Effect of Coriander Seed Addition at Different Stages of Brewing on Selected Parameters of Low-Alcohol Wheat Beers

Abstract

1. Introduction

2. Results

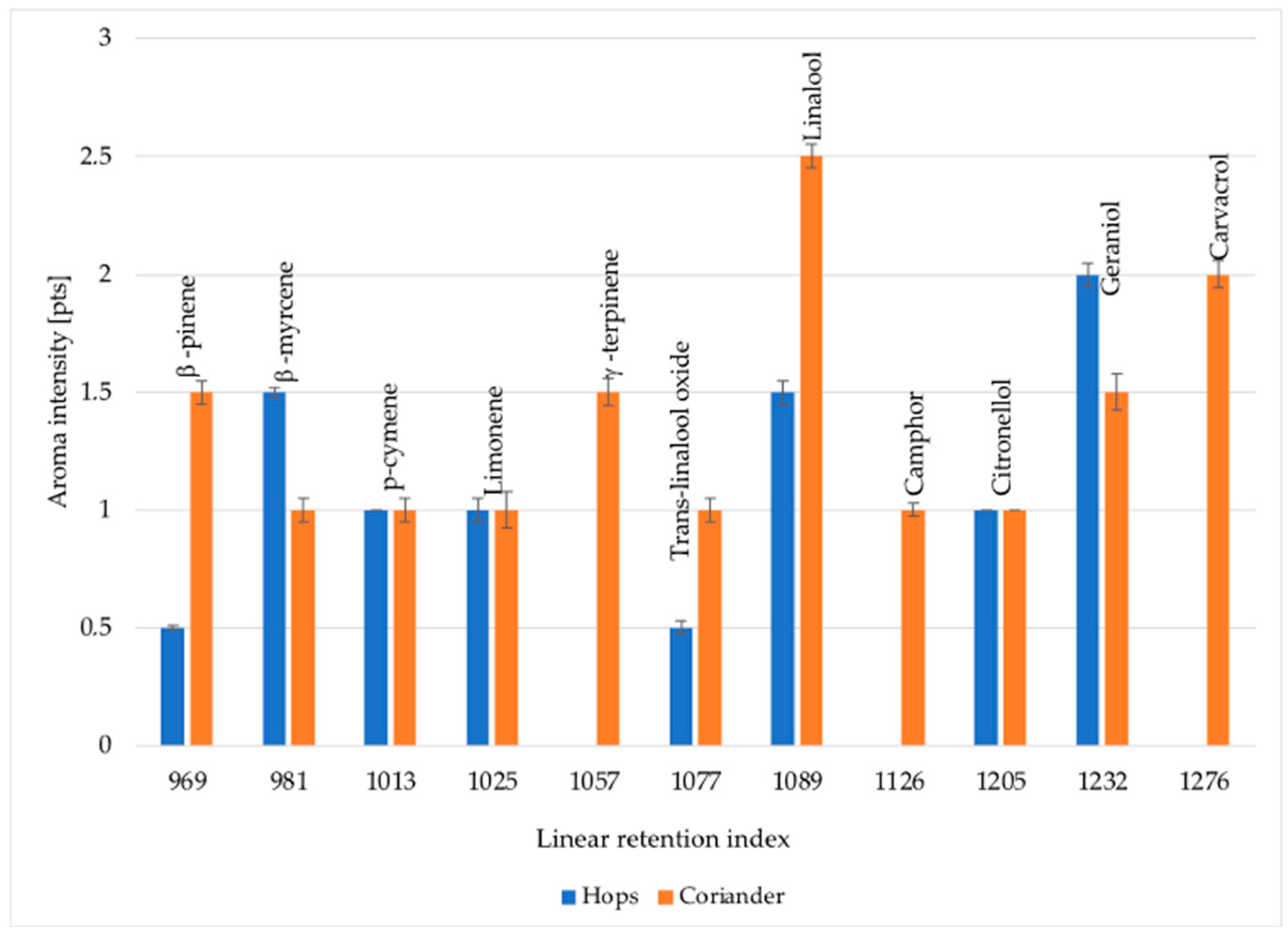

2.1. Characteristics of Raw Materials—The Key Aroma Compounds of Coriander Seeds and Hops

2.2. The Fermentation Kinetics and Physicochemical Parameters of the Obtained Beers

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Beer Production

4.2.1. Milling, Mashing, and Lautering

4.2.2. Boiling

4.2.3. Fermentation Trials

4.3. Analytical Determinations

4.3.1. The International Bitterness Unit (IBU)

4.3.2. Ethanol and Real Extract

4.3.3. The pH of the Obtained Wort and Beer

4.3.4. The Color of the Obtained Wort and Beer

4.3.5. The Turbidity of the Obtained Wort and Beer

4.3.6. Antioxidant Activity (AOX)

4.3.7. Sugar Analysis Using a High-Performance Liquid Chromatograph (HPLC)

4.3.8. Odor-Active Volatile Components (HS-SPME-GC-O)

4.3.9. Analysis of Volatile Compounds Using HS-SPME-GC-MS

4.3.10. Sensory Assessments

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De Francesco, G.; Turchetti, B.; Sileoni, V.; Marconi, O.; Perretti, G. Screening of new strains of Saccharomyces ludwigii and Zygosaccharomyces rouxii to produce low-alcohol beer. J. Inst. Brew. 2015, 121, 113–121. [Google Scholar] [CrossRef]

- Gould, K. “Functional Beverages” Are the Trend That Everyone’s Going to Be Talking about. Available online: https://www.forbes.com/sites/kennygould/2019/04/28/functional-beverage-beer/#7c43dd553910 (accessed on 20 November 2023).

