Reverse Mode Polymer Stabilized Cholesteric Liquid Crystal Flexible Films with Excellent Bending Resistance

Abstract

1. Introduction

2. Results and Discussion

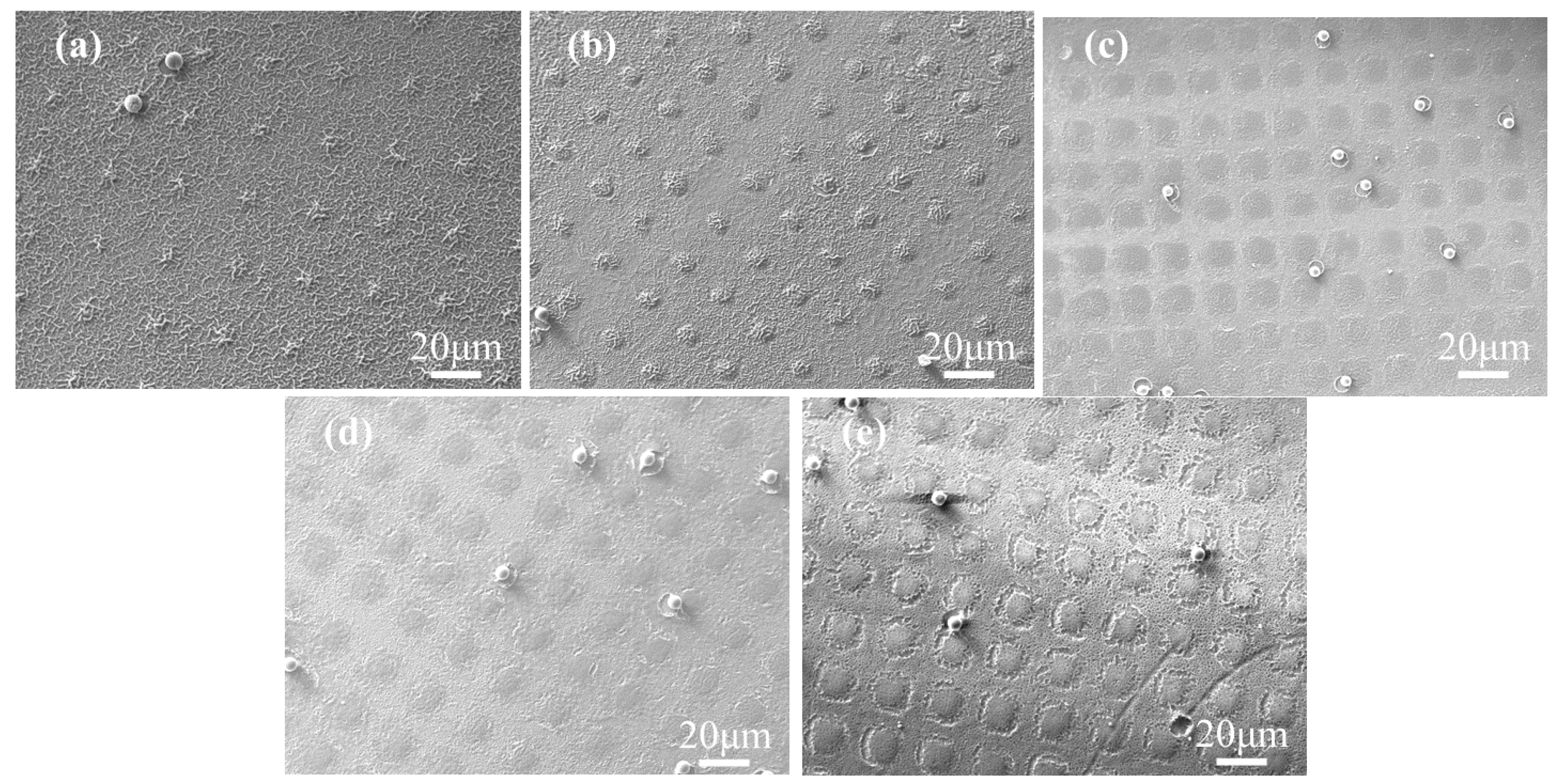

