Development and Evaluation of a Stable Oil-in-Water Emulsion with High Ostrich Oil Concentration for Skincare Applications

Abstract

1. Introduction

2. Results

2.1. Preparation and Evaluation of Ostrich Oil

2.2. Formulation and Evaluation of Emulsion Containing Ostrich Oil

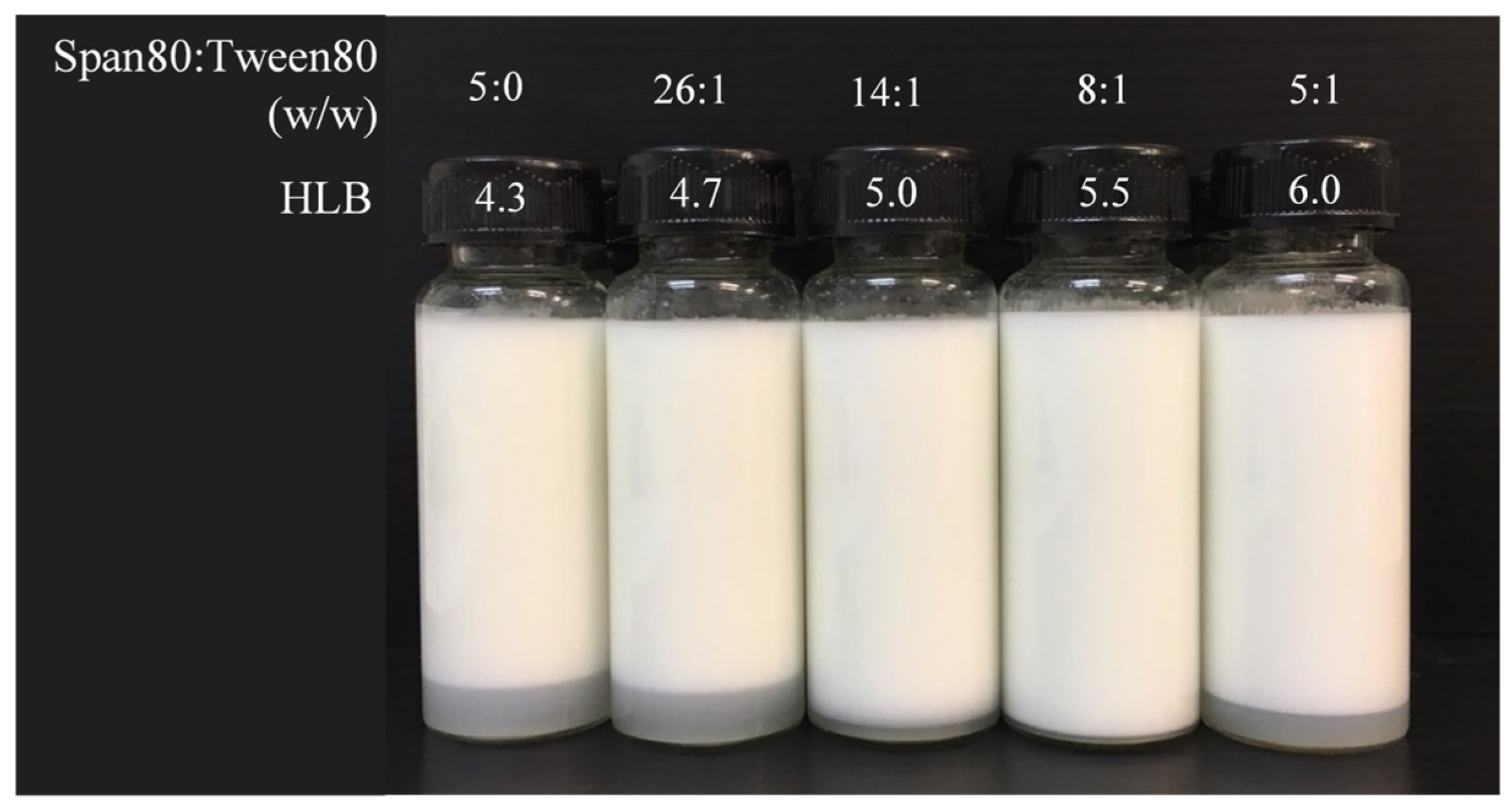

2.2.1. Determination of Required Ostrich Oil HLB

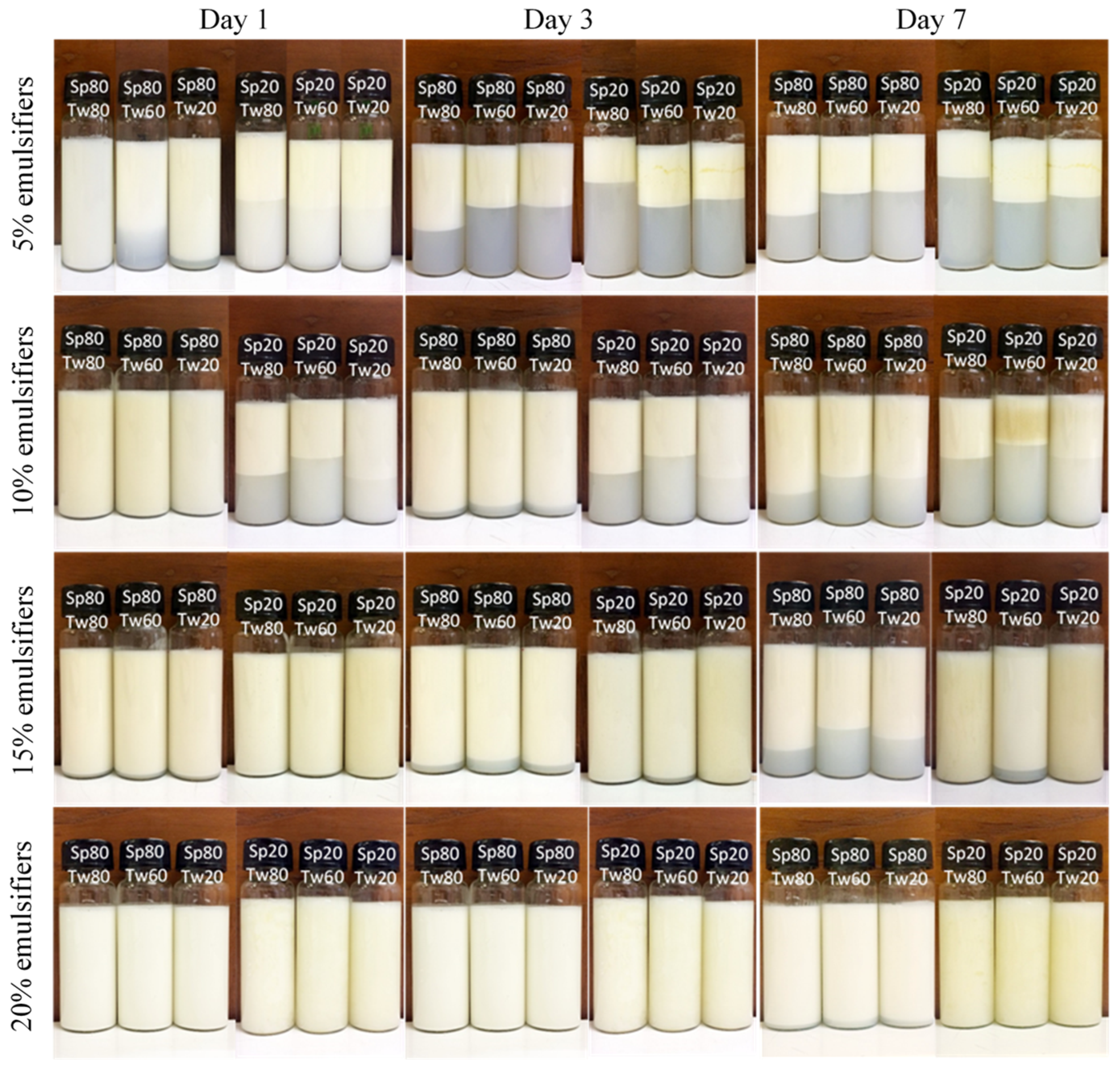

2.2.2. Effects of the Type and Concentration of Mixed Emulsifiers on the Properties of Emulsions

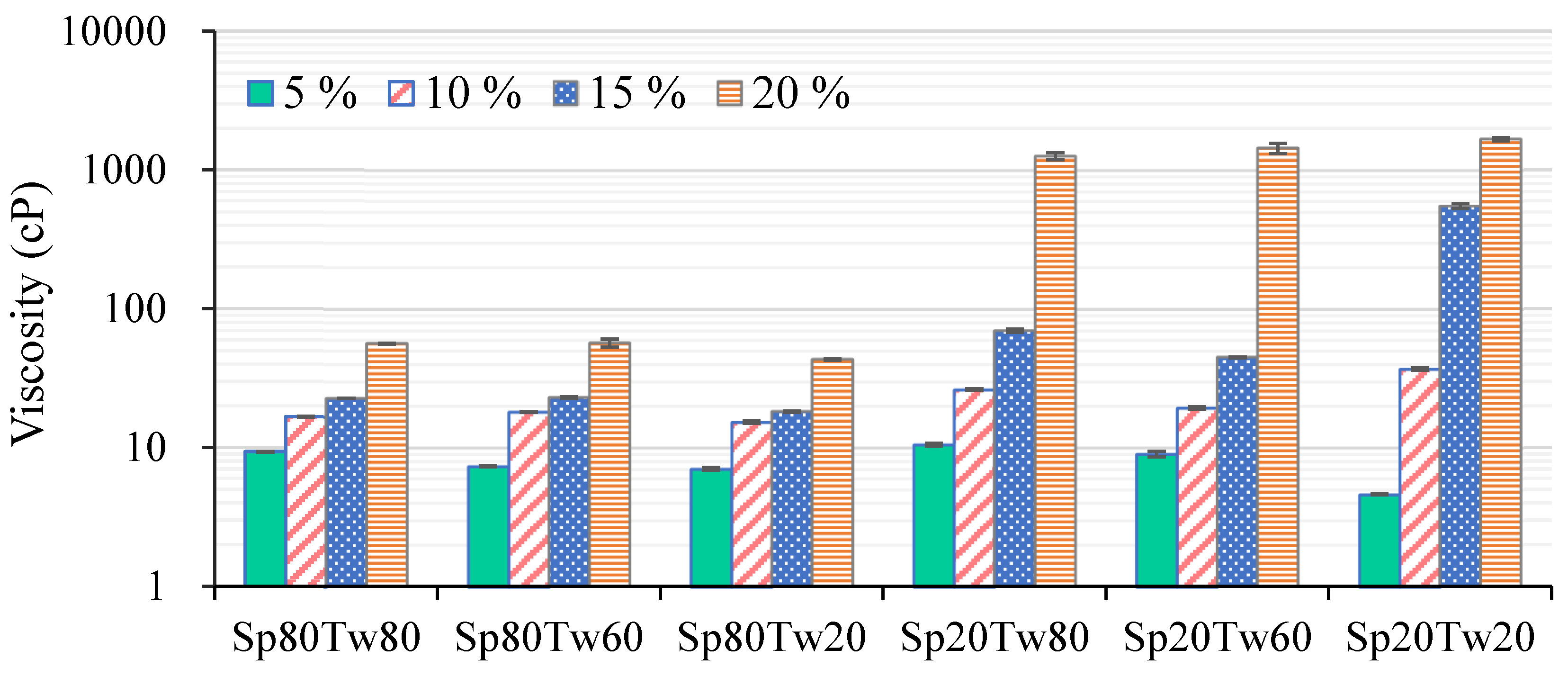

2.2.3. Viscosity

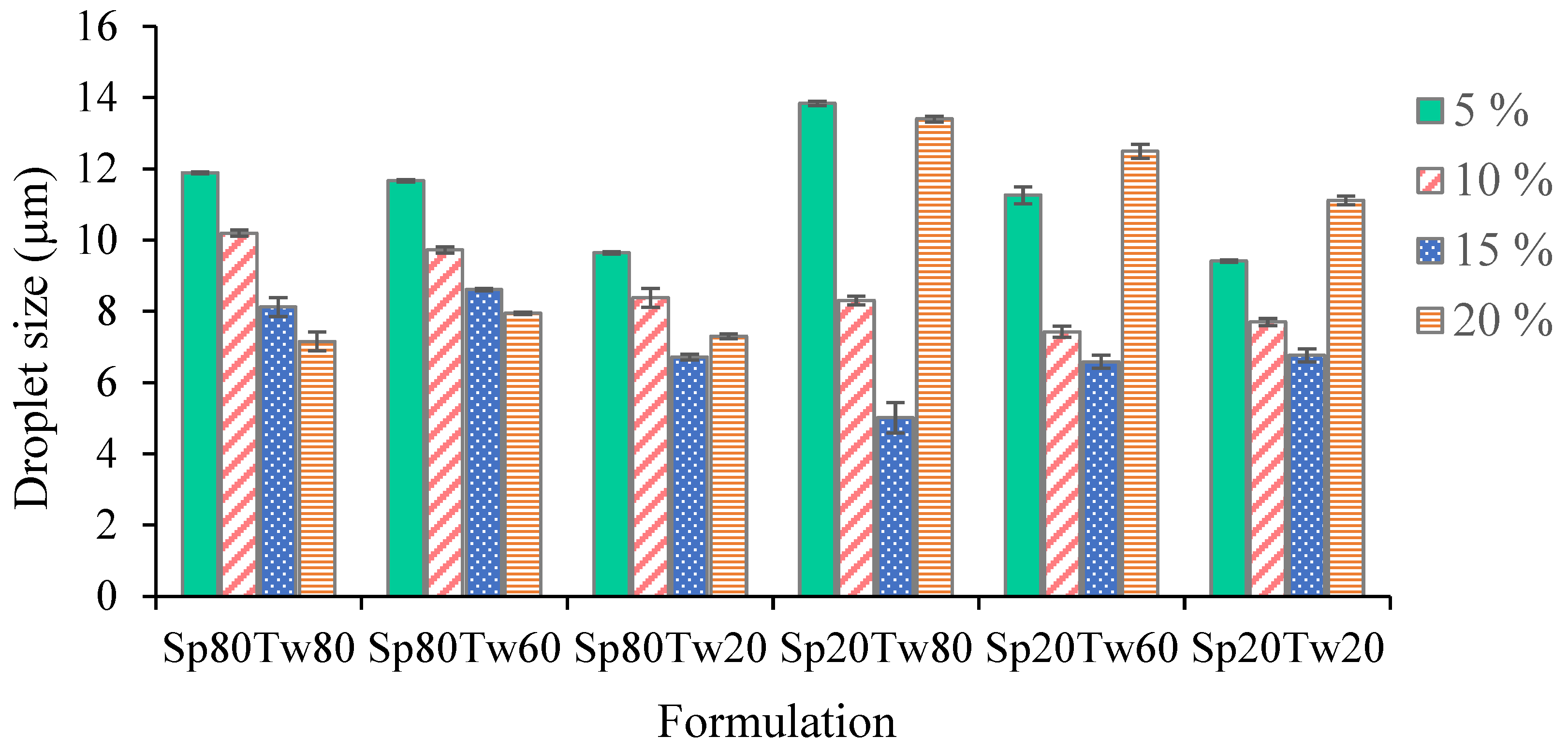

2.2.4. Droplet Size

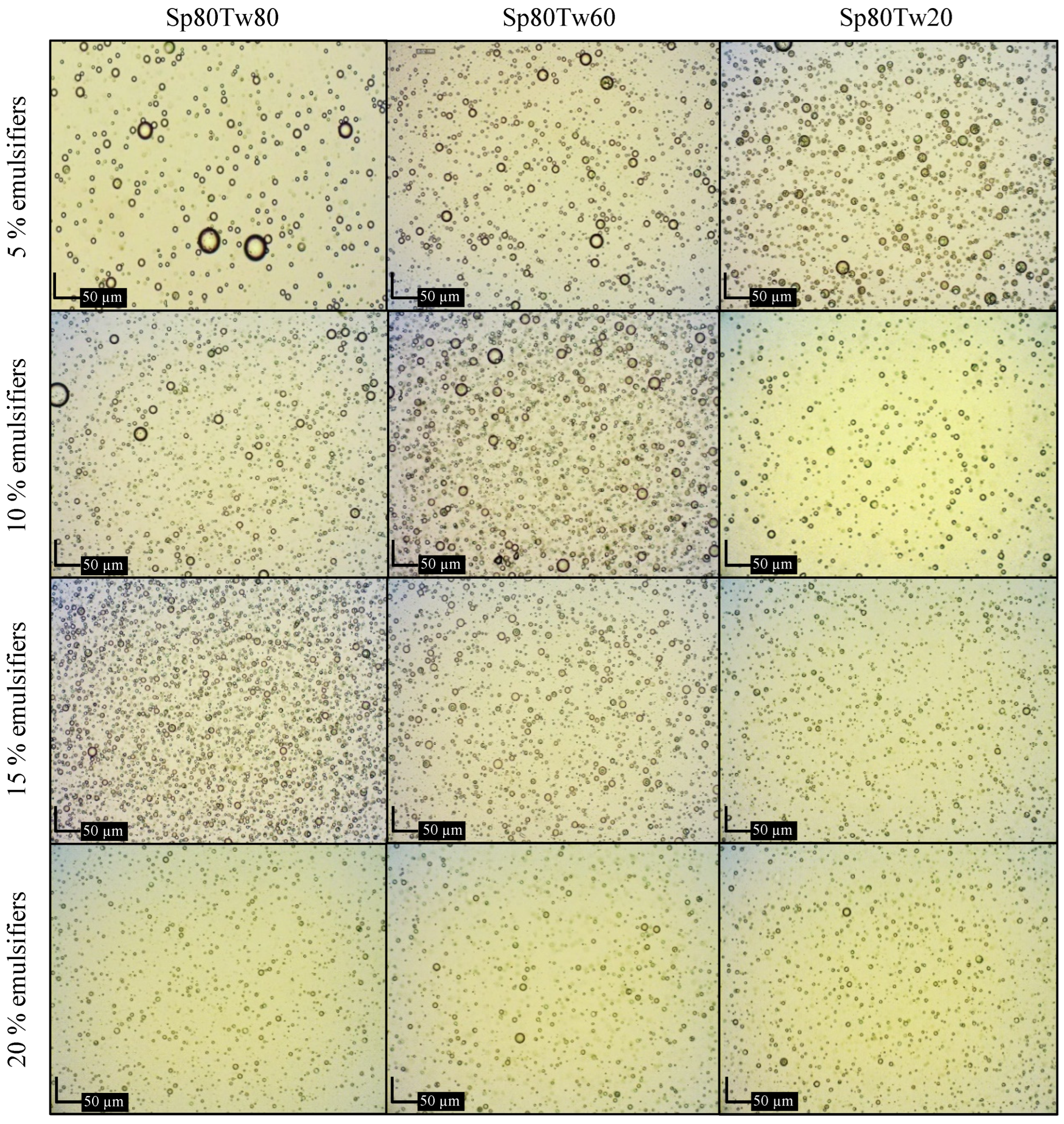

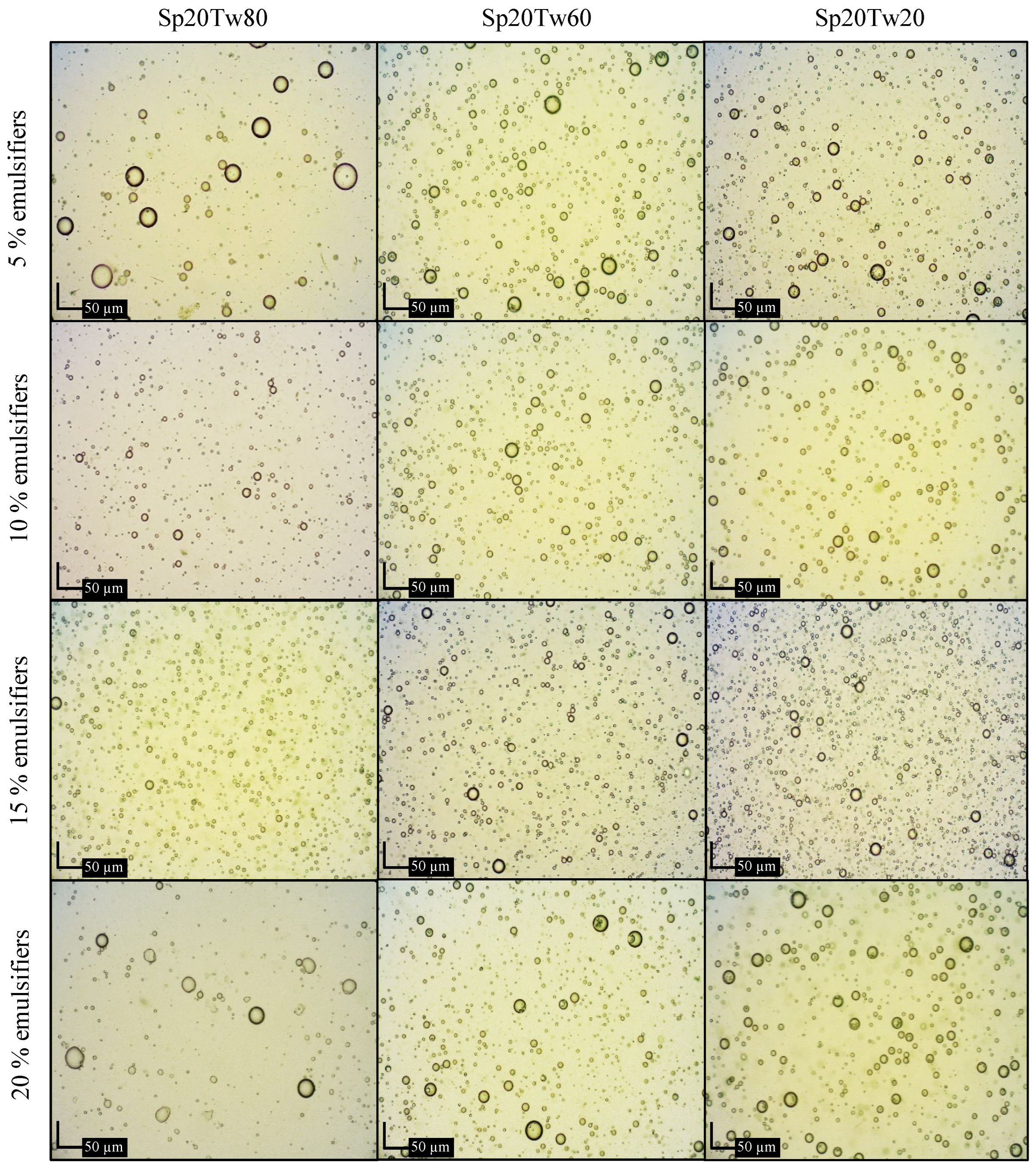

2.2.5. Microscopic Examination

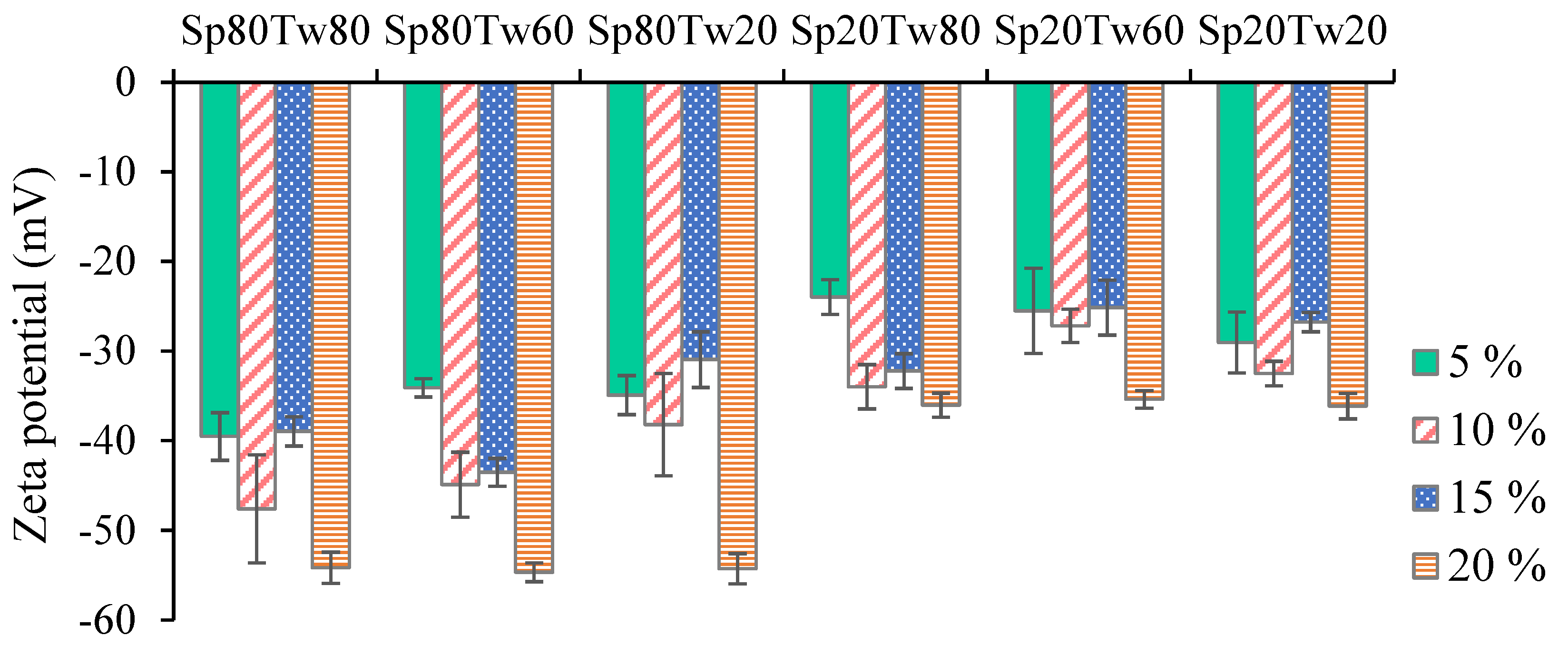

2.2.6. Zeta Potential

2.2.7. Stability

2.2.8. Cytotoxicity Assay

2.2.9. Antibacterial Assay

