High-Throughput Preparation and High-Throughput Detection of Polymer-Dispersed Liquid Crystals Based on Ink-Jet Printing and Grayscale Value Analysis

Abstract

1. Introduction

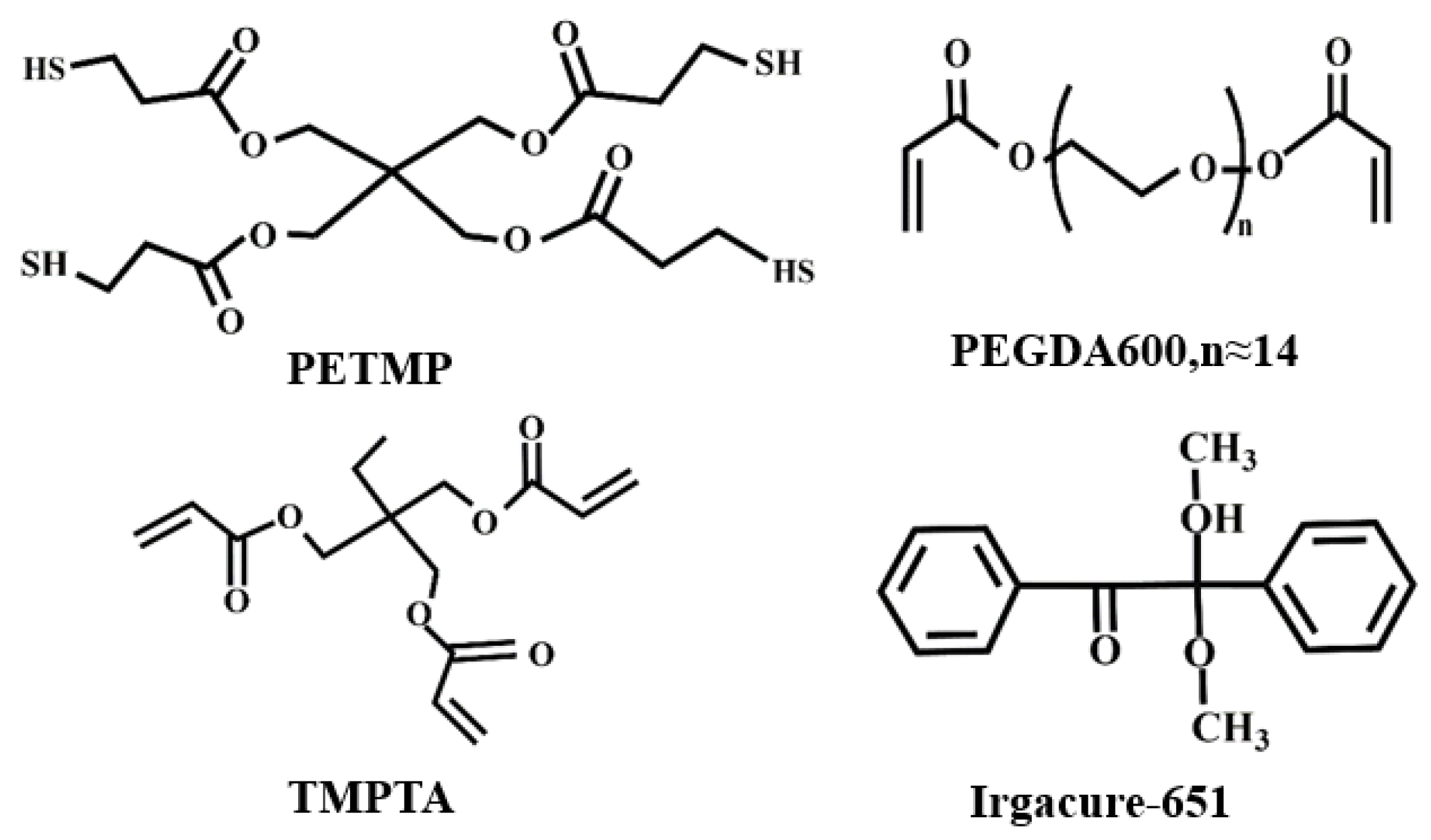

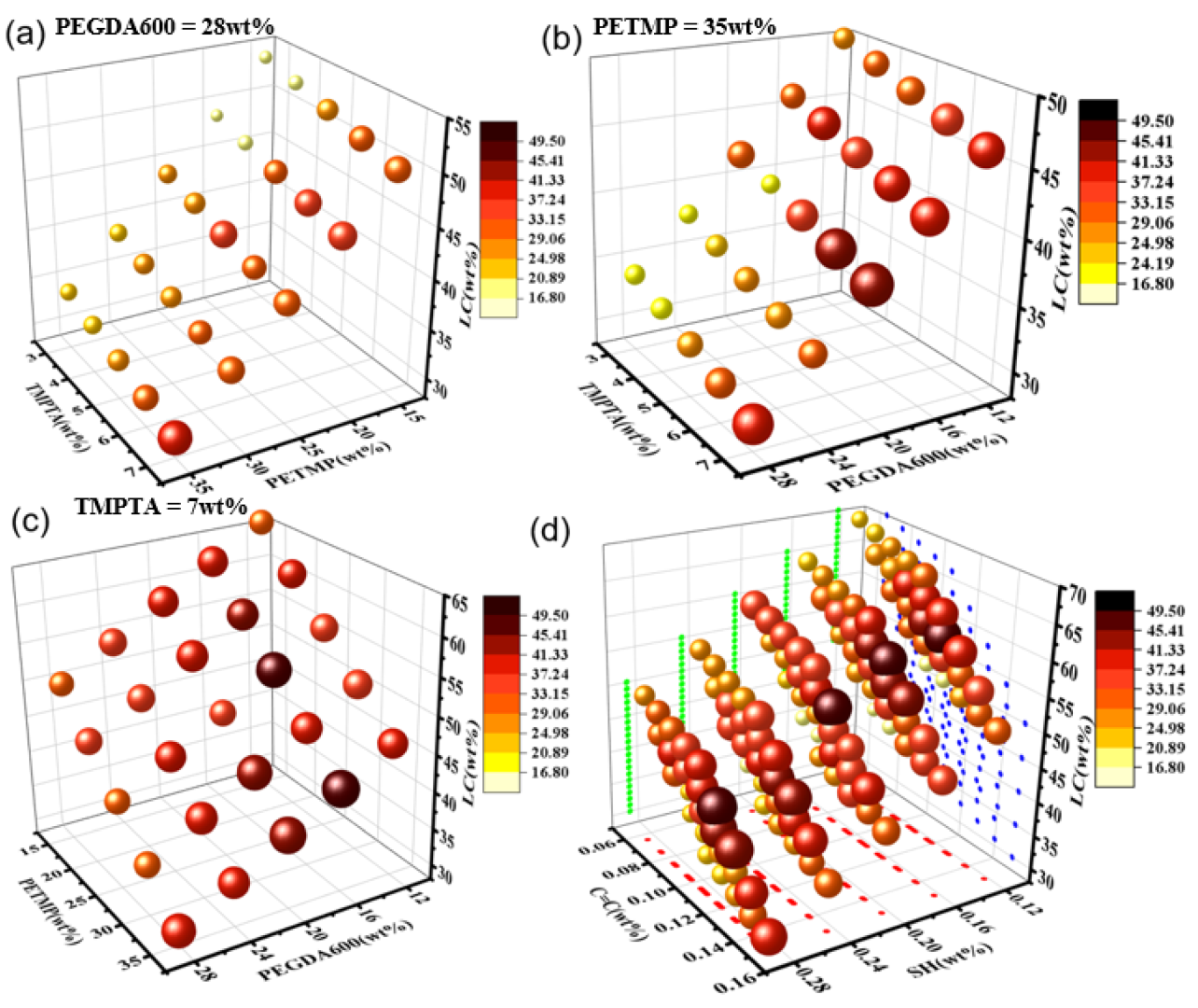

2. Results and Discussion

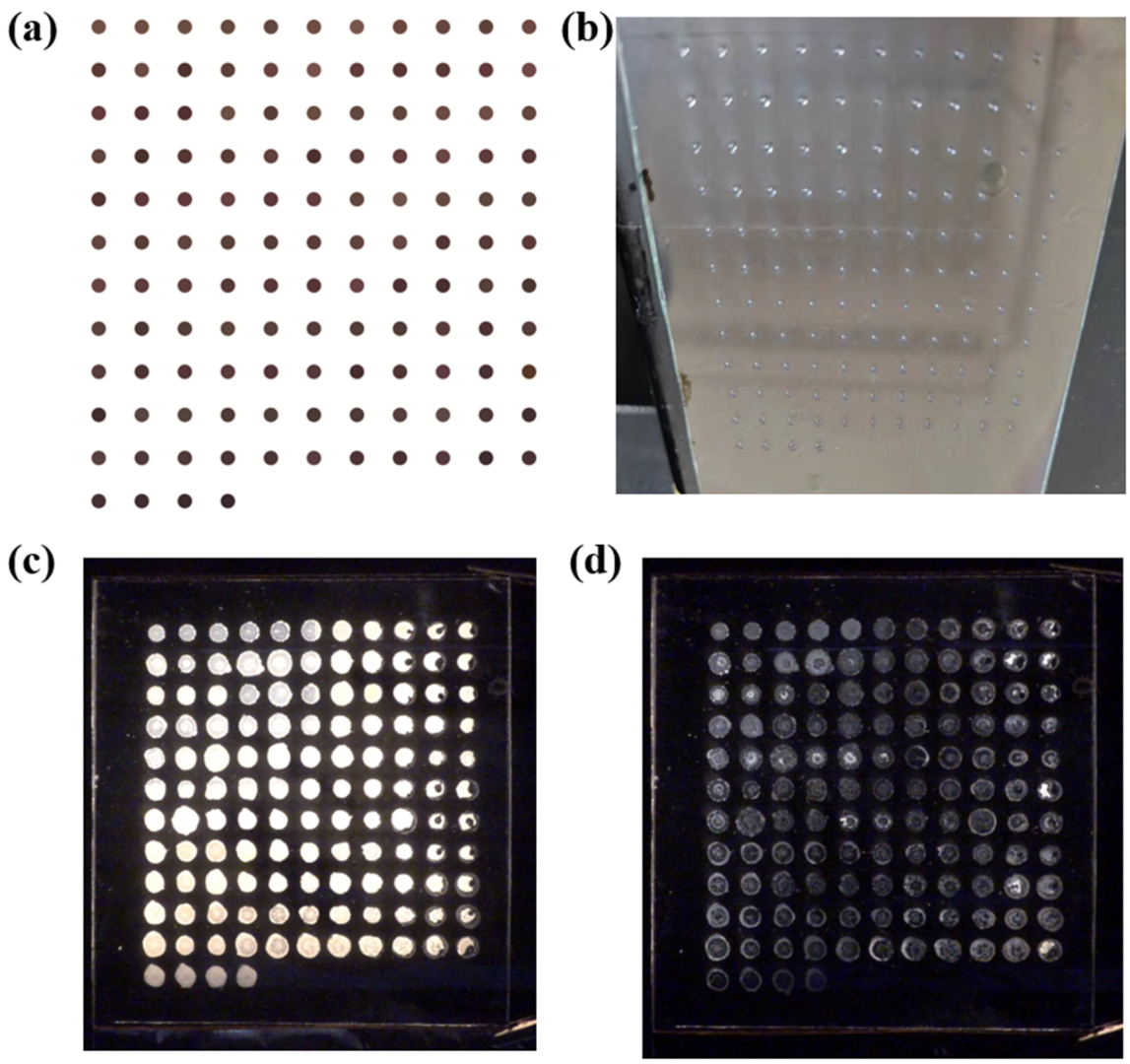

2.1. High-Throughput Preparation PDLC Samples

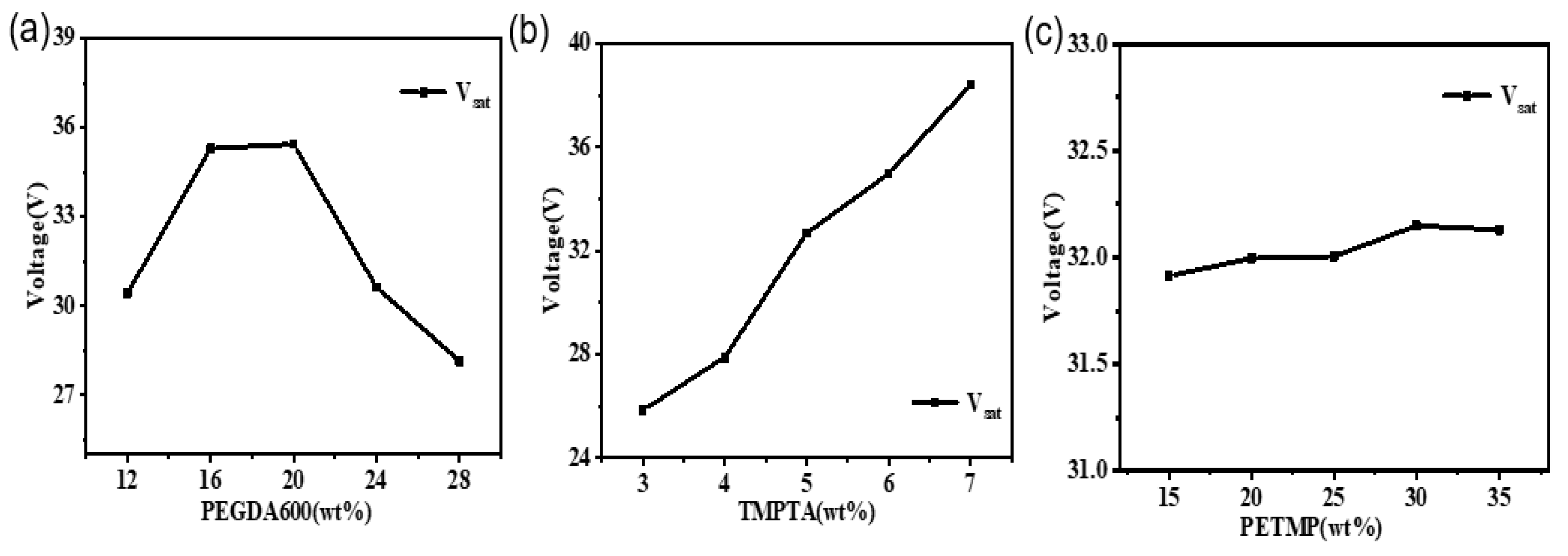

2.2. High-Throughput Detection of PDLC Sample Voltage

