Composition of Lignocellulose Hydrolysate in Different Biorefinery Strategies: Nutrients and Inhibitors

Abstract

1. Introduction

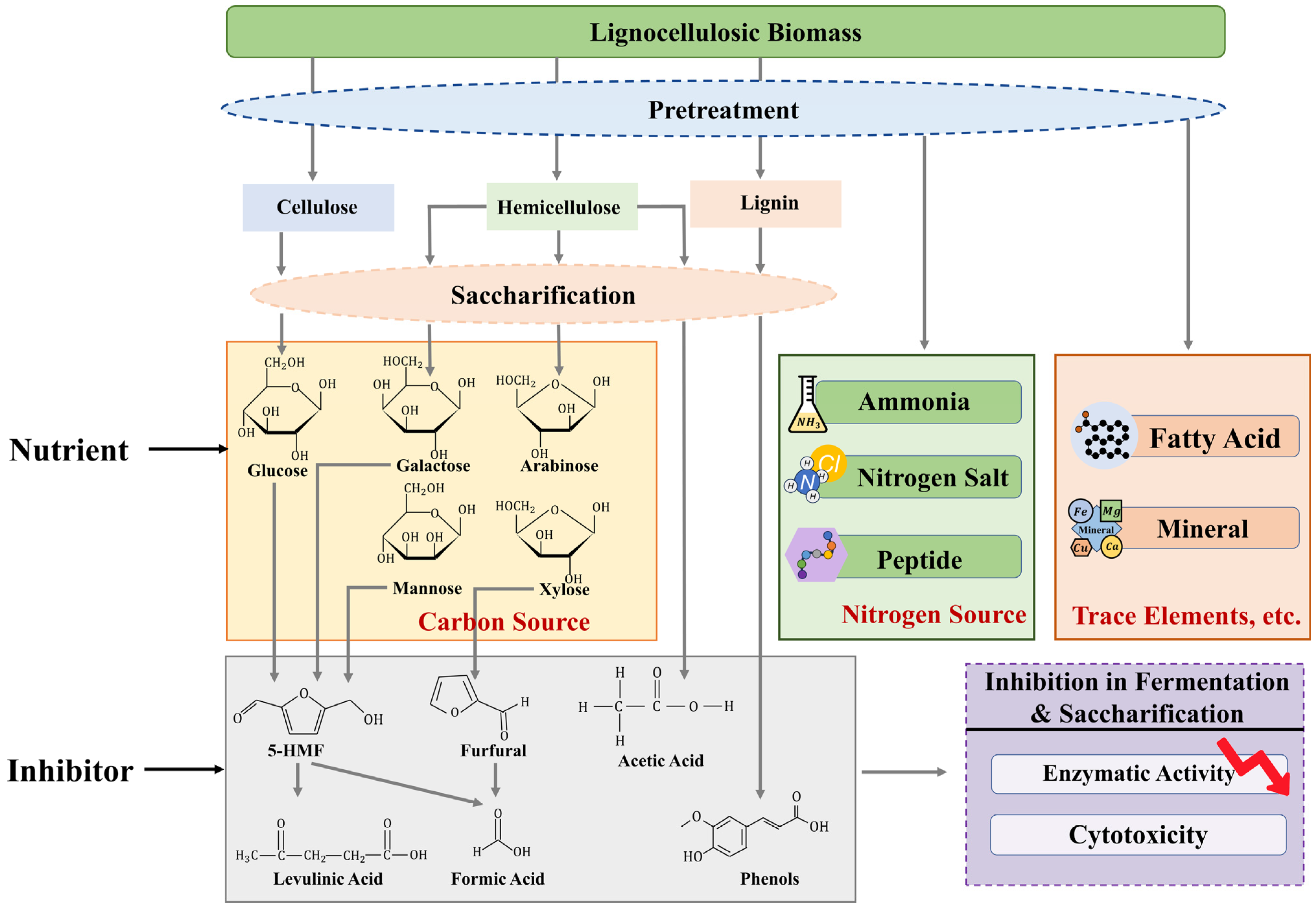

2. Composition of Lignocellulose Feedstocks

3. Pretreatment Process and Its Effects on Nutrients and Inhibitors

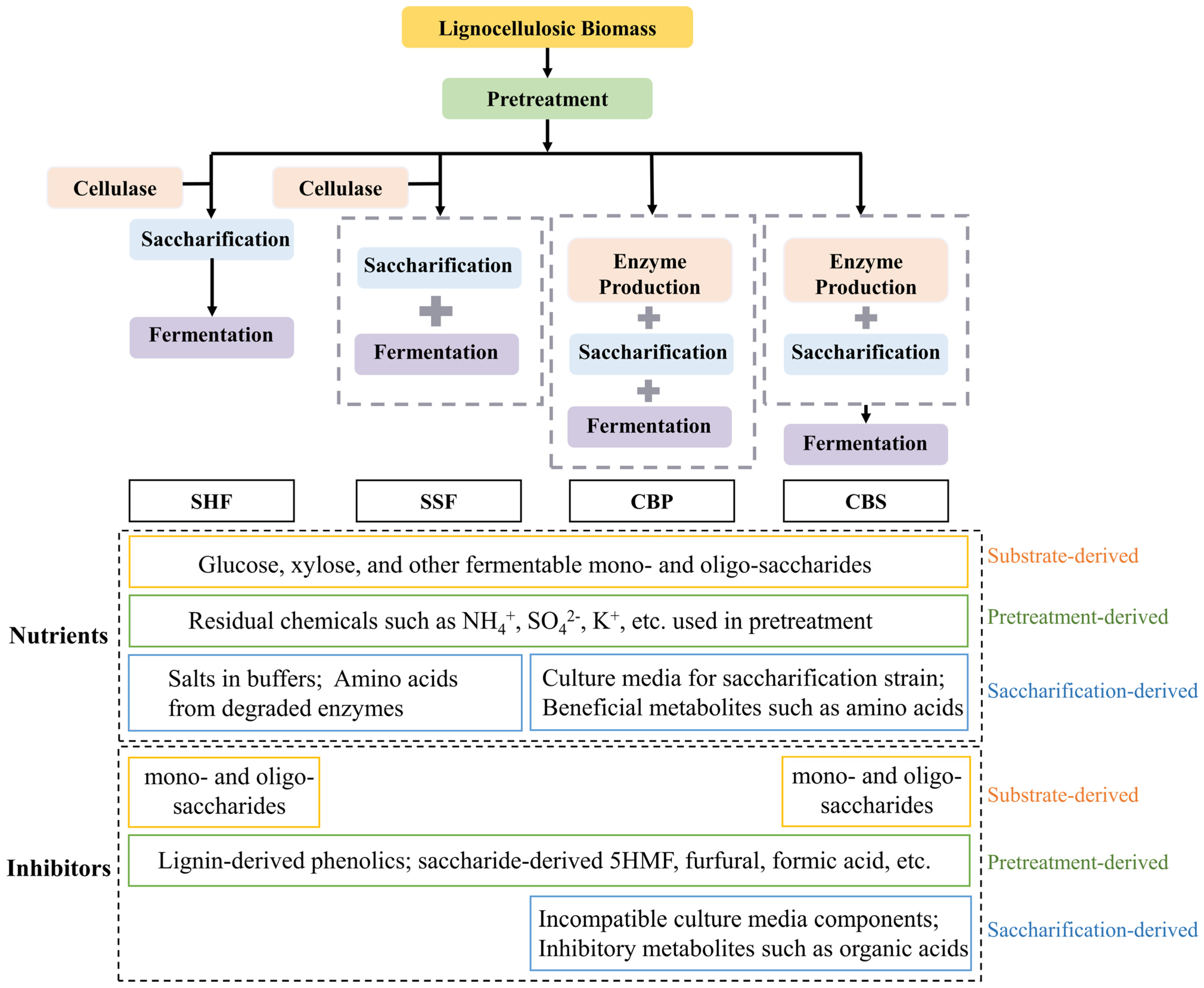

3.1. Alkaline Pretreatment

3.2. Acid Pretreatment

3.3. Hydrothermal Pretreatment

3.4. High-Pressure Explosion Pretreatment

3.5. Solvent Pretreament

3.6. Other Pretreatment Techniques

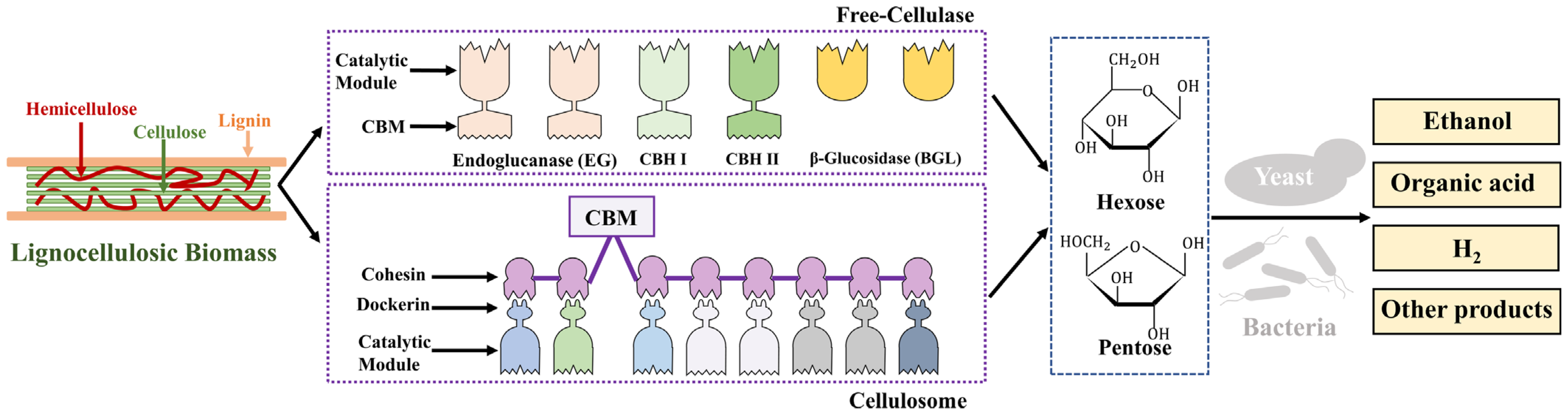

4. Saccharification Process

5. Lignocellulose Hydrolysate in Different Biorefinery Strategies

6. Conclusions and Perspective

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abraham, A.; Mathew, A.K.; Park, H.; Choi, O.; Sindhu, R.; Parameswaran, B.; Pandey, A.; Park, J.H.; Sang, B.-I. Pretreatment Strategies for Enhanced Biogas Production from Lignocellulosic Biomass. Bioresour. Technol. 2020, 301, 122725. [Google Scholar] [CrossRef]

