Sweet-Potato-Vine-Based High-Performance Porous Carbon for Methylene Blue Adsorption

Abstract

1. Introduction

2. Results and Discussion

2.1. Preparation Parameters of SPVPC

2.2. Physicochemical Properties of SPVPC

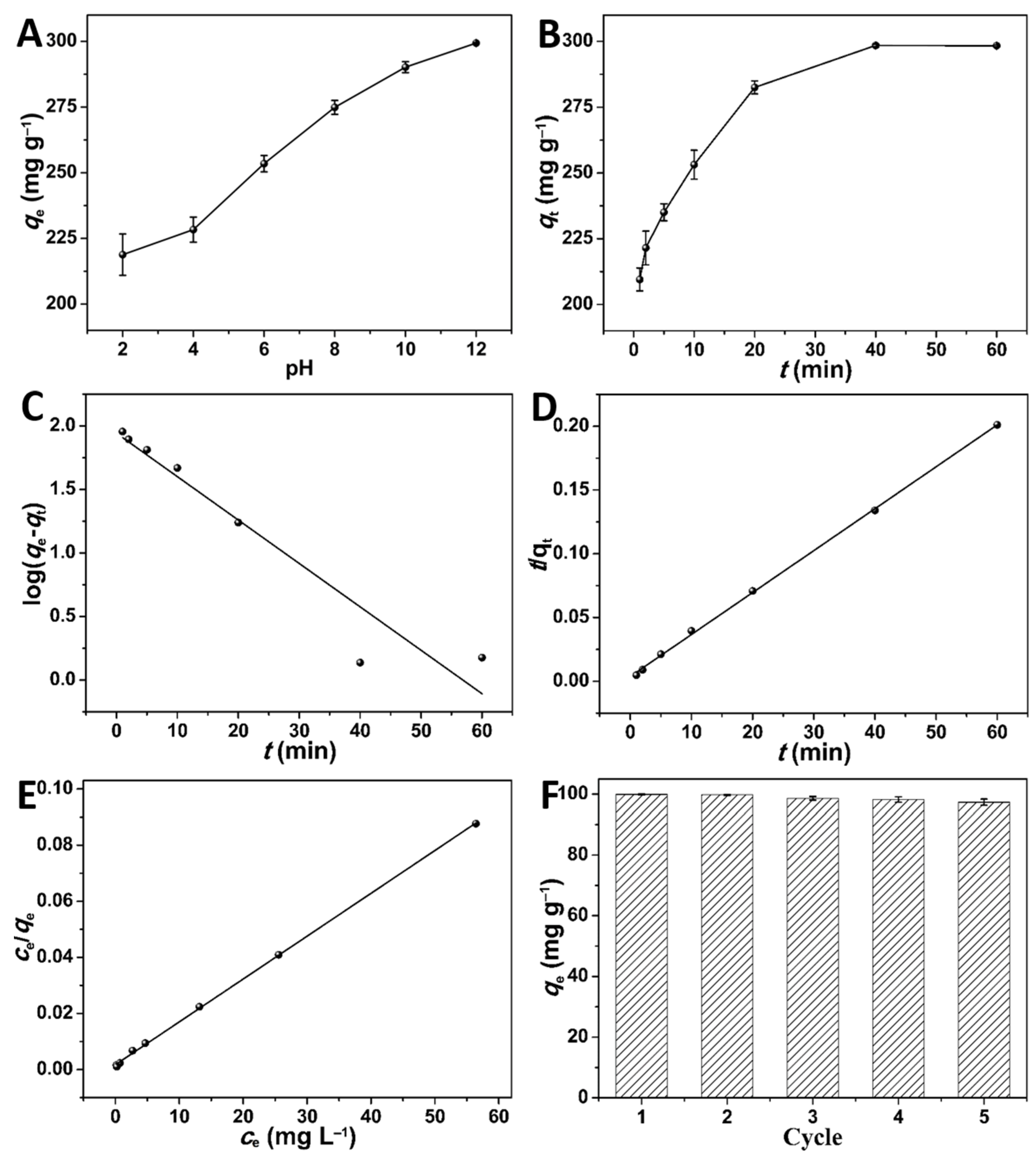

2.3. Adsorption and Reusability Properties of SPVPC

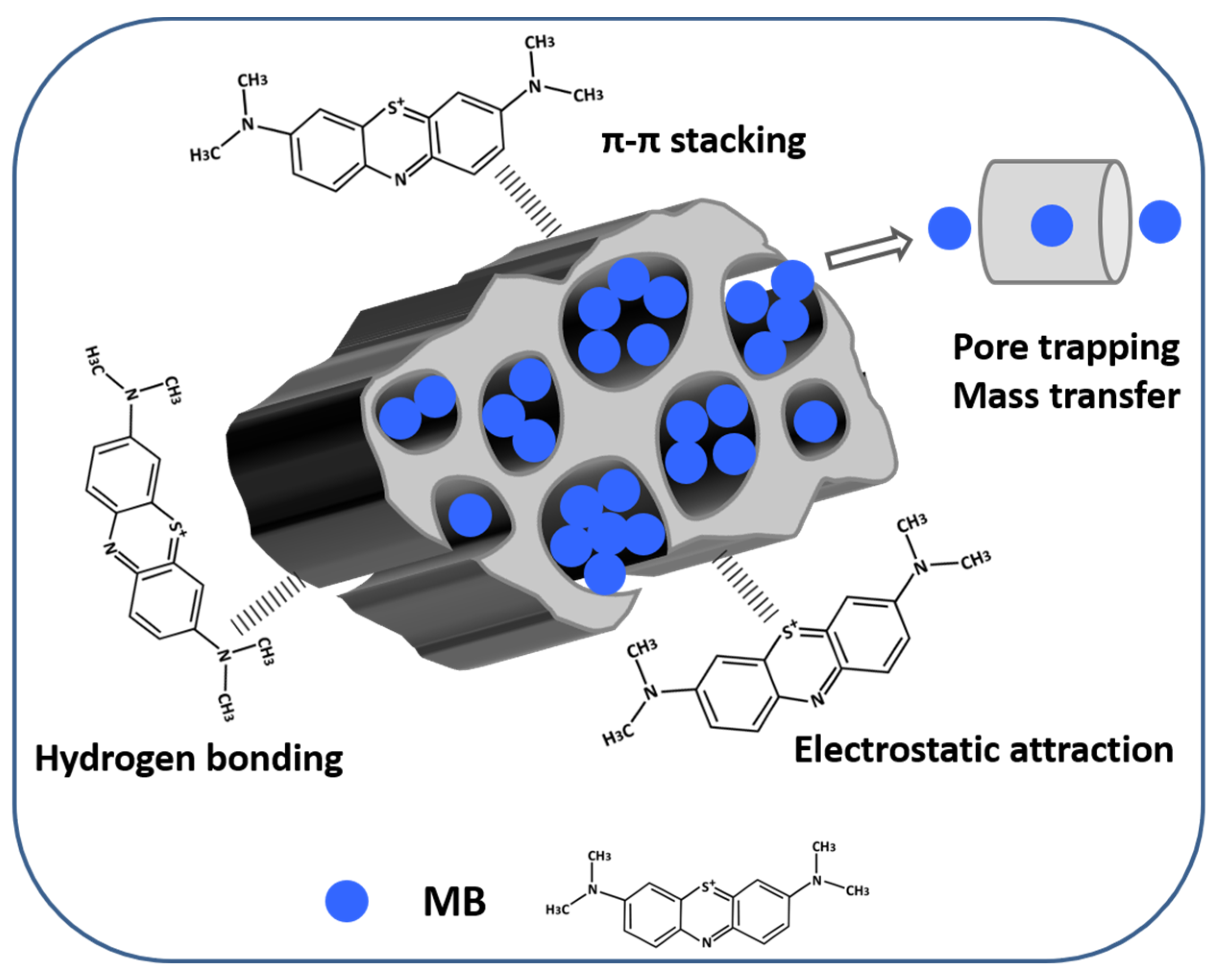

2.4. Adsorption Mechanism of SPVPC towards MB

3. Materials and Methods

3.1. Materials

3.2. Preparation of SPVPC

3.3. Characterisations of SPVPC

3.4. Adsorption of SPVPC

3.5. Reusability of SPVPC

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tan, Y.; Wang, X.; Xiong, F.; Ding, J.; Qing, Y.; Wu, Y. Preparation of lignin-based porous carbon as an efficient absorbent for the removal of methylene blue. Ind. Crop. Prod. 2021, 171, 113980. [Google Scholar] [CrossRef]

- Luo, L.; Wu, X.; Li, Z.; Zhou, Y.; Chen, T.; Fan, M.; Zhao, W. Synthesis of activated carbon from biowaste of fir bark for methylene blue removal. R. Soc. Open Sci. 2019, 6, 190523. [Google Scholar] [CrossRef]