2.3. Saturation Voltage Analysis of Samples

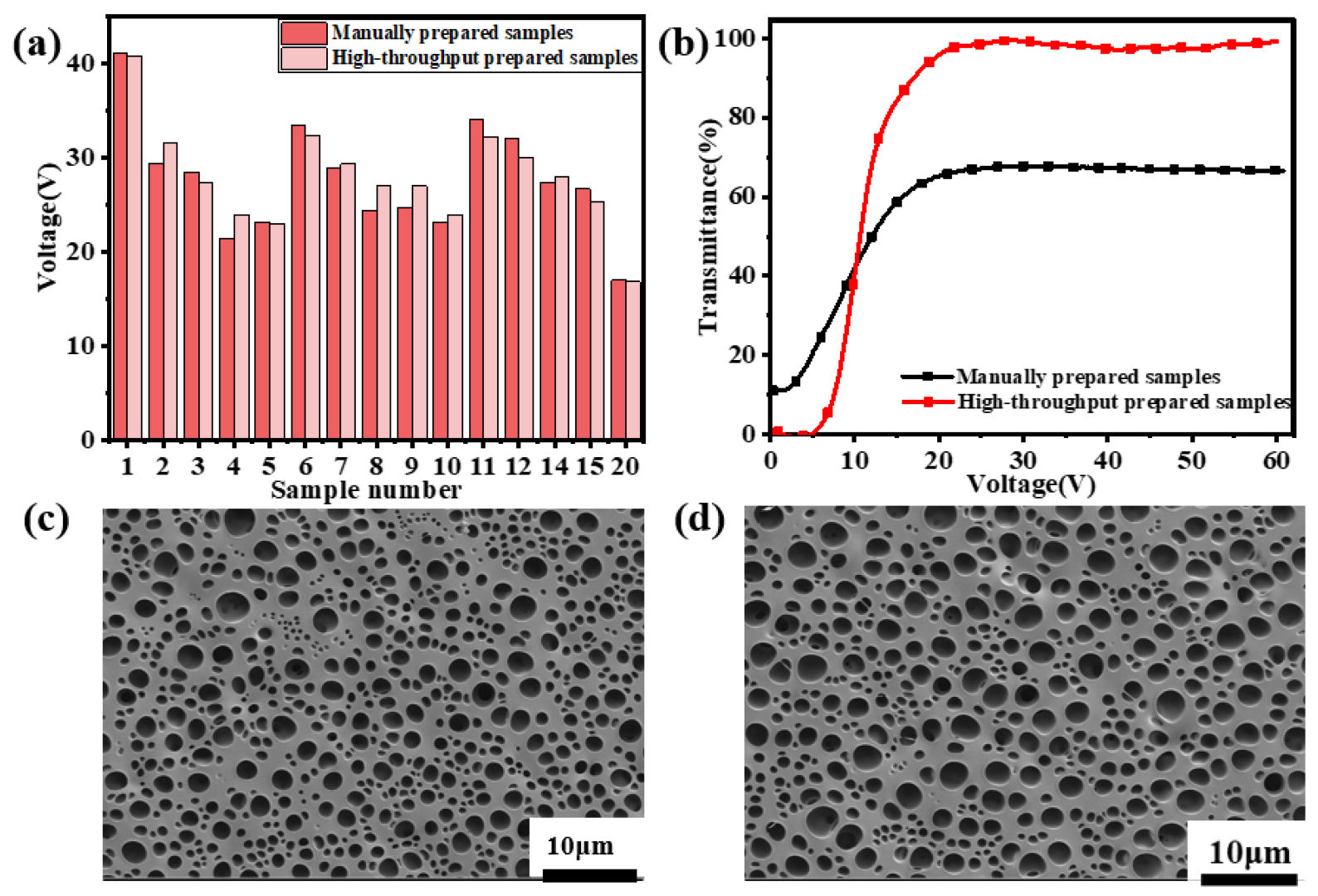

2.4. Comparative Experiments of High-Throughput Preparation versus Manual Preparation

3. Materials and Equipment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Coates, D. Polymer-dispersed liquid crystals. J. Mater. Chem. 1995, 5, 2063–2072. [Google Scholar] [CrossRef]

- Doane, J.W.; Golemme, A.; West, J.L.; Whitehead, J.B.; Wu, B.G. Polymer Dispersed Liquid Crystals for Display Application. Mol. Cryst. Liq. Cryst. 1988, 165, 511–532. [Google Scholar] [CrossRef]