- Basak, B.; Kumar, R.; Bharadwaj, A.V.S.L.S.; Kim, T.H.; Kim, J.R.; Jang, M.; Oh, S.-E.; Roh, H.-S.; Jeon, B.-H. Advances in Physicochemical Pretreatment Strategies for Lignocellulose Biomass and Their Effectiveness in Bioconversion for Biofuel Production. Bioresour. Technol. 2023, 369, 128413. [Google Scholar] [CrossRef]

- Liu, Y.-J.; Zhang, Y.; Chi, F.; Chen, C.; Wan, W.; Feng, Y.; Song, X.; Cui, Q. Integrated Lactic Acid Production from Lignocellulosic Agricultural Wastes under Thermal Conditions. J. Environ. Manag. 2023, 342, 118281. [Google Scholar] [CrossRef]

- Jia, Q.; Zhang, H.; Zhao, A.; Qu, L.; Xiong, W.; Alam, M.A.; Miao, J.; Wang, W.; Li, F.; Xu, J.; et al. Produce D-Allulose from Non-Food Biomass by Integrating Corn Stalk Hydrolysis with Whole-Cell Catalysis. Front. Bioeng. Biotechnol. 2023, 11, 1156953. [Google Scholar] [CrossRef]

- He, T.; Zhang, D.; Chen, W.; Liu, Z.; Zhao, R.; Li, J.; Wu, J.; Wang, Z.; Wu, J. Synergistic Oxidation-Reforming of Biomass for High Quality Syngas Production Based on a Bifunctional Catalyst. Green Carbon 2024, 2, 118–123. [Google Scholar] [CrossRef]

- Seo, M.W.; Lee, S.H.; Nam, H.; Lee, D.; Tokmurzin, D.; Wang, S.; Park, Y.-K. Recent Advances of Thermochemical Conversion Processes for Biorefinery. Bioresour. Technol. 2022, 343, 126109. [Google Scholar] [CrossRef]

- Dhakal, N.; Acharya, B. Syngas Fermentation for the Production of Bio-Based Polymers: A Review. Polymers 2021, 13, 3917. [Google Scholar] [CrossRef]

- Harahap, B.M.; Ahring, B.K. Acetate Production from Syngas Produced from Lignocellulosic Biomass Materials along with Gaseous Fermentation of the Syngas: A Review. Microorganisms 2023, 11, 995. [Google Scholar] [CrossRef]

- Yang, Z.; Leero, D.D.; Yin, C.; Yang, L.; Zhu, L.; Zhu, Z.; Jiang, L. Clostridium as Microbial Cell Factory to Enable the Sustainable Utilization of Three Generations of Feedstocks. Bioresour. Technol. 2022, 361, 127656. [Google Scholar] [CrossRef]

- Patel, A.; Shah, A.R. Integrated Lignocellulosic Biorefinery: Gateway for Production of Second Generation Ethanol and Value Added Products. J. Bioresour. Bioprod. 2021, 6, 108–128. [Google Scholar] [CrossRef]

- Xu, L.-H.; Ma, C.-Y.; Wang, P.-F.; Xu, Y.; Shen, X.-J.; Wen, J.-L.; Yuan, T.-Q. Conversion of Control and Genetically-Modified Poplar into Multi-Scale Products Using Integrated Pretreatments. Bioresour. Technol. 2023, 385, 129415. [Google Scholar] [CrossRef]

- Lu, H.; Xue, M.; Nie, X.; Luo, H.; Tan, Z.; Yang, X.; Shi, H.; Li, X.; Wang, T. Glycoside Hydrolases in the Biodegradation of Lignocellulosic Biomass. 3 Biotech 2023, 13, 402. [Google Scholar] [CrossRef]

- Adsul, M.; Sandhu, S.K.; Singhania, R.R.; Gupta, R.; Puri, S.K.; Mathur, A. Designing a Cellulolytic Enzyme Cocktail for the Efficient and Economical Conversion of Lignocellulosic Biomass to Biofuels. Enzym. Microb. Technol. 2020, 133, 109442. [Google Scholar] [CrossRef]

- Huang, C.; Jiang, X.; Shen, X.; Hu, J.; Tang, W.; Wu, X.; Ragauskas, A.; Jameel, H.; Meng, X.; Yong, Q. Lignin-Enzyme Interaction: A Roadblock for Efficient Enzymatic Hydrolysis of Lignocellulosics. Renew. Sustain. Energy Rev. 2022, 154, 111822. [Google Scholar] [CrossRef]

- Milagres, A.M.F.; Carvalho, W.; Ferraz, A. Topochemistry, Porosity and Chemical Composition Affecting Enzymatic Hydrolysis of Lignocellulosic Materials. In Routes to Cellulosic Ethanol; Buckeridge, M.S., Goldman, G.H., Eds.; Springer: New York, NY, USA, 2010; pp. 53–72. ISBN 978-0-387-92740-4. [Google Scholar]

- da Silva Perez, D.; Dupont, C.; Guillemain, A.; Jacob, S.; Labalette, F.; Briand, S.; Marsac, S.; Guerrini, O.; Broust, F.; Commandre, J.-M. Characterisation of the Most Representative Agricultural and Forestry Biomasses in France for Gasification. Waste Biomass Valor. 2015, 6, 515–526. [Google Scholar] [CrossRef]

- Lai, C.; Yang, C.; Jia, Y.; Xu, X.; Wang, K.; Yong, Q. Lignin Fractionation to Realize the Comprehensive Elucidation of Structure-Inhibition Relationship of Lignins in Enzymatic Hydrolysis. Bioresour. Technol. 2022, 355, 127255. [Google Scholar] [CrossRef]

- Malgas, S.; Kwanya Minghe, V.M.; Pletschke, B.I. The Effect of Hemicellulose on the Binding and Activity of Cellobiohydrolase I, Cel7A, from Trichoderma reesei to Cellulose. Cellulose 2020, 27, 781–797. [Google Scholar] [CrossRef]

- Cunha, J.T.; Romaní, A.; Costa, C.E.; Sá-Correia, I.; Domingues, L. Molecular and Physiological Basis of Saccharomyces cerevisiae Tolerance to Adverse Lignocellulose-Based Process Conditions. Appl. Microbiol. Biotechnol. 2019, 103, 159–175. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, W.; Luo, J.; Wan, Y. Exploring the Potential of Lactic Acid Production from Lignocellulosic Hydrolysates with Various Ratios of Hexose versus Pentose by Bacillus coagulans IPE22. Bioresour. Technol. 2018, 261, 342–349. [Google Scholar] [CrossRef]

- Han, Y.; Chen, H. Synergism between Corn Stover Protein and Cellulase. Enzym. Microb. Technol. 2007, 41, 638–645. [Google Scholar] [CrossRef]

- Jin, C.; Li, J.; Huang, Z.; Han, X.; Bao, J. Engineering Corynebacterium glutamicum for Synthesis of Poly(3-Hydroxybutyrate) from Lignocellulose Biomass. Biotechnol. Bioeng. 2022, 119, 1598–1613. [Google Scholar] [CrossRef]

- Latif, A.A.; Harun, S.; Shaiful, S.M.; Markom, M.; Jahim, J. Ammonia-Based Pretreatment for Ligno-Cellulosic Biomass Conversion—An Overview. J. Eng. Sci. Technol. 2018, 13, 1595–1620. [Google Scholar]

- Xu, F. Chapter 2—Structure, Ultrastructure, and Chemical Composition. In Cereal Straw as a Resource for Sustainable Biomaterials and Biofuels; Sun, R.-C., Ed.; Elsevier: Amsterdam, The Netherlands, 2010; pp. 9–47. ISBN 978-0-444-53234-3. [Google Scholar]

- He, Q.; Hemme, C.L.; Jiang, H.; He, Z.; Zhou, J. Mechanisms of Enhanced Cellulosic Bioethanol Fermentation by Co-Cultivation of Clostridium and Thermoanaerobacter spp. Bioresour. Technol. 2011, 102, 9586–9592. [Google Scholar] [CrossRef]

- Liu, G.; Zhao, X.; Chen, C.; Chi, Z.; Zhang, Y.; Cui, Q.; Chi, Z.; Liu, Y.-J. Robust Production of Pigment-Free Pullulan from Lignocellulosic Hydrolysate by a New Fungus Co-Utilizing Glucose and Xylose. Carbohydr. Polym. 2020, 241, 116400. [Google Scholar] [CrossRef]

- Xia, M.; Zhang, X.; Xiao, Y.; Sheng, Q.; Tu, L.; Chen, F.; Yan, Y.; Zheng, Y.; Wang, M. Interaction of Acetic Acid Bacteria and Lactic Acid Bacteria in Multispecies Solid-State Fermentation of Traditional Chinese Cereal Vinegar. Front. Microbiol. 2022, 13, 964855. [Google Scholar] [CrossRef]

- Intasit, R.; Cheirsilp, B.; Louhasakul, Y.; Thongchul, N. Enhanced Biovalorization of Palm Biomass Wastes as Biodiesel Feedstocks through Integrated Solid-State and Submerged Fermentations by Fungal Co-Cultures. Bioresour. Technol. 2023, 380, 129105. [Google Scholar] [CrossRef]

- Menegon, Y.A.; Gross, J.; Jacobus, A.P. How Adaptive Laboratory Evolution Can Boost Yeast Tolerance to Lignocellulosic Hydrolyses. Curr. Genet. 2022, 68, 319–342. [Google Scholar] [CrossRef]

- Sharma, S.; Nandal, P.; Arora, A. Ethanol Production from NaOH Pretreated Rice Straw: A Cost Effective Option to Manage Rice Crop Residue. Waste Biomass Valor. 2019, 10, 3427–3434. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, X.; Lei, F.; Jiang, J. Co-Production Bioethanol and Xylooligosaccharides from Sugarcane Bagasse via Autohydrolysis Pretreatment. Renew. Energy 2020, 162, 2297–2305. [Google Scholar] [CrossRef]

- Sharma, J.; Kumar, V.; Prasad, R.; Gaur, N.A. Engineering of Saccharomyces cerevisiae as a Consolidated Bioprocessing Host to Produce Cellulosic Ethanol: Recent Advancements and Current Challenges. Biotechnol. Adv. 2022, 56, 107925. [Google Scholar] [CrossRef]

- Awate, B.; Steidl, R.J.; Hamlischer, T.; Reguera, G. Stimulation of Electro-Fermentation in Single-Chamber Microbial Electrolysis Cells Driven by Genetically Engineered Anode Biofilms. J. Power Sources 2017, 356, 510–518. [Google Scholar] [CrossRef]