- Charola, S.; Patel, H.; Chandna, S.; Maiti, S. Optimization to prepare porous carbon from mustard husk using response surface methodology adopted with central composite design. J. Clean. Prod. 2019, 223, 969–979. [Google Scholar] [CrossRef]

- Zhao, H.; Zhong, H.; Jiang, Y.; Li, H.; Tang, P.; Li, D.; Feng, Y. Porous ZnCl2-activated carbon from shaddock peel: Methylene blue adsorption behavior. Materials 2022, 15, 895. [Google Scholar] [CrossRef]

- Sharma, K.; Sharma, S.; Sharma, V.; Mishra, P.K.; Ekielski, A.; Sharma, V.; Kumar, V. Methylene blue dye adsorption from wastewater using hydroxyapatite/gold nanocomposite: Kinetic and thermodynamics studies. Nanomaterials 2021, 11, 1403. [Google Scholar] [CrossRef]

- Zhang, N.; Cheng, N.; Liu, Q. Functionalized biomass carbon-based adsorbent for simultaneous removal of Pb2+ and MB in wastewater. Materials 2021, 14, 3537. [Google Scholar] [CrossRef]

- Katheresan, V.; Kansedo, J.; Lau, S.Y. Efficiency of various recent wastewater dye removal methods: A review. J. Environ. Chem. Eng. 2018, 6, 4676–4697. [Google Scholar] [CrossRef]

- Badawi, A.K.; Abd Elkodous, M.; Ali, G.A. Recent advances in dye and metal ion removal using efficient adsorbents and novel nano-based materials: An overview. RSC Adv. 2021, 11, 36528–36553. [Google Scholar] [CrossRef]

- ben Mosbah, M.; Mechi, L.; Khiari, R.; Moussaoui, Y. Current state of porous carbon for wastewater treatment. Processes 2020, 8, 1651. [Google Scholar] [CrossRef]

- Wu, Z.; Meng, Z.; Yao, C.; Deng, Y.; Zhang, G.; Wang, Y. Rice husk derived hierarchical porous carbon with lightweight and efficient microwave absorption. Mater. Chem. Phys. 2022, 275, 125246. [Google Scholar] [CrossRef]

- Sharma, P.; Singh, D.; Minakshi, M.; Quadsia, S.; Ahuja, R. Activation-induced surface modulation of biowaste-derived hierarchical porous carbon for supercapacitors. ChemPlusChem 2022, 87, e202200126. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, M.; Zhao, Y.; Liao, Q. Facile preparation of porous carbon derived from pomelo peel for efficient adsorption of methylene blue. Molecules 2022, 27, 3096. [Google Scholar] [CrossRef]

