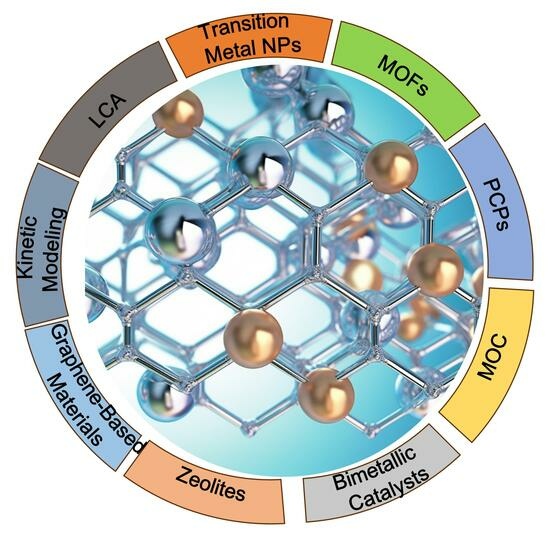

Transition Metal Catalysts for Atmospheric Heavy Metal Removal: A Review of Current Innovations and Advances

Abstract

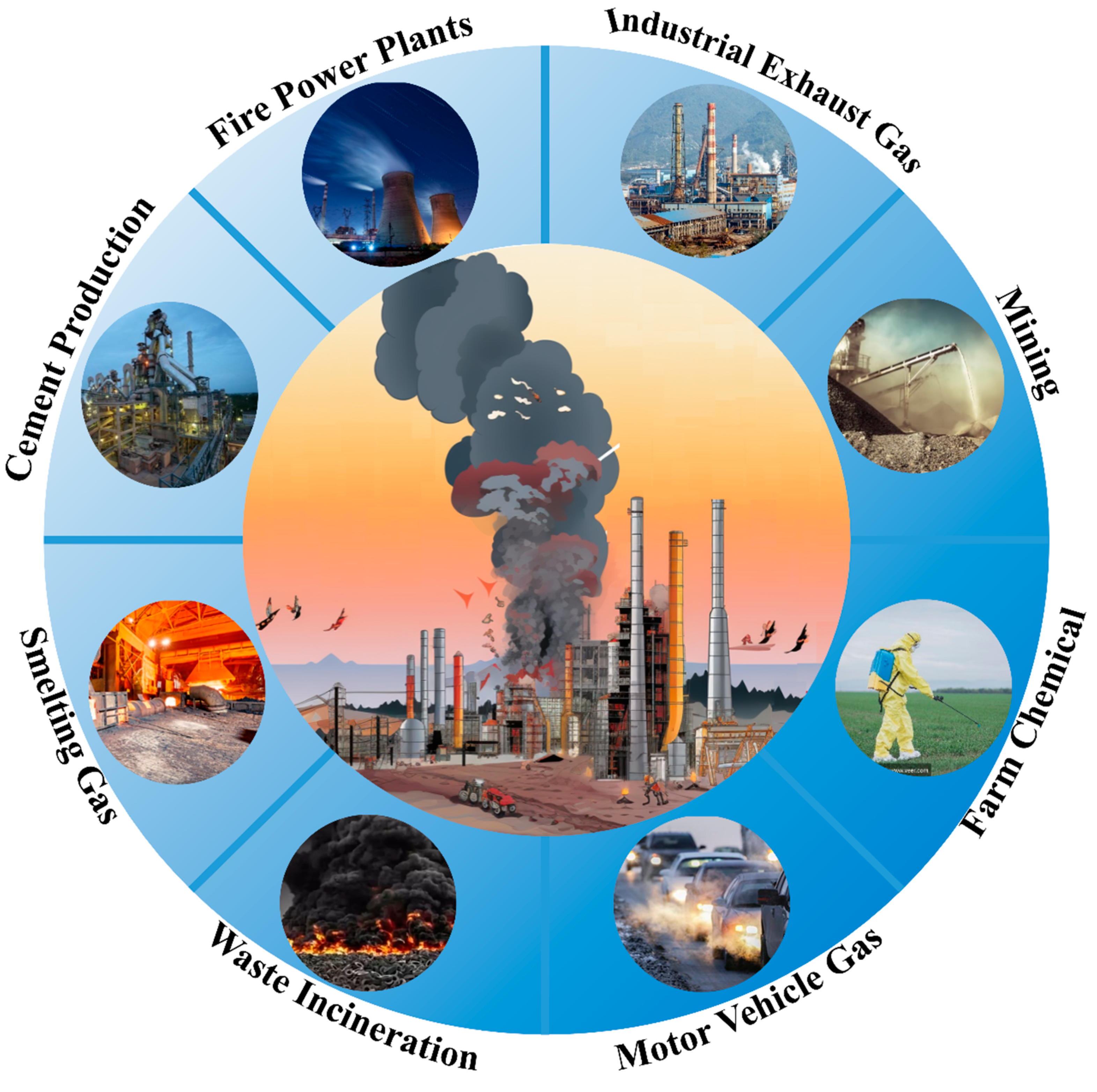

:1. Introduction

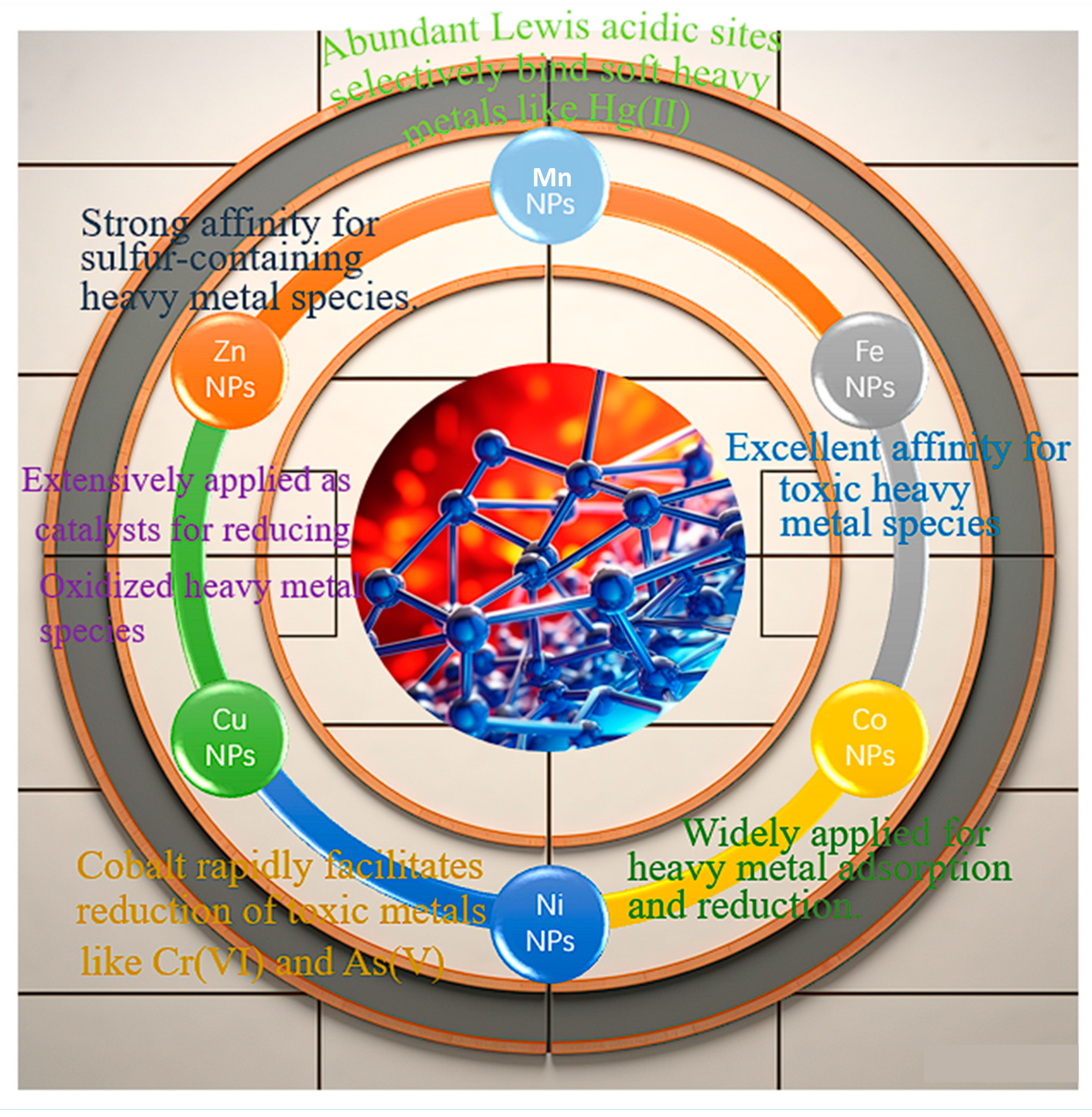

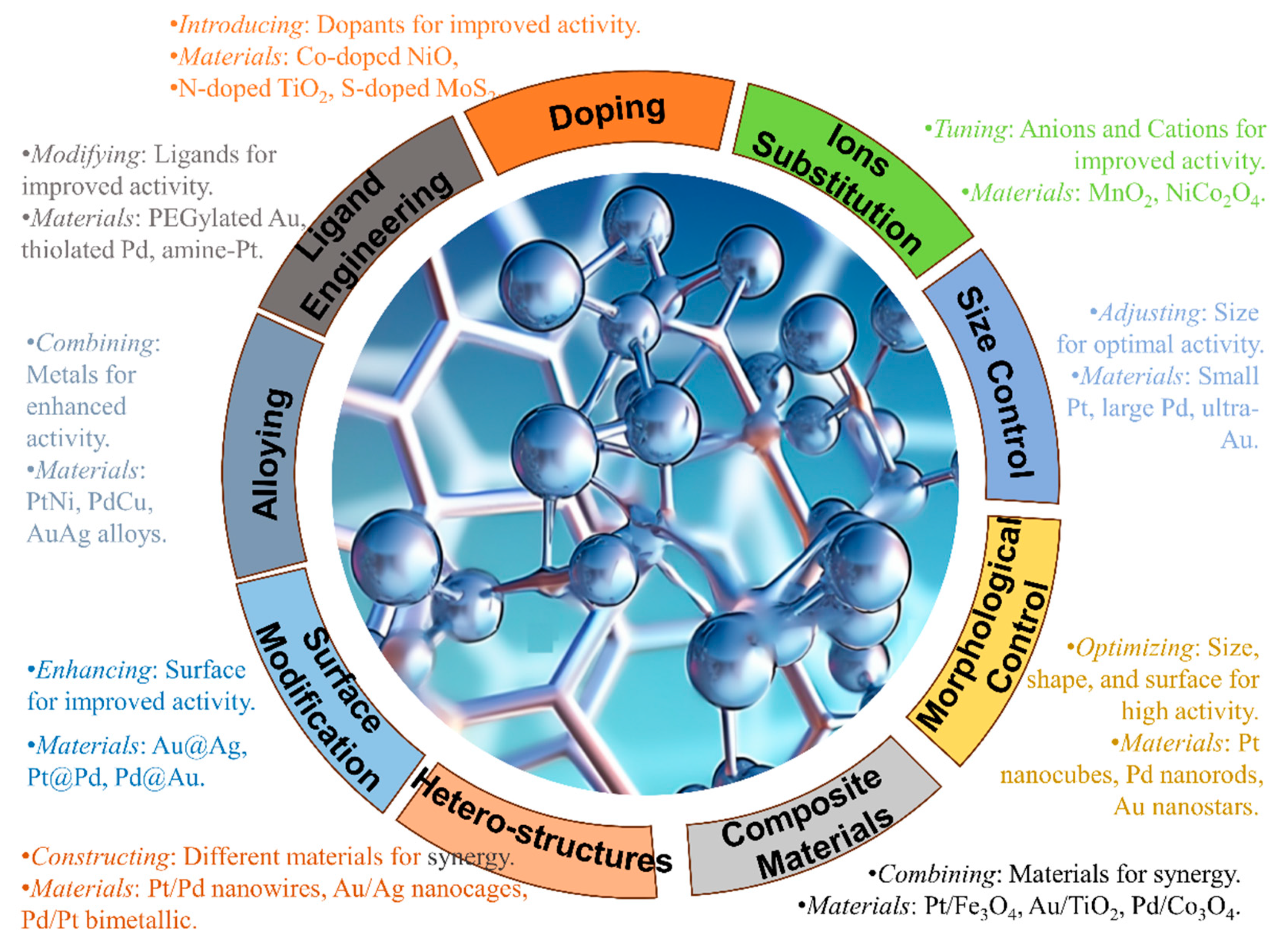

2. Transition Metal Nanoparticle Catalysts

2.1. Supported Manganese Nanoparticles

2.2. Supported Iron Nanoparticles

2.3. Supported Cobalt Nanoparticles

2.4. Supported Nickel Nanoparticles

2.5. Supported Copper Nanoparticles

2.6. Supported Zinc Nanoparticles

| Strategy | Description | Materials | Performance Metrics | Reference |

|---|---|---|---|---|

| Morphological control | Controlling the size, shape, and surface area of nanoparticles to optimize catalytic activity | Pt nanocubes, Pd nanorods, Au nanostars | High catalytic activity, high selectivity | [26] |

| Anion substitution | Replacing anions in the nanoparticle lattice to tune the electronic structure and improve catalytic activity | MnO2, NiCO2O4 | High catalytic activity, high stability | [27] |

| Cation substitution | Replacing cations in the nanoparticle lattice to tune the electronic structure and improve catalytic activity | CuFe2O4, CoFe2O4, MnFe2O4 | High catalytic activity, high stability | [28] |

| Composite materials | Combining two or more materials to create synergistic effects that enhance catalytic activity and selectivity | Pt/Fe3O4, Au/TiO2, Pd/CO3O4 | High catalytic activity, high selectivity | [29] |