- Shen, W.; Wang, L.; Zhong, T.; Chen, G.; Li, C.; Chen, M.; Zhang, C.; Zhang, L.; Li, K.; Yang, Z. Electrically switchable light transmittance of epoxy-mercaptan polymer/nematic liquid crystal composites with controllable microstructures. Polymer 2019, 160, 53–64. [Google Scholar] [CrossRef]

- Hu, G.; Chen, H.; Liu, Z.; Zhang, S.; Zhou, Y.; Zhu, B.; Gu, H. Tailoring structure and properties of polymer-dispersed liquid crystal by quenching process. Liq. Cryst. 2020, 46, 1–9. [Google Scholar] [CrossRef]

- Cupelli, D.; Nicoletta, F.P.; Manfredi, S. Self-adjusting smart windows based on polymer-dispersed liquid crystals. Sol. Energy Mater. Sol. Cells 2009, 93, 2008–2012. [Google Scholar] [CrossRef]

- Song, M.; Seo, J.; Kim, H.; Kim, Y. Ultrasensitive multi-functional flexible sensors based on organic field-effect transistors with polymer-dispersed liquid crystal sensing layers. Sci. Rep. 2017, 7, 2630. [Google Scholar] [CrossRef]

- Zhang, W.-W.; Li, P.-F.; Shen, J.-R. Electro-optical characteristics of polymer-dispersed liquid crystal gratings doped with multi-walled carbon nanotubes. Chin. J. Liq. Cryst. Displays 2020, 35, 1095–1102. [Google Scholar] [CrossRef]

- Ailincai, D.; Pamfil, D.; Marin, L. Multiple bio-responsive polymer dispersed liquid crystal composites for sensing applications. J. Mol. Liq. 2018, 272, 572–582. [Google Scholar] [CrossRef]