2.1. Effect of the Concentration of C6M

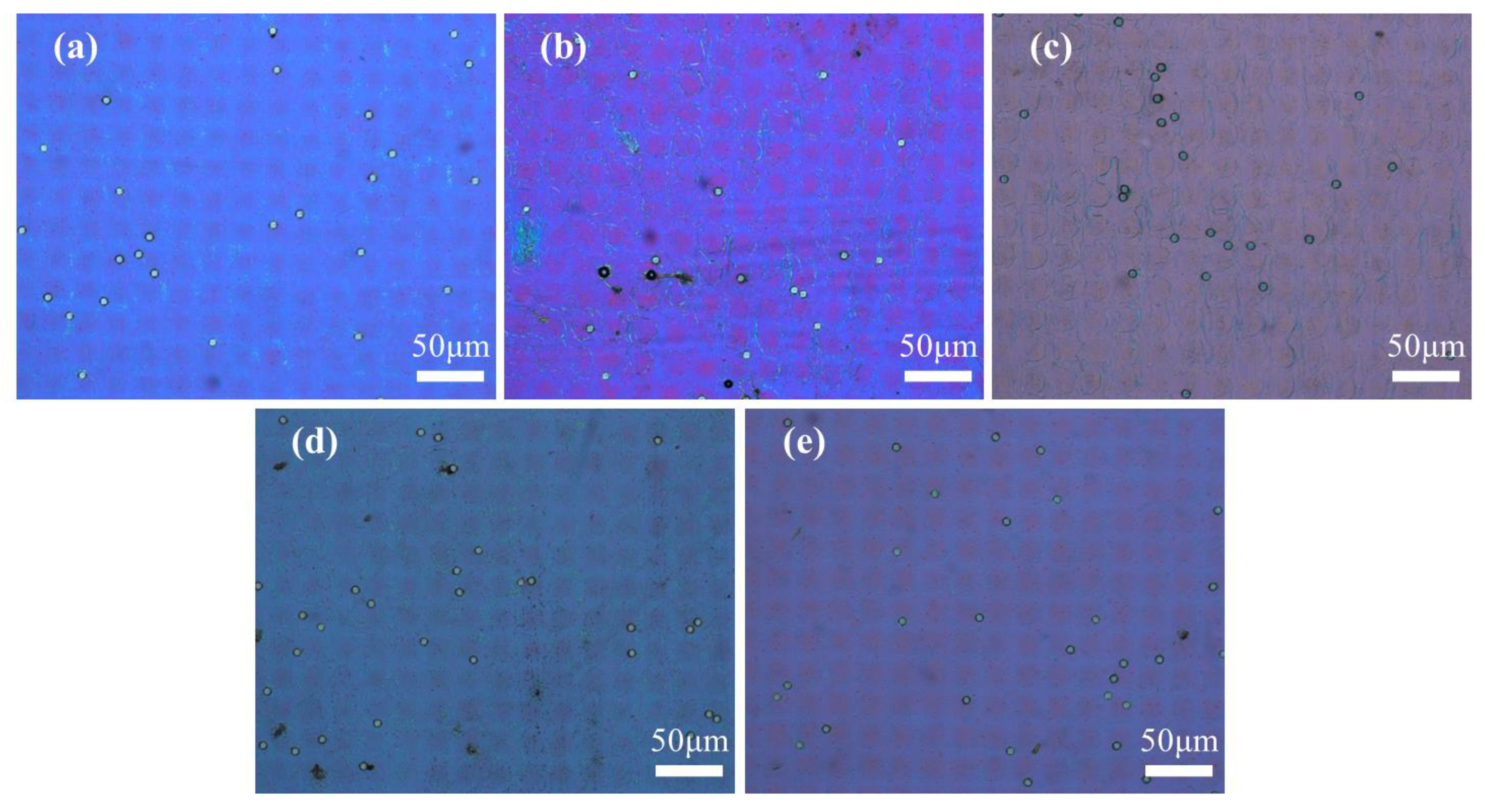

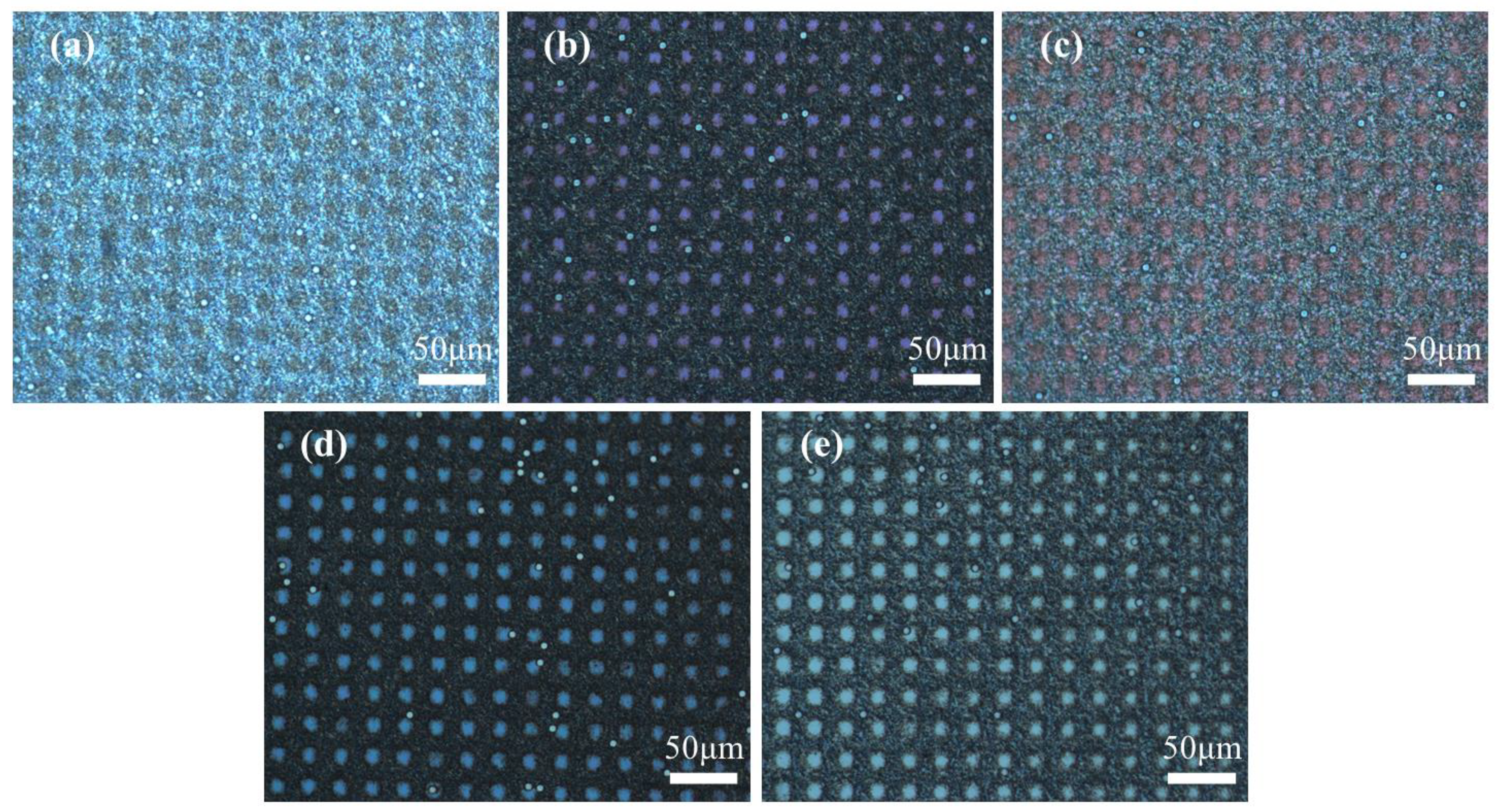

2.2. Effect of the Concentration of R811

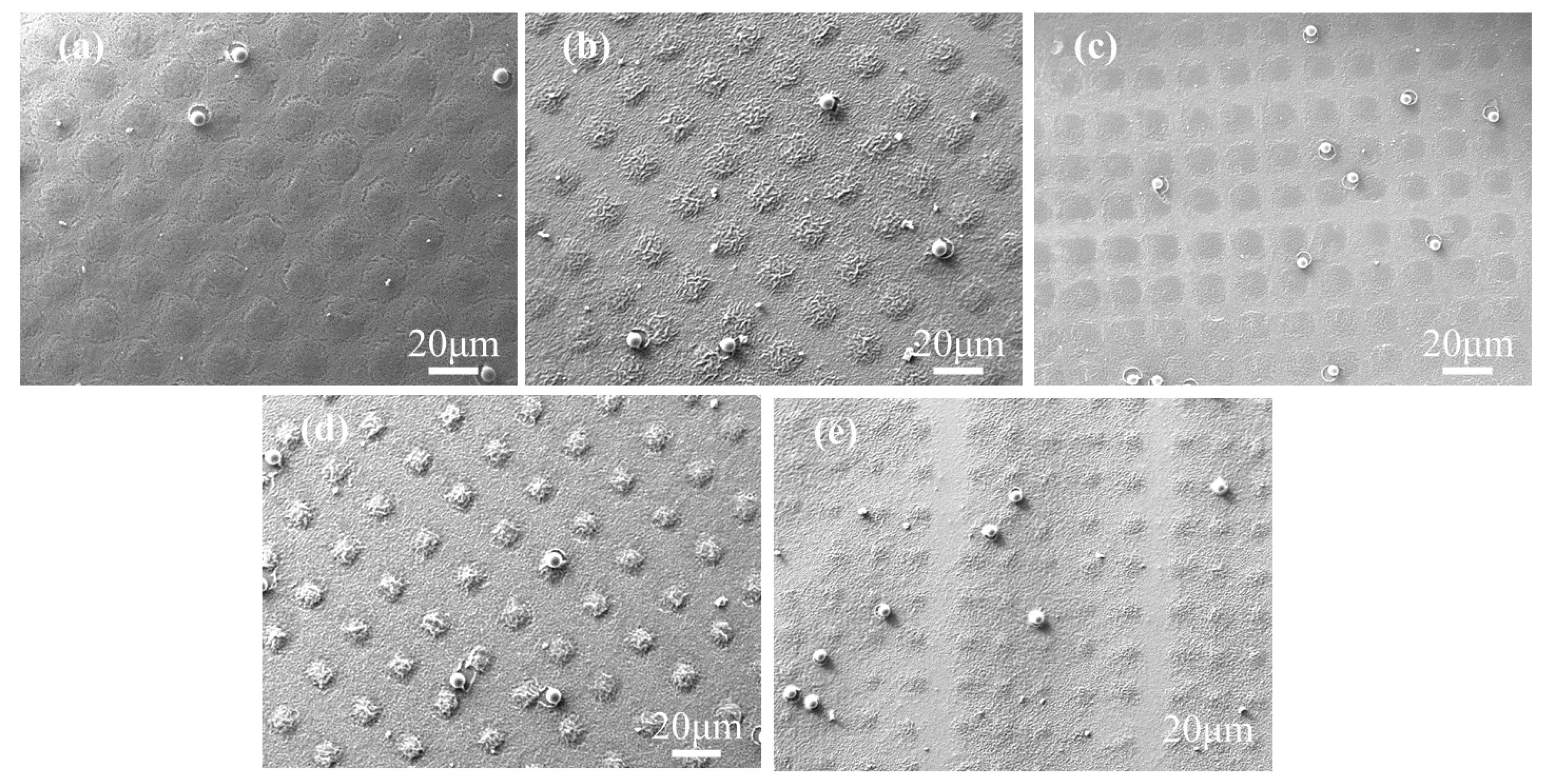