| Heterostructures | Constructing heterostructures by combining two or more materials with different properties to create synergistic effects that enhance catalytic activity and selectivity | Pt/Pd nanowires, Au/Ag nanocages, Pd/Pt bimetallic nanoparticles | High catalytic activity, high selectivity | [30] |

| Surface modification | Modifying the surface of nanoparticles to improve catalytic activity and selectivity | Au@Ag core–shell nanoparticles, Pt@Pd core-shell nanoparticles, Pd@Au core-shell nanoparticles | High catalytic activity, high selectivity | [27] |

| Alloying | Combining two or more metals to create alloys that exhibit enhanced catalytic activity and selectivity | PtNi alloy nanoparticles, PdCu alloy nanoparticles, AuAg alloy nanoparticles | High catalytic activity, high selectivity | [26,30] |

| Ligand engineering | Modifying the ligands on the surface of nanoparticles to improve catalytic activity and selectivity | PEGylated Au nanoparticles, thiolated Pd nanoparticles, amine-functionalized Pt nanoparticles | High catalytic activity, high selectivity | [26] |

| Size control | Controlling the size of nanoparticles to optimize catalytic activity and selectivity | Small Pt nanoparticles, large Pd nanoparticles, ultrasmall Au nanoparticles | High catalytic activity, high selectivity | [28] |

| Doping | Introducing dopants into the nanoparticle lattice to tune the electronic structure and improve catalytic activity | Co-doped NiO, N-doped TiO2, S-doped MoS2 | High catalytic activity, high stability | [30] |

