Comprehensive Utilization Technology of Aronia melanocarpa

Abstract

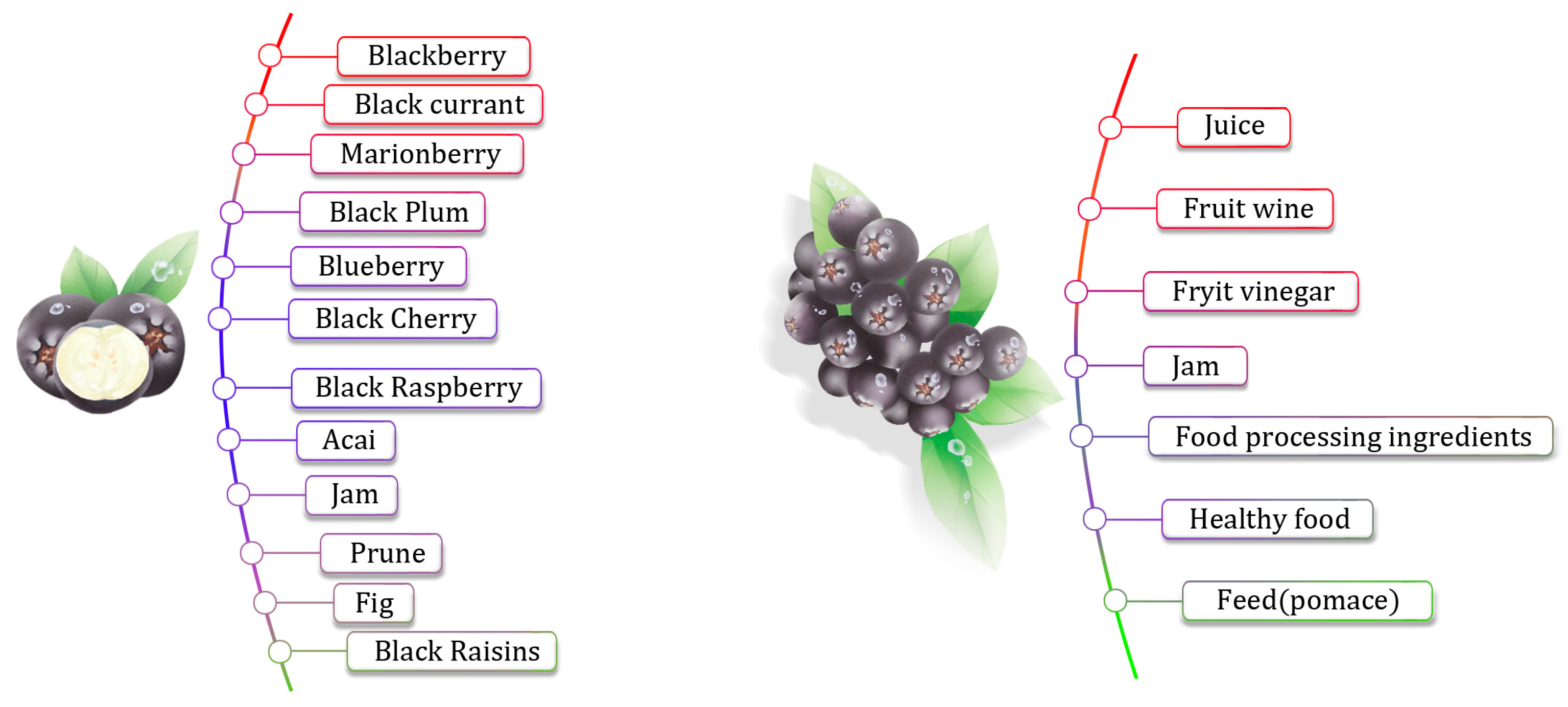

1. Introduction

2. Aronia melanocarpa’s Active Ingredients

2.1. Proanthocyanidins

2.2. Anthocyanins

2.3. Flavonoids

2.4. Phenolic Acids

2.5. Polysaccharides

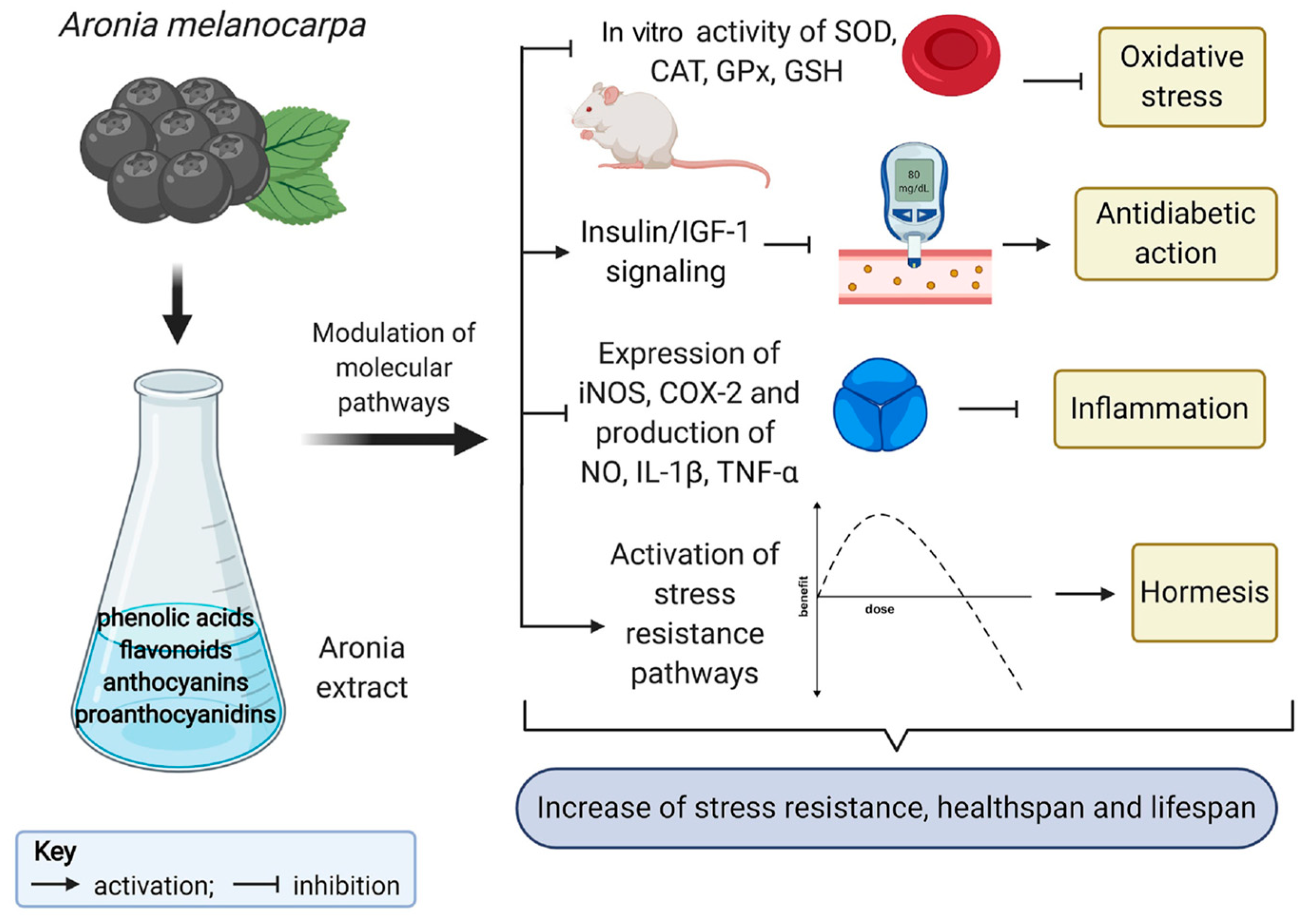

3. Aronia melanocarpa’s Physiological Functions

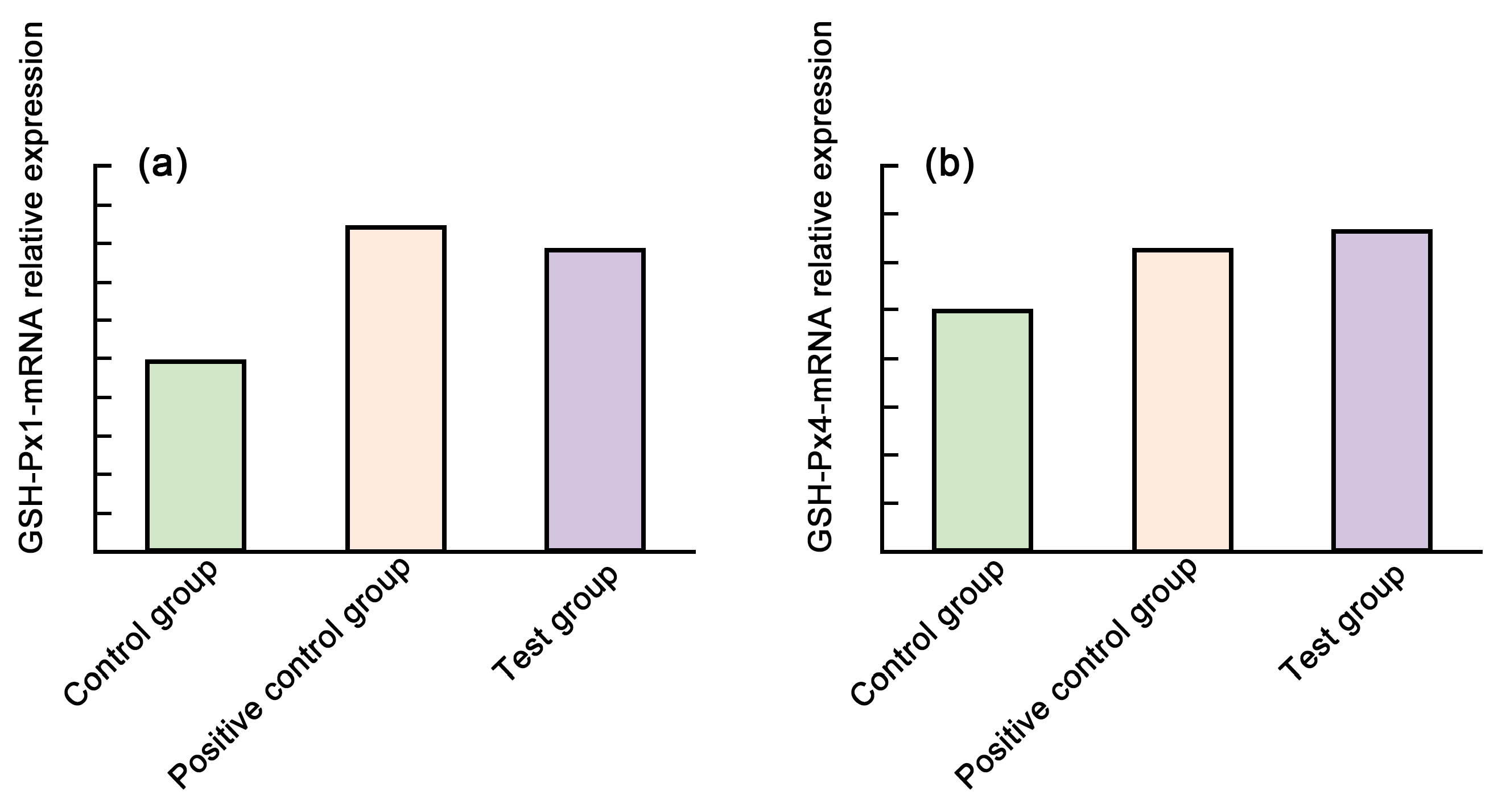

3.1. Antioxidant Properties

3.2. Antibacterial Properties

3.3. Anti-Inflammatory Properties

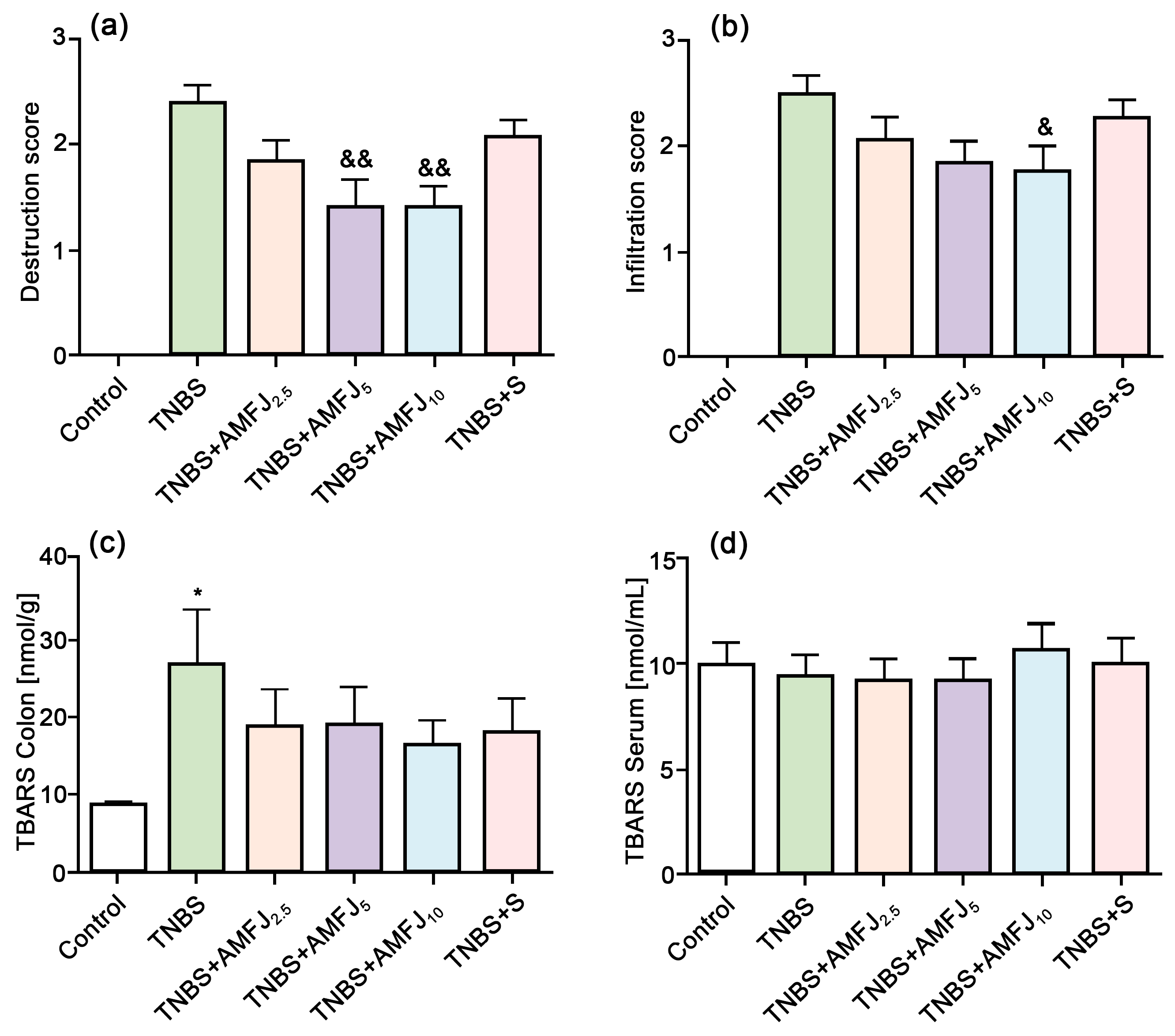

3.4. Inhibiting Tumor Cell Growth

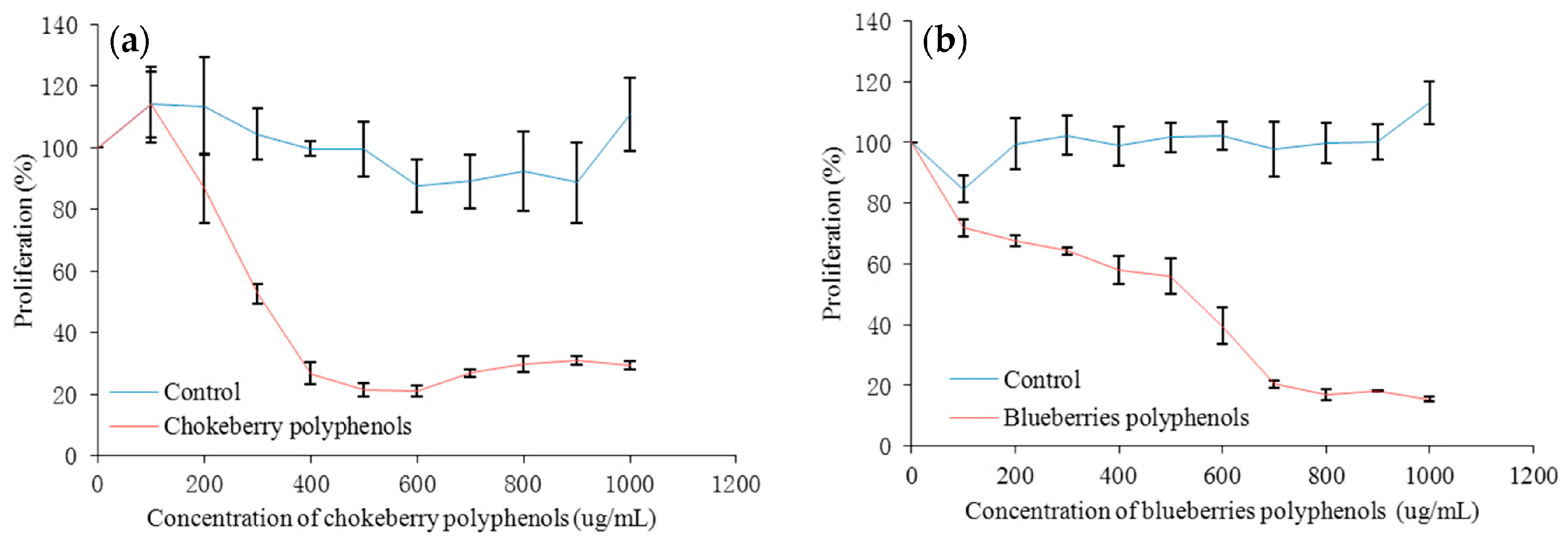

3.5. Lowering Blood Pressure

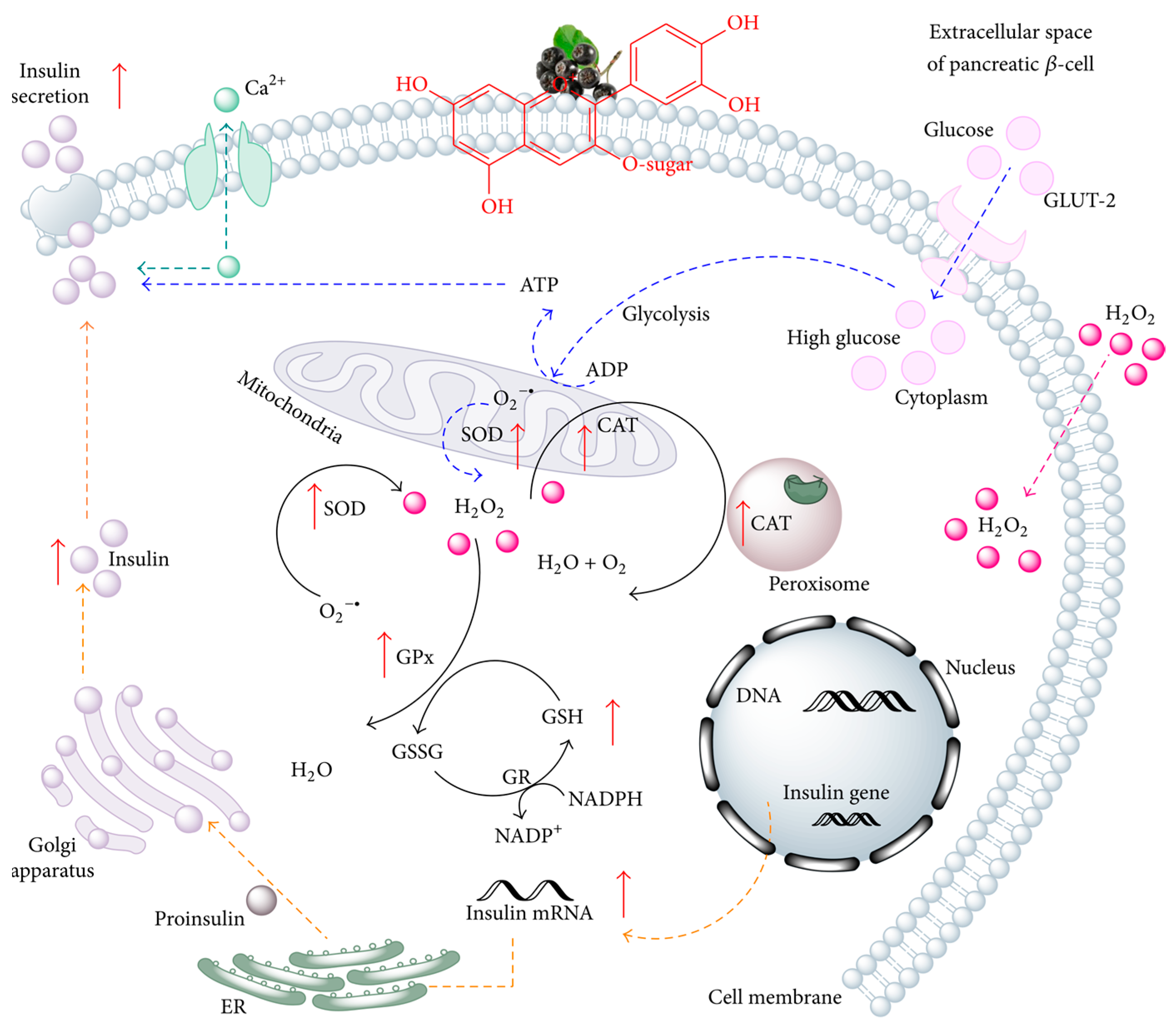

3.6. Lowering Blood Sugar

3.7. Preventing the Toxic Effects of Various Substances

3.8. Antidepressant Properties

