Graphene-Based Hybrid Fillers for Rubber Composites

Abstract

1. Introduction

2. Rubber Composites with Different Graphene Hybrid Fillers

2.1. Graphene/CB

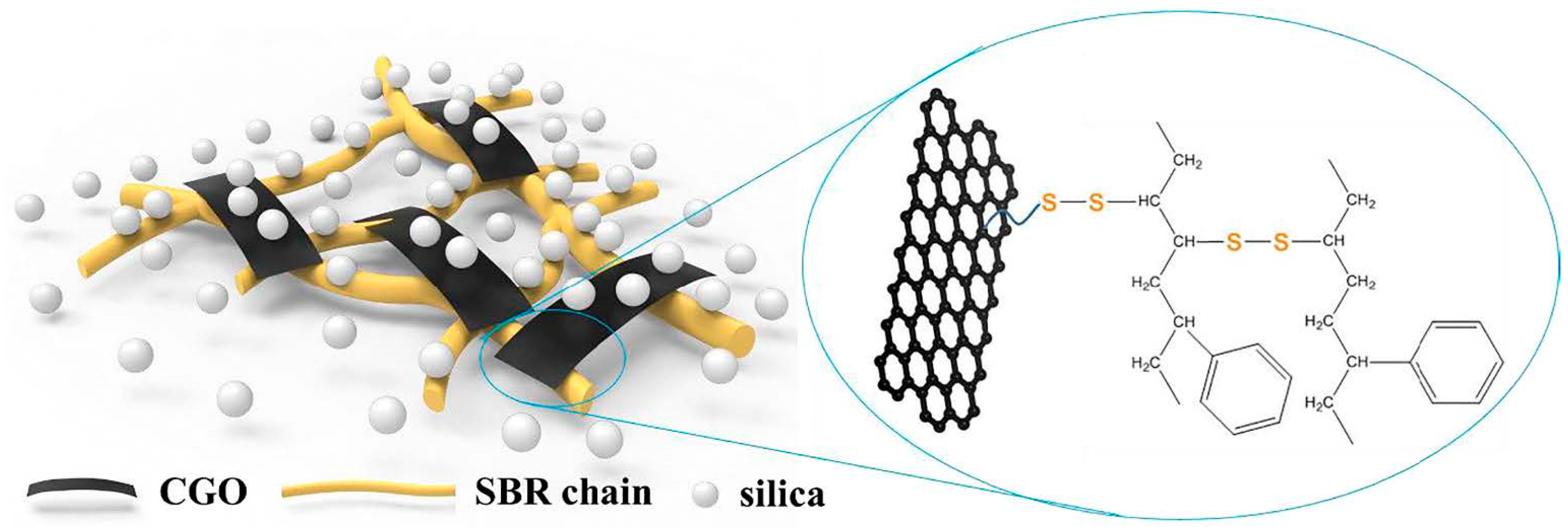

2.2. Graphene/Silica

2.3. Graphene/CNTs

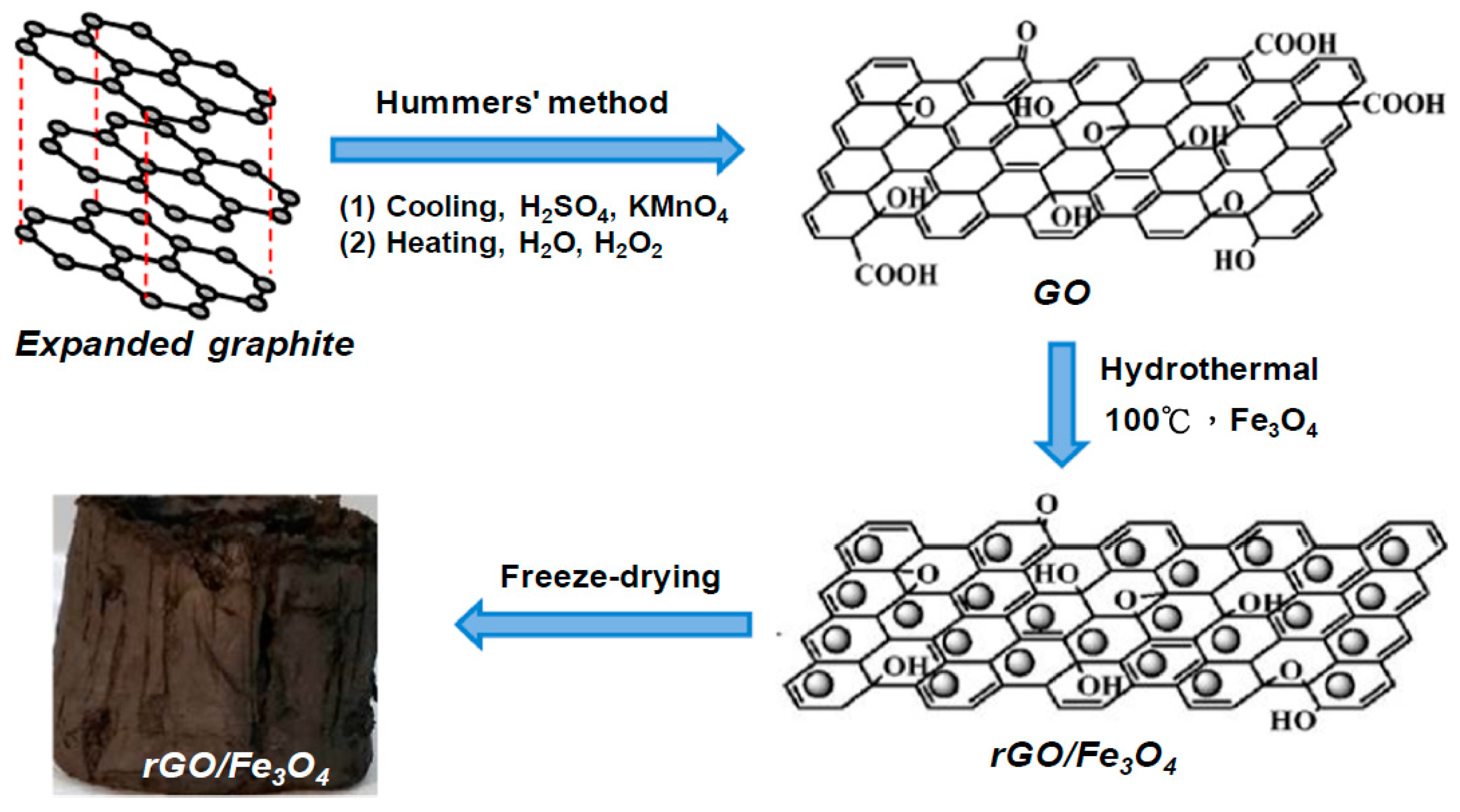

2.4. Graphene/Metal Oxide

2.5. Graphene/1D Nanowires (Microwires, Nanofibers)

2.6. Other Binary Graphene-Based Hybrid Fillers

2.7. Ternary Graphene-Based Hybrid Fillers

3. Approaches for Performance Enhancement of Rubber with Graphene-Based Fillers

3.1. Enhanced Preparation Methods

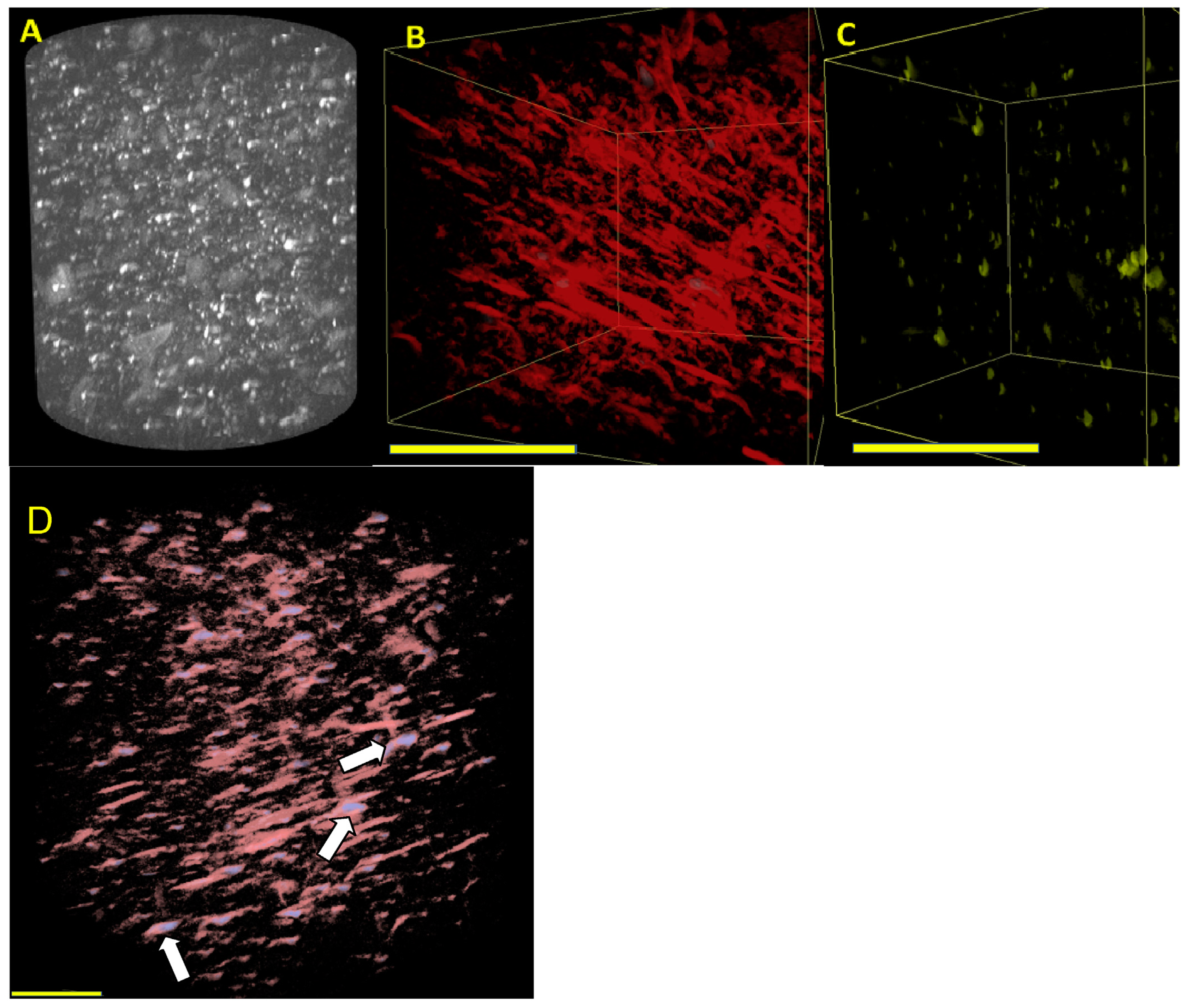

3.2. Controlling of 3D Networks of Graphene Hybrid Fillers

3.3. Surface Functionalization and Interface Improvement

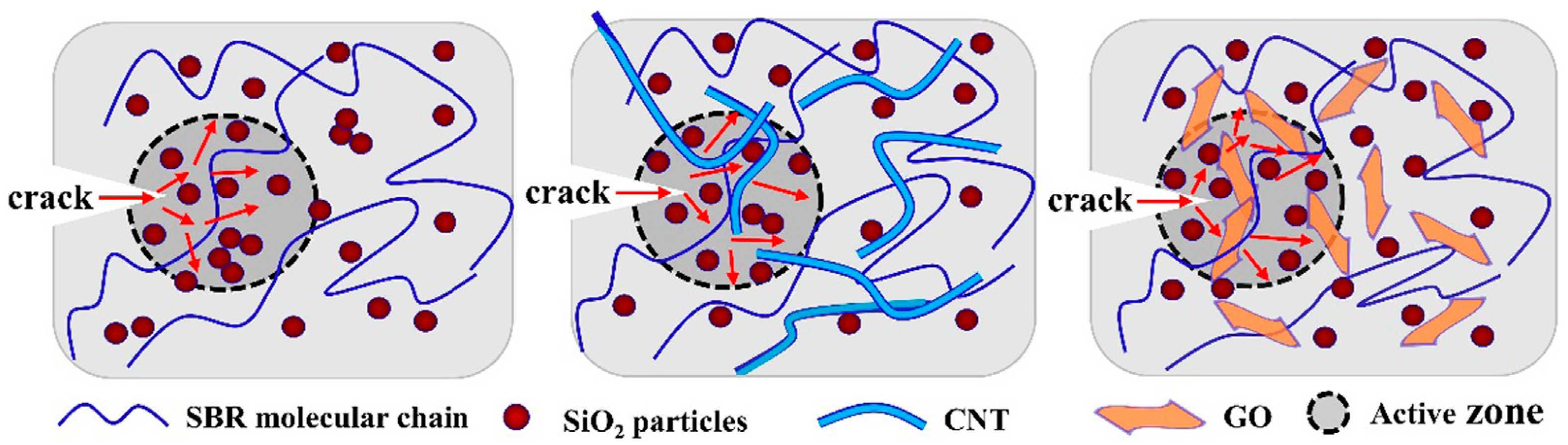

4. Reinforcing Mechanism of Hybrid Graphene Fillers for Rubber Composites

5. Conclusions and Perspectives

- Diversification of applications: Now it is the opportune moment to seize the significant decline in the cost of preparing graphene and its derivatives. This presents an opportunity to create graphene hybrid filler rubber composites with excellent properties and break away from the constraints of traditional rubber materials. The application of composites can be extended from traditional fields (such as tires and shoes) to more modern areas (such as healthcare and artificial intelligence) and extended from singularity to multi-dimensional development.

- Optimization of the fillers’ properties and the composites’ structures: There is also some room for improvement in increasing the fillers’ performance and the structure design of the rubber composites. In this way, rubber composites with more reliable and excellent properties can be created. For instance, combining graphene magnetic hybrid fillers with specific structures, such as gradient structures, layer-by-layer structures, or porous structures, can be an effective method for enhancing material absorption while reducing reflection. This is particularly significant for the preparation of “green” EMI-shielding materials with low reflection and high absorption [218,219,220].

- Diversified rubber matrices: Exploring the blending of the rubber matrix with other materials, such as chitosan, gelatin, polyurethane, and epoxy, can endow the composites with more advantages. By combining a broader range of materials, graphene hybrid fillers/rubber composites can be used in high-end precision applications with excellent properties.