3. Metal–Organic Frameworks (MOFs)

3.1. Adsorptive Heavy Metal Removal

3.2. Photocatalytic Oxidation

3.3. Enhancing Selectivity

4. Porous Coordination Polymers (PCPs)

4.1. Pore Size Effects

4.2. Active Site Modulation

4.3. Redox Catalysis

5. Metal Oxide Catalysts (MOC)

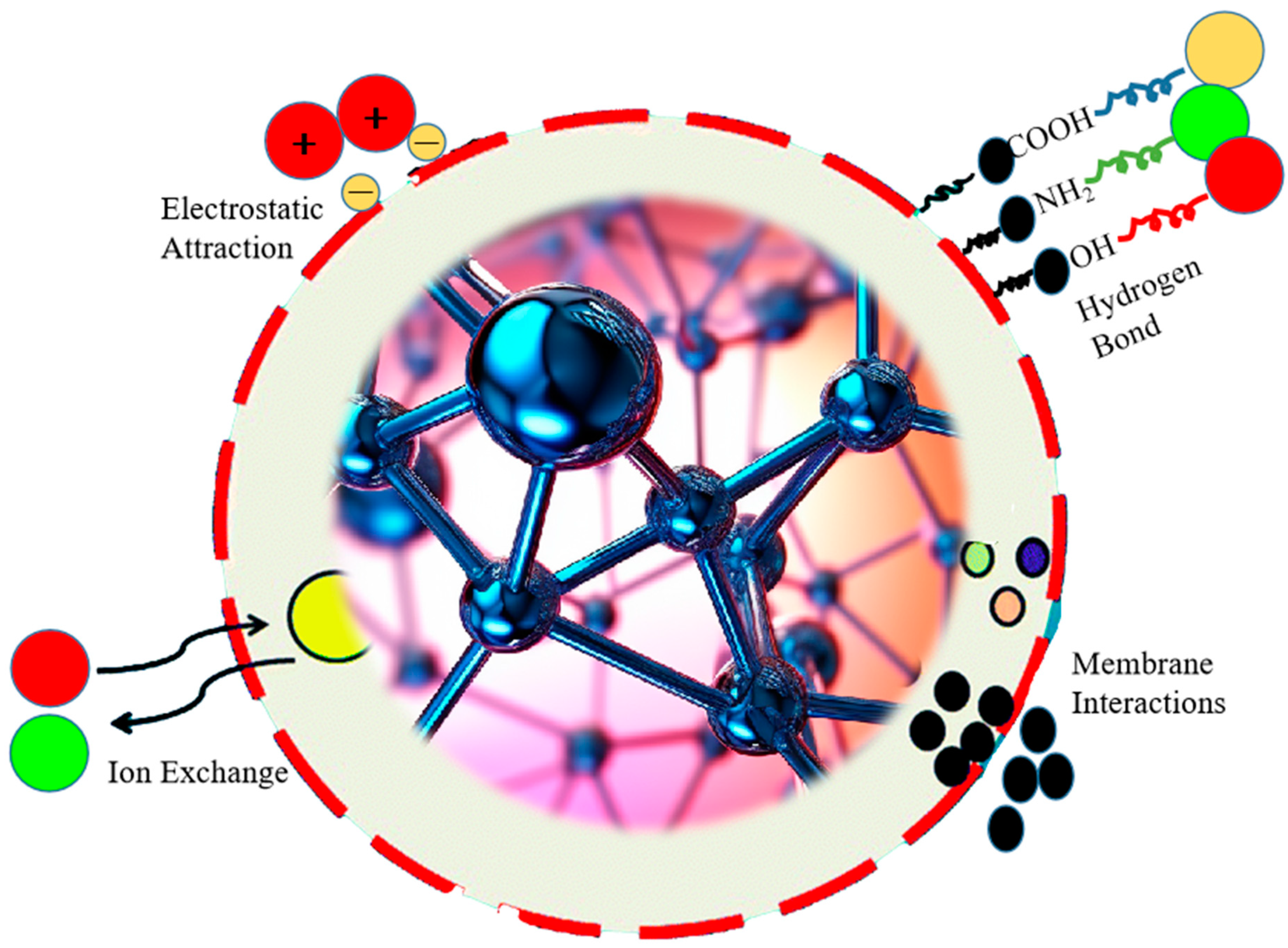

5.1. Adsorption Mechanisms

5.2. Photocatalytic Oxidation

5.3. Redox Catalysis

6. Bimetallic Catalysts

6.1. Enhanced Adsorption Capacity

6.2. Bifunctional Redox Sites

6.3. Tunable Electronic Properties

7. Zeolites

7.1. Porous Structure Effects

7.2. Ion Exchange Properties

7.3. Redox Functionalization

8. Graphene-Based Materials

8.1. Support for Nanocatalysts

8.2. Enhanced Electron Transfer

8.3. Functionalization

9. Kinetic Modeling Researches

10. Life Cycle Assessment

11. Challenges and Future Outlook

11.1. Environmental and Societal Challenges

11.2. Technological Challenges

11.3. Future Outlook

12. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| C | Concentration of contaminant; mg × L−1 |

| C0 | Initial concentration of contaminant; mg × L−1 |

| k | Reaction rate constant; varies |

| kr | Intrinsic reaction rate constant; s−1 |

| K | Adsorption equilibrium constant; L × mg−1 |

| t | Irradiation time; min |

| r | Reaction rate; mg × L−1∙min |

| θ | Surface coverage; dimensionless |

| q | Adsorbed amount; mg × g−1 |

| Qt | Adsorbed amount at time t; mg × g−1 |

| Qe | Adsorbed amount at equilibrium; mg × g−1 |

| N | Number of viable microbes at time t |

| N0: | Initial number of viable microbes |

| F | Photon flux; mW × cm−2 |

| D | Diffusion coefficient; m2 × s−1 |

| dp | Particle diameter; m |

References

- Tchounwou, P.B.; Yedjou, C.G.; Patlolla, A.K.; Sutton, D.J. Heavy metal toxicity and the environment. Exp. Suppl. 2012, 101, 133–164. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Hu, Y.; Cheng, H. Municipal solid waste (MSW) incineration fly ash as an important source of heavy metal pollution in China. Environ. Pollut. 2019, 252, 461–475. [Google Scholar] [CrossRef]

- Fu, B.; Liu, G.; Mian, M.M.; Sun, M.; Wu, D. Characteristics and speciation of heavy metals in fly ash and FGD gypsum from Chinese coal-fired power plants. Fuel 2019, 251, 593–602. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, B.; Zhang, S. A review of glass ceramic foams prepared from solid wastes: Processing, heavy-metal solidification and volatilization, applications. Sci. Total Environ. 2021, 781, 146727. [Google Scholar] [CrossRef]

- Shahid, M.; Dumat, C.; Khalid, S.; Schreck, E.; Xiong, T.; Niazi, N.K. Foliar heavy metal uptake, toxicity and detoxification in plants: A comparison of foliar and root metal uptake. J. Hazard. Mater. 2017, 325, 36–58. [Google Scholar] [CrossRef] [PubMed]

- Goswami, R.; Neog, N. Heavy Metal Pollution in the Environment: Impact on Air Quality and Human Health Implications. In Heavy Metal Toxicity: Environmental Concerns, Remediation and Opportunities; Singh, R.P., Singh, P., Srivastava, A., Eds.; Springer Nature Singapore: Singapore, 2023; pp. 75–103. [Google Scholar]

- Singh, A.; Prasad, S.M. Remediation of heavy metal contaminated ecosystem: An overview on technology advancement. Int. J. Environ. Sci. Technol. 2015, 12, 353–366. [Google Scholar] [CrossRef]

- Fechete, I.; Wang, Y.; Védrine, J.C. The past, present and future of heterogeneous catalysis. Catal. Today 2012, 189, 2–27. [Google Scholar] [CrossRef]

- Burakov, A.E.; Galunin, E.V.; Burakova, I.V.; Kucherova, A.E.; Agarwal, S.; Tkachev, A.G.; Gupta, V.K. Adsorption of heavy metals on conventional and nanostructured materials for wastewater treatment purposes: A review. Ecotoxicol. Environ. Saf. 2018, 148, 702–712. [Google Scholar] [CrossRef]

- Cai, G.; Yan, P.; Zhang, L.; Zhou, H.-C.; Jiang, H.-L. Metal–organic framework-based hierarchically porous materials: Synthesis and applications. Chem. Rev. 2021, 121, 12278–12326. [Google Scholar] [CrossRef]

- Cramer, C.J.; Truhlar, D.G. Density functional theory for transition metals and transition metal chemistry. Phys. Chem. Chem. Phys. 2009, 11, 10757–10816. [Google Scholar] [CrossRef]

- Lebechi, A.K.; Ipadeola, A.K.; Eid, K.; Abdullah, A.M.; Ozoemena, K.I. Porous spinel-type transition metal oxide nanostructures as emergent electrocatalysts for oxygen reduction reactions. Nanoscale 2022, 14, 10717–10737. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.; Sun, L.D.; Yan, C.H. Recent progress in well-controlled synthesis of ceria-based nanocatalysts towards enhanced catalytic performance. Adv. Energy Mater. 2016, 6, 1600501. [Google Scholar] [CrossRef]

- Park, J.C.; Song, H. Metal@ silica yolk-shell nanostructures as versatile bifunctional nanocatalysts. Nano Res. 2011, 4, 33–49. [Google Scholar] [CrossRef]

- Islam, F.; Shohag, S.; Uddin, M.J.; Islam, M.R.; Nafady, M.H.; Akter, A.; Mitra, S.; Roy, A.; Emran, T.B.; Cavalu, S. Exploring the Journey of Zinc Oxide Nanoparticles (ZnO-NPs) toward Biomedical Applications. Materials 2022, 15, 2160. [Google Scholar] [CrossRef] [PubMed]

- Azimi, A.; Azari, A.; Rezakazemi, M.; Ansarpour, M. Removal of heavy metals from industrial wastewaters: A review. ChemBioEng Rev. 2017, 4, 37–59. [Google Scholar] [CrossRef]

- Li, P.; Zeng, H.C. Hierarchical nanocomposite by the integration of reduced graphene oxide and amorphous carbon with ultrafine MgO nanocrystallites for enhanced CO2 capture. Environ. Sci. Technol. 2017, 51, 12998–13007. [Google Scholar] [CrossRef]

- Jomova, K.; Valko, M. Advances in metal-induced oxidative stress and human disease. Toxicology 2011, 283, 65–87. [Google Scholar] [CrossRef]

- Su, C. Environmental implications and applications of engineered nanoscale magnetite and its hybrid nanocomposites: A review of recent literature. J. Hazard. Mater. 2017, 322, 48–84. [Google Scholar] [CrossRef]

- Veerakumar, P.; Chen, S.-M.; Madhu, R.; Veeramani, V.; Hung, C.-T.; Liu, S.-B. Nickel nanoparticle-decorated porous carbons for highly active catalytic reduction of organic dyes and sensitive detection of Hg (II) ions. ACS Appl. Mater. Interfaces 2015, 7, 24810–24821. [Google Scholar] [CrossRef]

- Gautam, S.; Agrawal, H.; Thakur, M.; Akbari, A.; Sharda, H.; Kaur, R.; Amini, M. Metal oxides and metal organic frameworks for the photocatalytic degradation: A review. J. Environ. Chem. Eng. 2020, 8, 103726. [Google Scholar] [CrossRef]