- Hayward, L.; Wedel, A.; McSweeney, M.B. Acceptability of beer produced with dandelion, nettle and sage. Inst. J. Gastrom. Food Sci. 2009, 18, 100180. [Google Scholar] [CrossRef]

- Bellut, K.; Arendt, E.K. Chance and Challenge: Non-Saccharomyces Yeasts in Nonalcoholic and Low Alcohol Beer Brewing—A Review. J. Am. Soc. Brew. Chem. 2019, 77, 77–91. [Google Scholar] [CrossRef]

- Belcar, J.; Buczek, J.; Kapusta, I.; Gorzelany, J. Quality and Pro-Healthy Properties of Belgian Witbier-Style Beers Relative to the Cultivare of Winter Wheat and Raw Materials Used. Foods 2022, 11, 1150. [Google Scholar] [CrossRef]

- Byeon, Y.S.; Lim, S.-T.; Kim, H.-J.; Kwak, H.S.; Kim, S.S. Quality Characteristics of Wheat Malts with Different Country of Origin and Their Effect on Beer Brewing. J. Food Qual. 2021, 2021, 2146620. [Google Scholar] [CrossRef]

- Rosul, M.D.; Mandić, A.I.; Misan, A.C.; Derić, N.R.; Pejin, J.D. Review of trends in formulation of functional beer. Food Feed Res. 2019, 46, 23–25. [Google Scholar] [CrossRef]

- He, G.; Du, J.; Zhang, K.; Wei, G.; Wang, W. Antioxidant capability and potableness of fresh cloudy wheat beer stored at different temperatures. J. Inst. Brew. 2012, 118, 386–392. [Google Scholar] [CrossRef]

- Dordević, S.; Popovic, D.; Despotovic, S.; Veljovic, M.; Atanackovic, M.; Cvejic, J.; Nedovic, V.; Leskosek-Cukalovic, I. Extracts of medicinal plants as functional beer additives. Chem. Ind. Chem. Eng. Q. 2016, 22, 301–308. [Google Scholar]

