Network–Polymer–Modified Superparamagnetic Magnetic Silica Nanoparticles for the Adsorption and Regeneration of Heavy Metal Ions

Abstract

:1. Introduction

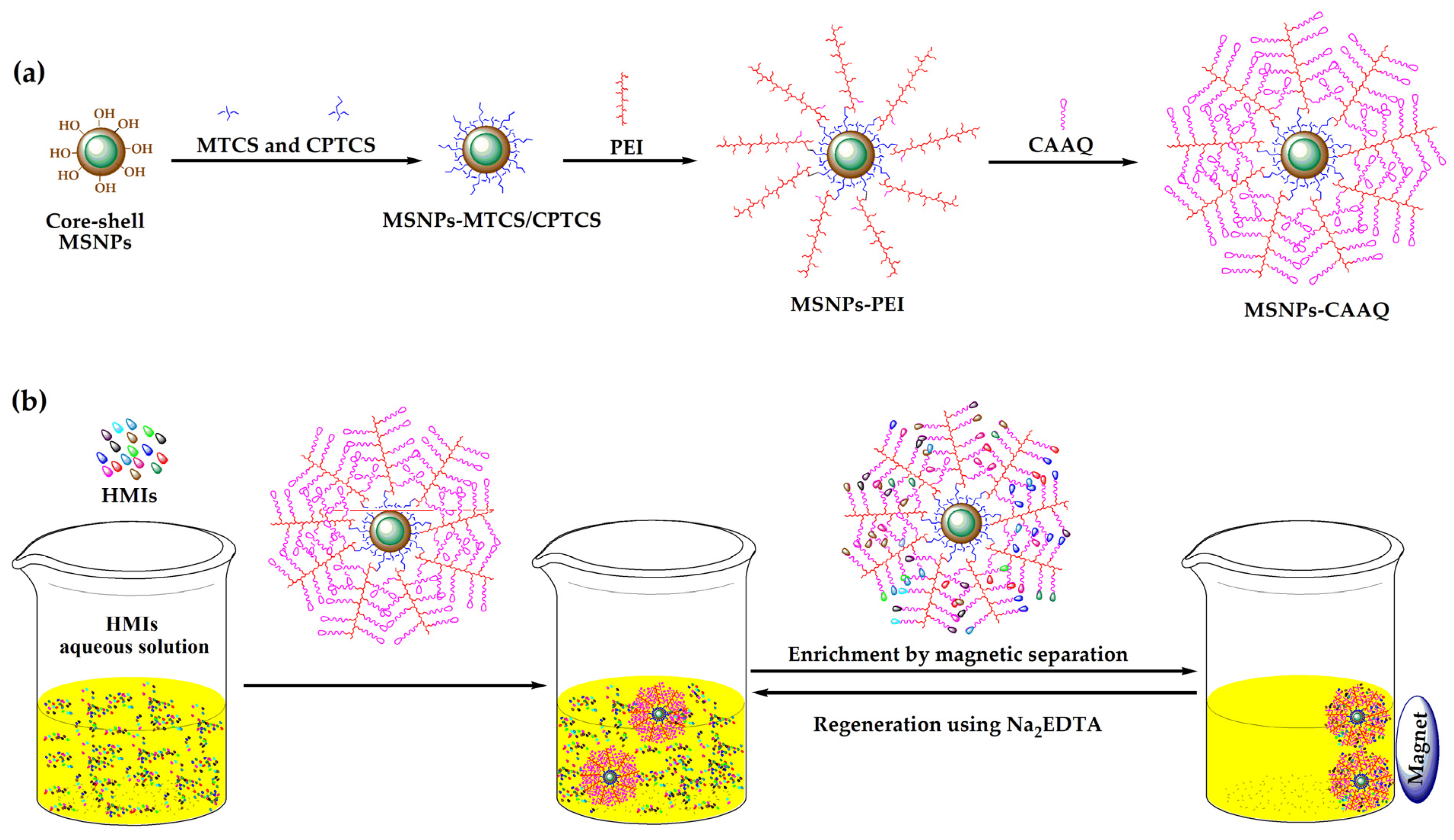

2. Results and Discussion

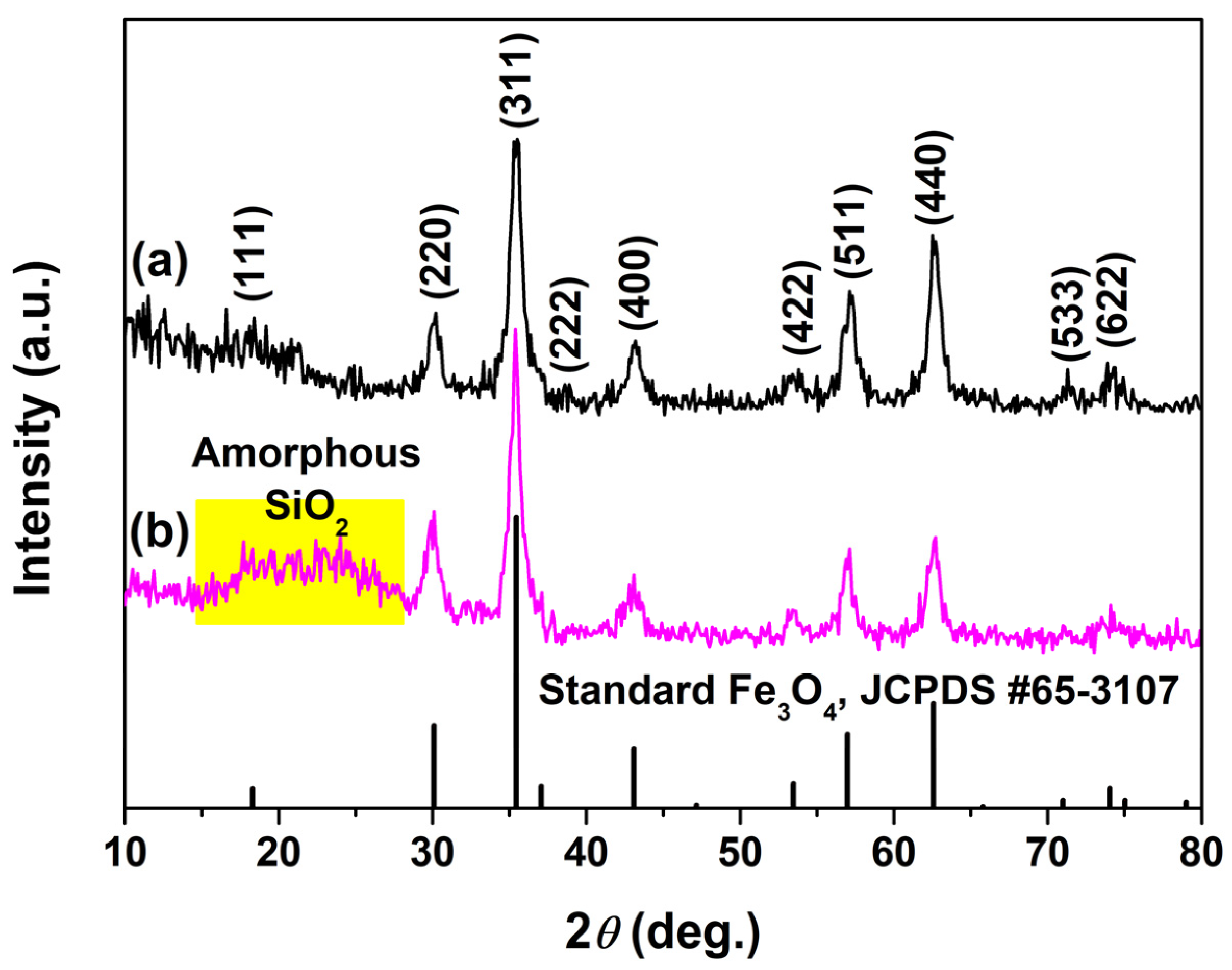

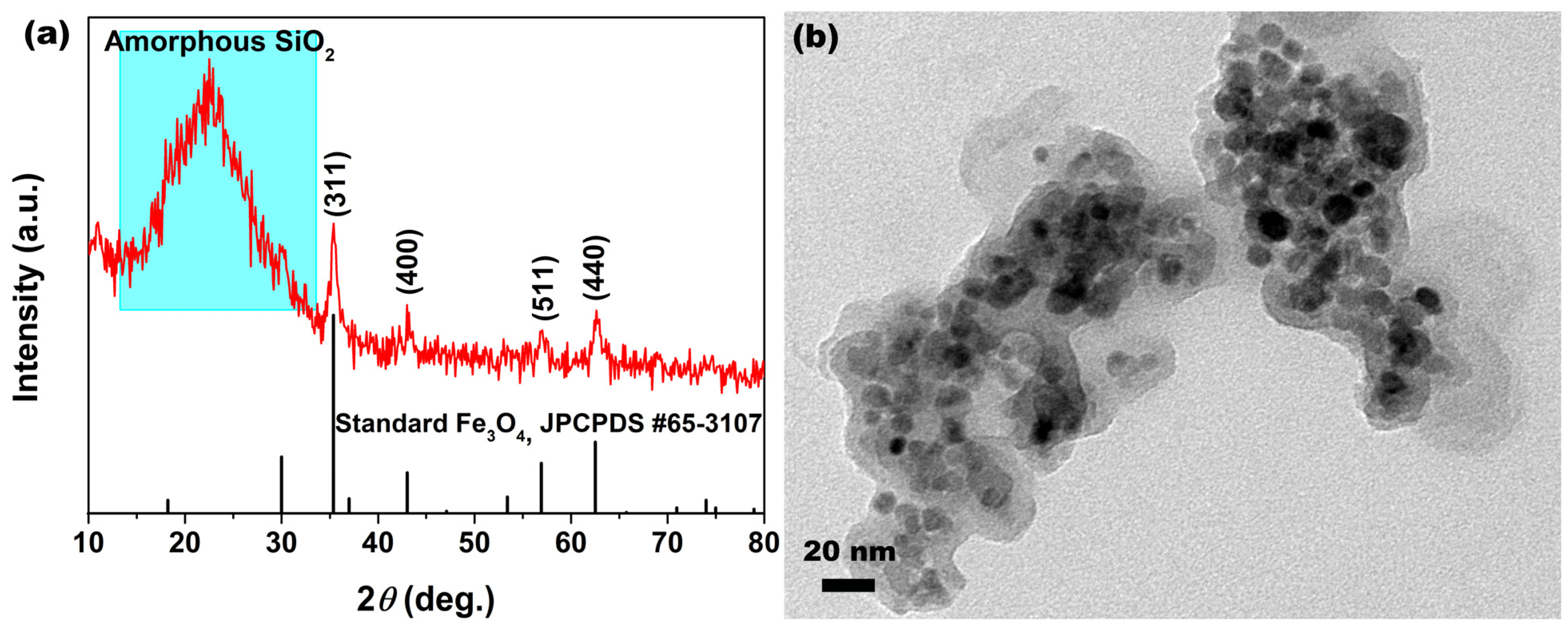

2.1. Characterizations of MNPs and MSNPs

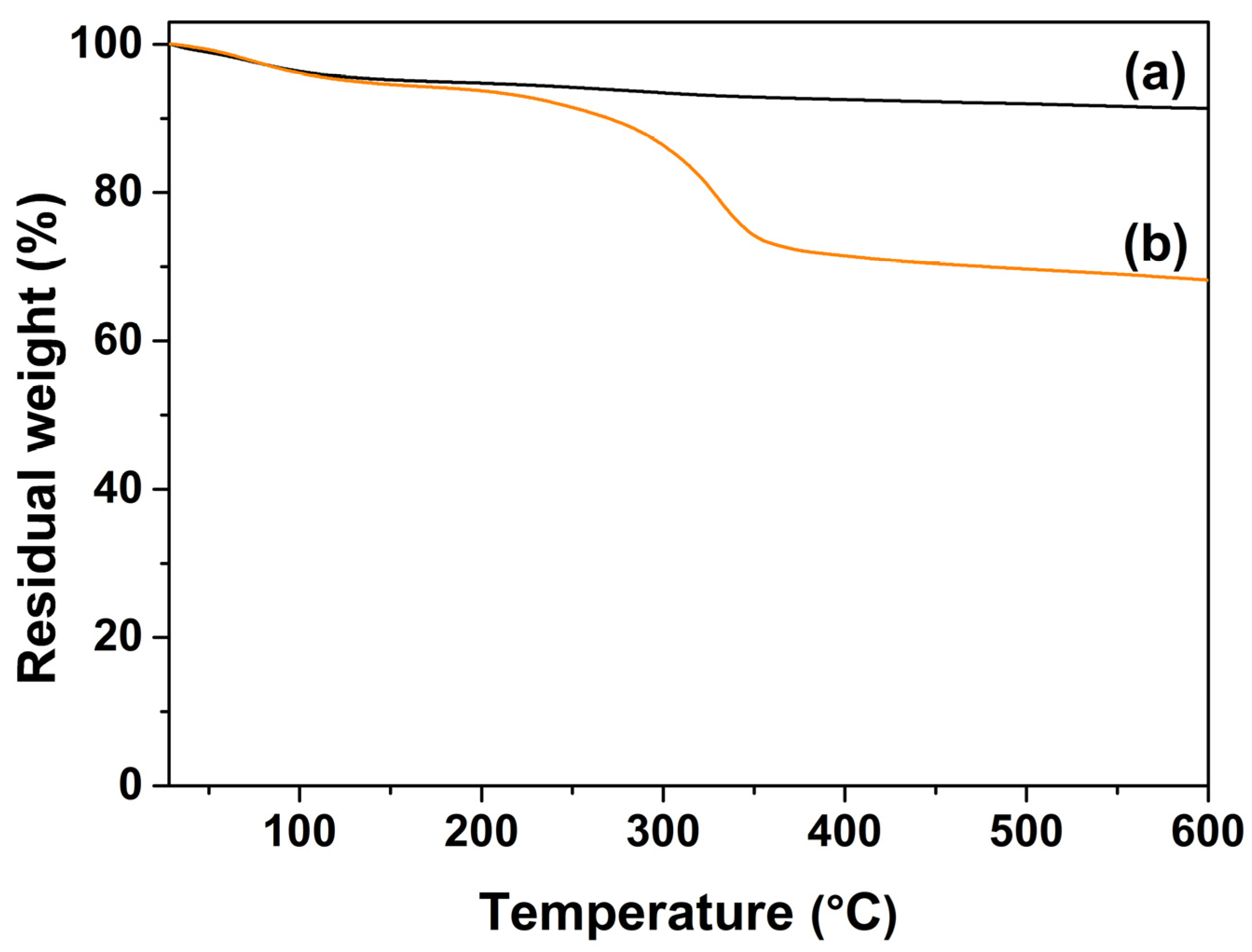

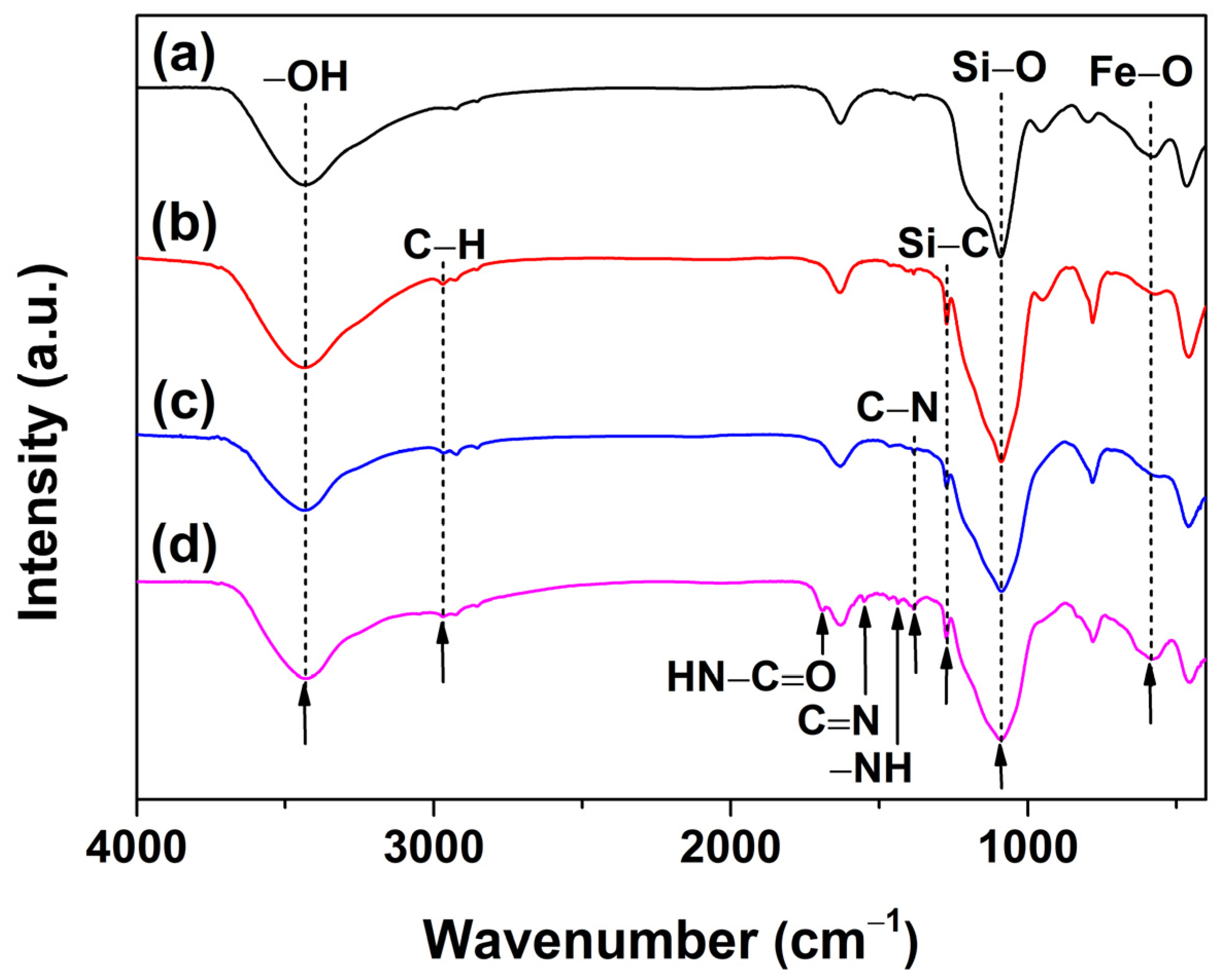

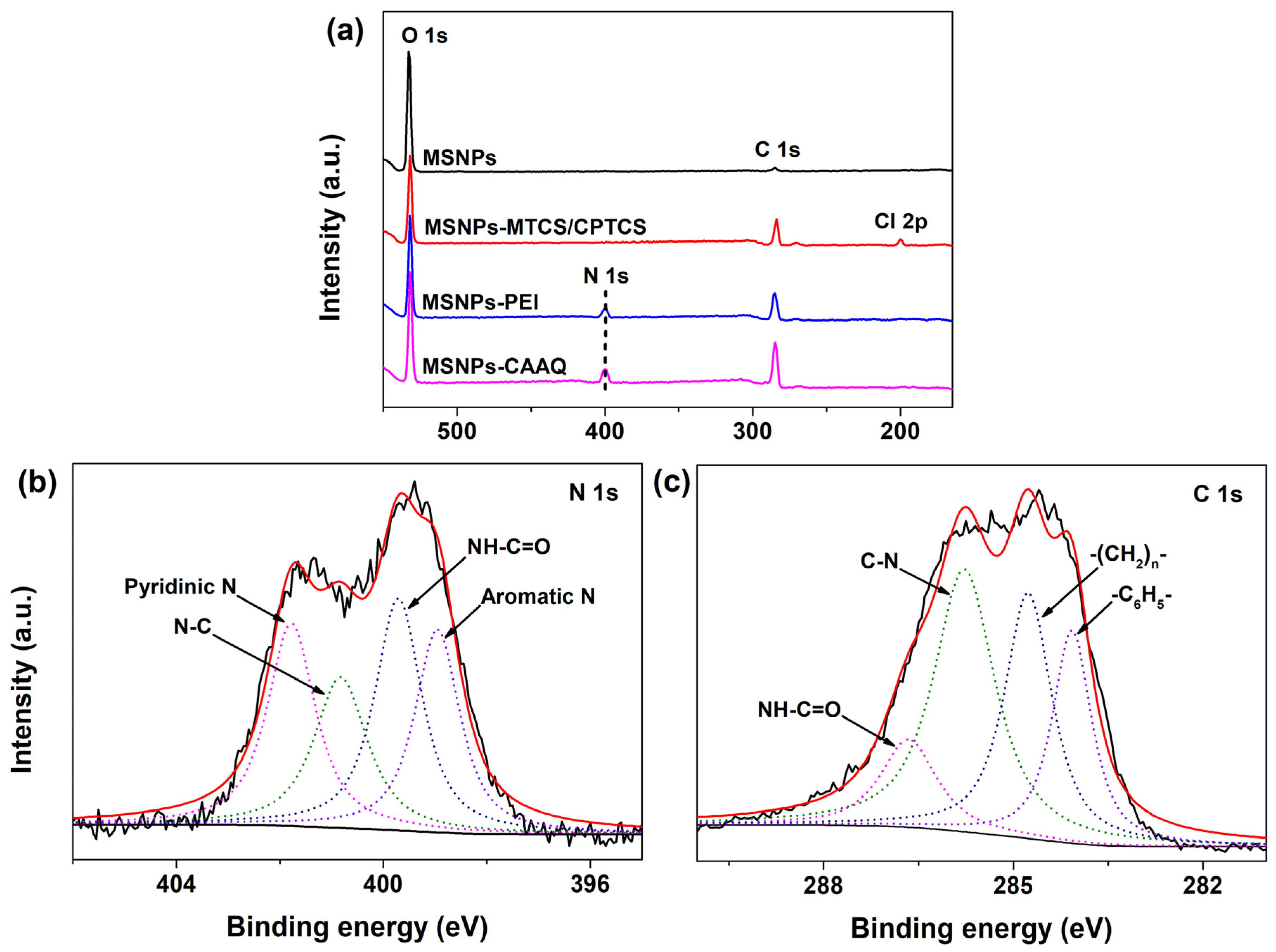

2.2. Characterizations of MSNPs–CAAQ

2.3. Magnetic Analysis of MNPs, MSNPs and MSNPs–CAAQ

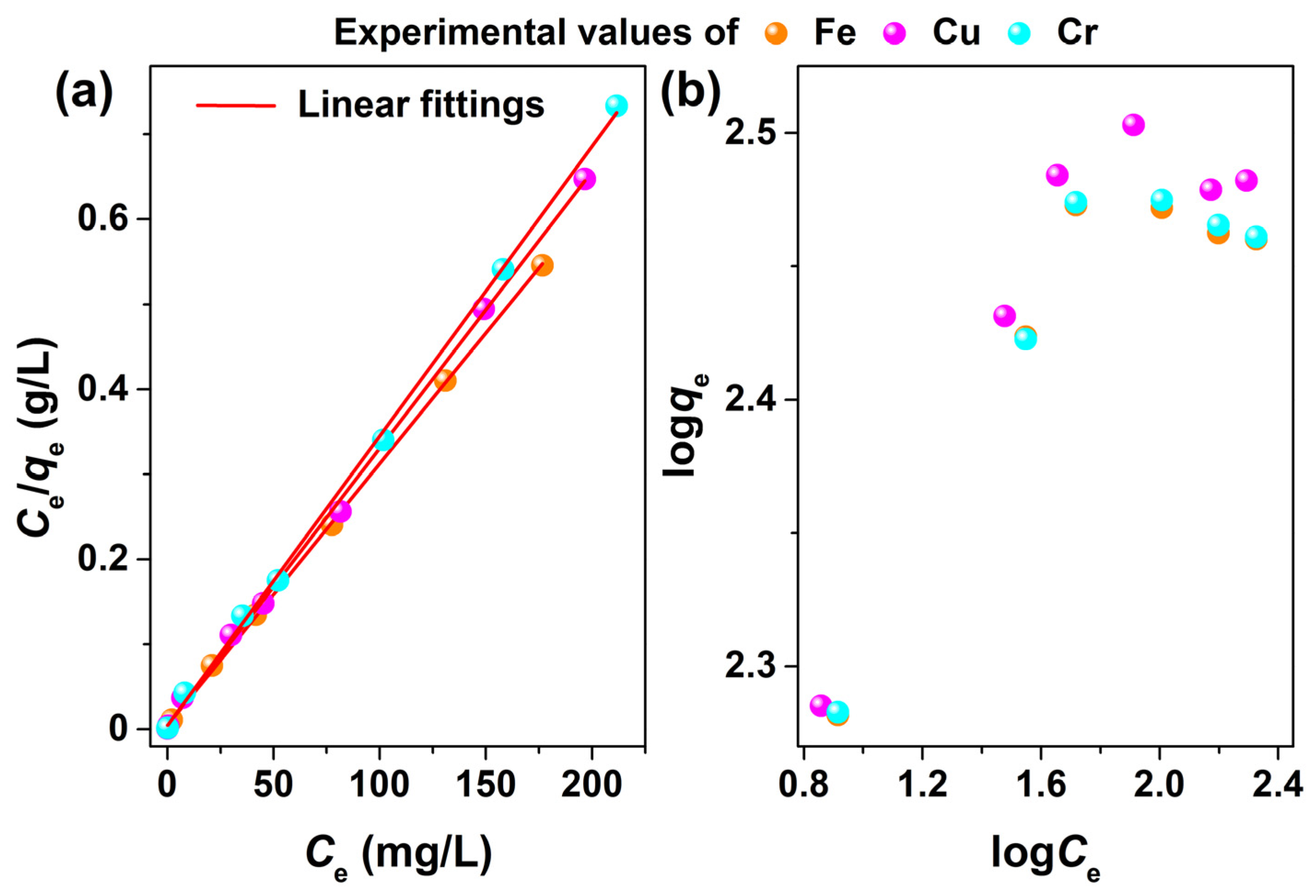

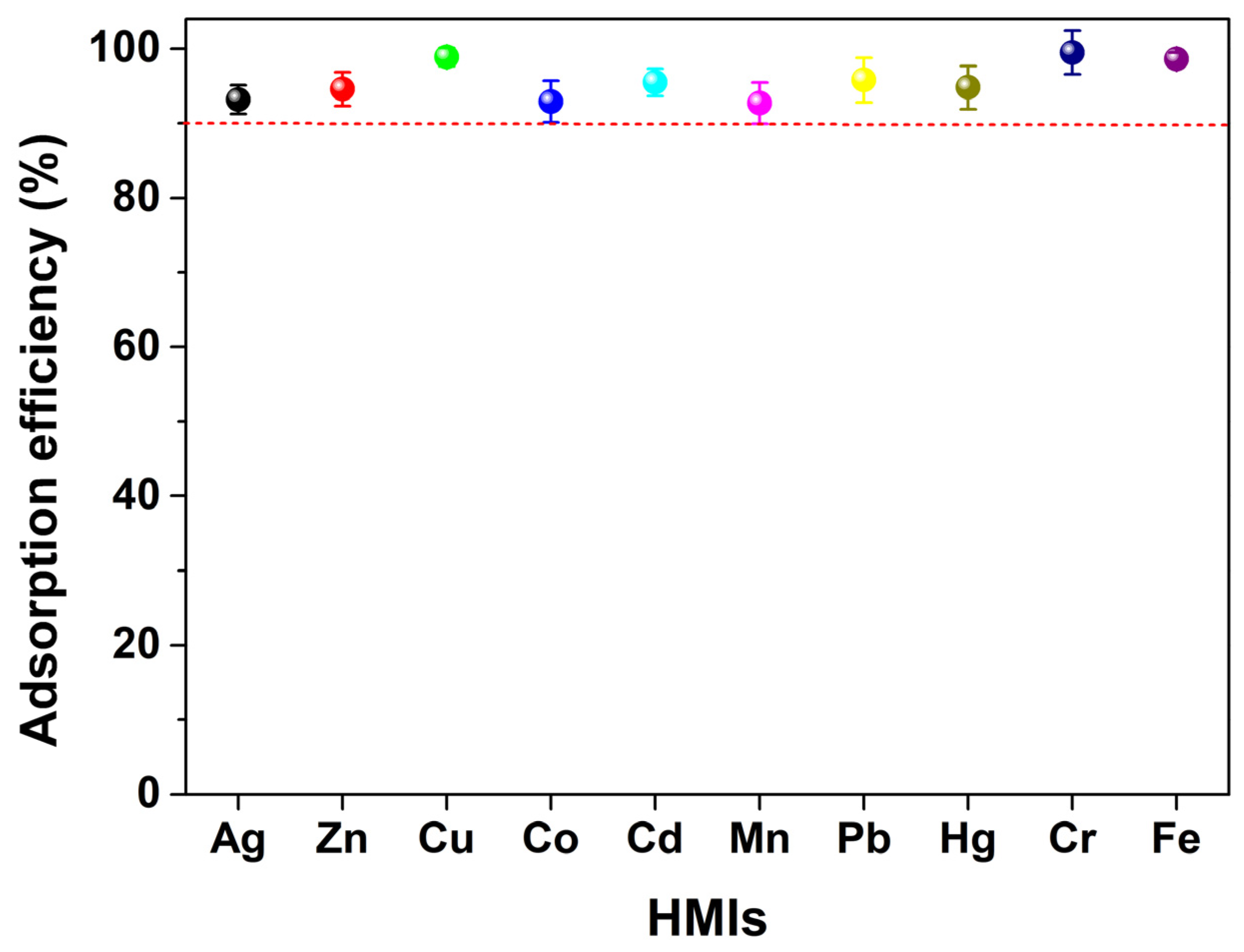

2.4. Adsorption Characteristics

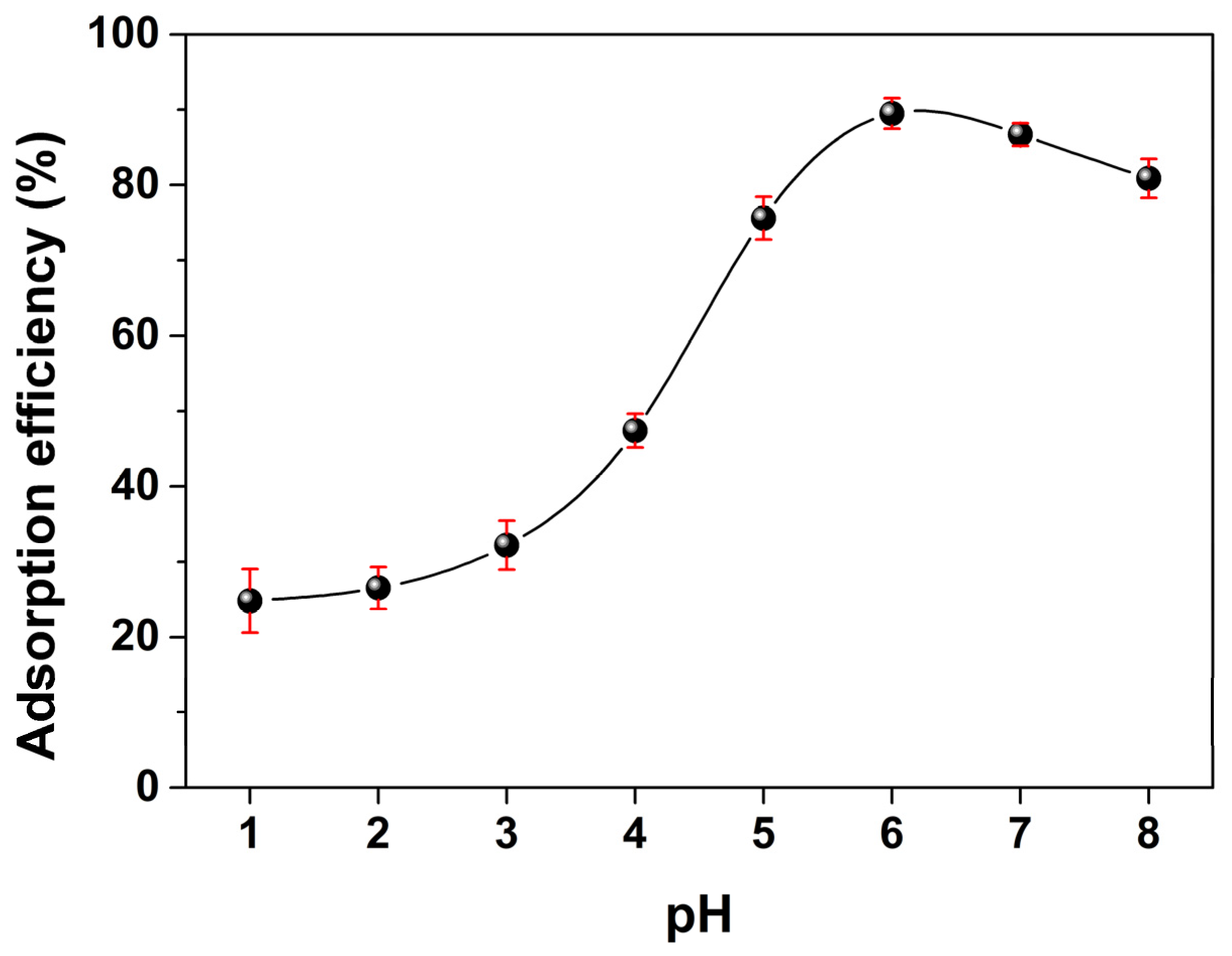

2.5. Effect of pH on Adsorption