- Singh, N.; Mathur, A.S.; Tuli, D.K.; Gupta, R.P.; Barrow, C.J.; Puri, M. Cellulosic Ethanol Production via Consolidated Bioprocessing by a Novel Thermophilic Anaerobic Bacterium Isolated from a Himalayan Hot Spring. Biotechnol. Biofuels 2017, 10, 73. [Google Scholar] [CrossRef] [PubMed]

- Cantero, D.; Jara, R.; Navarrete, A.; Pelaz, L.; Queiroz, J.; Rodríguez-Rojo, S.; Cocero, M.J. Pretreatment Processes of Biomass for Biorefineries: Current Status and Prospects. Annu. Rev. Chem. Biomol. Eng. 2019, 10, 289–310. [Google Scholar] [CrossRef] [PubMed]

- Alvira, P.; Tomás-Pejó, E.; Ballesteros, M.; Negro, M.J. Pretreatment Technologies for an Efficient Bioethanol Production Process Based on Enzymatic Hydrolysis: A Review. Bioresour. Technol. 2010, 101, 4851–4861. [Google Scholar] [CrossRef] [PubMed]

- Jönsson, L.J.; Martín, C. Pretreatment of Lignocellulose: Formation of Inhibitory by-Products and Strategies for Minimizing Their Effects. Bioresour. Technol. 2016, 199, 103–112. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, S.K.; Jagtap, S.S.; Bedekar, A.A.; Bhatia, R.K.; Patel, A.K.; Pant, D.; Rajesh Banu, J.; Rao, C.V.; Kim, Y.-G.; Yang, Y.-H. Recent Developments in Pretreatment Technologies on Lignocellulosic Biomass: Effect of Key Parameters, Technological Improvements, and Challenges. Bioresour. Technol. 2020, 300, 122724. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Zhai, R.; Leng, Y.; Deng, Q.; Jin, M. Understanding the Toxicity of Lignin-Derived Phenolics towards Enzymatic Saccharification of Lignocellulose for Rationally Developing Effective in-Situ Mitigation Strategies to Maximize Sugar Production from Lignocellulosic Biorefinery. Bioresour. Technol. 2022, 349, 126813. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.-J.; Li, B.; Feng, Y.; Cui, Q. Consolidated Bio-Saccharification: Leading Lignocellulose Bioconversion into the Real World. Biotechnol. Adv. 2020, 40, 107535. [Google Scholar] [CrossRef] [PubMed]

- Paulová, L.; Patáková, P.; Rychtera, M. High Solid Fed-Batch SSF with Delayed Inoculation for Improved Production of Bioethanol from Wheat Straw. Fuel 2014, 122, 294–300. [Google Scholar] [CrossRef]

- Liu, C.-G.; Xiao, Y.; Xia, X.-X.; Zhao, X.-Q.; Peng, L.; Srinophakun, P.; Bai, F.-W. Cellulosic Ethanol Production: Progress, Challenges and Strategies for Solutions. Biotechnol. Adv. 2019, 37, 491–504. [Google Scholar] [CrossRef]

- Suo, Y.; Li, W.; Wan, L.; Luo, L.; Liu, S.; Qin, S.; Wang, J. Transcriptome Analysis Reveals Reasons for the Low Tolerance of Clostridium tyrobutyricum to Furan Derivatives. Appl. Microbiol. Biotechnol. 2023, 107, 327–339. [Google Scholar] [CrossRef] [PubMed]

- Shabbir, S.; Wang, W.; Nawaz, M.; Boruah, P.; Kulyar, M.F.-A.; Chen, M.; Wu, B.; Liu, P.; Dai, Y.; Sun, L.; et al. Molecular Mechanism of Engineered Zymomonas mobilis to Furfural and Acetic Acid Stress. Microb. Cell Fact. 2023, 22, 88. [Google Scholar] [CrossRef] [PubMed]

- Michelin, M.; Ximenes, E.; Polizeli, M.d.L.T.M.; Ladisch, M.R. Inhibition of Enzyme Hydrolysis of Cellulose by Phenols from Hydrothermally Pretreated Sugarcane Straw. Enzym. Microb. Technol. 2023, 166, 110227. [Google Scholar] [CrossRef] [PubMed]

- Zeng, L.; Si, Z.; Zhao, X.; Feng, P.; Huang, J.; Long, X.; Yi, Y. Metabolome Analysis of the Response and Tolerance Mechanisms of Saccharomyces cerevisiae to Formic Acid Stress. Int. J. Biochem. Cell Biol. 2022, 148, 106236. [Google Scholar] [CrossRef] [PubMed]

- Ranzi, E.; Debiagi, P.E.A.; Frassoldati, A. Mathematical Modeling of Fast Biomass Pyrolysis and Bio-Oil Formation. Note I: Kinetic Mechanism of Biomass Pyrolysis. ACS Sustain. Chem. Eng. 2017, 5, 2867–2881. [Google Scholar] [CrossRef]

- Zhang, B.; Li, J.; Guo, L.; Chen, Z.; Li, C. Photothermally Promoted Cleavage of β-1,4-Glycosidic Bonds of Cellulosic Biomass on Ir/HY Catalyst under Mild Conditions. Appl. Catal. B Environ. 2018, 237, 660–664. [Google Scholar] [CrossRef]

- Ling, Z.; Chen, S.; Zhang, X.; Xu, F. Exploring Crystalline-Structural Variations of Cellulose during Alkaline Pretreatment for Enhanced Enzymatic Hydrolysis. Bioresour. Technol. 2017, 224, 611–617. [Google Scholar] [CrossRef] [PubMed]

- Gnanasekaran, L.; Priya, A.K.; Thanigaivel, S.; Hoang, T.K.A.; Soto-Moscoso, M. The Conversion of Biomass to Fuels via Cutting-Edge Technologies: Explorations from Natural Utilization Systems. Fuel 2023, 331, 125668. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhao, J.; Xu, F.; Li, Y. Pretreatment of Lignocellulosic Biomass for Enhanced Biogas Production. Prog. Energy Combust. Sci. 2014, 42, 35–53. [Google Scholar] [CrossRef]

- Varriale, L.; Ulber, R. Fungal-Based Biorefinery: From Renewable Resources to Organic Acids. ChemBioEng Rev. 2023, 10, 272–292. [Google Scholar] [CrossRef]

- Kim, D. Physico-Chemical Conversion of Lignocellulose: Inhibitor Effects and Detoxification Strategies: A Mini Review. Molecules 2018, 23, 309. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Lv, Z.-W.; Rao, J.; Tian, R.; Sun, S.-N.; Peng, F. Effects of Hydrothermal Pretreatment on the Dissolution and Structural Evolution of Hemicelluloses and Lignin: A Review. Carbohydr. Polym. 2022, 281, 119050. [Google Scholar] [CrossRef] [PubMed]

- Bals, B.; Rogers, C.; Jin, M.; Balan, V.; Dale, B. Evaluation of Ammonia Fibre Expansion (AFEX) Pretreatment for Enzymatic Hydrolysis of Switchgrass Harvested in Different Seasons and Locations. Biotechnol. Biofuels 2010, 3, 1. [Google Scholar] [CrossRef]

- Feng, J.; Techapun, C.; Phimolsiripol, Y.; Phongthai, S.; Khemacheewakul, J.; Taesuwan, S.; Mahakuntha, C.; Porninta, K.; Htike, S.L.; Kumar, A.; et al. Utilization of Agricultural Wastes for Co-Production of Xylitol, Ethanol, and Phenylacetylcarbinol: A Review. Bioresour. Technol. 2024, 392, 129926. [Google Scholar] [CrossRef]

- Zhang, Z.; Donaldson, A.A.; Ma, X. Advancements and Future Directions in Enzyme Technology for Biomass Conversion. Biotechnol. Adv. 2012, 30, 913–919. [Google Scholar] [CrossRef]

- Shen, X.; Sun, R. Recent Advances in Lignocellulose Prior-Fractionation for Biomaterials, Biochemicals, and Bioenergy. Carbohydr. Polym. 2021, 261, 117884. [Google Scholar] [CrossRef] [PubMed]

- Dharmaraja, J.; Shobana, S.; Arvindnarayan, S. Lignocellulosic Biomass Conversion via Greener Pretreatment Methods towards Biorefinery Applications. Bioresour. Technol. 2023, 369, 128328. [Google Scholar] [CrossRef]

- Kumar, V.; Yadav, S.K.; Kumar, J.; Ahluwalia, V. A Critical Review on Current Strategies and Trends Employed for Removal of Inhibitors and Toxic Materials Generated during Biomass Pretreatment. Bioresour. Technol. 2020, 299, 122633. [Google Scholar] [CrossRef] [PubMed]

- Risanto, L.; Adi, D.T.N.; Fajriutami, T.; Teramura, H.; Fatriasari, W.; Hermiati, E.; Kahar, P.; Kondo, A.; Ogino, C. Pretreatment with Dilute Maleic Acid Enhances the Enzymatic Digestibility of Sugarcane Bagasse and Oil Palm Empty Fruit Bunch Fiber. Bioresour. Technol. 2023, 369, 128382. [Google Scholar] [CrossRef]

- Hernández-Beltrán, J.U.; Hernández-Escoto, H. Enzymatic Hydrolysis of Biomass at High-Solids Loadings through Fed-Batch Operation. Biomass Bioenergy 2018, 119, 191–197. [Google Scholar] [CrossRef]

- Shah, T.A.; Ullah, R. Pretreatment of Wheat Straw with Ligninolytic Fungi for Increased Biogas Productivity. Int. J. Environ. Sci. Technol. 2019, 16, 7497–7508. [Google Scholar] [CrossRef]

- Sjulander, N.; Kikas, T. Two-Step Pretreatment of Lignocellulosic Biomass for High-Sugar Recovery from the Structural Plant Polymers Cellulose and Hemicellulose. Energies 2022, 15, 8898. [Google Scholar] [CrossRef]

- Raud, M.; Krennhuber, K.; Jäger, A.; Kikas, T. Nitrogen Explosive Decompression Pre-Treatment: An Alternative to Steam Explosion. Energy 2019, 177, 175–182. [Google Scholar] [CrossRef]

- Yu, J.; Paterson, N.; Blamey, J.; Millan, M. Cellulose, Xylan and Lignin Interactions during Pyrolysis of Lignocellulosic Biomass. Fuel 2017, 191, 140–149. [Google Scholar] [CrossRef]

- Sriariyanun, M.; Gundupalli, M.P.; Phakeenuya, V.; Phusamtisampan, T.; Cheng, Y.-S.; Venkatachalam, P. Biorefinery Approaches for Production of Cellulosic Ethanol Fuel Using Recombinant Engineered Microorganisms. J. Appl. Sci. Eng. 2024, 27, 1985–2005. [Google Scholar] [CrossRef]

