Insulin Conformation Changes in Hybrid Alginate–Gelatin Hydrogel Particles

Abstract

1. Introduction

2. Results

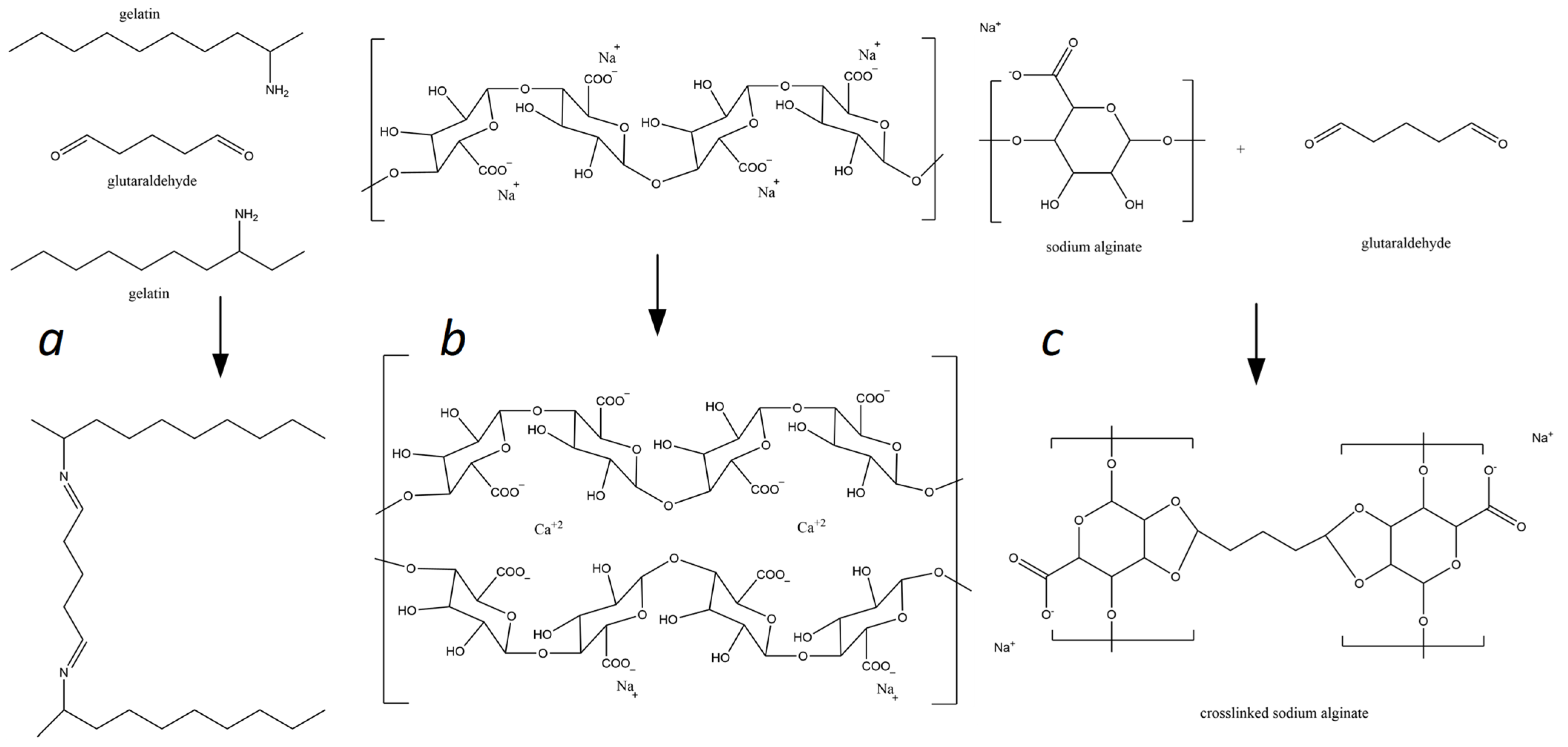

2.1. Matrix Design for the Hybrid Delivery System

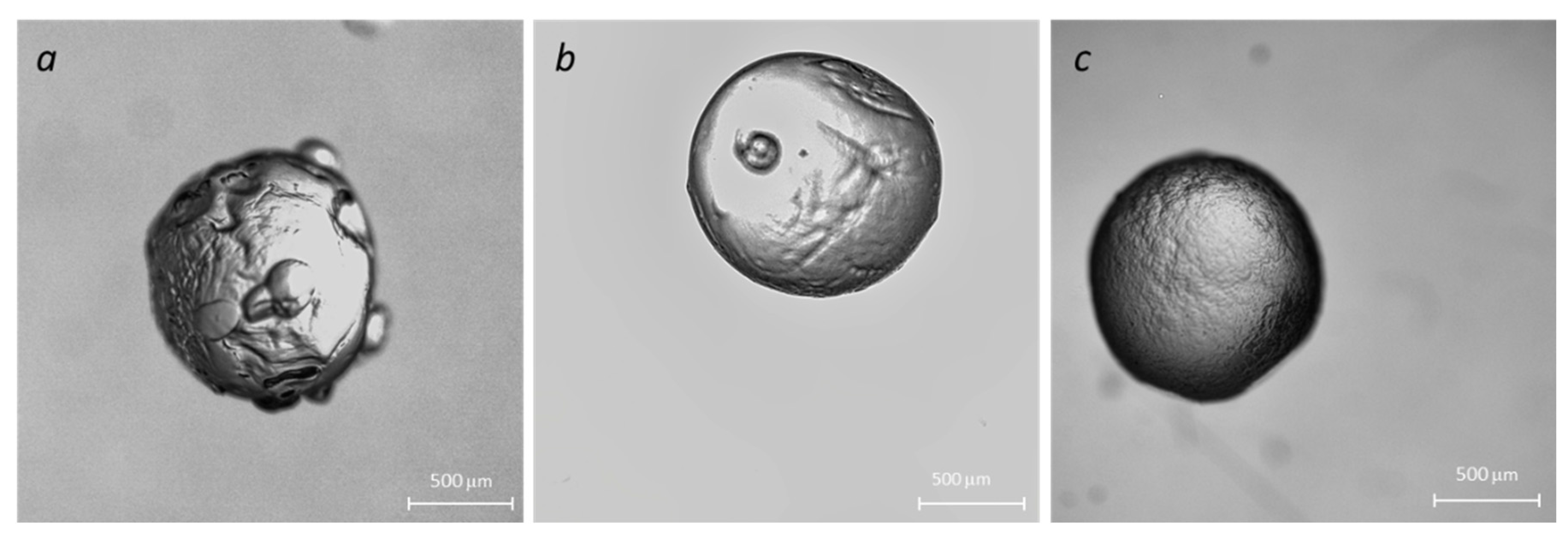

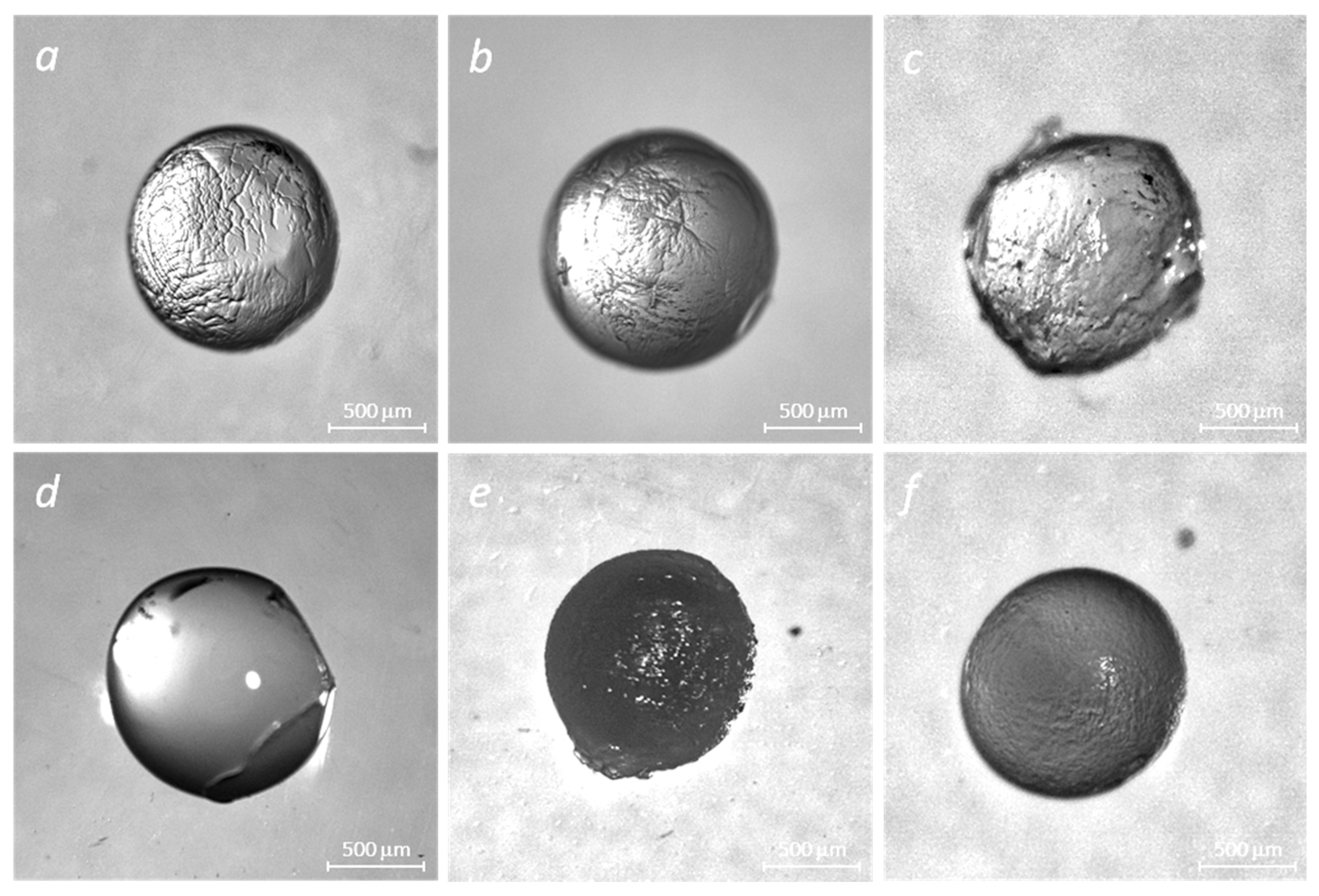

