar] [CrossRef]

- Aggarwal, K.; Khanuja, S.; Ahmad, A.; Santha Kumar, T.; Gupta, V.K.; Kumar, S. Antimicrobial activity profiles of the two enantiomers of limonene and carvone isolated from the oils of Mentha spicata and Anethum sowa. Flavour Fragr. J. 2002, 17, 59–63. [Google Scholar] [CrossRef]

- Andiloro, S.; Bombino, G.; Tamburino, V.; Zema, D.A.; Zimbone, S.M. Aerated lagooning of agro-industrial wastewater: Depuration performance and energy requirements. J. Agric. Eng. 2013, 44, 827–832. [Google Scholar] [CrossRef]

- Zema, D.A.; Andiloro, S.; Bombino, G.; Tamburino, V.; Sidari, R.; Caridi, A. Depuration in aerated ponds of citrus processing wastewater with a high concentration of essential oils. Environ. Technol. 2012, 33, 1255–1260. [Google Scholar] [CrossRef]

- Joglekar, S.N.; Pathak, P.D.; Mandavgane, S.A.; Kulkarni, B.D. Process of fruit peel waste biorefinery: A case study of citrus waste biorefinery, its environmental impacts and recommendations. Environ. Sci. Pollut. Res. 2019, 26, 34713–34722. [Google Scholar] [CrossRef]

- Villacis-Chiriboga, J.; Elst, K.; Van Camp, J.; Vera, E.; Ruales, J. Valorization of byproducts from tropical fruits: Extraction methodologies, applications, environmental, and economic assessment: A review (Part 1: General overview of the byproducts, traditional biorefinery practices, and possible applications). Compr. Rev. Food Sci. Food Saf. 2020, 19, 405–447. [Google Scholar] [CrossRef]

- Bilal, M.; Asgher, M.; Iqbal, H.M.; Hu, H.; Zhang, X. Biotransformation of lignocellulosic materials into value-added products—A review. Int. J. Biol. Macromol. 2017, 98, 447–458. [Google Scholar] [CrossRef]

- Rivas-Cantu, R.C.; Jones, K.D.; Mills, P.L. A citrus waste-based biorefinery as a source of renewable energy: Technical advances and analysis of engineering challenges. Waste Manag. Res. 2013, 31, 413–420. [Google Scholar] [CrossRef]

- Chen, W.; Zhou, Y.; Chen, Y. The environmental impacts of citrus residue management in China: A case study in the three gorges reservoir region. Waste Manag. 2021, 133, 80–88. [Google Scholar] [CrossRef]

- Negro, V.; Ruggeri, B.; Mancini, G.; Fino, D. Recovery of D-limonene through moderate temperature extraction and pyrolytic products from orange peels. J. Chem. Technol. Biotechnol. 2016, 92, 1186–1191. [Google Scholar] [CrossRef]

| Metabolites | Content |

|---|---|

| Sugars (mg/g FW) | 110–140 |

| Glucose (mg/g FW) | 10–40 |

| Fructose (mg/g FW) | 10–30 |

| Sucrose (mg/g FW) | 60–80 |

| Citric acid (g/L) | 8–12 |

| Malic acid (g/L) | 0.8–2 |

| Vitamin C (mg/g) | 0.20–0.57 |

| Carotenoids (μg/g FW) | 12–40 |

| Flavonoids (mg/g FW) | 0.20–1.0 |

| Phenolic acids (mg/g FW) | 0.50−0.85 |

| Year | Mandarin | Tangor 1 | Sum |

| 2021 | 520,135 (65,240) | 92,983 (1040) | 613,118 (66,280) |

| 2020 | 572,486 (76,989) | 82,378 (663) | 654,864 (77,602) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-H.; Park, S.H.; Park, H. Assessing the Feasibility of Biorefineries for a Sustainable Citrus Waste Management in Korea. Molecules 2024, 29, 1589. https://doi.org/10.3390/molecules29071589

Lee S-H, Park SH, Park H. Assessing the Feasibility of Biorefineries for a Sustainable Citrus Waste Management in Korea. Molecules. 2024; 29(7):1589. https://doi.org/10.3390/molecules29071589

Chicago/Turabian StyleLee, Sang-Hwan, Seong Hee Park, and Hyun Park. 2024. "Assessing the Feasibility of Biorefineries for a Sustainable Citrus Waste Management in Korea" Molecules 29, no. 7: 1589. https://doi.org/10.3390/molecules29071589

APA StyleLee, S.-H., Park, S. H., & Park, H. (2024). Assessing the Feasibility of Biorefineries for a Sustainable Citrus Waste Management in Korea. Molecules, 29(7), 1589. https://doi.org/10.3390/molecules29071589