Bioprocessed Wholegrain Spelt Flour Improves the Quality and Physicochemical Characteristics of Wheat Bread

Abstract

1. Introduction

2. Results and Discussion

2.1. Rheological Properties of Dough

2.2. Characteristics of the Breads Produced

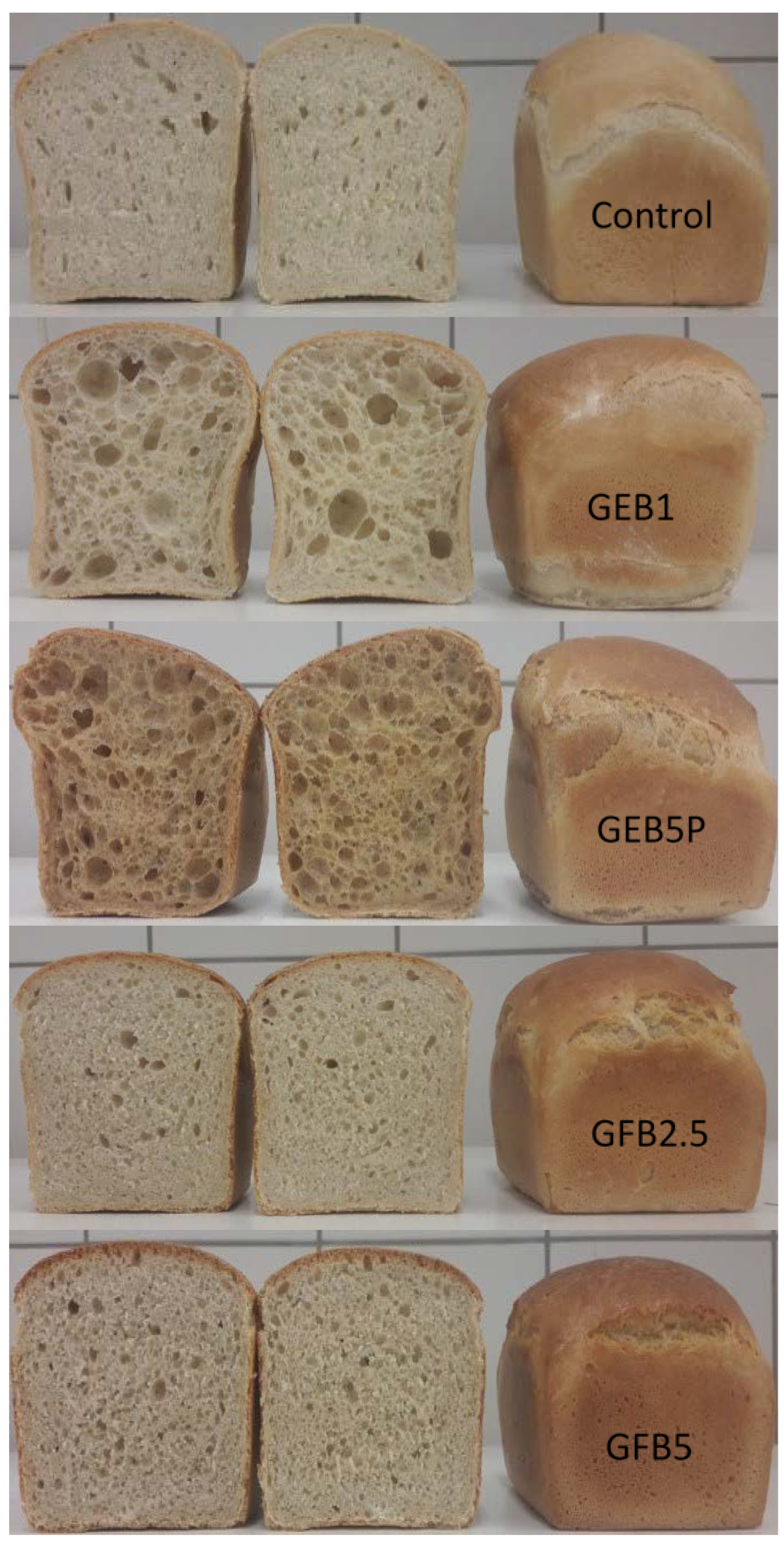

2.2.1. Specific Volume, Colour, Texture

2.2.2. Sensory Evaluation

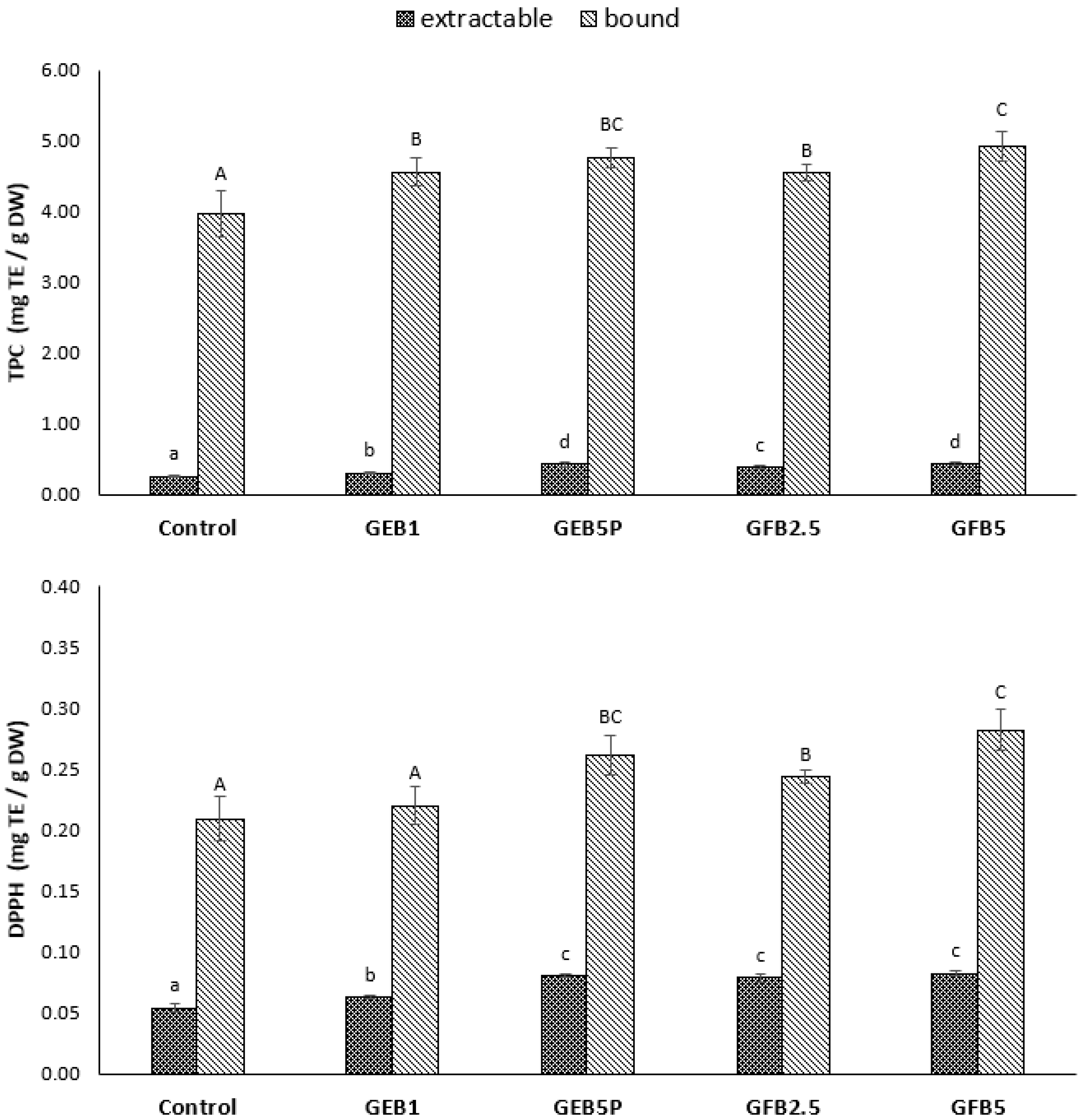

2.3. Total Phenolic Content and Antioxidant Activity in Breads

2.4. Phenolic Profile of Breads

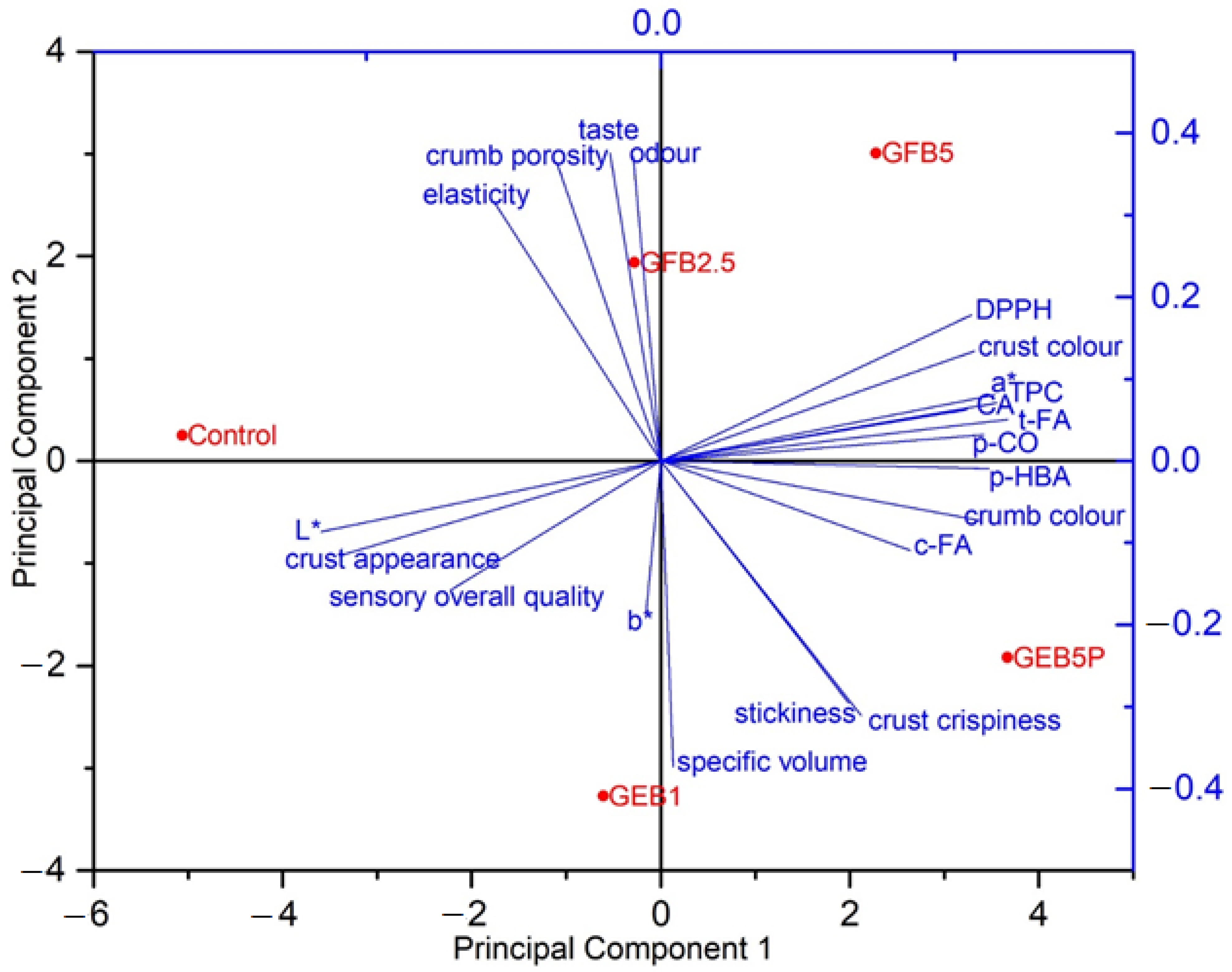

2.5. Principal Component Analysis

3. Materials and Methods

3.1. Materials

3.2. Preparation of Bioprocessed Spelt Flour

3.3. Bread-Making Procedure

