Epoxidation of Methyl Esters as Valuable Biomolecules: Monitoring of Reaction

Abstract

1. Introduction

2. Results and Discussion

2.1. 1H NMR

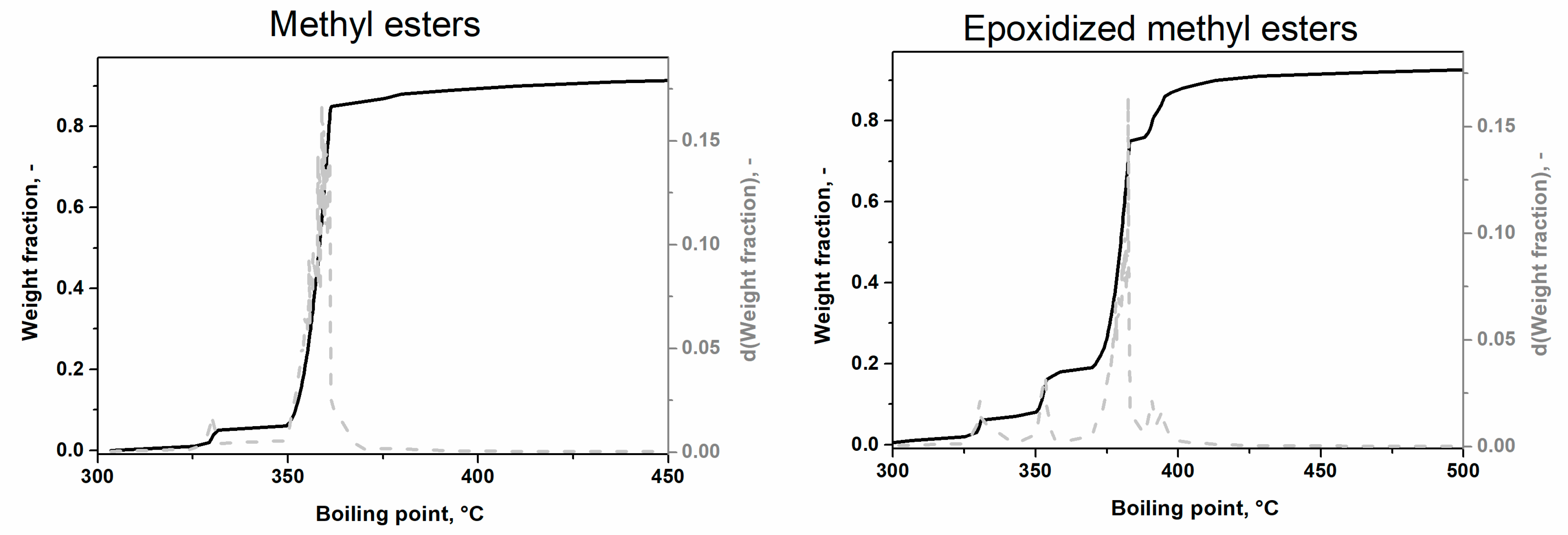

2.2. The Simulated Distillation

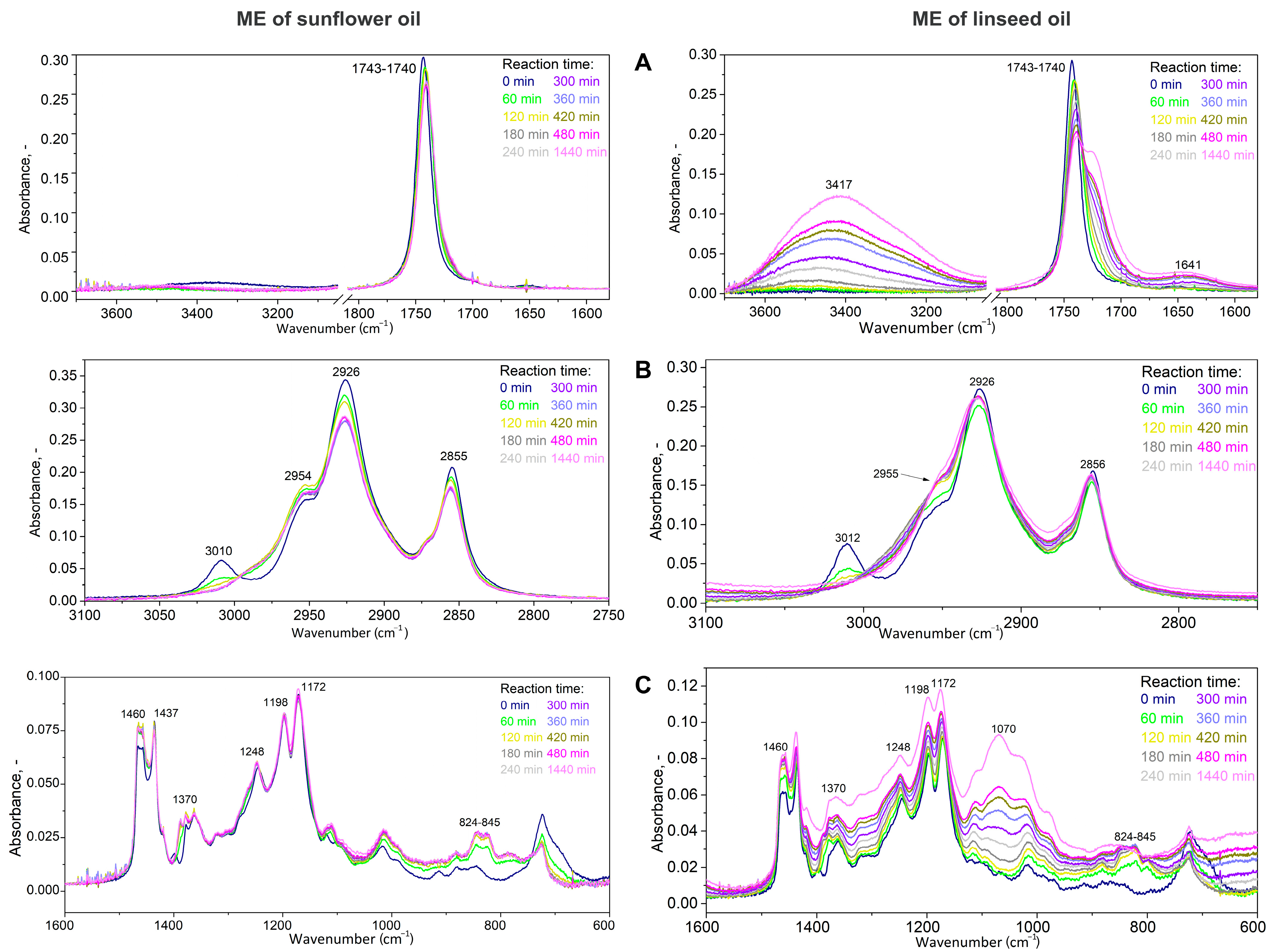

2.3. The Infrared Spectroscopy

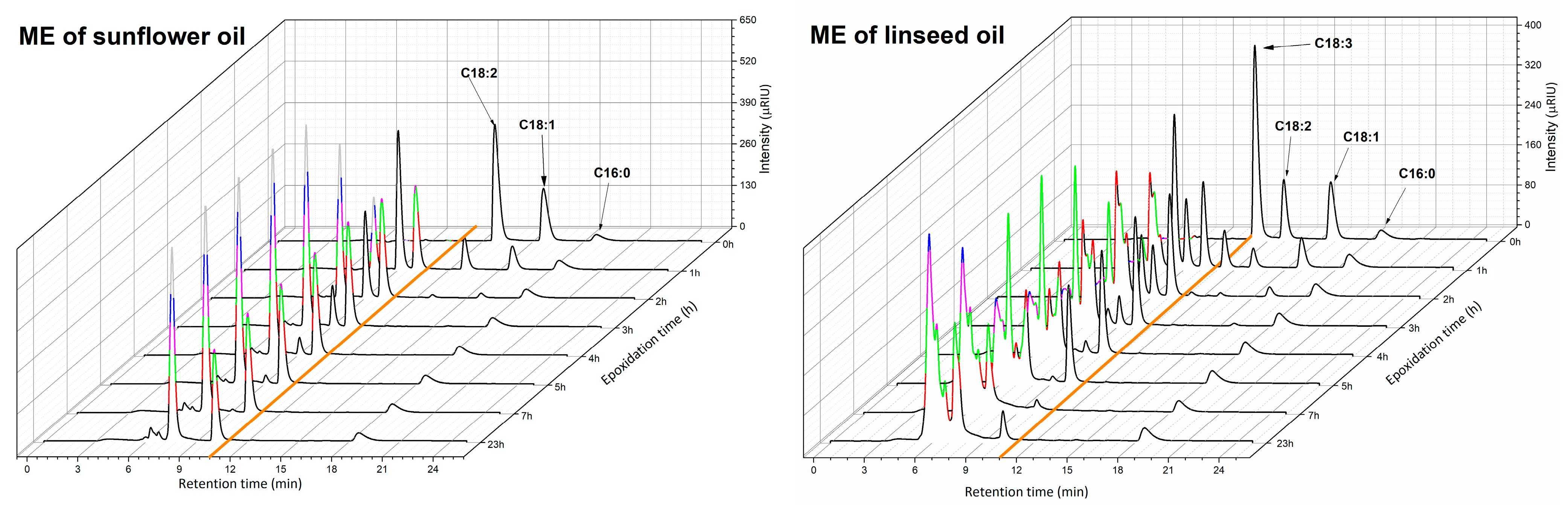

2.4. High Performance Liquid Chromatography with Refractometric Detection

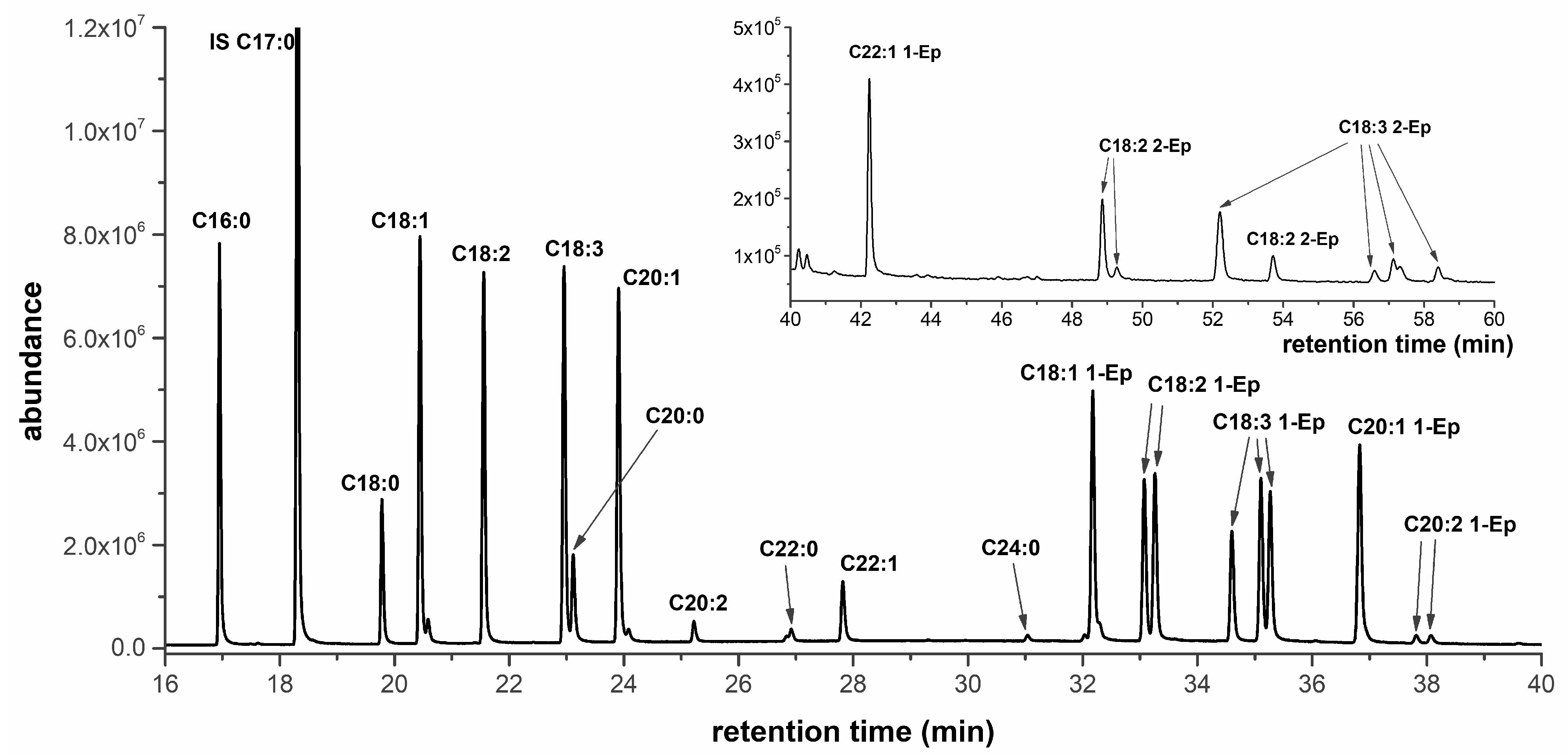

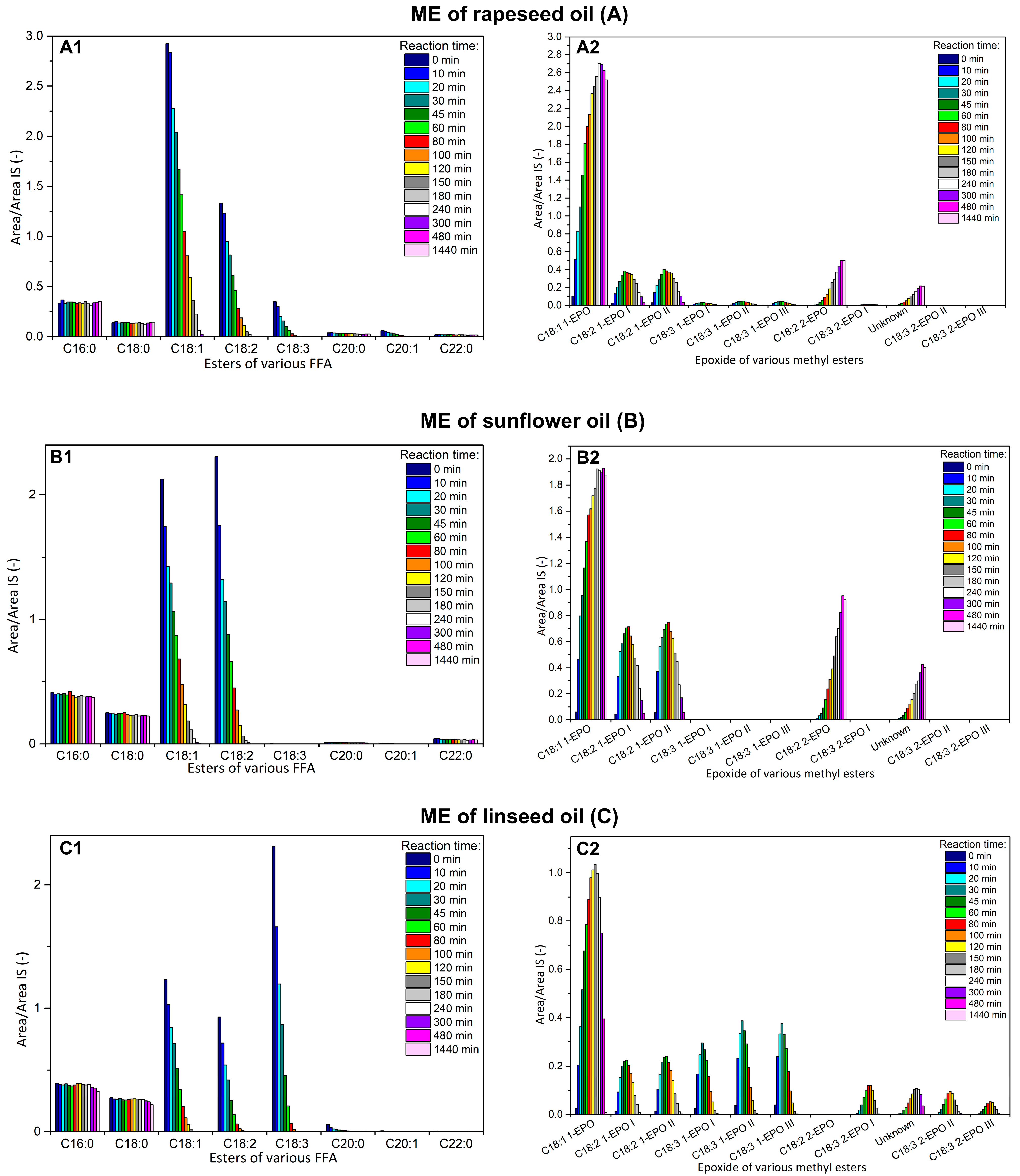

