Nutritionally Valuable Components and Heat-Induced Contaminants in Extruded Snack Products Enriched with Defatted Press Cakes

Abstract

1. Introduction

2. Results and Discussion

2.1. Dietary Fibre

2.2. Resistant Starch

2.3. Total Phenolic Content and DPPH Radical Scavenging Activity

2.4. Acrylamide and Hydroxymethylfurfural

3. Materials and Methods

3.1. Materials

3.2. Sample Preparation

3.3. Extrusion

3.4. Dietary Fibre

3.5. Resistant Starch

3.6. Total Phenolic Content and DPPH Radical Scavenging Activity

3.7. Contents of Acrylamide and Hydroxymethylfurfural

3.8. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Strategy. EUROPE 2020—A Strategy for Smart, Sustainable and Inclusive Growth; European Comission: Brussels, Belgium, 2020. [Google Scholar]

- Sert, D.; Rohm, H.; Struck, S. High-pressure-assisted protein isolation from pumpkin seed press cake. Int. J. Food Sci. Technol. 2024, 59, 368–379. [Google Scholar] [CrossRef]

- Gul, O.; Atalar, I.; Saricaoglu, F.T.; Yazici, F. Effect of multi-pass high pressure homogenization on physicochemical properties of hazelnut milk from hazelnut cake: An investigation by response surface methodology. J. Food Process. Preserv. 2018, 42, e13615. [Google Scholar] [CrossRef]

- Nakov, G.; Trajkovska, B.; Atanasova-Pancevska, N.; Daniloski, D.; Ivanova, N.; Lučan Čolić, M.; Jukić, M.; Lukinac, J. The Influence of the Addition of Hemp Press Cake Flour on the Properties of Bovine and Ovine Yoghurts. Foods 2023, 12, 958. [Google Scholar] [CrossRef] [PubMed]

- Drozłowska, E.; Starowicz, M.; Śmietana, N.; Krupa-Kozak, U.; Łopusiewicz, Ł. Spray-Drying Impact the Physicochemical Properties and Formation of Maillard Reaction Products Contributing to Antioxidant Activity of Camelina Press Cake Extract. Antioxidants 2023, 12, 919. [Google Scholar] [CrossRef] [PubMed]

- Lucarini, E.; Micheli, L.; Pagnotta, E.; Toti, A.; Ferrara, V.; Ciampi, C.; Margiotta, F.; Martelli, A.; Testai, L.; Calderone, V.; et al. The Efficacy of Camelina sativa Defatted Seed Meal against Colitis-Induced Persistent Visceral Hypersensitivity: The Relevance of PPAR α Receptor Activation in Pain Relief. Nutrients 2022, 14, 3137. [Google Scholar] [CrossRef]

- Apostol, L.; Popa, M.; Mustatea, G. Cannabis sativa L. partially skimmed flour as source of bio-compounds in the bakery industry. Rom. Biotechnol. Lett. 2015, 20, 10835–10844. [Google Scholar]

- Petraru, A.; Ursachi, F.; Amariei, S. Nurtional characteristics assessment of sunflower seeds, oil and cake. Perspective of using sunflower oilcakes as a functional ingredient. Plants 2021, 10, 2487. [Google Scholar] [CrossRef]

- Leonard, W.; Zhang, P.; Ying, D.; Fang, Z. Effect of extrusion technology on hempseed (Cannabis sativa L.) oil cake: Polyphenol profile and biological activities. Food Eng. Mater. Sci. Nanotechnol. 2021, 86, 3159–3175. [Google Scholar] [CrossRef]

- Leonard, W.; Zhang, P.; Ying, D.; Fang, Z. Application of extrusion technology in plant food processing byproducts: An overview. Compr. Rev. Food Sci. Food Saf. 2020, 19, 218–246. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Ryu, G.H. Physicochemical and antioxidant properties of extruded corn grits with corn fiber by CO2 injection extrusion process. J. Cereal Sci. 2013, 58, 110–116. [Google Scholar] [CrossRef]

- Mazlan, M.M.; Talib, R.A.; Mail, N.F.; Taip, F.S.; Chin, N.L.; Sulaiman, R.; Shukri, R.; Nor, M.Z.M. Effects of extrusion variables on corn-mango peel extrudates properties, torque and moisture loss. Int. J. Food Prop. 2019, 22, 54–70. [Google Scholar] [CrossRef]