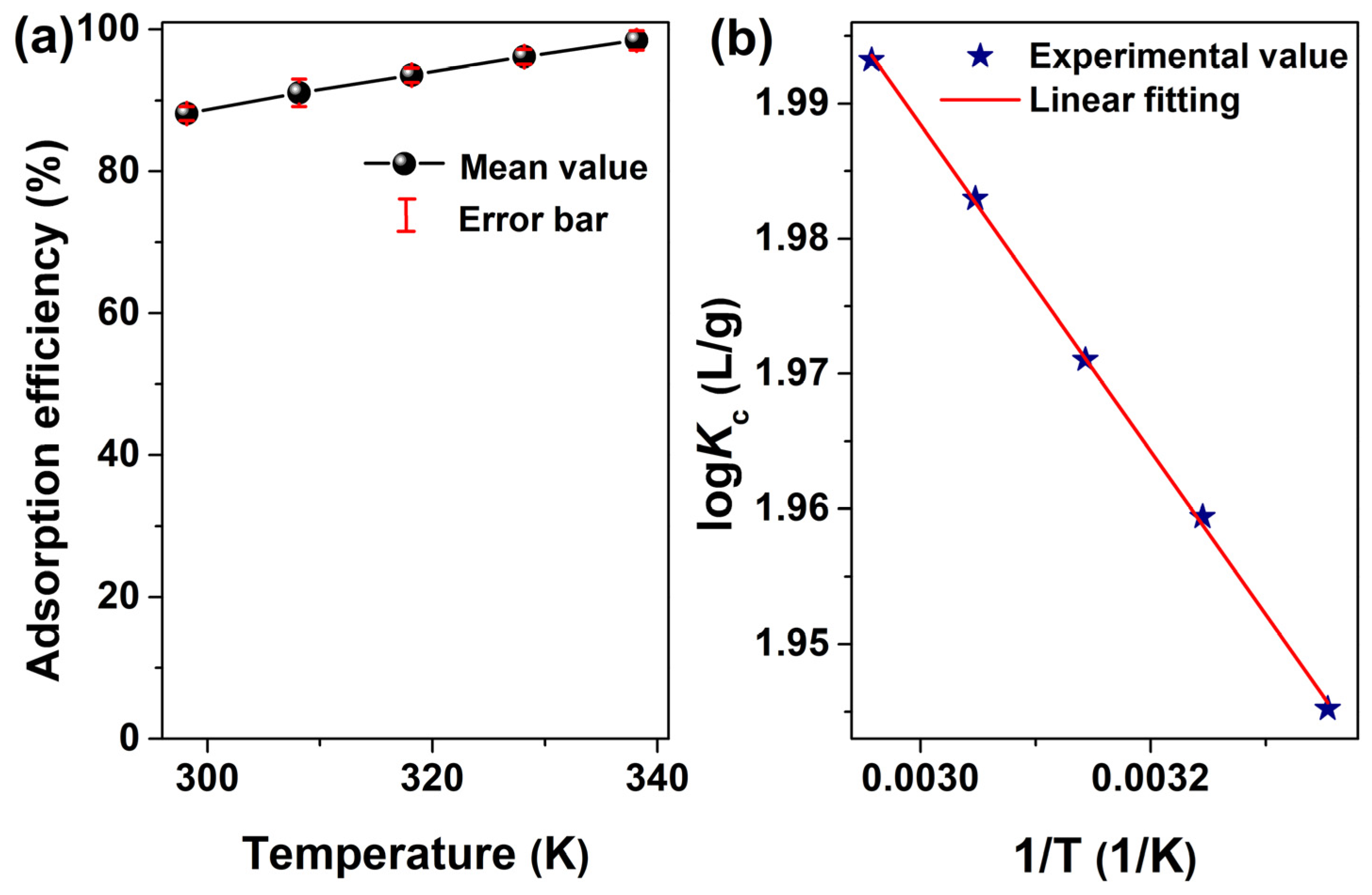

2.6. Effect of Temperature on Adsorption

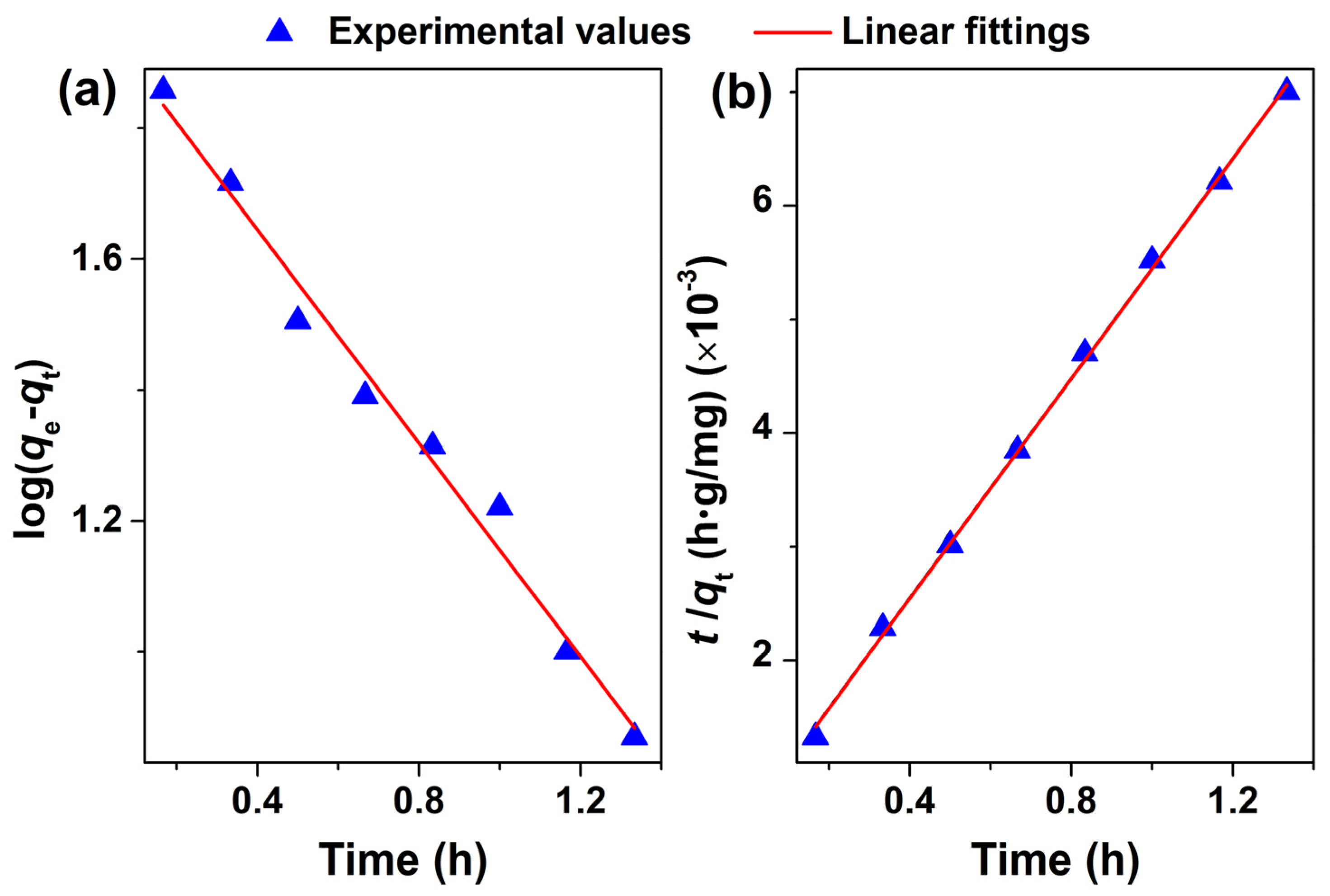

2.7. Adsorption Kinetics

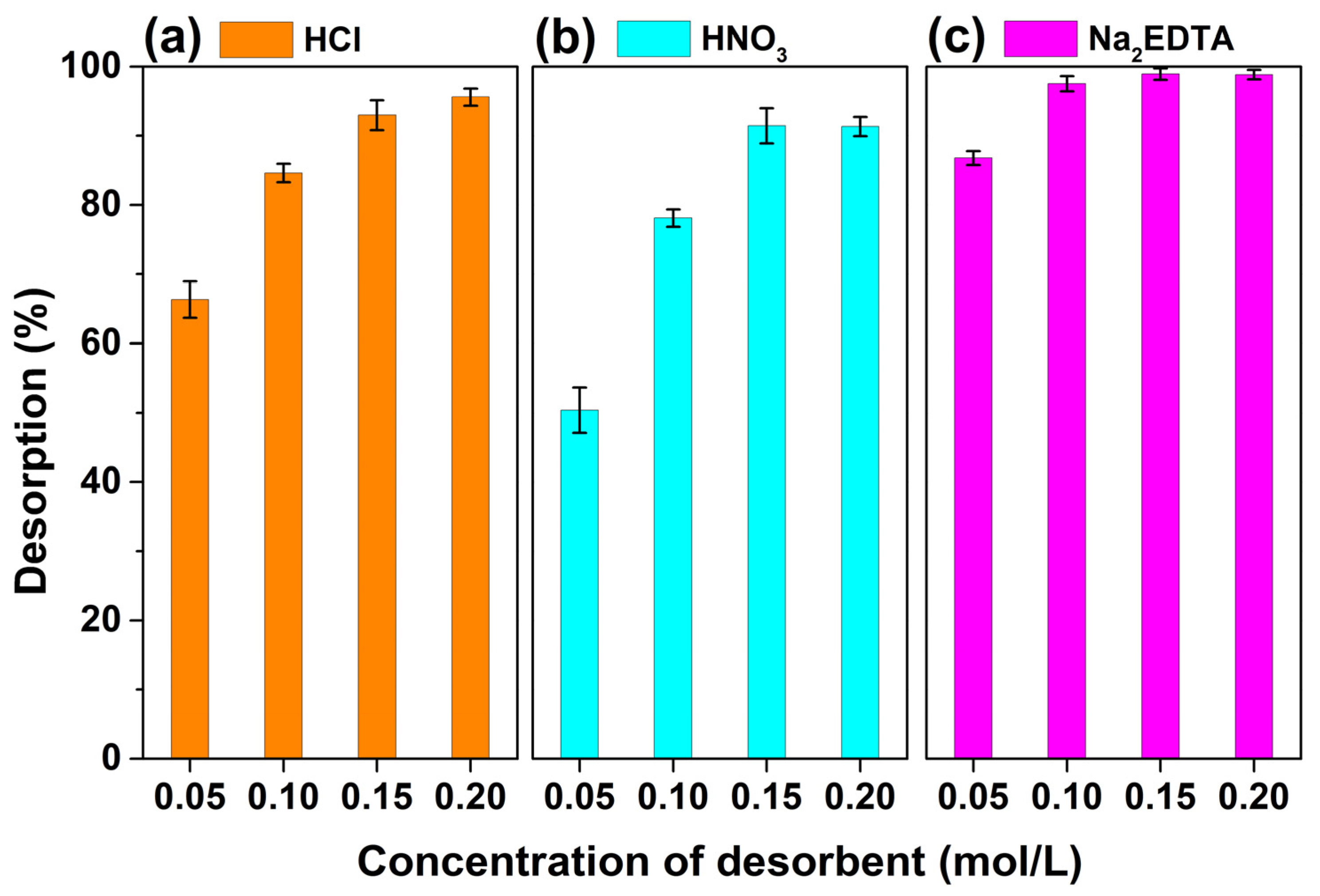

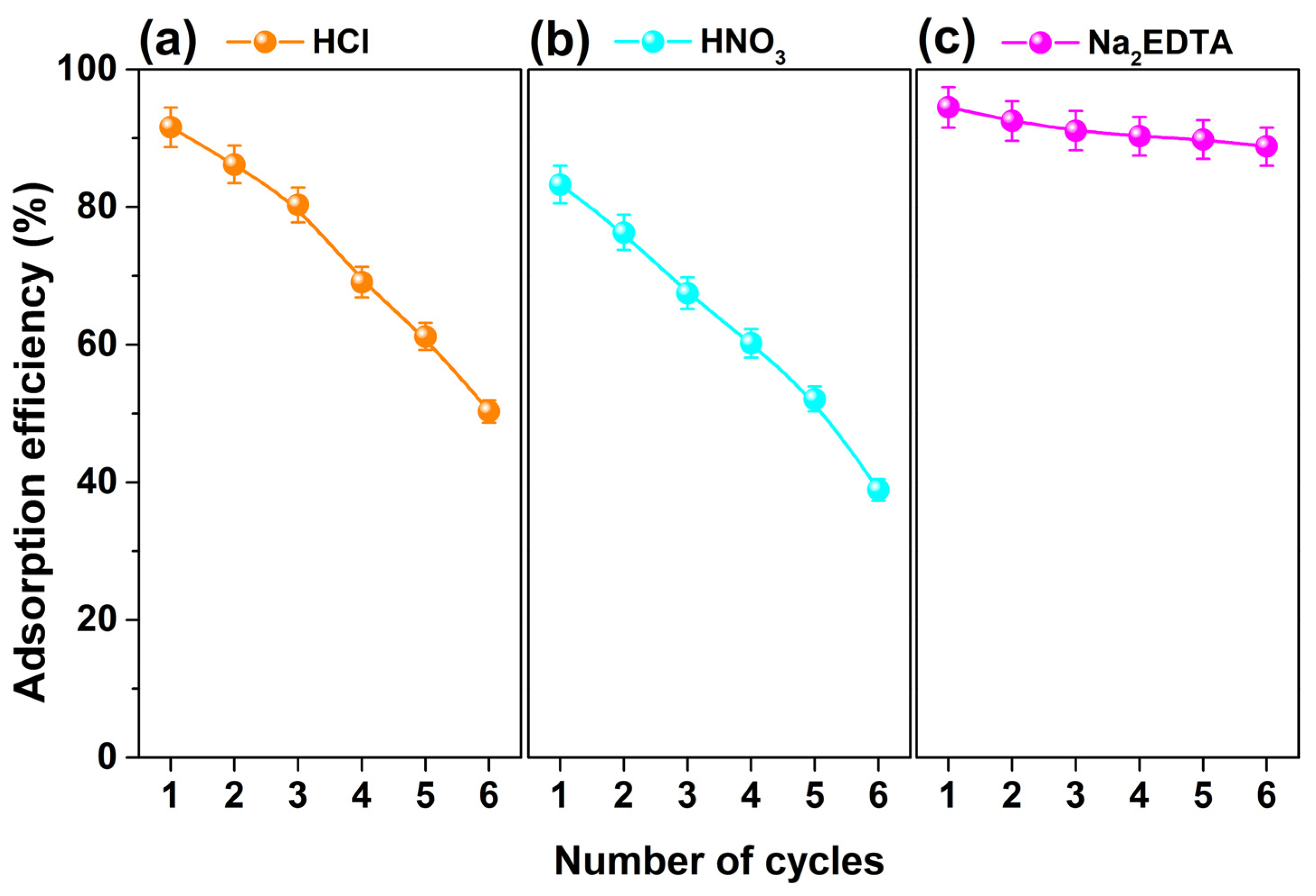

2.8. Desorption and Reusability

3. Experimental Procedure

3.1. Starting Materials

3.2. Synthesis

3.2.1. Synthesis of Core–Shell MSNPs

3.2.2. Synthesis of MTCS and CPTCS co–Modified MSNPs

3.2.3. Synthesis of PEI–Modified MSNPs

3.2.4. Pre–Synthesis of CAAQ and Synthesis of CAAQ–Modified MSNPs by “Grafting–to” Approach

3.3. Characterization

3.4. Adsorption Experiments

3.5. Desorption and Reusability Experiments

