Increasing Protein Content of Rice Flour with Maintained Processability by Using Granular Starch Hydrolyzing Enzyme

Abstract

1. Introduction

2. Results and Discussion

2.1. The Degree of Hydrolysis (DH), Total Starch, and Total Protein Contents

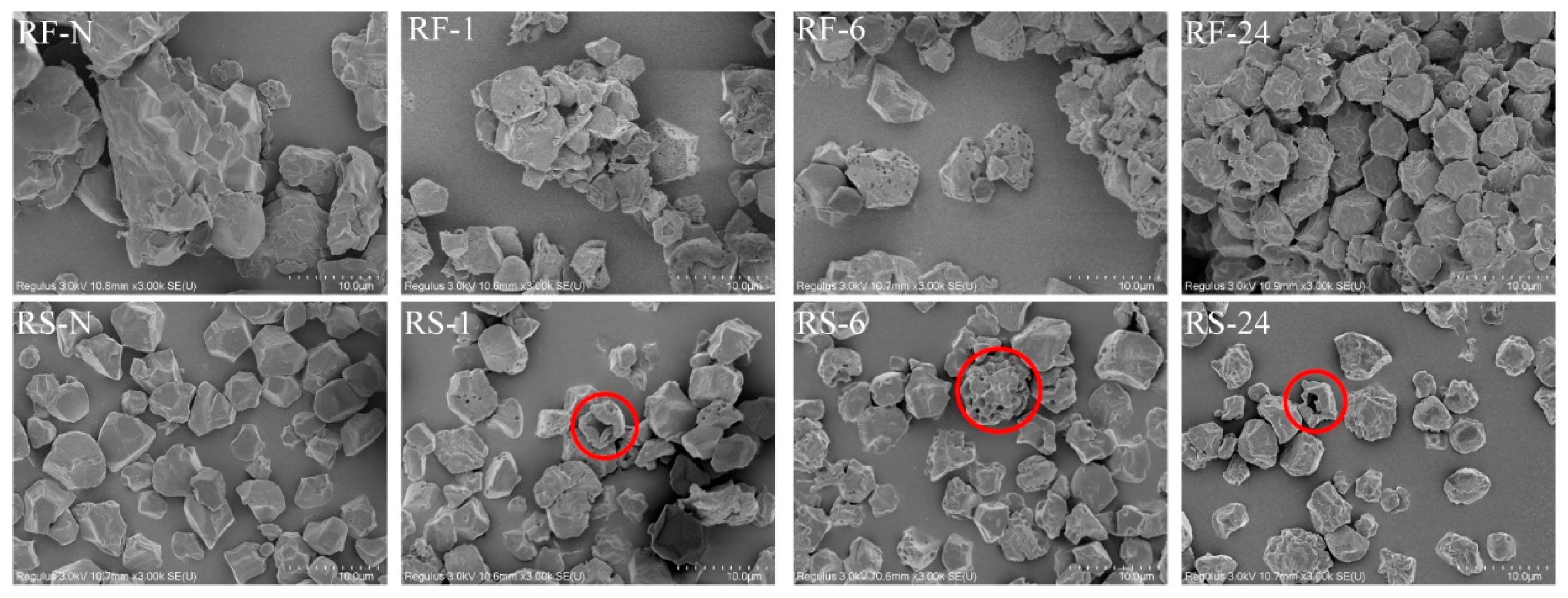

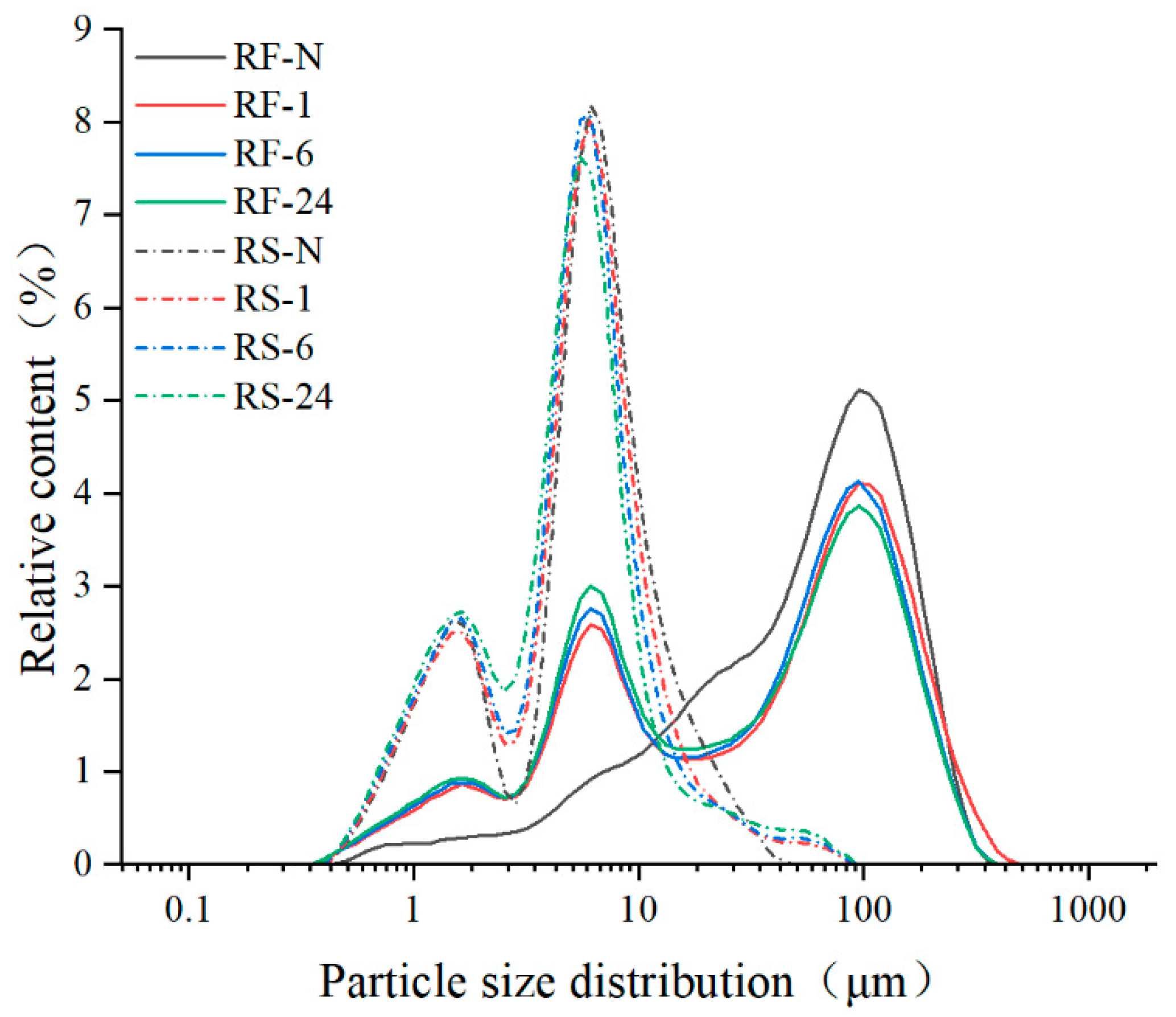

2.2. Morphological Structure and Particle Size Distribution