3.9. Improving Memory

3.10. Anti-Fatigue Properties

3.11. Other Functions

| Bioactive Ingredients | Responsible Compound/Ingredient | Physiological Function Mechanism |

|---|---|---|

| Antioxidant effect | Proanthocyanidins, anthocyanins, flavonoids | Reduce oxidative stress and protect cells from damage by scavenging free radicals and enhancing antioxidant enzyme activity. |

| Anti-inflammatory effect | Proanthocyanidins, anthocyanins | Inhibit the production of inflammatory mediators, e.g., reducing the production of prostaglandin E2 and proinflammatory cytokines (such as TNF-α, IL-6). |

| Cardiovascular protection | Proanthocyanidins, anthocyanins | It has a protective effect on the cardiovascular system by improving vasodilation, lowering blood pressure, reducing blood clot formation, and reducing LDL oxidation. |

| Anticancer effect | Proanthocyanidins, anthocyanins | Induces cancer cell apoptosis, inhibits tumor growth and metastasis, and enhances the effect of chemotherapy drugs. |

| Antidiabetic effect | Proanthocyanidins, anthocyanins | It is beneficial against diabetes through mechanisms such as improving insulin sensitivity, promoting glucose uptake, and lowering blood sugar levels. |

| Antibacterial effect | Proanthocyanidins, anthocyanins | Directly combats bacteria or inhibits bacterial growth through mechanisms such as affecting bacterial cell walls and membrane structures. |

| Antiviral effect | Proanthocyanidins, anthocyanins | Interferes with the virus replication process, including inhibiting virus adsorption and invading host cells or interfering with virus replication. |