- Jozinović, A.; Panak Balentić, J.; Ačkar, Đ.; Babić, J.; Pajin, B.; Miličević, B.; Guberac, S.; Vrdoljak, A.; Šubarić, D. Cocoa husk application in the enrichment of extruded snack products. J. Food Process. Preserv. 2019, 43, 13866. [Google Scholar] [CrossRef]

- Ačkar, Đ.; Jozinović, A.; Babić, J.; Miličević, B.; Panak Balentić, J.; Šubarić, D. Resolving the problem of poor expansion in corn extrudates enriched with food industry by-products. Innov. Food Sci. Emerg. Technol. 2018, 47, 517–524. [Google Scholar] [CrossRef]

- Liu, Q.; Guan, H.; Guo, Y.; Wang, D.; Yang, Y.; Ji, H.; Jiao, A.; Jin, Z. Structure and in vitro digestibility of amylose-lipid complexes formed by an extrusion-debranching-complexing strategy. Food Chem. 2024, 437, 137950. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; He, Z.; Tu, Y.; Li, X. Understanding synchronous regulating effects of starch-protein interactions on starch digestion and retrogradation under thermal shear processing. Carbohydr. Polym. 2024, 329, 121767. [Google Scholar] [CrossRef] [PubMed]

- Arora, B.; Rizvi, S.S.H. Process optimization and product characterization of milk protein concentrate extrudates expanded by supercritical carbon dioxide. Int. J. Dairy Technol. 2021, 74, 641–654. [Google Scholar] [CrossRef]

- Panak Balentić, J.; Jozinović, A.; Ačkar, Đ.; Babić, J.; Miličević, B.; Benšić, M.; Jokić, S.; Šarić, A.; Šubarić, D. Nutritionally improved third generation snacks produced by supercritical CO2 extrusion I. Physical and sensory properties. J. Food Process Eng. 2018, 42, e12961. [Google Scholar] [CrossRef]

- Yoshida, B.Y.; da Silva, P.R.C.; Prudencio, S.H. Extrusion or alkaline hydrogen peroxide prior to enzymatic hydrolysis by a carbohydrase mixture improves techno-functional properties of okara. Int. J. Food Sci. Technol. 2023, 58, 3752–3759. [Google Scholar] [CrossRef]

- Tovar-Jíménez, X.; Caro-Corrales, J.; Gómez-Aldapa, C.A.; Zazueta-Morales, J.; Limón-Valenzuela, V.; Castro-Rosas, J.; Hernández-Ávila, J.; Aguilar-Palazuelos, E. Third generation snacks manufactured from orange by-products: Physicochemical and nutritional characterization. J. Food Process. Technol. 2015, 52, 6607–6614. [Google Scholar] [CrossRef]

- Jiang, F.; Du, C.; Wang, L.; Du, S.K. The preparation, formation, fermentability, and applications of resistant starch. Int. J. Biol. Macromol. 2020, 150, 1155–1161. [Google Scholar] [CrossRef]

- Martinez, M.M.; Rosell, C.M.; Gómez, M. Modification of wheat flour functionality and digestibility through different extrusion conditions. J. Food Eng. 2014, 143, 74–79. [Google Scholar] [CrossRef]

- Arribas, C.; Cabelos, B.; Cuadrado, C.; Guillamon, E.; Pedrosa, M.M. The impact of extrusion on the nutritional composition, dietary fibre and in vitro digestibility of gluten-free snacks based on rice, pea and carob flour blends. Food Funct. 2017, 8, 3654. [Google Scholar] [CrossRef] [PubMed]

- Escobar-Puentes, A.; Rincón, S.; García-Gurrola, A.; Zepeda, A.; Calvo-López, A.D.; Martínez-Bustos, F. Development of a third-generation snack with type 4 resistant sorghum starch: Physicochemical and sensorial properties. Food Biosci. 2019, 32, 100474. [Google Scholar] [CrossRef]