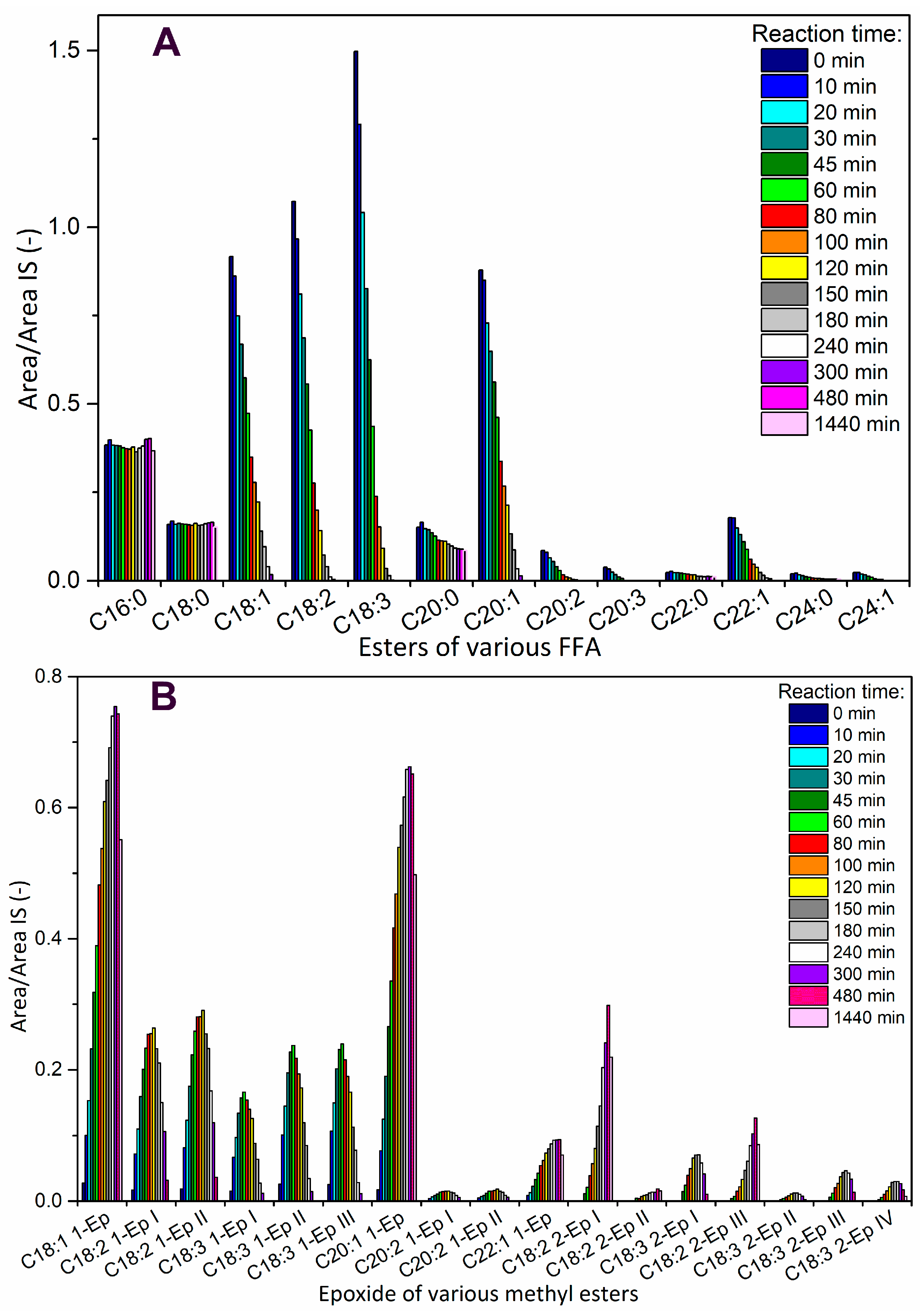

2.5. Gas Chromatography with Mass Spectrometry

3. Materials and Methods

3.1. Epoxidation of Esters of Higher Fatty Acids

3.2. Analytical Methods

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

Nomenclature

| E_ME | epoxide methyl ester (methyl ester with oxirane ring) |

| FA | fatty acids |

| FTIR | Fourier-transform infrared spectroscopy |

| GC-MS | gas chromatography with mass spectrometry |