3.4. Rheological Properties of the Dough

3.5. Bread Quality Characterisation

3.6. Sensory Evaluation of Bread

3.7. Extractable and Bound Phenolics Extraction

3.8. Total Phenolic Content

3.9. Phenolic Profile

3.10. DPPH• Radical Scavenging Activity

3.11. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alemu, D.; Firew, M.; Tadesse, D. Genetic Variability Studies on Bread Wheat (Triticum aestivum L.) Genotypes. J. Plant Breed. Crop Sci. 2019, 11, 41–54. [Google Scholar] [CrossRef]

- Escarnot, E.; Aguedo, M.; Paquot, M. Enzymatic Hydrolysis of Arabinoxylans from Spelt Bran and Hull. J. Cereal Sci. 2012, 55, 243–253. [Google Scholar] [CrossRef]

- Frakolaki, G.; Giannou, V.; Topakas, E.; Tzia, C. Chemical Characterization and Breadmaking Potential of Spelt versus Wheat Flour. J. Cereal Sci. 2018, 79, 50–56. [Google Scholar] [CrossRef]

- Pruska-Kedzior, A.; Kedzior, Z.; Klockiewicz-Kaminska, E. Comparison of Viscoelastic Properties of Gluten from Spelt and Common Wheat. Eur. Food Res. Technol. 2008, 227, 199–207. [Google Scholar] [CrossRef]

- Filipčev, B.; Bodroža-Solarov, M.; Pestorić, M.; Šimurina, O. Breadmaking Performance and Textural Changes during Storage of Composite Breads Made from Spelt Wheat and Different Forms of Amaranth Grain. Food Sci. Technol. Int. 2017, 23, 235–244. [Google Scholar] [CrossRef]