- Tian, J.; Zhang, T.; Talifu, D.; Abulizi, A.; Ji, Y. Porous carbon materials derived from waste cotton stalk with ultra-high surface area for high performance supercapacitors. Mater. Res. Bull. 2021, 143, 111457. [Google Scholar] [CrossRef]

- Deng, Q.; Liu, H.; Zhou, Y.; Luo, Z.; Wang, Y.; Zhao, Z.; Yang, R. N-doped three-dimensional porous carbon materials derived from bagasse biomass as an anode material for K-ion batteries. J. Electroanal. Chem. 2021, 899, 115668. [Google Scholar] [CrossRef]

- Matsagar, B.M.; Yang, R.X.; Dutta, S.; Ok, Y.S.; Wu, K.C.W. Recent progress in the development of biomass-derived nitrogen-doped porous carbon. J. Mater. Chem. A 2021, 9, 3703–3728. [Google Scholar] [CrossRef]

- Jo, Y.; Kim, S.M.; Choi, H.; Yang, J.W.; Lee, B.C.; Cho, W.K. Sweet potato viromes in eight different geographical regions in Korea and two different cultivars. Sci. Rep. 2020, 10, 1–16. [Google Scholar] [CrossRef]

- Dai, T.; Wang, J.; Dong, D.; Yin, X.; Zong, C.; Jia, Y.; Shao, T. Effects of brewers’ spent grains on fermentation quality, chemical composition and in vitro digestibility of mixed silage prepared with corn stalk, dried apple pomace and sweet potato vine. Ital. J. Anim. Sci. 2022, 21, 198–207. [Google Scholar] [CrossRef]

- Wang, T.; Dong, X.; Jin, Z.; Su, W.; Ye, X.; Dong, C.; Lu, Q. Pyrolytic characteristics of sweet potato vine. Bioresour. Technol. 2015, 192, 799–801. [Google Scholar] [CrossRef]

- Gao, S.; Li, L.; Geng, K.; Wei, X.; Zhang, S. Recycling the biowaste to produce nitrogen and sulfur self-doped porous carbon as an efficient catalyst for oxygen reduction reaction. Nano Energy 2015, 16, 408–418. [Google Scholar] [CrossRef]

- Angin, D. Production and characterization of activated carbon from sour cherry stones by zinc chloride. Fuel 2014, 115, 804–811. [Google Scholar] [CrossRef]

- Liu, J.; Li, H.; Zhang, H.; Liu, Q.; Li, R.; Li, B.; Wang, J. Three-dimensional hierarchical and interconnected honeycomb-like porous carbon derived from pomelo peel for high performance supercapacitors. J. Solid State Chem. 2018, 257, 64–71. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, L.Y.; Zhao, X.J.; Zhou, Z. Citrus pectin derived porous carbons as a superior adsorbent toward removal of methylene blue. J. Solid State Chem. 2016, 243, 101–105. [Google Scholar] [CrossRef]

- Zheng, J.; Yan, B.; Feng, L.; Zhang, Q.; Zhang, C.; Yang, W.; Han, J.; Jiang, S.; He, S. Potassium citrate assisted synthesis of hierarchical porous carbon materials for high performance supercapacitors. Diam. Relat. Mater. 2022, 128, 109247. [Google Scholar] [CrossRef]

- Vafaeinia, M.; Khosrowshahi, M.S.; Mashhadimoslem, H.; Emrooz, H.B.M.; Ghaemi, A. Oxygen and nitrogen enriched pectin-derived micro-meso porous carbon for CO2 uptake. RSC Adv. 2022, 12, 546–560. [Google Scholar] [CrossRef]

- Miao, Q.; Xu, Y.; Kang, R.; Peng, H. Foaming waste wine yeast mud into nitrogen doped porous carbon framework by recyclable activator for high specific energy supercapacitor. J. Energy Storage 2022, 55, 105590. [Google Scholar] [CrossRef]