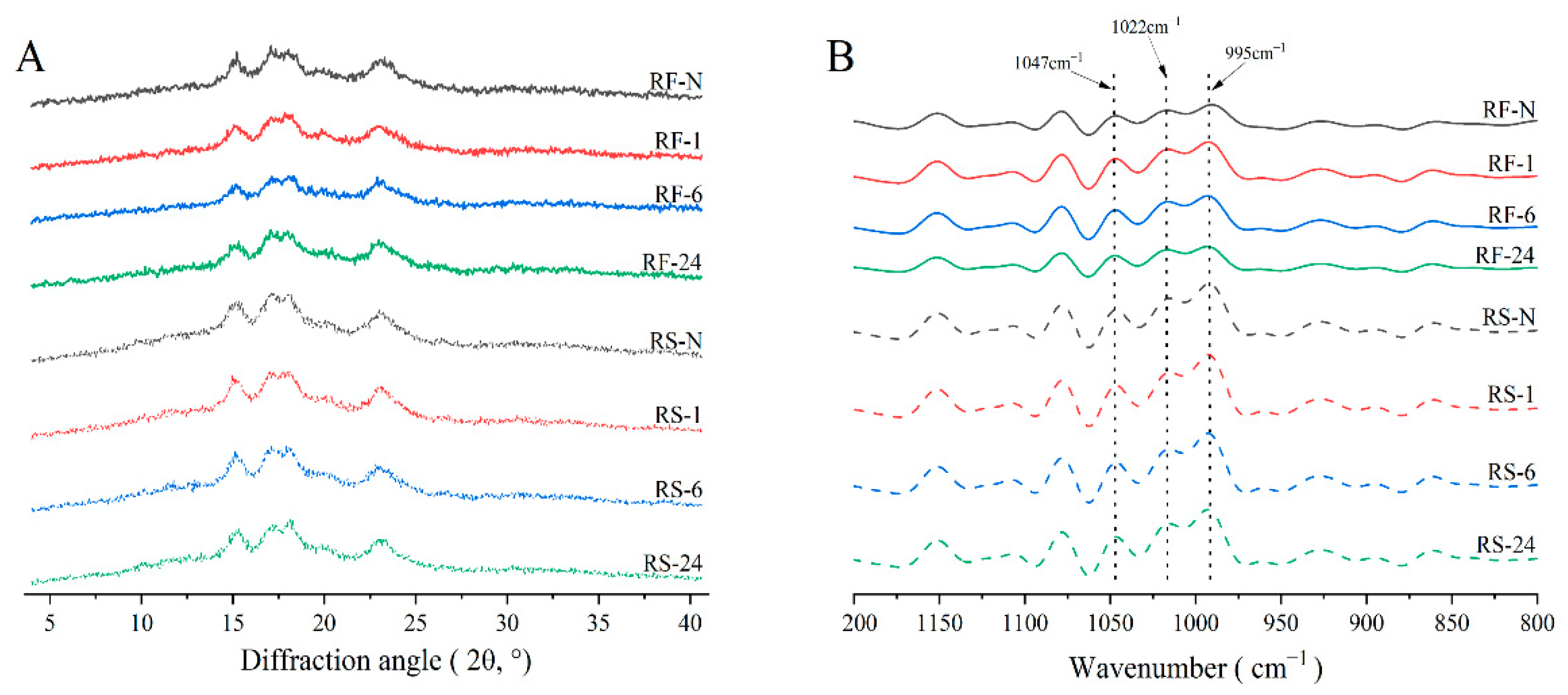

2.3. Crystalline Structure and Molecular Order

2.4. Amylose Content and Amylopectin Chain Length Distribution

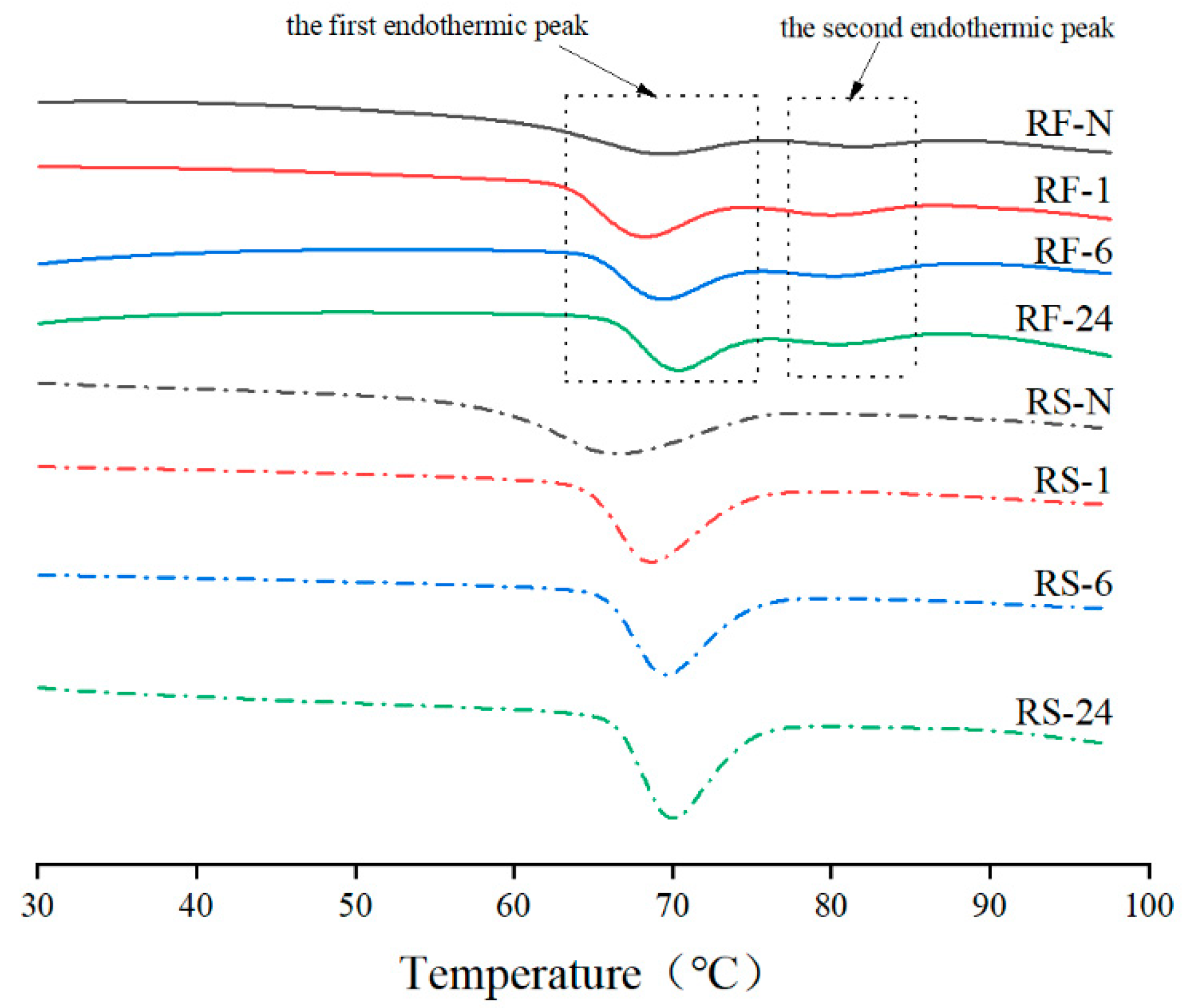

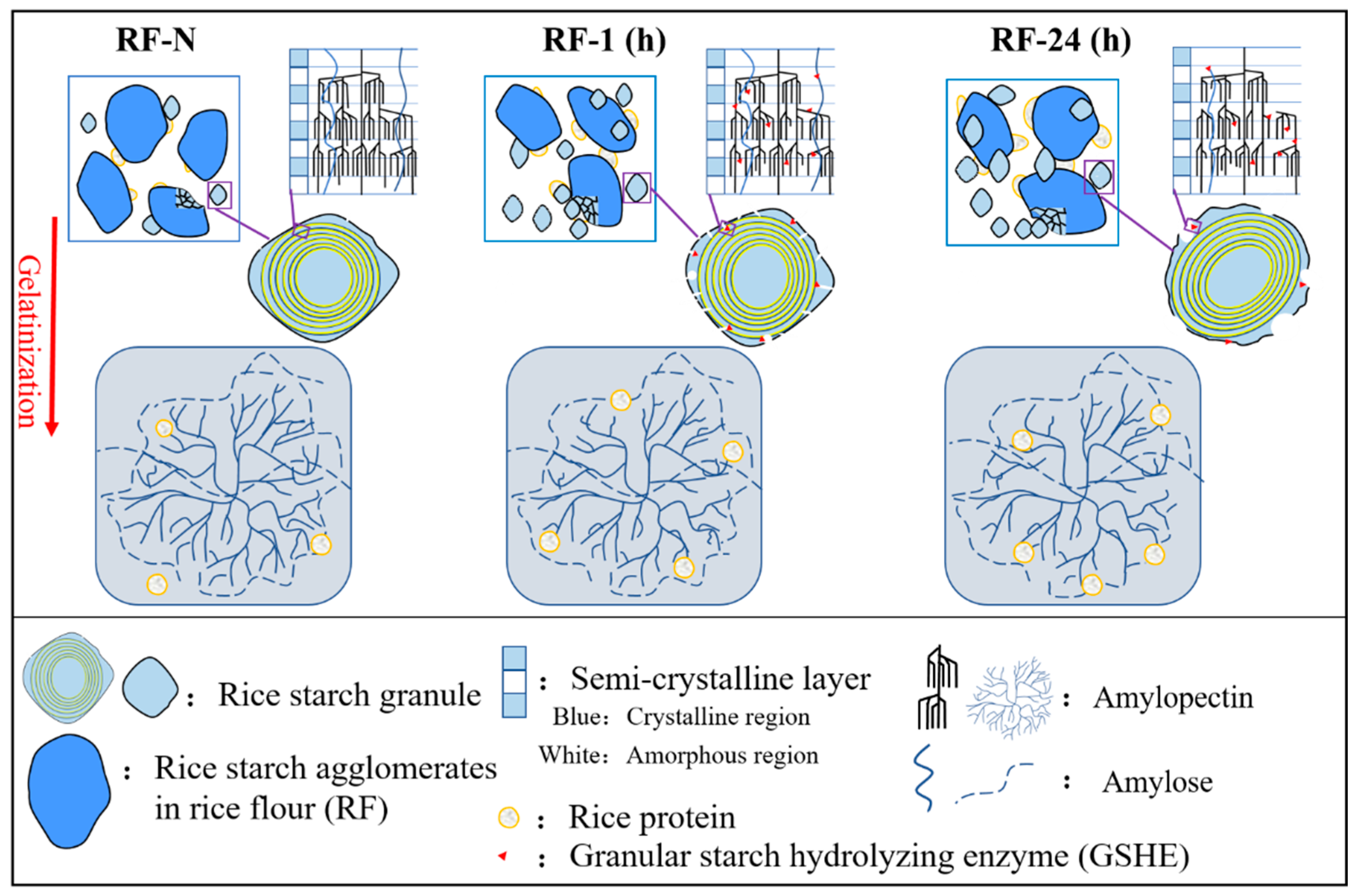

2.5. Thermal Properties

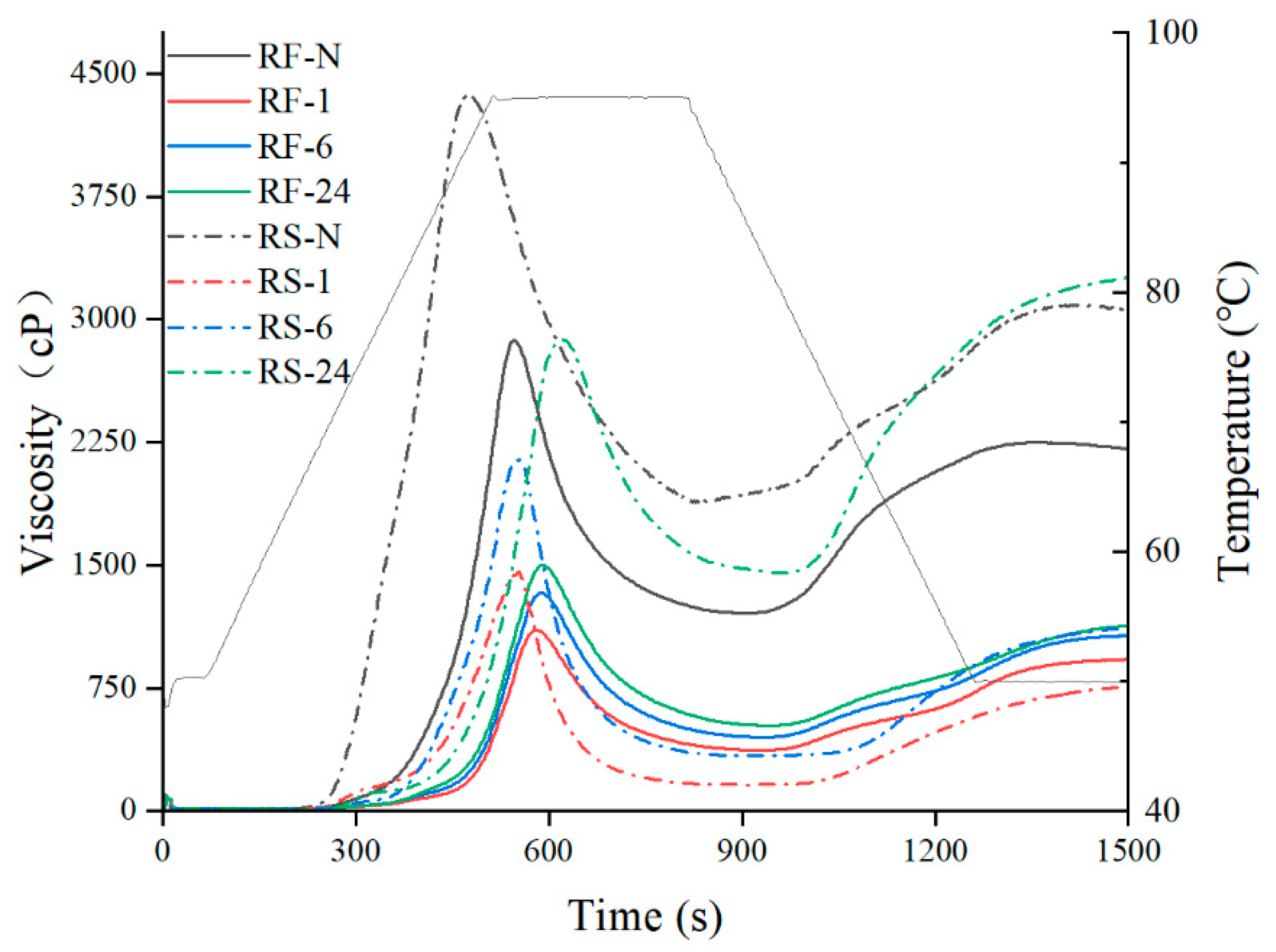

2.6. Pasting Behavior

