Physicochemical and Sensory Parameters of “Petipan” Enriched with Heme Iron and Andean Grain Flours

Abstract

1. Introduction

2. Results and Discussion

2.1. Analysis of the Centesimal Composition

2.2. Analysis of Iron Content and Physical Parameters

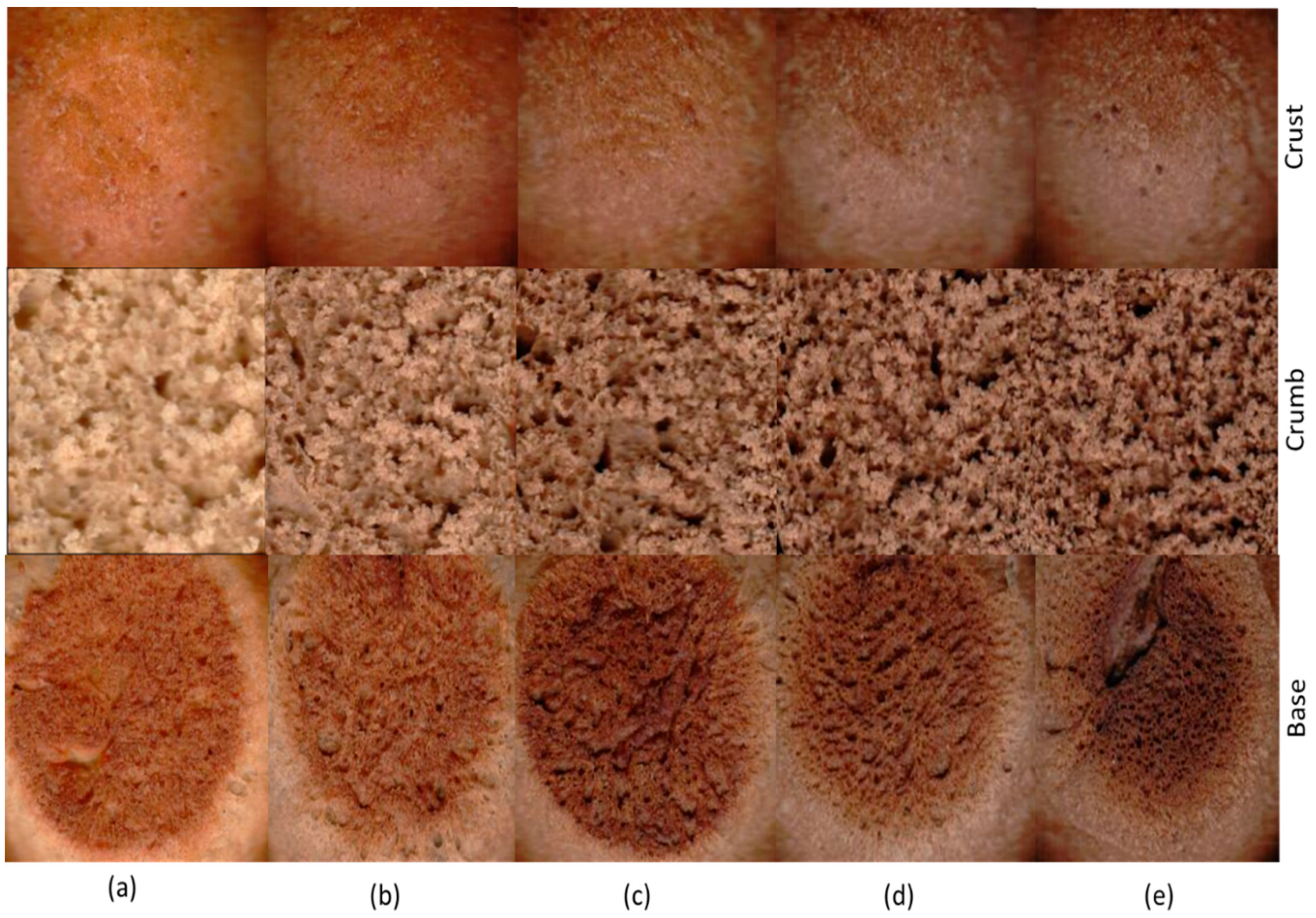

2.3. Colorimetric Parameters of Enriched Petipan

2.4. Instrumental Texture Analysis

2.5. Sensory Analysis

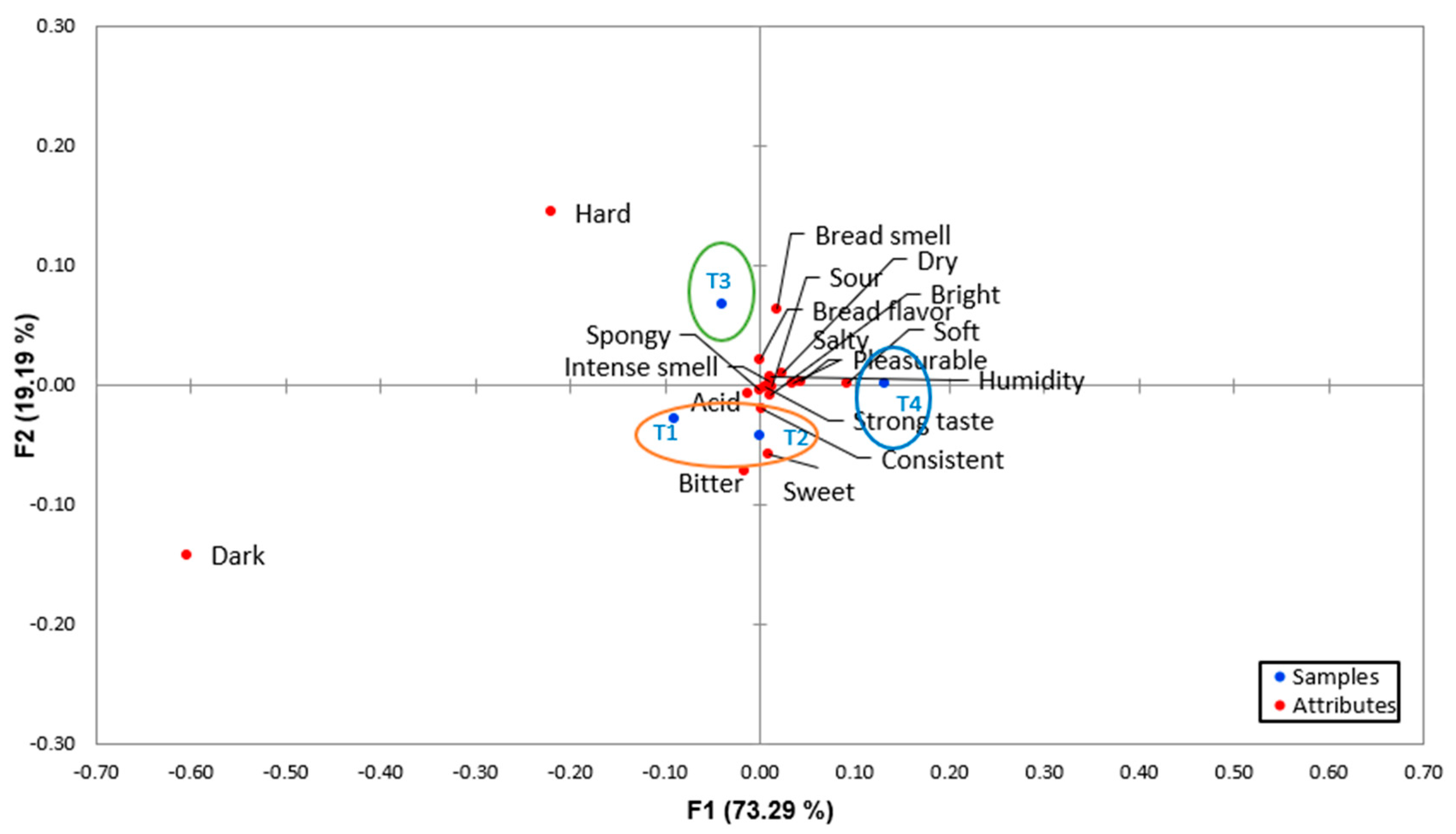

2.5.1. Pivot Profile

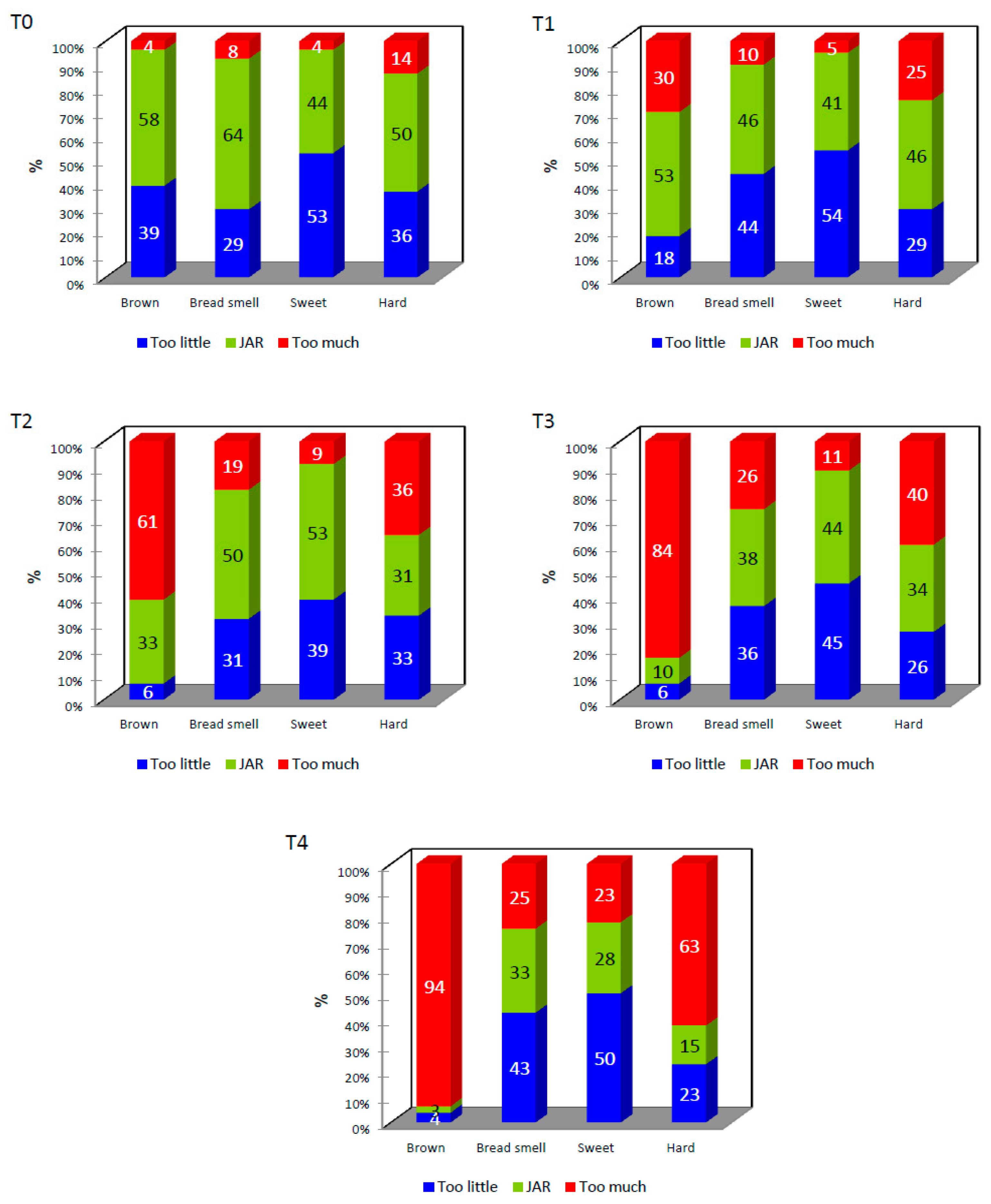

2.5.2. Just about Right (JAR)

3. Materials and Methods

3.1. Raw Material of Enriched Petipan

3.2. Elaboration Process of Enriched Petipan

3.3. Physicochemical Analysis

3.4. Analysis of Product Porosity

3.5. Color Parameters