4. Aronia melanocarpa’s Development Status

4.1. Aronia melanocarpa Juice

4.2. Aronia melanocarpa Fruit Wine

4.3. Aronia melanocarpa Fruit Vinegar

4.4. Aronia melanocarpa Jam

4.5. Food Processing Ingredients

4.6. Health Food

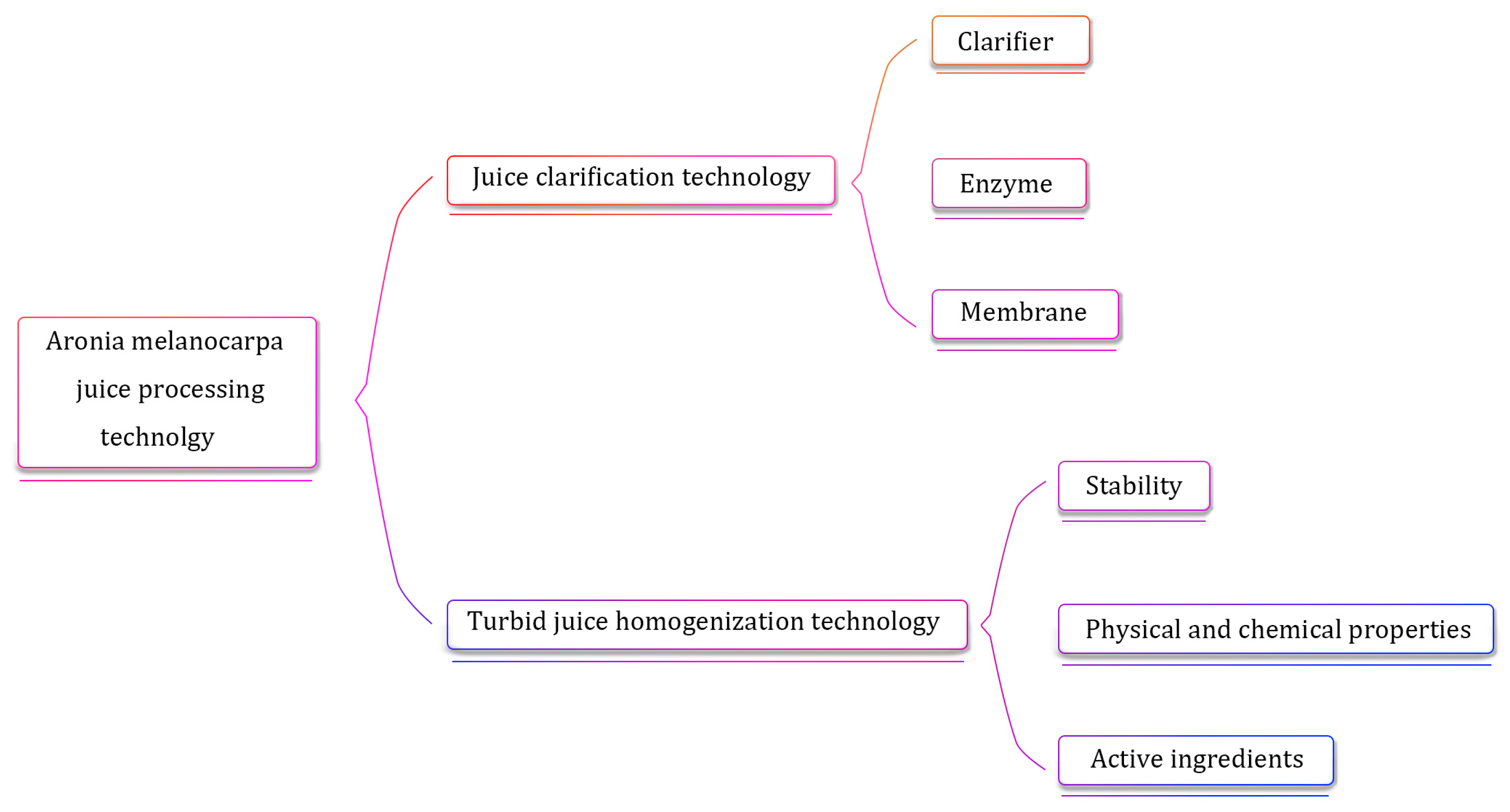

5. Aronia melanocarpa Juice Processing Technology

5.1. Juice Clarification Technology

5.1.1. Clarification Using a Clarifying Agent

5.1.2. Enzymatic Clarification

5.1.3. Membrane Clarification

5.2. Turbid Juice Homogenization Technology

5.2.1. Effect of Homogenization on Stability

5.2.2. Effect of Homogenization on Physical and Chemical Properties

5.2.3. Effect of Homogenization on Active Ingredients

6. Current Status of Utilization of Aronia melanocarpa Pomace in Feed

7. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shahin, L.; Phaal, S.S.; Vaidya, B.N.; Brown, J.E.; Joshee, N. Aronia (Chokeberry): An underutilized, highly nutraceutical plant. J. Med. Act. Plants 2019, 8, 46–63. [Google Scholar]

- Slimestad, R.; Torskangerpoll, K.; Nateland, H.S.; Johannessen, T.; Giske, N.H. Flavonoids from black chokeberries, Aronia melanocarpa. J. Food Compos. Anal. 2005, 18, 61–68. [Google Scholar] [CrossRef]

- Jun, Y. The introduction, cultivation and development status of Sorbus nigraensis in my country. Mod. Agric. Technol. 2020, 2. [Google Scholar]

- Xiaoyan, Z.; Mei, T.; Chunxiao, L. A Preliminary Report on the Introduction and Cultivation of Sorbus nigrum. Chin. For. By-Prod. 2018, 2. [Google Scholar] [CrossRef]

- Kokotkiewicz, A.; Jaremicz, Z.; Luczkiewicz, M. Aronia plants: A review of traditional use, biological activities, and perspectives for modern medicine. J. Med. Food 2010, 13, 255–269. [Google Scholar] [CrossRef]

- Szopa, A.; Kokotkiewicz, A.; Kubica, P.; Banaszczak, P.; Wojtanowska-Krośniak, A.; Krośniak, M.; Marzec-Wróblewska, U.; Badura, A.; Zagrodzki, P.; Bucinski, A. Comparative analysis of different groups of phenolic compounds in fruit and leaf extracts of Aronia sp.: A. melanocarpa, A. arbutifolia, and A.× prunifolia and their antioxidant activities. Eur. Food Res. Technol. 2017, 243, 1645–1657. [Google Scholar] [CrossRef]

- Sidor, A.; Gramza-Michałowska, A. Black chokeberry Aronia melanocarpa L.—A qualitative composition, phenolic profile and antioxidant potential. Molecules 2019, 24, 3710. [Google Scholar] [CrossRef]

- Jang, Y.; Koh, E. Characterisation and storage stability of aronia anthocyanins encapsulated with combinations of maltodextrin with carboxymethyl cellulose, gum Arabic, and xanthan gum. Food Chem. 2023, 405, 135002. [Google Scholar] [CrossRef]

- Chen, L.; Chen, W.; Li, D.; Liu, X. Anthocyanin and proanthocyanidin from Aronia melanocarpa (Michx.) Ell.: Purification, fractionation, and enzyme inhibition. Food Sci. Nutr. 2023, 11, 3911–3922. [Google Scholar] [CrossRef]

- Negreanu-Pirjol, B.-S.; Oprea, O.C.; Negreanu-Pirjol, T.; Roncea, F.N.; Prelipcean, A.-M.; Craciunescu, O.; Iosageanu, A.; Artem, V.; Ranca, A.; Motelica, L. Health Benefits of Antioxidant Bioactive Compounds in the Fruits and Leaves of Lonicera caerulea L. and Aronia melanocarpa (Michx.) Elliot. Antioxidants 2023, 12, 951. [Google Scholar] [CrossRef]

- Gao, N.; Shu, C.; Wang, Y.; Tian, J.; Lang, Y.; Jin, C.; Cui, X.; Jiang, H.; Li, Z.; Chen, W. Polyphenol components in black chokeberry (Aronia melanocarpa) as clinically proven diseases control factors—An overview. Food Sci. Hum. Wellness 2024, 13, 1152–1167. [Google Scholar] [CrossRef]

- Zare, R.; Kimble, R.; Redha, A.A.; Cerullo, G.; Clifford, T. How can chokeberry (Aronia)(poly) phenol-rich supplementation help athletes? A systematic review of human clinical trials. Food Funct. 2023, 14, 5478–5491. [Google Scholar] [CrossRef]

- Lei, W.; Rui, W.; Jinxu, D.; Yikai, W.; Huang, X.; Changbao, C. Research on the extraction, purification and determination of chemical components, biological activities, and applications in diet of black chokeberry (Aronia melanocarpa). Chin. J. Anal. Chem. 2023, 51, 100301. [Google Scholar]

- Jurikova, T.; Mlcek, J.; Skrovankova, S.; Sumczynski, D.; Sochor, J.; Hlavacova, I.; Snopek, L.; Orsavova, J. Fruits of black chokeberry Aronia melanocarpa in the prevention of chronic diseases. Molecules 2017, 22, 944. [Google Scholar] [CrossRef]

- Kulling, S.E.; Rawel, H.M. Chokeberry (Aronia melanocarpa)—A review on the characteristic components and potential health effects. Planta Med. 2008, 74, 1625–1634. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, J.-y.; Wei, Y.-l.; Hao, J.-y.; Lei, Y.-q.; Zhao, W.-b.; Xiao, Y.-h.; Sun, A.-d. The polyphenol-rich extract from chokeberry (Aronia melanocarpa L.) modulates gut microbiota and improves lipid metabolism in diet-induced obese rats. Nutr. Metab. 2020, 17, 54. [Google Scholar] [CrossRef]

- Thani, N.A.A.; Keshavarz, S.; Lwaleed, B.A.; Cooper, A.J.; Rooprai, H.K. Cytotoxicity of gemcitabine enhanced by polyphenolics from Aronia melanocarpa in pancreatic cancer cell line AsPC-1. J. Clin. Pathol. 2014, 67, 949–954. [Google Scholar] [CrossRef]

- Kedzierska, M.; Olas, B.; Wachowicz, B.; Stochmal, A.; Oleszek, W.; Jeziorski, A.; Piekarski, J.; Glowacki, R. An extract from berries of Aronia melanocarpa modulates the generation of superoxide anion radicals in blood platelets from breast cancer patients. Planta Med. 2009, 75, 1405–1409. [Google Scholar] [CrossRef]