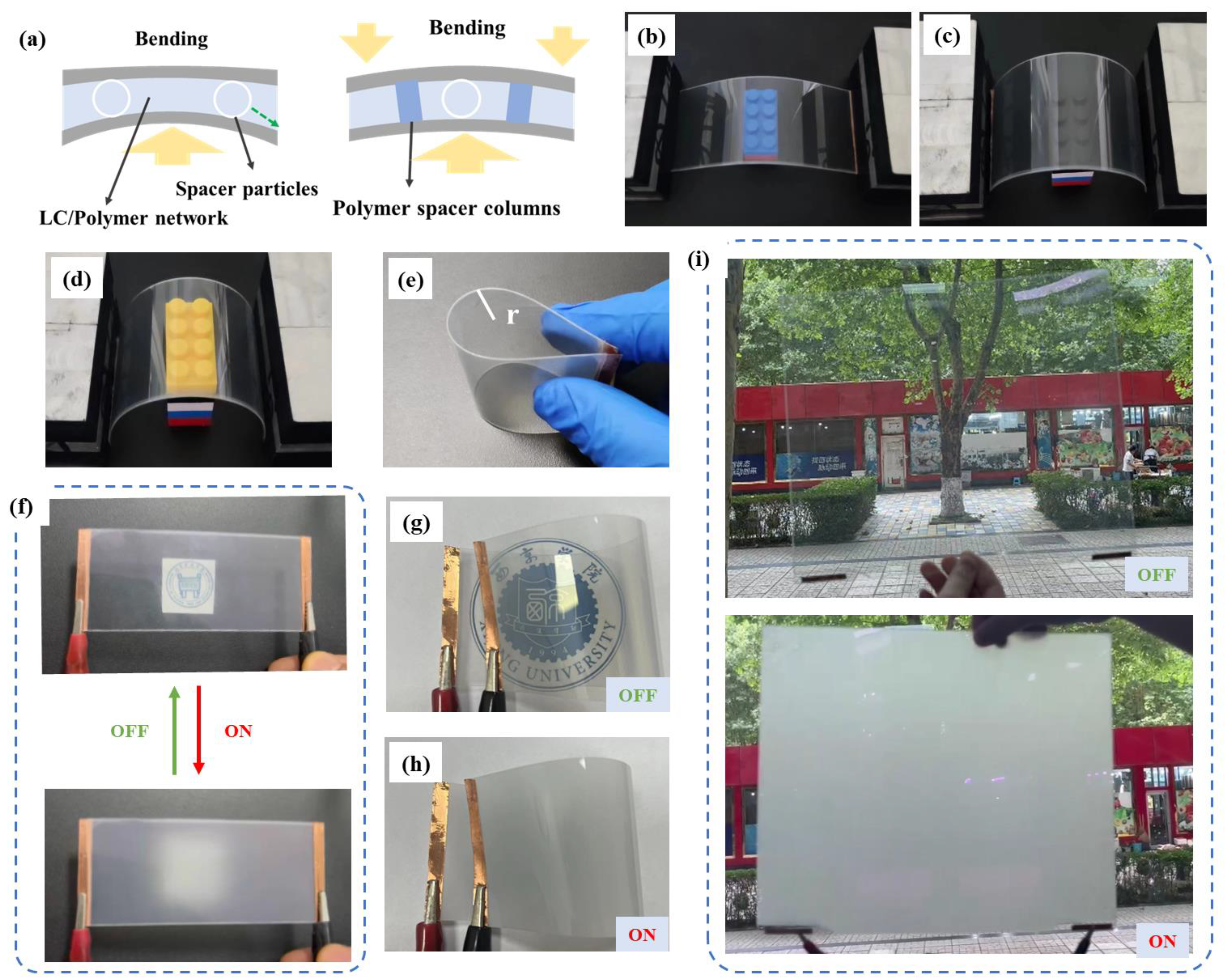

2.3. Physical Picture and Bending Resistance Test of the Optimal Sample

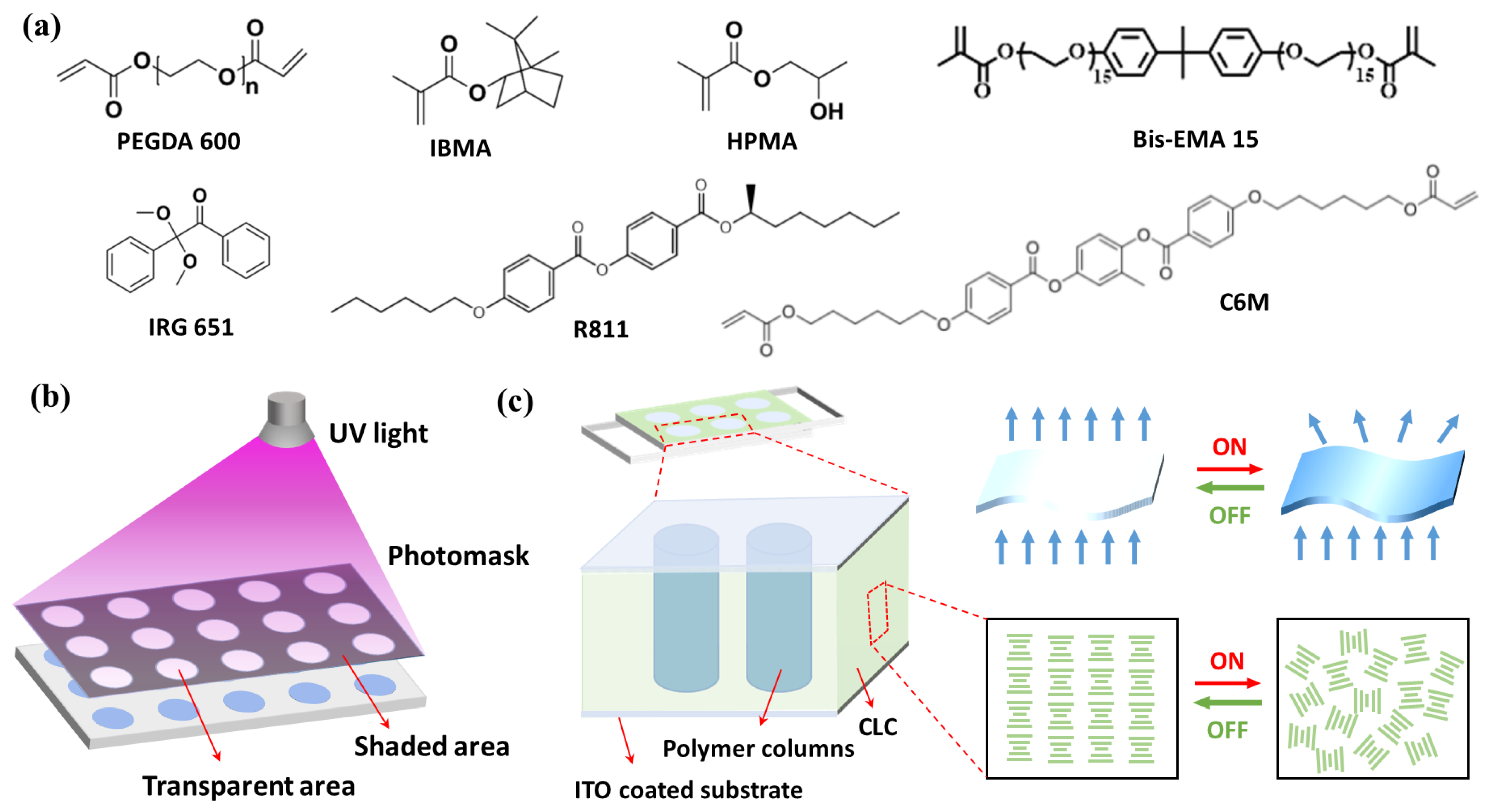

3. Experiments

3.1. Materials

3.2. Sample Preparation

3.3. Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Y.; Fan, F.; Liu, Y.; Liu, Y.; Zhao, S.; Xu, Q.; Wang, S.; Luo, D.; Long, Y. Unconventional smart windows: Materials, structures and designs. Nano Energy 2021, 90, 106613. [Google Scholar] [CrossRef]

- Kim, H.N.; Yang, S. Responsive smart windows from nanoparticle-polymer composites. Adv. Funct. Mater. 2020, 30, 1902597. [Google Scholar] [CrossRef]