2.2.10. Antioxidant Assay

2.2.11. In Vitro Release Study

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Preparation and Evaluation of Ostrich Oil

4.2.1. Preparation of Ostrich Oil

4.2.2. Fatty Acid Composition

4.2.3. Antioxidant Activity

4.2.4. Anti-Inflammatory Activity

4.2.5. Acid Value (AV) and Peroxide Value (PV)

4.2.6. Heavy Metal Contents

4.2.7. Microbial Contamination

4.3. Formulation and Evaluation of Emulsion Containing Ostrich Oil

4.3.1. Formulation of O/W Emulsion

- Determination of the required hydrophile-lipophile balance (HLB) for emulsification

- Effects of the type and concentration of mixed emulsifiers on the properties of emulsions

4.3.2. Evaluation of Emulsion

4.3.3. Stability Test

4.3.4. Cytotoxicity Assay

4.3.5. Antibacterial Assay

4.3.6. In Vitro Release Study

4.4. Statistical Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ponphaiboon, J.; Limmatvapirat, S.; Chaidedgumjorn, A.; Limmatvapirat, C. Physicochemical Property, Fatty Acid Composition, and Antioxidant Activity of Ostrich Oils using Different Rendering Methods. LWT-Food Sci. Technol. 2018, 93, 45–50. [Google Scholar] [CrossRef]

- Alm, M. Animal Fats-Edible Oil Processing, The American Oil Chemists’ Society (AOCS) Lipid Library. 2013. Available online: https://lipidlibrary.aocs.org/edible-oil-processing/animal-fats (accessed on 10 February 2023).

- Sharma, H.; Giriprasad, R.; Goswami, M. Animal Fat-processing and Its Quality Control. Int. J. Food Process. Technol. 2013, 4, 1000252. [Google Scholar] [CrossRef]

- Belichovska, D.; Hajrulai-Musliu, Z.; Uzunov, R.; Belichovska, K.; Arapcheska, M. Fatty Acid Composition of Ostrich (Struthio camelus) Abdominal Adipose Tissue. Maced. Vet. Rev. 2015, 38, 53–59. [Google Scholar] [CrossRef]

- Zhou, Y.; Xue, Y.; Chen, G.C.; Zhang, A.J.; Chen, Z.F.; Liao, X.; Ding, L.S. Rapid Separation and Characterisation of Triacylglycerols in Ostrich Oil by Ultra Performance Liquid Chromatography Coupled with Quadrupole Time-of-flight Mass Spectrometry. Food Chem. 2013, 141, 2098–2102. [Google Scholar] [CrossRef] [PubMed]

- Calder, P.C. n-3 Fatty acids, Inflammation, and Immunity-relevance to Postsurgical and Critically Ill Patients. Lipids 2004, 39, 1147–1161. [Google Scholar] [CrossRef] [PubMed]

- Gil, A.; Serra-Majem, L.; Calder, P.C.; Uauy, R. Systematic Reviews of the Role of Omega-3 Fatty Acids in the Prevention and Treatment of Disease. Br. J. Nutr. 2012, 107, S1–S2. [Google Scholar] [CrossRef] [PubMed]

- Gavanji, S.; Larki, B.; Taraghian, A.H. A Review of Application of Ostrich Oil in Pharmacy and Diseases Treatment. J. Nov. Appl. Sci. 2013, 2, 650–654. [Google Scholar]