Author Contributions

Funding

Conflicts of Interest

References

- Nazir, M.T.; Khalid, A.; Akram, S.; Mishra, P.; Kabir, I.I.; Yeoh, G.H.; Phung, B.T.; Wong, K.L. Electrical tracking, erosion and flammability resistance of high voltage outdoor composite insulation: Research, innovation and future outlook. Mater. Sci. Eng. R Rep. 2023, 156, 100757. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, K.Y.; Bu, Q.; Lavorgna, M.; Xia, H.S. Graphene-Rubber Nanocomposites: Preparation, Structure, and Properties. In Carbon-Related Materials in Recognition of Nobel Lectures by Prof. Akira Suzuki in ICCE; Springer: Berlin/Heidelberg, Germany, 2017; pp. 175–209. [Google Scholar]

- Lin, Y.; Liu, S.; Peng, J.; Liu, L. The filler–rubber interface and reinforcement in styrene butadiene rubber composites with graphene/silica hybrids: A quantitative correlation with the constrained region. Compos. Part A Appl. Sci. Manuf. 2016, 86, 19–30. [Google Scholar] [CrossRef]

- Dong, Y.; Ke, Y.; Zheng, Z.; Yang, H.; Yao, X. Effect of stress relaxation on sealing performance of the fabric rubber seal. Compos. Sci. Technol. 2017, 151, 291–301. [Google Scholar] [CrossRef]

- Burelo, M.; Martínez, A.; Hernández-Varela, J.D.; Stringer, T.; Ramírez-Melgarejo, M.; Yau, A.Y.; Luna-Bárcenas, G.; Treviño-Quintanilla, C.D. Recent Developments in Synthesis, Properties, Applications and Recycling of Bio-Based Elastomers. Molecules 2024, 29, 387. [Google Scholar] [CrossRef]

- Zheng, J.; Hanshe, M.; He, W.; Hang, T.; Li, Z.; Jiang, S.; E, S.; Li, X.; Chen, Y. Highly Stretchable Composite Foams via Sustainable Utilization of Waste Tire Rubbers for Temperature-Dependent Electromagnetic Wave Absorption. Molecules 2022, 27, 8971. [Google Scholar] [CrossRef]

- Mondal, T.; Bhowmick, A.K.; Ghosal, R.; Mukhopadhyay, R. Graphene-Based Elastomer Nanocomposites: Functionalization Techniques, Morphology, and Physical Properties. In Designing of Elastomer Nanocomposites: From Theory to Applications; Stöckelhuber, K.W., Das, A., Klüppel, M., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 267–318. [Google Scholar]

- Sethulekshmi, A.S.; Jayan, J.S.; Saritha, A.; Joseph, K. Recent developments in natural rubber nanocomposites containing graphene derivatives and its hybrids. Ind. Crops Prod. 2022, 177, 114529. [Google Scholar] [CrossRef]

- Kinloch, I.A.; Suhr, J.; Lou, J.; Young, R.J.; Ajayan, P.M. Composites with carbon nanotubes and graphene: An outlook. Science 2018, 362, 547–553. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Q.; Wang, S.J. A review on enhancement of mechanical and tribological properties of polymer composites reinforced by carbon nanotubes and graphene sheet: Molecular dynamics simulations. Compos. Part B-Eng. 2019, 160, 348–361. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior Thermal Conductivity of Single-Layer Graphene. Nano. Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Nair, R.R.; Blake, P.; Grigorenko, A.N.; Novoselov, K.S.; Booth, T.J.; Stauber, T.; Peres, N.M.R.; Geim, A.K. Fine Structure Constant Defines Visual Transparency of Graphene. Science 2008, 320, 1308. [Google Scholar] [CrossRef] [PubMed]

- Zhan, Y.; Meng, Y.; Li, Y.; Zhang, C.; Xie, Q.; Wei, S.; Lavorgna, M.; Chen, Z. Poly(vinyl alcohol)/reduced graphene oxide multilayered coatings: The effect of filler content on gas barrier and surface resistivity properties. Compos. Commun. 2021, 24, 100670. [Google Scholar] [CrossRef]

- Seenithurai, S.; Chai, J.D. Electronic Properties of Graphene Nano-Parallelograms: A Thermally Assisted Occupation DFT Computational Study. Molecules 2024, 29, 349. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Cheng, Y.; Li, S.J.; Liu, B.H.; Yang, L.; Geng, F.; Xie, S.Z.; Qi, R.; Zhang, Y.; Liu, D.Y.; et al. Enhanced properties of gelatin films incorporated with TiO2-loaded reduced graphene oxide aerogel microspheres for active food packaging applications. Int. J. Biol. Macromol. 2024, 261, 129772. [Google Scholar] [CrossRef]

- Huang, X.; Qi, X.; Boey, F.; Zhang, H. Graphene-based composites. Chem. Soc. Rev. 2012, 41, 666–686. [Google Scholar] [CrossRef]

- Sadasivuni, K.K.; Ponnamma, D.; Thomas, S.; Grohens, Y. Evolution from graphite to graphene elastomer composites. Prog. Polym. Sci. 2014, 39, 749–780. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, K.Y.; Hao, S.; Xia, H.S.; Lavorgna, M. Simultaneous reduction and surface functionalization of graphene oxide and the application for rubber composites. J. Appl. Polym. Sci. 2019, 136, 47375. [Google Scholar] [CrossRef]

- Bai, X.; Wan, C.; Zhang, Y.; Zhai, Y. Reinforcement of hydrogenated carboxylated nitrile–butadiene rubber with exfoliated graphene oxide. Carbon 2011, 49, 1608–1613. [Google Scholar] [CrossRef]

- Das, A.; Kasaliwal, G.R.; Jurk, R.; Boldt, R.; Fischer, D.; Stöckelhuber, K.W.; Heinrich, G. Rubber composites based on graphene nanoplatelets, expanded graphite, carbon nanotubes and their combination: A comparative study. Compos. Sci. Technol. 2012, 72, 1961–1967. [Google Scholar] [CrossRef]

- Zhan, Y.H.; Hao, S.; Li, Y.; Santillo, C.; Zhang, C.; Sorrentino, L.; Lavorgna, M.; Xia, H.S.; Chen, Z. High sensitivity of multi-sensing materials based on reduced graphene oxide and natural rubber: The synergy between filler segregation and macro-porous morphology. Compos. Sci. Technol. 2021, 205, 108689. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N.; Manikkavel, A.; Song, M.; Lee, D.-J.; Park, S.-S. Silicone Rubber Composites Reinforced by Carbon Nanofillers and Their Hybrids for Various Applications: A Review. Polymers 2021, 13, 2322. [Google Scholar] [CrossRef]

- Zhu, Q.; Wang, Z.; Zeng, H.; Yang, T.; Wang, X. Effects of graphene on various properties and applications of silicone rubber and silicone resin. Compos. Part A Appl. Sci. Manuf. 2021, 142, 106240. [Google Scholar] [CrossRef]

- Zhan, Y.H.; Wang, J.; Zhang, K.Y.; Li, Y.; Meng, Y.Y.; Yan, N.; Wei, W.; Peng, F.; Xia, H.S. Fabrication of a Flexible Electromagnetic Interference Shielding Fe3O4@ Reduced Graphene Oxide/Natural Rubber Composite with Segregated Network. Chem. Eng. J. 2018, 344, 184–193. [Google Scholar] [CrossRef]

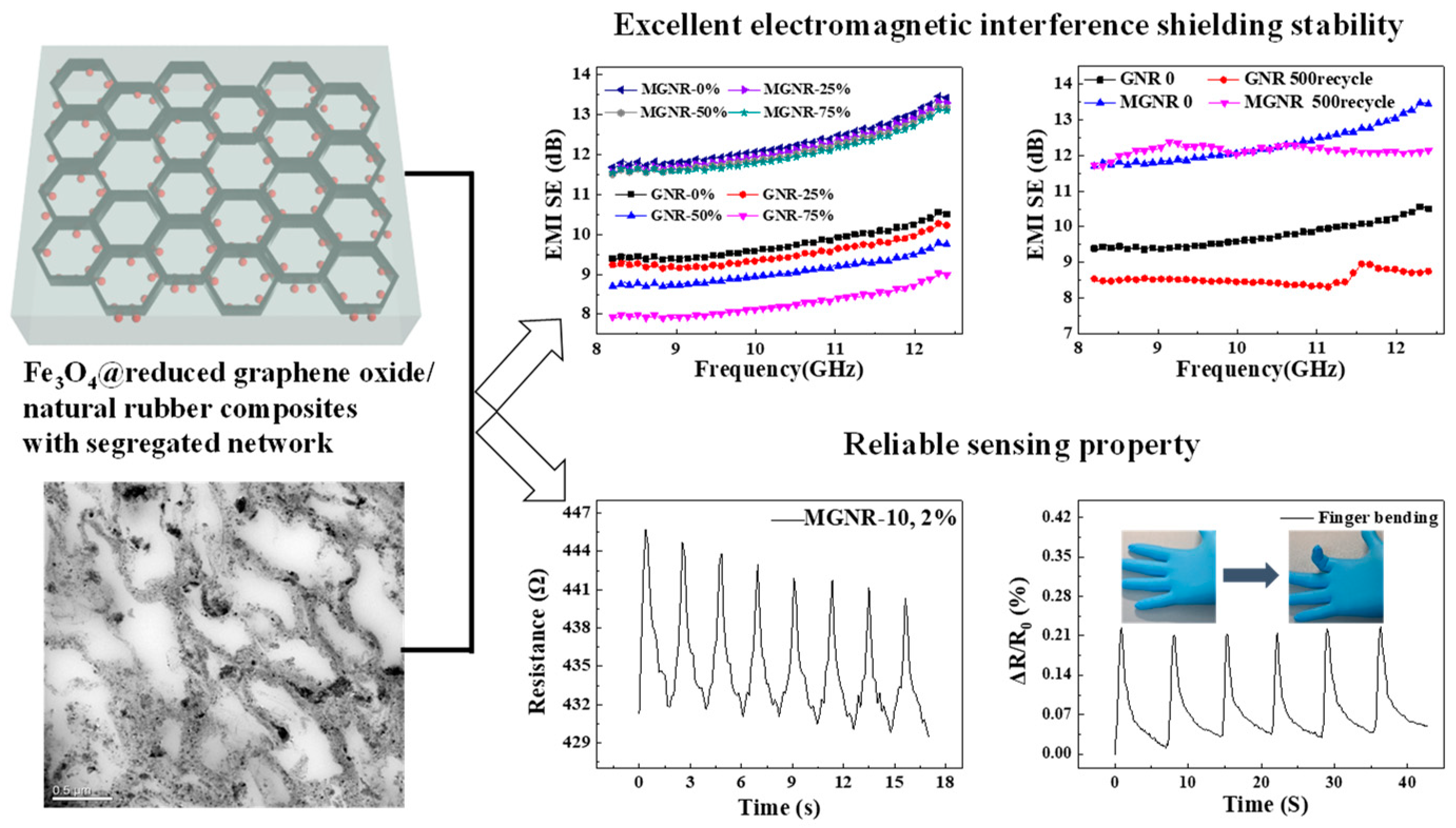

- Wang, J.; Liu, B.H.; Cheng, Y.; Ma, Z.W.; Zhan, Y.H.; Xia, H.S. Constructing a Segregated Magnetic Graphene Network in Rubber Composites for Integrating Electromagnetic Interference Shielding Stability and Multi-Sensing Performance. Polymers 2021, 13, 3277. [Google Scholar] [CrossRef]

- Liu, D.; Kong, Q.Q.; Jia, H.; Xie, L.J.; Chen, J.; Tao, Z.; Wang, Z.; Jiang, D.; Chen, C.M. Dual-functional 3D multi-wall carbon nanotubes/graphene/silicone rubber elastomer: Thermal management and electromagnetic interference shielding. Carbon 2021, 183, 216–224. [Google Scholar] [CrossRef]

- Barshutina, M.N.; Volkov, V.S.; Arsenin, A.V.; Nasibulin, A.G.; Barshutin, S.N.; Tkachev, A.G. Silicone Composites with CNT/Graphene Hybrid Fillers: A Review. Materials 2021, 14, 2418. [Google Scholar] [CrossRef]

- Pyo, S.; Eun, Y.; Sim, J.; Kim, K.; Choi, J. Carbon nanotube-graphene hybrids for soft electronics, sensors, and actuators. Micro Nano Syst. Lett. 2022, 10, 9. [Google Scholar] [CrossRef]

- Pazat, A.; Barrès, C.; Bruno, F.; Janin, C.; Beyou, E. Preparation and Properties of Elastomer Composites Containing “Graphene”-Based Fillers: A Review. Polym. Rev. 2018, 58, 403–443. [Google Scholar] [CrossRef]

- Ayub, S.; Guan, B.H.; Ahmad, F.; Oluwatobi, Y.A.; Nisa, Z.U.; Javed, M.F.; Mosavi, A.J.P. Graphene and iron reinforced polymer composite electromagnetic shielding applications: A review. Polymers 2021, 13, 2580. [Google Scholar] [CrossRef] [PubMed]

- Cai, W.; Huang, Y.; Wang, D.; Liu, C.; Zhang, Y. Piezoresistive behavior of graphene nanoplatelets/carbon black/silicone rubber nanocomposite. J. Appl. Polym. Sci. 2014, 131, 39778. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, C.; Zhang, Y. Preparation and properties of styrene-butadiene rubber nanocomposites blended with carbon black-graphene hybrid filler. J. Appl. Polym. Sci. 2015, 132, 41309. [Google Scholar] [CrossRef]

- Yang, G.; Liao, Z.; Yang, Z.; Tang, Z.; Guo, B. Effects of substitution for carbon black with graphene oxide or graphene on the morphology and performance of natural rubber/carbon black composites. J. Appl. Polym. Sci. 2015, 132, 41832. [Google Scholar] [CrossRef]

- Valentini, L.; Bittolo Bon, S.; Lopez-Manchado, M.A.; Verdejo, R.; Pappalardo, L.; Bolognini, A.; Alvino, A.; Borsini, S.; Berardo, A.; Pugno, N.M. Synergistic effect of graphene nanoplatelets and carbon black in multifunctional EPDM nanocomposites. Compos. Sci. Technol. 2016, 128, 123–130. [Google Scholar] [CrossRef]

- Mondal, S.; Khastgir, D. Elastomer reinforcement by graphene nanoplatelets and synergistic improvements of electrical and mechanical properties of composites by hybrid nano fillers of graphene-carbon black & graphene-MWCNT. Compos. Part A Appl. Sci. Manuf. 2017, 102, 154–165. [Google Scholar]

- Chen, Y.; Lin, Y.; Luo, Y.; Jia, D.; Liu, L. Morphology and performance of styrene butadiene rubber filled with modified graphite nanoplatelet and carbon black. Polym. Adv. Technol. 2016, 27, 830–840. [Google Scholar] [CrossRef]

- Kong, E.; Yoon, B.; Nam, J.-D.; Suhr, J. Accelerated Aging and Lifetime Prediction of Graphene-Reinforced Natural Rubber Composites. Macromol. Res. 2018, 26, 998–1003. [Google Scholar] [CrossRef]

- Kurian, A.S.; Mohan, V.B.; Bhattacharyya, D. Embedded large strain sensors with graphene-carbon black-silicone rubber composites. Sens. Actuators A Phys. 2018, 282, 206–214. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, K.Y.; Cheng, Z.G.; Lavorgna, M.; Xia, H.S. Graphene/carbon black/natural rubber composites prepared by a wet compounding and latex mixing process. Plast. Rubber Compos. 2018, 47, 398–412. [Google Scholar] [CrossRef]

- Guo, H.; Jerrams, S.; Xu, Z.; Zhou, Y.; Jiang, L.; Zhang, L.; Liu, L.; Wen, S. Enhanced fatigue and durability of carbon black/natural rubber composites reinforced with graphene oxide and carbon nanotubes. Eng. Fract. Mech. 2020, 223, 106764. [Google Scholar] [CrossRef]

- Xue, C.; Gao, H.; Hu, G. Viscoelastic and fatigue properties of graphene and carbon black hybrid structure filled natural rubber composites under alternating loading. Constr. Build. Mater. 2020, 265, 120299. [Google Scholar] [CrossRef]