- Piedrahita-Rodríguez, S.; Baumberger, S.; Cézard, L.; Poveda-Giraldo, J.A.; Alzate-Ramírez, A.F.; Cardona Alzate, C.A. Comparative Analysis of Trifluoracetic Acid Pretreatment for Lignocellulosic Materials. Materials 2023, 16, 5502. [Google Scholar] [CrossRef]

- García-Velásquez, C.A.; Cardona, C.A. Comparison of the Biochemical and Thermochemical Routes for Bioenergy Production: A Techno-Economic (TEA), Energetic and Environmental Assessment. Energy 2019, 172, 232–242. [Google Scholar] [CrossRef]

- Gao, J.; Chen, L.; Yuan, K.; Huang, H.; Yan, Z. Ionic Liquid Pretreatment to Enhance the Anaerobic Digestion of Lignocellulosic Biomass. Bioresour. Technol. 2013, 150, 352–358. [Google Scholar] [CrossRef]

- Sjulander, N.; Kikas, T. Origin, Impact and Control of Lignocellulosic Inhibitors in Bioethanol Production—A Review. Energies 2020, 13, 4751. [Google Scholar] [CrossRef]

- Wang, Z.; Pawar, P.M.-A.; Derba-Maceluch, M.; Hedenström, M.; Chong, S.-L.; Tenkanen, M.; Jönsson, L.J.; Mellerowicz, E.J. Hybrid Aspen Expressing a Carbohydrate Esterase Family 5 Acetyl Xylan Esterase Under Control of a Wood-Specific Promoter Shows Improved Saccharification. Front. Plant Sci. 2020, 11, 380. [Google Scholar] [CrossRef]

- Zhang, Y.; Mu, X.; Wang, H.; Li, B.; Peng, H. Combined Deacetylation and PFI Refining Pretreatment of Corn Cob for the Improvement of a Two-Stage Enzymatic Hydrolysis. J. Agric. Food Chem. 2014, 62, 4661–4667. [Google Scholar] [CrossRef] [PubMed]

- Świątek, K.; Gaag, S.; Klier, A.; Kruse, A.; Sauer, J.; Steinbach, D. Acid Hydrolysis of Lignocellulosic Biomass: Sugars and Furfurals Formation. Catalysts 2020, 10, 437. [Google Scholar] [CrossRef]

- Brethauer, S.; Antczak, A.; Balan, R.; Zielenkiewicz, T.; Studer, M.H. Steam Explosion Pretreatment of Beechwood. Part 2: Quantification of Cellulase Inhibitors and Their Effect on Avicel Hydrolysis. Energies 2020, 13, 3638. [Google Scholar] [CrossRef]

- Kim, Y.; Ximenes, E.; Mosier, N.S.; Ladisch, M.R. Soluble Inhibitors/Deactivators of Cellulase Enzymes from Lignocellulosic Biomass. Enzym. Microb. Technol. 2011, 48, 408–415. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhai, R.; Li, Y.; Yuan, X.; Liu, Z.-H.; Jin, M. Understanding the Structural Characteristics of Water-Soluble Phenolic Compounds from Four Pretreatments of Corn Stover and Their Inhibitory Effects on Enzymatic Hydrolysis and Fermentation. Biotechnol. Biofuels 2020, 13, 44. [Google Scholar] [CrossRef] [PubMed]

- Gundupalli, M.P.; Cheenkachorn, K.; Chuetor, S.; Kirdponpattara, S.; Gundupalli, S.P.; Show, P.-L.; Sriariyanun, M. Assessment of Pure, Mixed and Diluted Deep Eutectic Solvents on Napier Grass (Cenchrus purpureus): Compositional and Characterization Studies of Cellulose, Hemicellulose and Lignin. Carbohydr. Polym. 2023, 306, 120599. [Google Scholar] [CrossRef] [PubMed]

- Mikulski, D.; Kłosowski, G. High-Pressure Microwave-Assisted Pretreatment of Softwood, Hardwood and Non-Wood Biomass Using Different Solvents in the Production of Cellulosic Ethanol. Biotechnol. Biofuels Bioprod. 2023, 16, 19. [Google Scholar] [CrossRef]

- Awoyale, A.A.; Lokhat, D. Experimental Determination of the Effects of Pretreatment on Selected Nigerian Lignocellulosic Biomass in Bioethanol Production. Sci. Rep. 2021, 11, 557. [Google Scholar] [CrossRef]

- Vu, H.P.; Nguyen, L.N.; Vu, M.T.; Johir, M.A.H.; McLaughlan, R.; Nghiem, L.D. A Comprehensive Review on the Framework to Valorise Lignocellulosic Biomass as Biorefinery Feedstocks. Sci. Total Environ. 2020, 743, 140630. [Google Scholar] [CrossRef]

- Baruah, J.; Nath, B.K.; Sharma, R.; Kumar, S.; Deka, R.C.; Baruah, D.C.; Kalita, E. Recent Trends in the Pretreatment of Lignocellulosic Biomass for Value-Added Products. Front. Energy Res. 2018, 6, 141. [Google Scholar] [CrossRef]

- Liu, Q.; Fan, H. Preparation and Characterization of Xylan by an Efficient Approach with Mechanical Pretreatments. Ind. Crops Prod. 2021, 165, 113420. [Google Scholar] [CrossRef]

- Chen, Y.; Stevens, M.A.; Zhu, Y.; Holmes, J.; Xu, H. Understanding of Alkaline Pretreatment Parameters for Corn Stover Enzymatic Saccharification. Biotechnol. Biofuels 2013, 6, 8. [Google Scholar] [CrossRef] [PubMed]

- Ho, M.C.; Ong, V.Z.; Wu, T.Y. Potential Use of Alkaline Hydrogen Peroxide in Lignocellulosic Biomass Pretreatment and Valorization—A Review. Renew. Sustain. Energy Rev. 2019, 112, 75–86. [Google Scholar] [CrossRef]

- Wang, W.; Chen, X.; Tan, X.; Wang, Q.; Liu, Y.; He, M.; Yu, Q.; Qi, W.; Luo, Y.; Zhuang, X.; et al. Feasibility of Reusing the Black Liquor for Enzymatic Hydrolysis and Ethanol Fermentation. Bioresour. Technol. 2017, 228, 235–240. [Google Scholar] [CrossRef] [PubMed]

- Łukajtis, R.; Rybarczyk, P.; Kucharska, K.; Konopacka-Łyskawa, D.; Słupek, E.; Wychodnik, K.; Kamiński, M. Optimization of Saccharification Conditions of Lignocellulosic Biomass under Alkaline Pre-Treatment and Enzymatic Hydrolysis. Energies 2018, 11, 886. [Google Scholar] [CrossRef]

- Feng, N.; She, S.; Tang, F.; Zhao, X.; Chen, J.; Wang, P.; Wu, Q.; Rojas, O.J. Formation and Identification of Lignin-Carbohydrate Complexes in Pre-Hydrolysis Liquors. Biomacromolecules 2023, 24, 2541–2548. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhan, P.; Shao, L.; Zhang, L.; Qing, Y. Effects of Inhibitors Generated by Dilute Phosphoric Acid Plus Steam-Exploded Poplar on Saccharomyces cerevisiae Growth. Microorganisms 2022, 10, 1456. [Google Scholar] [CrossRef]

- Liu, B.; Liu, L.; Deng, B.; Huang, C.; Zhu, J.; Liang, L.; He, X.; Wei, Y.; Qin, C.; Liang, C.; et al. Application and Prospect of Organic Acid Pretreatment in Lignocellulosic Biomass Separation: A Review. Int. J. Biol. Macromol. 2022, 222, 1400–1413. [Google Scholar] [CrossRef] [PubMed]

- Domínguez-Gómez, C.X.; Nochebuena-Morando, L.E.; Aguilar-Uscanga, M.G.; López-Zamora, L. Statistical Optimization of Dilute Acid and H2O2 Alkaline Pretreatment Using Surface Response Methodology and Tween 80 for the Enhancement of the Enzymatic Hydrolysis of Corncob. Biomass Conv. Bioref. 2023, 13, 6185–6196. [Google Scholar] [CrossRef]

- Yan, Z.; Gao, X.; Gao, Q.; Bao, J. Mechanism of Tolerance to the Lignin-Derived Inhibitor p-Benzoquinone and Metabolic Modification of Biorefinery Fermentation Strains. Appl. Environ. Microbiol. 2019, 85, e01443-19. [Google Scholar] [CrossRef]

- Qiu, Z.; Fang, C.; He, N.; Bao, J. An Oxidoreductase Gene ZMO1116 Enhances the P-Benzoquinone Biodegradation and Chiral Lactic Acid Fermentability of Pediococcus acidilactici. J. Biotechnol. 2020, 323, 231–237. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Liu, B.; Liu, L.; Luo, Y.; Zeng, F.; Qin, C.; Liang, C.; Huang, C.; Yao, S. Pretreatment of Poplar with Eco-Friendly Levulinic Acid to Achieve Efficient Utilization of Biomass. Bioresour. Technol. 2023, 376, 128855. [Google Scholar] [CrossRef] [PubMed]

- Han, T.; Zhang, B.; Yang, H.; Liu, X.; Bao, J. Changes in pH Values Allow for a Visible Detection of the End Point in Submerged Liquid Biodetoxification during Biorefinery Processing. ACS Sustain. Chem. Eng. 2023, 11, 16608–16617. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, Q.; Li, H.; Qureshi, A.S.; Zhang, J.; Bao, X.; Bao, J. Dry Biorefining Maximizes the Potentials of Simultaneous Saccharification and Co-Fermentation for Cellulosic Ethanol Production. Biotechnol. Bioeng. 2018, 115, 60–69. [Google Scholar] [CrossRef]

- He, Y.; Zhang, J.; Bao, J. Dry Dilute Acid Pretreatment by Co-Currently Feeding of Corn Stover Feedstock and Dilute Acid Solution without Impregnation. Bioresour. Technol. 2014, 158, 360–364. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Bao, J. General Method to Correct the Fluctuation of Acid Based Pretreatment Efficiency of Lignocellulose for Highly Efficient Bioconversion. ACS Sustain. Chem. Eng. 2018, 6, 4212–4219. [Google Scholar] [CrossRef]

- Gomes, D.G.; Michelin, M.; Romaní, A.; Domingues, L.; Teixeira, J.A. Co-Production of Biofuels and Value-Added Compounds from Industrial Eucalyptus Globulus Bark Residues Using Hydrothermal Treatment. Fuel 2021, 285, 119265. [Google Scholar] [CrossRef]