- Zhong, T.; Mandle, R.J.; Goodby, J.W. Thiol-ene reaction based polymer dispersed liquid crystal composite films with low driving voltage and high contrast ratio. Liq Cryst. 2019, 47, 2171–2183. [Google Scholar] [CrossRef]

- Zhou, D.; Wang, Y.; Zhu, J. Mechanically strong and highly efficient healable organic/inorganic hybrid dynamic network. Polymer 2019, 167, 202–208. [Google Scholar] [CrossRef]

- Saeed, M.H.; Gao, Y.Z.; Zhou, L.; Zhong, T.J.; Zhang, S.F.; Li, C.Y.; Zhang, L.Y.; Yang, H. Effects of multifunctional acrylates and thiols on the morphology and electro-optical properties of polymer-dispersed liquid crystal films. Liq Cryst. 2021, 48, 1457–1466. [Google Scholar] [CrossRef]

- Ren, Y.-X.; Hu, W.; Sun, C.; Huang, J.-Y.; Hu, J.-M.; Shen, J.-Y.; He, W.-L.; Zhang, L.-Y.; Yuan, X.-T.; Yu, M.-N.; et al. Study on electro-optical and adhesion properties of polymer dispersed liquid crystal films from thiol-ene click reaction. Liq Cryst. 2021, 48, 2188–2199. [Google Scholar] [CrossRef]

- Xiang, X.-D.; Sun, X.; Briceño, G.; Lou, Y.; Wang, K.-A.; Chang, H.; Wallace-Freedman, W.G.; Chen, S.-W.; Schultz, P.G. A Combinatorial Approach to Materials Discovery. Science 1995, 268, 1738–1740. [Google Scholar] [CrossRef] [PubMed]

- Hansen, A.; Zhang, R.; Bradley, M. Fabrication of Arrays of Polymer Gradients Using Inkjet Printing. Macromol. Rapid Commun. 2012, 33, 1114–1118. [Google Scholar] [CrossRef]

- Batchelor, T.A.A.; Loffler, T.; Xiao, B.; Krysiak, O.A.; Strotkotter, V.; Pedersen, J.K.; Clausen, C.M.; Savan, A.; Li, Y.J.; Schuhmann, W.; et al. Complex-Solid-Solution Electrocatalyst Discovery by Computational Prediction and High-Throughput Experimentation. Angew. Chem.-Int. Edit. 2021, 60, 6932–6937. [Google Scholar] [CrossRef]

- Breidenbach, J.; Lemke, C.; Pillaiyar, T.; Schakel, L.; Al Hamwi, G.; Diett, M.; Gedschold, R.; Geiger, N.; Lopez, V.; Mirza, S.; et al. Targeting the Main Protease of SARS-CoV-2: From the Establishment of High-throughput Screening to the Design of Tailored Inhibitors. Angew. Chem.-Int. Edit. 2021, 60, 10423–10429. [Google Scholar] [CrossRef]

- Xia, R.-X.; Brabec, C.-J.; Yip, H.-L.; Cao, Y. High-Throughput Optical Screening for Efficient Semitransparent Organic Solar Cells. Joule 2019, 3, 2241–2254. [Google Scholar] [CrossRef]

- Li, W.; Cui, J.; Li, J.; Guo, J.; Huang, T.; Zhang, J.; Hu, H.; Liu, X. Analysis of the Fungi Community Variation during Rice Storage through High Throughput Sequencing. Processes 2022, 10, 754. [Google Scholar] [CrossRef]

- Welch, C.J. High-throughput analysis enables high-throughput experimentation in pharmaceutical process research. React Chem Eng. 2019, 4, 1895–1911. [Google Scholar] [CrossRef]

- Qi, N.; Wismer, M.K.; Conway, D.V.; Krska, S.W.; Dreher, S.D.; Lin, S.S. Development of a high intensity parallel photoreactor for high-throughput screening. React Chem. Eng. 2022, 7, 354–360. [Google Scholar] [CrossRef]