2.2. Optimization of Gel Microbead Fabrication and Immobilization of Insulin into Polymer Matrices

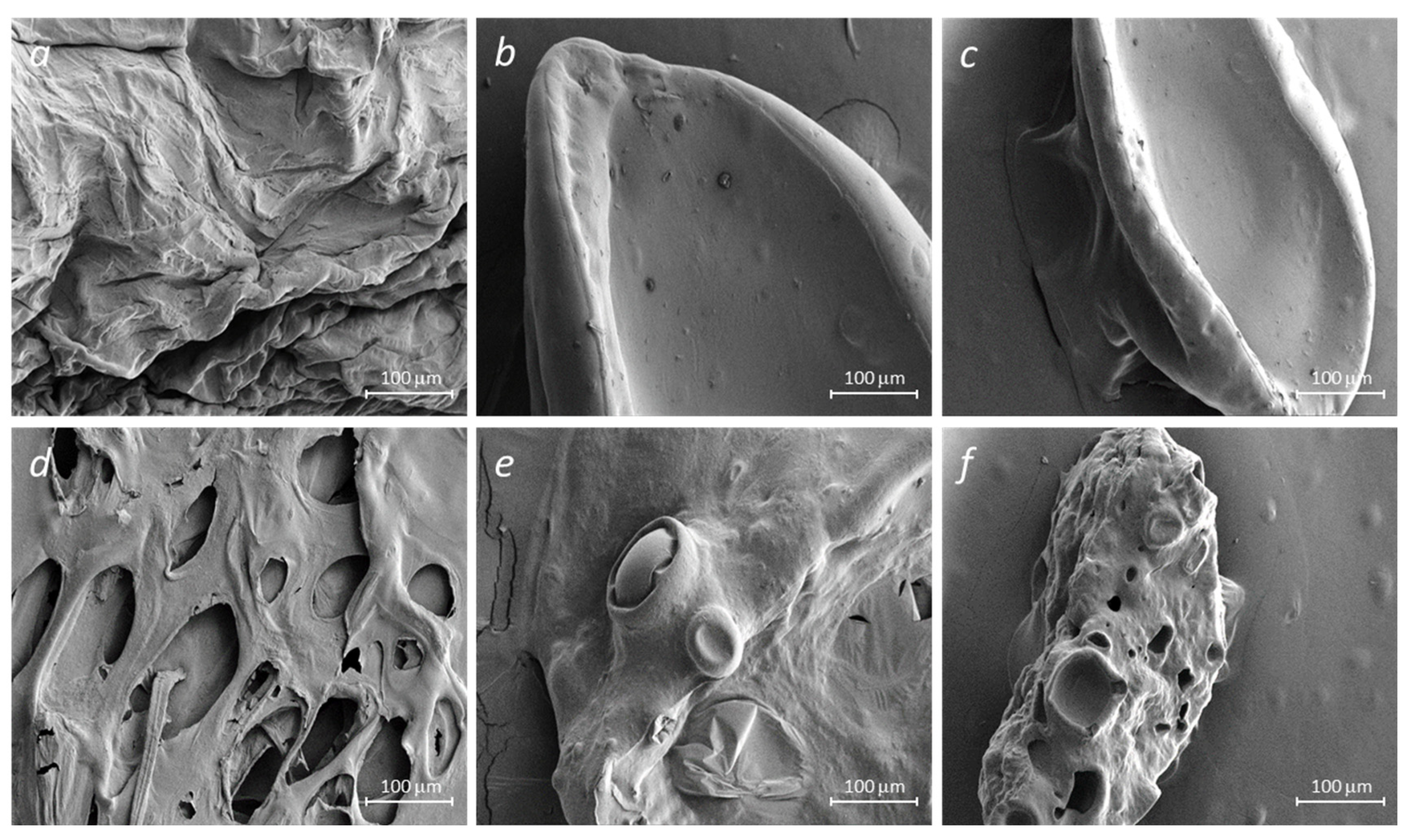

2.3. Scanning Electron Microscopy

2.4. Swelling Behavior and Encapsulation Efficacy

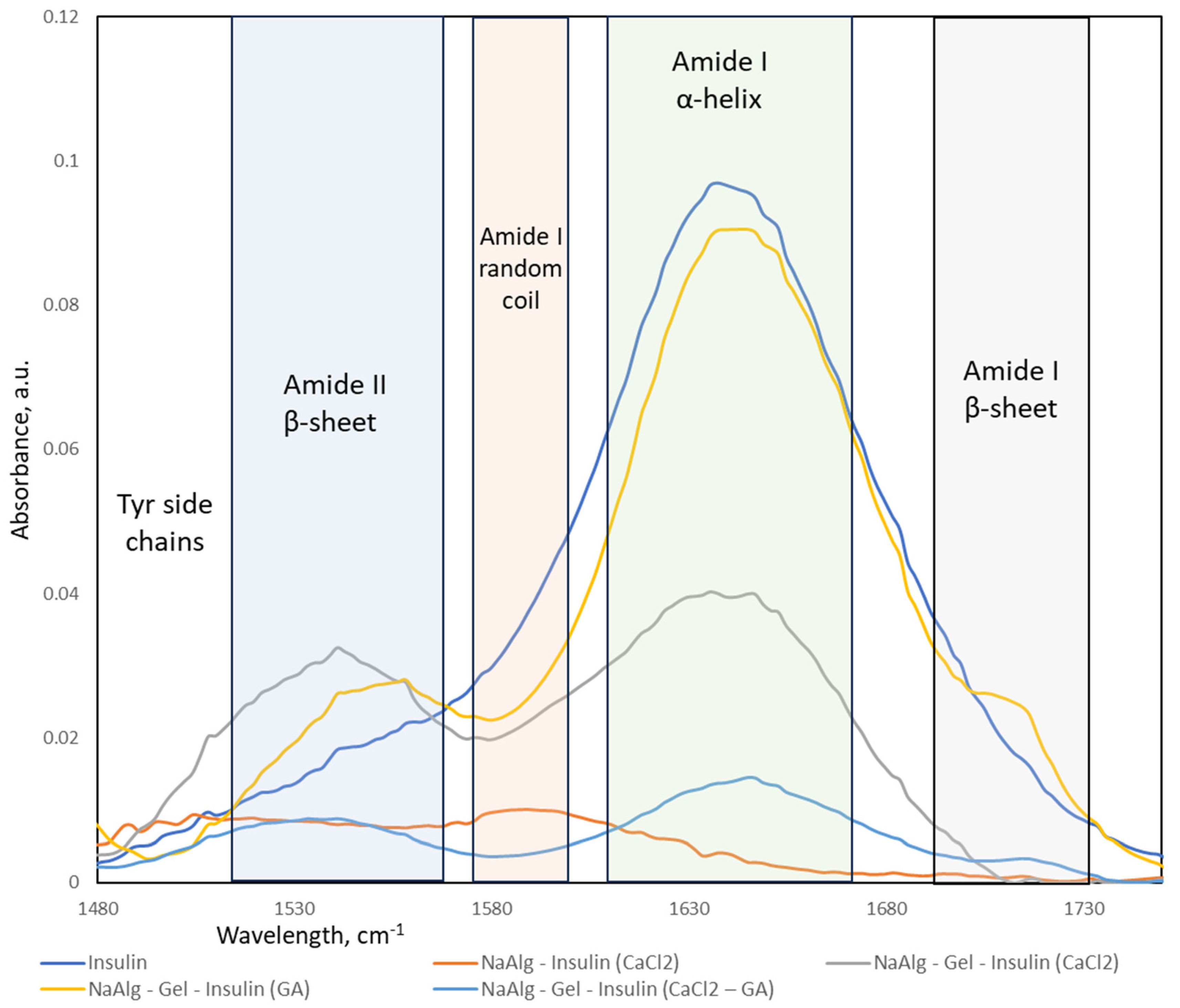