- Batista, G.; Souza, R.B.A.; Pratto, B.; dos Santos-Rocha, M.S.R.; Cruz, A.J.G. Effect of Severity Factor on the Hydrothermal Pretreatment of Sugarcane Straw. Bioresour. Technol. 2019, 275, 321–327. [Google Scholar] [CrossRef]

- Shinde, S.D.; Meng, X.; Kumar, R.; Ragauskas, A.J. Recent Advances in Understanding the Pseudo-Lignin Formation in a Lignocellulosic Biorefinery. Green Chem. 2018, 20, 2192–2205. [Google Scholar] [CrossRef]

- He, J.; Huang, C.; Lai, C.; Jin, Y.; Ragauskas, A.; Yong, Q. Investigation of the Effect of Lignin/Pseudo-Lignin on Enzymatic Hydrolysis by Quartz Crystal Microbalance. Ind. Crops Prod. 2020, 157, 112927. [Google Scholar] [CrossRef]

- Liu, Z.C.; Wang, Z.W.; Gao, S.; Tong, Y.X.; Le, X.; Hu, N.W.; Yan, Q.S.; Zhou, X.G.; He, Y.R.; Wang, L. Isolation and Fractionation of the Tobacco Stalk Lignin for Customized Value-Added Utilization. Front. Bioeng. Biotechnol. 2021, 9, 811287. [Google Scholar] [CrossRef] [PubMed]

- Camargo, F.P.; Sakamoto, I.K.; Duarte, I.C.S.; Varesche, M.B.A. Influence of Alkaline Peroxide Assisted and Hydrothermal Pretreatment on Biodegradability and Bio-Hydrogen Formation from Citrus Peel Waste. Int. J. Hydrog. Energy 2019, 44, 22888–22903. [Google Scholar] [CrossRef]

- Rocha, G.J.M.; Silva, V.F.N.; Martín, C.; Gonçalves, A.R.; Nascimento, V.M.; Souto-Maior, A.M. Effect of Xylan and Lignin Removal by Hydrothermal Pretreatment on Enzymatic Conversion of Sugarcane Bagasse Cellulose for Second Generation Ethanol Production. Sugar Technol. 2013, 15, 390–398. [Google Scholar] [CrossRef]

- Singh, R.D.; Bhuyan, K.; Banerjee, J.; Muir, J.; Arora, A. Hydrothermal and Microwave Assisted Alkali Pretreatment for Fractionation of Arecanut Husk. Ind. Crops Prod. 2017, 102, 65–74. [Google Scholar] [CrossRef]

- Sun, S.-F.; Yang, H.-Y.; Yang, J.; Shi, Z.-J. Structural Characterization of Poplar Lignin Based on the Microwave-Assisted Hydrothermal Pretreatment. Int. J. Biol. Macromol. 2021, 190, 360–367. [Google Scholar] [CrossRef] [PubMed]

- Yu, G.; Liu, S.; Feng, X.; Zhang, Y.; Liu, C.; Liu, Y.-J.; Li, B.; Cui, Q.; Peng, H. Impact of Ammonium Sulfite-Based Sequential Pretreatment Combinations on Two Distinct Saccharifications of Wheat Straw. RSC Adv. 2020, 10, 17129–17142. [Google Scholar] [CrossRef] [PubMed]

- Yao, S.; Nie, S.; Yuan, Y.; Wang, S.; Qin, C. Efficient Extraction of Bagasse Hemicelluloses and Characterization of Solid Remainder. Bioresour. Technol. 2015, 185, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Hou, Y.; Wang, S.; Deng, B.; Ma, Y.; Long, X.; Qin, C.; Liang, C.; Huang, C.; Yao, S. Selective Separation of Hemicellulose from Poplar by Hydrothermal Pretreatment with Ferric Chloride and pH Buffer. Int. J. Biol. Macromol. 2023, 251, 126374. [Google Scholar] [CrossRef]

- Zhao, X.; Moates, G.K.; Wilson, D.R.; Ghogare, R.J.; Coleman, M.J.; Waldron, K.W. Steam Explosion Pretreatment and Enzymatic Saccharification of Duckweed (Lemna Minor) Biomass. Biomass Bioenergy 2015, 72, 206–215. [Google Scholar] [CrossRef]

- Cui, W.; Wang, Y.; Sun, Z.; Cui, C.; Li, H.; Luo, K.; Cheng, A. Effects of Steam Explosion on Phenolic Compounds and Dietary Fiber of Grape Pomace. LWT 2023, 173, 114350. [Google Scholar] [CrossRef]

- Ghoreishi, S.; Løhre, C.; Hermundsgård, D.H.; Molnes, J.L.; Tanase-Opedal, M.; Brusletto, R.; Barth, T. Identification and Quantification of Valuable Platform Chemicals in Aqueous Product Streams from a Preliminary Study of a Large Pilot-Scale Steam Explosion of Woody Biomass Using Quantitative Nuclear Magnetic Resonance Spectroscopy. Biomass Conv. Bioref. 2024, 14, 3331–3349. [Google Scholar] [CrossRef]

- Hoang, A.T.; Nguyen, X.P.; Duong, X.Q.; Ağbulut, Ü.; Len, C.; Nguyen, P.Q.P.; Kchaou, M.; Chen, W.-H. Steam Explosion as Sustainable Biomass Pretreatment Technique for Biofuel Production: Characteristics and Challenges. Bioresour. Technol. 2023, 385, 129398. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.; Shan, J.; Chen, Y.; Zhong, L.; Shen, T.; Zhu, C.; Ying, H. Organic Amine Catalytic Organosolv Pretreatment of Corn Stover for Enzymatic Saccharification and High-Quality Lignin. Bioresour. Technol. 2017, 232, 222–228. [Google Scholar] [CrossRef] [PubMed]

- Chin, D.W.K.; Lim, S.; Pang, Y.L.; Lim, C.H.; Shuit, S.H.; Lee, K.M.; Chong, C.T. Effects of Organic Solvents on the Organosolv Pretreatment of Degraded Empty Fruit Bunch for Fractionation and Lignin Removal. Sustainability 2021, 13, 6757. [Google Scholar] [CrossRef]

- Zhao, X.; Cheng, K.; Liu, D. Organosolv Pretreatment of Lignocellulosic Biomass for Enzymatic Hydrolysis. Appl. Microbiol. Biotechnol. 2009, 82, 815–827. [Google Scholar] [CrossRef] [PubMed]

- Satlewal, A.; Agrawal, R.; Bhagia, S.; Sangoro, J.; Ragauskas, A.J. Natural Deep Eutectic Solvents for Lignocellulosic Biomass Pretreatment: Recent Developments, Challenges and Novel Opportunities. Biotechnol. Adv. 2018, 36, 2032–2050. [Google Scholar] [CrossRef] [PubMed]

- Saratale, R.G.; Ponnusamy, V.K.; Piechota, G.; Igliński, B.; Shobana, S.; Park, J.-H.; Saratale, G.D.; Shin, H.S.; Banu, J.R.; Kumar, V.; et al. Green Chemical and Hybrid Enzymatic Pretreatments for Lignocellulosic Biorefineries: Mechanism and Challenges. Bioresour. Technol. 2023, 387, 129560. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Lu, Y.; Li, X.; Ren, J.; Jiang, Z.; Jiang, B.; Wu, W. Comparison of the Degradation Performance of Seven Different Choline Chloride-Based DES Systems on Alkaline Lignin. Polymers 2022, 14, 5100. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Li, F.; Li, C.; Li, Y.; Jiang, D.; Zhang, T.; Lu, C.; Zhang, Q.; Jing, Y. Effect of Deep Eutectic Solvent Pretreatment on Biohydrogen Production from Corncob: Pretreatment Temperature and Duration. Bioengineered 2023, 14, 2252218. [Google Scholar] [CrossRef]

- Xiao, T.; Hou, M.; Guo, X. Recent Progress in Deep Eutectic Solvent (DES) Fractionation of Lignocellulosic Components: A Review. Renew. Sustain. Energy Rev. 2024, 192, 114243. [Google Scholar] [CrossRef]

- Kumar, B.; Bhardwaj, N.; Agrawal, K.; Chaturvedi, V.; Verma, P. Current Perspective on Pretreatment Technologies Using Lignocellulosic Biomass: An Emerging Biorefinery Concept. Fuel Process. Technol. 2020, 199, 106244. [Google Scholar] [CrossRef]

- Tan, Y.T.; Chua, A.S.M.; Ngoh, G.C. Deep Eutectic Solvent for Lignocellulosic Biomass Fractionation and the Subsequent Conversion to Bio-Based Products—A Review. Bioresour. Technol. 2020, 297, 122522. [Google Scholar] [CrossRef] [PubMed]

- Lobato-Rodríguez, Á.; Gullón, B.; Romaní, A.; Ferreira-Santos, P.; Garrote, G.; Del-Río, P.G. Recent Advances in Biorefineries Based on Lignin Extraction Using Deep Eutectic Solvents: A Review. Bioresour. Technol. 2023, 388, 129744. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Wilkins, M.R.; Wang, D. A Review on Strategies to Reduce Ionic Liquid Pretreatment Costs for Biofuel Production. Bioresour. Technol. 2022, 364, 128045. [Google Scholar] [CrossRef] [PubMed]

- Colussi, F.; Rodríguez, H.; Michelin, M.; Teixeira, J.A. Challenges in Using Ionic Liquids for Cellulosic Ethanol Production. Molecules 2023, 28, 1620. [Google Scholar] [CrossRef] [PubMed]

- Gallego-García, M.; Moreno, A.D.; Manzanares, P.; Negro, M.J.; Duque, A. Recent Advances on Physical Technologies for the Pretreatment of Food Waste and Lignocellulosic Residues. Bioresour. Technol. 2023, 369, 128397. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Ding, Z.; Shahadat Hossain, M.; Maurya, R.; Yang, Y.; Singh, V.; Kumar, D.; Salama, E.-S.; Sun, X.; Sindhu, R.; et al. Recent Advances in Lignocellulosic and Algal Biomass Pretreatment and Its Biorefinery Approaches for Biochemicals and Bioenergy Conversion. Bioresour. Technol. 2023, 367, 128281. [Google Scholar] [CrossRef] [PubMed]

- Ling, Z.; Tang, W.; Su, Y.; Shao, L.; Wang, P.; Ren, Y.; Huang, C.; Lai, C.; Yong, Q. Promoting Enzymatic Hydrolysis of Aggregated Bamboo Crystalline Cellulose by Fast Microwave-Assisted Dicarboxylic Acid Deep Eutectic Solvents Pretreatments. Bioresour. Technol. 2021, 333, 125122. [Google Scholar] [CrossRef] [PubMed]