- Roy, A.; Kar, S.; Ghosal, R.; Naskar, K.; Bhowmick, A.K.J.I.; Research, E.C. Flourishing an Electrochemical Synthetic Route toward Carbon Black-Intercalated Graphene As a Neoteric Hybrid Nanofiller for Multifunctional Polymer Nanocomposites. Ind. Eng. Chem. Res. 2021, 60, 5758–5769. [Google Scholar] [CrossRef]

- Frasca, D.; Schulze, D.; Wachtendorf, V.; Krafft, B.; Rybak, T.; Schartel, B. Multilayer Graphene/Carbon Black/Chlorine Isobutyl Isoprene Rubber Nanocomposites. Polymers 2016, 8, 95. [Google Scholar] [CrossRef] [PubMed]

- Song, S.H.; Kim, J.M.; Park, K.H.; Lee, D.J.; Kwon, O.S.; Kim, J.; Yoon, H.; Chen, X. High performance graphene embedded rubber composites. RSC Adv. 2015, 5, 81707–81712. [Google Scholar] [CrossRef]

- Liu, P.; Huang, Y.; Liu, C.; Wang, Y.; Guo, X.; Zhang, Y.; Ge, Y. Enhanced electrical conductivity and mechanical stability of flexible pressure-sensitive GNPs/CB/SR composites: Synergistic effects of GNPs and CB. J. Mater. Res. 2015, 30, 3394–3402. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, Y.; Kang, Z.; Zhao, G.; Liu, Y. Influence of partial substitution for carbon black with graphene oxide on dynamic properties of natural rubber composites. Micro Nano Lett. 2017, 12, 605–610. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Zhang, Y.F.; Wu, Z.K.; Bai, S.L. Synergic enhancement of thermal properties of polymer composites by graphene foam and carbon black. Compos. Part B-Eng. 2016, 84, 52–58. [Google Scholar] [CrossRef]

- Liu, C.; Wu, C.; Hao, C.; Liu, P.; Guo, X.; Zhang, Y.; Huang, Y. Electrical conductivity transformation mechanism of GNPs/CB/SR nanocomposite foams. J. Appl. Polym. Sci. 2018, 135, 45996. [Google Scholar] [CrossRef]

- Roy, A.; Kar, S.; Ghosal, R.; Mukhopadhyay, R.; Naskar, K.; Bhowmick, A.K. Unique graphene-carbon black hybrid nanofiller by a micromechanical cleavage technique as a reinforcing agent in elastomers: Fundamental and experimental studies. J. Appl. Polym. Sci. 2023, 140, e53575. [Google Scholar] [CrossRef]

- Manikkavel, A.; Kumar, V.; Park, S.-S. Mechanical performance of composites reinforced with carbon black and different types of graphitic nanofillers for different applications. J. Elastomers Plast. 2023, 55, 383–399. [Google Scholar] [CrossRef]

- Shahamatifard, F.; Rodrigue, D.; Park, K.-W.; Frikha, S.; Mighri, F. Synergistic effect between graphene nanoplatelets and carbon black to improve the thermal and mechanical properties of natural rubber nanocomposites. Polym. Plast. Technol. Mater. 2022, 61, 1578–1592. [Google Scholar] [CrossRef]

- Innes, J.R.; Young, R.J.; Papageorgiou, D.G. Graphene Nanoplatelets as a Replacement for Carbon Black in Rubber Compounds. Polymers 2022, 14, 1204. [Google Scholar] [CrossRef] [PubMed]

- Rajan, K.P.; Gopanna, A.; Theravalappil, R.; Abdelghani, E.A.M.; Thomas, S.P. Partial replacement of carbon black with graphene in natural rubber/butadiene rubber based tire compound: Investigation of critical properties. J. Polym. Res. 2022, 29, 76. [Google Scholar] [CrossRef]

- Huang, Y.; He, X.; Gao, L.; Wang, Y.; Liu, C.; Liu, P. Pressure-sensitive carbon black/graphene nanoplatelets-silicone rubber hybrid conductive composites based on a three-dimensional polydopamine-modified polyurethane sponge. J. Mater. Sci.-Mater. El. 2017, 28, 9495–9504. [Google Scholar] [CrossRef]

- Song, P.; Wang, G.; Zhang, Y. Preparation and performance of graphene/carbon black silicone rubber composites used for highly sensitive and flexible strain sensors. Sens. Actuators A Phys. 2021, 323, 112659. [Google Scholar] [CrossRef]

- Sarkawi, S.S.; Aziz, A.A.; Aziz, A.K.C.; Rahim, R.A.; Ismail, N.I.N. Properties of graphene nano-filler reinforced epoxidized natural rubber composites. J. Polym. Sci. Technol. 2017, 2, 36–44. [Google Scholar]

- Han, D.; Zhang, J.; Wang, L.; Wang, C. The impact of synergistic interaction between CBp and GO during the mixing process on metal friction and wear. Surf. Coat. Technol. 2023, 474, 130089. [Google Scholar] [CrossRef]

- Kim, S.; Dierkes, W.K.; Blume, A.; Talma, A.; Van Ommen, J.R.; Courtois, N.; Davin, J.; Recker, C.; Schoeffel, J. Plasma Polymerization of Precipitated Silica for Tire Application. Molecules 2023, 28, 6646. [Google Scholar] [CrossRef] [PubMed]

- Jermjun, K.; Khumho, R.; Thongoiam, M.; Yousatit, S.; Yokoi, T.; Ngamcharussrivichai, C.; Nuntang, S. Natural Rubber/Hexagonal Mesoporous Silica Nanocomposites as Efficient Adsorbents for the Selective Adsorption of (−)-Epigallocatechin Gallate and Caffeine from Green Tea. Molecules 2023, 28, 6019. [Google Scholar] [CrossRef]

- Zhang, S.; Zheng, L.; Liu, D.; Xu, Z.; Zhang, L.; Liu, L.; Wen, S. Improved mechanical and fatigue properties of graphene oxide/silica/SBR composites. RSC Adv. 2017, 7, 40813–40818. [Google Scholar] [CrossRef]

- Gu, X.; Qin, H.; Wang, C.; Deng, C.; Guan, G.; Lu, S.; Fan, H. Enhanced thermal conductivity and antistatic property of energy-saving tyres. J. Polym. Res. 2021, 28, 420. [Google Scholar] [CrossRef]

- Charoenchai, M.; Tangbunsuk, S.; Keawwattana, W. Silica-graphene oxide nanohybrids as reinforcing filler for natural rubber. J. Polym. Res. 2020, 27, 230. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, K.; Fei, G.; Salzano de Luna, M.; Lavorgna, M.; Xia, H. High Silica Content Graphene/Natural Rubber Composites Prepared by a Wet Compounding and Latex Mixing Process. Polymers 2020, 12, 2549. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, S.H.; Zou, Y.F.; Ma, W.S.; Huang, G.J.; Li, M.D. Improving the Thermal Conductivity and Mechanical Properties of Two-component Room Temperature Vulcanized Silicone Rubber by Filling with Hydrophobically Modified SiO2-Graphene Nanohybrids. Chin. J. Polym. Sci. 2019, 37, 189–196. [Google Scholar] [CrossRef]

- Mondal, D.; Ghorai, S.; Rana, D.; De, D.; Chattopadhyay, D. The rubber–filler interaction and reinforcement in styrene butadiene rubber/devulcanize natural rubber composites with silica–graphene oxide. Polym. Compos. 2019, 40, E1559–E1572. [Google Scholar] [CrossRef]

- Zhang, Z.; He, X.; Wang, X.; Rodrigues, A.M.; Zhang, R. Reinforcement of the mechanical properties in nitrile rubber by adding graphene oxide/silicon dioxide hybrid nanoparticles. J. Appl. Polym. Sci. 2018, 135, 46091. [Google Scholar] [CrossRef]

- Wang, C.; Chang, T.; Bian, H.; Zhang, L. Study on the preparation of graphene oxide/silica/natural rubber latex composites by different processes. Polym. Polym. Compos. 2018, 27, 135–142. [Google Scholar] [CrossRef]

- Dong, H.; Jia, Z.; Luo, Y.; Zhong, B.; Jia, D. In situ fabrication of graphene oxide supported nano silica for the preparation of rubber composites with high mechanical strength and thermal conductivity. Polym. Compos. 2019, 40, E1633–E1641. [Google Scholar] [CrossRef]

- Luo, Y.; Qian, J.; He, D.; Tao, J.; Zhao, P.; Gong, W.; Zhang, Z.; Peng, Z.; Chen, X.; Wang, H.; et al. Preparation of natural rubber/silica nanocomposites using one- and two-dimensional dispersants by latex blending process. Polym. Compos. 2018, 39, 1413–1419. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, H.; Song, S.; Zhang, Y. Improving thermal conductivity of styrene-butadiene rubber composites by incorporating mesoporous silica@ solvothermal reduced graphene oxide hybrid nanosheets with low graphene content. Compos. Sci. Technol. 2017, 150, 174–180. [Google Scholar] [CrossRef]

- Zhang, R.; Li, J.; Xu, Z.; Jerrams, S.; Hu, S.; Liu, L.; Wen, S.; Zhang, L. Achieving strong chemical interface and superior energy-saving capability at the crosslinks of rubber composites containing graphene oxide using thiol-vinyl click chemistry. Compos. Sci. Technol. 2023, 233, 109907. [Google Scholar] [CrossRef]

- Chen, J.; Li, C.; Chen, X.; Zhang, X.; Jia, H.; Luo, Z.; Luo, Y. Insights into the preparation and performance of SiO2@graphene oxide/epoxidized solution-polymerized styrene butadiene rubber composites through experiments and molecular simulations. J. Appl. Polym. Sci. 2022, 139, e52432. [Google Scholar] [CrossRef]

- Gheller, J.; Zanchet, A. Composition and processing influence on the performance of graphene-containing SBR/BR rubber compounds. J. Rubber Res. 2022, 25, 357–365. [Google Scholar] [CrossRef]

- Sarath, P.S.; Pahovnik, D.; Utroša, P.; Onder, O.C.; Thomas, S.; Haponiuk, J.T.; George, S.C. Study the synergistic effect of fumed silica and reduced graphene oxide insertion on the thermal, mechanical, tribological, and solvent transport properties of silicone rubber nanocomposites. J. Appl. Polym. Sci. 2022, 139, e52820. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, Y. Enhanced mechanical and thermal properties of SBR composites by introducing graphene oxide nanosheets decorated with silica particles. Compos. Part A Appl. Sci. Manuf. 2017, 102, 236–242. [Google Scholar] [CrossRef]

- Su, J.; Zhao, Z.; Huang, Y.; Liao, X.; Yang, Q. Thermal oxidative and ozone oxidative stabilization effect of hybridized functional graphene oxide in a silica-filled solution styrene butadiene elastomer. PCCP 2016, 18, 29423–29434. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Xie, S.; Sun, P.; Zhao, Z.; Li, L.; Shao, X.; Liu, X.; Xin, Z. Synergistic effect of graphene and silicon dioxide hybrids through hydrogen bonding self-assembly in elastomer composites. RSC Adv. 2018, 8, 17813–17825. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Sinha, T.K.; Tao, L.; Li, H.; Zong, C.; Kim, J.K. Synergistic reinforcement of silanized silica-graphene oxide hybrid in natural rubber for tire-tread fabrication: A latex based facile approach. Compos. Part B-Eng. 2019, 161, 667–676. [Google Scholar] [CrossRef]

- Wang, H.; Wu, J.; Gong, K.; Hao, Q.; Wang, X.; Jiang, J.; Li, Z.; Lai, G. Design of a nanoporous interfacial SiO2 layer in polysiloxane–graphene oxide nanocomposites for efficient stress transmission. RSC Adv. 2016, 6, 60160–60170. [Google Scholar] [CrossRef]

- Wang, H.; Yang, C.; Liu, R.; Gong, K.; Hao, Q.; Wang, X.; Wu, J.; Zhang, G.; Hu, Y.; Jiang, J. Build a Rigid–Flexible Graphene/Silicone Interface by Embedding SiO2 for Adhesive Application. ACS Omega 2017, 2, 1063–1073. [Google Scholar] [CrossRef]

- Li, C.; Cao, X.; Tong, Y.; Yang, Z.; Gao, D.; Ru, Y.; He, G. Hybrid Filler with Nanoparticles Grown in Situ on the Surface for the Modification of Thermal Conductive and Insulating Silicone Rubber. ACS. Appl. Polym. Mater. 2022, 4, 7152–7161. [Google Scholar] [CrossRef]

- Duan, X.; Cheng, S.; Tao, R.; Zhang, Z.; Zhao, G. Synergistically enhanced thermal control ability and mechanical properties of natural rubber for tires through a graphene/silica with a dot-face structure. Adv. Compos. Hybrid. Mater. 2022, 5, 1145–1157. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, Q.; Lu, Q.; Han, C.; Zhou, Z.; Liang, Z.; Liu, R.; Nie, Y. Reinforcement and Toughening of Rubber by Bridging Graphene and Nanosilica. J. Inorg. Organomet. Polym. Mater. 2020, 30, 337–348. [Google Scholar] [CrossRef]

- Zhao, S.; Xie, S.; Liu, X.; Shao, X.; Zhao, Z.; Xin, Z.; Li, L. Covalent hybrid of graphene and silicon dioxide and reinforcing effect in rubber composites. J. Polym. Res. 2018, 25, 225. [Google Scholar] [CrossRef]

- Zhang, H.; Cai, F.; Luo, Y.; Yu, X.; Wu, S. Grafting silica onto reduced graphene oxide via hydrosilylation for comprehensive rubber applications: Molecular simulation and experimental study. Polym. Compos. 2022, 43, 5332–5343. [Google Scholar] [CrossRef]

- Song, K.; Liu, X.; Yang, A.; Ding, B.; He, F.; Li, Y.; Zhong, H.; Yang, W. SR/GNPs/Pn@SiO2 shape-stabilized phase change composites with low leakage rate and adjustable thermal energy storage. Fuller. Nanotub. Carbon Nanostruct. 2023, 31, 120–129. [Google Scholar] [CrossRef]

- Kang, L.; Ren, L.; Niu, H.; Lv, R.; Guo, H.; Bai, S. Paraffin@SiO2 microcapsules-based phase change composites with enhanced thermal conductivity for passive battery cooling. Compos. Sci. Technol. 2022, 230, 109756. [Google Scholar] [CrossRef]

- Seo, J.G.; Lee, C.K.; Lee, D.; Song, S.H. High-performance Tires Based on Graphene Coated with Zn-free Coupling Agents. J. Ind. Eng. Chem. 2018, 66, 78–85. [Google Scholar] [CrossRef]

- Wang, J.; Fei, G.X.; Pan, Y.; Zhang, K.Y.; Hao, S.; Zheng, Z.; Xia, H.S. Simultaneous reduction and surface functionalization of graphene oxide by cystamine dihydrochloride for rubber composites. Compos. Part A Appl. Sci. Manuf. 2019, 122, 18–26. [Google Scholar] [CrossRef]

- Xu, Z.; Jerrams, S.; Guo, H.; Zhou, Y.; Jiang, L.; Gao, Y.; Zhang, L.; Liu, L.; Wen, S. Influence of graphene oxide and carbon nanotubes on the fatigue properties of silica/styrene-butadiene rubber composites under uniaxial and multiaxial cyclic loading. Int. J. Fatigue 2020, 131, 105388. [Google Scholar] [CrossRef]