| HPLC-RI | high performance liquid chromatography with refractometric detection |

| ME | methyl ester |

| SO | sunflower oil |

| LO | linseed oil |

| RO | rapeseed oil |

| IV | iodine value (g I2/100 g) |

| EI | epoxide index (mol/kg) |

References

- Ben Bacha, A.; Alonazi, M.; Alharbi, M.G.; Horchani, H.; Ben Abdelmalek, I. Biodiesel Production by Single and Mixed Immobilized Lipases Using Waste Cooking Oil. Molecules 2022, 27, 8736. [Google Scholar] [CrossRef] [PubMed]

- Hajek, M.; Vavra, A.; Carmona, H.D.; Kocik, J. The Catalysed Transformation of Vegetable Oils or Animal Fats to Biofuels and Bio-Lubricants: A Review. Catalysts 2021, 11, 1118. [Google Scholar] [CrossRef]

- Tan, H.W.; Aziz, A.R.A.; Aroua, M.K. Glycerol production and its applications as a raw material: A review. Renew. Sustain. Energy Rev. 2013, 27, 118–127. [Google Scholar] [CrossRef]

- Karak, N. Vegetable Oil-Based Epoxies; Woodhead Publishing: Sawston, England, 2012; ISBN 9780857097101. [Google Scholar]

- Nogales-Delgado, S.; Cabanillas, A.G.; Romero, A.G.; Martin, J.M.E. Monitoring tert-Butylhydroquinone Content and Its Effect on a Biolubricant during Oxidation. Molecules 2022, 27, 8931. [Google Scholar] [CrossRef]

- Atzori, L.; Comes, A.; Fusaro, L.; Aprile, C.; Cutrufello, M.G. Aluminosilicate-Supported Catalysts for the Synthesis of Cyclic Carbonates by Reaction of CO2 with the Corresponding Epoxides. Molecules 2022, 27, 8883. [Google Scholar] [CrossRef]