- Dai, L.; He, C.; Wang, Y.; Liu, Y.; Yu, Z.; Zhou, Y.; Fan, L.; Duan, D.; Ruan, R. Comparative Study on Microwave and Conventional Hydrothermal Pretreatment of Bamboo Sawdust: Hydrochar Properties and Its Pyrolysis Behaviors. Energy Convers. Manag. 2017, 146, 1–7. [Google Scholar] [CrossRef]

- Farmanbordar, S.; Amiri, H.; Karimi, K. Simultaneous Organosolv Pretreatment and Detoxification of Municipal Solid Waste for Efficient Biobutanol Production. Bioresour. Technol. 2018, 270, 236–244. [Google Scholar] [CrossRef]

- Guo, H.; Zhao, Y.; Chang, J.-S.; Lee, D.-J. Inhibitor Formation and Detoxification during Lignocellulose Biorefinery: A Review. Bioresour. Technol. 2022, 361, 127666. [Google Scholar] [CrossRef] [PubMed]

- Silveira, M.H.L.; Morais, A.R.C.; da Costa Lopes, A.M.; Olekszyszen, D.N.; Bogel-Łukasik, R.; Andreaus, J.; Pereira Ramos, L. Current Pretreatment Technologies for the Development of Cellulosic Ethanol and Biorefineries. ChemSusChem 2015, 8, 3366–3390. [Google Scholar] [CrossRef] [PubMed]

- Capolupo, L.; Faraco, V. Green Methods of Lignocellulose Pretreatment for Biorefinery Development. Appl. Microbiol. Biotechnol. 2016, 100, 9451–9467. [Google Scholar] [CrossRef] [PubMed]

- Vasić, K.; Knez, Ž.; Leitgeb, M. Bioethanol Production by Enzymatic Hydrolysis from Different Lignocellulosic Sources. Molecules 2021, 26, 753. [Google Scholar] [CrossRef] [PubMed]

- Xiao, M.; Liu, Y.-J.; Bayer, E.A.; Kosugi, A.; Cui, Q.; Feng, Y. Cellulosomal Hemicellulases: Indispensable Players for Ensuring Effective Lignocellulose Bioconversion. Green Carbon 2024, 2, 57–69. [Google Scholar] [CrossRef]

- You, C.; Liu, Y.-J.; Cui, Q.; Feng, Y. Glycoside Hydrolase Family 48 Cellulase: A Key Player in Cellulolytic Bacteria for Lignocellulose Biorefinery. Fermentation 2023, 9, 204. [Google Scholar] [CrossRef]

- Singh, N.; Singhania, R.R.; Nigam, P.S.; Dong, C.-D.; Patel, A.K.; Puri, M. Global Status of Lignocellulosic Biorefinery: Challenges and Perspectives. Bioresour. Technol. 2022, 344, 126415. [Google Scholar] [CrossRef] [PubMed]

- Ubando, A.T.; Felix, C.B.; Chen, W.-H. Biorefineries in Circular Bioeconomy: A Comprehensive Review. Bioresour. Technol. 2020, 299, 122585. [Google Scholar] [CrossRef] [PubMed]

- Rani Singhania, R.; Dixit, P.; Kumar Patel, A.; Shekher Giri, B.; Kuo, C.-H.; Chen, C.-W.; Di Dong, C. Role and Significance of Lytic Polysaccharide Monooxygenases (LPMOs) in Lignocellulose Deconstruction. Bioresour. Technol. 2021, 335, 125261. [Google Scholar] [CrossRef]

- Müller, G.; Várnai, A.; Johansen, K.S.; Eijsink, V.G.H.; Horn, S.J. Harnessing the Potential of LPMO-Containing Cellulase Cocktails Poses New Demands on Processing Conditions. Biotechnol. Biofuels 2015, 8, 187. [Google Scholar] [CrossRef]

- Moon, M.; Lee, J.-P.; Park, G.W.; Lee, J.-S.; Park, H.J.; Min, K. Lytic Polysaccharide Monooxygenase (LPMO)-Derived Saccharification of Lignocellulosic Biomass. Bioresour. Technol. 2022, 359, 127501. [Google Scholar] [CrossRef] [PubMed]

- Lopes, A.M.; Ferreira Filho, E.X.; Moreira, L.R.S. An Update on Enzymatic Cocktails for Lignocellulose Breakdown. J. Appl. Microbiol. 2018, 125, 632–645. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Zhang, T.; Hasunuma, T.; Kondo, A.; Zhao, X.-Q.; Feng, J.-X. Every Road Leads to Rome: Diverse Biosynthetic Regulation of Plant Cell Wall-Degrading Enzymes in Filamentous Fungi Penicillium oxalicum and Trichoderma reesei. Crit. Rev. Biotechnol. 2023; online ahead of print. [Google Scholar] [CrossRef]

- Ma, C.; Liu, J.; Tang, J.; Sun, Y.; Jiang, X.; Zhang, T.; Feng, Y.; Liu, Q.; Wang, L. Current Genetic Strategies to Investigate Gene Functions in Trichoderma reesei. Microb. Cell Fact. 2023, 22, 97. [Google Scholar] [CrossRef] [PubMed]

- Pant, S.; Ritika; Nag, P.; Ghati, A.; Chakraborty, D.; Maximiano, M.R.; Franco, O.L.; Mandal, A.K.; Kuila, A. Employment of the CRISPR/Cas9 System to Improve Cellulase Production in Trichoderma reesei. Biotechnol. Adv. 2022, 60, 108022. [Google Scholar] [CrossRef] [PubMed]

- Qi, W.; Feng, Q.; Wang, W.; Zhang, Y.; Hu, Y.; Shakeel, U.; Xiao, L.; Wang, L.; Chen, H.; Liang, C. Combination of Surfactants and Enzyme Cocktails for Enhancing Woody Biomass Saccharification and Bioethanol Production from Lab-Scale to Pilot-Scale. Bioresour. Technol. 2023, 384, 129343. [Google Scholar] [CrossRef] [PubMed]

- Ramos, M.D.N.; Sandri, J.P.; Claes, A.; Carvalho, B.T.; Thevelein, J.M.; Zangirolami, T.C.; Milessi, T.S. Effective Application of Immobilized Second Generation Industrial Saccharomyces cerevisiae Strain on Consolidated Bioprocessing. New Biotechnol. 2023, 78, 153–161. [Google Scholar] [CrossRef] [PubMed]

- Qiao, J.; Cui, H.; Wang, M.; Fu, X.; Wang, X.; Li, X.; Huang, H. Integrated Biorefinery Approaches for the Industrialization of Cellulosic Ethanol Fuel. Bioresour. Technol. 2022, 360, 127516. [Google Scholar] [CrossRef] [PubMed]

- Haldar, D.; Dey, P.; Thomas, J.; Singhania, R.R.; Patel, A.K. One Pot Bioprocessing in Lignocellulosic Biorefinery: A Review. Bioresour. Technol. 2022, 365, 128180. [Google Scholar] [CrossRef] [PubMed]

- Ilić, N.; Milić, M.; Beluhan, S.; Dimitrijević-Branković, S. Cellulases: From Lignocellulosic Biomass to Improved Production. Energies 2023, 16, 3598. [Google Scholar] [CrossRef]

- Nargotra, P.; Sharma, V.; Lee, Y.-C.; Tsai, Y.-H.; Liu, Y.-C.; Shieh, C.-J.; Tsai, M.-L.; Dong, C.-D.; Kuo, C.-H. Microbial Lignocellulolytic Enzymes for the Effective Valorization of Lignocellulosic Biomass: A Review. Catalysts 2023, 13, 83. [Google Scholar] [CrossRef]

- Singh, N.; Mathur, A.S.; Gupta, R.P.; Barrow, C.J.; Tuli, D.K.; Puri, M. Enzyme Systems of Thermophilic Anaerobic Bacteria for Lignocellulosic Biomass Conversion. Int. J. Biol. Macromol. 2021, 168, 572–590. [Google Scholar] [CrossRef] [PubMed]

- Béguin, P.; Lemaire, M. The Cellulosome: An Exocellular, Multiprotein Complex Specialized in Cellulose Degradation. Crit. Rev. Biochem. Mol. Biol. 1996, 31, 201–236. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Liu, Y.; Cui, Q. Research Progress in Cellulosomes and Their Applications in Synthetic Biology. Synth. Biol. J. 2022, 3, 138. [Google Scholar] [CrossRef]

- Xu, C.; Qin, Y.; Li, Y.; Ji, Y.; Huang, J.; Song, H.; Xu, J. Factors Influencing Cellulosome Activity in Consolidated Bioprocessing of Cellulosic Ethanol. Bioresour. Technol. 2010, 101, 9560–9569. [Google Scholar] [CrossRef] [PubMed]

- Alves, V.D.; Fontes, C.M.G.A.; Bule, P. Cellulosomes: Highly Efficient Cellulolytic Complexes. Subcell. Biochem. 2021, 96, 323–354. [Google Scholar] [CrossRef] [PubMed]

- Fierer, J.O.; Tovar-Herrera, O.E.; Weinstein, J.Y.; Kahn, A.; Moraïs, S.; Mizrahi, I.; Bayer, E.A. Affinity-Induced Covalent Protein-Protein Ligation via the SpyCatcher-SpyTag Interaction. Green Carbon 2023, 1, 33–42. [Google Scholar] [CrossRef]

- Yao, X.; Chen, C.; Wang, Y.; Dong, S.; Liu, Y.-J.; Li, Y.; Cui, Z.; Gong, W.; Perrett, S.; Yao, L.; et al. Discovery and Mechanism of a pH-Dependent Dual-Binding-Site Switch in the Interaction of a Pair of Protein Modules. Sci. Adv. 2020, 6, eabd7182. [Google Scholar] [CrossRef]

- Chen, C.; Yang, H.; Dong, S.; You, C.; Moraïs, S.; Edward, B.; Liu, Y.-J.; Xuan, J.; Cui, Q.; Mizrahi, I.; et al. A Cellulosomal Double-dockerin Module from Clostridium thermocellum Shows Distinct Structural and Cohesin-binding Features. Protein Sci. 2024, 33, e4937. [Google Scholar] [CrossRef]

- Artzi, L.; Bayer, E.A.; Moraïs, S. Cellulosomes: Bacterial Nanomachines for Dismantling Plant Polysaccharides. Nat. Rev. Microbiol. 2017, 15, 83–95. [Google Scholar] [CrossRef]

- Nataf, Y.; Bahari, L.; Kahel-Raifer, H.; Borovok, I.; Lamed, R.; Bayer, E.A.; Sonenshein, A.L.; Shoham, Y. Clostridium thermocellum Cellulosomal Genes Are Regulated by Extracytoplasmic Polysaccharides via Alternative Sigma Factors. Proc. Natl. Acad. Sci. USA 2010, 107, 18646–18651. [Google Scholar] [CrossRef]