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Su, X.; Kushima, A.; Halliday, C.; Zhou, J.; Li, J.; Hatton, T.A. Electrochemically–mediated selective capture of heavy metal chromium and arsenic oxyanions from water. Nat. Commun. 2018, 9, 4701. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Zhang, Y.; Ma, D.; Shi, Z.; Ma, S. Mercury nano–trap for effective, efficient removal of mercury(II) from aqueous solution. Nat. Commun. 2014, 5, 5537. [Google Scholar] [CrossRef]

- Liu, C.; Wu, T.; Hsu, P.C.; Xie, J.; Zhao, J.; Liu, K.; Sun, J.; Xu, J.; Tang, J.; Ye, Z.; et al. Direct/alternating current electrochemical method for removing and recovering heavy metal from water using graphene oxide electrode. ACS Nano 2019, 13, 6431–6437. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.S.; Khaing Oo, M.K.; Fan, X. Highly sensitive multiplexed heavy metal detection using quantum–dot–labeled dnazymes. ACS Nano 2010, 4, 5897–5904. [Google Scholar] [CrossRef] [PubMed]

- Ojeajiménez, I.; López, X.; Arbiol, J.; Puntes, V. Citrate–coated gold nanoparticles as smart scavengers for mercury(II) removal from polluted waters. ACS Nano 2012, 6, 2253–2260. [Google Scholar] [CrossRef]

- Salt, D.E.; Blaylock, M.; Kumar, N.P.B.A.; Dushenkov, V.; Ensley, B.D.; Chet, I.; Raskin, I. Phytoremediation: A novel strategy for the removal of toxic metals from the environment using plants. Nat. Biotechnol. 1995, 13, 468–474. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Patil, S.A. Removal of heavy metals using bioelectrochemical systems. In Integrated Microbial Fuel Cells for Wastewater Treatment; Butterworth–Heinemann: Oxford, UK, 2020; pp. 49–71. [Google Scholar] [CrossRef]