2.5. FTIR Spectroscopy of the Encapsulation Matrices and Insulin Delivery System

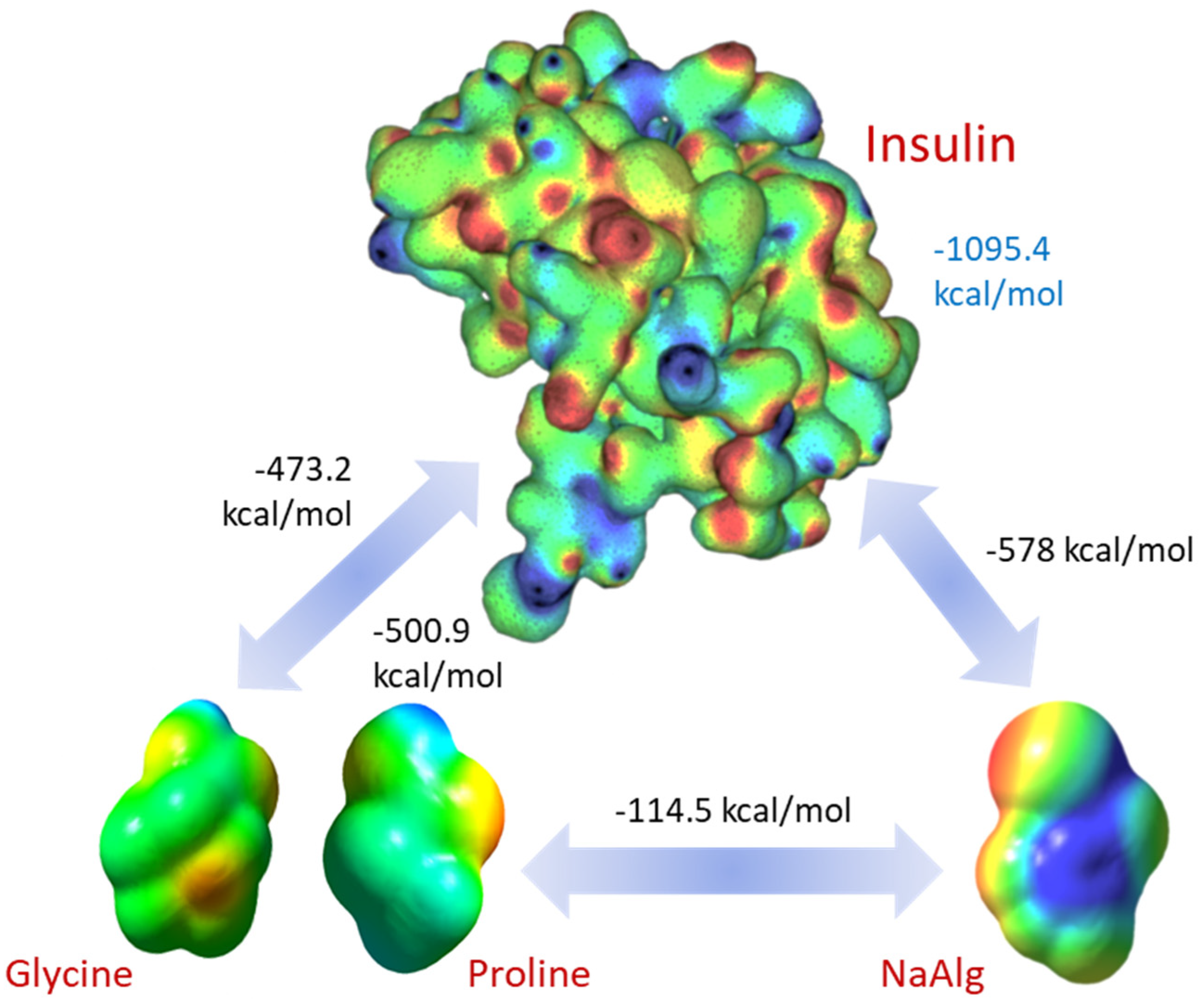

2.6. Molecular Dynamics Simulations

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Methods

4.2.1. Bead Preparation: Ionotropic Gelation and Crosslinking

4.2.2. Optical Microscopy

4.2.3. Scanning Electron Microscopy

4.2.4. FTIR Spectroscopy

4.2.5. Determination of the Degree of Swelling

4.2.6. Determination of Drug Content and Encapsulation Efficiency

4.2.7. Molecular Dynamic Simulation Methodology

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Harding, J.L.; Wander, P.L.; Zhang, X.; Li, X.; Karuranga, S.; Chen, H.; Sun, H.; Xie, Y.; Oram, R.A.; Magliano, D.J.; et al. The Incidence of Adult-Onset Type 1 Diabetes: A Systematic Review From 32 Countries and Regions. Diabetes Care 2022, 45, 994–1006. [Google Scholar] [CrossRef]