3.6. Instrumental Texture Profile

3.7. Sensory Analysis

3.7.1. Consumers

3.7.2. Descriptive Test—Pivot Profile

3.7.3. Affective Test—Just about Right (JAR)

3.8. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vishwakarma, S.; Genu Dalbhagat, C.; Mandliya, S.; Niwas Mishra, H. Investigation of natural food fortificants for improving various properties of fortified foods: A review. Food Res. Int. 2022, 156, 111186. [Google Scholar] [CrossRef] [PubMed]

- Diego Quintaes, K.; Barberá, R.; Cilla, A. Iron bioavailability in iron-fortified cereal foods: The contribution of in vitro studies. Critical. Rev. Food Sci. Nutr. 2017, 10, 2028–2041. [Google Scholar] [CrossRef] [PubMed]

- Acta Medica Scandinavica. Chapter II: Hemoglobin fortification of food. absorption of hemoglobin and non-heme iron. J. Intern. Med. 1979, 205, 21–30. [Google Scholar]

- Stekel, A.; Amar, M.; Calvo, E.; Chadud, P.; Hertrampf, E.; Llaguno, S.; Pizarro, F. Nutritional significance of interactions between iron and food components. Archivos Latinoamericanos de Nutricion 1983, 33, 33–41. [Google Scholar] [PubMed]

- Mesas, J.M.; Alegre, M.T. El pan y su proceso de elaboración. Ciencia y Tecnología de Alimentos 2002, 3, 307–313. [Google Scholar] [CrossRef]

- Infobae. Cuál es el Significado y Origen de la Palabra “Petipan” y por qué la RAE no lo Acepta. Available online: https://www.infobae.com/america/peru/2022/09/17/cual-es-el-signficado-y-origen-de-la-palabra-petipan-y-por-que-la-rae-no-lo-acepta/ (accessed on 1 January 2023).