- Tolic, M.-T.; Krbavcic, I.P.; Vujevic, P.; Milinovic, B.; Jurcevic, I.L.; Vahcic, N. Effects of weather conditions on phenolic content and antioxidant capacity in juice of chokeberries (Aronia melanocarpa L.). Pol. J. Food Nutr. Sci. 2017, 67, 67–74. [Google Scholar] [CrossRef]

- Bräunlich, M.; Slimestad, R.; Wangensteen, H.; Brede, C.; Malterud, K.E.; Barsett, H. Extracts, anthocyanins and procyanidins from Aronia melanocarpa as radical scavengers and enzyme inhibitors. Nutrients 2013, 5, 663–678. [Google Scholar] [CrossRef]

- Wu, X.; Gu, L.; Prior, R.L.; McKay, S. Characterization of anthocyanins and proanthocyanidins in some cultivars of Ribes, Aronia, and Sambucus and their antioxidant capacity. J. Agric. Food Chem. 2004, 52, 7846–7856. [Google Scholar] [CrossRef]

- Yue, Z.; Fenmei, L.; Yanli, W.; Ning, Z.; Haiping, Z.; Jianhui, A.; Aidong, S. Extraction and antibacterial activity of proanthocyanidins from Aroma nigrum. Food Ind. Technol. 2017, 38, 302–306. [Google Scholar]

- Yue, Z.; Haiping, Z.; Yanan, H.; Jianhui, A.; Xiaoru, F.; Wenxinya; Teng, L.; Aidong, S. Purification of proanthocyanidins from Sorbus nigra and determination of epicatechin and proanthocyanidin B2 contents. Food Ind. Technol. 2017, 38, 240–244. [Google Scholar]

- Wenjun, Z.; Guofeng, Z.; Li, W.; Xinjia, Y.; Shujing, W.; Zhixin, Y. Simultaneous determination of proanthocyanidin B1, proanthocyanidin B2, proanthocyanidin B4, rutin, and quercetin in Sorbus nigra berries by UPLC method. Chin. Herb. Med. 2016, 47, 4452–4455. [Google Scholar]

- Kaloudi, T.; Tsimogiannis, D.; Oreopoulou, V. Aronia melanocarpa: Identification and exploitation of its phenolic components. Molecules 2022, 27, 4375. [Google Scholar] [CrossRef]

- Jurendić, T.; Ščetar, M. Aronia melanocarpa products and by-products for health and nutrition: A review. Antioxidants 2021, 10, 1052. [Google Scholar] [CrossRef]

- Meng, L.; Zhu, J.; Ma, Y.; Sun, X.; Li, D.; Li, L.; Bai, H.; Xin, G.; Meng, X. Composition and antioxidant activity of anthocyanins from Aronia melanocarpa cultivated in Haicheng, Liaoning, China. Food Biosci. 2019, 30, 100413. [Google Scholar] [CrossRef]

- Dexian, O.; Jianying, L.; Yanfang, O.; Xingyu, C. Optimization of the extraction process of proanthocyanidins from Sorbus nigra and its antioxidant activity. Food Res. Dev. 2023, 44, 96–104. [Google Scholar]

- Ningxuan, G.; Xianjun, M.; Yuxi, L.; Bin, L. Research on the polyphenol components and cellular antioxidant activity of Aroma nigrum and its process optimization of pomace polymerization of proanthocyanidins into anthocyanins. Abstr. Annu. Meet. Chin. Soc. Food Sci. Technol. 2020, 2. [Google Scholar]

- Guoming, L.; Liping, Z.; Ping, Y.; Shouling, L. Analysis of chemical components and total flavonoids content of volatile oil from Sorbus nigrum. J. Food Saf. Qual. 2019, 10. [Google Scholar]

- Jiangang, S.; Fangli, Z.; Xiaolin, W.; Rongqin, M. Technology for Extracting Hypericin from Sorbus nigra Fruit. Food Ind. Technol. 2019, 7. [Google Scholar]

- Sidor, A.; Drożdżyńska, A.; Gramza-Michałowska, A. Black chokeberry (Aronia melanocarpa) and its products as potential health-promoting factors—An overview. Trends Food Sci. Technol. 2019, 89, 45–60. [Google Scholar] [CrossRef]

- Ochmian, I.D.; Grajkowski, J.; Smolik, M. Comparison of some morphological features, quality and chemical content of four cultivars of chokeberry fruits (Aronia melanocarpa). Not. Bot. Horti Agrobot. Cluj-Napoca 2012, 40, 253–260. [Google Scholar] [CrossRef]

- Lu, W.L.; Yang, L.; Yuehua, W.; Xianjun, M. Optimization of the extraction process of anthocyanins from Aroma nigrum and its antioxidant activity and composition identification. Food Sci. 2018, 39, 239–246. [Google Scholar]

- Hualin, S.; Liu, W.; He, M.; Yuye, S.; Weiden. Optimization of the extraction process of polysaccharide from Sorbus nigra gland ribs using response surface methodology. Mod. Food Technol. 2018, 21, 153–156. [Google Scholar]

- Deng, W.; Fenglin, L. Optimization of extraction process and antioxidant activity of polysaccharide from Sorbus nigrum. In Proceedings of the Compilation of Papers from the 11th Academic Conference on Special Nutrition of the Chinese Nutrition Society, Jilin, China, 11 August 2018. [Google Scholar]

- Huijuan, Q.; Chunying, Z.; Zhongbin, L.; Dewen, L.; Weili, Z. Comparative analysis of main quality characteristics of 6 kinds of berries in Daxinganling area. For. Sci. Technol. Inf. 2019, 6, 1–6. [Google Scholar]

- Liyang, Y.; Yu, Z.; Liyu, Z.; Yan, L.; Junxi, L. Comparison of flavonoids and polysaccharides content in Sorbus nigra and two small berries. Anhui Agric. Sci. 2016, 44, 122–124. [Google Scholar]

- Ningxuan, G.; Bin, L.; Hui, L.; Xianjun, M.; Xinyao, J.; Moon, T.; Ye, Z.; Yuan, L.; Shifu, C.; Feng, G. Optimization of polyphenol extraction process and antioxidant activity of Sorbus nigra based on RSM method. Food Ind. Technol. 2016, 249–254. [Google Scholar]

- Jiashuang, H.; Qingchao, C.; Yoon-Cheol, K.; Ok, P.J.; Sun, K.Y. Study on the polyphenol content and in vitro antioxidant activity of Sorbus nigra fruit. J. Yangzhou Univ. (Agric. Life Sci. Ed.) 2019, 40, 5. [Google Scholar]

- Rugină, D.; Diaconeasa, Z.; Coman, C.; Bunea, A.; Socaciu, C.; Pintea, A. Chokeberry anthocyanin extract as pancreatic β-cell protectors in two models of induced oxidative stress. Oxidative Med. Cell. Longev. 2015, 2015, 429075. [Google Scholar] [CrossRef]

- Meilan, L.; Beads, G.; Hongmei, L.; Chengzhe, J. Preliminary study on the antioxidant activity of Sorbus nigrum on liver and kidney of mice. Livest. Feed Sci. 2018, 39, 1–3. [Google Scholar]

- Yanyang, X.; Yang, Q.; Junyang, W.; Tiehua, Z.; Weiqiang, Y.; Chengjun, S. Antibacterial effect of Aroma nigrum polyphenols and inhibitory effect on α-amylase activity. Food Sci. 2018, 39, 51–57. [Google Scholar]

- Denev, P.; Číž, M.; Kratchanova, M.; Blazheva, D. Black chokeberry (Aronia melanocarpa) polyphenols reveal different antioxidant, antimicrobial and neutrophil-modulating activities. Food Chem. 2019, 284, 108–117. [Google Scholar] [CrossRef]

- Bräunlich, M.; Økstad, O.A.; Slimestad, R.; Wangensteen, H.; Malterud, K.E.; Barsett, H. Effects of Aronia melanocarpa constituents on biofilm formation of Escherichia coli and Bacillus cereus. Molecules 2013, 18, 14989–14999. [Google Scholar] [CrossRef]

- Bararu, I.; Badescu, L.; Badulescu, O.; Ciocoiu, M.; Badescu, M. Possibilities of limiting the inflammatory syndrome present in experimental diabetes mellitus by using natural poliphenols. Ann. Rom. Soc. Cell Biol. 2013, 18, 97–108. [Google Scholar]

- Valcheva-Kuzmanova, S.; Kuzmanov, A.; Kuzmanova, V.; Tzaneva, M. Aronia melanocarpa fruit juice ameliorates the symptoms of inflammatory bowel disease in TNBS-induced colitis in rats. Food Chem. Toxicol. 2018, 113, 33–39. [Google Scholar] [CrossRef]