- Elena, M.; Simon, M.; Jean-Christophe, L. Oral delivery of macromolecular drugs: Where we are after almost 100 years of attempts. Adv. Drug Deliv. Rev. 2016, 101, 108–121. [Google Scholar]

- Yapeng, F.; Saphwan, A.-A.; Glyn, O.P.; Katsuyoshi, N.; Takahiro, F.; Peter, A.W. Binding behavior of calcium to polyuronates: Comparison of pectin with alginate. Carbohydr. Polym. 2008, 72, 334–341. [Google Scholar]

- Mokhamad, N.; Todor, V. Insulin Inclusion into a Tragacanth Hydrogel: An Oral Delivery System for Insulin. Materials 2018, 11, 79. [Google Scholar]

- Yang, W.; Litao, H.; Hao, H.; Hao, W.; Tianmeng, Z.; Jian, C.; Guocheng, D.; Zhen, K. Eliminating the capsule-like layer to promote glucose uptake for hyaluronan production by engineered Corynebacterium glutamicum. Nat. Commun. 2020, 11, 3120. [Google Scholar]

- Michael, T.C.; George, T.; Dimitris, C.; Vitaliy, V.K. Microencapsulation of a synbiotic into PLGA/alginate multiparticulate gels. Int. J. Pharm. 2014, 466, 400–408. [Google Scholar]

- Giulia, A.; Paola, R.; Del, G.P.; Carlos, A.G.-G.; Mariana, L.; Patrizia, A.R. Technologies and Formulation Design of Polysaccharide-Based Hydrogels for Drug Delivery. Molecules 2020, 25, 3156. [Google Scholar]

- Yerlan, G.Y.; Tyussyupova, B.B.; Tazhibayeva, S.M.; Musabekov, K.B.; Balabushevich, N.G.; Kokanbayev, A.K. Encapsulation of Insulin in Biodegradable Polymers. Eurasian Chem.-Technol. J. 2022, 24, 351–361. [Google Scholar] [CrossRef]

- Kyekyoon Kevin, K.; Daniel, W.P. Microspheres for Drug Delivery. In BioMEMS and Biomedical Nanotechnology; Springer US: Greer, SC, USA, 2006; pp. 19–50. [Google Scholar]

- Anne, D.; Thierry, A.; Naira, Q.; Filip, M.; Véronique, S.-L. Gelatin structure and composition linked to hard capsule dissolution: A review. Food Hydrocoll. 2015, 43, 360–376. [Google Scholar]

- Hnin-Ei, T.; Shiow-Fern, N. Gelatine enhances drug dispersion in alginate bilayer film via the formation of crystalline microaggregates. Int. J. Pharm. 2013, 454, 99–106. [Google Scholar]

- Sung Bin, P.; Eugene, L.; Sook, P.K.; Ki, J.Y.; Keun, H.D. Biopolymer-based functional composites for medical applications. Prog. Polym. Sci. 2017, 68, 77–105. [Google Scholar]

- Long, T.; Tan, W.; Tian, X.; Tang, Z.; Hu, K.; Ge, L.; Mu, C.; Li, X.; Xu, Y.; Zhao, L. Gelatin/alginate-based microspheres with sphere-in-capsule structure for spatiotemporal manipulative drug release in gastrointestinal tract. Int. J. Biol. Macromol. 2023, 226, 485–495. [Google Scholar] [CrossRef]

- Junjie, L.; Daodong, P.; Yangying, S.; Changrong, O.; Ying, W.; Jinxuan, C. The modification of gelatin films: Based on various cross-linking mechanism of glutaraldehyde at acidic and alkaline conditions. Food Sci. Nutr. 2019, 7, 4140–4146. [Google Scholar]

- Soheila, M.; Yu, D. Fabrication and Characterization of Electrospun Silk Fibroin/Gelatin Scaffolds Crosslinked with Glutaraldehyde Vapor. Front. Mater. 2019, 6, 91. [Google Scholar]

- Zhihua, Z.; Siliang, H.; Tianlong, H.; Cheng, P.; Hu, Z.; Qingquan, L.; Wennan, Z.; Lihua, L.; Huihua, H.; Liujiao, X.; et al. Preparation of gelatin/hyaluronic acid microspheres with different morphologies for drug delivery. Polym. Bull. 2015, 72, 713–723. [Google Scholar]

- Jessica, D.S.; Caroline, L.S. Cross-Linking Chitosan Nanofibers. Biomacromolecules 2007, 8, 594–601. [Google Scholar]