- Wei, Z.; Chen, C.; Liu, Y.-J.; Dong, S.; Li, J.; Qi, K.; Liu, S.; Ding, X.; Ortiz de Ora, L.; Muñoz-Gutiérrez, I.; et al. Alternative σI/Anti-σI Factors Represent a Unique Form of Bacterial σ/Anti-σ Complex. Nucleic Acids Res. 2019, 47, 5988–5997. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Dong, S.; Yu, Z.; Qiao, Y.; Li, J.; Ding, X.; Li, R.; Lin, J.; Bayer, E.A.; Liu, Y.-J.; et al. Essential Autoproteolysis of Bacterial Anti-σ Factor RsgI for Transmembrane Signal Transduction. Sci. Adv. 2023, 9, eadg4846. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhang, H.; Li, D.; Liu, Y.-J.; Bayer, E.A.; Cui, Q.; Feng, Y.; Zhu, P. Structure of the Transcription Open Complex of Distinct σI Factors. Nat. Commun. 2023, 14, 6455. [Google Scholar] [CrossRef]

- Nhim, S.; Waeonukul, R.; Uke, A.; Baramee, S.; Ratanakhanokchai, K.; Tachaapaikoon, C.; Pason, P.; Liu, Y.-J.; Kosugi, A. Biological Cellulose Saccharification Using a Coculture of Clostridium thermocellum and Thermobrachium celere Strain A9. Appl. Microbiol. Biotechnol. 2022, 106, 2133. [Google Scholar] [CrossRef] [PubMed]

- Konar, S.; Sinha, S.K.; Datta, S.; Ghorai, P.K. Probing the Effect of Glucose on the Activity and Stability of β-Glucosidase: An All-Atom Molecular Dynamics Simulation Investigation. ACS Omega 2019, 4, 11189–11196. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, S.; Li, R.; Hong, W.; Xiao, Y.; Feng, Y.; Cui, Q.; Liu, Y.-J. Efficient Whole-Cell-Catalyzing Cellulose Saccharification Using Engineered Clostridium thermocellum. Biotechnol. Biofuels 2017, 10, 124. [Google Scholar] [CrossRef] [PubMed]

- Qi, K.; Chen, C.; Yan, F.; Feng, Y.; Bayer, E.A.; Kosugi, A.; Cui, Q.; Liu, Y.-J. Coordinated β-Glucosidase Activity with the Cellulosome Is Effective for Enhanced Lignocellulose Saccharification. Bioresour. Technol. 2021, 337, 125441. [Google Scholar] [CrossRef] [PubMed]

- Erkanli, M.E.; El-Halabi, K.; Kim, J.R. Exploring the Diversity of β-Glucosidase: Classification, Catalytic Mechanism, Molecular Characteristics, Kinetic Models, and Applications. Enzym. Microb. Technol. 2024, 173, 110363. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Qi, K.; Chi, F.; Song, X.; Feng, Y.; Cui, Q.; Liu, Y.-J. Dissolved Xylan Inhibits Cellulosome-Based Saccharification by Binding to the Key Cellulosomal Component of Clostridium thermocellum. Int. J. Biol. Macromol. 2022, 207, 784–790. [Google Scholar] [CrossRef]

- Qiao, J.; Sheng, Y.; Wang, M.; Li, A.; Li, X.; Huang, H. Evolving Robust and Interpretable Enzymes for the Bioethanol Industry. Angew. Chem. Int. Ed. 2023, 62, e202300320. [Google Scholar] [CrossRef]

- Zhao, X.-Q.; Liu, C.-G.; Bai, F.-W. Making the Biochemical Conversion of Lignocellulose More Robust. Trends Biotechnol. 2024, 42, 418–430. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.; Li, J.; Gao, H.; Zhou, D.; Xu, H.; Cong, Y.; Zhang, W.; Xin, F.; Jiang, M. Recent Progress on Bio-Succinic Acid Production from Lignocellulosic Biomass. World J. Microbiol. Biotechnol. 2021, 37, 16. [Google Scholar] [CrossRef] [PubMed]

- Ask, M.; Olofsson, K.; Di Felice, T.; Ruohonen, L.; Penttilä, M.; Lidén, G.; Olsson, L. Challenges in Enzymatic Hydrolysis and Fermentation of Pretreated Arundo Donax Revealed by a Comparison between SHF and SSF. Process Biochem. 2012, 47, 1452–1459. [Google Scholar] [CrossRef]

- Jesus, M.S.; Romaní, A.; Genisheva, Z.; Teixeira, J.A.; Domingues, L. Integral Valorization of Vine Pruning Residue by Sequential Autohydrolysis Stages. J. Clean. Prod. 2017, 168, 74–86. [Google Scholar] [CrossRef]

- Mohapatra, S.; Ranjan Mishra, R.; Nayak, B.; Chandra Behera, B.; Das Mohapatra, P.K. Development of Co-Culture Yeast Fermentation for Efficient Production of Biobutanol from Rice Straw: A Useful Insight in Valorization of Agro Industrial Residues. Bioresour. Technol. 2020, 318, 124070. [Google Scholar] [CrossRef]

- Chavan, S.; Shete, A.; Mirza, Y.; Dharne, M.S. Investigation of Cold-Active and Mesophilic Cellulases: Opportunities Awaited. Biomass Conv. Bioref. 2023, 13, 8829–8852. [Google Scholar] [CrossRef]

- Zhang, Q.; Bao, J. Industrial Cellulase Performance in the Simultaneous Saccharification and Co-Fermentation (SSCF) of Corn Stover for High-Titer Ethanol Production. Bioresour. Bioprocess. 2017, 4, 17. [Google Scholar] [CrossRef]

- Sóti, V.; Lenaerts, S.; Cornet, I. Of Enzyme Use in Cost-Effective High Solid Simultaneous Saccharification and Fermentation Processes. J. Biotechnol. 2018, 270, 70–76. [Google Scholar] [CrossRef]

- Zhang, K.; Jiang, Z.; Li, X.; Wang, D.; Hong, J. Enhancing Simultaneous Saccharification and Co-Fermentation of Corncob by Kluyveromyces Marxianus through Overexpression of Putative Transcription Regulator. Bioresour. Technol. 2024, 399, 130627. [Google Scholar] [CrossRef]

- Olofsson, K.; Bertilsson, M.; Lidén, G. A Short Review on SSF—An Interesting Process Option for Ethanol Production from Lignocellulosic Feedstocks. Biotechnol. Biofuels 2008, 1, 7. [Google Scholar] [CrossRef]

- Suriyachai, N.; Weerasaia, K.; Laosiripojana, N.; Champreda, V.; Unrean, P. Optimized Simultaneous Saccharification and Co-Fermentation of Rice Straw for Ethanol Production by Saccharomyces cerevisiae and Scheffersomyces stipitis Co-Culture Using Design of Experiments. Bioresour. Technol. 2013, 142, 171–178. [Google Scholar] [CrossRef]

- Golias, H.; Dumsday, G.J.; Stanley, G.A.; Pamment, N.B. Evaluation of a Recombinant Klebsiella oxytoca Strain for Ethanol Production from Cellulose by Simultaneous Saccharification and Fermentation: Comparison with Native Cellobiose-Utilising Yeast Strains and Performance in Co-Culture with Thermotolerant Yeast and Zymomonas mobilis. J. Biotechnol. 2002, 96, 155–168. [Google Scholar] [CrossRef] [PubMed]

- Miah, R.; Siddiqa, A.; Chakraborty, U.; Tuli, J.F.; Barman, N.K.; Uddin, A.; Aziz, T.; Sharif, N.; Dey, S.K.; Yamada, M.; et al. Development of High Temperature Simultaneous Saccharification and Fermentation by Thermosensitive Saccharomyces cerevisiae and Bacillus amyloliquefaciens. Sci. Rep. 2022, 12, 3630. [Google Scholar] [CrossRef]

- Wei, N.; Oh, E.J.; Million, G.; Cate, J.H.D.; Jin, Y.-S. Simultaneous Utilization of Cellobiose, Xylose, and Acetic Acid from Lignocellulosic Biomass for Biofuel Production by an Engineered Yeast Platform. ACS Synth. Biol. 2015, 4, 707–713. [Google Scholar] [CrossRef] [PubMed]

- Toor, M.; Kumar, S.S.; Malyan, S.K.; Bishnoi, N.R.; Mathimani, T.; Rajendran, K.; Pugazhendhi, A. An Overview on Bioethanol Production from Lignocellulosic Feedstocks. Chemosphere 2020, 242, 125080. [Google Scholar] [CrossRef]

- Haokok, C.; Lunprom, S.; Reungsang, A.; Salakkam, A. Efficient Production of Lactic Acid from Cellulose and Xylan in Sugarcane Bagasse by Newly Isolated Lactiplantibacillus plantarum and Levilactobacillus brevis through Simultaneous Saccharification and Co-Fermentation Process. Heliyon 2023, 9, e17935. [Google Scholar] [CrossRef]

- Tareen, A.K.; Punsuvon, V.; Sultan, I.N.; Khan, M.W.; Parakulsuksatid, P. Cellulase Addition and Pre-Hydrolysis Effect of High Solid Fed-Batch Simultaneous Saccharification and Ethanol Fermentation from a Combined Pretreated Oil Palm Trunk. ACS Omega 2021, 6, 26119–26129. [Google Scholar] [CrossRef]

- Liu, Y.; Tang, Y.; Gao, H.; Zhang, W.; Jiang, Y.; Xin, F.; Jiang, M. Challenges and Future Perspectives of Promising Biotechnologies for Lignocellulosic Biorefinery. Molecules 2021, 26, 5411. [Google Scholar] [CrossRef] [PubMed]

- Dev, C.; Jilani, S.B.; Yazdani, S.S. Adaptation on Xylose Improves Glucose–Xylose Co-Utilization and Ethanol Production in a Carbon Catabolite Repression (CCR) Compromised Ethanologenic Strain. Microb. Cell Fact. 2022, 21, 154. [Google Scholar] [CrossRef]

- Xin, F.; Dong, W.; Zhang, W.; Ma, J.; Jiang, M. Biobutanol Production from Crystalline Cellulose through Consolidated Bioprocessing. Trends Biotechnol. 2019, 37, 167–180. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, M.; Zhu, L.; Zhao, X.; Chen, J.; Chen, W.; Chang, C. Hydrolysis of Lignocellulose to Succinic Acid: A Review of Treatment Methods and Succinic Acid Applications. Biotechnol. Biofuels 2023, 16, 1. [Google Scholar] [CrossRef] [PubMed]