- Liu, H.; Yang, L.; Liu, X.; Cao, J.-P.; Zhang, J.; Luo, Z.; Gao, Z. Silicon dioxide nanoparticle decorated graphene with excellent dispersibility in natural rubber composites via physical mixing for application in green tires. Compos. Part B-Eng. 2023, 258, 110700. [Google Scholar] [CrossRef]

- Guo, C.; Xing, J.; Shamshad, A.; Jiang, J.; Wang, D.; Wang, X.; Bai, Y.; Chen, H.; Sun, W.; An, N.; et al. In Situ Growth of Sodium Manganese Hexacyanoferrate on Carbon Nanotubes for High-Performance Sodium-Ion Batteries. Molecules 2024, 29, 313. [Google Scholar] [CrossRef] [PubMed]

- Gu, W.; Shi, J.; Zhang, J.; Jia, Q.; Liu, C.; Ge, H.; Sun, Q.; Zhu, L. Fabrication and Investigation of the Microwave Absorption of Nonwovens Modified by Carbon Nanotubes and Graphene Flakes. Molecules 2023, 28, 6419. [Google Scholar] [CrossRef] [PubMed]

- Xu, P.; Zhang, R.; Zhang, N.; Cheng, J.; Wei, H.; Gao, S. Marangoni interface self-assembly hybrid carbon nano-network for transparent conductive silicone rubber. Prog. Org. Coat. 2019, 129, 26–31. [Google Scholar] [CrossRef]

- Valentini, L.; Bittolo Bon, S.; Hernández, M.; Lopez-Manchado, M.A.; Pugno, N.M. Nitrile butadiene rubber composites reinforced with reduced graphene oxide and carbon nanotubes show superior mechanical, electrical and icephobic properties. Compos. Sci. Technol. 2018, 166, 109–114. [Google Scholar] [CrossRef]

- Valentini, L.; Bittolo Bon, S.; Pugno, N.M. Graphene and Carbon Nanotube Auxetic Rubber Bionic Composites with Negative Variation of the Electrical Resistance and Comparison with Their Nonbionic Counterparts. Adv. Funct. Mater. 2017, 27, 1606526. [Google Scholar] [CrossRef]

- Valentini, L.; Bittolo Bon, S.; Pugno, N.M.; Hernandez Santana, M.; Lopez-Manchado, M.A.; Giorgi, G. Synergistic icephobic behaviour of swollen nitrile butadiene rubber graphene and/or carbon nanotube composites. Compos. Part B-Eng. 2019, 166, 352–360. [Google Scholar] [CrossRef]

- Li, H.; Yang, L.; Weng, G.; Xing, W.; Wu, J.; Huang, G. Toughening rubbers with a hybrid filler network of graphene and carbon nanotubes. J. Mater. Chem. A 2015, 3, 22385–22392. [Google Scholar] [CrossRef]

- Araby, S.; Saber, N.; Ma, X.; Kawashima, N.; Kang, H.; Shen, H.; Zhang, L.; Xu, J.; Majewski, P.; Ma, J. Implication of multi-walled carbon nanotubes on polymer/graphene composites. Mater. Des. 2015, 65, 690–699. [Google Scholar] [CrossRef]

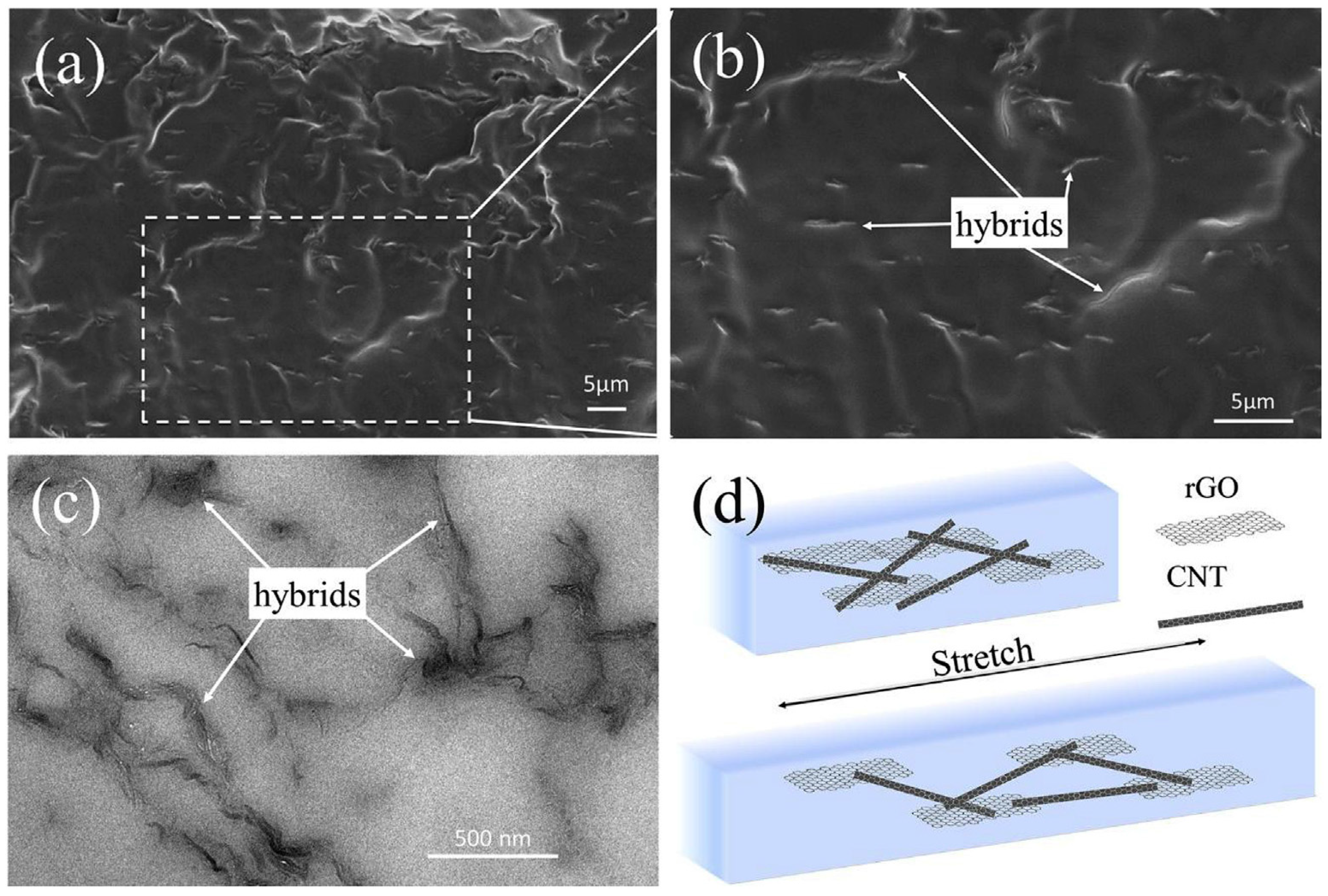

- Liu, Z.; Qian, Z.; Song, J.; Zhang, Y. Conducting and stretchable composites using sandwiched graphene-carbon nanotube hybrids and styrene-butadiene rubber. Carbon 2019, 149, 181–189. [Google Scholar] [CrossRef]

- Yang, H.; Yuan, L.; Yao, X.; Zheng, Z.; Fang, D. Monotonic strain sensing behavior of self-assembled carbon nanotubes/graphene silicone rubber composites under cyclic loading. Compos. Sci. Technol. 2020, 200, 108474. [Google Scholar] [CrossRef]

- Zhan, Y.H.; Li, Y.C.; Meng, Y.Y.; Xie, Q.; Lavorgna, M. Electric heating behavior of reduced oxide graphene/carbon nanotube/natural rubber composites with macro-porous structure and segregated filler network. Polymers 2020, 12, 2411. [Google Scholar] [CrossRef]

- Yang, H.; Yao, X.; Yuan, L.; Gong, L.; Liu, Y. Strain-sensitive electrical conductivity of carbon nanotube-graphene-filled rubber composites under cyclic loading. Nanoscale 2019, 11, 578–586. [Google Scholar] [CrossRef]

- Chen, J.; Huang, X.; He, Y.; Liu, L.; Sheng, H.; Hu, W.; Zhao, Z.; He, J. Synergistic effect of polyphosphazene nanotubes and graphene on enhancing ablative resistance of ethylene propylene diene monomer insulation composites. J. Appl. Polym. Sci. 2022, 139, e52834. [Google Scholar] [CrossRef]

- Liu, X.; Huang, J.; Yang, C.; Wang, P.; Xing, S.; Zhong, D.; Zhou, X. Effects of graphene and CNTs reinforcement on the friction mechanism of nitrile butadiene rubber under water lubrication conditions. Wear 2022, 500–501, 204334. [Google Scholar] [CrossRef]

- Lin, Y.; Yin, Q.; Ding, L.; Yuan, G.; Jia, H.; Wang, J. Ultra-sensitive flexible strain sensors based on hybrid conductive networks for monitoring human activities. Sens. Actuators A Phys. 2022, 342, 113627. [Google Scholar] [CrossRef]

- Hu, H.; Zhao, L.; Liu, J.; Liu, Y.; Cheng, J.; Luo, J.; Liang, Y.; Tao, Y.; Wang, X.; Zhao, J. Enhanced dispersion of carbon nanotube in silicone rubber assisted by graphene. Polymer 2012, 53, 3378–3385. [Google Scholar] [CrossRef]

- Amrei, S.S.; Asghari, M.; Esfahanian, M.; Zahraei, Z. Highly selective CNT-coupled-GO-incorporated polydimethylsiloxane membrane for pervaporative membrane bioreactor ethanol production. J. Chem. Technol. Biotechnol. 2020, 95, 1604–1613. [Google Scholar] [CrossRef]

- Oh, J.Y.; Jun, G.H.; Jin, S.; Ryu, H.J.; Hong, S.H. Enhanced Electrical Networks of Stretchable Conductors with Small Fraction of Carbon Nanotube/Graphene Hybrid Fillers. ACS Appl. Mater. Interfaces 2016, 8, 3319–3325. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, B.; Srivastava, S.K. Synergistic effect of three-dimensional multi-walled carbon nanotube–graphene nanofiller in enhancing the mechanical and thermal properties of high-performance silicone rubber. Polym. Int. 2014, 63, 1219–1228. [Google Scholar] [CrossRef]

- Kong, L.; Yin, X.; Yuan, X.; Zhang, Y.; Liu, X.; Cheng, L.; Zhang, L. Electromagnetic wave absorption properties of graphene modified with carbon nanotube/poly(dimethyl siloxane) composites. Carbon 2014, 73, 185–193. [Google Scholar] [CrossRef]

- Bian, H.; Xue, J.; Hao, G.; Hao, Y.; Xie, M.; Wang, C.; Wang, Z.; Zhu, L.; Xiao, Y. High thermal conductivity graphene oxide/carbon nanotubes/butyl rubber composites prepared by a dry ice expansion pre-dispersion flocculation method. J. Appl. Polym. Sci. 2022, 139, 51897. [Google Scholar] [CrossRef]

- Mishra, R.M.; Ahamad, A.; Vijayvargiya, R.; Pandey, K.N.; Mishra, S.; Rai, J.S.P. Effect of graphene on various properties of binary blend of polyetherimide/siliconerubber reinforced with halloysite nanotubes. Polym. Bull. 2022, 80, 5469–5479. [Google Scholar] [CrossRef]

- Kim, T.; Park, J.; Sohn, J.; Cho, D.; Jeon, S.J.A.n. Bioinspired, highly stretchable, and conductive dry adhesives based on 1D–2D hybrid carbon nanocomposites for all-in-one ECG electrodes. ACS Nano 2016, 10, 4770–4778. [Google Scholar] [CrossRef]

- Maya, M.G.; Abraham, J.; Arif, P.M.; Moni, G.; George, J.J.; George, S.C.; Thomas, S. A comprehensive study on the impact of RGO/MWCNT hybrid filler reinforced polychloroprene rubber multifunctional nanocomposites. Polym. Test. 2020, 87, 106525. [Google Scholar] [CrossRef]

- Chen, M.; Tao, T.; Zhang, L.; Gao, W.; Li, C. Highly conductive and stretchable polymer composites based on graphene/MWCNT network. Chem. Commun. 2013, 49, 1612–1614. [Google Scholar] [CrossRef]

- Sun, X.; Liu, X.; Shen, X.; Wu, Y.; Wang, Z.; Kim, J.K. Graphene foam/carbon nanotube/poly (dimethyl siloxane) composites for exceptional microwave shielding. Compos. Part A Appl. Sci. Manuf. 2016, 85, 199–206. [Google Scholar] [CrossRef]

- Jia, H.; Kong, Q.Q.; Liu, Z.; Wei, X.X.; Li, X.M.; Chen, J.P.; Li, F.; Yang, X.; Sun, G.H.; Chen, C.M. 3D graphene/carbon nanotubes/polydimethylsiloxane composites as high-performance electromagnetic shielding material in X-band. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105712. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, J.; He, J.; Zou, L.; Zhao, D.; Song, S. Waste Silicone Rubber in Three-Dimensional Conductive Networks as a Temperature and Movement Sensor. ACS Appl. Mater. Interfaces 2022, 14, 29250–29260. [Google Scholar] [CrossRef]

- Panahi-Sarmad, M.; Noroozi, M.; Abrisham, M.; Eghbalinia, S.; Teimoury, F.; Bahramian, A.R.; Dehghan, P.; Sadri, M.; Goodarzi, V. A Comprehensive Review on Carbon-Based Polymer Nanocomposite Foams as Electromagnetic Interference Shields and Piezoresistive Sensors. ACS Appl. Electron. Mater. 2020, 2, 2318–2350. [Google Scholar] [CrossRef]

- Wang, Z.X.; Han, X.S.; Zhou, Z.J.; Meng, W.Y.; Han, X.W.; Wang, S.J.; Pu, J.W. Lightweight and elastic wood-derived composites for pressure sensing and electromagnetic interference shielding. Compos. Sci. Technol. 2021, 213, 108931. [Google Scholar] [CrossRef]

- Zeng, Z.; Chen, M.; Jin, H.; Li, W.; Xue, X.; Zhou, L.; Pei, Y.; Zhang, H.; Zhang, Z. Thin and flexible multi-walled carbon nanotube/waterborne polyurethane composites with high-performance electromagnetic interference shielding. Carbon 2016, 96, 768–777. [Google Scholar] [CrossRef]

- Singh, K.; Ohlan, A.; Pham, V.H.; R, B.; Varshney, S.; Jang, J.; Hur, S.H.; Choi, W.M.; Kumar, M.; Dhawan, S.K.; et al. Nanostructured graphene/Fe3O4 incorporated polyaniline as a high performance shield against electromagnetic pollution. Nanoscale 2013, 5, 2411–2420. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Zhang, H.-B.; Li, X.; Gui, C.-X.; Yu, Z.-Z. Enhanced electromagnetic interference shielding efficiency of polystyrene/graphene composites with magnetic Fe3O4 nanoparticles. Carbon 2015, 82, 67–76. [Google Scholar] [CrossRef]

- Al-Ghamdi, A.A.; Al-Ghamdi, A.A.; Al-Turki, Y.; Yakuphanoglu, F.; El-Tantawy, F. Electromagnetic shielding properties of graphene/acrylonitrile butadiene rubber nanocomposites for portable and flexible electronic devices. Compos. Part B-Eng. 2016, 88, 212–219. [Google Scholar] [CrossRef]