- Zapolska-Downar, D.; Bryk, D.; Małecki, M.; Hajdukiewicz, K.; Sitkiewicz, D. Aronia melanocarpa fruit extract exhibits anti-inflammatory activity in human aortic endothelial cells. Eur. J. Nutr. 2012, 51, 563–572. [Google Scholar] [CrossRef]

- Bijak, M.; Saluk, J.; Antosik, A.; Ponczek, M.B.; Żbikowska, H.M.; Borowiecka, M.; Nowak, P. Aronia melanocarpa as a protector against nitration of fibrinogen. Int. J. Biol. Macromol. 2013, 55, 264–268. [Google Scholar] [CrossRef] [PubMed]

- Cvetanović, A.; Zengin, G.; Zeković, Z.; Švarc-Gajić, J.; Ražić, S.; Damjanović, A.; Mašković, P.; Mitić, M. Comparative in vitro studies of the biological potential and chemical composition of stems, leaves and berries Aronia melanocarpa’s extracts obtained by subcritical water extraction. Food Chem. Toxicol. 2018, 121, 458–466. [Google Scholar] [CrossRef] [PubMed]

- Rugină, D.; Sconţa, Z.; Leopold, L.; Pintea, A.; Bunea, A.; Socaciu, C. Antioxidant activities of chokeberry extracts and the cytotoxic action of their anthocyanin fraction on HeLa human cervical tumor cells. J. Med. Food 2012, 15, 700–706. [Google Scholar] [CrossRef] [PubMed]

- Choi, H.S.; Kim, J.H.; Kim, S.L.; Deng, H.Y.; Lee, D.; Kim, C.S.; Yun, B.S.; Lee, D.S. Catechol derived from aronia juice through lactic acid bacteria fermentation inhibits breast cancer stem cell formation via modulation Stat3/IL-6 signaling pathway. Mol. Carcinog. 2018, 57, 1467–1479. [Google Scholar] [CrossRef] [PubMed]

- Gao, N.; Wang, Y.; Jiao, X.; Chou, S.; Li, E.; Li, B. Preparative purification of polyphenols from Aronia melanocarpa (Chokeberry) with cellular antioxidant and antiproliferative activity. Molecules 2018, 23, 139. [Google Scholar] [CrossRef] [PubMed]

- Do Thi, N.; Hwang, E.-S. Effects of black chokeberry extracts on metastasis and cell-cycle arrest in SK-Hep1 human liver cancer cell line. Asian Pac. J. Trop. Biomed. 2018, 8, 285–291. [Google Scholar]

- Balansky, R.; Ganchev, G.; Iltcheva, M.; Kratchanova, M.; Denev, P.; Kratchanov, C.; Polasa, K.; D’Agostini, F.; Steele, V.E.; De Flora, S. Inhibition of lung tumor development by berry extracts in mice exposed to cigarette smoke. Int. J. Cancer 2012, 131, 1991–1997. [Google Scholar] [CrossRef] [PubMed]

- Kardum, N.; Takić, M.; Šavikin, K.; Zec, M.; Zdunić, G.; Spasić, S.; Konić-Ristić, A. Effects of polyphenol-rich chokeberry juice on cellular antioxidant enzymes and membrane lipid status in healthy women. J. Funct. Foods 2014, 9, 89–97. [Google Scholar] [CrossRef]

- Kardum, N.; Milovanović, B.; Šavikin, K.; Zdunić, G.; Mutavdžin, S.; Gligorijević, T.; Spasić, S. Beneficial effects of polyphenol-rich chokeberry juice consumption on blood pressure level and lipid status in hypertensive subjects. J. Med. Food 2015, 18, 1231–1238. [Google Scholar] [CrossRef]

- Loo, B.-M.; Erlund, I.; Koli, R.; Puukka, P.; Hellström, J.; Wähälä, K.; Mattila, P.; Jula, A. Consumption of chokeberry (Aronia mitschurinii) products modestly lowered blood pressure and reduced low-grade inflammation in patients with mildly elevated blood pressure. Nutr. Res. 2016, 36, 1222–1230. [Google Scholar] [CrossRef]

- Kardum, N.; Konić-Ristić, A.; Šavikin, K.; Spasić, S.; Stefanović, A.; Ivanišević, J.; Miljković, M. Effects of polyphenol-rich chokeberry juice on antioxidant/pro-oxidant status in healthy subjects. J. Med. Food 2014, 17, 869–874. [Google Scholar] [CrossRef]

- Lipińska, P.; Jóźwik, A. Hepatoprotective, hypoglycemic, and hypolipidemic effect of chokeberry pomace on polish merino lambs. Anim. Biotechnol. 2018, 29, 136–141. [Google Scholar] [CrossRef]

- Qin, B.; Anderson, R.A. An extract of chokeberry attenuates weight gain and modulates insulin, adipogenic and inflammatory signalling pathways in epididymal adipose tissue of rats fed a fructose-rich diet. Br. J. Nutr. 2012, 108, 581–587. [Google Scholar] [CrossRef]

- Takahashi, A.; Shimizu, H.; Okazaki, Y.; Sakaguchi, H.; Taira, T.; Suzuki, T.; Chiji, H. Anthocyanin-rich phytochemicals from aronia fruits inhibit visceral fat accumulation and hyperglycemia in high-fat diet-induced dietary obese rats. J. Oleo Sci. 2015, 64, 1243–1250. [Google Scholar] [CrossRef]

- Park, Y.M.; Park, J.B. The preventive and therapeutic effects of Aronox extract on metabolic abnormality and hypertension. J. Korean Soc. Hypertens. 2011, 17, 95–102. [Google Scholar] [CrossRef]

- Worsztynowicz, P.; Napierała, M.; Białas, W.; Grajek, W.; Olkowicz, M. Pancreatic α-amylase and lipase inhibitory activity of polyphenolic compounds present in the extract of black chokeberry (Aronia melanocarpa L.). Process Biochem. 2014, 49, 1457–1463. [Google Scholar] [CrossRef]

- Kozuka, M.; Yamane, T.; Nakano, Y.; Nakagaki, T.; Ohkubo, I.; Ariga, H. Identification and characterization of a dipeptidyl peptidase IV inhibitor from aronia juice. Biochem. Biophys. Res. Commun. 2015, 465, 433–436. [Google Scholar] [CrossRef] [PubMed]

- Borowska, S.; Brzóska, M.M. Chokeberries (Aronia melanocarpa) and their products as a possible means for the prevention and treatment of noncommunicable diseases and unfavorable health effects due to exposure to xenobiotics. Compr. Rev. Food Sci. Food Saf. 2016, 15, 982–1017. [Google Scholar] [CrossRef] [PubMed]

- Kondeva-Burdina, M.; Valcheva-Kuzmanova, S.; Markova, T.; Mitcheva, M.; Belcheva, A. Effects of Aronia melanocarpa fruit juice on isolated rat hepatocytes. Pharmacogn. Mag. 2015, 11, S592. [Google Scholar] [CrossRef] [PubMed]

- Valcheva-Kuzmanova, S. Comparative Study of the Protective Effect of Fruit Juice and Quercetin in a Model of Paracetamol-Induced Hepatotoxicity in Rats. J. Biomed. Clin. Res. 2015, 8, 118–123. [Google Scholar] [CrossRef][Green Version]

- Case, A.J.; Agraz, D.; Ahmad, I.M.; Zimmerman, M.C. Low-Dose Aronia melanocarpa concentrate attenuates paraquat-induced neurotoxicity. Oxidative Med. Cell. Longev. 2016, 2016, 5296271. [Google Scholar] [CrossRef]

- Brzóska, M.M.; Rogalska, J.; Galazyn-Sidorczuk, M.; Jurczuk, M.; Roszczenko, A.; Tomczyk, M. Protective effect of Aronia melanocarpa polyphenols against cadmium-induced disorders in bone metabolism: A study in a rat model of lifetime human exposure to this heavy metal. Chem. Biol. Interact. 2015, 229, 132–146. [Google Scholar] [CrossRef]

- Paulrayer, A.; Adithan, A.; Lee, J.H.; Moon, K.H.; Kim, D.G.; Im, S.Y.; Kang, C.-W.; Kim, N.S.; Kim, J.-H. Aronia melanocarpa (black chokeberry) reduces ethanol-induced gastric damage via regulation of HSP-70, NF-κB, and MCP-1 signaling. Int. J. Mol. Sci. 2017, 18, 1195. [Google Scholar] [CrossRef]

- Eftimov, M.; Dobreva, C.; Velkova, D.; Valcheva-Kuzmanova, S. Effect of Aronia melanocarpa fruit juice on behaviour of rats exposed to social isolation. Trakia J. Sci. 2014, 12, 123–126. [Google Scholar]