- Kumar, R.; Yadav, S.; Patil, S.A. Bioanode–Assisted Removal of Hg2+ at the Cathode of Microbial Fuel Cells. J. Hazard. Toxic Radio. 2020, 24, 04020034. [Google Scholar] [CrossRef]

- Nazir, M.A.; Bashir, M.A.; Najam, T.; Javad, M.S.; Suleman, S.; Hussain, S.; Kumar, O.P.; Shah, S.S.A.; Rehman, A.U. Combining structurally ordered intermetallic nodes: Kinetic and isothermal studies for removal of malachite green and methyl orange with mechanistic aspects. Microchem. J. 2021, 164, 105973. [Google Scholar] [CrossRef]

- Rauwel, P.; Rauwel, E. Towards the Extraction of Radioactive Cesium-137 from Water via Graphene/CNT and Nanostructured Prussian Blue Hybrid Nanocomposites: A Review. Nanomaterials 2019, 9, 682. [Google Scholar] [CrossRef]

- Zhang, Y.; Niu, Q.; Gu, X.; Yang, N.; Zhao, G. Recent progress of carbon nanomaterials for electrochemical detection and removal of environmental pollutants. Nanoscale 2019, 11, 11992–12014. [Google Scholar] [CrossRef]

- Kumar, R.; Rauwel, P.; Rauwel, E. Nanoadsorbants for the Removal of Heavy Metals from Contaminated Water: Current Scenario and Future Directions. Processes 2021, 9, 1379. [Google Scholar] [CrossRef]

- Jha, V.K.; Nagae, M.; Matsuda, M.; Miyake, M. Zeolite formation from coal fly ash and heavy metal ion removal characteristics of thus–obtained Zeolite X in multi–metal systems. J. Environ. Manag. 2009, 90, 2507–2514. [Google Scholar] [CrossRef] [PubMed]