- Froese, A.G.; Nguyen, T.-N.; Ayele, B.T.; Sparling, R. Digestibility of Wheat and Cattail Biomass Using a Co-Culture of Thermophilic Anaerobes for Consolidated Bioprocessing. Bioenerg. Res. 2020, 13, 325–333. [Google Scholar] [CrossRef]

- Mai, J.; Hu, B.-B.; Zhu, M.-J. Metabolic Division of Labor between Acetivibrio thermocellus DSM 1313 and Thermoanaerobacterium thermosaccharolyticum MJ1 Enhanced Hydrogen Production from Lignocellulose. Bioresour Technol. 2023, 390, 129871. [Google Scholar] [CrossRef] [PubMed]

- Roell, G.W.; Zha, J.; Carr, R.R.; Koffas, M.A.; Fong, S.S.; Tang, Y.J. Engineering Microbial Consortia by Division of Labor. Microb. Cell Factories 2019, 18, 35. [Google Scholar] [CrossRef]

- Holwerda, E.K.; Worthen, R.S.; Kothari, N.; Lasky, R.C.; Davison, B.H.; Fu, C.; Wang, Z.-Y.; Dixon, R.A.; Biswal, A.K.; Mohnen, D.; et al. Multiple Levers for Overcoming the Recalcitrance of Lignocellulosic Biomass. Biotechnol. Biofuels 2019, 12, 15. [Google Scholar] [CrossRef] [PubMed]

- Beri, D.; York, W.S.; Lynd, L.R.; Peña, M.J.; Herring, C.D. Development of a Thermophilic Coculture for Corn Fiber Conversion to Ethanol. Nat. Commun. 2020, 11, 1937. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Liu, Y.; Feng, Y.; Cui, Q. Progress in Synthetic Biology Research of Clostridium thermocellum for Biomass Energy Applications. Synth. Biol. J. 2023, 4, 1055. [Google Scholar] [CrossRef]

- Buehler, E.A.; Mesbah, A. Kinetic Study of Acetone-Butanol-Ethanol Fermentation in Continuous Culture. PLoS ONE 2016, 11, e0158243. [Google Scholar] [CrossRef] [PubMed]

- Ceaser, R.; Montané, D.; Constantí, M.; Medina, F. Current Progress on Lignocellulosic Bioethanol Including a Technological and Economical Perspective. Environ. Dev. Sustain. 2024; online ahead of print. [Google Scholar] [CrossRef]

- Banerjee, S.; Pandit, C.; Gundupalli, M.P.; Pandit, S.; Rai, N.; Lahiri, D.; Chaubey, K.K.; Joshi, S.J. Life Cycle Assessment of Revalorization of Lignocellulose for the Development of Biorefineries. Environ. Dev. Sustain. 2023; online ahead of print. [Google Scholar] [CrossRef]

- Hakeem, I.G.; Sharma, A.; Sharma, T.; Sharma, A.; Joshi, J.B.; Shah, K.; Ball, A.S.; Surapaneni, A. Techno-Economic Analysis of Biochemical Conversion of Biomass to Biofuels and Platform Chemicals. Biofuels Bioprod. Biorefining 2023, 17, 718–750. [Google Scholar] [CrossRef]

- Bilal, M.; Iqbal, H.M.N. Recent Advancements in the Life Cycle Analysis of Lignocellulosic Biomass. Curr. Sustain. Renew. Energy Rep. 2020, 7, 100–107. [Google Scholar] [CrossRef]

- Unrean, P. Techno-Economic Assessment of Bioethanol Production from Major Lignocellulosic Residues Under Different Process Configurations. In Sustainable Biotechnology—Enzymatic Resources of Renewable Energy; Singh, O.V., Chandel, A.K., Eds.; Springer International Publishing: Cham, Germany, 2018; pp. 177–204. ISBN 978-3-319-95480-6. [Google Scholar]

- Fernández-Rodríguez, J.; Erdocia, X.; Alriols, M.G.; Labidi, J. Techno-Economic Analysis of Different Integrated Biorefinery Scenarios Using Lignocellulosic Waste Streams as Source for Phenolic Alcohols Production. J. Clean. Prod. 2021, 285, 124829. [Google Scholar] [CrossRef]

- Sassner, P.; Galbe, M.; Zacchi, G. Techno-Economic Evaluation of Bioethanol Production from Three Different Lignocellulosic Materials. Biomass Bioenergy 2008, 32, 422–430. [Google Scholar] [CrossRef]

- Mu, D.; Seager, T.; Rao, P.S.; Zhao, F. Comparative Life Cycle Assessment of Lignocellulosic Ethanol Production: Biochemical Versus Thermochemical Conversion. Environ. Manag. 2010, 46, 565–578. [Google Scholar] [CrossRef]

- Prasad, A.; Sotenko, M.; Blenkinsopp, T.; Coles, S.R. Life Cycle Assessment of Lignocellulosic Biomass Pretreatment Methods in Biofuel Production. Int. J. Life Cycle Assess. 2016, 21, 44–50. [Google Scholar] [CrossRef]

- Wingren, A.; Galbe, M.; Zacchi, G. Techno-Economic Evaluation of Producing Ethanol from Softwood: Comparison of SSF and SHF and Identification of Bottlenecks. Biotechnol. Prog. 2003, 19, 1109–1117. [Google Scholar] [CrossRef] [PubMed]

- Kadhum, H.J.; Mahapatra, D.M.; Murthy, G.S. A Comparative Account of Glucose Yields and Bioethanol Production from Separate and Simultaneous Saccharification and Fermentation Processes at High Solids Loading with Variable PEG Concentration. Bioresour. Technol. 2019, 283, 67–75. [Google Scholar] [CrossRef] [PubMed]

- Khajeeram, S.; Unrean, P. Techno-Economic Assessment of High-Solid Simultaneous Saccharification and Fermentation and Economic Impacts of Yeast Consortium and on-Site Enzyme Production Technologies. Energy 2017, 122, 194–203. [Google Scholar] [CrossRef]

- Dempfle, D.; Kröcher, O.; Studer, M.H.-P. Techno-Economic Assessment of Bioethanol Production from Lignocellulose by Consortium-Based Consolidated Bioprocessing at Industrial Scale. New Biotechnol. 2021, 65, 53–60. [Google Scholar] [CrossRef] [PubMed]

- Raftery, J.P.; Karim, M.N. Economic Viability of Consolidated Bioprocessing Utilizing Multiple Biomass Substrates for Commercial-Scale Cellulosic Bioethanol Production. Biomass Bioenergy 2017, 103, 35–46. [Google Scholar] [CrossRef]

- Andhalkar, V.V.; Foong, S.Y.; Kee, S.H.; Lam, S.S.; Chan, Y.H.; Djellabi, R.; Bhubalan, K.; Medina, F.; Constantí, M. Integrated Biorefinery Design with Techno-Economic and Life Cycle Assessment Tools in Polyhydroxyalkanoates Processing. Macromol. Mater. Eng. 2023, 308, 2300100. [Google Scholar] [CrossRef]

| Biomass | Cellulose (%) | Hemicellulose (%) | Lignin (%) | Reference |

|---|---|---|---|---|

| Sugarcane bagasse | 32–55 | 22–36 | 14–30 | [61] |

| Sugarcane straw | 29 | 28.8 | 32.2 | [45] |

| Sorghum straw | 26.93 | 32.57 | 10.16 | [62] |

| Wheat straw | 43.4 | 26.9 | 22.2 | [63] |

| Barley straw | 35.73–45.73 | 26.8–32.6 | 5.3–5.9 | [64,65] |

| Aspen wood | 50.7 | 16.6 | 13.3 | [64] |

| Oak | 43.2 | 21.9 | 35.4 | [66] |

| Corn stover | 38 | 23 | 20 | [67] |

| Switchgrass | 50 | 40 | 20 | [67] |

| Pine chip | 33–44.78 | 17.56–23.75 | 20.22–26.29 | [68,69] |

| Spruce | 24.7 | 10.2 | 35 | [70] |

| Pretreatment Method | Nutrient Retention | Inhibitor Production | Reference |

|---|---|---|---|

| Alkaline pretreatment | Removal of lignin, partial hemicellulose; less sugar dissolution | Formic acid; acetic acid; hydroxy acid; phenols | [37,77] |

| Acid pretreatment | Partial or complete removal of hemicellulose; more sugar dissolution | Furfural; 5-HMF; phenols; quinones; acetic acid | [91,92] |

| Steam explosion | Significant dissolution of hemicellulose, minor dissolution of cellulose; less degradation of sugar | Furfural; 5-HMF; formic acid; acetic acid | [36,111,112,113] |

| Nitrogen explosion | Hemicellulose dissolution | [65] | |

| Liquid hot water | More hemicellulose dissolved; higher sugar recovery; less cellulose loss | Furfural; 5-HMF; acetic acid; phenols; pseudo-lignin | [2,36,54] |

| Organic solvent | Removal of part of the hemicellulose, dissolution of lignin | Furfural; 5-HMF | [132] |

| Deep eutectic solvents | Removal of hemicellulose and lignin | Furfural; 5-HMF; levulinic acid | [123] |

| Ionic liquid | High lignin extraction rate, partial degradation of hemicellulose, possibly reduced cellulose crystallinity | Furfural; 5-HMF; weak acid | [37,126,133,134] |

| Physical pretreatment | Reduced cellulose crystallinity, less sugar degradation | Furfural; phenols | [36,133,135] |

| Biological pretreatment | High lignin degradation, low cellulose degradation, reduced sugar | Furfural; 5-HMF; organic acids | [36,133] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhang, Y.; Cui, Q.; Feng, Y.; Xuan, J. Composition of Lignocellulose Hydrolysate in Different Biorefinery Strategies: Nutrients and Inhibitors. Molecules 2024, 29, 2275. https://doi.org/10.3390/molecules29102275

Wang Y, Zhang Y, Cui Q, Feng Y, Xuan J. Composition of Lignocellulose Hydrolysate in Different Biorefinery Strategies: Nutrients and Inhibitors. Molecules. 2024; 29(10):2275. https://doi.org/10.3390/molecules29102275

Chicago/Turabian StyleWang, Yilan, Yuedong Zhang, Qiu Cui, Yingang Feng, and Jinsong Xuan. 2024. "Composition of Lignocellulose Hydrolysate in Different Biorefinery Strategies: Nutrients and Inhibitors" Molecules 29, no. 10: 2275. https://doi.org/10.3390/molecules29102275

APA StyleWang, Y., Zhang, Y., Cui, Q., Feng, Y., & Xuan, J. (2024). Composition of Lignocellulose Hydrolysate in Different Biorefinery Strategies: Nutrients and Inhibitors. Molecules, 29(10), 2275. https://doi.org/10.3390/molecules29102275