- Li, J.; Zhao, X.; Wu, W.; Ji, X.; Lu, Y.; Zhang, L. Bubble-templated rGO-graphene nanoplatelet foams encapsulated in silicon rubber for electromagnetic interference shielding and high thermal conductivity. Chem. Eng. J. 2021, 415, 129054. [Google Scholar] [CrossRef]

- Zhang, Z.; He, X.; Zhang, J.; Lu, X.; Yang, C.; Liu, T.; Wang, X.; Zhang, R. Influence of graphene/ferriferrous oxide hybrid particles on the properties of nitrile rubber. RSC Adv. 2016, 6, 91798–91805. [Google Scholar] [CrossRef]

- Zhou, G.; Wang, D.-W.; Li, F.; Zhang, L.; Li, N.; Wu, Z.S.; Wen, L.; Lu, G.Q.; Cheng, H.M. Graphene-Wrapped Fe3O4 Anode Material with Improved Reversible Capacity and Cyclic Stability for Lithium Ion Batteries. Chem. Mater. 2010, 22, 5306–5313. [Google Scholar] [CrossRef]

- Qu, B.; Zhu, C.; Li, C.; Zhang, X.; Chen, Y. Coupling Hollow Fe3O4–Fe Nanoparticles with Graphene Sheets for High-Performance Electromagnetic Wave Absorbing Material. ACS Appl. Mater. Interfaces 2016, 8, 3730–3735. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Y.; Ma, Y.; Lu, H.; Sun, Y.; Zhao, G.; Liu, Y. Preparation of a Natural Rubber Nanocomposite Coating based on Fe3O4@ Carbon materials and their Corrosion Resistance. Int. J. Electrochem. Sci. 2017, 12, 9798–9811. [Google Scholar] [CrossRef]

- Hu, J.; Liang, C.; Li, J.; Liang, Y.; Li, S.; Li, G.; Wang, Z.; Dong, D. Flexible reduced graphene oxide@ Fe3O4/silicone rubber composites for enhanced microwave absorption. Appl. Surf. Sci. 2021, 570, 151270. [Google Scholar] [CrossRef]

- Alam, M.N.; Choi, J. Highly reinforced magneto-sensitive natural-rubber nanocomposite using iron oxide/multilayer graphene as hybrid filler. Compos. Commun. 2022, 32, 101169. [Google Scholar] [CrossRef]

- Essabir, H.; Raji, M.; Rodrigue, D.; Bouhfid, R.; Qaiss, A.E.K. Multifunctional poly (vinylidene fluoride) and styrene butadiene rubber blend magneto-responsive nanocomposites based on hybrid graphene oxide and Fe3O4: Synthesis, preparation and characterization. J. Polym. Res. 2021, 28, 437. [Google Scholar] [CrossRef]

- Jia, L.C.; Yan, D.X.; Yang, Y.; Zhou, D.; Cui, C.H.; Bianco, E.; Lou, J.; Vajtai, R.; Li, B.; Ajayan, P.M.; et al. High Strain Tolerant EMI Shielding Using Carbon Nanotube Network Stabilized Rubber Composite. Adv. Mater. Technol. 2017, 2, 1700078. [Google Scholar] [CrossRef]

- Xu, Z.; Zheng, L.; Wen, S.; Liu, L. Graphene oxide-supported zinc oxide nanoparticles for chloroprene rubber with improved crosslinking network and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105492. [Google Scholar] [CrossRef]

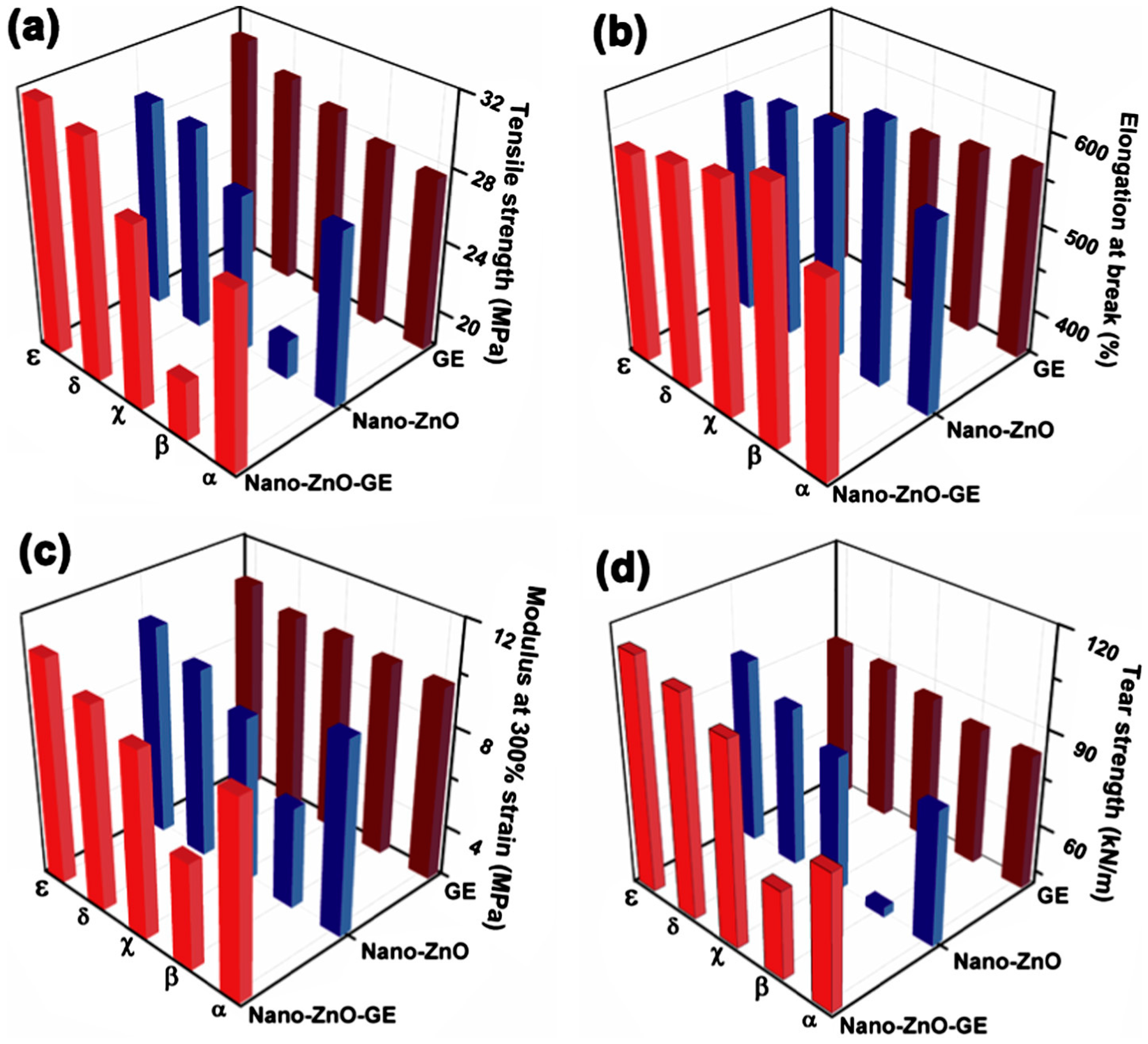

- Lin, Y.; Chen, Y.; Zeng, Z.; Zhu, J.; Wei, Y.; Li, F.; Liu, L. Effect of ZnO nanoparticles doped graphene on static and dynamic mechanical properties of natural rubber composites. Compos. Part A Appl. Sci. Manuf. 2015, 70, 35–44. [Google Scholar] [CrossRef]

- Lin, Y.; Zeng, Z.; Zhu, J.; Chen, S.; Yuan, X.; Liu, L. Graphene nanosheets decorated with ZnO nanoparticles: Facile synthesis and promising application for enhancing the mechanical and gas barrier properties of rubber nanocomposites. RSC Adv. 2015, 5, 57771–57780. [Google Scholar] [CrossRef]

- Lin, C.K.; Huang, T.M.; Liu, J.H.; Tu, J.W.; Liu, Y.T.; Hsieh, W.Y.; Chang, J.H.; Wu, R.J.; Chavali, M. Preparation and improved properties (electrical, mechanical and microwave absorption) of graphene/ZnO/XNBR nanocomposites. Polym. Bull. 2022, 80, 685–701. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, W.; Zhang, L.; Yin, J.; Wang, J.; Xie, H. Thermal Conductivity and Mechanical Properties of Low-Density Silicone Rubber Filled With Al2O3 and Graphene Nanoplatelets. J. Therm. Sci. Eng. Appl. 2018, 10, 011014. [Google Scholar] [CrossRef]

- Li, J.; Zhao, X.; Zhang, Z.; Xian, Y.; Lin, Y.; Ji, X.; Lu, Y.; Zhang, L. Technology, construction of interconnected Al2O3 doped rGO network in natural rubber nanocomposites to achieve significant thermal conductivity and mechanical strength enhancement. Compos. Sci. Technol. 2020, 186, 107930. [Google Scholar] [CrossRef]

- Zhuang, C.; Tao, R.; Liu, X.; Zhang, L.; Cui, Y.; Liu, Y.; Zhang, Z. Enhanced thermal conductivity and mechanical properties of natural rubber-based composites co-incorporated with surface treated alumina and reduced graphene oxide. Diam. Relat. Mater. 2021, 116, 108438. [Google Scholar] [CrossRef]

- Han, R.; Wang, Z.; Zhang, Y.; Niu, K. Thermal stability of CeO2/graphene/phenyl silicone rubber composites. Polym. Test. 2019, 75, 277–283. [Google Scholar] [CrossRef]

- Kumar, V.; Kumar, A.; Song, M.; Lee, D.J.; Han, S.S.; Park, S.S. Properties of silicone rubber-based composites reinforced with few-layer graphene and iron oxide or titanium dioxide. Polymers 2021, 13, 1550. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.H.; Huang, W.C.; Wang, J.C.; Hung, W.C. Infrared stealth and microwave absorption properties of reduced graphene oxide functionalized with Fe3O4. Mater. Sci. Eng. B 2022, 276, 115575. [Google Scholar] [CrossRef]

- Zhu, J.; Liang, Y.; Si, W.; Zhang, S. Bubblegum inspired epoxidized natural rubber composites for superior mechanical and electrical properties. Polymer 2022, 257, 125286. [Google Scholar] [CrossRef]

- Yang, W.; Xue, Y.; Zhang, L.; Chen, Y. Enhanced nonlinear conductivity of silicone rubber composites with hybrid graphene and alumina for cable accessory. Polym. Test. 2023, 124, 108080. [Google Scholar] [CrossRef]

- Oh, J.Y.; Lee, D.; Jun, G.H.; Ryu, H.J.; Hong, S.H. High conductivity and stretchability of 3D welded silver nanowire filled graphene aerogel hybrid nanocomposites. J. Mater. Chem. C 2017, 5, 8211–8218. [Google Scholar] [CrossRef]

- Li, Y.; Li, C.; Zhao, S.; Cui, J.; Zhang, G.; Gao, A.; Yan, Y. Facile fabrication of highly conductive and robust three-dimensional graphene/silver nanowires bicontinuous skeletons for electromagnetic interference shielding silicone rubber nanocomposites. Compos. Part A Appl. Sci. Manuf. 2019, 119, 101–110. [Google Scholar] [CrossRef]

- Ge, J.; Yao, H.B.; Wang, X.; Ye, Y.D.; Wang, J.L.; Wu, Z.Y.; Liu, J.W.; Fan, F.J.; Gao, H.L.; Zhang, C.L.; et al. Stretchable conductors based on silver nanowires: Improved performance through a binary network design. Angew. Chem. Int. Ed. 2013, 52, 1654–1659. [Google Scholar] [CrossRef]

- Xu, F.; Zhu, Y. Highly conductive and stretchable silver nanowire conductors. Adv. Mater. 2012, 24, 5117–5122. [Google Scholar] [CrossRef]

- He, F.F.; Mensitieri, G.; Lavorgna, M.; de Luna, M.S.; Filippone, G.; Xia, H.; Esposito, R.; Scherillo, G. Tailoring gas permeation and dielectric properties of bromobutyl rubber—Graphene oxide nanocomposites by inducing an ordered nanofiller microstructure. Compos. Part B-Eng. 2017, 116, 361–368. [Google Scholar] [CrossRef]

- Wang, Y.; Guan, Y.; Liao, D.; He, Y.; Li, S.; Zhou, L.; Yu, C.; Chen, Y.; Liu, Y.; Liu, H. Fabrication of cellulose nanofiber/reduced graphene oxide/nitrile rubber flexible films using Pickering emulsion technology for electromagnetic interference shielding and piezoresistive sensor. Macromol. Mater. Eng. 2021, 306, 2100070. [Google Scholar] [CrossRef]

- Song, J.; Zhang, Y. Vertically aligned silicon carbide nanowires/reduced graphene oxide networks for enhancing the thermal conductivity of silicone rubber composites. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105873. [Google Scholar] [CrossRef]

- Amutha Jeevakumari, S.A.; Indhumathi, K.; Arun Prakash, V.R. Role of cobalt nanowire and graphene nanoplatelet on microwave shielding behavior of natural rubber composite in high frequency bands. Polym. Compos. 2020, 41, 4362–4371. [Google Scholar] [CrossRef]

- Jung, J.; Sodano, H.A. Synergetic effect of aramid nanofiber-graphene oxide hybrid filler on the properties of rubber compounds for tire tread application. J. Appl. Polym. Sci. 2022, 139, 51856. [Google Scholar] [CrossRef]

- Wang, L.; Ning, N.; Zhang, L.; Lu, Y.; Tian, M.; Chan, T. Filler dispersion evolution of acrylonitrile–butadiene rubber/graphite nanocomposites during processing. Compos. Part A Appl. Sci. Manuf. 2013, 47, 135–142. [Google Scholar] [CrossRef]

- Song, P.; Liu, B.; Liang, C.; Ruan, K.; Qiu, H.; Ma, Z.; Guo, Y.; Gu, J. Lightweight, Flexible Cellulose-Derived Carbon Aerogel@Reduced Graphene Oxide/PDMS Composites with Outstanding EMI Shielding Performances and Excellent Thermal Conductivities. Nano-Micro Lett. 2021, 13, 91. [Google Scholar] [CrossRef]

- Lin, Y.; Yin, Q.; Wang, J.; Jia, H.; Yuan, G.; Wang, J. Sensitivity enhanced, highly stretchable, and mechanically robust strain sensors based on reduced graphene oxide-aramid nanofibers hybrid fillers. Chem. Eng. J. 2022, 443, 136468. [Google Scholar] [CrossRef]

- Xu, Y.; Uddin, A.; Estevez, D.; Luo, Y.; Peng, H.; Qin, F. Lightweight microwire/graphene/silicone rubber composites for efficient electromagnetic interference shielding and low microwave reflectivity. Compos. Sci. Technol. 2020, 189, 108022. [Google Scholar] [CrossRef]

- Xiong, X.-q.; Bao, Y.-l.; Liu, H.; Zhu, Q.; Lu, R.; Miyakoshi, T. Study on mechanical and electrical properties of cellulose nanofibrils/graphene-modified natural rubber. Mater. Chem. Phys. 2019, 223, 535–541. [Google Scholar] [CrossRef]