- Neder-Suarez, D.; Amaya-Guerra, C.A.; Perez-Cabillo, E.; Quintero-Ramos, A.; Mendez-Zamora, G.; Sanchez-Madrigal, M.A.; Barba-Davila, B.A.; Lardizabal-Gutierrez, D. Optimization o fan extrusion cooking process to increase formation of resistant starch from corn starch with addition of citric acid. Starch 2020, 72, 1900150. [Google Scholar] [CrossRef]

- Barba, F.J.; Boussetta, N.; Vorobiev, E. Emerging technologies for the recovery of isothiocyanates, protein and phenolic compounds from rapeseed and rapeseed press-cake: Effect of high voltage electrical discharges. Innov. Food Sci. Emerg. Technol. 2015, 31, 67–72. [Google Scholar] [CrossRef]

- Mierina, I.; Adere, L.; Krasauska, K.; Zoltnere, E.; Skrastina, D.Z.; Jure, M. Antioxidant properties of Camelina sativa oil and press-cakes. Proc. Latv. Acad. Sci. Sect. B 2017, 71, 515–521. [Google Scholar] [CrossRef]

- Moorthy, M.; Chaiyakunapruk, N.; Jacob, S.A.; Palanisamy, U.D. Prebiotic potential of polyphenols, its effect on gut microbiota and anthropometric/clinical markers: A systematic review of randomised controlled trials. Trends Food Sci. Technol. 2020, 99, 634–649. [Google Scholar] [CrossRef]

- Quero, J.; Marmol, I.; Cerrada, E.; Rodriguez-Yoldi, M.J. Insight into the potential application of polyphenol-rich dietary intervention in degenerative disease management. Food Funct. 2020, 11, 2805–2825. [Google Scholar] [CrossRef]

- Delgado-Licon, E.; Ayala, A.L.M.; Rocha-Guzman, N.E.; Gallegos-Infante, J.A.; Atienzo-Lazos, M.; Drzewiecki, J.; Martínez-Sánchez, C.E.; Gorinstein, S. Influence of extrusion on the bioactive compounds and the antioxidant capacity of the bean/corn mixtures. Int. J. Food Sci. Nutr. 2009, 60, 522–532. [Google Scholar] [CrossRef]

- Peksa, A.; Kita, A.; Carbonell-Barrachina, A.A.; Miedzianka, J.; Kolniak-Ostek, J.; Tajner-Czopek, A.; Rytel, E.; Siwek, A.; Miarka, D.; Drozdz, W. Sensory attributes and physicochemical features of corn snacks as affected by different flour types and extrusion conditions. LWT Food Sci. Technol. 2016, 72, 26–36. [Google Scholar] [CrossRef]

- Yagci, S.; Gogus, F. Effect of incorporation of various food by-products on some nutritional properties of rice-based extruded foods. Food Sci. Technol. Int. 2009, 15, 571–581. [Google Scholar] [CrossRef]

- Obradović, V.; Babić, J.; Šubarić, D.; Jozinović, A.; Ačkar, Đ.; Klarić, I. Influence of dried Hokkaido pumpkin and ascorbic acid addition on chemical properties and colour of corn extrudates. Food Chem. 2015, 183, 136–143. [Google Scholar] [CrossRef] [PubMed]

- Neder-Suarez, D.; Vazquez-Rodriguez, J.A.; Gonzales-Martinez, B.E.; Melendez-Pizarro, C.O.; Hernandez-Ochoa, L.R.; Murowaniecki-Otero, D.; Rodriguez-Roque, M.J.; Quintero-Ramos, A. Effect of using alternative flours on the development and characteristics of a third-generation snacks. Food Chem. Adv. 2024, 4, 100571. [Google Scholar] [CrossRef]

- Navarro-Cortez, R.O.; Aguilar-Palazuelos, E.; Zazueta-Morales, J.J.; Castro-Rosas, J.; Hernández-Ávila, J.; Gómez-Aldapa, C.A.; Aguirre-Tostado, F.S. Microstructure of an extruded third-generation snack made from a whole blue corn and corn starch mixture. Int. J. Food Process. Technol. 2014, 1, 10–17. [Google Scholar]

- EFSA. Scientific Opinion on acrylamide in food. EFSA J. 2015, 13, 4104. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (EU) 2017/2158 of 20 November 2017 establishing mitigation measures and benchmark levels for the reduction of the presence of acrylamide in food (Text with EEA relevance.) C/2017/7658. Off. J. Eur. Union 2017, 304, 24–44. [Google Scholar]