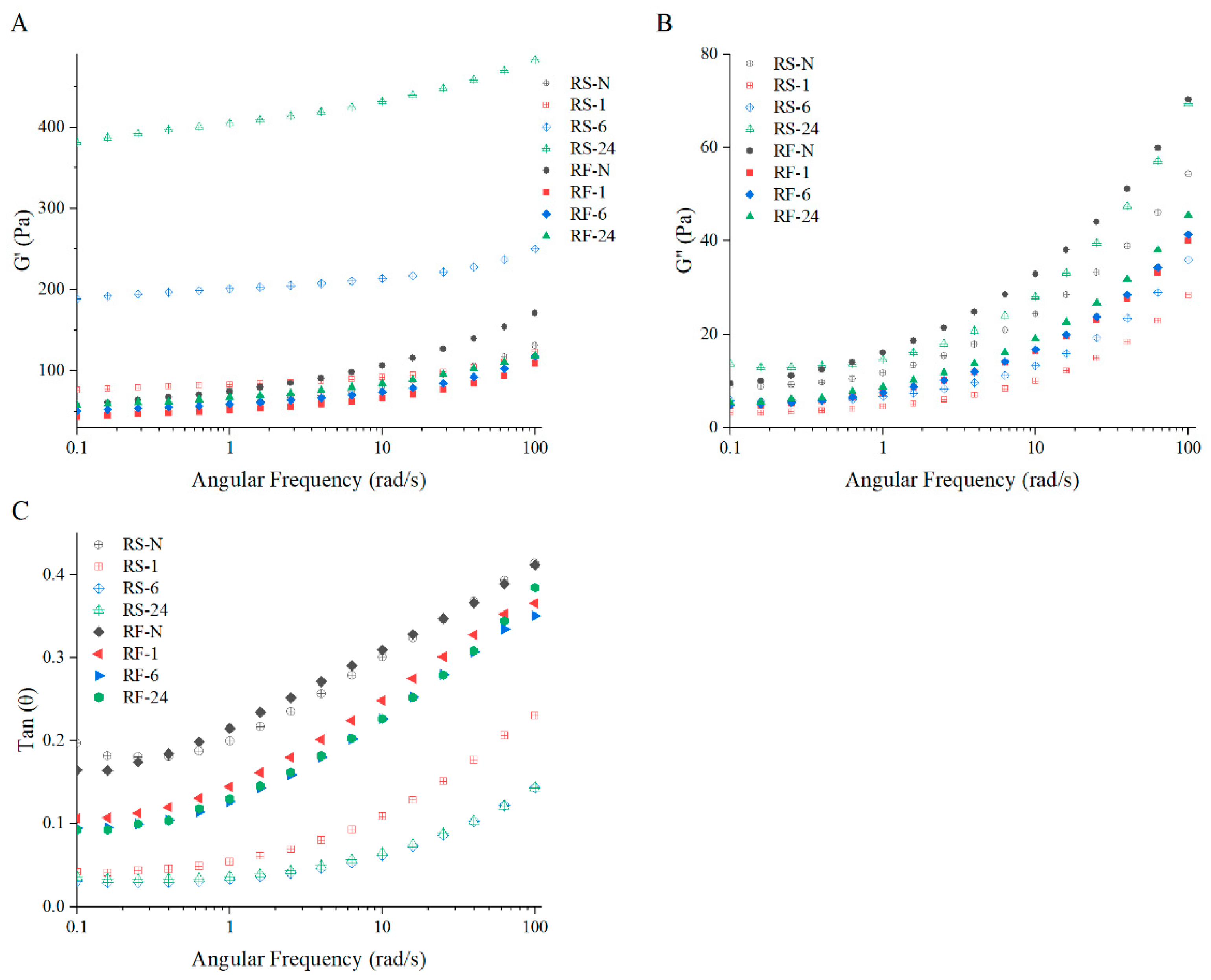

2.7. Frequency Sweep

2.8. Discussion

3. Materials and Methods

3.1. Materials

3.2. RS Isolation

3.3. Preparation of Hydrolyzed RF and RS by GSHE

3.4. Determination of Total Starch, Total Protein, Amylose Contents, DH, and the Released Oligosaccharides

3.5. Particle Size Distribution

3.6. Scanning Electron Microscopy (SEM)

3.7. XRD

3.8. FTIR

3.9. HPAEC

3.10. DSC

3.11. RVA

3.12. Rheological Measurement

3.13. Statistic Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Muthayya, S.; Sugimoto, J.D.; Montgomery, S.; Maberly, G.F. An overview of global rice production, supply, trade, and consumption. Ann. N. Y. Acad. Sci. 2014, 1324, 7–14. [Google Scholar] [CrossRef] [PubMed]

