Enhanced Performance of Flexible Organic Photovoltaics Based on MoS2 Micro-Nano Array

Abstract

1. Introduction

2. Results and Discussion

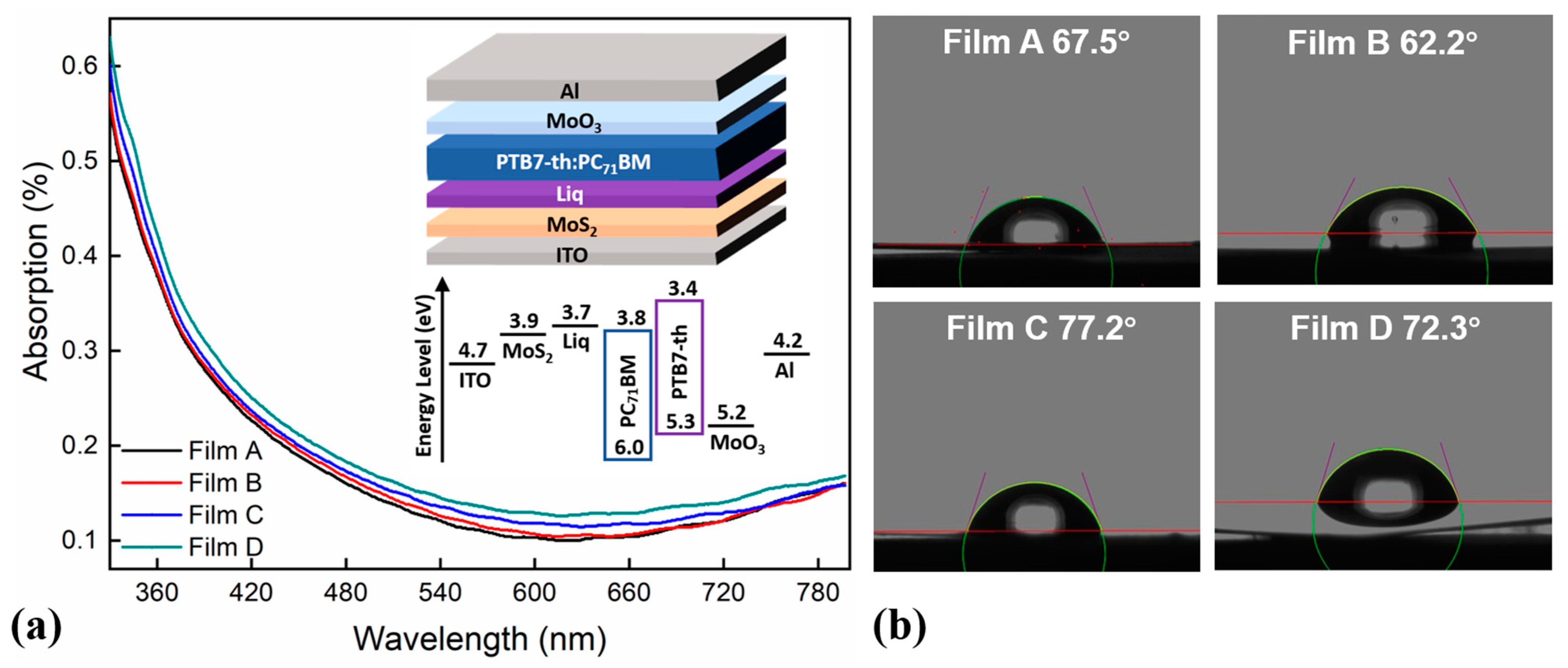

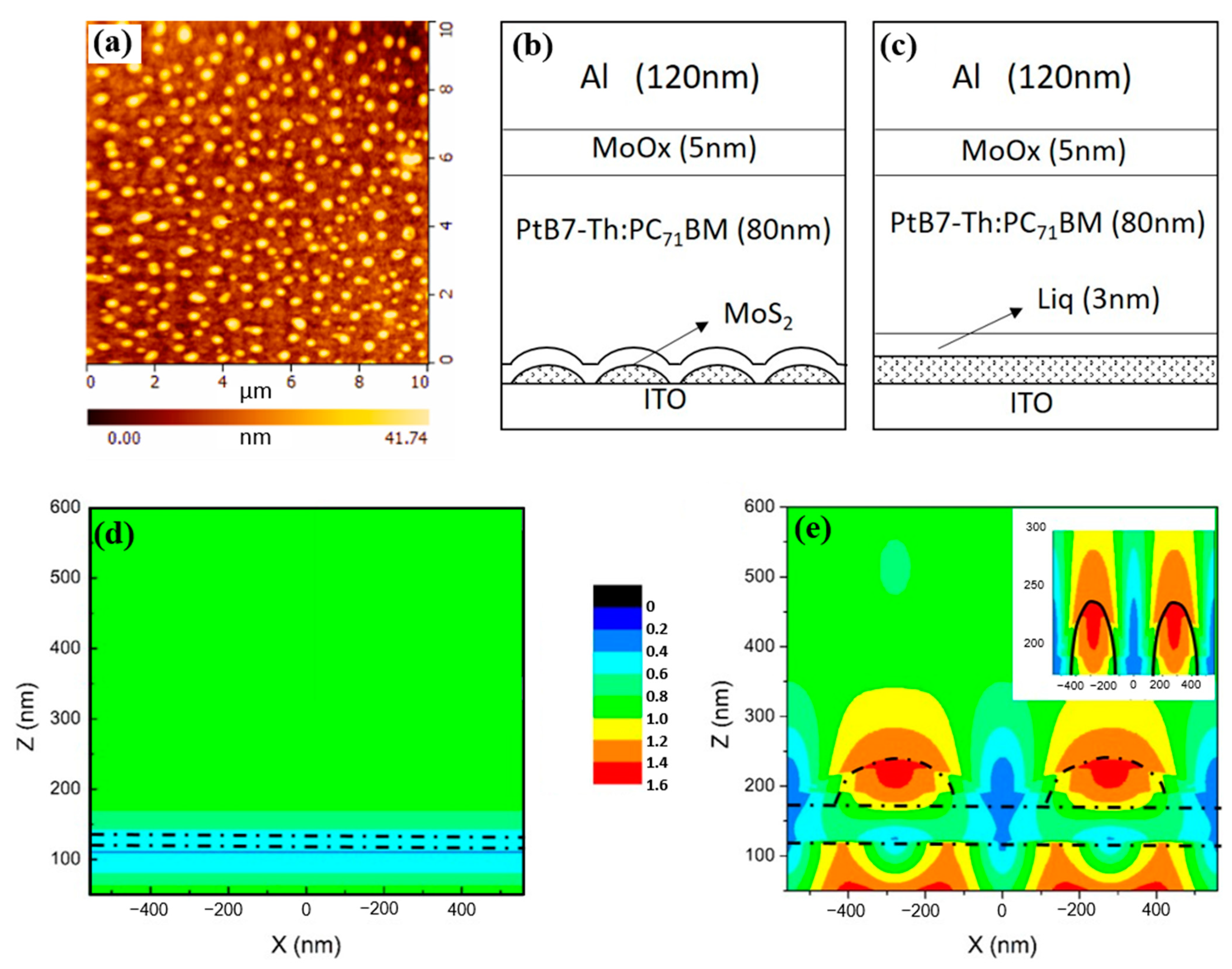

2.1. Characterization of the ETLs

2.2. Effect of Difference ETLs on the Performance of FOPVs

2.3. Performance of FOPV with Different Illumination and Bending Angles

3. Experimental Section

3.1. Materials and Device Fabrication

3.2. Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Xu, G.; Hu, X.; Liao, X.; Chen, Y. Bending-stability Interfacial Layer as Dual Electron Transport Layer for Flexible Organic Photovoltaics. Chin. J. Polym. Sci. 2021, 39, 1441–1447. [Google Scholar] [CrossRef]

- Park, Y.; Berger, J.; Tang, Z.; Mueller-Meskamp, L.; Lasagni, A.F.; Vandewal, K.; Leo, K. Optical display film as flexible and light trapping substrate for organic photovoltaics. Appl. Phys. Lett. 2016, 109, 093301. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, J.; Zhang, C.; Sun, M.; Han, S.; Zhang, R.; Liang, N.; Sun, D.; Liu, H. Energy-efficient, fully flexible, high-performance tactile sensor based on piezotronic effect: Piezoelectric signal amplified with organic field-effect transistors. Nano Energy 2020, 76, 105050. [Google Scholar] [CrossRef]