- de Almeida, S.S.; da Costa, G.B.M.; Barreto, M.S.; Freire, D.M.G.; Lobo, L.A.; Domingues, R.M.C.P.; Moura-Nunes, N.; Monteiro, M.; Perrone, D. Bioaccessibility and Gut Metabolism of Phenolic Compounds of Breads Added with Green Coffee Infusion and Enzymatically Bioprocessed. Food Chem. 2020, 333, 127473. [Google Scholar] [CrossRef]

- Fardet, A. New Hypotheses for the Health-Protective Mechanisms of Whole-Grain Cereals: What Is beyond Fibre? Nutr. Res. Rev. 2010, 23, 65–134. [Google Scholar] [CrossRef]

- Acosta-Estrada, B.A.; Gutiérrez-Uribe, J.A.; Serna-Saldívar, S.O. Bound Phenolics in Foods, a Review. Food Chem. 2014, 152, 46–55. [Google Scholar] [CrossRef]

- Mencin, M.; Jamnik, P.; Mikulič Petkovšek, M.; Veberič, R.; Terpinc, P. Improving Accessibility and Bioactivity of Raw, Germinated and Enzymatic-Treated Spelt (Triticum spelta L.) Seed Antioxidants by Fermentation. Food Chem. 2022, 394, 133483. [Google Scholar] [CrossRef]

- Angelino, D.; Cossu, M.; Marti, A.; Zanoletti, M.; Chiavaroli, L.; Brighenti, F.; Rio, D.D.; Martini, D. Bioaccessibility and Bioavailability of Phenolic Compounds in Bread: A Review. Food Funct. 2017, 8, 2368–2393. [Google Scholar] [CrossRef]

- Mencin, M.; Abramovič, H.; Jamnik, P.; Mikulič Petkovšek, M.; Veberič, R.; Terpinc, P. Abiotic Stress Combinations Improve the Phenolics Profiles and Activities of Extractable and Bound Antioxidants from Germinated Spelt (Triticum spelta L.) Seeds. Food Chem. 2021, 344, 128704. [Google Scholar] [CrossRef] [PubMed]

- Mencin, M.; Jamnik, P.; Mikulič Petkovšek, M.; Veberič, R.; Terpinc, P. Enzymatic Treatments of Raw, Germinated and Fermented Spelt (Triticum spelta L.) Seeds Improve the Accessibility and Antioxidant Activity of Their Phenolics. LWT 2022, 169, 114046. [Google Scholar] [CrossRef]

- Coda, R.; Katina, K.; Rizzello, C.G. Bran Bioprocessing for Enhanced Functional Properties. Curr. Opin. Food Sci. 2015, 1, 50–55. [Google Scholar] [CrossRef]

- Katina, K.; Juvonen, R.; Laitila, A.; Flander, L.; Nordlund, E.; Kariluoto, S.; Piironen, V.; Poutanen, K. Fermented Wheat Bran as a Functional Ingredient in Baking. Cereal Chem. 2012, 89, 126–134. [Google Scholar] [CrossRef]

- Ktenioudaki, A.; Alvarez-Jubete, L.; Smyth, T.J.; Kilcawley, K.; Rai, D.K.; Gallagher, E. Application of Bioprocessing Techniques (Sourdough Fermentation and Technological Aids) for Brewer’s Spent Grain Breads. Food Res. Int. 2015, 73, 107–116. [Google Scholar] [CrossRef]

- Poutanen, K.; Flander, L.; Katina, K. Sourdough and Cereal Fermentation in a Nutritional Perspective. Food Microbiol. 2009, 26, 693–699. [Google Scholar] [CrossRef]

- Hartikainen, K.; Poutanen, K.; Katina, K. Influence of Bioprocessed Wheat Bran on the Physical and Chemical Properties of Dough and on Wheat Bread Texture. Cereal Chem. 2014, 91, 115–123. [Google Scholar] [CrossRef]

- Katina, K.; Liukkonen, K.-H.; Kaukovirta-Norja, A.; Adlercreutz, H.; Heinonen, S.-M.; Lampi, A.-M.; Pihlava, J.-M.; Poutanen, K. Fermentation-Induced Changes in the Nutritional Value of Native or Germinated Rye. J. Cereal Sci. 2007, 46, 348–355. [Google Scholar] [CrossRef]