- Eltom, S.E.M.; Abdellatif, A.A.H.; Maswadeh, H.; Al-Omar, M.S.; Abdel-Hafez, A.A.; Mohammed, H.A.; Agabein, E.M.; Alqasoomi, I.; Alrashidi, S.A.; Sajid, M.S.M.; et al. The Anti-inflammatory Effect of γ-Lactone Isolated from Ostrich Oil of Struthio camelus (Ratite) and Its Formulated Nano-emulsion in Formalin-induced Paw Edema. Molecules 2021, 26, 3701. [Google Scholar] [CrossRef] [PubMed]

- Alshahrani, S.M. Preparation, Characterization and In Vivo Anti-inflammatory Studies of Ostrich Oil Based Nanoemulsion. J. Oleo Sci. 2019, 68, 203–208. [Google Scholar] [CrossRef]

- Bennett, D.C.; Leung, G.; Wang, E.; Ma, S.; Lo, B.K.; McElwee, K.J.; Cheng, K.M. Ratite Oils Promote Keratinocyte Cell Growth and Inhibit Leukocyte Activation. Poult. Sci. 2015, 94, 2288–2296. [Google Scholar] [CrossRef]

- Farahpour, M.R.; Vahid, M.; Oryan, A. Effectiveness of Topical Application of Ostrich Oil on the Healing of Staphylococcus aureus and Pseudomonas aeruginosa-infected Wounds. Connect. Tissue Res. 2018, 59, 212–222. [Google Scholar] [CrossRef]

- Pezzuto, J.M.; Park, E.J. Autooxidation and Antioxidation. In Encyclopedia of Pharmaceutical Technology, 3rd ed.; Swarbrick, J., Ed.; PharmaceuTech, Inc.: Pinehurst, NC, USA, 2002; Volume 1, pp. 97–113. [Google Scholar]

- Khan, B.A.; Akhtar, N.; Khan, H.M.S.; Waseem, K.; Mahmood, T.; Rasul, A.; Iqbal, M.; Khan, H. Basics of Pharmaceutical Emulsions: A Review. Afr. J. Pharm. Pharmacol. 2011, 5, 2715–2725. [Google Scholar] [CrossRef]

- Berton-Carabin, C.C.; Ropers, M.H.; Genot, C. Lipid Oxidation in Oil-in-Water Emulsions: Involvement of the Interfacial Layer. Compr. Rev. Food Sci. Food Saf. 2014, 13, 945–977. [Google Scholar] [CrossRef]

- Balić, A.; Vlašić, D.; Žužul, K.; Marinović, B.; Mokos1, Z.B. Omega-3 Versus Omega-6 Polyunsaturated Fatty Acids in the Prevention and Treatment of Inflammatory Skin Diseases. Int. J. Mol. Sci. 2020, 21, 741. [Google Scholar] [CrossRef] [PubMed]

- Farag, M.A.; Gad, M.Z. Omega-9 Fatty Acids: Potential Roles in Inflammation and Cancer Management. J. Genet. Eng. Biotechnol. 2022, 20, 48. [Google Scholar] [CrossRef] [PubMed]

- Yff, B.T.S.; Lindsey, K.L.; Taylor, M.B.; Erasmus, D.G.; Jäger, A.K. The Pharmacological Screening of Pentanisia prunelloides and the Isolation of the Antibacterial Compound Palmitic Acid. J. Ethnopharmacol. 2002, 79, 101–107. [Google Scholar] [CrossRef]

- Khalil, M.H.; Marcelletti, J.F.; Katz, L.R.; Katz, D.H.; Pope, L.E. Topical Application of Docosanol- or Stearic Acid-containing Creams Reduces Severity of Phenol Burn Wounds in Mice. Contact Dermat. 2000, 43, 79–81. [Google Scholar] [CrossRef] [PubMed]

- FAO/WHO. Codex Standard for Fats and Oils from Animal Sources, Codex Standard for Named Animal Fats (CODEX-STAN 211-1999), Codex Alimentarius: Fats, Oils and Related Products; Food and Agriculture Organization of the United Nations: Rome, Italy, 2001. [Google Scholar]

- Santin, J.R.; Kopp, M.A.T.; Correa, T.P.; Melato, J.; Benvenutti, L.; Nunes, R.; Goldoni, F.C.; Patel, Y.B.K.; Souza, J.A.; Soczek, S.H.S.; et al. Neuroinflammation and Hypersensitivity Evidenced by the Acute and 28-day Repeated Dose Toxicity Tests of Ostrich Oil in Mice. Food Chem. Toxicol. 2023, 177, 113852. [Google Scholar] [CrossRef] [PubMed]

- Sajjadi, S. Effect of Mixing Protocol on Formation of Fine Emulsions. Chem. Eng. Sci. 2006, 61, 3009–3017. [Google Scholar] [CrossRef]

- El-Sayed, W.; Mohammad, T.G. Effect of Hydrophilic-lipophilic Balance (HLB) Values of Surfactant Mixtures on the Physicochemical Properties of Emulsifiable Concentrate Formulations of Difenoconazole. J. Appl. Life Sci. Int. 2019, 22, 1–10. [Google Scholar] [CrossRef]

- Dantas, M.G.B.; Reis, S.A.G.B.; Damasceno, C.M.D.; Rolim, L.A.; Rolim-Neto, P.J.; Carvalho, F.O.; Quintans-Junior, L.J.; da Silva Almeida, J.R.G. Development and Evaluation of Stability of a Gel Formulation Containing the Monoterpene Borneol. Sci. World J. 2016, 2016, 7394685. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, M.R.A.; Santiago, R.R.; de Souza, T.P.; Egito, E.S.T.; Oliveira, E.E.; Soares, L.A.L. Development and Evaluation of Emulsions from Carapa guianensis (Andiroba) Oil. AAPS PharmSciTech 2010, 11, 1383–1390. [Google Scholar] [CrossRef] [PubMed]

- Badr, M.M.; Badawy, M.E.I.; Taktak, N.E.M. Characterization, Antimicrobial Activity, and Antioxidant Activity of the Nanoemulsions of Lavandula spica Essential Oil and Its Main Monoterpenes. J. Drug Deliv. Sci. Technol. 2021, 65, 102732. [Google Scholar] [CrossRef]

- Adheeb Usaid, A.S.; Premkumar, J.; Ranganathan, T.V. Emulsion and It’s Applications in Food Processing—A Review. Int. J. Eng. Res. Appl. 2014, 4, 241–248. [Google Scholar]

- Ramisetty, K.A.; Shyamsunder, R. Effect of Ultrasonication on Stability of Oil in Water Emulsions. Int. J. Drug Deliv. 2011, 3, 133–142. [Google Scholar] [CrossRef]

- Shuai, X.; Chen, J.; Liu, Q.; Dong, H.; Dai, T.; Li, Z.; Liu, C.; Wang, R. The Effects of Pectin Structure on Emulsifying, Rheological, and In Vitro Digestion Properties of Emulsion. Foods 2022, 11, 3444. [Google Scholar] [CrossRef]

- Stachurski, J.; MichaŁek, M. The Effect of the ζ Potential on the Stability of a Non-Polar Oil-in-Water Emulsion. J. Colloid Interface Sci. 1996, 184, 433–436. [Google Scholar] [CrossRef]

- Honary, S.; Zahir, F. Effect of Zeta Potential on the Properties of Nano-Drug Delivery Systems—A Review (Part 1). Trop. J. Pharm. Res. 2013, 12, 255–264. [Google Scholar] [CrossRef]

- Pignitter, M.; Somoza, V. Critical Evaluation of Methods for the Measurement of Oxidative Rancidity in Vegetable Oils. J. Food Drug Anal. 2012, 20, 772–777. [Google Scholar] [CrossRef]