- Niu, Y.; Zhou, Y.; Du, D.; Ouyang, X.; Yang, Z.; Lan, W.; Fan, F.; Zhao, S.; Liu, Y.; Chen, S.; et al. Energy saving and energy generation smart window with active control and antifreezing functions. Adv. Sci. 2022, 9, 2105184. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Wang, K.; Yang, J.; Huang, J.; Chen, Z.; Zheng, J.X.; Wang, J.; Yang, H.; Li, S.; Miao, Y.; et al. Printable thermochromic hydrogel-based smart window for all-weather building temperature regulation in diverse climates. Adv. Mater. 2023, 35, 2211716. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Wang, H.; Liang, M.; Ma, H.; Zhang, C.; Zhao, Y.; Qu, Y.; Miao, Z. Controlled synthesis of spindle-like CoNi2S4 as electrode material for aqueous energy storage application. Int. J. Hydrog. Energy 2024, 49, 81–89. [Google Scholar] [CrossRef]

- King, M.F.L.; Rao, P.N.; Sivakumar, A.; Mamidi, V.K.; Richard, S.; Vijayakumar, M.; Arunprasath, K.; Kumar, P.M. Thermal performance of a double-glazed window integrated with a phase change material (PCM). Mater. Today Proc. 2022, 50, 1516–1521. [Google Scholar] [CrossRef]

- Dong, X.; Tang, Y.; Li, Y.; Li, X.; Zhao, Y.; Song, W.; Wang, F.; Xu, S.; Zhou, Y.; Ran, C.; et al. Boosting MA-based two-dimensional Ruddlesden-Popper perovskite solar cells by incorporating a binary spacer. J. Energy Chem. 2024, 95, 348–356. [Google Scholar] [CrossRef]

- Kim, J.; Rémond, M.; Kim, D.; Jang, H.; Kim, E. Electrochromic conjugated polymers for multifunctional smart windows with integrative functionalities. Adv. Mater. Technol. 2020, 5, 1900890. [Google Scholar] [CrossRef]

- Song, R.; Li, G.; Zhang, Y.; Rao, B.; Xiong, S.; He, G. Novel electrochromic materials based on chalcogenoviologens for smart windows, E-price tag and flexible display with improved reversibility and stability. Chem. Eng. J. 2021, 422, 130057. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Q.; Han, L.; Zhao, Y.; He, Z.; Song, W.; Song, C.; Miao, Z. Spintronic phenomena and applications in hybrid organic-inorganic perovskites. Adv. Funct. Mater. 2024, 34, 2314427. [Google Scholar] [CrossRef]

- Bisoyi, H.K.; Li, Q. Liquid crystals: Versatile self-organized smart soft materials. Chem. Rev. 2021, 122, 4887–4926. [Google Scholar] [CrossRef]

- Niu, H.; Zhang, N.; Lu, Y.; Zhang, Z.; Li, M.; Liu, J.; Song, W.; Miao, Z. Strategies toward the development of high-energy-density lithium batteries. J. Energy Storage 2024, 88, 111666. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhou, Y.; Wang, M.; Wang, M.; Yang, D.K. Smart thermally switchable liquid crystal window. Adv. Photonics Res. 2021, 2, 2000156. [Google Scholar] [CrossRef]

- Cupelli, D.; Nicoletta, F.P.; Manfredi, S.; Vivacqua, M.; Formoso, P.; De, F.G.; Chidichimo, G. Self-adjusting smart windows based on polymer-dispersed liquid crystals. Sol. Energy Mater. Sol. Cells 2009, 93, 2008–2012. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, X.; Zhan, Y.; Zhang, Y.; He, J.; Lv, P.; Yuan, D.; Hu, X.; Liu, D.; Broer, D.J.; et al. Electroconvection in zwitterion-doped nematic liquid crystals and application as smart windows. Adv. Opt. Mater. 2021, 9, 2001465. [Google Scholar] [CrossRef]

- Li, C.C.; Tseng, H.Y.; Chen, C.W.; Wang, C.T.; Jau, H.C.; Wu, Y.C.; Hsu, W.H.; Lin, T.H. Versatile energy-saving smart glass based on tristable cholesteric liquid crystals. ACS Appl. Energy Mater. 2020, 3, 7601–7609. [Google Scholar] [CrossRef]

- Mitov, M. Cholesteric liquid crystals with a broad light reflection band. Adv. Mater. 2012, 24, 6260–6276. [Google Scholar] [CrossRef] [PubMed]

- Zhan, X.; Xu, F.F.; Zhou, Z.; Yan, Y.; Yao, J.; Zhao, Y.S. 3D laser displays based on circularly polarized lasing from cholesteric liquid crystal arrays. Adv. Mater. 2021, 33, 2104418. [Google Scholar] [CrossRef] [PubMed]

- Tamaoki, N. Cholesteric liquid crystals for color information technology. Adv. Mater. 2001, 13, 1135–1147. [Google Scholar] [CrossRef]