- Katina, K.; Salmenkallio-Marttila, M.; Partanen, R.; Forssell, P.; Autio, K. Effects of Sourdough and Enzymes on Staling of High-Fibre Wheat Bread. LWT-Food Sci. Technol. 2006, 39, 479–491. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, X.; Yang, S.; Li, L.; Tan, S. Improvement of the Breadmaking Quality of Wheat Flour by the Hyperthermophilic Xylanase B from Thermotoga Maritima. Food Res. Int. 2005, 38, 37–43. [Google Scholar] [CrossRef]

- Bae, W.; Lee, S.H.; Yoo, S.-H.; Lee, S. Utilization of a Maltotetraose-Producing Amylase as a Whole Wheat Bread Improver: Dough Rheology and Baking Performance. J. Food Sci. 2014, 79, E1535–E1540. [Google Scholar] [CrossRef]

- Indrani, D.; Venkateswara Rao, G. Rheological Characteristics of Wheat Flour Dough as Influenced by Ingredients of Parotta. J. Food Eng. 2007, 79, 100–105. [Google Scholar] [CrossRef]

- Schmiele, M.; Jaekel, L.Z.; Patricio, S.M.C.; Steel, C.J.; Chang, Y.K. Rheological Properties of Wheat Flour and Quality Characteristics of Pan Bread as Modified by Partial Additions of Wheat Bran or Whole Grain Wheat Flour. Int. J. Food Sci. Technol. 2012, 47, 2141–2150. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Guan, X. Effects of Adding Quinoa Flour on the Composite Wheat Dough: A Comprehensive Analysis of the Pasting, Farinograph and Rheological Properties. Int. J. Food Sci. Technol. 2022, 57, 7099–7106. [Google Scholar] [CrossRef]

- Olaerts, H.; Vandekerckhove, L.; Courtin, C.M. A Closer Look at the Bread Making Process and the Quality of Bread as a Function of the Degree of Preharvest Sprouting of Wheat (Triticum aestivum). J. Cereal Sci. 2018, 80, 188–197. [Google Scholar] [CrossRef]

- Altınel, B.; Ünal, S.S. The Effects of Certain Enzymes on the Rheology of Dough and the Quality Characteristics of Bread Prepared from Wheat Meal. J. Food Sci. Technol. 2017, 54, 1628–1637. [Google Scholar] [CrossRef]

- Banu, I.; Măcelaru, I.; Aprodu, I. Bioprocessing for Improving the Rheological Properties of Dough and Quality of the Wheat Bread Supplemented with Oat Bran. J. Food Process. Preserv. 2017, 41, e13112. [Google Scholar] [CrossRef]

- Goesaert, H.; Slade, L.; Levine, H.; Delcour, J.A. Amylases and Bread Firming—An Integrated View. J. Cereal Sci. 2009, 50, 345–352. [Google Scholar] [CrossRef]

- Matsushita, K.; Santiago, D.M.; Noda, T.; Tsuboi, K.; Kawakami, S.; Yamauchi, H. The Bread Making Qualities of Bread Dough Supplemented with Whole Wheat Flour and Treated with Enzymes. Food Sci. Technol. Res. 2017, 23, 403–410. [Google Scholar] [CrossRef]

- Khalil, A.H.; Mansour, E.H.; Dawoud, F.M. Influence of Malt on Rheological and Baking Properties of Wheat–Cassava Composite Flours. LWT-Food Sci. Technol. 2000, 33, 159–164. [Google Scholar] [CrossRef]

- Mau, J.-L.; Lee, C.-C.; Yang, C.-W.; Chen, R.-W.; Zhang, Q.-F.; Lin, S.-D. Physicochemical, Antioxidant and Sensory Characteristics of Bread Partially Substituted with Aerial Parts of Sweet Potato. LWT 2020, 117, 108602. [Google Scholar] [CrossRef]

- Diowksz, A.; Kordialik-Bogacka, E.; Ambroziak, W. Se-Enriched Sprouted Seeds as Functional Additives in Sourdough Fermentation. LWT-Food Sci. Technol. 2014, 56, 524–528. [Google Scholar] [CrossRef]

- Levent, H.; Bilgiçli, N.; Ertaş, N. The Assessment of Leavened and Unleavened Flat Breads Properties Enriched with Wheat Germ. Qual. Assur. Saf. Crops Foods 2014, 7, 321–326. [Google Scholar] [CrossRef]

- Millar, K.A.; Barry-Ryan, C.; Burke, R.; McCarthy, S.; Gallagher, E. Dough Properties and Baking Characteristics of White Bread, as Affected by Addition of Raw, Germinated and Toasted Pea Flour. Innov. Food Sci. Emerg. Technol. 2019, 56, 102189. [Google Scholar] [CrossRef]

- Wiley. Bakery Products: Science and Technology; Wiley: Beijing, China, 2007; Available online: https://www.wiley.com/en-us/Bakery+Products%3A+Science+and+Technology-p-9780470277553 (accessed on 10 November 2022).