- Lara, L.F. Diccionario de americanismos. Panace 2012, 13, 352–355. [Google Scholar]

- Darniadi, S.; Luna, P.; Juniawati, J.; Sunarmani, S.; Widowati, S. Effect of zinc-rice grit flour on the physicochemical, nutritional, and sensory properties of gluten-free biscuits. Int. Food Res. J. 2022, 29, 1360–1371. [Google Scholar] [CrossRef]

- Helmizar; Sakinah, R. Characteristics of nutrients on functional bread with additional red bean, soy bean, and corn as food supplementation for stunting children under five. Paper presented at the IOP Conference Series. Earth Environ. Sci. 2022, 1018, 012029. [Google Scholar]

- Calderon, A.; Bonilla, S.; Schmiele, M.; Navarrete, D.; Vernaza, M.G. Study of Lupinus mutabilis sweet flour incorporation on the rheological, physical, chemical, and sensory properties of wheat bread. J. Food Process. Preserv. 2022, 46, e17027. [Google Scholar] [CrossRef]

- Gutierrez-Castillo, C.; Alcázar-Alay, S.; Vidaurre-Ruiz, J.; Correa, M.J.; Cabezas, D.M.; Repo-Carrasco-Valencia, R.; Encina-Zelada, C.R. Effect of partial substitution of wheat flour by quinoa (Chenopodium quinoa Willd.) and tarwi (Lupinus mutabilis Sweet) flours on dough and bread quality. Food Sci. Technol. Int. 2022, 10820132221106332. [Google Scholar] [CrossRef]

- Miranda-Ramos, K.C.; Haros, C.M. Combined effect of chia, quinoa and amaranth incorporation on the physico-chemical, nutritional and functional quality of fresh bread. Foods 2020, 9, 1859. [Google Scholar] [CrossRef]

- Zula, A.T.; Ayele, D.A.; Egigayhu, W.A. Proximate, antinutritional, microbial, and sensory acceptability of bread formulated from wheat (Triticum aestivum) and amaranth (Amaranthus caudatus). Int. J. Food Sci. 2020, 2020, 9429584. [Google Scholar] [CrossRef]

- Montero-Quintero, K.C.; Moreno-Rojas, R.; Alí Molina, E.; Colina, M.S.; Sánchez-Urdaneta, A.B. Evaluation of amaranth enriched bread for dietary regimes. Interciencia 2015, 40, 473–478. [Google Scholar]

- Arias, L.; Ospino, K.S.; Zapata, J.E. Elaboration of flavored milk fortified with hemic iron from of bovine hemoglobin hydrolyzed. Inf. Tecnológica 2018, 29, 65–75. [Google Scholar] [CrossRef]

- Pineau, N.; Girardi, A.; Lacoste Gregorutti, C.; Fillion, L.; Labbe, D. Comparison of RATA, CATA, sorting and napping® as rapid alternatives to sensory profiling in a food industry environment. Food Res. Int. 2022, 158, 111467. [Google Scholar] [CrossRef]

- Iwamura, L.S.; Tridapalli, L.P.; Cardoso, F.A.R.; Droval, A.A.; Marques, L.L.M.; Fuchs, R.H.B. Sensory description of gluten-free bread using rapid sensory methodologies. Int. J. Food Sci. Technol. 2022, 57, 4277–4285. [Google Scholar] [CrossRef]

- Lee, S.; Kwak, H.S.; Kim, S.S.; Lee, Y. Combination of the Check-All-That-Apply (CATA) Method and Just-About-Right (JAR) Scale to Evaluate Korean Traditional Rice Wine (Yakju). Foods 2021, 10, 1895. [Google Scholar] [CrossRef]

- Belahcen, L.; Cassan, D.; Canaguier, E.; Robin, M.; Chiffoleau, Y.; Samson, M.; Jard, G. Physicochemical and sensorial characterization of artisanal pasta from the occitanie region in france. Foods 2022, 11, 3208. [Google Scholar] [CrossRef]

- Camacho, A.; Montero, P.M.; Duran, M. Efecto de la adición de plasma sanguíneo de bovino en el contenido proteico, aceptabilidad y calidad microbiológica de una bebida a base de arroz. Rev. Aliment. Hoy 2014, 22, 104–108. [Google Scholar]

- CIP. Conferencia: Ciencia y Tecnología de Alimentos en la Lucha Contra la Anemia, Realizado el 20 de Setiembre de 2021, Organizado por el Colegio de Ingenieros del Perú; Consejo Departamental Lima: Lima, Peru, 2021. [Google Scholar]