- Tomić, M.; Ignjatović, Đ.; Tovilović-Kovačević, G.; Krstić-Milošević, D.; Ranković, S.; Popović, T.; Glibetić, M. Reduction of anxiety-like and depression-like behaviors in rats after one month of drinking Aronia melanocarpa berry juice. Food Funct. 2016, 7, 3111–3120. [Google Scholar] [CrossRef] [PubMed]

- Valcheva-Kuzmanova, S.V.; Eftimov, M.T.; Tashev, R.E.; Belcheva, I.P.; Belcheva, S.P. Memory effects of Aronia melanocarpa fruit juice in a passive avoidance test in rats. Folia Med. 2014, 56, 199. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Ruifang, L. Ultrasound-assisted extraction of flavonoids from Aroma nigrum and its anti-exercise fatigue research. Food Res. Dev. 2017, 38, 63–68. [Google Scholar]

- Gramza-Michałowska, A.; Sidor, A.; Kulczyński, B. Berries as a potential anti-influenza factor—A review. J. Funct. Foods 2017, 37, 116–137. [Google Scholar] [CrossRef]

- Park, S.; Kim, J.I.; Lee, I.; Lee, S.; Hwang, M.-W.; Bae, J.-Y.; Heo, J.; Kim, D.; Han, S.-Z.; Park, M.-S. Aronia melanocarpa and its components demonstrate antiviral activity against influenza viruses. Biochem. Biophys. Res. Commun. 2013, 440, 14–19. [Google Scholar] [CrossRef]

- Yongxiang, Z.; Shilei, G.; Penlisa; Fengmei, Z.; Jun, L. Protective effect of Aroma nigrum anthocyanins against ultraviolet radiation damage in human skin fibroblasts. Nat. Prod. Res. Dev. 2016, 28, 1088–1092. [Google Scholar]

- Suljević, D.; Mitrašinović-Brulić, M.; Klepo, L.; Škrijelj, R.; Fočak, M. Impact of dietary supplementation with chokeberry (Aronia melanocarpa, Michx.) on tetrachloride-induced liver injury in Wistar rats: Hematological and biochemical implication. Cell Biochem. Funct. 2023, 41, 801–813. [Google Scholar] [CrossRef]

- Navrátilová, A.; Kovár, M.; Kopčeková, J.; Mrázová, J.; Trakovická, A.; Požgajová, M. Protective effect of Aronia melanocarpa juice against acrylamide-induced cellular toxicity. J. Environ. Sci. Health Part B 2023, 58, 139–149. [Google Scholar] [CrossRef]

- Mijatović, E.; Harej Hrkać, A.; Gržeta, N.; Pilipović, K. Exploration of the Protective Effects of Aronia melanocarpa Extract in an in vitro Model of Parkinson’s Disease. Med. Flum. Med. Flum. 2023, 59, 280–289. [Google Scholar] [CrossRef]

- Yanzhu, C.; Wenzhong, H.; Aili, J.; Chenghui, L.; Xue, Y.; Xingbo, L. Research progress on functional effects and food processing of Sorbus nigrum. Food Ind. Technol. 2016, 37, 397–400. [Google Scholar]

- Haiping, Z.; Yue, Z.; Yulong, W.; Teng, L.; Ning, Y.; Ning, Z.; Zhilin, G.; Aidong, S. Optimization of the fermentation process of Sorbus nigra juice by Lactobacillus plantarum. Food Ind. Technol. 2018, 39, 133–138. [Google Scholar]

- Yanmin, C.; Mingyue, W.; Yuqi, T.; Jinhong, H.; Xianjun, M.; Li, L. Study on the Effect of Ultra-high Pressure Treatment on the Quality of Apple-Black Sorbus Compound Juice. Agric. Technol. Equip. 2019, 6. [Google Scholar]

- Peng, W. Study on the biological hypoglycemic process of Sorbus nigra fruit juice. For. Technol. 2019, 2. [Google Scholar]

- Wenzhong, H.; Xinghua, M.; Zhenrong, J.; Wensheng, S.; Peng, W.; Yanli, M.; Yufeng, W.; Weidong, Z.; Shuhua, W. Black-fruited rowanberry fruit wine and brewing method. J. Forest Sci. Technol. 2012, 3, 53–55. [Google Scholar]

- Jingruo, Y.; Zuomin, W.; Yuncai, Z. Black fruit glandular rib fermented wine. Wine Mak. 2020, 47, 121–123. [Google Scholar]

- Yinlu, G. Research on the Fermentation Technology of Black Fruit Arwana Japonica Dry Wine. Master’s Thesis, Jilin Agricultural University, Changchun, China, 2017. [Google Scholar]

- Lijuan, H. “Yiyi Brewing Fruit” Brand Value Enhancement Strategy. Master’s Thesis, Shanxi University, Taiyuan, China, 2020. [Google Scholar]

- Zuodi, W. A 100% Fermented Black Fruit Gland-Ribbed Rowan Vinegar Beverage and Its Preparation Method. CN Patent 201711468481.9, 29 December 2017. [Google Scholar]

- Feng, W.; Fengwu, W.; Xinxin, C.; Yong, C. Production and processing technology of astringent removal and jam of Aralia japonica from black fruit. Food Technol. 2018, 43, 6. [Google Scholar]

- Fengwu, W.; Miko, P. A Method for Making Jam Using Sorbus nigra as Raw Material. CN Patent 106616711A, 10 May 2017. [Google Scholar]

- Yoon, H.-S.; Kim, J.W.; Kim, S.H.; Kim, Y.G.; Eom, H.-J. Quality characteristics of bread added with aronia powder (Aronia melanocarpa). J. Korean Soc. Food Sci. Nutr. 2014, 43, 273–280. [Google Scholar] [CrossRef]

- Kaack, K.; Kühn, B.F. Black chokeberry (Aronia melanocarpa) for manufacture of a food colorant. Tidsskr. Planteavl 1992, 96, 183–196. [Google Scholar]

- Lu, T. Study on the Extraction, Isolation, Purification and Microencapsulation of Anthocyanins from Aroma Nigrum. Master’s Thesis, Jilin Agricultural University, Changchun, China, 2019. [Google Scholar]

- Xinya, W. Study on the Effect of Modification Treatment on the Quality of Soluble Dietary Fiber in Sorbus Nigra Pomace. Master’s Thesis, Beijing Forestry University, Beijing, China, 2018. [Google Scholar]

- Xiaolin, W.; Zhenbiao, C.; Fangli, Z.; Jiangang, S. Study on the preparation technology of effervescent granules of Sorbus nigricans. Food Res. Dev. 2020, 41, 7. [Google Scholar]

- Fei, T. Analysis of Proanthocyanidin Components of Sorbus Nigra and Research and Development of Functional Food. Master’s Thesis, Changchun Normal University, Changchun, China, 2019. [Google Scholar]

- Jingren, H.; Shuangyan, T.; Linyuan, W.; Fangxiong, S.; Bodi, H.; Yuehuan, L. Compound Nutrients for Preventing and Treating Hypertension and Hyperlipidemia and Preparation Methods and Applications Thereof. CN Patent 201910023454, 10 January 2019. [Google Scholar]

- Platonova, E.Y.; Shaposhnikov, M.V.; Lee, H.-Y.; Lee, J.-H.; Min, K.-J.; Moskalev, A. Black chokeberry (Aronia melanocarpa) extracts in terms of geroprotector criteria. Trends Food Sci. Technol. 2021, 114, 570–584. [Google Scholar] [CrossRef]

- Rahim, R.; Raman, A.A.A. Cleaner production implementation in a fruit juice production plant. J. Clean. Prod. 2015, 101, 215–221. [Google Scholar] [CrossRef]

- Galaverna, G.; Dall’Asta, C. Production processes of orange juice and effects on antioxidant components. In Processing and Impact on Antioxidants in Beverages; Elsevier: Amsterdam, The Netherlands, 2014; pp. 203–214. [Google Scholar]

- De Paepe, D.; Coudijzer, K.; Noten, B.; Valkenborg, D.; Servaes, K.; De Loose, M.; Diels, L.; Voorspoels, S.; Van Droogenbroeck, B. A comparative study between spiral-filter press and belt press implemented in a cloudy apple juice production process. Food Chem. 2015, 173, 986–996. [Google Scholar] [CrossRef] [PubMed]

- Vardin, H.; Fenercioǧlu, H. Study on the development of pomegranate juice processing technology: Clarification of pomegranate juice. Food/Nahrung 2003, 47, 300–303. [Google Scholar] [CrossRef] [PubMed]

- Echavarría, A.; Torras, C.; Pagán, J.; Ibarz, A. Fruit juice processing and membrane technology application. Food Eng. Rev. 2011, 3, 136–158. [Google Scholar] [CrossRef]