- Manka, D.; Siewniak, A. Deep Eutectic Solvents as Catalysts for Cyclic Carbonates Synthesis from CO2 and Epoxides. Molecules 2022, 27, 9006. [Google Scholar] [CrossRef]

- Dunn, R.O. Thermal analysis of alternative diesel fuels from vegetable oils. J. Am. Oil Chem. Soc. 1999, 76, 109–115. [Google Scholar] [CrossRef]

- Orsavova, J.; Misurcova, L.; Ambrozova, J.; Vicha, R.; Mlcek, J. Fatty Acids Composition of Vegetable Oils and Its Contribution to Dietary Energy Intake and Dependence of Cardiovascular Mortality on Dietary Intake of Fatty Acids. Int. J. Mol. Sci. 2015, 16, 12871–12890. [Google Scholar] [CrossRef]

- Fukuda, H.; Kondo, A.; Noda, H. Biodiesel fuel production by transesterification of oils. J. Biosci. Bioeng. 2001, 92, 405–416. [Google Scholar] [CrossRef] [PubMed]

- Bhuiya, M.M.K.; Rasul, M.G.; Khan, M.M.K.; Ashwath, N. Biodiesel production and characterisation of poppy (Papaver somniferum L.) seed oil methyl ester as a source of 2nd generation biodiesel feedstock. Ind. Crops Prod. 2020, 152, 112493. [Google Scholar] [CrossRef]

- Wahl, H.G.; Habel, S.Y.; Schmieder, N.; Liebich, H.M. Identification of Cis-Trans-Isomers of Methyl-Ester and Oxazoline Derivatives of Unsaturated Fatty-Acids Using Gc-Ftir-Ms. J. High Resolut. Chromatogr. 1994, 17, 543–548. [Google Scholar] [CrossRef]

- Santacesaria, E.; Turco, R.; Russo, V.; Tesser, R.; Di Serio, M. Soybean Oil Epoxidation: Kinetics of the Epoxide Ring Opening Reactions. Processes 2020, 8, 1134. [Google Scholar] [CrossRef]

- Kousaalya, A.B.; Beyene, S.D.; Gopal, V.; Ayalew, B.; Pilla, S. Green epoxy synthesized from Perilla frutescens: A study on epoxidation and oxirane cleavage kinetics of high-linolenic oil. Ind. Crop Prod. 2018, 123, 25–34. [Google Scholar] [CrossRef]

- Mecozzi, F.; Dong, J.J.; Angelone, D.; Browne, W.R.; Eisink, N. Oxidative Cleavage of Alkene C=C Bonds Using a Manganese Catalyzed Oxidation with H2O2 Combined with Periodate Oxidation. Eur. J. Org. Chem. 2019, 2019, 7151–7158. [Google Scholar] [CrossRef] [PubMed]

- Nogales-Delgado, S.; Martin, J.M.E.; Ocana, M.S. Use of mild reaction conditions to improve quality parameters and sustainability during biolubricant production. Biomass Bioenerg. 2022, 161, 106456. [Google Scholar] [CrossRef]

- Pantone, V.; Laurenza, A.G.; Annese, C.; Fracassi, F.; Fusco, C.; Nacci, A.; Russo, A.; D’Accolti, L. Methanolysis of epoxidized soybean oil in continuous flow conditions. Ind. Crop Prod. 2017, 109, 1–7. [Google Scholar] [CrossRef]

- Polese, R.; Pintus, E.; Nuvoli, L.; Tiana, M.; Pintus, S.; Satta, G.; Beccu, A.; Gaspa, S.; Carraro, M.; De Luca, L.; et al. Aquivion perfluorosulfonic superacid as an effective catalyst for selective epoxidation of vegetable oils. R. Soc. Open Sci. 2022, 9, 211554. [Google Scholar] [CrossRef]

- Japir, A.; Salimon, J.; Derawi, D.; Bahadi, M.; Yusop, M.R. Separation of Free Fatty Acids from High Free Fatty Acid Crude Palm Oil Using Short-Path Distillation. AIP Conf. Proc. 2016, 1784, 030001. [Google Scholar] [CrossRef]

- Ceron, A.A.; Boas, R.N.V.; Biaggio, F.C.; de Castro, H.F. Synthesis of biolubricant by transesterification of palm kernel oil with simulated fusel oil: Batch and continuous processes. Biomass Bioenerg. 2018, 119, 166–172. [Google Scholar] [CrossRef]

- Mungroo, R.; Pradhan, N.C.; Goud, V.V.; Dalai, A.K. Epoxidation of canola oil with hydrogen peroxide catalyzed by acidic ion exchange resin. J. Am. Oil Chem. Soc. 2008, 85, 887–896. [Google Scholar] [CrossRef]