- Chai, Z.; Abbasi, S.A.; Busnaina, A.A. Solution-processed organic field-effect transistors using directed assembled carbon nanotubes and 2, 7-dioctyl [1] benzothieno [3, 2-b][1] benzothiophene (C8-BTBT). Nanotechnology 2019, 30, 485203. [Google Scholar] [CrossRef]

- Liu, J.; Li, P.; Chen, Y.; Song, X.; Qi, F.; Zheng, B.; He, J.; Wen, Q.; Zhang, W. Graphene field effect transistor-based terahertz modulator with small operating voltage and low insertion loss. Chin. Opt. Lett. 2016, 14, 052301. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Wang, T.; Liu, S.; Chen, Z.; Duan, S. Low-temperature nanowelding silver nanowire hybrid flexible transparent conductive film for green light OLED devices. Nanotechnology 2022, 33, 455201. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, M.; Jiao, B.; Lu, W.; Xu, D.; Huang, L.; Hou, X.; Wu, Z. Smooth and mechanically robust random metallic mesh electrode modified by thermally transferred PEDOT: PSS for ITO-Free flexible organic light-emitting diodes. Org. Electron. 2022, 106, 106498. [Google Scholar] [CrossRef]

- Kovrov, A.; Helgesen, M.; Boeffel, C.; Kroepke, S.; Sondergaard, R.R. Novel acrylic monomers for organic photovoltaics encapsulation. Sol. Energy Mater. Sol. Cells 2020, 204, 110210. [Google Scholar] [CrossRef]

- Zhou, W.; Chen, J.; Li, Y.; Wang, D.; Chen, J.; Feng, X.; Huang, Z.; Liu, R.; Lin, X.; Zhang, H.; et al. Copper mesh templated by breath-figure polymer films as flexible transparent electrodes for organic photovoltaic devices. ACS Appl. Mater. Interfaces 2016, 8, 11122–11127. [Google Scholar] [CrossRef]

- Wang, X.; Xiao, C.; Sun, X.; Saparbaev, A.; Lei, S.; Zhang, M.; Zhong, T.; Li, Z.; Zhang, J.; Zhang, M.; et al. Hammer throw-liked hybrid cyclic and alkyl chains: A new side chain engineering for over 18% efficiency organic solar cells. Nano Energy 2022, 101, 107538. [Google Scholar] [CrossRef]

- Wang, J.; Cui, Y.; Xu, Y.; Xian, K.; Bi, P.; Chen, Z.; Zhou, K.; Ma, L.; Zhang, T.; Yang, Y.; et al. A New Polymer Donor Enables Binary All-Polymer Organic Photovoltaic Cells with 18% Efficiency and Excellent Mechanical Robustness. Adv. Mater. 2022, 34, 2205009. [Google Scholar] [CrossRef] [PubMed]

- Kushto, G.P.; Kim, W.H.; Kafafi, Z.H. Flexible organic photovoltaics using conducting polymer electrodes. Appl. Phys. Lett. 2005, 86, 093502. [Google Scholar] [CrossRef]

- Yambem, S.D.; Liao, K.-S.; Curran, S.A. Flexible Ag electrode for use in organic photovoltaics. Sol. Energy Mater. Sol. Cells 2011, 95, 3060–3064. [Google Scholar] [CrossRef]

- Sun, Y.; Chang, M.; Meng, L.; Wan, X.; Gao, H.; Zhang, Y.; Zhao, K.; Sun, Z.; Li, C.; Liu, S.; et al. Flexible organic photovoltaics based on water-processed silver nanowire electrodes. Nat. Electron. 2019, 2, 513–520. [Google Scholar] [CrossRef]

- Sun, Y.; Meng, L.; Wan, X.; Guo, Z.; Ke, X.; Sun, Z.; Zhao, K.; Zhang, H.; Li, C.; Chen, Y. Flexible High-Performance and Solution-Processed Organic Photovoltaics with Robust Mechanical Stability. Adv. Funct. Mater. 2021, 31, 2010000. [Google Scholar] [CrossRef]

- Zhang, D.; Alami, A.H.; Choy, W.C.H. Recent Progress on Emerging Transparent Metallic Electrodes for Flexible Organic and Perovskite Photovoltaics. Sol. RRL 2022, 6, 2100830. [Google Scholar] [CrossRef]

- Kim, J.W.; Yuk, D.; Lee, W.; Rasool, S.; Kim, J.Y. Flexible organic photovoltaics with colorful semi-transparent metal/dielectric/metal top electrode. ESC J. Solid State Sci. Technol. 2021, 10, 065007. [Google Scholar] [CrossRef]