- Korus, A.; Witczak, M.; Korus, J.; Juszczak, L. Dough rheological properties and characteristics of wheat bread with the addition of lyophilized kale (Brassica oleracea L. var. sabellica) powder. Appl. Sci. 2023, 13, 29. [Google Scholar] [CrossRef]

- Korus, J.; Witczak, M.; Korus, A.; Juszczak, L. Mesquite (Prosopis L.) as a functional ingredient in gluten-free dough and bread. LWT 2022, 168, 113957. [Google Scholar] [CrossRef]

- Jamanca-Gonzales, N.C.; Ocrospoma-Dueñas, R.W.; Quintana-Salazar, N.B.; Siche, R.; Silva-Paz, R.J. Influence of preferments on the physicochemical and sensory quality of traditional panettone. Foods 2022, 11, 2566. [Google Scholar] [CrossRef] [PubMed]

- Scanlon, M.G.; Zghal, M.C. Propiedades del pan y estructura de la miga. Aliment. Res. Ent. 2001, 34, 841–864. [Google Scholar]

- Silva, T.H.L.; Monteiro, R.L.; Salvador, A.A.; Laurindo, J.B.; Carciofi, B.A.M. Cinética de las propiedades físicas del pan en la cocción en función de la temperatura real finamente controlada. Control. De Aliment. 2022, 137, 108898. [Google Scholar]

- Borrelli, R.C.; Fogliano, V. Bread crust melanoidins as potential prebiotic ingredients. Mol. Nutr. Food Res. 2005, 49, 673–678. [Google Scholar] [CrossRef]

- Smith, B.M.; Ramsay, S.A.; Roe, A.; Ferrante, M.J.; Brooks, S.W. Reducing visual differences in whole grain bread prepared with hard red and hard white wheat: Application for sensory studies. J. Food Sci. 2019, 84, 2325–2329. [Google Scholar] [CrossRef]

- Domínguez Zárate, P.A.; García Martínez, I.; Güemes-Vera, N.; Totosaus, A.; Pássaro Carvalho, C.P. Textura, color y aceptación sensorial de tortillas y pan producidos con harina de ramón (Brosimum alicastrum) para incrementar la fibra dietética total. Ciencia y Tecnología Agropecuaria 2019, 20, 699–719. [Google Scholar] [CrossRef]

- Cauvain, S.P. Improving the control of staling in frozen bakery products. Trends Food Sci. Technol. 1998, 9, 56–61. [Google Scholar] [CrossRef]

- Benejam, W.; Steffolani, M.E.; León, A.E. Use of enzyme to improve the technological quality of a panettone like baked product. Int. J. Food Sci. Technol. 2009, 44, 2431–2437. [Google Scholar] [CrossRef]

- Esteller, M.S.; Amaral, R.L.; Lannes, S.C.S. Effect of sugar and fat replacers on the texture of baked goods. J. Texture Stud. 2004, 35, 383–393. [Google Scholar] [CrossRef]

- Guiné, R.P.F. Textural properties of bakery products: A review of instrumental and sensory evaluation studies. Appl. Sci. 2022, 12, 8628. [Google Scholar] [CrossRef]

- Symoneaux, R.; Galmarini, M.V.; Mehinagic, E. Comment analysis of consumer’s likes and dislikes as an alternative tool to preference mapping. A case study on apples. Food Qual. Prefer. 2012, 24, 59–66. [Google Scholar] [CrossRef]

- Beaulieu, A.; Giraud, V.; Magro, P.; Nougarede, S.; Maza, E.; Samson, A.; Geffroy, O.; Chervin, C. Development of the Adapted Pivot Test method for descriptive sensory analyses with young untrained students. J. Sens. Stud. 2022, 37, e12779. [Google Scholar] [CrossRef]

- Instituto Nacional de Calidad—INACAL. NTP 206.007:1976 (Revisada el 2016). Productos de Panadería. Determinación del Porcentaje de Cenizas; Instituto Nacional de Calidad: Lima, Peru, 2016. [Google Scholar]

- AOAC. Método Oficial de la AOAC 935.39; Ítem, D.C., Ed.; Baked Products Fat: Rockville, MD, USA, 2005. [Google Scholar]

- Instituto Nacional de Calidad–INACAL. NTP 206.011:2018-Bizcochos, Galletas y Pastas o Fideos. Determinación de Humedad, 2nd ed.; Instituto Nacional de Calidad—INACAL: Lima, Peru, 2005; Available online: https://www.inacal.gob.pe/cid/categoria/normas-tecnicas-peruanas (accessed on 12 January 2023).