- La Scala, J.; Wool, R.P. Effect of FA composition on epoxidation kinetics of TAG. J. Am. Oil Chem. Soc. 2002, 79, 373–378. [Google Scholar] [CrossRef]

- Sammaiah, A.; Padmaja, K.V.; Prasad, R.B.N. Synthesis of Epoxy Jatropha Oil and its Evaluation for Lubricant Properties. J. Oleo Sci. 2014, 63, 637–643. [Google Scholar] [CrossRef] [PubMed]

- Xia, W.; Budge, S.M.; Lumsden, M.D. H-1-NMR Characterization of Epoxides Derived from Polyunsaturated Fatty Acids. J. Am. Oil Chem. Soc. 2016, 93, 467–478. [Google Scholar] [CrossRef]

- Piazza, G.J.; Nunez, A.; Foglia, T.A. Epoxidation of fatty acids, fatty methyl esters, and alkenes by immobilized oat seed peroxygenase. J. Mol. Catal. B Enzym. 2003, 21, 143–151. [Google Scholar] [CrossRef]

- Mushtaq, M.; Tan, I.M.; Nadeem, M.; Devi, C.; Lee, S.Y.C.; Sagir, M.; Rashid, U. Epoxidation of methyl esters derived from Jatropha oil: An optimization study. Grasas Aceites 2013, 64, 103–114. [Google Scholar] [CrossRef]

- Bachler, C.; Schober, S.; Mittelbach, M. Simulated Distillation for Biofuel Analysis. Energy Fuels 2010, 24, 2086–2090. [Google Scholar] [CrossRef]

- Yuan, W.; Hansen, A.C.; Zhang, Q. Vapor pressure and normal boiling point predictions for pure methyl esters and biodiesel fuels. Fuel 2005, 84, 943–950. [Google Scholar] [CrossRef]

- Lee, P.L.; Yunus, W.M.Z.W.; Yeong, S.K.; Abdullah, D.K.; Lim, W.H. Optimization of the Epoxidation of Methyl Ester of Palm Fatty Acid Distillate. J. Oil Palm. Res. 2009, 21, 675–682. [Google Scholar]

- Wadumesthrige, K.; Salley, S.O.; Ng, K.Y.S. Effects of partial hydrogenation, epoxidation, and hydroxylation on the fuel properties of fatty acid methyl esters. Fuel Process. Technol. 2009, 90, 1292–1299. [Google Scholar] [CrossRef]

- Turco, R.; Tesser, R.; Russo, V.; Cogliano, T.; Di Serio, M.; Santacesaria, E. Epoxidation of Linseed Oil by Performic Acid Produced In Situ. Ind. Eng. Chem. Res. 2021, 60, 16607–16618. [Google Scholar] [CrossRef]

- de Haro, J.C.; Izarra, I.; Rodriguez, J.F.; Perez, A.; Carmona, M. Modelling the epoxidation reaction of grape seed oil by peracetic acid. J. Clean. Prod. 2016, 138, 70–76. [Google Scholar] [CrossRef]

- Hajek, M.; Skopal, F.; Kwiecien, J.; Cernoch, M. Determination of esters in glycerol phase after transesterification of vegetable oil. Talanta 2010, 82, 283–285. [Google Scholar] [CrossRef]

- Holcapek, M.; Lisa, M.; Jandera, P.; Kabatova, N. Quantitation of triacylglycerols in plant oils using HPLC with APCI-MS, evaporative light-scattering, and UV detection. J. Sep. Sci. 2005, 28, 1315–1333. [Google Scholar] [CrossRef] [PubMed]

- Anuar, S.T.; Zhao, Y.Y.; Mugo, S.M.; Curtis, J.M. Monitoring the Epoxidation of Canola Oil by Non-aqueous Reversed Phase Liquid Chromatography/Mass Spectrometry for Process Optimization and Control. J. Am. Oil Chem. Soc. 2012, 89, 1951–1960. [Google Scholar] [CrossRef]

- Christie, W.W. Mass Spectrometry of Methyl Esters. Available online: https://www.lipidmaps.org/resources/lipidweb/lipidweb_html/ms/methesters/me-epoxy/index.htm (accessed on 10 January 2023).