- Raffan, S.; Halford, N.G. Acrylamide in food: Progress in and prospects for genetic and agronomic solutions. Ann. Appl. Biol. 2019, 175, 259–281. [Google Scholar] [CrossRef]

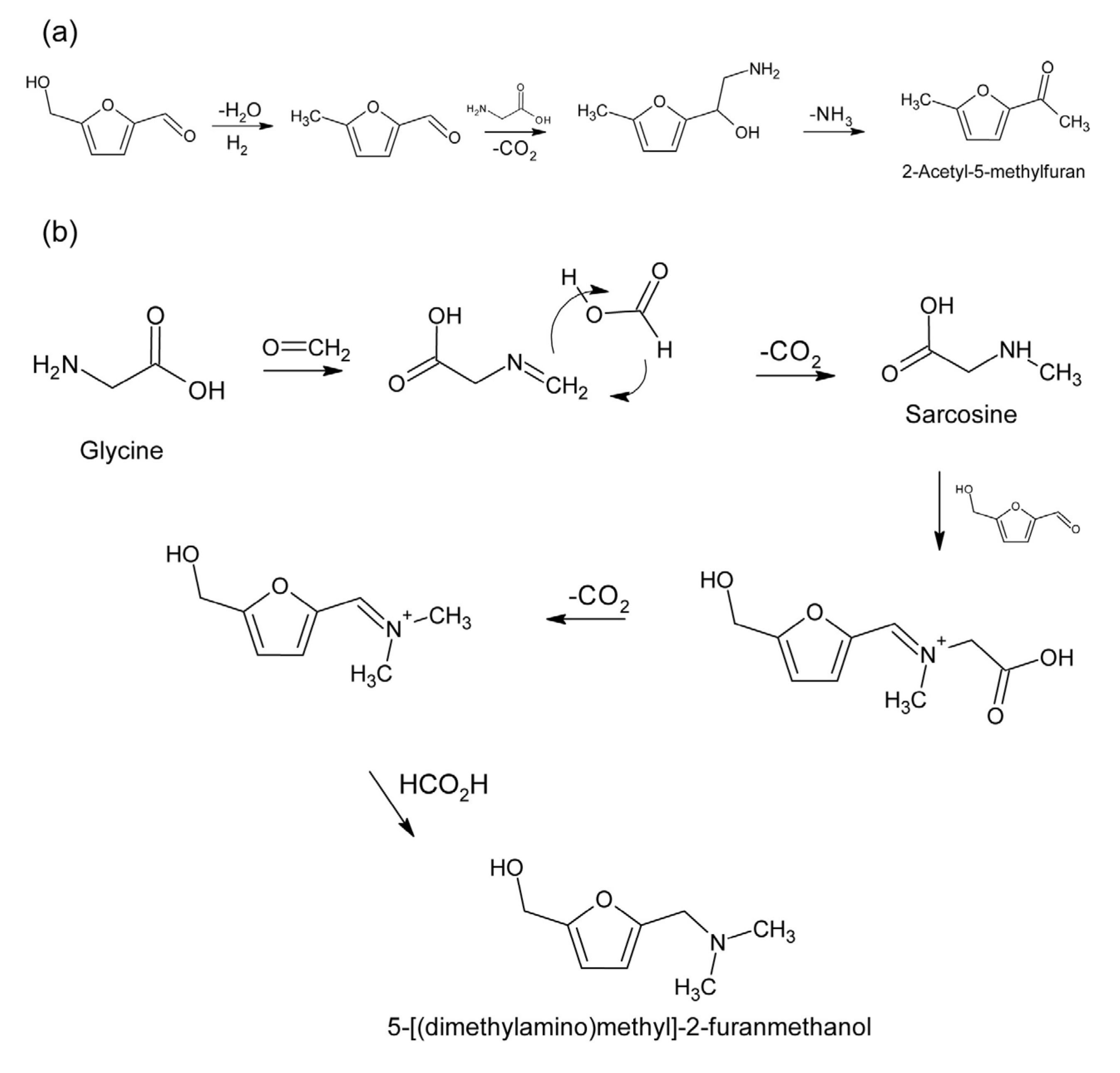

- Nikolov, P.Y.; Yaylayan, V.A. Thermal decomposition of 5-(hydroxymethyl)-2-furaldehyde (HMF) and its further transformations in the presence of glycine. J. Agric. Food Chem. 2011, 59, 10104–10113. [Google Scholar] [CrossRef]