- Ma, J.; Yang, Y.; Valenzuela, C.; Zhang, X.; Wang, L.; Feng, W. Mechanochromic, shape-programmable and self-healable cholesteric liquid crystal elastomers enabled by dynamic covalent boronic ester bonds. Angew. Chem. Int. Ed. 2022, 61, e202116219. [Google Scholar] [CrossRef]

- Hussain, S.; Park, S. Photonic cholesteric liquid-crystal elastomers with reprogrammable helical pitch and handedness. ACS Appl. Mater. Interfaces 2021, 13, 59275–59287. [Google Scholar] [CrossRef] [PubMed]

- Pagidi, S.; Kim, M.S.; Manda, R.; Ahn, S.; Jeon, M.Y.; Lee, S.H. Ideal micro-lenticular lens based on phase modulation of optically isotropic liquid crystal-polymer composite with three terminals. J. Mol. Liq. 2023, 380, 121730. [Google Scholar] [CrossRef]

- Ruan, K.; Gu, J. Ordered alignment of liquid crystalline graphene fluoride for significantly enhancing thermal conductivities of liquid crystalline polyimide composite films. Macromolecules 2022, 55, 4134–4145. [Google Scholar] [CrossRef]

- Ruan, K.; Zhong, X.; Shi, X.; Dang, J.; Gu, J.; Ruan, K.; Zhong, X.; Shi, X.; Dang, J.; Gu, J. Liquid crystal epoxy resins with high intrinsic thermal conductivities and their composites: A mini-review. Mater. Today Phys. 2021, 20, 100456. [Google Scholar] [CrossRef]

- Ahmad, F.; Luqman, M.; Jamil, M. Advances in the metal nanoparticles (MNPs) doped liquid crystals and polymer dispersed liquid crystal (PDLC) composites and their applications-a review. Mol. Cryst. Liq. Cryst. 2021, 731, 1–33. [Google Scholar] [CrossRef]

- Hemaida, A.; Ghosh, A.; Sundaram, S.; Mallick, T.K. Evaluation of thermal performance for a smart switchable adaptive polymer dispersed liquid crystal (PDLC) glazing. Sol. Energy 2020, 195, 185–193. [Google Scholar] [CrossRef]

- Balenko, N.; Shibaev, V.; Bobrovsky, A. Mechanosensitive polymer-dispersed cholesteric liquid crystal composites based on various polymer matrices. Polymer 2023, 281, 126119. [Google Scholar] [CrossRef]

- Sharma, V.; Kumar, P.; Raina, K.K. Simultaneous effects of external stimuli on preparation and performance parameters of normally transparent reverse mode polymer-dispersed liquid crystals-a review. J. Mater. Sci. 2021, 56, 18795–18836. [Google Scholar] [CrossRef]

- Zhang, Z.; Bolshakov, A.; Han, J.; Zhu, J.; Yang, K.L. Electrospun core-sheath fibers with a uniformly aligned polymer network liquid crystal (PNLC). ACS Appl. Mater. Interfaces 2023, 15, 14800–14809. [Google Scholar] [CrossRef]

- Yamaguchi, R.; Inoue, K.; Kurosawa, R. Effect of liquid crystal material on polymer network structure in polymer stabilized liquid crystal cell. J. Photopolym. Sci. Technol. 2016, 29, 289–292. [Google Scholar] [CrossRef]

- Guillard, H.; Sixou, P.; Reboul, L.; Perichaud, A. Electrooptical characterizations of polymer stabilized cholesteric liquid crystals. Polymer 2001, 42, 9753–9762. [Google Scholar] [CrossRef]

- Zhang, W.; Lub, J.; Schenning, A.P.H.J.; Zhou, G.; de Haan, L.T. Polymer stabilized cholesteric liquid crystal siloxane for temperature-responsive photonic coatings. Int. J. Mol. Sci. 2020, 21, 1803. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yuan, X.; Xie, M.; Liu, Z.; Zhao, X.; Cao, H.; Wang, H.; Yang, Z.; Wang, D.; He, W. Flexible, easy-to-produce, gradient distributed pitch broadband infrared reflectors with polymer-stabilized cholesteric liquid crystals. J. Mol. Liq. 2024, 408, 125369. [Google Scholar] [CrossRef]

- Yang, D.K.; Chien, L.C.; Doane, J.W. Cholesteric liquid crystal/polymer dispersion for haze-free light shutters. Appl. Phys. Lett. 1992, 60, 3102–3104. [Google Scholar] [CrossRef]

- Ren, H.; Wu, S.T. Reflective reversed-mode polymer stabilized cholesteric texture light switches. J. Appl. Phys. 2002, 92, 797–800. [Google Scholar] [CrossRef]

- McConney, M.E.; Tondiglia, V.P.; Natarajan, L.V.; Lee, K.M.; White, T.; Bunning, T. Electrically induced color changes in polymer-stabilized cholesteric liquid crystals. Adv. Opt. Mater 2013, 1, 417–421. [Google Scholar] [CrossRef]