- Bao, J.; Bergman, C.J. Chapter 10—Rice Flour and Starch Functionality. In Starch in Food, 2nd ed.; Sjöö, M., Nilsson, L., Eds.; Woodhead Publishing: Cambridge, MA, USA, 2018; pp. 373–419. [Google Scholar]

- Matsuda, T. Rice flour: A promising food material for nutrition and global health. J. Nutr. Sci. Vitaminol. 2019, 65, S13–S17. [Google Scholar] [CrossRef] [PubMed]

- Amagliani, L.; O’Regan, J.; Kelly, A.L.; O’Mahony, J.A. The composition, extraction, functionality and applications of rice proteins: A review. Trends Food Sci. Technol. 2017, 64, 1–12. [Google Scholar] [CrossRef]

- Yonghui, Y.; Kumar Gaine, G.; Linyue, Z.; Jingjie, Z.; Jing, W.; Baoguo, S. The classical and potential novel healthy functions of rice bran protein and its hydrolysates. Crit. Rev. Food Sci. Nutr. 2022, 62, 8454–8466. [Google Scholar]

- Wang, L.F.; Zhang, L.; Wang, H.L.; Ai, L.Z.; Xiong, W.F. Insight into protein-starch ratio on the gelatinization and retrogradation characteristics of reconstituted rice flour. Int. J. Biol. Macromol. 2020, 146, 524–529. [Google Scholar] [CrossRef]

- Teba, C.D.; da Silva, E.M.M.; Chavez, D.W.H.; de Carvalho, C.W.P.; Ascheri, J.L.R. Effects of whey protein concentrate, feed moisture and temperature on the physicochemical characteristics of a rice-based extruded flour. Food Chem. 2017, 228, 287–296. [Google Scholar] [CrossRef]

- Oszvald, M.; Balazs, G.; Toemoeskoezi, S.; Bekes, F.; Tamas, L. Comparative study of the effect of incorporated individual wheat storage proteins on mixing properties of rice and wheat doughs. J. Agric. Food Chem. 2011, 59, 9664–9672. [Google Scholar] [CrossRef] [PubMed]

- Shih, F.F.; Champagne, E.T.; Daigle, K.; Zarins, Z. Use of enzymes in the processing of protein products from rice bran and rice flour. Nahrung-Food 1999, 43, 14–18. [Google Scholar] [CrossRef]

- Xia, N.; Wang, J.M.; Gong, Q.; Yang, X.Q.; Yin, S.W.; Qi, J.R. Characterization and in vitro digestibility of rice protein prepared by enzyme-assisted microfluidization: Comparison to alkaline extraction. J. Cereal Sci. 2012, 56, 482–489. [Google Scholar] [CrossRef]

- Paraman, I.; Wagner, M.E.; Rizvi, S.S.H. Micronutrient and protein-fortified whole grain puffed rice made by supercritical fluid extrusion. J. Agr. Food Chem. 2012, 60, 11188–11194. [Google Scholar] [CrossRef]

- Yang, X.; Li, Y.L.; Li, S.Y.; Oladejo, A.O.; Wang, Y.C.; Huang, S.F.; Zhou, C.S.; Ye, X.F.; Ma, H.L.; Duan, Y.Q. Effects of ultrasound-assisted α-amylase degradation treatment with multiple modes on the extraction of rice protein. Ultrason. Sonochem. 2018, 40, 890–899. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.T.; Pan, Z.; Shen, K.Q.; Cai, X.H.; Zheng, B.D.; Miao, S. Influence of ultrasound-assisted alkali treatment on the structural properties and functionalities of rice protein. J. Cereal Sci. 2018, 79, 204–209. [Google Scholar] [CrossRef]

- Shih, F.F.; Daigle, K. Use of enzymes for the separation of protein from rice flour. Cereal Chem. 1997, 74, 437–440. [Google Scholar] [CrossRef]

- Shih, F.F.; Daigle, K.W. Preparation and characterization of rice protein isolates. J. Am. Oil Chem. Soc. 2000, 77, 885–889. [Google Scholar] [CrossRef]

- Ju, Z.Y.; Hettiarachchy, N.S.; Rath, N. Extraction, denaturation and hydrophobic properties of rice flour proteins. J. Food Sci. 2001, 66, 229–232. [Google Scholar] [CrossRef]

- Li, Y.; Lu, F.; Luo, C.R.; Chen, Z.X.; Mao, J.; Shoemaker, C.; Zhong, F. Functional properties of the Maillard reaction products of rice protein with sugar. Food Chem. 2009, 117, 69–74. [Google Scholar] [CrossRef]

- Wenefrida, I.; Utomo, H.S.; Linscombe, S.D. Development and registration of ‘Frontière’, a high-protein rice cultivar. J. Plant Regist. 2017, 11, 240–244. [Google Scholar] [CrossRef]

- Aleman, R.S.; Morris, A.; Prinyawiwatkul, W.; Moncada, M.; King, J.M. Physicochemical properties of Frontière rice flour and its application in a gluten-free cupcake. Cereal Chem. 2022, 99, 303–315. [Google Scholar] [CrossRef]

- Paz, G.M. High Protein Rice Flour in the Development of Gluten-Free Muffins and Bread. Master’s Thesis, Louisiana State University, Baton Rouge, LA, USA, 2019. [Google Scholar]

- Sun, H.Y.; Zhao, P.J.; Ge, X.Y.; Xia, Y.J.; Hao, Z.K.; Liu, J.W.; Peng, M. Recent advances in microbial raw starch degrading enzymes. Appl. Biochem. Biotech. 2010, 160, 988–1003. [Google Scholar] [CrossRef]

- Zhong, Y.Y.; Xu, J.C.; Liu, X.X.; Ding, L.; Svensson, B.; Herburger, K.; Guo, K.; Pang, C.F.; Blennow, A. Recent advances in enzyme biotechnology on modifying gelatinized and granular starch. Trends Food Sci. Technol. 2022, 123, 343–354. [Google Scholar] [CrossRef]

- Cinelli, B.A.; Castilho, L.R.; Freire, D.M.G.; Castro, A.M. A brief review on the emerging technology of ethanol production by cold hydrolysis of raw starch. Fuel 2015, 150, 721–729. [Google Scholar] [CrossRef]