- Leal de Sousa, C.; Suelane Maia da Costa, L.; Ferreira, L.P.; Silva, K.J.S.; Azevedo, M.M.R.; Bressan, C.R.; Gul, K.; Malik, S.; Taube, P.T. Witiber craft beer with added acerola pulp (Malpighia emarginata): Characterization and analysis. Res. Sq. 2023. [Google Scholar]

- Spence, C. Coriander (cilantro): A most divisive herb. Int. J. Gastron. Food Sci. 2023, 33, 100779. [Google Scholar] [CrossRef]

- ISO 3516; Oil of Coriander. International Organization for Standarization: Geneva, Switzerland, 1980.

- Ravi, R.; Praksah, M.; Bhat, K.K. Aroma characterization of coriander (Coriandrum sativum L.) oil samples. Eur. Food Res. Technol. 2007, 225, 367–374. [Google Scholar] [CrossRef]

- Shahwar, M.K.; El-Ghorab, A.H.; Anjum, F.M.; Butt, M.S.; Hussain, S.; Nadeem, M. Characterization of Coriander (Coriandrum sativum L.) Seeds and Leaves: Volatile and Non-Volatile Extracts. Int. J. Food Prop. 2012, 15, 736–747. [Google Scholar] [CrossRef]

- Dhankar, S.; Kaur, R.; Ruhil, S.; Balhara, M.; Dhankhar, S.; Chhillar, A.K. A review on Justicia adhatoda. A potential source of natural medicine. Afr. J. Plant Sci. 2011, 5, 620–627. [Google Scholar]

- Takoi, K.; Itoga, Y.; Koie, K.; Kosugi, T.; Shimase, M.; Katayama, Y.; Nakayama, Y.; Watari, J. The Contribution of Geraniol Metabolism to the Citrus Flavour of Beer: Synergy of Geraniol and β-Citronellol Under Coexistence with Excess Linalool. J. Inst. Brew. 2010, 116, 251–260. [Google Scholar] [CrossRef]

- Burdock, G.A. Fenaroli’s Handbook of Flavor Ingredients; CRC Press: Boca Raton, FL, USA, 2005; ISBN 0849330343. [Google Scholar]

- Gugino, J.M.; Vincenzo, A.; Mansour, R.A.; Ombretta, M.; Pirrone, A.; Nicola, F.; Cinotta, F.; Verzera, A.; Todaro, A. Maiorca wheat malt: A comprehensive analysis of physicochemical properties, volatile compounds, and sensory evaluation in brewing process and final product quality. Food Chem. 2024, 435, 137517. [Google Scholar] [CrossRef] [PubMed]

- Paszkot, J.; Gasiński, A.; Kawa-Rygielska, J. Evaluation of volatile compound profiles and sensory properties of dark and pale beers fermented by different strains of brewing yeast. Sci. Rep. 2023, 13, 6725. [Google Scholar] [CrossRef] [PubMed]

- Habschied, K.; Zivković, A.; Krstanović, V.; Mastanjević, K. Functional Beer—A Review on Possibilities. Beverages 2020, 6, 51. [Google Scholar] [CrossRef]

- Branyik, T.; Silva, D.P.; Baszczynski, M.; Lehnert, R.; Almeida e Silva, J.B. A review of methods of low alcohol and alcohol-free beer production. J. Food Eng. 2012, 108, 493–506. [Google Scholar] [CrossRef]

- Muller, R.E. The effects of mashing temperature and mash thickness on wort carbohydrate composition. J. Inst. Brew. 2000, 97, 85–92. [Google Scholar] [CrossRef]

- Zdanieiwcz, M.; Pater, A.; Hrabia, O.; Duliński, R.; Cioch-Skoneczny, M. Tritordeum malt: An innovative raw material for beer production. J. Cell. Sci. 2020, 96, 103095. [Google Scholar]