- Efome, J.E.; Rana, D.; Matsuura, T.; Lan, C.Q. Metal–organic frameworks supported on nanofibers to remove heavy metals. J. Mater. Chem. A 2018, 6, 4550–4555. [Google Scholar] [CrossRef]

- Yan, H.; Li, H.; Tao, X.; Li, K.; Yang, H.; Li, A.; Xiao, S.; Cheng, R. Rapid Removal and Separation of Iron(II) and Manganese(II) from Micropolluted Water Using Magnetic Graphene Oxide. ACS Appl. Mater. Interfaces 2014, 6, 9871–9880. [Google Scholar] [CrossRef]

- Bolisetty, S.; Peydayesh, M.; Mezzenga, R. Sustainable technologies for water purification from heavy metals: Review and analysis. Chem. Soc. Rev. 2019, 48, 463–487. [Google Scholar] [CrossRef]

- Zhao, W.; Chen, I.W.; Huang, F. Toward large–scale water treatment using nanomaterials. Nano Today 2019, 27, 11–27. [Google Scholar] [CrossRef]

- Kumar, R.; Rauwel, P.; Kriipsalu, M.; Wragg, D.; Rauwel, E. Nanocobalt based (Co@Co(OH)2) sand nanocomposite applied to manganese extraction from contaminated water. J. Environ. Chem. Eng. 2023, 11, 109818. [Google Scholar] [CrossRef]

- Kulpa–Koterwa, A.; Ossowski, T.; Niedziałkowski, P. Functionalized Fe3O4 Nanoparticles as Glassy Carbon Electrode Modifiers for Heavy Metal Ions Detection—A Mini Review. Materials 2021, 14, 7725. [Google Scholar] [CrossRef]

- Lisjak, D.; Mertelj, A. Anisotropic magnetic nanoparticles: A review of their properties, syntheses and potential applications. Prog. Mater. Sci. 2018, 95, 286–328. [Google Scholar] [CrossRef]

- Han, X.; Deng, Z.; Yang, Z.; Wang, Y.; Zhu, H.; Chen, B.; Cui, Z.; Ewing, R.; Shi, D. Biomarkerless targeting and photothermal cancer cell killing by surface–electrically–charged superparamagnetic Fe3O4 composite nanoparticles. Nanoscale 2017, 9, 1457–1465. [Google Scholar] [CrossRef]

- Young, K.L.; Xu, C.; Xie, J.; Sun, S. Conjugating methotrexate to magnetite (Fe3O4) nanoparticles via trichloro–s–triazine. J. Mater. Chem. 2009, 19, 6400–6406. [Google Scholar] [CrossRef]

- Liu, S.; Guo, S.; Sun, S.; You, X.Z. Dumbbell–like Au–Fe3O4 nanoparticles: A new nanostructure for supercapacitors. Nanoscale 2015, 7, 4890–4893. [Google Scholar] [CrossRef]

- Shi, X.; You, W.B.; Zhao, Y.; Li, X.; Shao, Z.; Che, R. Multi–scale magnetic coupling of Fe@SiO2@C–Ni yolk@triple–shell microsphere for broadband microwave absorption. Nanoscale 2019, 11, 17270–17276. [Google Scholar] [CrossRef]

- Ni, Q.; Chen, B.; Dong, S.; Tian, L.; Bai, Q. Preparation of core–shell structure Fe3O4@SiO2 superparamagnetic microspheres immoblized with iminodiacetic acid as immobilized metal ion affinity adsorbents for His–tag protein purification. Biomed. Chromatogr. 2015, 30, 566–573. [Google Scholar] [CrossRef]

- Jin, S.; Park, B.C.; Ham, W.S.; Pan, L.; Kim, Y.K. Effect of the magnetic core size of amino–functionalized Fe3O4–mesoporous SiO2 core–shell nanoparticles on the removal of heavy metal ions. Colloids Surf. A 2017, 531, 133–140. [Google Scholar] [CrossRef]

- Liu, Y.; Fu, R.; Sun, Y.; Zhou, X.; Baig, S.A.; Xu, X. Multifunctional nanocomposites Fe3O4@SiO2–EDTA for Pb(II) and Cu(II) removal from aqueous solutions. Appl. Surf. Sci. 2016, 369, 267–276. [Google Scholar] [CrossRef]

- Pogorilyi, R.; Pylypchuk, I.; Melnyk, I.; Zub, Y.; Seisenbaeva, G.; Kessler, V. Sol–gel derived adsorbents with enzymatic and complexonate functions for complex water remediation. Nanomaterials 2017, 7, 298. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.; Liu, J.; Xu, Q.; Xiao, H.; Wang, X.; Xu, H.; Zhou, J. Thiol modified Fe3O4@SiO2 as a robust, high effective, and recycling magnetic sorbent for mercury removal. Chem. Eng. J. 2013, 226, 30–38. [Google Scholar] [CrossRef]

- Chen, Y.; Xiong, Z.; Zhang, L.; Zhao, J.; Zhang, Q.; Peng, L.; Zhang, W.; Ye, M.; Zou, H. Facile synthesis of zwitterionic polymer–coated core–shell magnetic nanoparticles for highly specific capture of N–linked glycopeptides. Nanoscale 2015, 7, 3100–3108. [Google Scholar] [CrossRef]

- Li, S.; Li, N.; Yang, S.; Liu, F.; Zhou, J. The synthesis of a novel magnetic demulsifier and its application for the demulsification of oil–charged industrial wastewaters. J. Mater. Chem. A 2014, 2, 94–99. [Google Scholar] [CrossRef]

- Liu, G.; Cai, M.; Wang, X.; Zhou, F.; Liu, W. Core–shell–corona–structured polyelectrolyte brushes–grafting magnetic nanoparticles for water harvesting. ACS Appl. Mater. Inter. 2014, 6, 11625–11632. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.A.; Khan, I.A.; Siyal, M.I.; Lee, C.K.; Kim, J.O. Optimization of membrane modification using SiO2 for robust anti–fouling performance with calcium–humic acid feed in membrane distillation. Environ. Res. 2019, 170, 374–382. [Google Scholar] [CrossRef] [PubMed]

- Ruhi, G.; Bhandari, H.; Dhawan, S.K. Designing of corrosion resistant epoxy coatings embedded with polypyrrole/SiO2 composite. Prog. Org. Coat. 2014, 77, 1484–1498. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, J.; Pu, Z.; Zhao, Y.; Jia, D.; Chen, H.; Wen, T.; Hu, B.; Alsaedi, A.; Hayat, T.; et al. Synthesis of magnetic Fe3O4/CFA composites for the efficient removal of U(VI) from wastewater. Chem. Eng. J. 2017, 320, 448–457. [Google Scholar] [CrossRef]

- Duffy, E.; Mitev, D.P.; Thickett, S.C.; Townsend, A.T.; Paull, B.; Nesterenko, P.N. Assessing the extent, stability, purity and properties of silanised detonation nanodiamond. Appl. Surf. Sci. 2015, 357, 397–406. [Google Scholar] [CrossRef]

- Zhang, S.; Kai, C.; Liu, B.; Zhang, S.; Wei, W.; Xu, X.; Zhou, Z. Facile fabrication of cellulose membrane containing polyiodides and its antibacterial properties. Appl. Surf. Sci. 2020, 500, 144046.1–144046.6. [Google Scholar] [CrossRef]

- Karimi Shervedani, R.; Rezvaninia, Z.; Sabzyan, H. Oxinate–aluminum(III) nanostructure assemblies formed via in–situ and ex–situ oxination of gold–self–assembled monolayers characterized by electrochemical, attenuated total reflectance fourier transform infrared spectroscopy, and X–ray photoelectron spectroscopy methods. Electrochim. Acta 2015, 180, 722–736. [Google Scholar] [CrossRef]

- Beard, B.C. Cellulose nitrate as a binding energy reference in N(1s) XPS studies of nitrogen–containing organic molecules. Appl. Surf. Sci. 1990, 45, 221–227. [Google Scholar] [CrossRef]

- Liu, H.; Zhou, Y.; Yang, Y.; Zou, K.; Wu, R.; Xia, K.; Xie, S. Synthesis of polyethylenimine/graphene oxide for the adsorption of U(VI) from aqueous solution. Appl. Surf. Sci. 2019, 471, 88–95. [Google Scholar] [CrossRef]

- El–Rahman, H.A.A.; Schultze, J.W. New quaternized aminoquinoline polymer films: Electropolymerization and characterization. J. Electroanal. Chem. 1996, 416, 67–74. [Google Scholar] [CrossRef]

- Jackson, S. Determining hybridization differences for amorphous carbon from the XPS C 1s envelope. Appl. Surf. Sci. 1995, 90, 195–203. [Google Scholar] [CrossRef]

- Choi, S.J.; Kim, S.J.; Kim, I.D. Ultrafast optical reduction of graphene oxide sheets on colorless polyimide film for wearable chemical sensors. NPG Asia Mater. 2016, 8, e315. [Google Scholar] [CrossRef]