- Vaclavik, A.; Christian, E.W. Essentials of Food Science; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Joback, K.G.; Reid, R.C. Estimation of Pure-Component Properties from Group-Contributions. Chem. Eng. Commun. 1987, 57, 233–243. [Google Scholar] [CrossRef]

- Akasaka, K.; Akama, T.; Ohrui, H.; Meguro, H. Measurement of Hydroxy and Hydroperoxy Fatty-Acids by a High-Pressure Liquid-Chromatography with a Column-Switching System. Biosci. Biotechnol. Biochem. 1993, 57, 2016–2019. [Google Scholar] [CrossRef]

- Hajek, M.; Skopal, F.; Machek, J. Simplification of separation of the reaction mixture after transesterification of vegetable oil. Eur. J. Lipid Sci. Technol. 2008, 110, 347–350. [Google Scholar] [CrossRef]

- Musil, M.; Hajek, M.; Skopal, F.; Vavra, A. Improved method of water removal from vegetable oil. Chem. Pap. 2019, 73, 767–769. [Google Scholar] [CrossRef]

| Type of Oil (Abbreviation) | IV (g I2/100 g) | Water Content (ppm) | Profile of Higher Fatty Acids 1 (wt.%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 16:0 | 18:0 | 18:1 | 18:2 | 18:3 | 20:1 | 20:2 | 22:1 | |||

| Rapeseed (RO) | 106.9 | 260 | 6.4 | 2.7 | 55.9 | 25.5 | 6.7 | 1.2 | - * | 0.1 |

| Sunflower (SO) | 111.4 | 440 | 8.0 | 4.8 | 41.1 | 44.6 | -* | 0.1 | - * | - * |

| Linseed (LO) | 181.3 | 350 | 7.6 | 5.3 | 23.6 | 17.8 | 44.3 | 0.1 | - * | - * |

| Camelina sativa (CS) | 151.3 | 430 | 7.1 | 2.9 | 16.9 | 19.8 | 27.6 | 16.2 | 1.6 | 3.3 |

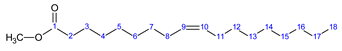

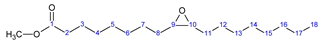

| Type of Fatty Acid Methyl Ester | Type of Epoxy Fatty Acid Methyl Ester | M (g/mol) | |

|---|---|---|---|

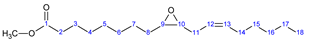

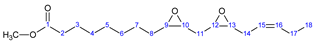

| cis-9-octadecenoic (oleic) acid ME | Monoepoxy (C18:1-Ep) | cis-9,10-epoxy octadecanoate ME | |

|  | 312.5 | |

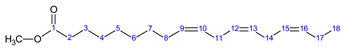

| cis,cis-9,12-octadecenoic (linoleic) acid ME | Monoepoxy (C18:2 1-Ep) | cis-9,10-epoxy octadec-12-enoate ME | 310.5 |

|  | ||

| cis-12,13-epoxy octadec-9-enoate ME | |||

| |||

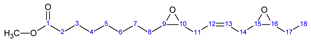

| Diepoxy (C18:2 2- Ep) | cis,cis-9,10;12-13-diepoxy octadecanoate ME | ||

| 326.5 | ||

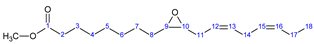

| cis,cis,cis-9,12,15-octadecenoic (linolenic) acid ME | Monoepoxy (C18:3 1-Ep) | cis-9,10-epoxy octadec-12,15-dienoate ME | |

|  | 308.5 | |

| cis-12,13-epoxy octadec-9,15-dienoate ME | |||

| |||

| cis-15,16-epoxy octadec-9,12-dienoate ME | |||

| |||

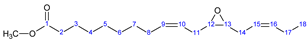

| Diepoxy (C18:3 2-EPO) | cis,cis-9,10;12,13-diepoxy octadec-12-enoate ME | ||

| 324.5 | ||

| cis,cis-12,13;15,16-diepoxy octadec-9-enoate ME | |||

| |||

| cis,cis-9,10;15,16-diepoxy octadec-12-enoate ME | |||

| |||

| Triepoxy (C18:3 3-Ep) | cis,cis,cis-9,10;12,13;15,16-triepoxy octadecanoic acid ME | ||

| 340.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hájek, M.; Hájek, T.; Kocián, D.; Frolich, K.; Peller, A. Epoxidation of Methyl Esters as Valuable Biomolecules: Monitoring of Reaction. Molecules 2023, 28, 2819. https://doi.org/10.3390/molecules28062819

Hájek M, Hájek T, Kocián D, Frolich K, Peller A. Epoxidation of Methyl Esters as Valuable Biomolecules: Monitoring of Reaction. Molecules. 2023; 28(6):2819. https://doi.org/10.3390/molecules28062819

Chicago/Turabian StyleHájek, Martin, Tomáš Hájek, David Kocián, Karel Frolich, and András Peller. 2023. "Epoxidation of Methyl Esters as Valuable Biomolecules: Monitoring of Reaction" Molecules 28, no. 6: 2819. https://doi.org/10.3390/molecules28062819

APA StyleHájek, M., Hájek, T., Kocián, D., Frolich, K., & Peller, A. (2023). Epoxidation of Methyl Esters as Valuable Biomolecules: Monitoring of Reaction. Molecules, 28(6), 2819. https://doi.org/10.3390/molecules28062819