- Zhang, B.; Lian, T.; Shao, X.; Tian, M.; Ning, N.; Zhang, L.; Wang, W. Surface coating of aramid fiber by a graphene/aramid nanofiber hybrid material to enhance interfacial adhesion with rubber matrix. Ind. Eng. Chem. Res. 2021, 60, 2472–2480. [Google Scholar] [CrossRef]

- Cao, J.; Zhang, X.; Wu, X.; Wang, S.; Lu, C. Cellulose nanocrystals mediated assembly of graphene in rubber composites for chemical sensing applications. Carbohydr. Polym. 2016, 140, 88. [Google Scholar] [CrossRef]

- Dong, J.; Wang, C.; Fan, X.; Wei, L.; Shen, G.; Sun, R.; Li, R. Mechanical and Dielectric Properties of a Flexible Anisotropic Rubber-Based Composite. Nanomaterials 2022, 12, 2182. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Guo, J.; Xu, P.; Hu, W.; Lv, J.; Shi, B.; Zhang, Z.; Li, R. Facile preparation of superior compressibility and hydrophobic reduced graphene oxide@cellulose nanocrystals/EPDM composites for highly efficient oil/organic solvent adsorption and enhanced electromagnetic interference shielding. Sep. Purif. Technol. 2023, 307, 122775. [Google Scholar] [CrossRef]

- Li, J.S.; Hsu, T.C.; Hwang, C.C.; Lu, K.T.; Yeh, T.F. Preparation and characterization of microwave absorbing composite materials with GSs or FeCo/GS composites. Mater. Res. Bull. 2018, 107, 218–224. [Google Scholar] [CrossRef]

- Li, T.; Su, Y.; Wang, D.; Mao, Y.; Wang, W.; Liu, L.; Wen, S. High antibacterial and barrier properties of natural rubber comprising of silver-loaded graphene oxide. Int. J. Biol. Macromol. 2022, 195, 449–455. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Z.; Li, W.; Li, C.; Ye, L. Construction of multiple crosslinking networks in EPDM rubber: Synergistic reinforcing effect of graphene-zinc dimethacrylate on EPDM and improvement mechanism of sealing resilience. Compos. Part A Appl. Sci. Manuf. 2019, 121, 254–264. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, Y.; Li, J.; Zhou, H.; Xiao, Q.; Yang, X.; He, S.; Li, G.; Yang, Y. Graphene nanoplatelets/barium titanate hybrid nanoparticles via ball milling for enhanced dielectric and mechanical properties of fluorosilicone rubber composites. Ceram. Int. 2022, 49, 9017–9025. [Google Scholar] [CrossRef]

- Wang, Y.; Xing, T.; Deng, Y.; Zhang, K.; Wu, Y.; Yan, L. Silanized Graphene Oxide-Supported Pd Nanoparticles and Silicone Rubber for Enhanced Hydrogen Elimination. Materials 2022, 15, 4578. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Q.; Cao, Y.; Qie, J.; Zou, J.; You, J.; Lu, H.; Wang, W.; Wang, G. The effect of graphene-coating material (G-Fe) on the dynamic mechanical characteristics of magnetorheological elastomer (MRE). Appl. Phys. A 2022, 128, 657. [Google Scholar] [CrossRef]

- Li, J.; Zhao, X.; Wu, W.; Zhang, Z.; Xian, Y.; Lin, Y.; Lu, Y.; Zhang, L. Advanced flexible rGO-BN natural rubber films with high thermal conductivity for improved thermal management capability. Carbon 2020, 162, 46–55. [Google Scholar] [CrossRef]

- An, D.; Cheng, S.; Zhang, Z.; Jiang, C.; Fang, H.; Li, J.; Liu, Y.; Wong, C.P. A polymer-based thermal management material with enhanced thermal conductivity by introducing three-dimensional networks and covalent bond connections. Carbon 2019, 155, 258–267. [Google Scholar] [CrossRef]

- An, D.; Li, Z.; Chen, H.; Liang, C.; Sun, Z.; Li, J.; Yao, J.; Liu, Y.; Wong, C. Modulation of covalent bonded boron nitride/graphene and three-dimensional networks to achieve highly thermal conductivity for polymer-based thermal interfacial materials. Compos. Part A Appl. Sci. Manuf. 2022, 156, 106890. [Google Scholar] [CrossRef]

- Öztürk, A.; Özçelik, N.; Yurtcan, A.B. Platinum/graphene nanoplatelets/silicone rubber composites as polymer electrolyte membrane fuel cell catalysts. Mater. Chem. Phys. 2021, 260, 124110. [Google Scholar] [CrossRef]

- Liu, C.; Huang, S.; Hou, J.; Zhang, W.; Wang, J.; Yang, H.; Zhang, J. Natural Rubber Latex Reinforced by Graphene Oxide/Zwitterionic Chitin Nanocrystal Hybrids for High-Performance Elastomers without Sulfur Vulcanization. ACS Sustain. Chem. Eng. 2021, 9, 6470–6478. [Google Scholar] [CrossRef]

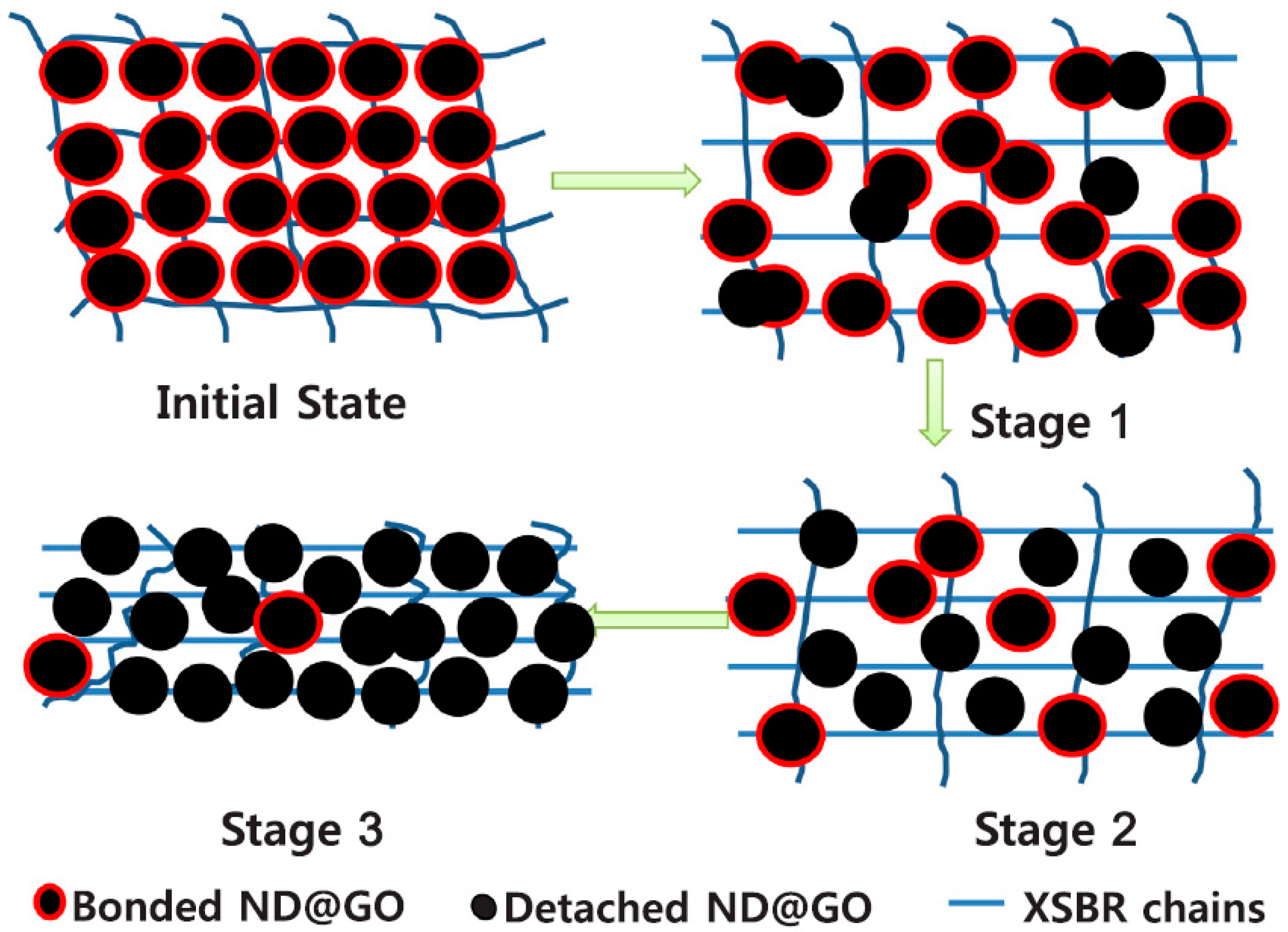

- Zhang, Y.; Park, S.J. Influence of the nanoscaled hybrid based on nanodiamond@graphene oxide architecture on the rheological and thermo-physical performances of carboxylated-polymeric composites. Compos. Part A Appl. Sci. Manuf. 2018, 112, 356–364. [Google Scholar] [CrossRef]

- Khan, A.; Kian, L.K.; Jawaid, M.; Khan, A.A.P.; Marwani, H.M.; Alotaibi, M.M.; Asiri, A.M. Preparation and characterization of lignin/nano graphene oxide/styrene butadiene rubber composite for automobile tyre application. Int. J. Biol. Macromol. 2022, 206, 363–370. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, M.; Lu, J.; Han, F.; Yan, P. Amine-functionalized fibrous sepiolite and graphene oxide in situ self-assembled hybrid network for reinforcement of natural rubber composite. J. Polym. Res. 2022, 29, 526. [Google Scholar] [CrossRef]

- Khan, A.; Kian, L.K.; Jawaid, M.; Khan, A.A.; Alotaibi, M.M.; Asiri, A.M.; Marwani, H.M. Preparation of Styrene-Butadiene Rubber (SBR) Composite Incorporated with Collagen-Functionalized Graphene Oxide for Green Tire Application. Gels 2022, 8, 161. [Google Scholar] [CrossRef]

- Cheng, S.; Duan, X.; Cui, Y.; Liang, C.; Zhang, Z.; Zhao, G.; Liu, Y. Facile strategy for the preparation of green graphene rubber with enhanced interfacial interaction and thermal management capability. J. Appl. Polym. Sci. 2022, 139, e52882. [Google Scholar] [CrossRef]

- Pan, H.; Wang, Z.; Cui, Y.; Cao, L.; Zong, C. Influences of porous reduction graphene oxide/molybdenum disulfide as filler on dielectric properties, thermal stability, and mechanical properties of natural rubber. J. Vinyl Addit. Technol. 2021, 27, 868–880. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N.; Park, S.S.; Lee, D.J. New Insight into Rubber Composites Based on Graphene Nanoplatelets, Electrolyte Iron Particles, and Their Hybrid for Stretchable Magnetic Materials. Polymers 2022, 14, 4826. [Google Scholar] [CrossRef]

- Shi, H.H.; Ruan, H.X.; Chen, Z.J.; Zhang, Y.; Zou, C.L.; Zhang, X.C.; Liu, B.; Xu, M.J.; Li, B. Shape memory, thermal conductivity, and mechanical property of polylactic acid and natural rubber composites reinforced by an inorganic thermal conductive network. J. Appl. Polym. Sci. 2022, 139, e52668. [Google Scholar] [CrossRef]

- Song, J.; Zhang, X.; Wang, J.; Zhang, K. Bioinspired structural silicone rubber composites with high thermal conductivity based on vertically aligned hybrid filler film. Compos. Commun. 2022, 34, 101242. [Google Scholar] [CrossRef]

- Duan, X.; Tao, R.; Chen, Y.; Zhang, Z.; Zhao, G.; Liu, Y.; Cheng, S. Improved mechanical, thermal conductivity and low heat build-up properties of natural rubber composites with nano-sulfur modified graphene oxide/silicon carbide. Ceram. Int. 2022, 48, 22053–22063. [Google Scholar] [CrossRef]

- Wang, X.; Wang, B.; Wei, S.; Zhu, X.; Wang, Y.; Liang, Y.; Guo, L.; Lu, F.; Xu, B. Preparation and derivation mechanism of methyl methacrylate/nitrile butadiene rubber/graphene oxide composites by ball-milling. J. Appl. Polym. Sci. 2023, 140, e53329. [Google Scholar] [CrossRef]

- Shahdan, D.; Rosli, N.A.; Chen, R.S.; Ahmad, S. A Feasible Compatibilization Processing Technique for Improving the Mechanical and Thermal Performance of Rubbery Biopolymer/Graphene Nanocomposites. Polymers 2022, 14, 5009. [Google Scholar] [CrossRef]

- Mensah, B.; Efavi, J.K.; Konadu, D.S.; Manu, G.P. Graphene-maleic anhydride-grafted-carboxylated acrylonitrile butadiene-rubber nanocomposites. Heliyon 2022, 8, e11974. [Google Scholar] [CrossRef]

- Sun, X.; Meng, X.; Dai, P.; Xu, R.; Cheng, A.; Guo, Y.; Jiao, Y.; Lu, Y.; Wang, L. Enhancement of nuclear radiation shielding properties of silicone rubber with γ-ray irradiation induced graphene oxide modified carbonyl iron powder hybrid fillers. J. Appl. Polym. Sci. 2023, 140, e54363. [Google Scholar] [CrossRef]

- Wang, Y.; Suo, J.; Wang, H.; Wang, D.; Wei, L.; Zhu, H. Preparation and reinforcement performance of RGO-CNTs-SiO2 three-phase filler for rubber composites. Compos. Sci. Technol. 2022, 228, 109633. [Google Scholar] [CrossRef]

- Wei, L.Y.; Fu, X.; Luo, M.C.; Xie, Z.T.; Huang, C.; Zhou, J.J.; Zhu, Y.; Huang, G.S.; Wu, J.R. Synergistic effect of CB and GO/CNT hybrid fillers on the mechanical properties and fatigue behavior of NR composites. RSC Adv. 2018, 8, 10573–10581. [Google Scholar] [CrossRef]

- Sun, H.; Bu, Y.; Liu, H.; Wang, J.; Yang, W.; Li, Q.; Guo, Z.; Liu, C.; Shen, C. Superhydrophobic conductive rubber band with synergistic dual conductive layer for wide-range sensitive strain sensor. Sci. Bull. 2022, 67, 1669–1678. [Google Scholar] [CrossRef]

- Lin, L.; Ecke, N.; Kamerling, S.; Sun, C.; Wang, H.; Song, X.; Wang, K.; Zhao, S.; Zhang, J.; Schlarb, A.K. Study on the impact of graphene and cellulose nanocrystal on the friction and wear properties of SBR/NR composites under dry sliding conditions. Wear 2018, 414–415, 43–49. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, S.; Su, L.; Nan, F. Study on Mechanical Properties of Natural Rubber by Carbon Black/Graphene/White Carbon Black. IOP Conf. Ser. Mater. Sci. Eng. 2020, 772, 012021. [Google Scholar] [CrossRef]

- Pirityi, D.Z.; Bárány, T.; Pölöskei, K. Hybrid reinforcement of styrene-butadiene rubber nanocomposites with carbon black, silica, and graphene. J. Appl. Polym. Sci. 2022, 139, e52766. [Google Scholar] [CrossRef]