- de Almeida, S.S.; Brito-Silva, L.; da Costa, G.B.M.; Barreto, M.S.; Freire, D.M.G.; Cadena, R.S.; Monteiro, M.; Perrone, D.; Moura-Nunes, N. Whole-Wheat Bread Enzymatically Bioprocessed and Added with Green Coffee Infusion Had Improved Volume and Were Sensory Accepted When Consumers Were Informed of the Presence of Healthy Substances. Int. J. Food Sci. Technol. 2022, 57, 6112–6121. [Google Scholar] [CrossRef]

- Sajdakowska, M.; Gębski, J.; Żakowska-Biemans, S.; Jeżewska-Zychowicz, M. Willingness to Eat Bread with Health Benefits: Habits, Taste and Health in Bread Choice. Public Health 2019, 167, 78–87. [Google Scholar] [CrossRef]

- Hung, P.V.; Hatcher, D.W.; Barker, W. Phenolic Acid Composition of Sprouted Wheats by Ultra-Performance Liquid Chromatography (UPLC) and Their Antioxidant Activities. Food Chem. 2011, 126, 1896–1901. [Google Scholar] [CrossRef]

- Cornejo, F.; Caceres, P.J.; Martínez-Villaluenga, C.; Rosell, C.M.; Frias, J. Effects of Germination on the Nutritive Value and Bioactive Compounds of Brown Rice Breads. Food Chem. 2015, 173, 298–304. [Google Scholar] [CrossRef]

- Anson, N.M.; Selinheimo, E.; Havenaar, R.; Aura, A.-M.; Mattila, I.; Lehtinen, P.; Bast, A.; Poutanen, K.; Haenen, G.R.M.M. Bioprocessing of Wheat Bran Improves in Vitro Bioaccessibility and Colonic Metabolism of Phenolic Compounds. J. Agric. Food Chem. 2009, 57, 6148–6155. [Google Scholar] [CrossRef]

- Amaya Villalva, M.F.; González-Aguilar, G.; Sández, O.R.; Astiazarán García, H.; Ledesma Osuna, A.I.; López-Ahumada, G.A.; Robles-Sánchez, R.M. Bioprocessing of Wheat (Triticum aestivum Cv. Kronstad) Bran from Northwest Mexico: Effects on Ferulic Acid Bioaccessibility in Breads. CyTA-J. Food 2018, 16, 570–579. [Google Scholar] [CrossRef]

- Koistinen, V.M.; Nordlund, E.; Katina, K.; Mattila, I.; Poutanen, K.; Hanhineva, K.; Aura, A.-M. Effect of Bioprocessing on the In Vitro Colonic Microbial Metabolism of Phenolic Acids from Rye Bran Fortified Breads. J. Agric. Food Chem. 2017, 65, 1854–1864. [Google Scholar] [CrossRef]

- Cereals & Grains Association. Available online: https://www.cerealsgrains.org/Pages/default.aspx (accessed on 13 September 2022).

- Demirkesen, I.; Sumnu, G.; Sahin, S. Quality of Gluten-Free Bread Formulations Baked in Different Ovens. Food Bioprocess Technol. 2013, 6, 746–753. [Google Scholar] [CrossRef]

- Morales, R.; Guerrero, L.; Serra, X.; Gou, P. Instrumental Evaluation of Defective Texture in Dry-Cured Hams. Meat Sci. 2007, 76, 536–542. [Google Scholar] [CrossRef]

| Dough | ||||

|---|---|---|---|---|

| Control | GFB2.5 | GFB5 | ||

| Farinographic parameters | Water absorption (%) | 60.1 | 56.8 | 56.0 |

| Development time (min) | 2.0 | 1.7 | 1.5 | |

| Stability time (min) | 3.3 | 1.8 | 3.1 | |

| Degree of softening (12 min after max.) (FU) | 48 | 159 | 180 | |

| Farinograph quality number | 48 | 28 | 31 | |

| Extensiographic parameters * | Energy (cm2) | 88 | 38 | 25 |

| Resistance to extension (BU) | 404 | 163 | 116 | |

| Maximum resistance to extension (BU) | 517 | 179 | 119 | |

| Extensibility (mm) | 129 | 144 | 140 | |

| Bread | Specific Volume (mL/g) | Lightness (L*) | Redness (a*) | Yellowness (b*) | ΔE | Firmness (g Force) |

|---|---|---|---|---|---|---|

| Control | 2.57 ± 0.11 c | 69.82 ± 1.31 f | 6.69 ± 0.73 a | 33.74 ± 0.70 cd | 352.24 ± 39.91 a | |