- Darwish, M.; Mohammadi, A. Functionalized nanomaterial for environmental techniques. In Nanotechnology in Environmental Science; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2018; pp. 315–350. [Google Scholar] [CrossRef]

- Mensah, M.B.; Lewis, D.J.; Boadi, N.O.; Awudza, J.A. Heavy metal pollution and the role of inorganic nanomaterials in environmental remediation. R. Soc. Open Sci. 2021, 8, 201485. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Wang, R.; Jia, T.; Wu, J.; Xu, C.; Sun, Y.; Wang, X.; Wu, W.; Qi, Y. Spherical-shaped CuS modified carbon nitride nanosheet for efficient capture of elemental mercury from flue gas at low temperature. J. Hazard. Mater. 2021, 415, 125692. [Google Scholar] [CrossRef] [PubMed]

- Dupont, J.; Scholten, J.D. On the structural and surface properties of transition-metal nanoparticles in ionic liquids. Chem. Soc. Rev. 2010, 39, 1780–1804. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Li, H.; Yang, J.; Lei, Y.; Wang, C.; Wang, J.; Tang, Y.; Mao, Z. Recent advances in Pt-based electrocatalysts for PEMFCs. RSC Adv. 2021, 11, 13316–13328. [Google Scholar] [CrossRef]

- Franco, F.; Rettenmaier, C.; Jeon, H.S.; Roldan Cuenya, B. Transition metal-based catalysts for the electrochemical CO2 reduction: From atoms and molecules to nanostructured materials. Chem. Soc. Rev. 2020, 49, 6884–6946. [Google Scholar] [CrossRef]

- Ju, M.; Wang, X.; Long, X.; Yang, S. Recent advances in transition metal based compound catalysts for water splitting from the perspective of crystal engineering. CrystEngComm 2020, 22, 1531–1540. [Google Scholar] [CrossRef]

- Wang, R.; He, C.; Chen, W.; Fu, L.; Zhao, C.; Huo, J.; Sun, C. Design strategies of two-dimensional metal–organic frameworks toward efficient electrocatalysts for N2 reduction: Cooperativity of transition metals and organic linkers. Nanoscale 2021, 13, 19247–19254. [Google Scholar] [CrossRef]

- Zeng, C.; Dai, L.; Jin, Y.; Liu, J.; Zhang, Q.; Wang, H. Design strategies toward transition metal selenide-based catalysts for electrochemical water splitting. Sustain. Energy Fuels 2021, 5, 1347–1365. [Google Scholar] [CrossRef]

- Farha, O.K.; Eryazici, I.; Jeong, N.C.; Hauser, B.G.; Wilmer, C.E.; Sarjeant, A.A.; Snurr, R.Q.; Nguyen, S.T.; Yazaydın, A.Ö.; Hupp, J.T. Metal–organic framework materials with ultrahigh surface areas: Is the sky the limit? J. Am. Chem. Soc. 2012, 134, 15016–15021. [Google Scholar] [CrossRef]

- Huang, L.; Cao, H.; Ma, J.; Wang, X. Efficient removal of Pb(II) by UiO-66-NH2: A combined experimental and spectroscopic studies. Environ. Nanotechnol. Monit. Manag. 2022, 18, 100741. [Google Scholar] [CrossRef]

- Vishnyakov, A.; Ravikovitch, P.I.; Neimark, A.V.; Bülow, M.; Wang, Q.M. Nanopore Structure and Sorption Properties of Cu−BTC Metal−Organic Framework. Nano Lett. 2003, 3, 713–718. [Google Scholar] [CrossRef]

- Li, X.; Gao, X.; Ai, L.; Jiang, J. Mechanistic insight into the interaction and adsorption of Cr (VI) with zeolitic imidazolate framework-67 microcrystals from aqueous solution. Chem. Eng. J. 2015, 274, 238–246. [Google Scholar] [CrossRef]

- Cui, Y.; Xu, H.; Yue, Y.; Guo, Z.; Yu, J.; Chen, Z.; Gao, J.; Yang, Y.; Qian, G.; Chen, B. A luminescent mixed-lanthanide metal-organic framework thermometer. J. Am. Chem. Soc. 2012, 134, 3979–3982. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, H.L. Metal–organic frameworks for photocatalytic water splitting. Sol. RRL 2021, 5, 2100198. [Google Scholar] [CrossRef]

- Gatou, M.-A.; Vagena, I.-A.; Lagopati, N.; Pippa, N.; Gazouli, M.; Pavlatou, E.A. Functional MOF-Based Materials for Environmental and Biomedical Applications: A Critical Review. Nanomaterials 2023, 13, 2224. [Google Scholar] [CrossRef] [PubMed]

- Furukawa, H.; Cordova, K.E.; O’Keeffe, M.; Yaghi, O.M. The chemistry and applications of metal-organic frameworks. Science 2013, 341, 1230444. [Google Scholar] [CrossRef]

- Lan, G.; Ni, K.; Lin, W. Nanoscale metal–organic frameworks for phototherapy of cancer. Coord. Chem. Rev. 2019, 379, 65–81. [Google Scholar] [CrossRef]

- Mondloch, J.E.; Katz, M.J.; Planas, N.; Semrouni, D.; Gagliardi, L.; Hupp, J.T.; Farha, O.K. Are Zr(6)-based MOFs water stable? Linker hydrolysis vs. capillary-force-driven channel collapse. Chem. Commun. Camb. 2014, 50, 8944–8946. [Google Scholar] [CrossRef]

- Wang, C.; Xie, Z.; deKrafft, K.E.; Lin, W. Doping metal-organic frameworks for water oxidation, carbon dioxide reduction, and organic photocatalysis. J. Am. Chem. Soc. 2011, 133, 13445–13454. [Google Scholar] [CrossRef]

- Huang, L.; Shen, R.; Liu, R.; Shuai, Q. Thiol-functionalized magnetic covalent organic frameworks by a cutting strategy for efficient removal of Hg2+ from water. J. Hazard. Mater. 2020, 392, 122320. [Google Scholar] [CrossRef]

- Rodríguez, N.A.; Savateev, A.; Grela, M.A.; Dontsova, D. Facile Synthesis of Potassium Poly (heptazine imide) (PHIK)/Ti-Based Metal-Organic Framework (MIL-125-NH2) Composites for Photocatalytic Applications. ACS Appl. Mater. Interfaces 2017, 9, 22941–22949. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wang, X.; Zhao, G.; Chen, C.; Chai, Z.; Alsaedi, A.; Hayat, T.; Wang, X. Metal–organic framework-based materials: Superior adsorbents for the capture of toxic and radioactive metal ions. Chem. Soc. Rev. 2018, 47, 2322–2356. [Google Scholar] [CrossRef] [PubMed]

- Gong, W.; Chen, Z.; Dong, J.; Liu, Y.; Cui, Y. Chiral metal–organic frameworks. Chem. Rev. 2022, 122, 9078–9144. [Google Scholar] [CrossRef] [PubMed]

- Firooz, S.K.; Armstrong, D.W. Metal-organic frameworks in separations: A review. Anal. Chim. Acta 2022, 1234, 340208. [Google Scholar] [CrossRef]

- Yuan, S. Developing a Synthetic Toolkit for Multi-Component Metal–Organic Frameworks. Ph.D. Thesis, Texas A & M University, College Station, TX, USA, 2018. [Google Scholar]

- Sohrabi, H.; Ghasemzadeh, S.; Shakib, S.; Majidi, M.R.; Razmjou, A.; Yoon, Y.; Khataee, A. Metal–Organic Framework-Based Biosensing Platforms for the Sensitive Determination of Trace Elements and Heavy Metals: A Comprehensive Review. Ind. Eng. Chem. Res. 2023, 62, 4611–4627. [Google Scholar] [CrossRef]

- Barthelet, K.; Merlier, C.; Serre, C.; Riou-Cavellec, M.; Riou, D.; Férey, G. Microporous hybrid compounds: Hydrothermal synthesis and characterization of two zinciomethylenediphosphonates with 3D structures, structure determination of their dehydrated forms. J. Mater. Chem. 2002, 12, 1132–1137. [Google Scholar] [CrossRef]

- Stadler, B.; Meng, H.H.Y.; Belazregue, S.; Webster, L.; Collauto, A.; Byrne, K.M.; Krämer, T.; Chadwick, F.M. PCP Pincer Complexes of Titanium in the +3 and +4 Oxidation States. Organometallics 2023, 42, 1278–1285. [Google Scholar] [CrossRef]

- Maity, R.; Birenheide, B.S.; Breher, F.; Sarkar, B. Cooperative Effects in Multimetallic Complexes Applied in Catalysis. ChemCatChem 2021, 13, 2337–2370. [Google Scholar] [CrossRef]