- Qiu, J.; Zhang, K.; Yan, L. Mercaptopropyl-doped ultra-small silica modified GO nanosheets to enhance mechanical properties of nitrile butadiene rubber. Polymer 2022, 243, 124627. [Google Scholar] [CrossRef]

- Yang, Z.; Huang, Y.; Xiong, Y. A functional modified graphene oxide/nanodiamond/nano zinc oxide composite for excellent vulcanization properties of natural rubber. RSC Adv. 2020, 10, 41857–41870. [Google Scholar] [CrossRef]

- Mathew, J.; Kumar, R.; Mathew, M.; George, S.C. A study on graphene based elastomer with TiO2 and Ni nanoparticles. AIP Conf. Proc. 2020, 2236, 040014. [Google Scholar]

- Khan, H.; Amin, M.; Yasin, M.; Ali, M.; Ahmad, A. Effect of hybrid-SiO2 particles on characterization of EPDM and silicone rubber composites for outdoor high-voltage insulations. J. Polym. Eng. 2017, 37, 671–680. [Google Scholar] [CrossRef]

- Azizi, S.; Momen, G.; Ouellet-Plamondon, C.; David, E. Performance improvement of EPDM and EPDM/Silicone rubber composites using modified fumed silica, titanium dioxide and graphene additives. Polym. Test. 2020, 84, 106281. [Google Scholar] [CrossRef]

- Zirnstein, B.; Tabaka, W.; Frasca, D.; Schulze, D.; Schartel, B. Graphene / hydrogenated acrylonitrile-butadiene rubber nanocomposites: Dispersion, curing, mechanical reinforcement, multifunctional filler. Polym. Test. 2018, 66, 268–279. [Google Scholar] [CrossRef]

- .Nazir, M.T.; Khalid, A.; Wang, C.; Baena, J.C.; Phung, B.T.; Akram, S.; Wong, K.L.; Yeoh, G.H. Enhanced fire retardancy with excellent electrical breakdown voltage, mechanical and hydrophobicity of silicone rubber/aluminium trihydroxide composites by milled glass fibres and graphene nanoplatelets. Surf. Interfaces 2022, 35, 102494. [Google Scholar] [CrossRef]

- Guo, X.; Hong, W.; Zhao, Y.; Zhu, T.; Liu, L.; Li, H.; Wang, Z.; Wang, D.; Mai, Z.; Zhang, T.; et al. Bioinspired Dual-Mode Stretchable Strain Sensor Based on Magnetic Nanocomposites for Strain/Magnetic Discrimination. Small 2023, 19, 2205316. [Google Scholar] [CrossRef] [PubMed]

- Song, P.; Zhang, Y. Vertically aligned carbon nanotubes/graphene/cellulose nanofiber networks for enhancing electrical conductivity and piezoresistivity of silicone rubber composites. Compos. Sci. Technol. 2022, 222, 109366. [Google Scholar] [CrossRef]

- Su, Y.; Li, T.; Mao, Y.; Liu, L.; Wen, S. High-efficiency antibacterial and barrier properties of natural rubber/graphene oxide@Ag/carboxymethyl chitosan composites. Polym.-Plast. Technol. Mater. 2023, 62, 270–280. [Google Scholar] [CrossRef]

- Zhang, R.; Li, J.; Jerrams, S.; Hu, S.; Liu, L.; Wen, S.; Zhang, L. Constructing a fine dispersion and chemical interface based on an electrostatic self-assembly and aqueous phase compound in GO/SiO2/SBR composites to achieve high-wear resistance in eco-friendly green tires. Chem. Eng. J. 2023, 452, 139113. [Google Scholar] [CrossRef]

- Mei, S.; Wang, J.; Wan, J.; Wu, X. Preparation Methods and Properties of CNT/CF/G Carbon-Based Nano-Conductive Silicone Rubber. Appl. Sci. 2023, 13, 6726. [Google Scholar] [CrossRef]

- Zhao, S.; Yan, Y.; Gao, A.; Zhao, S.; Cui, J.; Zhang, G. Flexible Polydimethylsilane Nanocomposites Enhanced with a Three-Dimensional Graphene/Carbon Nanotube Bicontinuous Framework for High-Performance Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2018, 10, 26723–26732. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.; Cheng, Q.; Yu, C.; Pan, X.; Zuo, X.; Liu, J.; Chen, M.; Li, W.; Li, Q.; Liu, L. Flexible Fe3O4/graphene foam/poly dimethylsiloxane composite for high-performance electromagnetic interference shielding. Compos. Sci. Technol. 2020, 189, 108012. [Google Scholar] [CrossRef]

- Das, A.; Boldt, R.; Jurk, R.; Jehnichen, D.; Fischer, D.; Stockelhuber, K.W.; Heinrich, G. Nano-scale morphological analysis of graphene-rubber composites using 3D transmission electron microscopy. RSC Adv. 2014, 4, 9300–9307. [Google Scholar] [CrossRef]

- Xu, Z.; Song, Y.; Zheng, Q. Payne effect of carbon black filled natural rubber compounds and their carbon black gels. Polymer 2019, 185, 121953. [Google Scholar] [CrossRef]

- Montes, H.; Lequeux, F.; Berriot, J. Influence of the Glass Transition Temperature Gradient on the Nonlinear Viscoelastic Behavior in Reinforced Elastomers. Macromolecules 2003, 36, 8107–8118. [Google Scholar] [CrossRef]

- Ponnamma, D.; Sadasivuni, K.K.; Strankowski, M.; Guo, Q.; Thomas, S. Synergistic effect of multi walled carbon nanotubes and reduced graphene oxides in natural rubber for sensing application. Soft Matter 2013, 9, 10343–10353. [Google Scholar] [CrossRef]

- Funt, J. Dynamic testing and reinforcement of rubber. Rubber Chem. Technol. 1988, 61, 842–865. [Google Scholar] [CrossRef]

- Heinrich, G.; Klüppel, M. Recent advances in the theory of filler networking in elastomers. In Filled Elastomers Drug Delivery Systems; Springer: Berlin/Heidelberg, Germany, 2002; pp. 1–44. [Google Scholar]

- Wei, Z.J.; Cai, Y.F.; Zhan, Y.H.; Meng, Y.Y.; Pan, N.; Jiang, X.C.; Xia, H.S. Ultra-Low Loading of Ultra-Small Fe3O4 Nanoparticles on Nonmodified CNTs to Improve Green EMI Shielding Capability of Rubber Composites. Small 2023, 2307148. [Google Scholar] [CrossRef]

- Zhan, Y.H.; Santillo, C.; Meng, Y.Y.; Lavorgna, M. Recent advances and perspectives on silver-based polymer composites for electromagnetic interference shielding. J. Mater. Chem. C 2023, 11, 859–892. [Google Scholar] [CrossRef]

- Wei, Z.; Cai, Y.; Xie, Z.; Meng, Y.; Zhan, Y.; Hu, X.; Xia, H. Green electromagnetic interference shielding films with unique and interconnected 3D magnetic/conductive interfaces. Appl. Surf. Sci. 2023, 636, 157841. [Google Scholar] [CrossRef]

| Hybrid Fillers | Rubber Matrix | Preparation Methods | Improved Properties | Application | Year and Reference |

|---|---|---|---|---|---|

| GNPs/CB | SR | Solution mixing | Electrical conductivity and piezoresistivity | Piezoresistive sensors | 2014 [33] |

| GO/CB, rGO/CB | NR | Preparing the GO/NR and rGO/NR composites based on latex mixing, followed by mechanical mixing with CB and rubber | Static and dynamic mechanical properties, flex cracking resistance | 2015 [35] | |

| rGO/CB | SBR | Solution mixing to initially prepare the rGO/CB, followed by mechanical mixing with SBR | Electrical conductivity and tensile properties | 2015 [34] | |

| l-GFs/CB, GO/CB | SBR | Preparing the masterbatch using latex mixing, followed by mechanical mixing with CB and rubber | Mechanical, thermal, electrical, and gas barrier properties | 2015 [46] | |

| GNPs/CB | SR | Solution mixing | Electrical and mechanical performance | Flexible pressure sensor | 2015 [47] |

| MLG/CB | CIIR | Preparing the MLG/rubber masterbatch using latex mixing, followed by mechanical mixing with CB and rubber | Mechanical properties and weathering resistance | 2016 [45] | |

| GNPs/CB | EPDM | Mechanical mixing | Thermal conductivity, damping properties, and mechanical properties | 2016 [36] | |

| GF/CB | PDMS | Solution mixing | Thermal conductivity and storage modulus | 2016 [49] | |

| GNPs/CB | SR | Solution mixing | Sensitivity, stability, and compressibility | Piezoresistive sensors | 2017 [56] |

| GO/CB | NR | Preparing the GO/NR masterbatch initially by latex mixing firstly and then performing mechanical mixing with CB and rubber | Dynamic and static mechanical properties, heat buildup | 2017 [48] | |

| GNPs/CB | NBR | Solution mixing | Mechanical properties, electrical properties, and thermal stability | 2017 [37] | |

| GE/CB GE/SiO2 | ENR | Mechanical mixing | Dynamic properties and wet grip | 2017 [58] | |

| GE/CB | NR | Mechanical mixing of the GE/NR masterbatch with CB and NR | Reduce heat build-up, accelerate aging and lifetime | 2018 [39] | |

| GNPs/CB | SR | Solution mixing | Electrical conductivity and sensing property | Strain sensor | 2018 [40] |

| GNPs/CB | SR | Solution mixing with GNPs/CB, prefoamed, and solution mixing again with SR | Decrease percolation threshold and improve electrical conductivity | Robotic sensory systems and real-time wearable health monitoring devices | 2018 [50] |

| rGO/CB | NR | Wet compounding process, combined with ultrasonically assisted latex mixing | Hardness, thermal conductivity, and anti-aging properties | 2018 [41] | |

| GO/CB | NR | Preparing the GO/NR masterbatch by latex mixing, followed by mechanical mixing with CB and rubber | Strain-induced crystallization, modulus at 100% strain, tear strength, fatigue, and durability | 2020 [42] | |

| GO/CB, rGO/CB, and mGO/CB | NR | Solution mixing | Fatigue resistance and dynamic mechanical property | 2020 [43] | |

| GE/CCB | SR | Solution mixing followed by mechanical mixing | Deformation recovery properties and electrical conductivity | Strain sensor | 2021 [57] |

| GE/CB | SBR | Latex mixing | Mechanical property, specific capacitance, and magnetic hysteresis at room temperature with fairly low remnant magnetization | 2021 [44] | |

| GE/CB | SBR | Mechanical mixing | Tensile strength, modulus, and abrasion resistance | 2023 [51] | |

| GO/CBp | NR | Mechanical mixing | Decrease the metal wear | 2023 [59] |

| Hybrid Fillers | Rubber Matrix | Preparation Methods | Rubber Performance | Application | Year and Reference |

|---|---|---|---|---|---|

| rGO/SiO2 | SBR | Electrostatic self-assembly | Mechanical properties, high wet-grip property, and low rolling resistance | Green tire materials | 2016 [3] |

| mGO/SiO2 | SSBR | Electrostatic self-assembly | Higher retention ratio of elongation and strength, resist ozone attacking. | 2016 [78] | |

| GO/SiO2 | SR | Sol–gel method to prepare GO/SiO2 hybrid fillers firstly, followed by mechanical mixing with SR | Mechanical property | 2016 [81] | |

| rGO/SiO2 | SR | Using the sol–gel method to prepare rGO/SiO2 hybrid fillers, followed by mechanical mixing with SR | Mechanical and thermal performances | 2017 [82] | |

| rGO/mesoporous silica | SBR | Preparing the rGO/mesoporous silica hybrid fillers using the electrostatic self-assembly method, followed by mixing with SBR | Thermal conductivity | 2017 [72] | |

| GO/SiO2 | SBR | Preparing the GO/NR masterbatch by latex mixing, followed by mechanical mixing with silica and other agents | Mechanical properties and fatigue lifetimes | 2017 [62] | |

| GO/SiO2 | SBR | Preparing the SiO2/GO hybrid fillers using the electrostatic self-assembly method, followed by solution mixing with SBR | Mechanical, dielectric, and thermal properties | 2017 [77] | |

| GO/SiO2 | NBR | Using solution mixing to prepare the GO/SiO2 hybrid fillers, followed by solution mixing with NBR | Mechanical properties and elasticity | 2018 [68] | |

| mGO/SiO2 | NR | Preparing the mGO/SiO2 hybrid fillers using the hydrogen-bonding self-assembly method, followed by mechanical mixing with NR | Thermal property, tensile Strength, and tear strength | 2018 [79] | |

| GO/mSiO2 | NR | Latex mixing | Tensile and tear strengths | 2018 [71] | |

| GE/SiO2 | NR | The SiO2 particles were uniformly decorated on the surface of graphene using the the Michael addition reaction firstly, and then mechanical mixing with NR | Tensile strength, tear strength compression set, thermal conductivity, and abrasive resistant capacity | 2018 [86] | |

| GO/SiO2 | NR | Spray sputtering drying method, dry-ice expansion pre-dispersion method, and mechanical stirring method | Tensile strength, tear strength, and wear resistance | 2018 [69] | |

| mGO/SiO2 | SBR | Preparing the mGO firstly; mixing the latex with silica secondly; mechanically mixing with other additives in Banbury mixer finally | Dry and wet braking and rolling resistance | Green tires | 2018 [90] |

| mGO/mSiO2 | SBR | Preparing the mGO, followed by latex mixing with modified silica and SBR | Mechanical properties and thermal conductivity | Tire Products | 2019 [91] |

| mGO/mSiO2 | NR | Chemical reaction method was used to prepare mGO/mSiO2, followed by latex mixing with NR | Wear resistance, wet-skid resistance, and decreases the rolling resistance | Green tire-tread | 2019 [80] |

| rGO/SiO2 | SR | Sol–gel method was used to prepare rGO/SiO2 hybrid fillers, followed by solution mixing with SR | Thermal stability, mechanical properties, and thermal conductivity | 2019 [66] | |

| mGO/mSiO2 | NR | Preparing the H-bonded mSiO2/mGO hybrid fillers, followed by latex mixing with NR | High-grip performance, superior rolling, and wear resistance | Tire-tread | 2019 [80] |

| GO/SiO2 | SBR | Preparing the SiO2-GO hybrid nanofillers by in situ hydrolysis and condensation of tetraethyl orthosilicate on the surface of GO nanosheets, followed by latex mixing with SBR | Mechanical property and thermal conductivity | 2019 [70] | |

| GO/SiO2 | Devulcanized NR/SBR | Mechanical mixing | Tensile strength, higher storage modulus, and lower tan δ | 2019 [67] | |

| GO/SiO2 | SR | The SiO2 nanoparticles were coated on the surface of GO by sol–gel method, followed by solution mixing with PDMS to obtain the composites | Thermal stability, mechanical properties, and thermal conductivity | 2019 [66] | |

| rGO/SiO2 | NR | Wet compounding and latex mixing process using a novel interface modifier cystamine dihydrochloride | Mechanical property and low water vapor permeability | 2020 [65] | |

| GO/SiO2 | SBR | Mechanical mixing | Mechanical property, lowest crack growth rate, and longer fatigue lives | 2020 [92] | |

| GO/mSiO2 | NR | Bridging GO and nanosilica by covalent bonding, followed by latex mixing with NR | Tensile strength, covalent bridging, and orientations of chain segments in interfacial regions | 2020 [85] | |

| GO/SiO2 | NR | Preparing the SiO2@GO using the sol–gel method, followed by mechanical mixing with NR | Crosslink Density and storage modulus in all temperature range | compressive or abrasive applications | 2020 [64] |

| GNs/SiO2 | NR | Preparing the GNs/NR masterbatch by latex mixing, followed by mechanical mixing with silica and rubber | Thermal conductivity and antistatic property | 2021 [63] | |