- Van Iersel, M.F.M.; Van Dieren, B.; Rombouts, F.M.; Abbe, T. Flavor formation and cel physiology during the production of alcohol-free beer with immobilized Saccharomyces cerevisiae. Enzyme Microb. Technol. 1999, 24, 407–411. [Google Scholar] [CrossRef]

- Dziedziński, M.; Stachowiak, B.; Kobus-Cisowska, J.; Faria, M.A.; Ferreira, I.M.P.L.V.O. Antioxidant, sensory, and functional properties of low-alcoholic IPA beer with Pinus sylvestris L. shoots addition fermented using unconventional yeast. Open Chem. 2023, 21, 2022036. [Google Scholar] [CrossRef]

- Yang, G.; Nie, C.; Zhang, H.; Sun, S.; Wang, X.; Zhang, J.; Xu, H.; Liu, J. The tolerance of brewing-related microorganisms to isomerized hop products and the effect on beer stability and quality. Eur. Food Res. Technol. 2021, 247, 555–567. [Google Scholar] [CrossRef]

- Mendoza, D.G.; Camacho, O.T.; Trujillo, V.M. Determination of antioxidant activity and phenolic compounds in different Mexican craft beers. Rev. Colomb. Investig. Agroindustriales 2022, 9, 46–54. [Google Scholar] [CrossRef]

- Lin, H.-H.; Lin, K.-H.; Yang, M.-J.; Nguyen, H.C.; Wang, H.-J.; Huang, H.-X.; Huang, M.-Y. Physiological responses and antioxidant properties of coriander plant (Coriandur sativum L.) under different light intensities of red and blue lights. Sci. Rep. 2022, 12, 21139. [Google Scholar] [CrossRef] [PubMed]

- Mannaa, M.; Han, G.; Seo, Y.-S.; Park, I. Evaluation of Food Fermentation Processes and the Use of Multi-Omics in Deciphering the Roles of the Microbiota. Foods 2021, 10, 2861. [Google Scholar] [CrossRef] [PubMed]

- Wajda, Ł.; Januszek, M. The application of Solid State Fermentation for Obtaining Substances Useful in Healthcare. In Biotehnological Applications Biomass; IntechOpen: London, UK, 2020. [Google Scholar]

- Blanco, C.A.; Andres-Iglesias, C.; Monero, O. Low-alcohol beers: Flavor compounds, defects and improvement strategies. Food Sci. Nutr. 2013, 56, 1379–1388. [Google Scholar] [CrossRef]

- Saison, D.; Schutter, D.P.; Delvaux, F.; Delvaux, F.R. Determination of carbonyl compounds in beer by derivatization and headspace solid-phase microextraction in combination with gas chromatography and mass spectrometry. J. Chromatogr. A. 2009, 1216, 5061–5068. [Google Scholar] [CrossRef]

- Faltermaier, A.; Waters, D.; Becker, T.; Arendt, E.; Gastl, M. Common wheat (Triticum aestivum L.) and its use as a brewing cereal—A review. J. Inst. Brew. 2014, 120, 1–15. [Google Scholar] [CrossRef]

- Rettberg, N.; Biendl, M.; Garbe, L.A. Hop aroma and hoppy beer flavor: Chemical backgrounds and analytical tools: A review. J. Am. Soc. Brew. Chem. 2018, 76, 1–20. [Google Scholar] [CrossRef]

- Jeleń, H.H.; Marcinkowska, M.A.; Marek, M. Determination of Volatile Terpenes in Coriander Cold Pressed Oil by Vacuum Assisted Sorbent Extraction (VASE). Molecules. 2021, 26, 884. [Google Scholar] [CrossRef]

- Tettnang Hops. Available online: https://yakimavalleyhops.com/products/tettnang-hop-pellets (accessed on 20 November 2023).