- FAO. Food and Nutrition Paper; FAO: Rome, Italy, 1986; Volume 14/7, pp. 221–223. [Google Scholar]

- Centro Nacional de Alimentación y Nutrición. Tablas Peruanas de Composición de Alimentos; Ministerio de Salud: Lima, Peru, 2017; Available online: http://bvs.minsa.gob.pe/local/INS/843_MS-INS77.pdf (accessed on 12 January 2023).

- AOAC. AOAC official method of analysis. In Method 968.08, Determination of Minerals in Animal Feed and Pet Food; AOAC: Rockville, MD, USA, 2020; Chapter 4; p. 40. [Google Scholar]

- Díaz-García, A.; Salvá-Ruíz, B.; Bautista-Cruz, N.; Condezo-Hoyos, L. Optimization of a natural low-calorie antioxidant tea prepared from purple corn (Zea mays L.) cobs and stevia (Stevia rebaudiana Bert.). LWT 2021, 150, 111952. [Google Scholar] [CrossRef]

- Rahimi, J.; Baur, J.; Singh, A. Digital imaging as a tool to study the structure of porous baked foods. J. Cereal Sci. 2020, 95, 103084. [Google Scholar] [CrossRef]

- Valcarcel-Yamani, B.; Caetano, S. Quality parameters of some Brazilian panettones. Braz. J. Pharm. Sci. 2013, 49, 511–519. [Google Scholar] [CrossRef]

- CIE (Commission Internationale de l’Éclairage). Technical Report: Colorimetry, 3rd ed.; CIE 15: Washington, WA, USA, 2004. [Google Scholar]

- Zegarra, S.; Muñoz, A.M.; Ramos-Escudero, F. Elaboración de un pan libre de gluten a base de harina de cañihua (Chenopodium pallidicaule Aellen) y evaluación de la aceptabilidad sensorial. Revista Chilena de Nutrición 2019, 46, 561–570. [Google Scholar] [CrossRef]

- Sławińska, A.; Sołowiej, B.G.; Radzki, W.; Fornal, E. Wheat bread supplemented with Agaricus bisporus powder: Effect on bioactive substances content and technological quality. Foods 2022, 11, 3786. [Google Scholar] [CrossRef]

- Saldaña, E.; Saldarriaga, L.; Cabrera, J.; Behrens, J.H.; Selani, M.M.; Rios-Mera, J.; Contreras-Castillo, C.J. Descriptive and hedonic sensory perception of brazilian consumers for smoked bacon. Meat Sci. 2019, 147, 60–69. [Google Scholar] [CrossRef]

- Miraballes, M.; Gámbaro, A. Influence of Images on the Evaluation of Jams Using Conjoint Analysis Combined with Check-All-That-Apply (CATA) Questions. J. Food Sci. 2018, 83, 167–174. [Google Scholar] [CrossRef]

- Varela, P.; Ares, G. Sensory profiling, the blurred line between sensory and consumer science. A review of novel methods for product characterization. Food Res. Int. 2012, 48, 893–908. [Google Scholar] [CrossRef]

- Gere, A.; Szabó, Z.; Pásztor-Huszár, K.; Orbán, C.; Kókai, Z.; Sipos, L. Use of JAR-Based Analysis for Improvement of Product Acceptance: A Case Study on Flavored Kefirs. J. Food Sci. 2017, 82, 1200–1207. [Google Scholar] [CrossRef] [PubMed]

- Ortega-Heras, M.; Gómez, I.; de Pablos-Alcalde, S.; González-Sanjosé, M.L. Application of the Just-About-Right Scales in the Development of New Healthy Whole-Wheat Muffins by the Addition of a Product Obtained from White and Red Grape Pomace. Foods 2019, 8, 419. [Google Scholar] [CrossRef] [PubMed]

| Sample | Ash (g) | Fat (g) | Moisture (g) | Protein (g) | Carbohydrates (g) | Energy (kcal/100 g) |

|---|---|---|---|---|---|---|

| T0 | 2.145 ± 0.007 a,b | 7.525 ± 0.078 a | 24.885 ± 0.092 a | 9.285 ± 0.050 d | 56.160 ± 0.057 a | 329.505 ± 0.728 a |

| T1 | 2.210 ± 0.014 a | 7.365 ± 0.233 a | 24.595 ± 0.035 b | 9.880 ± 0.113 c | 55.950 ± 0.170 a | 329.605 ± 0.969 a |

| T2 | 2.130 ± 0.014 b | 7.270 ± 0.170 a | 24.440 ± 0.042 b | 10.275 ± 0.035 b | 55.885 ± 0.177 a | 330.070 ± 0.962 a |