- Bangar, S.P.; Ashogbon, A.O.; Singh, A.; Chaudhary, V.; Whiteside, W.S. Enzymatic modification of starch: A green approach for starch applications. Carbohyd. Polym. 2022, 287, 119265. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.L.; Mun, S.; Park, K.H.; Shim, J.Y.; Kim, Y.R. Physicochemical functionality of 4-α-glucanotransferase-treated rice flour in food application. Int. J. Biol. Macromol. 2013, 60, 422–426. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.T.B.; Shelat, K.J.; Tang, D.; Li, E.; Gilbert, R.G.; Hasjim, J. Milling of rice grains. the degradation on three structural levels of starch in rice flour can be independently controlled during grinding. J. Agric. Food Chem. 2011, 59, 3964–3973. [Google Scholar] [CrossRef] [PubMed]

- Han, H.M.; Cho, J.H.; Koh, B.K. Processing properties of Korean rice varieties in relation to rice noodle quality. Food Sci. Biotechnol. 2011, 20, 1277–1282. [Google Scholar] [CrossRef]

- Yan, C.J.; Xin, L.; Rong, Z.; Sui, J.M.; Liang, G.H.; Shen, X.P.; Guo, S.L.; Gu, M.H. Performance and inheritance of rice starch RVA profile characteristics. Rice Sci. 2005, 12, 39. [Google Scholar]

- Araki, E.; Ashida, K.; Aoki, N.; Takahashi, M.; Hamada, S. Characteristics of rice flour suitable for the production of rice flour bread containing gluten and methods of reducing the cost of producing rice flour. Jpn. Agric. Res. Q. JARQ 2016, 50, 23–31. [Google Scholar] [CrossRef]

- Ye, J.P.; Hu, X.T.; Luo, S.J.; McClements, D.J.; Liang, L.; Liu, C.M. Effect of endogenous proteins and lipids on starch digestibility in rice flour. Food Res. Int. 2018, 106, 404–409. [Google Scholar] [CrossRef]

- Li, C.F.; Cao, P.P.; Wu, P.; Yu, W.W.; Gilbert, R.G.; Li, E.P. Effects of endogenous proteins on rice digestion during small intestine (in vitro) digestion. Food Chem. 2020, 344, 128687. [Google Scholar] [CrossRef]

- Vela, A.J.; Villanueva, M.; Ronda, F. Low-frequency ultrasonication modulates the impact of annealing on physicochemical and functional properties of rice flour. Food Hydrocoll. 2021, 120, 106933. [Google Scholar] [CrossRef]

- Leewatchararongjaroen, J.; Anuntagool, J. Effects of dry-milling and wet-milling on chemical, physical and gelatinization properties of rice flour. Rice Sci. 2016, 23, 274–281. [Google Scholar] [CrossRef]

- Oates, C.G. Towards an understanding of starch granule structure and hydrolysis. Trends Food Sci. Technol. 1997, 8, 375–382. [Google Scholar] [CrossRef]

- Warren, F.J.; Royall, P.G.; Gaisford, S.; Butterworth, P.J.; Ellis, P.R. Binding interactions of α-amylase with starch granules: The influence of supramolecular structure and surface area. Carbohyd. Polym. 2011, 86, 1038–1047. [Google Scholar] [CrossRef]

- Dhital, S.; Shrestha, A.K.; Gidley, M.J. Relationship between granule size and in vitro digestibility of maize and potato starches. Carbohyd. Polym. 2010, 82, 480–488. [Google Scholar] [CrossRef]

- van Soest, J.J.G.; Tournois, H.; de Wit, D.; Vliegenthart, J.F.G. Short-range structure in (partially) crystalline potato starch determined with attenuated total reflectance Fourier-transform IR spectroscopy. Carbohyd. Res. 1995, 279, 201–214. [Google Scholar] [CrossRef]

- Yu, S.F.; Ma, Y.; Menager, L.; Sun, D.W. Physicochemical properties of starch and flour from different rice cultivars. Food Bioprocess Technol. 2012, 5, 626–637. [Google Scholar] [CrossRef]

- Tien, T.N.; Nguyen, T.C.; Nguyen, C.N.; Nguyen, T.T.; Pham, T.A.; Pham, N.H.; Chu-Ky, S. Protease increases ethanol yield and decreases fermentation time in no-cook process during very-high-gravity ethanol production from rice. Process. Biochem. 2022, 117, 10–18. [Google Scholar] [CrossRef]

- Uthumporn, U.; Shariffa, Y.N.; Karim, A.A. Hydrolysis of native and heat-treated starches at sub-gelatinization temperature using granular starch hydrolyzing enzyme. Appl. Biochem. Biotech. 2012, 166, 1167–1182. [Google Scholar] [CrossRef]

- Foresti, M.L.; Williams, M.D.; Martinez-Garcia, R.; Vazquez, A. Analysis of a preferential action of α-amylase from B-licheniformis towards amorphous regions of waxy maize starch. Carbohyd. Polym. 2014, 102, 80–87. [Google Scholar] [CrossRef]

- Bao, J.S.; Ying, Y.N.; Zhou, X.; Xu, Y.J.; Wu, P.; Xu, F.F.; Pang, Y.H. Relationships among starch biosynthesizing protein content, fine structure and functionality in rice. Carbohyd. Polym. 2020, 237, 116118. [Google Scholar] [CrossRef]

- Sui, Z.Q.; Yao, T.M.; Ye, X.T.; Bao, J.S.; Kong, X.L.; Wu, Y. Physicochemical properties and starch digestibility of in-kernel heat-moisture-treated waxy, low-, and high-amylose rice starch. Starch-Stärke 2017, 69, 1600164. [Google Scholar] [CrossRef]

- Tong, Z.Y.; Tong, Y.; Shi, Y.C. Partial swelling of granules enables high conversion of normal maize starch to glucose catalyzed by granular starch hydrolyzing enzyme. Ind. Crops Prod. 2019, 140, 111626. [Google Scholar] [CrossRef]

- Cappa, C.; Lucisano, M.; Barbosa-Canovas, G.V.; Mariotti, M. Physical and structural changes induced by high pressure on corn starch, rice flour and waxy rice flour. Food Res. Int. 2016, 85, 95–103. [Google Scholar] [CrossRef]

- Cooke, D.; Gidley, M.J. Loss of crystalline and molecular order during starch gelatinisation: Origin of the enthalpic transition. Carbohyd. Res. 1992, 227, 103–112. [Google Scholar] [CrossRef]

- Sarka, E.; Dvoracek, V. New processing and applications of waxy starch (a review). J. Food Eng. 2017, 206, 77–87. [Google Scholar] [CrossRef]