- Pan, N.; Li, L.; Ding, J.; Wang, R.; Jin, Y.; Xia, C. A schiff base/quaternary ammonium salt bifunctional graphene oxide as an efficient adsorbent for removal of Th(IV)/U(VI). J. Colloid Interface Sci. 2017, 508, 303–312. [Google Scholar] [CrossRef]

- Kosa, S.A.; Al–Zhrani, G.; Abdel Salam, M. Removal of heavy metals from aqueous solutions by multi–walled carbon nanotubes modified with 8–hydroxyquinoline. Chem. Eng. J. 2012, 181–182, 159–168. [Google Scholar] [CrossRef]

- Lv, Z.P.; Luan, Z.Z.; Cai, P.Y.; Wang, T.; Li, C.H.; Wu, D.; Zuo, J.L.; Sun, S. Enhancing magnetoresistance in tetrathiafulvalene carboxylate modified iron oxide nanoparticle assemblies. Nanoscale 2016, 8, 12128–12133. [Google Scholar] [CrossRef] [PubMed]

- Maneechakr, P.; Karnjanakom, S. Environmental surface chemistries and adsorption behaviors of metal cations (Fe3+, Fe2+, Ca2+ and Zn2+) on manganese dioxide–modified green biochar. RSC Adv. 2019, 9, 24074–24086. [Google Scholar] [CrossRef] [PubMed]

- Maneechakr, P.; Karnjanakom, S. The essential role of Fe(III) ion removal over efficient/low–cost activated carbon: Surface chemistry and adsorption behavior. Res. Chem. Intermed. 2019, 45, 4583–4605. [Google Scholar] [CrossRef]

- Liu, P.; Borrell, P.F.; Božič, M.; Kokol, V.; Oksman, K.; Mathew, A.P. Nanocelluloses and their phosphorylated derivatives for selective adsorption of Ag+, Cu2+ and Fe3+ from industrial effluents. J. Hazard. Mater. 2015, 294, 177–185. [Google Scholar] [CrossRef]

- Behbahani, E.S.; Dashtian, K.; Ghaedi, M. Fe3O4–FeMoS4: Promise magnetite LDH–based adsorbent for simultaneous removal of Pb (II), Cd (II), and Cu (II) heavy metal ions. J. Hazard. Mater. 2021, 410, 124560. [Google Scholar] [CrossRef]

- Cao, J.; Wang, P.; Shen, J.; Sun, Q. Core–shell Fe3O4@zeolite NaA as an adsorbent for Cu2+. Materials 2020, 13, 5047. [Google Scholar] [CrossRef]

- Panja, S.; Hanson, S.; Wang, C. EDTA–inspired polydentate hydrogels with exceptionally high heavy metal adsorption capacity as reusable adsorbents for wastewater purification. ACS Appl. Mater. Interfaces 2020, 12, 25276–25285. [Google Scholar] [CrossRef] [PubMed]

- Macedo, J.C.A.; Gontijo, E.S.J.; Herrera, S.G.; Rangel, E.C.; Komatsu, D.; Landers, R.; Rosa, A.H. Organosulphur–modified biochar: An effective green adsorbent for removing metal species in aquatic systems. Surf. Interfaces 2021, 22, 100822. [Google Scholar] [CrossRef]

- Dias, D.; Bernardo, M.; Matos, I.; Fonseca, I.; Pinto, F.; Lapa, N. Activation of co–pyrolysis chars from rice wastes to improve the removal of Cr3+ from simulated and real industrial wastewaters. J. Clean. Prod. 2020, 267, 121993. [Google Scholar] [CrossRef]

- Deraeve, C.; Maraval, A.; Vendier, L.; Faugeroux, V.; Pitié, M.; Meunier, B. Preparation of new bis(8–aminoquinoline) ligands and comparison with bis(8–hydroxyquinoline) ligands on their ability to chelate CuII and ZnII, Eur. J. Inorg. Chem. 2008, 2008, 5622–5631. [Google Scholar] [CrossRef]

- Huang, J.; Xu, Y.; Qian, X. Rhodamine–based fluorescent off–on sensor for Fe3+–in aqueous solution and in living cells: 8–aminoquinoline receptor and 2:1 binding. Dalton Trans. 2014, 43, 5983–5989. [Google Scholar] [CrossRef] [PubMed]

- Mirzaei, M.; Eshtiagh–Hosseini, H.; Bolouri, Z.; Rahmati, Z.; Esmaeilzadeh, A.; Hassanpoor, A.; Bauza, A.; Ballester, P.; Mague, J.T.; Notash, B.; et al. Rationalization of noncovalent interactions within six new MII/8–aminoquinoline supramolecular complexes (MII = Mn, Cu, and Cd): A combined experimental and theoretical DFT study. Cryst. Growth Des. 2015, 15, 1351–1361. [Google Scholar] [CrossRef]

- Langmuir, I. The adsorption of gases on plane surfaces of glass, mica and platinum. J. Am. Chem. Soc. 1918, 40, 1361–1403. [Google Scholar] [CrossRef]

- Freundlich, H. Uber die adsorption in lo sungen. J. Phys. Chem. 1907, 57, 385–470. [Google Scholar] [CrossRef]

- Das, S.; Mishra, S. Insight into the isotherm modelling, kinetic and thermodynamic exploration of iron adsorption from aqueous media by activated carbon developed from Limonia acidissima shell. Mater. Chem. Phys. 2020, 245, 122751. [Google Scholar] [CrossRef]

- Schiewer, S.; Patil, S.B. Pectin–rich fruit wastes as biosorbents for heavy metal removal: Equilibrium and kinetics. Bioresour. Technol. 2008, 99, 1896–1903. [Google Scholar] [CrossRef]

| Langmuir Isotherm Model | |||

|---|---|---|---|

| Parameters | qm (mg/g) | KL | R2 |

| Fe3+ | 324.7 | 0.7016 | 0.9997 |

| Cu2+ | 306.8 | 0.6981 | 0.9988 |

| Cr3+ | 293.3 | 0.7894 | 0.9990 |

| Adsorbent | HMIs | Adsorption Capacity (qm, mg/g) | Reference |

|---|---|---|---|

| Manganese dioxide–modified biochar | Fe3+ | 52.39 | [47] |

| Activated biochars prepared by leucaena leucocephala | Fe3+ | 32.89 | [48] |

| Phosphorylated nanocellulose (Phos–CNCSL) | Fe3+ | 115 | [49] |

| Cu2+ | 117 | ||

| Fe3O4/FeMoS4/MgAl–LDH nanocomposite | Cu2+ | 108.28 | [50] |

| Core–shell magnetic Fe3O4@zeolite NaA | Cu2+ | 86.54 | [51] |

| EDTA–inspired polydentate hydrogels | Cu2+ | 436.5 | [52] |

| Cr3+ | 340.6 | ||

| Organosulphur–modified biochar | Cr3+ | 35.2 | [53] |

| Porous carbon materials derived from rice wastes | Cr3+ | 9.23 | [54] |

| MSNPs–CAAQ nanocomposite | Fe3+ | 324.7 | This work |

| Cu2+ | 306.8 | ||

| Cr3+ | 293.3 |

| Van’t Hoff Thermodynamic Equation | |||

|---|---|---|---|

| Parameters | ΔH0 (KJ/mol) | ΔS0 (J/mol·K) | R2 |

| 2.31 | 45.00 | 0.9993 | |

| Kinetic Model | Pseudo–First–Order | Pseudo–Second–Order | ||||

|---|---|---|---|---|---|---|

| Parameters | qe1,cal (mg/g) | K1 (1/h) | R2 | qe2,cal (mg/g) | K1 (g/mg·h) | R2 |

| 93.61 | 1.8801 | 0.9841 | 206.61 | 0.03839 | 0.9989 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Li, Y.; Ding, Z. Network–Polymer–Modified Superparamagnetic Magnetic Silica Nanoparticles for the Adsorption and Regeneration of Heavy Metal Ions. Molecules 2023, 28, 7385. https://doi.org/10.3390/molecules28217385

Xu Y, Li Y, Ding Z. Network–Polymer–Modified Superparamagnetic Magnetic Silica Nanoparticles for the Adsorption and Regeneration of Heavy Metal Ions. Molecules. 2023; 28(21):7385. https://doi.org/10.3390/molecules28217385

Chicago/Turabian StyleXu, Yaohui, Yuting Li, and Zhao Ding. 2023. "Network–Polymer–Modified Superparamagnetic Magnetic Silica Nanoparticles for the Adsorption and Regeneration of Heavy Metal Ions" Molecules 28, no. 21: 7385. https://doi.org/10.3390/molecules28217385

APA StyleXu, Y., Li, Y., & Ding, Z. (2023). Network–Polymer–Modified Superparamagnetic Magnetic Silica Nanoparticles for the Adsorption and Regeneration of Heavy Metal Ions. Molecules, 28(21), 7385. https://doi.org/10.3390/molecules28217385