- Dickinson, J.R. Terpenoids in Beer. Beer Compos. Prop. 2009, 31, 327–332. [Google Scholar]

- Fritsch, H.T.; Schieberle, P. Identification based on quantitative measurements and aroma recombination of the character impact odorants in a Bavarian Pilsner-type beer. J. Agric. Food Chem. 2005, 53, 7544–7551. [Google Scholar] [CrossRef] [PubMed]

- Praet, T.; Van Opstaele, F.; Jaskula-Goiris, B.; Aerts, G.; De Cooman, L. Biotransformations of hop-derived aroma compounds by Saccharomyces cerevisiae upon fermentation. Cerevisia 2012, 36, 125–132. [Google Scholar] [CrossRef]

- Johnson, L.A.; Lusas, E.W. Comparision of Alternative Solvents for Oils Extraction. JAOCS 1983, 60, 229–242. [Google Scholar] [CrossRef]

- Takoi, K.; Ong, P.K.C.; Acree, T.E. Gas chromatography/olfactory analysis of lychee (Litchi chinesis Sonn). J. Agric. Food Chem. 1998, 46, 2282–2286. [Google Scholar]

- Ong, P.K.C.; Acree, T.E. Similarities in the aroma chemistry of Gewürztraminer variety wines and lychee (Litchi chinesis Sonn). fruit. J. Agric. Food Chem. 1999, 47, 665–670. [Google Scholar] [CrossRef]

- Peacock, V.E.; Deinzer, M.L.; Likens, S.T.; Nickerson, G.B.; McGill, L.A. Floral hop aroma in beer. Agric. Food Chem. 1981, 29, 1265–1269. [Google Scholar] [CrossRef]

- Parker, D.K.; Campden, B.R.I. Beer: Production, Sensory Characteristics and Sensory Analysis; Woodhead Publishing Limited: Cambridge, UK, 2012; Volume 6, pp. 133–158. [Google Scholar]

- Kolbach, P.; Wilharm, G. Hop addition to the mash. Wkly. Mag. Brew. 1943, 60, 66–67. [Google Scholar]

- Schur, F.; Pfenninger, H. Semi-continuous wort preparation—Mash hopping. Swiss Brew. Rev. 1974, 85, 65–84. [Google Scholar]

- Piornos, J.A.; Koussissi, E.; Balagiannis, D.P.; Brouwer, E.; Parker, J.K. Alcohol-free and low-alcohol beers: Aroma chemistry and sensory characteristics. CRFSFS 2022, 22, 233–259. [Google Scholar] [CrossRef] [PubMed]

- Lutosławski, K.; Olędzki, R.; Kiebel, Ł. Sensory quality of bright beers of top fermentation, home and commercial production. Sci. Work. Univ. Econ. 2018, 542, 77–89. [Google Scholar]

- The, S.; Standard, I.; Method, E.B.C.; The, P.; See, R.; Method, E.B.C.; See, A.; Method, E.B.C.; Clarify, S. Bitterness of Wort 8.8 2004; BrewUp: Brussels, Belgium, 2013; pp. 8–9. [Google Scholar]

- Standard, I.; Methods, T. Colour of Wort: Spectrophotometric Method (IM) 8.5 2000; BrewUp: Brussels, Belgium, 2013; pp. 8–10. [Google Scholar]

- Tarko, T.; Kostrz, M.; Duda-Chodak, A.; Semik-Szczurak, D.; Sroka, P.; Senczyszyn, T. The effect of apple cultivars and yeast strains on selected quality parameters and antioxidant activity of fermented apple beverages. CyTA J. Food 2018, 16, 892–900. [Google Scholar] [CrossRef]