- Lee, B.B.; Ravindra, P.; Chan, E.S. Size and shape of calcium alginate beads produced by extrusion dripping. Chem. Eng. Technol. 2013, 36, 1627–1642. [Google Scholar] [CrossRef]

- Bennacef, C.; Desobry-Banon, S.; Probst, L.; Desobry, S. Alginate Core-Shell Capsules Production through Coextrusion Methods: Principles and Technologies. Mar. Drugs 2023, 21, 235. [Google Scholar] [CrossRef]

- Simonescu, C.M.; Mason, T.J.; Călinescu, I.; Lavric, V.; Vînătoru, M.; Melinescu, A.; Culiţă, D.C. Ultrasound assisted preparation of calcium alginate beads to improve absorption of Pb+2 from water. Ultrason. Sonochem. 2020, 68, 105191. [Google Scholar] [CrossRef] [PubMed]

- Del Gaudio, P.; Colombo, P.; Colombo, G.; Russo, P.; Sonvico, F. Mechanisms of formation and disintegration of alginate beads obtained by prilling. Int. J. Pharm. 2005, 302, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Dong, Z.; Wang, Q.; Du, Y. Alginate/gelatin blend films and their properties for drug controlled release. J. Membr. Sci. 2006, 280, 37–44. [Google Scholar] [CrossRef]

- Li, Y.; Jia, H.; Cheng, Q.; Pan, F.; Jiang, Z. Sodium alginate–gelatin polyelectrolyte complex membranes with both high water vapor permeance and high permselectivity. J. Membr. Sci. 2011, 375, 304–312. [Google Scholar] [CrossRef]

- Kamata, H.; Li, X.; Chung, U.-I.; Sakai, T. Design of Hydrogels for Biomedical Applications. Adv. Healthc. Mater. 2015, 4, 2360–2374. [Google Scholar] [CrossRef] [PubMed]

- Sartori, C.; Finch, D.S.; Ralph, B.; Gilding, K. Determination of the cation content of alginate thin films by FTi.r. spectroscopy. Polymer 1997, 38, 43–51. [Google Scholar] [CrossRef]

- Caruso, F. Nanoengineering of Particle Surfaces. Adv. Mater. 2001, 13, 11–22. [Google Scholar] [CrossRef]

- Xiao, C.; Liu, H.; Lu, Y.; Zhang, L. Blend Films from Sodium Alginate and Gelatin Solutions. J. Macromol. Sci. Part A 2001, 38, 317–328. [Google Scholar] [CrossRef]

- Hadi Hashemi, G.; Esmaeil, Z.; Hadi, E.M.; Hashem, H.S.M. Characterization of basil seed gum-based edible films incorporated with Zataria multiflora essential oil nanoemulsion. Carbohydr. Polym. 2017, 166, 93–103. [Google Scholar] [CrossRef]

- Xueyun, C.; Ming, F.; Huaping, T.; Bowen, R.; Guoliang, Y.; Yang, J.; Jianliang, L.; Dangsheng, X.; Xiaodong, X.; Xiaohong, N.; et al. Magnetic and self-healing chitosan-alginate hydrogel encapsulated gelatin microspheres via covalent cross-linking for drug delivery. Mater. Sci. Eng. C 2019, 101, 619–629. [Google Scholar]

- Eisa, J.; Alizadeh, K.M.; Hadi, A.; Reza, H. Physicochemical properties of Carum copticum essential oil loaded chitosan films containing organic nanoreinforcements. Carbohydr. Polym. 2017, 164, 325–338. [Google Scholar]

- Bertrand, M.; Shuqin, X.; Xiaoming, Z. Gelatin and high methyl pectin coacervates crosslinked with tannic acid: The characterization, rheological properties, and application for peppermint oil microencapsulation. Food Hydrocoll. 2019, 97, 105174. [Google Scholar]

- Te Nijenhuis, K. Gelatin. In Thermoreversible Networks: Viscoelastic Properties and Structure of Gels; Springer: Berlin/Heidelberg, Germany, 1997; pp. 160–193. [Google Scholar]

- Ni, F.; Luo, X.; Zhao, Z.; Yuan, J.; Song, Y.; Liu, C.; Huang, M.; Dong, L.; Xie, H.; Cai, L. Enhancing viability of Lactobacillus plantarum encapsulated by alginate-gelatin hydrogel beads during gastrointestinal digestion, storage and in the mimic beverage systems. Int. J. Biol. Macromol. 2023, 224, 94–104. [Google Scholar] [CrossRef] [PubMed]