- Wen, X.; Yi, F.; Ji, J.; Bi, Y.; Zhang, W.; Wang, W. S-1805/Ag/Au Hybrid Transparent Electrodes for ITO-free Flexible Organic Photovoltaics. Chem. Res. Chin. Univ. 2019, 35, 509–513. [Google Scholar] [CrossRef]

- Park, Y.; Nehm, F.; Mueller-Meskamp, L.; Vandewal, K.; Leo, K. Optical display film as flexible and light trapping substrate for organic photovoltaics. Opt. Express 2016, 24, 1–7. [Google Scholar] [CrossRef]

- Wang, X.; Jin, H.; Nagiri, R.C.R.; Poliquit, B.Z.L.; Subbiah, J.; Jones, D.J.; Kopidakis, N.; Burn, P.L.; Yu, J. Flexible ITO-free organic photovoltaics on ultra-thin flexible glass substrates with high efficiency and improved stability. Sol. RRL 2019, 3, 1800286. [Google Scholar] [CrossRef]

- Chen, S.; Dai, Y.; Zhao, D.; Zhang, H. ITO-free flexible organic photovoltaics with multilayer MoO3/LiF/MoO3/Ag/MoO3 as the transparent electrode. Semicond. Sci. Technol. 2016, 31, 055013. [Google Scholar] [CrossRef]

- Kwon, H.-C.; Jeong, W.; Lee, Y.S.; Jang, J.H.; Jeong, H.S.; Kim, S.; Song, D.; Park, A.; Noh, E.; Lee, K.; et al. Overcoming the Low-Surface-Energy-Induced Wettability Problem of Flexible and Transparent Electrodes for Large-Area Organic Photovoltaic Modules over 500 cm2. Adv. Energy Mater. 2022, 12, 2200023. [Google Scholar] [CrossRef]

- Haldar, A.; Liao, K.-S.; Curran, S.A. Fabrication of inkjet printed organic photovoltaics on flexible Ag electrode with additives. Sol. Energy Mater. Sol. Cells 2014, 125, 283–290. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, C.; Xu, F.; Du, H. Performance in Emerging Technology of Printed and Flexible Organic Photovoltaics. J. Nanosci. Nanotechnol. 2016, 16, 12507–12516. [Google Scholar] [CrossRef]

- Chen, N.; Kovacik, P.; Howden, R.M.; Wang, X.; Lee, S.; Gleason, K.K. Low substrate temperature encapsulation for flexible electrodes and organic photovoltaics. Adv. Energy Mater. 2015, 5, 1401442. [Google Scholar] [CrossRef]

- Park, S.; Heo, S.W.; Lee, W.; Inoue, D.; Jiang, Z.; Yu, K.; Jinno, H.; Hashizume, D.; Sekino, M.; Yokota, T.; et al. Self-powered ultra-flexible electronics via nano-grating-patterned organic photovoltaics. Nature 2018, 561, 516. [Google Scholar] [CrossRef]

- Al-Ahmad, A.; Vaughan, B.; Holdsworth, J.; Belcher, W.; Zhou, X.; Dastoor, P. The Role of the Electron Transport Layer in the Degradation of Organic Photovoltaic Cells. Coatings 2022, 12, 1071. [Google Scholar] [CrossRef]

- Lin, C.-T.; Hsieh, C.T.; Macdonald, T.J.; Chang, J.F.; Lin, P.C.; Cha, H.; Steier, L.; Wadsworth, A.; McCulloch, I.; Chueh, C.C.; et al. Water-Insensitive Electron Transport and Photoactive Layers for Improved Underwater Stability of Organic Photovoltaics. Adv. Funct. Mater. 2022, 32, 2203487. [Google Scholar] [CrossRef]

- Dong, Y.; Yu, R.; Zhao, B.; Gong, Y.; Jia, H.; Ma, Z.; Gao, H.; Tan, Z.A. Revival of Insulating Polyethylenimine by Creatively Carbonizing with Perylene into Highly Crystallized Carbon Dots as the Cathode Interlayer for High-Performance Organic Solar Cells. ACS Appl. Mater. Interfaces 2022, 14, 1280–1289. [Google Scholar] [CrossRef]