- Kongpatpanich, K.; Horike, S.; Sugimoto, M.; Fukushima, T.; Umeyama, D.; Tsutsumi, Y.; Kitagawa, S. Synthesis and Porous Properties of Chromium Azolate Porous Coordination Polymers. Inorg. Chem. 2014, 53, 9870–9875. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, X.; Xing, H. Recent advances in the capture and abatement of toxic gases and vapors by metal–organic frameworks. Mater. Chem. Front. 2021, 5, 5970–6013. [Google Scholar] [CrossRef]

- Boorboor Ajdari, F.; Kowsari, E.; Niknam Shahrak, M.; Ehsani, A.; Kiaei, Z.; Torkzaban, H.; Ershadi, M.; Kholghi Eshkalak, S.; Haddadi-Asl, V.; Chinnappan, A.; et al. A review on the field patents and recent developments over the application of metal organic frameworks (MOFs) in supercapacitors. Coord. Chem. Rev. 2020, 422, 213441. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, M.; Zhu, X.; Xu, H.; Ma, S.; Zhi, Y.; Xia, H.; Liu, X.; Pan, J.; Tang, J.-Y.; et al. 2020 Roadmap on two-dimensional nanomaterials for environmental catalysis. Chin. Chem. Lett. 2019, 30, 2065–2088. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Siddiqui, M.T.H.; Mubarak, N.M.; Baloch, H.A.; Abdullah, E.C.; Mazari, S.A.; Griffin, G.J.; Srinivasan, M.P.; Tanksale, A. Chapter 17—Iron Oxide Nanomaterials for the Removal of Heavy Metals and Dyes From Wastewater. In Nanoscale Materials in Water Purification; Thomas, S., Pasquini, D., Leu, S.-Y., Gopakumar, D.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 447–472. [Google Scholar]

- Zhang, K.; Gao, H.; Rui, Z.; Liu, P.; Li, Y.; Lin, Y. High-temperature stability of palladium membranes on porous metal supports with different intermediate layers. Ind. Eng. Chem. Res. 2009, 48, 1880–1886. [Google Scholar] [CrossRef]

- Liu, J.; Redfern, L.R.; Liao, Y.; Islamoglu, T.; Atilgan, A.; Farha, O.K.; Hupp, J.T. Metal–organic-framework-supported and-isolated ceria clusters with mixed oxidation states. ACS Appl. Mater. Interfaces 2019, 11, 47822–47829. [Google Scholar] [CrossRef] [PubMed]

- Fawzi Suleiman Khasawneh, O.; Palaniandy, P. Removal of organic pollutants from water by Fe2O3/TiO2 based photocatalytic degradation: A review. Environ. Technol. Innov. 2021, 21, 101230. [Google Scholar] [CrossRef]

- Güy, N.; Özacar, M. The influence of noble metals on photocatalytic activity of ZnO for Congo red degradation. Int. J. Hydrogen Energy 2016, 41, 20100–20112. [Google Scholar] [CrossRef]

- Kefeni, K.K.; Mamba, B.B.; Msagati, T.A.M. Application of spinel ferrite nanoparticles in water and wastewater treatment: A review. Sep. Purif. Technol. 2017, 188, 399–422. [Google Scholar] [CrossRef]

- Nwanya, A.C.; Razanamahandry, L.C.; Bashir, A.K.H.; Ikpo, C.O.; Nwanya, S.C.; Botha, S.; Ntwampe, S.K.O.; Ezema, F.I.; Iwuoha, E.I.; Maaza, M. Industrial textile effluent treatment and antibacterial effectiveness of Zea mays L. Dry husk mediated bio-synthesized copper oxide nanoparticles. J. Hazard. Mater. 2019, 375, 281–289. [Google Scholar] [CrossRef]

- Al-Hamdi, A.M.; Rinner, U.; Sillanpää, M. Tin dioxide as a photocatalyst for water treatment: A review. Process Saf. Environ. Prot. 2017, 107, 190–205. [Google Scholar] [CrossRef]

- Ruiz Puigdollers, A.; Schlexer, P.; Tosoni, S.; Pacchioni, G. Increasing oxide reducibility: The role of metal/oxide interfaces in the formation of oxygen vacancies. ACS Catal. 2017, 7, 6493–6513. [Google Scholar] [CrossRef]

- Hua, M.; Zhang, S.; Pan, B.; Zhang, W.; Lv, L.; Zhang, Q. Heavy metal removal from water/wastewater by nanosized metal oxides: A review. J. Hazard. Mater. 2012, 211–212, 317–331. [Google Scholar] [CrossRef]

- Shaheen, S.M.; Natasha; Mosa, A.; El-Naggar, A.; Faysal Hossain, M.; Abdelrahman, H.; Khan Niazi, N.; Shahid, M.; Zhang, T.; Fai Tsang, Y.; et al. Manganese oxide-modified biochar: Production, characterization and applications for the removal of pollutants from aqueous environments—A review. Bioresour. Technol. 2022, 346, 126581. [Google Scholar] [CrossRef] [PubMed]

- Baruah, S.; Rafique, R.F.; Dutta, J. Visible light photocatalysis by tailoring crystal defects in zinc oxide nanostructures. Nano 2008, 3, 399–407. [Google Scholar] [CrossRef]

- Zhang, H. Photochemical Redox Reactions of Mercury. In Recent Developments in Mercury Science; Atwood, D.A., Ed.; Springer: Berlin/Heidelberg, Germany, 2006; pp. 37–79. [Google Scholar]

- Worathanakul, P.; Kongkachuichay, P.; Noel, J.D.; Suriyawong, A.; Giammar, D.E.; Biswas, P. Evaluation of nanostructured sorbents in differential bed reactors for elemental mercury capture. Environ. Eng. Sci. 2008, 25, 1061–1070. [Google Scholar] [CrossRef]

- Gupta, K.; Joshi, P.; Gusain, R.; Khatri, O.P. Recent advances in adsorptive removal of heavy metal and metalloid ions by metal oxide-based nanomaterials. Coord. Chem. Rev. 2021, 445, 214100. [Google Scholar] [CrossRef]

- Pang, Y.; Kong, L.; Chen, D.; Yuvaraja, G. Rapid Cr(VI) reduction in aqueous solution using a novel microwave-based treatment with MoS2-MnFe2O4 composite. Appl. Surf. Sci. 2019, 471, 408–416. [Google Scholar] [CrossRef]

- Singh, A.K.; Xu, Q. Synergistic catalysis over bimetallic alloy nanoparticles. ChemCatChem 2013, 5, 652–676. [Google Scholar] [CrossRef]

- Singh, C.; Mehata, A.K.; Priya, V.; Malik, A.K.; Setia, A.; Suseela, M.N.L.; Vikas; Gokul, P.; Samridhi; Singh, S.K.; et al. Bimetallic Au-Ag Nanoparticles: Advanced Nanotechnology for Tackling Antimicrobial Resistance. Molecules 2022, 27, 7059. [Google Scholar] [CrossRef]

- Sohn, H.; Celik, G.; Gunduz, S.; Dean, S.L.; Painting, E.; Edmiston, P.L.; Ozkan, U.S. Hydrodechlorination of trichloroethylene over Pd supported on swellable organically-modified silica (SOMS). Appl. Catal. B Environ. 2017, 203, 641–653. [Google Scholar] [CrossRef]

- Xu, W.; Yang, T.; Liu, S.; Du, L.; Chen, Q.; Li, X.; Dong, J.; Zhang, Z.; Lu, S.; Gong, Y.; et al. Insights into the Synthesis, types and application of iron Nanoparticles: The overlooked significance of environmental effects. Environ. Int. 2022, 158, 106980. [Google Scholar] [CrossRef]

- Pandey, L.M. Surface engineering of nano-sorbents for the removal of heavy metals: Interfacial aspects. J. Environ. Chem. Eng. 2021, 9, 104586. [Google Scholar] [CrossRef]

- Xia, Z.; Min, J.; Zhou, S.; Ma, H.; Zhang, B.; Tang, X. Photocatalytic performance and antibacterial mechanism of Cu/Ag-molybdate powder material. Ceram. Int. 2021, 47, 12667–12679. [Google Scholar] [CrossRef]

- Wei, R.; Tang, N.; Jiang, L.; Yang, J.; Guo, J.; Yuan, X.; Liang, J.; Zhu, Y.; Wu, Z.; Li, H. Bimetallic nanoparticles meet polymeric carbon nitride: Fabrications, catalytic applications and perspectives. Coord. Chem. Rev. 2022, 462, 214500. [Google Scholar] [CrossRef]

- Liu, S.; Qiu, Y.; Liu, Y.; Zhang, W.; Dai, Z.; Srivastava, D.; Kumar, A.; Pan, Y.; Liu, J. Recent advances in bimetallic metal–organic frameworks (BMOFs): Synthesis, applications and challenges. New J. Chem. 2022, 46, 13818–13837. [Google Scholar] [CrossRef]

- Liu, H.; Mei, H.; Miao, N.; Pan, L.; Jin, Z.; Zhu, G.; Gao, J.; Wang, J.; Cheng, L. Synergistic photocatalytic NO removal of oxygen vacancies and metallic bismuth on Bi12TiO20 nanofibers under visible light irradiation. Chem. Eng. J. 2021, 414, 128748. [Google Scholar] [CrossRef]