- Lin, Q.L.; Xiao, H.X.; Fu, X.J.; Tian, W.; Li, L.H.; Yu, F.X. Physico-chemical properties of flour, starch, and modified starch of two rice varieties. Agr. Sci. China 2011, 10, 960–968. [Google Scholar] [CrossRef]

- Zhai, Y.T.; Li, X.X.; Bai, Y.X.; Jin, Z.Y.; Svensson, B. Maltogenic a-amylase hydrolysis of wheat starch granules: Mechanism and relation to starch retrogradation. Food Hydrocoll. 2021, 124, 107256. [Google Scholar] [CrossRef]

- Zhao, Y.T.; Dai, X.G.; Mackon, E.; Ma, Y.F.; Liu, P.Q. Impacts of protein from high-protein rice on gelatinization and retrogradation properties in high- and low-amylose reconstituted rice flour. Agronomy 2022, 12, 1431. [Google Scholar] [CrossRef]

- Vamadevan, V.; Bertoft, E. Observations on the impact of amylopectin and amylose structure on the swelling of starch granules. Food Hydrocoll. 2020, 103, 105663. [Google Scholar] [CrossRef]

- Tao, K.Y.; Li, C.; Yu, W.W.; Gilbert, R.G.; Li, E.P. How amylose molecular fine structure of rice starch affects functional properties. Carbohyd. Polym. 2019, 204, 24–31. [Google Scholar] [CrossRef]

- Jia, Z.Y.; Luo, Y.; Barba, F.J.; Wu, Y.; Ding, W.P.; Xiao, S.S.; Lyu, Q.Y.; Wang, X.D.; Fu, Y. Effect of β-cyclodextrins on the physical properties and anti-staling mechanisms of corn starch gels during storage. Carbohyd. Polym. 2022, 284, 119187. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.F.; Chen, C.; Chen, Y.; Chen, Y. Effect of rice protein on the water mobility, water migration and microstructure of rice starch during retrogradation. Food Hydrocoll. 2019, 91, 136–142. [Google Scholar] [CrossRef]

- Chen, S.; Qin, L.; Chen, T.; Yu, Q.; Chen, Y.; Xiao, W.H.; Ji, X.Y.; Xie, J.H. Modification of starch by polysaccharides in pasting, rheology, texture and in vitro digestion: A review. Int. J. Biol. Macromol. 2022, 207, 81–89. [Google Scholar] [CrossRef]

- Lu, X.X.; Xu, R.; Zhan, J.L.; Chen, L.; Jin, Z.Y.; Tian, Y.Q. Pasting, rheology, and fine structure of starch for waxy rice powder with high-temperature baking. Int. J. Biol. Macromol. 2020, 146, 620–626. [Google Scholar] [CrossRef] [PubMed]

- Miller, G.L. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Liu, X.L.; Zhang, J.; Yang, X.J.; Sun, J.W.; Zhang, Y.Y.; Su, D.M.; Zhang, H.; Wang, H.W. Combined molecular and supramolecular structural insights into pasting behaviors of starches isolated from native and germinated waxy brown rice. Carbohyd. Polym. 2022, 283, 119148. [Google Scholar] [CrossRef]

- Wang, R.; Li, M.; Liu, J.; Wang, F.; Wang, J.; Zhou, Z. Dual modification manipulates rice starch characteristics following debranching and propionate esterification. Food Hydrocoll. 2021, 119, 106833. [Google Scholar] [CrossRef]

- Yuan, M.; Wang, Y.L.; Bai, Y.X.; Svensson, B. Distinct effects of different α-amylases on cross-linked tapioca starch and gel-improving mechanism. Food Hydrocoll. 2022, 128, 107580. [Google Scholar] [CrossRef]