| GFB30 | 1.37 ± 0.19 a | 28.46 ± 0.96 a | 10.16 ± 0.56 b | 12.29 ± 0.88 a | 46.72 | / |

| GEB30 | / | / | / | / | / | / |

| GFB5 | 2.00 ± 0.16 b | 52.09 ± 0.79 c | 14.18 ± 0.58 f | 33.71 ± 0.24 cd | 19.25 | 744.89 ± 70.60 b |

| GEB5 | 1.98 ± 0.09 b | 52.75 ± 1.17 c | 11.51 ± 1.24 cd | 33.05 ± 0.27 c | 17.75 | / |

| GFB2.5 | 2.28 ± 0.09 bc | 57.37 ± 0.42 d | 12.66 ± 0.24 de | 36.09 ± 0.26 e | 14.00 | 420.83 ± 27.82 a |

| GEB1 | 2.99 ± 0.07 d | 60.82 ± 2.63 e | 11.00 ± 0.64 bc | 37.21 ± 0.41 f | 10.56 | / |

| GEB10P | 2.23 ± 0.30 bc | 47.43 ± 1.29 b | 14.32 ± 0.59 f | 31.07 ± 0.62 b | 23.81 | / |

| GEB5P | 3.03 ± 0.18 d | 53.50 ± 1.70 c | 13.64 ± 0.60 ef | 34.27 ± 0.46 d | 17.75 | / |

| Attributes | Control | GFB5 | GFB2.5 | GEB1 | GEB5P |

|---|---|---|---|---|---|

| Overall quality | 0 | −1.5 (smaller bread volume) | −2 | −1 (irregular shape, cracked) | −1 (irregular shape, cracked) |

| Crust appearance | 0 (crust cracks) | −1 (crust does not crack, appropriate thick) | −1 | −0.5 (less cracked bread) | −1 (does not crack) |

| Crust colour | 0 | 2 | 1.5 | 1 | 1.5 |

| Crust crispiness | 0 | 0.5 | 0.5 | 2 | 2 (crispy, but the crumb is not suitable for eating) |

| Crumb porosity | 0 | −0.5 (uniform pores) | −0.5 (smaller air bubbles, more uniform porosity, less distinct water ring) | 2 (larger air bubble, pores, uneven porosity) | 2 (larger air bubble, pores, uneven porosity) |

| Crumb colour | 0 | 1 | 0.5 | 0.5 | 2 (darker crumb) |

| Elasticity | 0 | −0.5 (it returns to its original shape quite fast) | −1 (returns to its original shape more slowly) | −3 (does not return to its original shape) | −2.5 (does not return to its original shape) |

| Stickiness | 0 | 0.5 (less sticky than GFB2.5) | 1.5 (a bit sticky) | 3 (extremely sticky) | 3 (unacceptable) |

| Odour | 0 | 0.5 (slightly more distinct smell) | 0.5 (slightly more intense smell after spelt) | −0.5 (indistinct smell) | −0.5 (indistinct smell) |

| Taste | 0 | 1 (slightly more distinct, after spelt, less sour, after cheese-yeast extract) | 1 (slightly more distinct, after spelt, crust- taste after cheese and caramel) | /(not suitable for consuming) | −2 (sweet taste, uncharacteristic for bread) |

| Phenolics Content (µg/g DW) | Breads | |||||

|---|---|---|---|---|---|---|

| Control | GEB1 | GEB5P | GFB2.5 | GFB5 | ||

| trans-Ferulic acid | Extractable | 0.56 ± 0.04 a | 0.75 ± 0.03 b | 2.35 ± 0.08 e | 1.49 ± 0.08 c | 2.10 ± 0.18 d |

| Bound | 45.88 ± 3.12 A | 69.31 ± 3.68 B | 108.60 ± 5.06 E | 81.73 ± 3.41 C | 99.31 ± 4.46 D | |

| cis-Ferulic acid | Extractable | 0.16 ± 0.02 a | 0.22 ± 0.02 b | 0.56 ± 0.01 e | 0.33 ± 0.02 c | 0.39 ± 0.02 d |

| Bound | 18.78 ± 0.18 B | 24.47 ± 1.54 C | 27.15 ± 0.56 D | 15.98 ± 0.28 A | 27.03 ± 1.06 D | |

| p-Coumaric acid | Extractable | 0.12 ± 0.00 a | 0.11 ± 0.01 a | 0.15 ± 0.01 c | 0.13 ± 0.00 b | 0.17 ± 0.01 d |

| Bound | 1.25 ± 0.12 A | 2.07 ± 0.11 B | 6.86 ± 0.49 E | 2.71 ± 0.07 C | 5.44 ± 0.40 D | |