- Hong, M.; Yu, L.; Wang, Y.; Zhang, J.; Chen, Z.; Dong, L.; Zan, Q.; Li, R. Heavy metal adsorption with zeolites: The role of hierarchical pore architecture. Chem. Eng. J. 2019, 359, 363–372. [Google Scholar] [CrossRef]

- Ezugwu, C.I.; Sonawane, J.M.; Rosal, R. Redox-active metal-organic frameworks for the removal of contaminants of emerging concern. Sep. Purif. Technol. 2022, 284, 120246. [Google Scholar] [CrossRef]

- Adam, M.R.; Othman, M.H.D.; Hubadillah, S.K.; Abd Aziz, M.H.; Jamalludin, M.R. Application of natural zeolite clinoptilolite for the removal of ammonia in wastewater. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Jiménez-Reyes, M.; Almazán-Sánchez, P.T.; Solache-Ríos, M. Radioactive waste treatments by using zeolites. A short review. J. Environ. Radioact. 2021, 233, 106610. [Google Scholar] [CrossRef]

- Hu, G.; Yang, J.; Duan, X.; Farnood, R.; Yang, C.; Yang, J.; Liu, W.; Liu, Q. Recent developments and challenges in zeolite-based composite photocatalysts for environmental applications. Chem. Eng. J. 2021, 417, 129209. [Google Scholar] [CrossRef]

- Zhou, T.; Wang, B.; Dai, Z.; Jiang, X.; Wang, Y. Organotemplate-free synthesis of MOR zeolite from coal fly ash through simultaneously effective extraction of Si and Al. Microporous Mesoporous Mater. 2021, 314, 110872. [Google Scholar] [CrossRef]

- Palčić, A.; Valtchev, V. Analysis and control of acid sites in zeolites. Appl. Catal. A Gen. 2020, 606, 117795. [Google Scholar] [CrossRef]

- Chen, Y.; Wei, S.; Dong, S.; Gu, J.; Jiang, W. A Mesoporous Faujasite Prepared by Space-Confined Method for Highly Effective Selectivity of Copper Ions. Water 2022, 14, 2040. [Google Scholar] [CrossRef]

- Kabtamu, D.M.; Wu, Y.-N.; Li, F. Hierarchically porous metal–organic frameworks: Synthesis strategies, structure(s), and emerging applications in decontamination. J. Hazard. Mater. 2020, 397, 122765. [Google Scholar] [CrossRef]

- Zhou, J.; Guo, R.-T.; Zhang, X.-F.; Liu, Y.-Z.; Duan, C.-P.; Wu, G.-L.; Pan, W.-G. Cerium Oxide-Based Catalysts for Low-Temperature Selective Catalytic Reduction of NOx with NH3: A Review. Energy Fuels 2021, 35, 2981–2998. [Google Scholar] [CrossRef]

- Li, Z.; Sun, D.; Chi, J.; Zhao, S. Efficient mercury removal at low temperature in flue gas with metal-organic frameworks modified by iodine. Colloids Surf. A Physicochem. Eng. Asp. 2021, 626, 126983. [Google Scholar] [CrossRef]

- Hassan, H.M.; Abdelsayed, V.; Abd El Rahman, S.K.; AbouZeid, K.M.; Terner, J.; El-Shall, M.S.; Al-Resayes, S.I.; El-Azhary, A.A. Microwave synthesis of graphene sheets supporting metal nanocrystals in aqueous and organic media. J. Mater. Chem. 2009, 19, 3832–3837. [Google Scholar] [CrossRef]

- Park, M.; Jeon, I.Y.; Ryu, J.; Baek, J.B.; Cho, J. Exploration of the effective location of surface oxygen defects in graphene-based electrocatalysts for all-vanadium redox-flow batteries. Adv. Energy Mater. 2015, 5, 1401550. [Google Scholar] [CrossRef]

- Wang, J.; Chen, B. Adsorption and coadsorption of organic pollutants and a heavy metal by graphene oxide and reduced graphene materials. Chem. Eng. J. 2015, 281, 379–388. [Google Scholar] [CrossRef]

- You, J.; Li, J.; Wang, Z.; Baghayeri, M.; Zhang, H. Application of Co3O4 nanocrystal/rGO for simultaneous electrochemical detection of cadmium and lead in environmental waters. Chemosphere 2023, 335, 139133. [Google Scholar] [CrossRef]

- Liu, X.; Ma, R.; Wang, X.; Ma, Y.; Yang, Y.; Zhuang, L.; Zhang, S.; Jehan, R.; Chen, J.; Wang, X. Graphene oxide-based materials for efficient removal of heavy metal ions from aqueous solution: A review. Environ. Pollut. 2019, 252, 62–73. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Li, D.; Luo, B.; Chen, M.; Shi, W. Two-dimensional heterojunction photocatalysts constructed by graphite-like C3N4 and Bi2WO6 nanosheets: Enhanced photocatalytic activities for water purification. J. Alloys Compd. 2017, 694, 193–200. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Zhai, B.; Liang, Y. Enhanced photocatalytic degradation of RhB by two-dimensional composite photocatalyst. Colloids Surf. A Physicochem. Eng. Asp. 2019, 568, 429–435. [Google Scholar] [CrossRef]

- Tian, P.; Tang, L.; Teng, K.S.; Lau, S.P. Graphene quantum dots from chemistry to applications. Mater. Today Chem. 2018, 10, 221–258. [Google Scholar] [CrossRef]

- Vats, T.; Gogoi, R.; Gaur, P.; Sharma, A.; Ghosh, S.; Siril, P.F. Pristine graphene–copper (II) oxide nanocatalyst: A novel and green approach in CuAAC reactions. ACS Sustain. Chem. Eng. 2017, 5, 7632–7641. [Google Scholar] [CrossRef]

- Chen, R.; Sheehan, T.; Ng, J.L.; Brucks, M.; Su, X. Capacitive deionization and electrosorption for heavy metal removal. Environ. Sci. Water Res. Technol. 2020, 6, 258–282. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, X.; Li, L.; Zhang, L.; Bao, J.; Zhang, N. Using the composite material of GO and g-C3N4 nanosheets as substrate to in-situ grow Co3O4 nanosheets for efficient Hg0 removal. Fuel 2023, 340, 127413. [Google Scholar] [CrossRef]

- Jyoti; Kaur, R.; Komal; Renu; Singh, P.; Kaur, N.; Rana, S.; Singhal, S. 2-(Anthracen-9-yl)benzothiazole–modified graphene oxide–nickel ferrite nanocomposite for anodic stripping voltammetric detection of heavy metal ions. Microchim. Acta 2022, 189, 186. [Google Scholar] [CrossRef]

- Huang, L.; Shuai, Q. Facile approach to prepare sulfur-functionalized magnetic amide-linked organic polymers for enhanced Hg (II) removal from water. ACS Sustain. Chem. Eng. 2019, 7, 9957–9965. [Google Scholar] [CrossRef]

- Zheng, X.; Yi, M.; Chen, Z.; Zhang, Z.; Ye, L.; Cheng, G.; Xiao, Y. Efficient removal of As (V) from simulated arsenic-contaminated wastewater via a novel metal–organic framework material: Synthesis, structure, and response surface methodology. Appl. Organomet. Chem. 2020, 34, e5584. [Google Scholar] [CrossRef]

- Tan, K.L.; Hameed, B.H. Insight into the adsorption kinetics models for the removal of contaminants from aqueous solutions. J. Taiwan Inst. Chem. Eng. 2017, 74, 25–48. [Google Scholar] [CrossRef]

- Wadhawan, S.; Jain, A.; Nayyar, J.; Mehta, S.K. Role of nanomaterials as adsorbents in heavy metal ion removal from waste water: A review. J. Water Process Eng. 2020, 33, 101038. [Google Scholar] [CrossRef]

- Bykov, Y.V.; Rybakov, K.; Semenov, V. High-temperature microwave processing of materials. J. Phys. D Appl. Phys. 2001, 34, R55. [Google Scholar] [CrossRef]

- Mansoorianfar, M.; Nabipour, H.; Pahlevani, F.; Zhao, Y.; Hussain, Z.; Hojjati-Najafabadi, A.; Hoang, H.Y.; Pei, R. Recent progress on adsorption of cadmium ions from water systems using metal-organic frameworks (MOFs) as an efficient class of porous materials. Environ. Res. 2022, 214, 114113. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Gao, B.; Wang, Z.; Li, J.; Du, Y.; He, C.; Liu, Y.; Yao, G.; Lai, B. Efficient wastewater disinfection by raised 1O2 yield through enhanced electron transfer and intersystem crossing via photocatalysis of peroxymonosulfate with CuS quantum dots modified MIL-101(Fe). Water Res. 2023, 229, 119489. [Google Scholar] [CrossRef]