- Kraus, J.; Nakov, S.; Repin, S. Reliable computer simulation methods for electrostatic biomolecular models based on the Poisson-Boltzmann equation. arXiv 2018, arXiv:1805.11441. [Google Scholar] [CrossRef]

- Glazova, I.; Smirnova, L.; Zamyshlyayeva, O.; Zaitsev, S.; Avdoshin, A.; Naumov, V.; Ignatov, S. Interpolymer interaction in insulin-chitosan complexes. Supramol. Chem. 2019, 31, 412–423. [Google Scholar] [CrossRef]

- Nielsen, L.; Frokjaer, S.; Carpenter, J.F.; Brange, J. Studies of the structure of insulin fibrils by Fourier transform infrared (FTIR) spectroscopy and electron microscopy. J. Pharm. Sci. 2001, 90, 29–37. [Google Scholar] [CrossRef]

- Kalikmanov, V.I. Nucleation Theory; Springer: Dordrecht, The Netherlands, 2012. [Google Scholar]

- Anal, A.K.; Bhopatkar, D.; Tokura, S.; Tamura, H.; Stevens, W.F. Chitosan-alginate multilayer beads for gastric passage and controlled intestinal release of protein. Drug Dev. Ind. Pharm. 2003, 29, 713–724. [Google Scholar] [CrossRef]

| System | Encapsulation Efficiency, PBS | Swelling Coefficient, SGF, 10 min | Swelling Coefficient, SGF, 30 min | Observation |

|---|---|---|---|---|

| NaAlg + CaCl2 + Ins | 67.4 ± 2.4 | 1.6 ± 0.18 | 2.4 ± 0.23 | Leakage |

| Gel-GA + Ins | 70.2 ± 3.3 | 1.1 ± 0.16 | 1.2 ± 0.18 | Expulsion |

| NaAlg + Gel + CaCl2 + Ins | 74.1 ± 1.8 | 1.2 ± 0.11 | 1.4 ± 0.12 | Good |

| NaAlg + Gel + GA + Ins | 81.2 ± 2.3 | 1.1 ± 0.09 | 1.3 ± 0.14 | Good |

| NaAlg + Gel + CaCl2 + GA + Ins | 72.4 ± 2.1 | 1.3 ± 0.12 | 1.8 ± 0.21 | Leakage |

| Energy (kcal/mol) | Sodium Alginate | Proline | Glycine | Insulin |

|---|---|---|---|---|

| Sodium Alginate | −215.5 | −81.9 | −114.5 | −578.1 |

| Proline | −81.91 | 11.19 | 0.757 | −501.0 |

| Glycine | −114.47 | 0.76 | −17.31 | −473.2 |

| Insulin | −578.1 | −501.0 | −473.2 | −1095.4 |

| Formulation | Amyloid I a-Helix | Amyloid I b-Sheet | Amyloid I Random | Amyloid II b-Sheet | Tyr Side Chains |

|---|---|---|---|---|---|

| Insulin | 89 | - | - | 11 | - |

| NaAlg-Insulin (CaCl2) | - | - | 54 | - | 46 |

| NaAlg-Gel-Insulin (CaCl2) | 55 | - | - | 45 | - |

| NaAlg-Gel-Insulin (GA) | 75 | 7 | - | 18 | - |

| NaAlg-Gel-Insulin (CaCl2-GA) | 59 | 4 | - | 37 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yerlan, G.Y.; Shen, M.; Tyussyupova, B.B.; Tazhibayeva, S.M.; Musabekov, K.; Takhistov, P. Insulin Conformation Changes in Hybrid Alginate–Gelatin Hydrogel Particles. Molecules 2024, 29, 1254. https://doi.org/10.3390/molecules29061254

Yerlan GY, Shen M, Tyussyupova BB, Tazhibayeva SM, Musabekov K, Takhistov P. Insulin Conformation Changes in Hybrid Alginate–Gelatin Hydrogel Particles. Molecules. 2024; 29(6):1254. https://doi.org/10.3390/molecules29061254

Chicago/Turabian StyleYerlan, Gulzhan Ye., Michael Shen, Bakyt B. Tyussyupova, Sagdat M. Tazhibayeva, Kuanyshbek Musabekov, and Paul Takhistov. 2024. "Insulin Conformation Changes in Hybrid Alginate–Gelatin Hydrogel Particles" Molecules 29, no. 6: 1254. https://doi.org/10.3390/molecules29061254

APA StyleYerlan, G. Y., Shen, M., Tyussyupova, B. B., Tazhibayeva, S. M., Musabekov, K., & Takhistov, P. (2024). Insulin Conformation Changes in Hybrid Alginate–Gelatin Hydrogel Particles. Molecules, 29(6), 1254. https://doi.org/10.3390/molecules29061254