- Satora, P.; Pater, A. The Influence of Different Non-Conventional Yeasts on the Odour-Active Compounds of Produced Beers. Appl. Sci. 2023, 13, 2872. [Google Scholar] [CrossRef]

| (μg/g) | m/z | LRI 2 | Threshold 3 | Coriander Seeds | Hops (Tettnanger 5.5 % Alpha Acids) | Sig 1 | GC-O Descriptors 4 |

|---|---|---|---|---|---|---|---|

| Terpenes | |||||||

| β-pinene | 41, 69, and 93 | 969 | 4 | 85 a | 203 b | ** | Pine and coriander [H] |

| β-myrcene | 41, 69, and 93 | 981 | 350 | 206 a | 2394 b | *** | Floral [FL] |

| p-cymene | 91, 119, and 134 | 1013 | 55.7 | 2 | 4 | ns | Citrus [FR] |

| Limonene | 68, 79, and 93 | 1025 | 65 | 343 a | 74 b | ** | Lemon and citrus [FR] |

| γ-terpinene | 91, 93, and 136 | 1057 | 25 | 1232 a | 0 b | ** | Floral and coriander [FL] |

| Trans-linalool oxide | 43, 59, and 94 | 1077 | 5 | 295 | 229 | ns | Flower [FL] |

| Linalool | 55, 71, and 93 | 1089 | 6 | 27,934 a | 1706 b | *** | Floral, lavender, and lille [FL] |

| Camphor | 41, 81, and 95 | 1126 | 80 | 5646 a | 0 b | *** | Woody [W] |

| Citronellol | 41, 67, and 69 | 1205 | 3.55 | 97 a | 16 b | ** | Rose [FL] |

| Geraniol | 41, 69, and 93 | 1232 | 4 | 2713 a | 163 b | ** | Rose and geranium [FL] |

| Carvacrol | 90, 135, and 150 | 1276 | 2900 | 65 a | 0 b | *** | Grassy and herbaceous [H] |

| Parameter | Extract (°P) | Color (EBC Units) | Turbidity (EBC Units) | pH | Ethanol (% v/v) | Real Extract (% w/w) | Bitterness (IBU Units) | Antioxidant Activity (mg/100 mL) | Glucose (g/L) | Fructose (g/L) | Maltose (g/L) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wort | 9.0 (±0.0) | 10.3 a (±1.28) | 17.6 a (±1.53) | 5.9 a (±0.0) | - | - | - | 125 a (±0.02) | 51.8 a (±7.93) | 10.8 (±1.18) | 7.62 (±1.81) |

| Control sample | - | 11.3 a (±1.99) | 115 b (±177.8) | 4.6 c (±0.21) | 1.3 a (±0.05) | 5.0 b (±0.28) | 30 c (±0.52) | 130 b (±0.52) | 0.14 b (±0.02) | 0.22 b (±0.02) | 2.41 b (±1.4) |

| Coriander seeds for mashing | - | 20.8 b (±5.35) | 109 b (±102.1) | 4.2 bc (±0.19) | 1.7 b (±0.13) | 4.3 a (±0.18) | 2.6 a (±0.02) | 135 b (±0.08) | 0.08 b (±0.03) | 0.26 b (±0.04) | 6.61 a (±1.04) |

| Coriander seeds for fermentation | - | 25.7 b (±4.52) | 120 b (±194.2) | 3.8 b (±0.14) | 1.5 ab (±0.07) | 4.6 ab (±0.11) | 3.0 a (±0.25) | 142 c (±0.25) | 0.16 b (±0.02) | 0.15 b (±0.05) | 4.87 b (±1.83) |

| Coriander seeds and hop for boiling | - | 20.4 b (±4.7) | 154 b (±23.7) | 4.7 c (±0.38) | 1.4 a (±0.12) | 4.7 ab (±0.10) | 25 b (±0.97) | 138 bc (±0.01) | 0.14 b (±0.05) | 0.21 b (±0.05) | 2.54 b (±1.97) |

| 1 Sig | - | * | * | *** | * | * | *** | ** | *** | *** | ** |

| (μg/L) | m/z | LRI 2 | Threshold 3 | Control Sample | Coriander Seeds for Mashing | Coriander Seeds for Fermentation | Coriander Seeds and Hop for Boiling | Sig 1 | GC-O Descriptors 4 |