- Zhu, G.; Liu, Q.; Cao, F.; Qin, Q.; Jiao, M. Silkworm cocoon derived N, O-codoped hierarchical porous carbon with ultrahigh specific surface area for efficient capture of methylene blue with exceptionally high uptake: Kinetics, isotherm, and thermodynamics. RSC Adv. 2019, 9, 33872–33882. [Google Scholar] [CrossRef]

- Guo, H.; Li, Y.; Wang, C.; He, L.; Li, C.; Guo, Y.; Zhou, Y. Effect of the air oxidation stabilization of pitch on the microstructure and sodium storage of hard carbons. New Carbon Mater. 2021, 36, 1073–1078. [Google Scholar] [CrossRef]

- Zhang, S.; Zeng, M.; Li, J.; Li, J.; Xu, J.; Wang, X. Porous magnetic carbon sheets from biomass as an adsorbent for the fast removal of organic pollutants from aqueous solution. J. Mater. Chem. A 2014, 2, 4391–4397. [Google Scholar] [CrossRef]

- Cheng, S.; Zhang, L.; Ma, A.; Xia, H.; Peng, J.; Li, C.; Shu, J. Comparison of activated carbon and iron/cerium modified activated carbon to remove methylene blue from wastewater. J. Environ. Sci. 2018, 65, 92–102. [Google Scholar] [CrossRef]

- Zhang, Y.; Ji, G.; Li, C.; Wang, X.; Li, A. Templating synthesis of hierarchical porous carbon from heavy residue of tire pyrolysis oil for methylene blue removal. Chem. Eng. J. 2020, 390, 124398. [Google Scholar] [CrossRef]

- Hao, Y.; Wang, Z.; Wang, Z.; He, Y. Preparation of hierarchically porous carbon from cellulose as highly efficient adsorbent for the removal of organic dyes from aqueous solutions. Ecotox. Environ. Safe. 2019, 168, 298–303. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Li, H.; Tang, J.; Lu, H.; Liu, Y. Ginger straw waste-derived porous carbons as effective adsorbents toward methylene blue. Molecules 2019, 24, 469. [Google Scholar] [CrossRef] [PubMed]

- Jawad, A.H.; Abdulhameed, A.S.; Wilson, L.D.; Syed-Hassan, S.S.A.; ALOthman, Z.A.; Khan, M.R. High surface area and mesoporous activated carbon from KOH-activated dragon fruit peels for methylene blue dye adsorption: Optimization and mechanism study. Chin. J. Chem. Eng. 2021, 32, 281–290. [Google Scholar] [CrossRef]

- Chen, S.; Chen, G.; Chen, H.; Sun, Y.; Yu, X.; Su, Y.; Tang, S. Preparation of porous carbon-based material from corn straw via mixed alkali and its application for removal of dye. Colloids Surfaces A 2019, 568, 173–183. [Google Scholar] [CrossRef]

- Novais, R.M.; Caetano, A.P.; Seabra, M.P.; Labrincha, J.A.; Pullar, R.C. Extremely fast and efficient methylene blue adsorption using eco-friendly cork and paper waste-based activated carbon adsorbents. J. Clean. Prod. 2018, 197, 1137–1147. [Google Scholar] [CrossRef]

- Bedin, K.C.; Souza, I.P.; Cazetta, A.L.; Spessato, L.; Ronix, A.; Almeida, V.C. CO2-spherical activated carbon as a new adsorbent for methylene blue removal: Kinetic, equilibrium and thermodynamic studies. J. Mol. Liq. 2018, 269, 132–139. [Google Scholar] [CrossRef]

- Lonappan, L.; Rouissi, T.; Das, R.K.; Brar, S.K.; Ramirez, A.A.; Verma, M.; Surampalli, R.Y.; Valero, J.R. Adsorption of methylene blue on biochar microparticles derived from different waste materials. Waste Manag. 2016, 49, 537–544. [Google Scholar] [CrossRef] [PubMed]