| Caffeic acid | Extractable | 0.06 ± 0.01 a | 0.09 ± 0.01 b | 0.10 ± 0.01 b | 0.07 ± 0.00 a | 0.12 ± 0.01 c |

| Bound | 0.30 ± 0.02 A | 0.46 ± 0.04 B | 1.89 ± 0.14 C | 0.51 ± 0.07 B | 1.80 ± 0.06 C | |

| p-Hydroxybenzoic acid | Extractable | 0.27 ± 0.01 a | 0.30 ± 0.02 a | 0.37 ± 0.03 b | 0.44 ± 0.02 c | 0.70 ± 0.02 d |

| Bound | 3.76 ± 0.13 A | 4.67 ± 0.14 B | 8.23 ± 0.18 E | 5.25 ± 0.26 C | 6.04 ± 0.13 D | |

| Apigenin hexoside pentoside I | Extractable | 0.28 ± 0.02 a | 0.32 ± 0.01 b | 0.53 ± 0.02 d | 0.33 ± 0.00 b | 0.38 ± 0.02 c |

| Bound | 0.89 ± 0.02 A | 1.29 ± 0.01 C | 2.26 ± 0.08 D | 1.00 ± 0.01 B | 2.36 ± 0.06 D | |

| Apigenin hexoside pentoside II | Extractable | 0.08 ± 0.01 a | 0.10 ± 0.01 b | 0.18 ± 0.01 d | 0.11 ± 0.00 b | 0.14 ± 0.01 c |

| Bound | 0.22 ± 0.01 A | 0.49 ± 0.01 C | 1.12 ± 0.05 D | 0.39 ± 0.00 B | 1.28 ± 0.03 E | |

| Apigenin hexoside pentoside III | Extractable | 0.30 ± 0.02 b | 0.33 ± 0.01 c | 0.41 ± 0.02 d | 0.28 ± 0.01 b | 0.25 ± 0.01 a |

| Bound | 1.41 ± 0.04 A | 1.67 ± 0.03 B | 2.38 ± 0.10 C | 1.41 ± 0.01 A | 2.43 ± 0.08 C | |

| Unknown C-glycosyl derivative | Extractable | 0.10 ± 0.00 b | 0.09 ± 0.00 b | 0.10 ± 0.01 b | 0.07 ± 0.01 a | 0.07 ± 0.01 a |

| Bound | 0.39 ± 0.01 A | 1.01 ± 0.01 B | 2.69 ± 0.18 C | 1.09 ± 0.05 B | 3.17 ± 0.03 D | |

| Ingredients | Control | GFB30 | GEB30 | GFB5 | GEB5 | GFB2.5 | GEB1 | GEB10P | GEB5P |

|---|---|---|---|---|---|---|---|---|---|

| white wheat flour (g) | 1000 | 700 | 700 | 950 | 950 | 975 | 990 | 900 | 950 |

| bioprocessed flour (g) | |||||||||

| germinated + fermented | / | 300 | / | 50 | / | 25 | / | / | / |

| germinated + enzymatic treated | / | / | 300 | / | 50 | / | 10 | 100 | 50 |

| water (mL) | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

| instant baker’s yeast (g) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| salt (g) | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 |

| sunflower oil (mL) | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mencin, M.; Markanovič, N.; Mikulič Petkovšek, M.; Veberič, R.; Terpinc, P. Bioprocessed Wholegrain Spelt Flour Improves the Quality and Physicochemical Characteristics of Wheat Bread. Molecules 2023, 28, 3428. https://doi.org/10.3390/molecules28083428

Mencin M, Markanovič N, Mikulič Petkovšek M, Veberič R, Terpinc P. Bioprocessed Wholegrain Spelt Flour Improves the Quality and Physicochemical Characteristics of Wheat Bread. Molecules. 2023; 28(8):3428. https://doi.org/10.3390/molecules28083428

Chicago/Turabian StyleMencin, Marjeta, Nika Markanovič, Maja Mikulič Petkovšek, Robert Veberič, and Petra Terpinc. 2023. "Bioprocessed Wholegrain Spelt Flour Improves the Quality and Physicochemical Characteristics of Wheat Bread" Molecules 28, no. 8: 3428. https://doi.org/10.3390/molecules28083428

APA StyleMencin, M., Markanovič, N., Mikulič Petkovšek, M., Veberič, R., & Terpinc, P. (2023). Bioprocessed Wholegrain Spelt Flour Improves the Quality and Physicochemical Characteristics of Wheat Bread. Molecules, 28(8), 3428. https://doi.org/10.3390/molecules28083428