| Samples 2 | DH (%) | Total Protein (%) | Total Starch (%) | |

|---|---|---|---|---|

| RF | RF-N | — | 8.52 ± 1.12 c | 89.90 ± 0.06 a |

| RF-1 | 24.15 ± 0.15 c | 10.57 ± 0.31 b | 86.37 ± 0.27 b | |

| RF-6 | 29.41 ± 0.51 b | 11..20 ± 0.19 b | 84.05 ± 0.16 c | |

| RF-24 | 33.95 ± 0.12 a | 13.17 ± 0.35 a | 82.22 ± 0.62 d | |

| RS | RS-N | — | 0.34 ± 0.08 | 98.27 ± 0.88 |

| RS-1 | 21.02 ± 0.68 C | — | — | |

| RS-6 | 33.43 ± 0.31 B | — | — | |

| RS-24 | 44.54 ± 0.53 A | — | — | |

| Samples 2 | d50 (μm) | D[4,3] (μm) | D[3,2] (μm) | Span Factor | |

|---|---|---|---|---|---|

| RF | RF-N | 63.26 ± 0.16 a | 75.47 ± 0.13 a | 15.18 ± 0.04 a | 2.46 ± 0.01 d |

| RF-1 | 45.90 ± 0.45 b | 66.22 ± 0.66 b | 7.34 ± 0.02 b | 3.49 ± 0.01 c | |

| RF-6 | 41.11 ± 0.78 c | 60.77 ± 1.82 c | 7.04 ± 0.04 c | 3.62 ± 0.04 b | |

| RF-24 | 33.14 ± 0.22 d | 56.90 ± 0.02 d | 6.56 ± 0.00 d | 4.34 ± 0.04 a | |

| RS | RS-N | 5.99 ± 0.12 A | 7.50 ± 0.84 A | 3.29 ± 0.10 A | 2.25 ± 0.26 A |

| RS-1 | 5.50 ± 0.02 B | 7.02 ± 0.10 A | 3.10 ± 0.01 AB | 2.05 ± 0.06 A | |

| RS-6 | 5.20 ± 0.06 C | 6.77 ± 0.05 A | 2.95 ± 0.04 B | 1.97 ± 0.06 A | |

| RS-24 | 4.88 ± 0.00 D | 6.76 ± 0.04 A | 2.83 ± 0.00 C | 2.08 ± 0.01 A | |

| Samples 2 | RC (%) | R1047/1022 | R995/1022 | |

|---|---|---|---|---|

| RF | RF-N | 19.72 ± 0.91 a | 0.5373 ± 0.0539 a | 1.4243 ± 0.0599 a |

| RF-1 | 19.83 ± 0.83 a | 0.5862 ± 0.0158 a | 1.2673 ± 0.0711 ab | |

| RF-6 | 21.03 ± 0.49 a | 0.5868 ± 0.0153 a | 1.2871 ± 0.0864 ab | |

| RF-24 | 21.19 ± 0.18 a | 0.6599 ± 0.0095 b | 1.2145 ± 0.0313 b | |

| RS | RS-N | 18.44 ± 0.28 A | 0.5841 ± 0.0178 A | 1.5158 ± 0.0814 A |

| RS-1 | 18.62 ± 0.26 A | 0.5773 ± 0.0026 A | 1.4989 ± 0.0739 A | |

| RS-6 | 19.32 ± 0.86 A | 0.5639 ± 0.0055 A | 1.5079 ± 0.0255 A | |

| RS-24 | 20.21 ± 0.39 A | 0.5605 ± 0.0155 A | 1.4506 ± 0.0888 A | |

| Samples 2 | Amylose Content (%) | Chain Length Distribution (%) | ||||

|---|---|---|---|---|---|---|

| DP < 6 | DP 6–12 | DP 13–24 | DP 25–36 | DP ≥ 36 | ||

| RS-N | 17.99 ± 0.28 A | 3.65 | 31.29 | 53.16 | 10.20 | 1.69 |

| RS-C | 13.98 ± 0.41 C | 3.69 | 31.03 | 53.11 | 10.52 | 1.65 |

| RS-1 | 17.79 ± 0.13 AB | 18.30 | 28.71 | 43.01 | 8.57 | 1.41 |

| RS-3 | 17.86 ± 0.91 A | 19.87 | 27.79 | 42.55 | 8.41 | 1.39 |

| RS-6 | 17.37 ± 0.25 AB | 18.89 | 28.45 | 42.72 | 8.55 | 1.38 |

| RS-9 | 16.37 ± 0.08 B | 15.60 | 28.56 | 45.43 | 8.81 | 1.60 |

| RS-24 | 10.98 ± 0.40 D | 13.91 | 28.30 | 47.11 | 9.04 | 1.65 |

| Samples 2 | To1 (°C) | Tp1 (°C) | Tc1 (°C) | Tc1-To1 (°C) | ΔH1 (mJ/mg) | |

|---|---|---|---|---|---|---|

| RF | RF-N | 63.51 ± 0.01 c | 69.47 ± 0.18 b | 72.33 ± 0.15 b | 8.81 ± 0.17 a | 4.40 ± 0.57 b |

| RF-1 | 65.62 ± 0.69 b | 68.31 ± 0.08 c | 71.13 ± 0.18 c | 5.51 ± 0.55 b | 6.42 ± 0.41 a | |

| RF-6 | 66.45 ± 0.18 b | 69.14 ± 0.28 b | 71.95 ± 0.05 b | 5.51 ± 0.14 b | 6.52 ± 0.14 a | |

| RF-24 | 67.99 ± 0.20 a | 70.15 ± 0.19 a | 73.39 ± 0.35 a | 5.40 ± 0.15 b | 5.31 ± 0.11 b | |

| RS | RS-N | 59.61 ± 0.21 C | 66.64 ± 0.29 B | 72.95 ± 0.14 AB | 13.34 ± 0.24 A | 13.35 ± 0.32 B |

| RS-1 | 66.11 ± 0.02 B | 68.59 ± 0.03 A | 72.50 ± 0.08 B | 6.39 ± 0.10 B | 12.60 ± 0.26 B | |

| RS-6 | 67.34 ± 0.02 A | 69.60 ± 0.06 A | 73.07 ± 0.20 A | 5.73 ± 0.19 BC | 12.77 ± 0.37 B | |

| RS-24 | 67.73 ± 0.27 A | 69.57 ± 0.78 A | 73.20 ± 0.29 A | 5.47 ± 0.55 C | 14.34 ± 0.23 A | |

| Samples 2 | PV (cP) | TV (cP) | BV (cP) | FV (cP) | SV (cP) | PT (°C) | |

|---|---|---|---|---|---|---|---|

| RF | RF-N | 2868.67 ± 9.45 a | 1223.00 ± 13.45 a | 1645.67 ± 16.80 a | 2230.00 ± 17.35 a | 1007.00 ± 4.00 a | 76.52 ± 0.81 b |

| RF-1 | 1077.00 ± 27.51 d | 345.33 ± 30.55 d | 731.67 ± 7.09 d | 894.33 ± 28.57 d | 549.00 ± 7.94 d | 82.68 ± 0.23 a | |

| RF-6 | 1316.00 ± 38.74 c | 431.33 ± 26.50 c | 884.67 ± 15.82 c | 1061.67 ± 28.92 c | 630.33 ± 9.71 b | 82.33 ± 0.96 a | |

| RF-24 | 1488.67 ± 22.28 b | 525.67 ± 8.14 b | 963.00 ± 19.97 b | 1131.00 ± 15.10 b | 605.33 ± 10.79 c | 81.12 ± 0.90 a | |

| RS | RS-N | 4383.33 ± 9.50 A | 1888.00 ± 14.73 A | 2495.33 ± 18.04 A | 3061.33 ± 9.61 B | 1173.33 ± 9.07 B | 69.88 ± 0.03 B |

| RS-1 | 1486.67 ± 25.54 D | 164.67 ± 5.69 D | 1322.00 ± 20.88 D | 779.00 ± 14.73 D | 614.33 ± 11.59 C | 73.32 ± 0.36 A | |

| RS-6 | 2165.67 ± 20.64 C | 304.50 ± 21.92 C | 1579.00 ± 32.53 B | 1502.00 ± 107.48 C | 1197.50 ± 85.56 B | 73.52 ± 0.80 A | |

| RS-24 | 2886.00 ± 4.24 B | 1437.00 ± 22.63 B | 1449.00 ± 26.87 C | 3240.00 ± 18.38 A | 1803.00 ± 4.24 A | 74.68 ± 0.86 A | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, J.; Li, X.; Svensson, B.; Jin, Z.; Bai, Y. Increasing Protein Content of Rice Flour with Maintained Processability by Using Granular Starch Hydrolyzing Enzyme. Molecules 2023, 28, 3522. https://doi.org/10.3390/molecules28083522

Zhai J, Li X, Svensson B, Jin Z, Bai Y. Increasing Protein Content of Rice Flour with Maintained Processability by Using Granular Starch Hydrolyzing Enzyme. Molecules. 2023; 28(8):3522. https://doi.org/10.3390/molecules28083522

Chicago/Turabian StyleZhai, Jinxing, Xiaoxiao Li, Birte Svensson, Zhengyu Jin, and Yuxiang Bai. 2023. "Increasing Protein Content of Rice Flour with Maintained Processability by Using Granular Starch Hydrolyzing Enzyme" Molecules 28, no. 8: 3522. https://doi.org/10.3390/molecules28083522

APA StyleZhai, J., Li, X., Svensson, B., Jin, Z., & Bai, Y. (2023). Increasing Protein Content of Rice Flour with Maintained Processability by Using Granular Starch Hydrolyzing Enzyme. Molecules, 28(8), 3522. https://doi.org/10.3390/molecules28083522