- Bilal, M.; Asgher, M.; Iqbal, H.M.; Hu, H.; Zhang, X. Gelatin-immobilized manganese peroxidase with novel catalytic characteristics and its industrial exploitation for fruit juice clarification purposes. Catal. Lett. 2016, 146, 2221–2228. [Google Scholar] [CrossRef]

- Solís-Fuentes, J.A.; Galán-Méndez, F.; del Rosario Hernández-Medel, M.; García-Gómez, R.S.; Bernal-González, M.; Mendoza-Pérez, S.; del Carmen Durán-Domínguez-de, M. Effectiveness of bagasse activated carbon in raw cane juice clarification. Food Biosci. 2019, 32, 100437. [Google Scholar] [CrossRef]

- Taştan, Ö.; Baysal, T. Chitosan as a novel clarifying agent on clear apple juice production: Optimization of process conditions and changes on quality characteristics. Food Chem. 2017, 237, 818–824. [Google Scholar] [CrossRef] [PubMed]

- Xin, X.; Hao, S. Production of new compound fruit and vegetable juice drinks. J. Dalian Univ. Technol. 2010, 29, 4. [Google Scholar]

- Changjiao, L.; Ping, Y.; Shu, Y.; Ping, Y. Development of Schisandra fruit juice drink. Anhui Agric. Sci. 2011, 39, 3. [Google Scholar]

- Sharma, H.P.; Patel, H.; Sugandha, C. Enzymatic added extraction and clarification of fruit juices—A review. Crit. Rev. Food Sci. Nutr. 2017, 57, 1215–1227. [Google Scholar] [CrossRef]

- Yinyin, S. Research on Processing Technology and Stability of Ginkgo Beverage. Master’s Thesis, Nanjing Forestry University, Nanjing, China, 2010. [Google Scholar]

- Bhattacharjee, C.; Saxena, V.; Dutta, S. Fruit juice processing using membrane technology: A review. Innov. Food Sci. Emerg. Technol. 2017, 43, 136–153. [Google Scholar] [CrossRef]

- Conidi, C.; Drioli, E.; Cassano, A. Perspective of membrane technology in pomegranate juice processing: A review. Foods 2020, 9, 889. [Google Scholar] [CrossRef] [PubMed]

- Zhiwei, Q.; Radium, J.; Mingsheng, S. Study on clarification of longan juice by ultrafiltration. J. Fruit Sci. 2011, 28, 4. [Google Scholar]

- Yanwen, G.; Yanmin, S.; Xueni, C. Research on ultrafiltration and clarification process of orange juice. Food Technol. 2010, 35, 131–134. [Google Scholar]

- Leite, T.S.; Augusto, P.E.; Cristianini, M. Frozen concentrated orange juice (FCOJ) processed by the high pressure homogenization (HPH) technology: Effect on the ready-to-drink juice. Food Bioprocess Technol. 2016, 9, 1070–1078. [Google Scholar] [CrossRef]

- Szczepańska, J.; Skąpska, S.; Marszałek, K. Continuous high-pressure cooling-assisted homogenization process for stabilization of apple juice. Food Bioprocess Technol. 2021, 14, 1101–1117. [Google Scholar] [CrossRef]

- Salehi, F. Physico-chemical and rheological properties of fruit and vegetable juices as affected by high pressure homogenization: A review. Int. J. Food Prop. 2020, 23, 1136–1149. [Google Scholar] [CrossRef]

- Sauceda-Gálvez, J.N.; Codina-Torrella, I.; Martinez-Garcia, M.; Hernández-Herrero, M.M.; Gervilla, R.; Roig-Sagués, A. Combined effects of ultra-high pressure homogenization and short-wave ultraviolet radiation on the properties of cloudy apple juice. LWT 2021, 136, 110286. [Google Scholar] [CrossRef]

- Wellala, C.K.D.; Bi, J.; Liu, X.; Liu, J.; Lyu, J.; Zhou, M. Effect of high pressure homogenization on mixed juice stability, rheology, physicochemical properties and microorganism reduction. J. Food Sci. Technol. 2020, 57, 1944–1953. [Google Scholar] [CrossRef]

- Kruszewski, B.; Zawada, K.; Karpiński, P. Impact of high-pressure homogenization parameters on physicochemical characteristics, bioactive compounds content, and antioxidant capacity of blackcurrant juice. Molecules 2021, 26, 1802. [Google Scholar] [CrossRef]

- Yu, W.; Cui, J.; Zhao, S.; Feng, L.; Wang, Y.; Liu, J.; Zheng, J. Effects of high-pressure homogenization on pectin structure and cloud stability of not-from-concentrate orange juice. Front. Nutr. 2021, 8, 647748. [Google Scholar] [CrossRef]

- Yildiz, G. Application of ultrasound and high-pressure homogenization against high temperature-short time in peach juice. J. Food Process Eng. 2019, 42, e12997. [Google Scholar] [CrossRef]

- Martínez-Sánchez, A.; Tarazona-Díaz, M.P.; García-González, A.; Gómez, P.A.; Aguayo, E. Effect of high-pressure homogenization on different matrices of food supplements. Food Sci. Technol. Int. 2016, 22, 708–719. [Google Scholar] [CrossRef]

- Tribst, A.A.L.; Franchi, M.A.; de Massaguer, P.R.; Cristianini, M. Quality of mango nectar processed by high-pressure homogenization with optimized heat treatment. J. Food Sci. 2011, 76, M106–M110. [Google Scholar] [CrossRef] [PubMed]

- Xixiang, S.; Liqing, D.; Xinghao, T.; Ming, Z. Effect of high-pressure homogenization on antioxidant components and antioxidant activity in strawberry juice. Food Ind. Technol. 2017, 38, 5. [Google Scholar]

- Marszałek, K.; Woźniak, Ł.; Kruszewski, B.; Skąpska, S. The effect of high pressure techniques on the stability of anthocyanins in fruit and vegetables. Int. J. Mol. Sci. 2017, 18, 277. [Google Scholar] [CrossRef] [PubMed]

- Frank, K.; Köhler, K.; Schuchmann, H.P. Stability of anthocyanins in high pressure homogenisation. Food Chem. 2012, 130, 716–719. [Google Scholar] [CrossRef]

- Uribe, J.A.R.; Perez, J.I.N.; Kauil, H.C.; Rubio, G.R.; Alcocer, C.G. Extraction of oil from chia seeds with supercritical CO2. J. Supercrit. Fluids 2011, 56, 174–178. [Google Scholar] [CrossRef]

- Larrauri, J. New approaches in the preparation of high dietary fibre powders from fruit by-products. Trends Food Sci. Technol. 1999, 10, 3–8. [Google Scholar] [CrossRef]

- Sójka, M.; Kołodziejczyk, K.; Milala, J. Polyphenolic and basic chemical composition of black chokeberry industrial by-products. Ind. Crops Prod. 2013, 51, 77–86. [Google Scholar] [CrossRef]

- Ying, J.; Xuzhou, L.; Liling, H.; Yanglan, L.; Mingzhi, L.; Naixin, C.; Yong, Y. Effects of Sorbus nigra pomace on growth performance and antioxidant function of weaned piglets. Feed Ind. 2021, 42, 6. [Google Scholar]

| Element | Mass Contents (μg/g) |

|---|---|

| Proanthocyanidin B1 | 129.78 |

| Proanthocyanidins B2 | 3834.99 |

| Proanthocyanidin B4 | 196.02 |

| Rutin | 134.40 |

| Quercetin | 79.10 |

| Variety | Polysaccharide Contents (mg/g) |

|---|---|

| Wild blueberries | 79.86 |

| viburnum | 63.68 |

| Hawthorn | 122.27 |

| Shanjingzi | 163.62 |

| Aronia melanocarpa | 140.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, D.; Xu, J.; Sheng, L.; Song, K. Comprehensive Utilization Technology of Aronia melanocarpa. Molecules 2024, 29, 1388. https://doi.org/10.3390/molecules29061388

Shi D, Xu J, Sheng L, Song K. Comprehensive Utilization Technology of Aronia melanocarpa. Molecules. 2024; 29(6):1388. https://doi.org/10.3390/molecules29061388

Chicago/Turabian StyleShi, Dongfang, Jing Xu, Li Sheng, and Kai Song. 2024. "Comprehensive Utilization Technology of Aronia melanocarpa" Molecules 29, no. 6: 1388. https://doi.org/10.3390/molecules29061388

APA StyleShi, D., Xu, J., Sheng, L., & Song, K. (2024). Comprehensive Utilization Technology of Aronia melanocarpa. Molecules, 29(6), 1388. https://doi.org/10.3390/molecules29061388