- The United States Pharmacopeial Convention. 〈1111〉 Microbiological Examination of Nonsterile Products: Acceptance Criteria for Pharmaceutical Preparations and Substances for Pharmaceutical Use; The United States Pharmacopeia 43 and the National Formulary 38 (USP 43-NF 38); USP-NF: Rockville, MD, USA, 2023. [Google Scholar] [CrossRef]

- Dai, S.; Yu, C.; Liang, M.; Cheng, H.; Li, W.; Lai, F.; Ma, L.; Liu, X. Oxidation Characteristics and Thermal Stability of Butylated Hydroxytoluene. Arab. J. Chem. 2023, 16, 104932. [Google Scholar] [CrossRef]

- Breijyeh, Z.; Jubeh, B.; Karaman, R. Resistance of Gram-Negative Bacteria to Current Antibacterial Agents and Approaches to Resolve It. Molecules 2020, 25, 1340. [Google Scholar] [CrossRef] [PubMed]

- Puca, V.; Marulli, R.Z.; Grande, R.; Vitale, I.; Niro, A.; Molinaro, G.; Prezioso, S.; Muraro, R.; Giovanni, P.D. Microbial Species Isolated from Infected Wounds and Antimicrobial Resistance Analysis: Data Emerging from a Three-Years Retrospective Study. Antibiotics 2021, 10, 1162. [Google Scholar] [CrossRef] [PubMed]

- Parsons, J.B.; Yao, J.; Frank, M.W.; Jackson, P.; Rock, C.O. Membrane Disruption by Antimicrobial Fatty Acids Releases Low-Molecular-Weight Proteins from Staphylococcus aureus. J. Bacteriol. 2012, 194, 5294–5304. [Google Scholar] [CrossRef]

- Upender, I.; Yoshida, O.; Schrecengost, A.; Ranson, H.; Wu, Q.; Rowley, D.C.; Kishore, S.; Cywes, C.; Miller, E.L.; Whalen, K.E. A Marine-derived Fatty Acid Targets the Cell Membrane of Gram-positive Bacteria. J. Bacteriol. 2023, 205, e0031023. [Google Scholar] [CrossRef] [PubMed]

- Soliman, H.M.; Abdel-Wahhab, M.A. Synthesis of Antibacterial Bioactive Compounds Using Linoleic Acid Extracted from Melon Seeds Oil and Evaluation of Its Waste Meal Ash for Fried Oil Regeneration. Waste Biomass Valori. 2024, 15, 487–499. [Google Scholar] [CrossRef]

- Kusumah, D.; Wakui, M.; Murakami, M.; Xie, X.; Yukihito, K.; Maeda, I. Linoleic Acid, α-Linolenic Acid, and Monolinolenins as Antibacterial Substances in the Heat-processed Soybean Fermented with Rhizopus oligosporus. Biosci. Biotechnol. Biochem. 2020, 84, 1285–1290. [Google Scholar] [CrossRef]

- Huang, C.B.; George, B.; Ebersole, J.L. Antimicrobial Activity of n-6, n-7 and n-9 Fatty Acids and Their Esters for Oral Microorganisms. Arch. Oral Biol. 2010, 55, 555–560. [Google Scholar] [CrossRef]

- Lunde, C.S.; Hartouni, S.R.; Janc, J.W.; Mammen, M.; Humphrey, P.P.; Benton, B.M. Telavancin Disrupts the Functional Integrity of the Bacterial Membrane through Targeted Interaction with the Cell Wall Precursor Lipid II. Antimicrob. Agents Chemother. 2009, 53, 3375–3383. [Google Scholar] [CrossRef]

- Ameta, R.K.; Soni, K.; Bhattarai, A. Recent Advances in Improving the Bioavailability of Hydrophobic/Lipophilic Drugs and Their Delivery via Self-Emulsifying Formulations. Colloids Interfaces 2023, 7, 16. [Google Scholar] [CrossRef]

- Anwer, M.K.; Iqbal, M.; Aldawsari, M.F.; Alalaiwe, A.; Ahmed, M.M.; Muharram, M.M.; Ezzeldin, E.; Mahmoud, M.A.; Imam, F.; Ali, R. Improved Antimicrobial Activity and Oral Bioavailability of Delafloxacin by Self-nanoemulsifying Drug Delivery System (SNEDDS). J. Drug Deliv. Sci. Technol. 2021, 64, 102572. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhao, Y.; Chang, Y.; Ma, Z.; Kobayashi, I.; Nakajima, M.; Neves, M.A. Enhancing the Formation and Stability of Oil-In-Water Emulsions Prepared by Microchannels Using Mixed Protein Emulsifiers. Front. Nutr. 2022, 9, 822053. [Google Scholar] [CrossRef] [PubMed]

- Clavijo-Romero, A.; Quintanilla-Carvajal, M.X.; Ruiz, Y. Stability and Antimicrobial Activity of Eucalyptus Essential Oil Emulsions. Food Sci. Technol. Int. 2018, 25, 24–37. [Google Scholar] [CrossRef] [PubMed]

- Lobo, V.; Patil, A.; Phatak, A.; Chandra, N. Free Radicals, Antioxidants and Functional Foods: Impact on Human Health. Phcog. Rev. 2010, 4, 118–126. [Google Scholar] [CrossRef]

- Arulselvan, P.; Fard, M.T.; Tan, W.S.; Gothai, S.; Fakurazi, S.; Norhaizan, M.E.; Kumar, S.S. Role of Antioxidants and Natural Products in Inflammation. Oxid. Med. Cell. Longev. 2016, 38, 5276130. [Google Scholar] [CrossRef]

- Comino-Sanz, I.M.; López-Franco, M.D.; Castro, B.; Pancorbo-Hidalgo, P.L. The Role of Antioxidants on Wound Healing: A Review of the Current Evidence. J. Clin. Med. 2021, 10, 3558. [Google Scholar] [CrossRef]

- Musa, S.H.; Basri, M.; Fard Masoumi, H.R.; Shamsudin, N.; Salim, N. Enhancement of Physicochemical Properties of Nanocolloidal Carrier Loaded with Cyclosporine for Topical Treatment of Psoriasis: In vitro Diffusion and in vivo Hydrating Action. Int. J. Nanomed. 2017, 12, 2427–2441. [Google Scholar] [CrossRef]

- Fratianni, F.; d’Acierno, A.; Ombra, M.N.; Amato, G.; De Feo, V.; Ayala-Zavala, J.F.; Coppola, R.; Nazzaro, F. Fatty Acid Composition, Antioxidant, and in vitro Anti-inflammatory Activity of Five Cold-Pressed Prunus Seed Oils, and Their Anti-biofilm Effect Against Pathogenic Bacteria. Front. Nutr. 2021, 8, 775751. [Google Scholar] [CrossRef]

- Wei, C.; Yen, P.; Chang, S.; Cheng, P.; Lo, Y.; Liao1, V.H. Antioxidative Activities of Both Oleic Acid and Camellia tenuifolia Seed Oil Are Regulated by the Transcription Factor DAF-16/FOXO in Caenorhabditis elegans. PLoS ONE 2016, 11, e0157195. [Google Scholar] [CrossRef]

- Syed Azhar, S.N.A.; Ashari, S.E.; Salim, N. Development of a Kojic Monooleate-enriched Oil-in-water Nanoemulsion as a Potential Carrier for Hyperpigmentation Treatment. Int. J. Nanomed. 2018, 13, 6465–6479. [Google Scholar] [CrossRef]

- Li, J.; Mcclements, D.J.; Mclandsborough, L.A. Interaction Between Emulsion Droplets and Escherichia coli Cells. J. Food Sci. 2001, 66, 570–574. [Google Scholar] [CrossRef]