- Wang, S.; Xia, Y.; Yan, G.; Chen, M.; Wang, X.; Wu, L.; Liang, R. PDI bridged MIL-125(Ti)-NH2 heterojunction with frustrated Lewis pairs: A promising photocatalyst for Cr(VI) reduction and antibacterial application. Appl. Catal. B Environ. 2022, 317, 121798. [Google Scholar] [CrossRef]

- Li, C.; Sriram, V.; Lee, J.-Y. A kinetic study of Hg(0) oxidation over Mo-promoted V-based SCR catalyst. Chem. Eng. J. 2022, 427, 131864. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, X.; Li, H. Kinetics and equilibrium study of phenol adsorption by activated carbon derived from pig blood. Carbon Trends 2023, 12, 100281. [Google Scholar] [CrossRef]

- Somyanonthanakun, W.; Ahmed, R.; Krongtong, V.; Thongmee, S. Studies on the adsorption of Pb(II) from aqueous solutions using sugarcane bagasse-based modified activated carbon with nitric acid: Kinetic, isotherm and desorption. Chem. Phys. Impact 2023, 6, 100181. [Google Scholar] [CrossRef]

- Ma, Q.; Li, Y.; Tan, Y.; Xu, B.; Cai, J.; Zhang, Y.; Wang, Q.; Wu, Q.; Yang, B.; Huang, J. Recent Advances in Metal-Organic Framework (MOF)-Based Photocatalysts: Design Strategies and Applications in Heavy Metal Control. Molecules 2023, 28, 6681. [Google Scholar] [CrossRef]

- Ma, Q.; Jiang, L.; Yang, B.; Xu, B.; Wang, Q.; Wu, Q.; Ning, P.; Zhang, Y.; Huang, J.; Hao, J. Mn/Ce@HKUST-1 for Efficient Removal of Gaseous Thallium: Insights from Kinetic and Experimental Studies. Langmuir 2023, 39, 13090–13102. [Google Scholar] [CrossRef] [PubMed]

- Efremova, A.; Rajkumar, T.; Szamosvölgyi, Á.; Sápi, A.; Baán, K.; Szenti, I.; Gómez-Pérez, J.; Varga, G.; Kiss, J.; Halasi, G.; et al. Complexity of a Co3O4 System under Ambient-Pressure CO2 Methanation: Influence of Bulk and Surface Properties on the Catalytic Performance. J. Phys. Chem. C 2021, 125, 7130–7141. [Google Scholar] [CrossRef]

- Bhattacharyya, P.; Parmar, P.R.; Basak, S.; Dubey, K.K.; Sutradhar, S.; Bandyopadhyay, D.; Chakrabarti, S. Metal organic framework–derived recyclable magnetic coral Co@Co3O4/C for adsorptive removal of antibiotics from wastewater. Environ. Sci. Pollut. Res. 2023, 30, 50520–50536. [Google Scholar] [CrossRef] [PubMed]

- Meng, F.; Yang, M.; Li, Z.; Zhang, R. HCOOH dissociation over the Pd-decorated Cu bimetallic catalyst: The role of the Pd ensemble in determining the selectivity and activity. Appl. Surf. Sci. 2020, 511, 145554. [Google Scholar] [CrossRef]

- Dadi, R.K.; Daya, R.; Kumar, A.; Joshi, S.Y.; An, H.; Cunningham, M.J.; Currier, N.W.; Yezerets, A. A modeling and experimental study on hydrothermal aging deactivation of NO oxidation activity on Pt-Pd catalyst. Appl. Catal. B Environ. 2021, 283, 119655. [Google Scholar] [CrossRef]

- Lei, H.; Li, L.; Yang, W.; Bian, Y.; Li, C.-Q. An analytical review on application of life cycle assessment in circular economy for built environment. J. Build. Eng. 2021, 44, 103374. [Google Scholar] [CrossRef]

- Vance, C.; Sweeney, J.; Murphy, F. Space, time, and sustainability: The status and future of life cycle assessment frameworks for novel biorefinery systems. Renew. Sustain. Energy Rev. 2022, 159, 112259. [Google Scholar] [CrossRef]

- Martin, N.; Madrid-López, C.; Villalba-Méndez, G.; Talens-Peiró, L. New Techniques for Assessing Critical Raw Material Aspects in Energy and Other Technologies. Environ. Sci. Technol. 2022, 56, 17236–17245. [Google Scholar] [CrossRef]

- Deng, B.; Meng, W.; Advincula, P.A.; Eddy, L.; Ucak-Astarlioglu, M.G.; Wyss, K.M.; Chen, W.; Carter, R.A.; Li, G.; Cheng, Y.; et al. Heavy metal removal from coal fly ash for low carbon footprint cement. Commun. Eng. 2023, 2, 13. [Google Scholar] [CrossRef]

| Heavy Metal | Sources | Chemical Forms | Toxicity Mechanisms | Exposure Risks | Associated Health Effects |

|---|---|---|---|---|---|

| Lead (Pb) | Mining, smelting, battery manufacturing, paint pigments | Inorganic (Pb2+), organic (tetraethyl lead) | Interference with heme synthesis and neurotransmitter release; oxidative stress; DNA damage | Inhalation of lead dust or fumes; ingestion of contaminated food or water; dermal contact with lead-containing substances | Neurological damage; developmental delays; anemia; hypertension |

| Mercury (Hg) | Coal-fired power plants, mining, dental amalgams | Elemental (Hg0), inorganic (Hg2+), organic (methylmercury) | Inhibition of enzymes involved in heme synthesis and antioxidant defense; oxidative stress; DNA damage | Inhalation of mercury vapor or dust; ingestion of contaminated fish or water; dermal contact with mercury-containing substances | Neurological damage; developmental delays; kidney damage |

| Cadmium (Cd) | Mining, smelting, battery manufacturing | Inorganic (Cd2+), organic (cadmium chloride) | Interference with calcium signaling and antioxidant defense; oxidative stress; DNA damage | Inhalation of cadmium fumes or dust; ingestion of contaminated food or water; dermal contact with cadmium-containing substances | Kidney damage; osteoporosis |

| Chromium (Cr) | Electroplating, leather tanning, stainless steel production | Inorganic (Cr3+, Cr6+), organic (chromium picolinate) | Interference with DNA repair and antioxidant defense; oxidative stress; DNA damage | Inhalation of chromium fumes or dust; ingestion of contaminated food or water; dermal contact with chromium-containing substances | Lung cancer |

| Arsenic (As) | Mining, smelting, pesticide production | Inorganic (As3+, As5+), organic (arsenobetaine) | Interference with ATP production and antioxidant defense; oxidative stress; DNA damage | Inhalation of arsenic dust or fumes; ingestion of contaminated food or water; dermal contact with arsenic-containing substances | Skin cancer |

| Thallium (Tl) | Coal-fired power plants, cement production, electronics manufacturing | Inorganic (Tl+) | Interference with potassium channels and antioxidant defense; oxidative stress; DNA damage | Inhalation of thallium dust or fumes; ingestion of contaminated food or water; dermal contact with thallium-containing substances | Nerve damage |

| Method | Materials | Advantages | Disadvantages | Future Directions |

|---|---|---|---|---|

| Adsorption | Activated carbon, zeolites, chitosan, etc. | High efficiency, low cost, easy operation | Limited reusability, low selectivity | Development of novel adsorbents |

| Photocatalysis | TiO2, ZnO, Fe2O3, etc. | High efficiency, no secondary pollution | Limited light absorption range, high cost | Development of visible-light-responsive photocatalysts |

| Membrane separation | Ultrafiltration membranes, nanofiltration membranes, reverse osmosis membranes, etc. | High selectivity and efficiency | Membrane fouling, high energy consumption | Development of antifouling membranes |

| Ion exchange | Resins, zeolites, etc. | High selectivity and efficiency | Limited reusability, low capacity for heavy metals with low concentrations | Development of novel ion exchangers |

| Electrochemical treatment | Electrodes (Fe, Al), electrolytes (NaCl), etc. | High efficiency and selectivity, no secondary pollution | High energy consumption, limited application range | Development of novel electrode materials |

| Phytoremediation | Plants (e.g., sunflower, Indian mustard) | Low cost, eco-friendly, aesthetically pleasing | Limited application range, slow process | Development of plants with higher heavy metal uptake capacity |

| Bioremediation | Microorganisms (e.g., bacteria, fungi) | Low cost, eco-friendly, high efficiency | Limited application range, slow process | Development of microorganisms with higher heavy metal uptake capacity |

| Coagulation/flocculation | Coagulants (e.g., alum, ferric chloride), flocculants (e.g., polyacrylamide) | High efficiency, easy operation | High chemical consumption, secondary pollution | Development of novel coagulants/flocculants |

| Electrocoagulation | Electrodes (e.g., iron, aluminum), electrolytes (e.g., NaCl) | High efficiency and selectivity, no secondary pollution | High energy consumption, limited application range | Development of novel electrode materials |