|---|---|---|---|---|---|---|---|---|---|

| Alcohols | |||||||||

| 3-methyl-1-butanol | 42, 55, and 70 | 716 | 1000 | 67,970 a | 82,495 ab | 88,412 b | 68,531 ab | * | Bready, alcoholic, and fruity [R] |

| 2-methyl-1-butanol | 41, 57, and 70 | 724 | 15.9 | 21,189 | 21,001 | 20,966 | 27,719 | ns | Malt and sweet [FR] |

| 2-phenylethanol | 91, 65, and 122 | 1091 | 1000 | 815 | 1325 | 1090 | 799 | ns | Rose [FL] |

| Esters | |||||||||

| Ethyl acetate | 43, 61, and 70 | 598 | 5000 | 27,277 a | 43,318 b | 46,379 b | 33,029 a | ** | Floral and solvent [FL] |

| Isobutyl acetate | 43, 56, and 73 | 758 | 100 | 87.7 a | 2119 b | 177 a | 131 a | ** | Fruit, apple, and banana [FR] |

| Ethyl butyrate | 43, 71, and 88 | 784 | 150 | 99 a | 207 b | 118 a | 118 a | ** | Pineapple, sweet, and fruity [FR] |

| Ethyl 2-methylobutyrate | 41, 57, and 102 | 836 | 0.3 | 12 | 13 | 18 | 15 | ns | Fruity, apple, and peach [FR] |

| 1-butanol 3-methyl acetate | 43, 55, and 70 | 860 | 220 | 1397 | 1644 | 1029 | 1656 | ns | Fruity and apple [FR] |

| Ethyl valerate | 57, 85, and 88 | 883 | 1 | 8 a | 9 a | 13 b | 6 a | * | Yeast and fruit [FR] |

| Ethyl hexanoate | 43, 88, and 99 | 980 | 5 | 546 a | 1417 b | 1428 b | 538 a | ** | Fruity and red apple [FR] |

| Ethyl octanoate | 57, 88, and 101 | 1179 | 70 | 747 | 1005 | 1010 | 747 | ns | Sweet, fruity, and winey [FR] |

| Ethyl decanoate | 43, 88, and 10 | 1373 | 200 | 927 | 1266 | 1081 | 941 | ns | Sweet, fruity, and brandy [FR] |

| Terpenes | |||||||||

| β-pinene | 41, 69, and 93 | 969 | 4 | 1 a | 1 a | 14 b | 5 ab | * | Pine and coriander [H] |

| β-myrcene | 41, 69, and 93 | 981 | 13 | 223 a | 5 b | 15 b | 1492 c | ** | X |

| p-cymene | 91, 119, and 134 | 1013 | 55.7 | 1 a | 1 a | 6 b | 13 c | ** | Citrus [FR] |

| Limonene | 68, 79, and 93 | 1025 | 65 | 8 a | 2 a | 14 b | 63 c | ** | Lemon and citrus [FR] |

| γ-terpinene | 91, 93, and 136 | 1057 | 25 | 2 a | 3 a | 46 b | 25 b | * | Floral and coriander [FL] |

| Trans-linalool oxide | 43, 59, and 94 | 1077 | 5 | 70 a | 75 a | 369 b | 274 c | ** | X |

| Linalool | 55, 71, and 93 | 1089 | 6 | 1112 a | 484 b | 0 c | 7416 d | *** | Flower and lavender [FL] |

| Camphor | 41, 81, and 95 | 1126 | 80 | 0 a | 49 a | 2721 b | 1239 c | *** | X |

| Citronellol | 41, 67, and 69 | 1205 | 8 | 209 a | 11 b | 163 a | 272 a | ** | Rose [FL] |

| Geraniol | 41, 69, and 93 | 1232 | 4 | 203 a | 19 b | 439 c | 365 d | *** | X |

| Carvacrol | 90, 135, and 150 | 1276 | 2900 | 0.9 a | 7 b | 12 b | 7 b | ** | X |