- Kikuchi, H.; Yamamoto, H.; Sato, H.; Kawakita, M.; Takizawa, K.; Fujikake, H. Bend-mode liquid crystal cells stabilized by aligned polymer walls. Jpn. J. Appl. Phys. 2005, 44, 981. [Google Scholar] [CrossRef]

- Kawamorita, S.; Shibata, Y.; Ishinabe, T.; Fujikake, H. Formation of polymer walls by monomer aggregation control utilizing substrate-surface wettability for flexible LCDs. IEICE Trans. Electron. 2017, 100, 1005–1011. [Google Scholar] [CrossRef]

- Li, H.; Xu, J.; Ren, Y.; Han, R.; Song, H.; Huang, R.; Wang, X.; Zhang, L.; Cao, H.; Zou, C.; et al. Preparation of highly durable reverse-mode polymer-stabilized liquid crystal films with polymer walls. ACS Appl. Mater. Interfaces 2022, 15, 2228–2236. [Google Scholar] [CrossRef]

- Chen, G.; Hu, J.; Xu, J.; Sun, J.; Xiao, J.; Zhang, L.; Wang, X.; Hu, W.; Yang, H. Liquid crystalline composite stabilized by epoxy polymer with boscage-like morphology for energy-efficient smart windows with high stability. Macromol. Mater. Eng. 2022, 307, 2100991. [Google Scholar] [CrossRef]

- Yoon, W.J.; Choi, Y.J.; Lim, S.I.; Koo, J.; Yang, S.; Jung, D.; Kang, S.W.; Jeong, K.U. A single-step dual stabilization of smart window by the formation of liquid crystal physical gels and the construction of liquid crystal chambers. Adv. Funct. Mater. 2020, 30, 1906780. [Google Scholar] [CrossRef]

- Lin, K.W.; Tseng, H.Y.; Chang, L.M.; Li, C.C.; Wang, C.T.; Lin, T.H. Mechanism of scattering bistable light valves based on salt-doped cholesteric liquid crystals. Opt. Express 2021, 29, 41213–41221. [Google Scholar] [CrossRef]

- Nemati, H.; Liu, S.; Zola, R.S.; Tondiglia, V.P.; Lee, K.M.; White, T.; Bunning, T.; Yang, D.K. Mechanism of electrically induced photonic band gap broadening in polymer stabilized cholesteric liquid crystals with negative dielectric anisotropies. Soft Matter 2015, 11, 1208–1213. [Google Scholar] [CrossRef] [PubMed]

| Samples a | CLC | Pitch (μm) | NLCM (wt%) b | C6M (wt%) | IRG 651 | |

|---|---|---|---|---|---|---|

| SLC 3MV-8173 | R811 | |||||

| Group Ⅰ | ||||||

| A1 | 91 | 5 | 1.44 | 3 | 1 | 0.5 |

| A2 | 90 | 5 | 1.43 | 3 | 2 | 0.5 |

| A3 | 89 | 5 | 1.41 | 3 | 3 | 0.5 |

| A4 | 88 | 5 | 1.40 | 3 | 4 | 0.5 |

| A5 | 87 | 5 | 1.38 | 3 | 5 | 0.5 |

| Group Ⅱ | ||||||

| B1 | 93 | 1 | 7.07 | 3 | 3 | 0.5 |

| B2 | 91 | 3 | 2.36 | 3 | 3 | 0.5 |

| B3 | 89 | 5 | 1.41 | 3 | 3 | 0.5 |

| B4 | 87 | 7 | 1.01 | 3 | 3 | 0.5 |

| B5 | 85 | 9 | 0.79 | 3 | 3 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, P.; He, Z.; Zhao, Y.; Song, W.; Miao, Z. Reverse Mode Polymer Stabilized Cholesteric Liquid Crystal Flexible Films with Excellent Bending Resistance. Molecules 2024, 29, 4276. https://doi.org/10.3390/molecules29174276

Yu P, He Z, Zhao Y, Song W, Miao Z. Reverse Mode Polymer Stabilized Cholesteric Liquid Crystal Flexible Films with Excellent Bending Resistance. Molecules. 2024; 29(17):4276. https://doi.org/10.3390/molecules29174276

Chicago/Turabian StyleYu, Ping, Zemin He, Yuzhen Zhao, Wenqi Song, and Zongcheng Miao. 2024. "Reverse Mode Polymer Stabilized Cholesteric Liquid Crystal Flexible Films with Excellent Bending Resistance" Molecules 29, no. 17: 4276. https://doi.org/10.3390/molecules29174276

APA StyleYu, P., He, Z., Zhao, Y., Song, W., & Miao, Z. (2024). Reverse Mode Polymer Stabilized Cholesteric Liquid Crystal Flexible Films with Excellent Bending Resistance. Molecules, 29(17), 4276. https://doi.org/10.3390/molecules29174276