| MOFs | Method | Mechanism | Capacity | Target | Reuse Cycles | References |

|---|---|---|---|---|---|---|

| UiO-66-NH2 | Solvothermal | Photoreduction | 198.7 mg/g | Pb(II) | 4 | [32] |

| Cu-BTC | Hydrothermal | Photoreduction | 167.2 mg/g | Hg(II) | 5 | [33] |

| Cd-MOFs | Microwave assisted | Photoreduction | 71.4 mg/g | Cr(VI) | 3 | [34] |

| MIL-53 | Ultrasonication | Photooxidation | 92.6 mg/g | Methyl orange dye | 6 | [35] |

| Zn-MOFs | Solvothermal | Photooxidation | 248.7 mg/g | Rhodamine B dye | 4 | [36] |

| NH2-MIL-125 | Solvothermal | Photoreduction | 175.4 mg/g | Ag(I) | 5 | [37,38] |

| ZIF-8 | STP synthesis | Photooxidation | 104.7 mg/g | Methylene blue dye | 3 | [38] |

| Cu-BTC/GO | Hydrothermal | Photoreduction | 152.6 mg/g | Cd(II) | 4 | [39] |

| Fe-MIL-101 | Solvothermal | Photoreduction | 198.4 mg/g | Cr(VI) | 3 | [40] |

| UiO-66 | Microwave assisted | Photooxidation | 167.9 mg/g | Orange II dye | 5 | [41] |

| PCP Composition | Pore Size | Target Heavy Metal | Removal Capacity | Mechanism | Ref. |

|---|---|---|---|---|---|

| Zn-based PCP | 0.9 nm | Hg2+ | 387 mg/g | Size-selective adsorption | [48] |

| Al-methylphosphonate PCP | Microporous | As(III), As(V) | 1025 mg/g | Ligand exchange at Al(III) sites | [49] |

| Ti(IV)-based PCP | <2 nm | Hg0 | - | Photooxidation to HgO | [50] |

| Ti(IV)-based PCP | Microporous | Cr(VI) | - | Photoreduction to Cr(III) | [51] |

| Fe-azolate PCP | 1.5 nm | Hg2+ | 296 mg/g | Coordinative binding at metal sites | [52] |

| Bimetallic Catalyst | Properties | Application | Reference |

|---|---|---|---|

| TiO2 | Bandgap: ~3.2 eV—High photocatalytic activity—Stability under UV light | Removal of Cr(VI), Cd(II), and organic pollutants—Water and wastewater treatment | [59] |

| ZnO | Bandgap: ~3.37 eV—Good photocatalytic efficiency—Low cost | Degradation of organic dyes and heavy metals—Environmental remediation | [60] |

| Fe2O3 | Hematite structure—High surface area—Photocorrosion resistance | Elimination of arsenic, chromium, and lead—Groundwater purification | [61] |

| CuO | Cupric oxide—Visiblelight absorption—Antibacterial properties | Copper ion removal—Microbial disinfection—Industrial wastewater treatment | [62] |

| SnO2 | Tin dioxide—Stable and nontoxic—Photocatalytic activity—Wide bandgap | Removal of Hg(II), As(III), and Cr(VI)—Air and water purification | [63] |

| Bimetallic Catalyst | Composition | Properties | Application | Reference |

|---|---|---|---|---|

| AuAg Nanoparticles | AuAg alloy | Synergistic effect—Enhanced catalytic activity—High stability | Removal of Hg(II) and Cr(VI)—Water treatment | [73] |

| PdCu Nanoparticles | PdCu alloy | High catalytic selectivity—Improved electron transfer—Resistance to deactivation | Degradation of chlorinated organics—Groundwater remediation | [74] |

| PtFe Nanoparticles | PtFe alloy | Excellent catalytic performance—Magnetic properties—Good reusability | Reduction of nitroaromatic compounds—Soil and sediment remediation | [75] |

| NiCo Nanoparticles | NiCo alloy | Tunable composition—High surface area—Enhanced adsorption | Removal of heavy metals from industrial effluents—Environmental cleanup | [76] |

| CuAg Nanoparticles | CuAg alloy | Surface plasmon resonance—Photocatalytic activity—Low toxicity | Disinfection of microbes—fluegas and wastewater treatment | [77] |

| Zeolite Type | Composition | Properties | Application | Ref. |

|---|---|---|---|---|

| Natural Clinoptilolite | Aluminosilicate | High cation exchange capacity Selective adsorption Low cost | Removal of ammonium and heavy metals, Soil and water remediation | [83] |

| NaX Zeolite | Sodium aluminosilicate | Large surface area High ionexchange capacity Selective adsorption | Removal of Cs, Sr, and heavy metals from nuclear wastewater Water purification | [84] |

| Ferrierite Zeolite | Aluminosilicate | Acidic properties Mesoporous structure High thermal stability | Adsorption of heavy metals and organic pollutants Catalytic applications | [85] |

| Mordenite Zeolite | Aluminosilicate | Long pore channels High aluminum content Excellent stability | Removal of ammonium and heavy metals from wastewater Catalytic processes | [86] |

| Faujasite Zeolite | Aluminosilicate | Cage-like structure Acidic sites Hydrophobic and hydrophilic regions | Adsorption of heavy metals and organic compounds Petroleum refining | [87] |

| Material Type | Composition | Properties | Application | Reference |

|---|---|---|---|---|

| Graphene Oxide (GO) | Carbon-based | Large surface area | Adsorption of heavy metals and organic pollutants Water and wastewater treatment | [94] |

| Reduced Graphene Oxide (rGO) | Reduced form of GO | Restored conductivity Enhanced adsorption properties | Removal of heavy metals from industrial effluents Electrochemical sensors | [95] |

| Graphene-Based Nanocomposites | Graphene combined with other materials (e.g., nanoparticles) | Synergistic properties Improved stability | Efficient removal of heavy metals Environmental remediation | [96] |

| Graphene Nanosheets | Two-dimensional carbon structure | High surface area Enhanced reactivity | Adsorption and catalytic degradation of pollutants Water purification | [97,98] |

| Graphene Quantum Dots | Quantum-sized graphene particles | Size-dependent properties Excellent photoluminescence | Sensing and detection of heavy metals Bioimaging applications | [99] |

| Materials | Metals | Kinetic Model | Rate Expression | Reference |

|---|---|---|---|---|

| -TiO2 nanocomposites | Hg0 | Langmuir–Hinshelwood | r = kθC/(1 + KC) | [112] |

| Fe-ZSM-5 zeolite | Hg0 | Pseudo-first-order | ln(C0/C) = k’t | [113] |

| Ni-CeO2 nanocatalyst | Pb(II) | Pseudo-second-order | t/Qt = 1/k’Qe2 + t/Qe | [114] |

| MOF-5 | Cd(II) | Elovich | qt = (1/β)ln(αβ) + (1/β)lnt | [115,116] |

| Co@Co3O4 core-shell | As(III) | Intraparticle diffusion | qt = k’√t | [117,118] |

| Ag-ZnO nanoparticles | Hg0 | Chick–Watson | ln(N/N0) = −k’C’t | [115] |

| Pd-Cu bimetallic catalyst | Hg0 | Hom model | ln(N/N0) = −k’C’ntm−1 | [119,120] |

| Impact Metric | Description |

|---|---|

| Embodied energy | Energy utilized for materials synthesis and processing |

| GWP | Greenhouse gas emissions across life cycle |

| Eutrophication potential | Impacts on aquatic ecosystems from discharges |

| Human health criteria | Exposure to hazardous substances |

| Material use | Consumption of resources, recyclability |

| Synthesis greenness | Use of biogenic/waste precursors, benign solvents |

| Stability/reusability | Lifetime, metal leaching, structural integrity |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Q.; Zhang, X.; Li, J.; Zhang, Y.; Wang, Q.; Zeng, L.; Yang, Y.; Xie, Y.; Huang, J. Transition Metal Catalysts for Atmospheric Heavy Metal Removal: A Review of Current Innovations and Advances. Molecules 2023, 28, 7620. https://doi.org/10.3390/molecules28227620

Ma Q, Zhang X, Li J, Zhang Y, Wang Q, Zeng L, Yang Y, Xie Y, Huang J. Transition Metal Catalysts for Atmospheric Heavy Metal Removal: A Review of Current Innovations and Advances. Molecules. 2023; 28(22):7620. https://doi.org/10.3390/molecules28227620

Chicago/Turabian StyleMa, Qiang, Xianglong Zhang, Jie Li, Yingjie Zhang, Qingyuan Wang, Li Zeng, Yige Yang, Yonghong Xie, and Jin Huang. 2023. "Transition Metal Catalysts for Atmospheric Heavy Metal Removal: A Review of Current Innovations and Advances" Molecules 28, no. 22: 7620. https://doi.org/10.3390/molecules28227620

APA StyleMa, Q., Zhang, X., Li, J., Zhang, Y., Wang, Q., Zeng, L., Yang, Y., Xie, Y., & Huang, J. (2023). Transition Metal Catalysts for Atmospheric Heavy Metal Removal: A Review of Current Innovations and Advances. Molecules, 28(22), 7620. https://doi.org/10.3390/molecules28227620