| Others | |||||||||

| Acetophenone | 51, 77, and 105 | 1036 | 65 | 12 a | 4 b | 4 b | 4 b | ** | Sweet, pungent, and chemical [C] |

| Decanal | 41, 43, and 57 | 1182 | 0.1 | 26 a | 24 a | 0 b | 30 a | ** | Aldehydic, citrus, and floral [FL] |

| Benzothiazole | 69, 108, and 135 | 1196 | 80 | 197 | 184 | 153 | 158 | ns | Gasoline and rubber [C] |

| Compound | 1 LRI | Control Sample | Coriander Seeds for Mashing | Coriander Seeds for Fermentation | Coriander Seeds and Hop for Boiling |

|---|---|---|---|---|---|

| 3-methyl-1-butanol | 716 | 0.5 | 0.8 | 1.0 | 1.0 |

| 2-methyl-1-butanol | 724 | 1.3 | 0.8 | 1.0 | 1.2 |

| 2-phenylethanol | 1091 | 0.0 | 0.5 | 1.2 | 0.6 |

| Ethyl acetate | 598 | 1.0 | 0.6 | 1.2 | 0.3 |

| Isobutyl acetate | 758 | 0.6 | 0.0 | 1.0 | 1.0 |

| Ethyl butyrate | 784 | 0.6 | 0.8 | 1.0 | 1.4 |

| Ethyl 2-methylobutyrate | 836 | 0.6 | 0.8 | 0.6 | 0.8 |

| 3-Methylbutyl acetate1-butanol 3-methyl acetate | 860 | 0.6 | 1.0 | 0.6 | 0.6 |

| Ethyl valerate | 883 | 1.3 | 0.8 | 1.0 | 1.2 |

| Ethyl hexanoate | 980 | 1.3 | 1.3 | 1.0 | 0.3 |

| Ethyl octanoate | 1179 | 1.0 | 0.0 | 1.3 | 1.2 |

| Ethyl decanoate | 1373 | 1.0 | 0.2 | 1.2 | 0.3 |

| β-pinene | 969 | 0.0 | 0.6 | 1.2 | 0.6 |

| Limonene | 1025 | 0.6 | 0.0 | 0.3 | 0.0 |

| γ-terpinene | 1057 | 0.0 | 0.3 | 1.0 | 1.0 |

| Linalool | 1089 | 0.6 | 0.8 | 1.6 | 0.6 |

| Citronellol | 1205 | 0.6 | 0.0 | 0.3 | 0.0 |

| Acetophenone | 1036 | 0.8 | 0.3 | 1.2 | 1.0 |

| Decanal | 1182 | 0.0 | 0.8 | 0.3 | 0.0 |

| Benzothiazole | 1196 | 0.8 | 0.3 | 1.0 | 0.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pater, A.; Satora, P.; Januszek, M. Effect of Coriander Seed Addition at Different Stages of Brewing on Selected Parameters of Low-Alcohol Wheat Beers. Molecules 2024, 29, 844. https://doi.org/10.3390/molecules29040844

Pater A, Satora P, Januszek M. Effect of Coriander Seed Addition at Different Stages of Brewing on Selected Parameters of Low-Alcohol Wheat Beers. Molecules. 2024; 29(4):844. https://doi.org/10.3390/molecules29040844

Chicago/Turabian StylePater, Aneta, Paweł Satora, and Magdalena Januszek. 2024. "Effect of Coriander Seed Addition at Different Stages of Brewing on Selected Parameters of Low-Alcohol Wheat Beers" Molecules 29, no. 4: 844. https://doi.org/10.3390/molecules29040844

APA StylePater, A., Satora, P., & Januszek, M. (2024). Effect of Coriander Seed Addition at Different Stages of Brewing on Selected Parameters of Low-Alcohol Wheat Beers. Molecules, 29(4), 844. https://doi.org/10.3390/molecules29040844