- Hua, Y.; Xiao, J.; Zhang, Q.; Cui, C.; Wang, C. Facile synthesis of surface-functionalized magnetic nanocomposites for effectively selective adsorption of cationic dyes. Nanoscale Res. Lett. 2018, 13, 99. [Google Scholar] [CrossRef]

- Xing, Y.; Liu, D.; Zhang, L.-P. Enhanced adsorption of Methylene Blue by EDTAD-modified sugarcane bagasse and photocatalytic regeneration of the adsorbent. Desalination 2010, 259, 187–191. [Google Scholar] [CrossRef]

- Qiao, X.-Q.; Hu, F.-C.; Tian, F.-Y.; Hou, D.-F.; Li, D.-S. Equilibrium and kinetic studies on MB adsorption by ultrathin 2D MoS2nanosheets. RSC Adv. 2016, 6, 11631–11636. [Google Scholar] [CrossRef]

- Bentahar, S.; Dbik, A.; El Khomri, M.; El Messaoudi, N.; Lacherai, A. Adsorption of methylene blue, crystal violet and congo red from binary and ternary systems with natural clay: Kinetic, isotherm, and thermodynamic. J. Environ. Chem. Eng. 2017, 5, 5921–5932. [Google Scholar] [CrossRef]

- Bradder, P.; Ling, S.K.; Wang, S.; Liu, S. Dye Adsorption on Layered Graphite Oxide. J. Chem. Eng. Data 2011, 56, 138–141. [Google Scholar] [CrossRef]

- Ji, Y.; Xu, F.; Wei, W.; Gao, H.; Zhang, K.; Zhang, G.; Xu, Y.; Zhang, P. Efficient and fast adsorption of methylene blue dye onto a nanosheet MFI zeolite. J. Solid State Chem. 2021, 295, 121917. [Google Scholar] [CrossRef]

- Sun, Z.; Qu, K.; Cheng, Y.; You, Y.; Huang, Z.; Umar, A.; Ibrahim, Y.S.A.; Algadi, H.; Castañeda, L.; Colorado, H.A.; et al. Corncob-derived Activated Carbon for Efficiently Adsorption Dye in Sewage. ES Food Agrofor. 2021, 4, 61–73. [Google Scholar] [CrossRef]

- Fan, X.; Wang, X.; Cai, Y.; Xie, H.; Han, S.; Hao, C. Functionalized cotton charcoal/chitosan biomass-based hydrogel for capturing Pb2+, Cu2+ and MB. J. Hazard. Mater. 2022, 423, 127191. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Zhao, Y.; Liao, Q.; Li, Z.; Jue, D.; Tang, J. Sweet-Potato-Vine-Based High-Performance Porous Carbon for Methylene Blue Adsorption. Molecules 2023, 28, 819. https://doi.org/10.3390/molecules28020819

Zhang W, Zhao Y, Liao Q, Li Z, Jue D, Tang J. Sweet-Potato-Vine-Based High-Performance Porous Carbon for Methylene Blue Adsorption. Molecules. 2023; 28(2):819. https://doi.org/10.3390/molecules28020819

Chicago/Turabian StyleZhang, Wenlin, Yuhong Zhao, Qinhong Liao, Zhexin Li, Dengwei Jue, and Jianmin Tang. 2023. "Sweet-Potato-Vine-Based High-Performance Porous Carbon for Methylene Blue Adsorption" Molecules 28, no. 2: 819. https://doi.org/10.3390/molecules28020819

APA StyleZhang, W., Zhao, Y., Liao, Q., Li, Z., Jue, D., & Tang, J. (2023). Sweet-Potato-Vine-Based High-Performance Porous Carbon for Methylene Blue Adsorption. Molecules, 28(2), 819. https://doi.org/10.3390/molecules28020819