- He, W.-L.; Cui, Y.-F.; Luo, S.-G.; Hu, W.-T.; Wang, K.-N.; Yang, Z.; Cao, H.; Wang, D. High-Throughput Preparation and Machine Learning Screening of a Blue-Phase Liquid Crystal Based on Inkjet Printing. Molecules 2022, 27, 6938. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Yao, D.; Luo, S.; Xiong, R.; Yuan, X. Broadband Reflective Liquid Crystal Films Prepared by Rapid Inkjet Printing and Superposition Polymerization. Crystals 2022, 12, 473. [Google Scholar] [CrossRef]

- Chidichimo, G.; Arabia, G.; Golemme, A. Electrooptic properties of polymer dispersed liquid-crystals. Liq. Cryst. 1989, 5, 1443–1452. [Google Scholar] [CrossRef]

- Kato, K.; Tanaka, K.; Tsuru, S. Multipage dispersed display using stacked polymer-dispersed liquid crystal. Jpn. J. Appl. Phys. Part 1 1993, 32, 4594–4604. [Google Scholar] [CrossRef]

- White, T.J.; Natarajan, L.V.; Tondiglia, V.P.; Bunning, T.J.; Guymon, C.A. Polymerization kinetics and monomer functionality effects in thiol-ene polymer dispersed liquid crystals. Macromolecules 2007, 40, 1112–1120. [Google Scholar] [CrossRef]

- Kashima, M.; Cao, H.; Liu, H.-J.; Meng, Q.-Y.; Wang, D.; Li, F.-S.; Yang, H. Effects of the chain length of crosslinking agents on the electro-optical properties of polymer-dispersed liquid crystal films. Liq. Cryst. 2010, 37, 339–343. [Google Scholar] [CrossRef]

- Kashima, M.; Cao, H.; Meng, Q.-Y.; Liu, H.-J.; Wang, D.; Li, F.-S.; Yang, H. The Influence of Crosslinking Agents on the Morphology and Electro-Optical Performances of PDLC Films. J. Appl. Polym. Sci. 2010, 117, 3434–3440. [Google Scholar] [CrossRef]

- Sun, Y.-J.; Zhang, C.-H.; Cao, H.; Xiao, J.-M.; Ding, H.-J.; Li, F.-S.; Yu, H.-F.; Yang, Z.; Yang, H. Effects of functionality of thiol monomer on electro-optical properties of polymer-dispersed liquid crystal films. Liq. Cryst. 2017, 44, 1086–1092. [Google Scholar] [CrossRef]

| Factor Value | PEGDA-600 (wt%) | PETMP (wt%) | TMPTA (wt%) | |

|---|---|---|---|---|

| Level Value | ||||

| 1 | 28 | 35 | 7 | |

| 2 | 24 | 30 | 6 | |

| 3 | 20 | 25 | 5 | |

| 4 | 16 | 20 | 4 | |

| 5 | 12 | 15 | 3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, R.-J.; Ren, Y.-X.; Cui, Y.-F.; Cai, S.-F.; He, W.-L.; Yuan, X.-T. High-Throughput Preparation and High-Throughput Detection of Polymer-Dispersed Liquid Crystals Based on Ink-Jet Printing and Grayscale Value Analysis. Molecules 2023, 28, 2253. https://doi.org/10.3390/molecules28052253

Xiong R-J, Ren Y-X, Cui Y-F, Cai S-F, He W-L, Yuan X-T. High-Throughput Preparation and High-Throughput Detection of Polymer-Dispersed Liquid Crystals Based on Ink-Jet Printing and Grayscale Value Analysis. Molecules. 2023; 28(5):2253. https://doi.org/10.3390/molecules28052253

Chicago/Turabian StyleXiong, Rui-Juan, Yun-Xiao Ren, Yong-Feng Cui, Shu-Feng Cai, Wan-Li He, and Xiao-Tao Yuan. 2023. "High-Throughput Preparation and High-Throughput Detection of Polymer-Dispersed Liquid Crystals Based on Ink-Jet Printing and Grayscale Value Analysis" Molecules 28, no. 5: 2253. https://doi.org/10.3390/molecules28052253

APA StyleXiong, R.-J., Ren, Y.-X., Cui, Y.-F., Cai, S.-F., He, W.-L., & Yuan, X.-T. (2023). High-Throughput Preparation and High-Throughput Detection of Polymer-Dispersed Liquid Crystals Based on Ink-Jet Printing and Grayscale Value Analysis. Molecules, 28(5), 2253. https://doi.org/10.3390/molecules28052253