- Teixé-Roig, J.; Oms-Oliu, G.; Odriozola-Serrano, I.; Martín-Belloso, O. Emulsion-Based Delivery Systems to Enhance the Functionality of Bioactive Compounds: Towards the Use of Ingredients from Natural, Sustainable Sources. Foods 2023, 12, 1502. [Google Scholar] [CrossRef]

- Li, X.; Tu, Z.; Sha, X.; Ye, Y.; Li, Z. Flavor, Antimicrobial Activity, and Physical Properties of Composite Film Prepared with Different Surfactants. Food Sci. Nutr. 2020, 8, 3099–3109. [Google Scholar] [CrossRef]

- Jaramillo, V.; Díaz, E.; Muñoz, L.N.; González-Barrios, A.F.; Rodríguez-Cortina, J.; Cruz, J.C.; Muñoz-Camargo, C. Enhancing Wound Healing: A Novel Topical Emulsion Combining CW49 Peptide and Lavender Essential Oil for Accelerated Regeneration and Antibacterial Protection. Pharmaceutics 2023, 15, 1739. [Google Scholar] [CrossRef]

- Limmatvapirat, C.; Limmatvapirat, S.; Krongrawa, W.; Ponphaiboon, J.; Witchuchai, T.; Jiranuruxwong, P.; Theppitakpong, P.; Pathomcharoensukchai, P. Beef Tallow: Extraction, Physicochemical Property, Fatty Acid Composition, Antioxidant Activity, and Formulation of Lotion Bars. J. Appl. Pharm. Sci. 2021, 11, 018–028. [Google Scholar] [CrossRef]

- Limmatvapirat, C.; Limmatvapirat, S.; Chansatidkosol, S.; Krongrawa, W.; Liampipat, N.; Leechaiwat, S.; Lamaisri, P.; Siangjong, L.; Meetam, P.; Tiankittumrong, K. Preparation and properties of anti-nail-biting lacquers containing shellac and bitter herbal extract. Int. J. Polym. Sci. 2021, 2021, 8537544. [Google Scholar] [CrossRef]

- The American Oil Chemists’ Society. AOCS Official Method Cd 3d-63: Acid Value of Fats and Oils. In Official Methods and Recommended Practices of the AOCS, 7th ed.; AOCS Headquarters: Champaign, IL, USA, 2017. [Google Scholar]

- The American Oil Chemists’ Society. AOCS Official Method Cd 8b-90: Peroxide Value, Acetic Acid, Isooctane Method. In Official Methods and Recommended Practices of the AOCS, 7th ed.; AOCS Headquarters: Champaign, IL, USA, 2017. [Google Scholar]

- Limmatvapirat, C.; Limmatvapirat, S.; Charoenteeraboon, J.; Wessapan, C.; Kumsum, A.; Jenwithayaamornwech, S.; Luangthuwapranit, P. Comparison of Eleven Heavy Metals in Moringa oleifera Lam. Products. Indian J. Pharm. Sci. 2015, 77, 485–490. [Google Scholar] [CrossRef]

- The United States Pharmacopeial Convention. 〈61〉 Microbiological Examination of Nonsterile Products: Microbial Enumeration Tests; The United States Pharmacopeia 43 and the National Formulary 38 (USP 43-NF 38); USP-NF: Rockville, MD, USA, 2023. [Google Scholar] [CrossRef]

- Schultz, S.; Wagner, G.; Urban, K.; Ulrich, J. High-Pressure Homogenization as a Process for Emulsion Formation. Chem. Eng. Technol. 2004, 27, 361–368. [Google Scholar] [CrossRef]

- Nirwana, I.; Munadziroh, E.; Yogiartono, R.M.; Thiyagu, C.; Ying, C.S.; Dinaryanti, A. Cytotoxicity and Proliferation Evaluation on Fibroblast after Combining Calcium Hydroxide and Ellagic Acid. J. Adv. Pharm. Technol. Res. 2021, 12, 27–31. [Google Scholar] [CrossRef] [PubMed]

- Bauer, A.W.; Kirby, W.M.; Sherris, J.C.; Turck, M. Antibiotic Susceptibility Testing by a Standardized Single Disk Method. Am. J. Clin. Pathol. 1966, 45, 493–496. [Google Scholar] [CrossRef]

- Sharkawy, A.; Casimiro, F.M.; Barreiro, M.F.; Rodrigues, A.E. Enhancing Trans-resveratrol Topical Delivery and Photostability through Entrapment in Chitosan/Gum Arabic Pickering Emulsions. Int. J. Biol. Macromol. 2020, 147, 150–153. [Google Scholar] [CrossRef] [PubMed]

| FAME Standards | Retention Time (min) | Regression Equation (y = ax + b) | Correlation Coefficient (r2) |

|---|---|---|---|

| Methyl laurate | 2.8 | y = 1.0931x + 0.0013 | 0.9998 |

| Methyl myristate | 4.1 | y = 1.1781x + 0.0023 | 0.9998 |

| Methyl palmitate | 6.8 | y = 0.8441x − 0.0100 | 0.9998 |

| Methyl stearate | 12.2 | y = 0.9189x − 0.0121 | 0.9998 |

| Methyl oleate | 13.1 | y = 1.2001x − 0.0087 | 0.9999 |

| Methyl linoleate | 15.1 | y = 1.1643x + 0.0116 | 0.9998 |

| Methyl linolenate | 18.5 | y = 1.1147x − 0.0014 | 0.9998 |

| Formulation | Distilled Water (% w/w) | Ostrich Oil (% w/w) | Emulsifier (5% w/w) | HLB | Creaming Index (%) | ||

|---|---|---|---|---|---|---|---|

| Span 80 (% w/w) | Tween 80 (% w/w) | Span 80:Tween 80 (w/w) | |||||

| 1 | 75 | 20 | 5 | 0 | 5:0 | 4.3 | 12.38 |

| 2 | 75 | 20 | 4.82 | 0.18 | 26:1 | 4.7 | 11.29 |

| 3 | 75 | 20 | 4.67 | 0.33 | 14:1 | 5.0 | 4.27 |

| 4 | 75 | 20 | 4.44 | 0.56 | 8:1 | 5.5 | 0.00 |

| 5 | 75 | 20 | 4.20 | 0.80 | 5:1 | 6.0 | 9.69 |

| Fomulation | Distilled Water (% w/w) | Ostrich Oil (% w/w) | Span (Sp) (% w/w) | Tween (Tw) (% w/w) |