| T3 | 2.125 ± 0.035 b | 7.435 ± 0.050 a | 24.945 ± 0.064 a | 10.400 ± 0.028 b | 55.095 ± 0.078 b | 328.895 ± 0.643 a |

| T4 | 2.180 ± 0.014 a,b | 7.225 ± 0.134 a | 25.030 ± 0.014 a | 11.080 ± 0.028 a | 54.485 ± 0.078 c | 327.285 ± 0.785 a |

| Sample | Iron (mg/kg) | pH | % Acidity (Expressed in Sulfuric Acid) | Bulk Density (g/mL) | Specific Volumen (mL/g) | Porosity (%) |

|---|---|---|---|---|---|---|

| T0 | 46.600 ± 0.424 e | 5.720 ± 0.014 a | 0.031 ± 0.002 c | 0.436 ± 0.055 a | 2.323 ± 0.303 a | 8.049 ± 1.362 b,c |

| T1 | 61.050 ± 1.202 d | 5.615 ± 0.007 b | 0.033 ± 0.001 c | 0.425 ± 0.032 a | 2.362 ± 0.178 a | 26.810± 5.190 a |

| T2 | 67.440 ± 3.020 c | 5.590 ± 0.014 b | 0.040 ± 0.001 b | 0.419 ± 0.006 a | 2.390 ± 0.034 a | 16.170 ± 4.870 b |

| T3 | 82.350 ± 0.354 b | 5.465 ± 0.007 c | 0.042 ± 0.001 b | 0.416 ± 0.045 a | 2.427 ± 0.258 a | 13.180 ± 2.690 b,c |

| T4 | 93.750 ± 1.202 a | 5.465 ± 0.007 c | 0.056 ± 0.004 a | 0.407 ± 0.051 a | 2.493 ± 0.319 a | 6.290 ± 2.230 c |

| Sample | L* | a* | b* | C* | h* |

|---|---|---|---|---|---|

| Crust | |||||

| T0 | 53.870 ± 3.010 a | 18.195 ± 0.387 a | 29.010 ± 2.130 a | 57.870 ± 2.580 a | 34.422 ± 1.864 a |

| T1 | 45.310 ± 2.910 b | 14.533 ± 0.282 b | 23.270 ± 3.880 b | 55.540 ± 2.250 ab | 25.770 ± 1.976 b |

| T2 | 44.810 ± 2.560 b | 12.653 ± 0.497 c | 19.120 ± 1.705 bc | 56.190 ± 2.080 ab | 22.815 ± 1.526 b |

| T3 | 45.275 ± 1.591 b | 10.563 ± 0.177 d | 16.192 ± 0.203 cd | 56.810 ± 0.418 ab | 19.333 ± 0.236 c |

| T4 | 40.477 ± 1.483 b | 9.883 ± 0.297 d | 13.405 ± 0.724 d | 53.572 ± 1.546 b | 16.657 ± 0.634 c |

| Crumb | |||||

| T0 | 61.270 ± 2.470 a | 9.197± 0.426 a | 23.523 ± 0.508 a | 68.698 ± 0.441 a | 25.250 ± 0.616 a |

| T1 | 50.085 ± 1.214 b | 10.512 ± 0.368 b | 19.505 ± 0.364 b | 61.683 ± 0.455 b | 22.165 ± 0.481 b |

| T2 | 44.250 ± 2.080 c | 9.408± 0.300 b | 16.692 ± 0.869 c | 60.962 ± 0.416 b | 19.380 ± 0.562 c |

| T3 | 43.745 ± 1.012 cd | 9.550 ± 0.061 b | 15.963 ± 0.138 c | 59.102 ± 0.338 c | 18.598 ± 0.102 cd |

| T4 | 40.493 ± 0.949 d | 9.675 ± 0.260 b | 14.720± 0.557 d | 56.670 ± 0.704 d | 17.618 ± 0.574 d |

| Base | |||||

| T0 | 40.877 ± 0.662 a | 19.403 ± 0.777 ab | 26.780 ± 2.760 a | 53.037 ± 0.065 a | 32.270 ± 1.293 a |

| T1 | 36.427 ± 1.111 b | 22.807 ± 0.933 a | 16.667 ± 0.355 b | 36.167 ± 0.696 b | 27.910 ± 1.333 ab |

| T2 | 33.777 ± 1.269 bc | 18.970 ± 2.750 ab | 12.270 ± 1.970 b | 32.850 ± 1.429 b | 22.600 ± 3.330 bc |

| T3 | 34.457 ± 1.284 b | 20.270 ± 2.660 ab | 15.280 ± 1.552 b | 28.840 ± 12.310 b | 23.850 ± 5.010 bc |