- Zubr, J. Oil-seed crop: Camelina sativa. Ind. Crops Prod. 1997, 6, 113–119. [Google Scholar] [CrossRef]

- Jokić, S.; Horvat, G.; Aladić, K. Design of SFE system using a holistic approach—Problems and challenges. In Supercritical Fluid Extraction: Technology, Applications and Limitations; Lindy, J., Ed.; Nova Publishers: New York, NY, USA, 2015; pp. 95–122. [Google Scholar]

- AOAC 991.43; Total, Soluble, and Insoluble. Dietary Fiber in Foods, Enymatic Gravimetric Method, MES-TRIS Buffer. AOAC Official Methods of Analysis. Association of Official Analytical Chemists: Gaithersburg, MD, USA, 1995.

- AOAC 2002.02; Resistant Starch in Starch and Plant Materials. AOCA Official Methods of Analysis. Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2002.

- Jozinović, A.; Šarkanj, B.; Ačkar, Đ.; Panak Balentić, J.; Šubarić, D.; Cvetković, T.; Ranilović, J.; Guberac, D.; Babić, J. Simultaneous Determination of Acrylamide and Hydroxymethylfurfural in Extruded Products by LC-MS/MS Method. Molecules 2019, 24, 1971. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (EU) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods. Off. J. Eur. Union 2006, 404, 9–25. [Google Scholar]

- European Commission. Commission Regulation (EU) No 1047/2012 of 8 November 2012 amending Regulation (EC) No 1924/2006 with regard to the list of nutrition claims Text with EEA relevance. Off. J. Eur. Union 2012, 310, 36–37. [Google Scholar]

| Variables | Grouping Variables | Welch p * |

|---|---|---|

| Polyphenol content (mg GAE/100 g d. m.) | Type of cake | <0.000001 |

| Content of cake | 0.000115 | |

| Type of product | 0.000009 | |

| % DPPH | Type of cake | <0.000001 |

| Content of cake | <0.000001 | |

| Type of product | 0.000203 | |

| HMF (μg/kg) | Type of cake | 0.000004 |

| Content of cake | 0.358336 | |

| Type of product | 0.000195 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jozinović, A.; Panak Balentić, J.; Ačkar, Đ.; Benšić, M.; Babić, J.; Barišić, V.; Lončarić, A.; Miličević, B.; Šubarić, D. Nutritionally Valuable Components and Heat-Induced Contaminants in Extruded Snack Products Enriched with Defatted Press Cakes. Molecules 2024, 29, 791. https://doi.org/10.3390/molecules29040791

Jozinović A, Panak Balentić J, Ačkar Đ, Benšić M, Babić J, Barišić V, Lončarić A, Miličević B, Šubarić D. Nutritionally Valuable Components and Heat-Induced Contaminants in Extruded Snack Products Enriched with Defatted Press Cakes. Molecules. 2024; 29(4):791. https://doi.org/10.3390/molecules29040791

Chicago/Turabian StyleJozinović, Antun, Jelena Panak Balentić, Đurđica Ačkar, Mirta Benšić, Jurislav Babić, Veronika Barišić, Ante Lončarić, Borislav Miličević, and Drago Šubarić. 2024. "Nutritionally Valuable Components and Heat-Induced Contaminants in Extruded Snack Products Enriched with Defatted Press Cakes" Molecules 29, no. 4: 791. https://doi.org/10.3390/molecules29040791

APA StyleJozinović, A., Panak Balentić, J., Ačkar, Đ., Benšić, M., Babić, J., Barišić, V., Lončarić, A., Miličević, B., & Šubarić, D. (2024). Nutritionally Valuable Components and Heat-Induced Contaminants in Extruded Snack Products Enriched with Defatted Press Cakes. Molecules, 29(4), 791. https://doi.org/10.3390/molecules29040791