|---|---|---|---|---|

| 5% w/w mixed emulsifiers | ||||

| Sp80Tw80 | 75 | 20 | 4.44 | 0.56 |

| Sp80Tw60 | 75 | 20 | 4.42 | 0.58 |

| Sp80Tw20 | 75 | 20 | 4.52 | 0.48 |

| Sp20Tw80 | 75 | 20 | 3.72 | 1.28 |

| Sp20Tw60 | 75 | 20 | 3.70 | 1.30 |

| Sp20Tw20 | 75 | 20 | 3.76 | 1.24 |

| 10% w/w mixed emulsifiers | ||||

| Sp80Tw80 | 70 | 20 | 8.88 | 1.12 |

| Sp80Tw60 | 70 | 20 | 8.86 | 1.14 |

| Sp80Tw20 | 70 | 20 | 9.04 | 0.96 |

| Sp20Tw80 | 70 | 20 | 7.54 | 2.46 |

| Sp20Tw60 | 70 | 20 | 7.52 | 2.48 |

| Sp20Tw20 | 70 | 20 | 7.84 | 2.16 |

| 15% w/w mixed emulsifiers | ||||

| Sp80Tw80 | 65 | 20 | 13.32 | 1.68 |

| Sp80Tw60 | 65 | 20 | 13.30 | 1.70 |

| Sp80Tw20 | 65 | 20 | 13.54 | 1.46 |

| Sp20Tw80 | 65 | 20 | 11.30 | 3.70 |

| Sp20Tw60 | 65 | 20 | 11.28 | 3.72 |

| Sp20Tw20 | 65 | 20 | 11.74 | 3.26 |

| 20% w/w mixed emulsifiers | ||||

| Sp80Tw80 | 60 | 20 | 17.76 | 2.24 |

| Sp80Tw60 | 60 | 20 | 17.74 | 2.26 |

| Sp80Tw20 | 60 | 20 | 18.06 | 1.94 |

| Sp20Tw80 | 60 | 20 | 15.08 | 4.52 |

| Sp20Tw60 | 60 | 20 | 15.04 | 4.96 |

| Sp20Tw20 | 60 | 20 | 15.66 | 4.34 |

| Formulation | Percent of Creaming Index | ||

|---|---|---|---|

| Day 1 | Day 3 | Day 7 | |

| 5% w/w mixed emulsifiers | |||

| Sp80Tw80 | 0.00 | 11.32 | 25.45 |

| Sp80Tw60 | 30.48 | 34.55 | 45.45 |

| Sp80Tw20 | 7.41 | 20.00 | 23.64 |

| Sp20Tw80 | 50.91 | 60.00 | 60.00 |

| Sp20Tw60 | 46.73 | 50.91 | 54.55 |

| Sp20Tw20 | 46.73 | 50.91 | 54.55 |

| 10% w/w mixed emulsifiers | |||

| Sp80Tw80 | 0.00 | 5.56 | 23.64 |

| Sp80Tw60 | 0.00 | 7.41 | 36.36 |

| Sp80Tw20 | 0.00 | 7.41 | 35.71 |

| Sp20Tw80 | 40.00 | 41.07 | 52.63 |

| Sp20Tw60 | 51.79 | 52.63 | 61.02 |

| Sp20Tw20 | 35.71 | 35.09 | 51.67 |

| 15% w/w mixed emulsifiers | |||

| Sp80Tw80 | 0.00 | 7.14 | 18.97 |

| Sp80Tw60 | 0.00 | 9.09 | 36.84 |

| Sp80Tw20 | 0.00 | 7.14 | 44.83 |

| Sp20Tw80 | 0.00 | 0.00 | 0.00 |

| Sp20Tw60 | 0.00 | 3.45 | 8.20 |

| Sp20Tw20 | 0.00 | 0.00 | 0.00 |

| 20% w/w mixed emulsifiers | |||

| Sp80Tw80 | 0.00 | 0.00 | 0.00 |

| Sp80Tw60 | 0.00 | 0.00 | 6.52 |

| Sp80Tw20 | 0.00 | 0.00 | 6.52 |

| Sp20Tw80 | 0.00 | 0.00 | 0.00 |

| Sp20Tw60 | 0.00 | 0.00 | 0.00 |

| Sp20Tw20 | 0.00 | 0.00 | 0.00 |

| Sample | Storage Temperature (°C) | AV (mg KOH/g Sample) | PV (mEq O2/kg Sample) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Initial | 1 Month | 3 Months | 6 Months | Initial | 1 Month | 3 Months | 6 Months | ||

| Optimized emulsion with BHT | 4 °C | 0.09 ± 0.01 | 0.12 ± 0.01 | 0.12 ± 0.01 | 0.12 ± 0.01 | 2.50 ± 0.10 | 2.50 ± 0.10 | 2.50 ± 0.11 | 2.50 ± 0.10 |

| 25 °C | 0.12 ± 0.01 | 0.12 ± 0.01 | 0.12 ± 0.01 | 2.50 ± 0.10 | 2.61 ± 0.12 | 2.61 ± 0.11 | |||

| 45 °C | 0.13 ± 0.01 | 0.14 ± 0.01 | 0.23 ± 0.02 | 2.55 ± 0.10 | 2.98 ± 0.15 | 3.72 ± 0.21 | |||

| Optimized emulsion without BHT | 4 °C | 0.09 ± 0.01 | 0.12 ± 0.01 | 0.12 ± 0.01 | 0.12 ± 0.01 | 2.50 ± 0.10 | 2.51 ± 0.10 | 2.95 ± 0.13 | 3.30 ± 0.20 |

| 25 °C | 0.13 ± 0.01 | 0.14 ± 0.02 | 0.17 ± 0.02 | 2.51 ± 0.11 | 2.98 ± 0.12 | 4.51 ± 0.21 | |||

| 45 °C | 0.14 ± 0.02 | 0.16 ± 0.02 | 0.32 ± 0.02 | 3.31 ± 0.11 | 5.61 ± 0.19 | 7.51 ± 0.25 | |||

| Ostrich oil | 4 °C | 0.09 ± 0.01 | 0.12 ± 0.01 | 0.12 ± 0.01 | 0.12 ± 0.01 | 2.50 ± 0.10 | 2.51 ± 0.10 | 2.95 ± 0.13 | 3.30 ± 0.20 |

| 25 °C | 0.13 ± 0.01 | 0.14 ± 0.02 | 0.18 ± 0.01 | 2.55 ± 0.13 | 3.18 ± 0.10 | 4.89 ± 0.15 | |||

| 45 °C | 0.14 ± 0.02 | 0.17 ± 0.01 | 0.34 ± 0.02 | 3.50 ± 0.14 | 5.80 ± 0.19 | 8.91 ± 0.20 | |||

| Samples | Inhibition Zone (mm) | DPPH IC50 (mg/mL) | Linoleic Acid Inhibition (%), Day 5 | ||

|---|---|---|---|---|---|

| S. aureus | E. coli | P. aeruginosa | |||

| Optimized emulsion | 12.32 ± 0.19 a | 6.93 ± 0.18 a | 6.3 ± 0.14 a | 23.52 ± 1.09 b | 52.20 ± 2.01 a |

| Ostrich oil | 6.12 ± 0.15 b | 0 b | 0 b | 39.92 ± 1.51 a | 44.70 ± 1.94 b |

| Lincomycin | 27.00 ± 0.65 | 21.03 ± 0.25 | 8.02 ± 0.18 | NA | NA |

| Trolox | NA | NA | NA | 0.0043 ± 0.0001 | 58.20 ± 5.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ponphaiboon, J.; Limmatvapirat, S.; Limmatvapirat, C. Development and Evaluation of a Stable Oil-in-Water Emulsion with High Ostrich Oil Concentration for Skincare Applications. Molecules 2024, 29, 982. https://doi.org/10.3390/molecules29050982

Ponphaiboon J, Limmatvapirat S, Limmatvapirat C. Development and Evaluation of a Stable Oil-in-Water Emulsion with High Ostrich Oil Concentration for Skincare Applications. Molecules. 2024; 29(5):982. https://doi.org/10.3390/molecules29050982

Chicago/Turabian StylePonphaiboon, Juthaporn, Sontaya Limmatvapirat, and Chutima Limmatvapirat. 2024. "Development and Evaluation of a Stable Oil-in-Water Emulsion with High Ostrich Oil Concentration for Skincare Applications" Molecules 29, no. 5: 982. https://doi.org/10.3390/molecules29050982

APA StylePonphaiboon, J., Limmatvapirat, S., & Limmatvapirat, C. (2024). Development and Evaluation of a Stable Oil-in-Water Emulsion with High Ostrich Oil Concentration for Skincare Applications. Molecules, 29(5), 982. https://doi.org/10.3390/molecules29050982