| T4 | 31.430 ± 0.212 c | 16.903 ± 0.555 b | 3.003 ± 1.125 c | 10.100 ± 3.940 c | 17.193 ± 0.378 c |

| Sample | Hardness (N) | Adhesiveness (N) | Resilience | Fractureability (N) | Cohesiveness | Elasticity | Chewiness (N) |

|---|---|---|---|---|---|---|---|

| T0 | 19.520 ± 2.620 b | 0.012 ± 0.003 a | 0.140 ± 0.000 a | 19.520 ± 2.620 b | 0.380 ± 0.014 a | 0.785 ± 0.007 ª | 5.864 ± 0.918 b |

| T1 | 24.508 ± 0.323 b | 0.039 ± 0.014 a | 0.125 ± 0.007 a | 24.508 ± 0.323 b | 0.355 ± 0.007 ab | 0.740 ± 0.014 b | 6.426 ± 0.148 b |

| T2 | 25.592 ± 0.121 b | 0.032 ± 0.010 a | 0.135 ± 0.007 a | 25.592 ± 0.121 b | 0.360 ± 0.014 ab | 0.745 ± 0.007 ab | 6.860 ± 0.205 ab |

| T3 | 25.180 ± 1.740 b | 0.047 ± 0.052 a | 0.125 ± 0.007 a | 25.180 ± 1.740 b | 0.355 ± 0.007 ab | 0.760 ± 0.014 ab | 6.793 ± 0.179 ab |

| T4 | 38.980 ± 1.910 a | 0.017 ± 0.001 a | 0.095 ± 0.007 b | 38.980 ± 1.910 a | 0.320 ± 0.014 b | 0.720 ± 0.001 b | 8.970 ± 0.972 a |

| Category | Descriptors | T1 | T2 | T3 | T4 |

|---|---|---|---|---|---|

| Flavor | Acid | 48 | 44 | 45 | 45 |

| Pleasurable | 46 | 47 | 47 | 51 | |

| Sour | 46 | 46 | 46 | 47 | |

| Bitter | 44 | 46 | 38 | 40 | |

| Sweet | 67 | 56 | 52 | 63 | |

| Bread flavor | 46 | 45 | 48 | 46 | |

| Strong taste | 45 | 45 | 45 | 45 | |

| Salty | 46 | 44 | 45 | 49 | |

| Visual appearance | Dark | 16 (−) * | 11 | 10 | 0 (+) *** |

| Bright | 48 | 51 | 49 | 49 | |

| Texture | Consistent | 46 | 46 | 44 | 45 |

| Hard | 34 | 22 | 37 (−) * | 19 (+) * | |

| Spongy | 49 | 48 | 48 | 48 | |

| Humidity | 46 | 46 | 47 | 47 | |

| Dry | 43 | 46 | 46 | 46 | |

| Soft | 48 | 51 | 50 | 60 | |

| Smell | Bread smell | 43 | 44 | 51 | 47 |

| Intense smell | 47 | 48 | 48 | 48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jamanca-Gonzales, N.C.; Ocrospoma-Dueñas, R.W.; Quintana-Salazar, N.B.; Jimenez-Bustamante, J.N.; Huaman, E.E.H.; Silva-Paz, R.J. Physicochemical and Sensory Parameters of “Petipan” Enriched with Heme Iron and Andean Grain Flours. Molecules 2023, 28, 3073. https://doi.org/10.3390/molecules28073073

Jamanca-Gonzales NC, Ocrospoma-Dueñas RW, Quintana-Salazar NB, Jimenez-Bustamante JN, Huaman EEH, Silva-Paz RJ. Physicochemical and Sensory Parameters of “Petipan” Enriched with Heme Iron and Andean Grain Flours. Molecules. 2023; 28(7):3073. https://doi.org/10.3390/molecules28073073

Chicago/Turabian StyleJamanca-Gonzales, Nicodemo C., Robert W. Ocrospoma-Dueñas, Norma B. Quintana-Salazar, Jose N. Jimenez-Bustamante, Eduardo E. Herrera Huaman, and Reynaldo J. Silva-Paz. 2023. "Physicochemical and Sensory Parameters of “Petipan” Enriched with Heme Iron and Andean Grain Flours" Molecules 28, no. 7: 3073. https://doi.org/10.3390/molecules28073073

APA StyleJamanca-Gonzales, N. C., Ocrospoma-Dueñas, R. W., Quintana-Salazar, N. B., Jimenez-Bustamante, J. N., Huaman, E. E. H., & Silva-Paz, R. J. (2023). Physicochemical and Sensory Parameters of “Petipan” Enriched with Heme Iron and Andean Grain Flours. Molecules, 28(7), 3073. https://doi.org/10.3390/molecules28073073