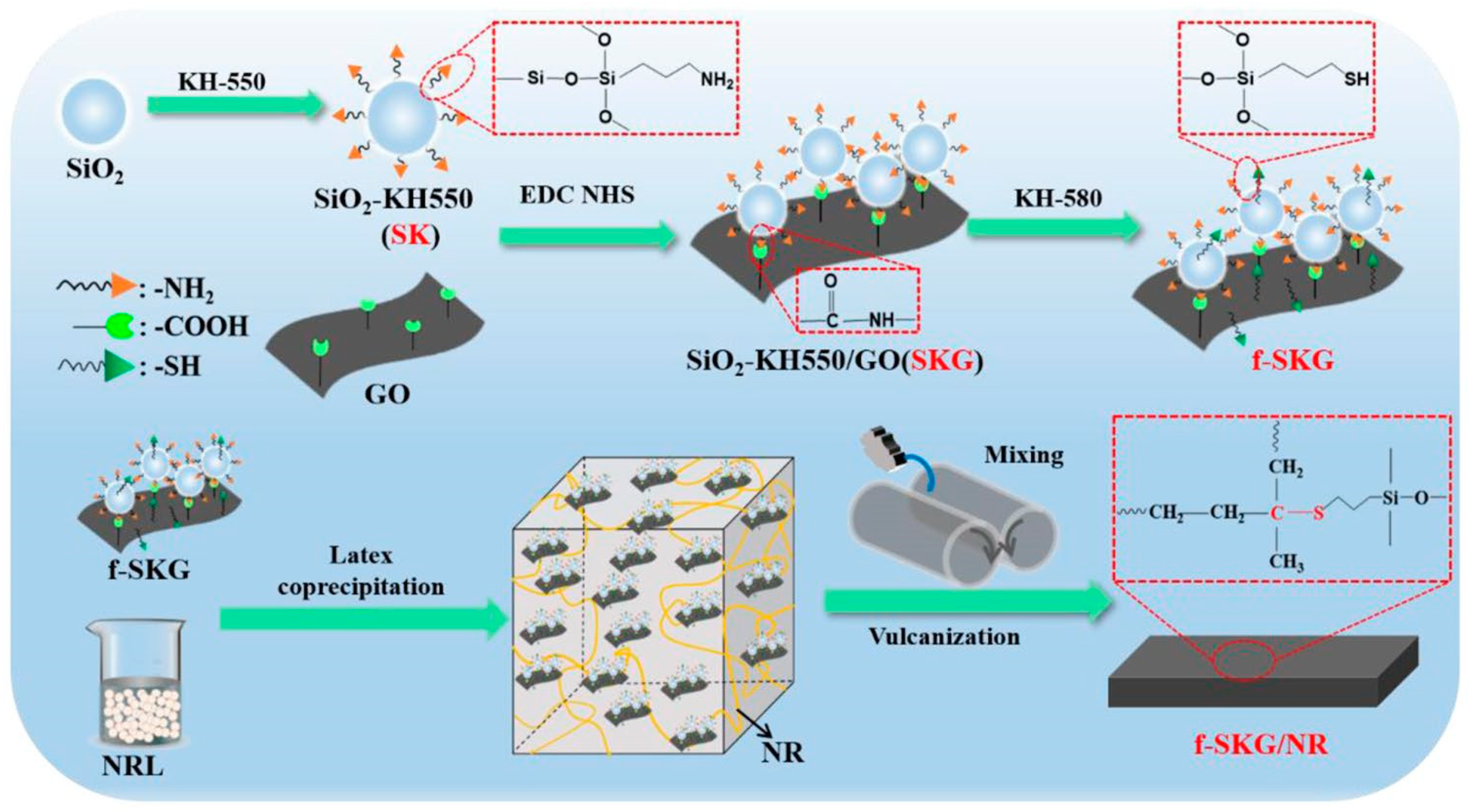

| GO/mSiO2 | NR | Preparing the mSiO2-KH550/GO hybrid fillers by solution mixing and freeze-drying process, followed by mixing with NR by latex co-precipitation method | Mechanical properties, low heat generation performance, and thermal conductivity | Tire rubber | 2022 [84] |

| GE/Paraffin@SiO2 | SR | Mechanical mixing | Thermal conductivity | Passive thermal regulation | 2022 [89] |

| mGO/SiO2 | SSBR | Preparing the mGO/SSBR masterbatch by latex mixing, followed by mechanical mixing with silica and rubber | Rolling resistance, wet skid, and abrasion resistances | green tire | 2023 [73] |

| GNPs/paraffin@SiO2 | SR | Solution mixing and met blending | Mechanical property, thermal conductivity, and low leakage rate | Thermal storage | 2023 [88] |

| rGO/NSi | NR | Mechanical mixing | Decrease the heat build-up and Akron abrasion loss, increase the mechanical property | Green tire | 2023 [93] |

| Hybrid Fillers | Rubber Matrix | Preparation Methods | Improved Properties | Application | Year and Reference |

|---|---|---|---|---|---|

| GE/MWNTs | SR | Solution mixing | Electrical property | 2012 [109] | |

| GE/MWCNTs | PDMS | Using organic sol–gel chemistry method to prepare GE/MWCNT aerogel, followed by backfilling PDMS to obtain the composites | Mechanical property and electrical conductivity | 2013 [118] | |

| GE/MWCNTs | SR | Solution mixing | Tensile strength, Young’s modulus, crosslink density, thermal stability, and solvent resistance | 2014 [112] | |

| rGO/CNT | PDMS | CNTs were in situ formed on a reduced graphene sheet by the catalytic growth procedure, followed by solution mixing with PDMS to obtain the composites | Lower interfacial contact electrical resistance and absorbing EM power | 2014 [113] | |

| GE/CNTs | NR | Latex mixing | Fracture toughness and tensile strength, also suppresses the crack growth | 2015 [100] | |

| GNPs/MWCNTs | EPDM | Mechanical mixing | Electrical conductivity, tensile strength, Young’s modulus, and tear strength | 2015 [101] | |

| GE/CNTs | PDMS | Mechanical mixing | Cyclic adhesion and electrical conductivity | Conductive dry adhesives | 2016 [116] |

| GE/CNTs | PDMS | Solution mixing | Electrical conductivity | Stretchable conductors | 2016 [111] |

| GF/CNTs | PDMS | PDMS and CNTs solutions were deposited onto the surface of GF/Ni foam, followed by etching the Ni skeleton to obtain the composites | Electrical conductivity and EMI SE | 2017 [119] | |

| GNPs/CNTs | SR | Simultaneous reactions of beer’s yeast fermentation and the gelation of liquid SR mixed with GNPs and CNTs | Stretchability, and damage resistance with reduced density | Bionic composites | 2017 [98] |

| rGO/MWCNTs | NBR | Mechanical mixing | Mechanical strength, electrical conductivity, and decreased ice adhesion strength | 2018 [97] | |

| GE/CNTs | NBR | Mechanical mixing | Icephobic surface | Components that need to survive in extreme cold environments | 2019 [99] |

| rGO/CNT | SBR | Preparing the rGO-CNT hybrids firstly; mixing the latex with SBR secondly; using freeze-drying to obtain the composite foam finally | Electrical conductivity and stretchable performance | 2019 [102] | |

| GE/CNT | SR | Solution mixing | Sensing property | 2019 [105] | |

| GE/CNTs | SR | Solution mixing | Electrical conductivity, optical transmittance, and mechanical adhesion | 2019 [96] | |

| rGO/MWCNT | CR | Solution mixing to prepare the hybrid fillers, followed by mechanical mixing with CR | Thermal stability, dielectric conductivity, and high energy storage efficiency | Electronic devices | 2020 [117] |

| rGO/ MWCNTs | PDMS | Using the freeze-casting method to prepare 3D rGO/MWCNTs foam, followed by impregnating liquid PDMS into the hybrid foam | Thermal conductivity compressive strength and electromagnetic interference shielding effectiveness | Carbon-based electromagnetic shielding materials | 2020 [120] |

| GE/CNTs | SR | Solution mixing | Reduced the percolation threshold and enhancing strain sensing | 2020 [103] | |

| rGO/CNT | NR | Latex mixing | Electrical conductivity and mechanical property | 2020 [104] | |

| rGO/ MWCNTs | SR | Preparing the 3D rGO/MWCNTs aerogel, followed by solution mixing with SR | Thermal conductivity, electric conductivity, and EMI SE | Flexible electronic devices | 2021 [28] |

| GO/MWCNTs | IIR | Latex mixing with ice expansion and pre-dispersion flocculation method | Thermal conductivity | 2022 [114] | |

| GO/CNT | Waste silicone rubber | Solution mixing followed by freeze-drying | Mechanical properties, electrical and thermal conductivity, and detection range | Wearable sensors and electronic skin | 2022 [121] |

| GE/PNTs | EPDM | Mechanical mixing | Ablation performance and mechanical property | High performance ablative materials | 2022 [106] |

| GE/CNTs | NBR | Emulsification and mechanical blending | Wear performance | 2022 [107] | |

| rGO/CNT | NR | Solution and latex mixing | Strain sensing properties | Wearable electronic device | 2022 [108] |

| Hybrid Fillers | Rubber Matrix | Preparation Methods | Improved Properties | Application | Year and Reference |

|---|---|---|---|---|---|

| GE/NZG | NR | Using the solvothermal method to prepare the GE/NZG hybrid fillers, followed by mechanical mixing with NR | Mechanical performance and gas barrier properties | 2015 [139] | |

| GE/ZnO | NR | Preparing ZnO–GE using the sol–gel method, followed by mechanical mixing with NR | Mechanical property, wet-grip property, and rolling resistance | 2015 [138] | |

| GO/Fe3O4 | NR | Latex mixing | Corrosion resistance and flexible anticorrosive properties | 2017 [132] | |

| rGO/Fe3O4 | NR | Latex mixing | Magnetic property and EMI SE | 2018 [26] | |

| GnPs/S-Al2O3 | SR | Solution mixing | Thermal conductivity, tensile strength, and low density | Heat dissipation of light-emitting diode | 2018 [141] |

| GO/ZnO | CR | Preparing the GO/ZnO by electrostatic adsorption and the in situ growth method, followed by mechanical mixing with CR to obtain the composites | Crosslinking efficiency and density, tensile modulus at 300% elongation, and tensile strength | 2019 [137] | |

| GE/CeO2 | PMVQ | Solution mixing | Thermal stability and mechanical properties | 2019 [144] | |

| rGO/Al2O3 | NR | Preparing rGO/Al2O3 using the electrostatic self-assembly method, followed by latex mixing with NR | Thermal conductivity | 2020 [142] | |

| rGO/mAl2O3 | NR | Solution mixing | Thermal conductivity, mechanical properties, and electrical insulation | Electronic packaging materials | 2021 [143] |

| FLG/Fe3O4, FLG/TiO2 | SR | Solution mixing | Mechanical, actuation, and magnetic properties | Magnetic sensor | 2021 [145] |

| rGO/Fe3O4 | SR | Preparing the rGO@Fe3O4 nanocomposites using the thermal decomposition method, followed by mechanical mixing with SR | High microwave-absorption efficiency and wide absorption bandwidth. | Aerospace and flexible electronics | 2021 [133] |

| GON/Fe3O4 | PVDF-SBR | Preparing the PVDF-SBR/GON and PVDF-SBR/Fe3O4 masterbatch using the solution mixing method, followed by mechanical mixing with two masterbatches and PVDF-SBR to obtain the composites | Thermal, mechanical, rheological, electrical, and magnetic properties | 2021 [135] | |

| rGO/Fe3O4 | NR | Latex mixing | EMI-shielding stability under tensile permanent deformation, cyclic stretching, and cyclic bending; sensing properties | Wearable electronic flexibility devices | 2021 [27] |

| rGO/Fe3O4 | SR | Using hydrothermal and freeze-drying processes to prepare rGO/Fe3O4 hybrid fillers, followed by solution mixing with SR | Microwave-absorbing properties | 2022 [146] | |

| MLG/Fe3O4 | NR | Solvent mixing | Mechanical and magnetic properties | 2022 [134] | |

| rGO/Fe3O4 | ENR | In situ reduction with latex mixing | Mechanical, electrical conductivity, magnetic, and sensing properties | 2022 [147] | |

| GE/ZnO | XNBR | Mixing GE and XNBR latex in a ball-mill tank, followed by mechanical mixing with ZnO | Electrical conductivity, mechanical property, and microwave absorption | 2022 [140] | |

| GE/Al2O3 | SR | Mechanical mixing | Nonlinear electrical conductivity, thermal conductivity | Cable accessory | 2023 [148] |

| Hybrid Fillers | Rubber Matrix | Preparation Methods | Improved Properties | Application | Year and Reference |

|---|---|---|---|---|---|

| rGO/CNC | NR | Preparing the rGO/CNC hybrid fillers by solution mixing, followed by latex mixing with NR | Electric conductivity and mechanical properties | Sensing materials with superior resistivity responses for organic liquids | 2016 [164] |

| GA/AGNWs | PDMS | Preparing the GA using the hydrothermal reduction and freeze-drying process, followed by solution mixing with AgNWs and PDMS to obtain the composites | Electrical conductivity | Skin patch sensors and wearable electronic devices | 2017 [149] |

| rGO/AgNWs | PDMS | Preparing the rGO/AgNWs hybrid fillers using the sol–gel method with the freeze-drying process, followed by backfilling PDMS into the hybrid filer to obtain the composites | EMWs absorption, good compression, excellent thermal stability, and flame-retardant properties | 2019 [150] | |

| GE/CNF | NR | Using solution mixing to prepare the hybrid fillers, followed by latex mixing with NR to obtain the composites | Mechanical property and electrical conductivity | 2019 [162] | |

| GNPs/cobalt nanowire | NR | Mechanical mixing | Tensile strength, tear strength, microwave shielding ability, and magnetic property | 2020 [156] | |

| rGO/SiCNWs | SR | Solution mixing to prepare hybrid fillers, ice-templated assembly of hybrid fillers, and then infiltrated with the SR to obtain the composites | Thermal conductivity | 2020 [155] | |

| Graphene fibers/magnetic microwires | SR | Solution mixing | EMI SE and microwave reflectivity | 2020 [161] | |

| rGO/CNF | NBR | Pickering emulsion and the hot-pressing method | EMI SE and EMI SE stability | Piezoresistive Sensor | 2021 [154] |

| GE/ANFs | NR | Using the solution mixing method to prepare the GE/ANF hybrid fillers, followed by mechanical mixing with NR | Enhanced mechanical interlocking and stress transfer between fiber and rubber | 2021 [163] | |

| rGO aerogels/Cellulose carbon aerogel | PDMS | Preparing cellulose carbon aerogel @rGO aerogels by vacuum impregnation, freeze-drying, and thermal annealing, followed by backfilling PDMS to obtain the composites | EMI SE, thermal stability, and thermal conductivity | 2021 [159] | |