- Zhang, T.; He, Q.; Yu, J.; Chen, A.; Zhang, Z.; Pan, J. Recent progress in improving strategies of inorganic electron transport layers for perovskite solar cells. Nano Energy 2022, 104, 107918. [Google Scholar] [CrossRef]

- Chakravarthi, N.; Park, H.-Y.; Kranthiraja, K.; Kim, H.; Shin, J.; Song, M.; Jin, S.-H. Substituent position engineering of phosphine oxide functionalized triazine-based cathode interfacial materials for flexible organic and perovskite solar cells. Org. Electron. 2018, 54, 54–63. [Google Scholar] [CrossRef]

- Aryal, U.K.; Ahmadpour, M.; Turkovic, V.; Rubahn, H.-G.; Di Carlo, A.; Madsen, M. 2D materials for organic and perovskite photovoltaics. Nano Energy 2022, 94, 106833. [Google Scholar] [CrossRef]

- Guo, J.; Ma, D.; Sun, F.; Zhuang, G.; Wang, Q.; Al-Enizi, A.M.; Nafady, A.; Ma, S. Substituent engineering in g-C3N4/COF heterojunctions for rapid charge separation and high photo-redox activity. Sci. China Chem. 2022, 65, 1704–1709. [Google Scholar] [CrossRef]

- Fu, Y.; Tan, M.; Guo, Z.; Hao, D.; Xu, Y.; Du, H.; Zhang, C.; Guo, J.; Li, Q.; Wang, Q. Fabrication of wide-spectra-responsive NA/NH2-MIL-125 (Ti) with boosted activity for Cr (VI) reduction and antibacterial effects. Chem. Eng. J. 2023, 452, 139417. [Google Scholar] [CrossRef]

- Fu, Y.; Zhang, K.; Zhang, Y.; Cong, Y.; Wang, Q. Fabrication of visible-light-active MR/NH2-MIL-125 (Ti) homojunction with boosted photocatalytic performance. Chem. Eng. J. 2021, 412, 128722. [Google Scholar] [CrossRef]

- Jeon, I.S.; Kim, S.J.; Song, W.; Myung, S.; Lim, J.; Lee, S.S.; Jung, H.-K.; Hwang, J.; An, K.-S. One-step synthesis of Zn-doped MoS2 nanosheets with tunable doping concentration using dopants-loaded seeding promoters for visible-light flexible photodetectors. J. Alloys Compd. 2020, 835, 155383. [Google Scholar] [CrossRef]

- Kang, K.; Xie, S.; Huang, L.; Han, Y.; Huang, P.Y.; Mak, K.F.; Kim, C.-J.; Muller, D.; Park, J. High-mobility three-atom-thick semiconducting films with wafer-scale homogeneity. Nature 2015, 520, 656–660. [Google Scholar] [CrossRef]

- Bellani, S.; Najafi, L.; Martin-Garcia, B.; Ansaldo, A.; Castillo, A.E.D.R.; Prato, M.; Moreels, I.; Bonaccorso, F. Graphene-based hole-selective layers for high-efficiency, solution-processed, large-area, flexible, hydrogen-evolving organic photocathodes. J. Phys. Chem. C 2017, 121, 21887–21903. [Google Scholar] [CrossRef]

- Sarma, S.; Ray, S.C. Magnetic behaviors of single crystal-MoS2 (MoS2-SC) and nanoparticle-MoS2 (MoS2-NP) and bi-layer-MoS2 thin film. J. Magn. Magn. Mater. 2022, 546, 168863. [Google Scholar] [CrossRef]

- Lee, K.S.; Park, Y.J.; Shim, J.; Lee, C.H.; Lim, G.H.; Kim, H.Y.; Choi, J.W.; Lee, C.L.; Jin, Y.; Yu, K.; et al. Effective charge separation of inverted polymer solar cells using versatile MoS 2 nanosheets as an electron transport layer. J. Mater. Chem. A 2019, 7, 15356–15363. [Google Scholar] [CrossRef]

- Zhang, J.; Guan, Y.; Yang, J.; Hua, W.; Wang, S.; Ling, Z.; Lian, H.; Liao, Y.; Lan, W.; Wei, B.; et al. Highly-efficient solution-processed green phosphorescent organic light-emitting diodes with reduced efficiency roll-off using ternary blend hosts. J. Mater. Chem. C 2019, 7, 11109–11117. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, G.; Jiang, F.; Qin, Y.; Cong, H. Temperature sensor of MoS2 based on hybrid plasmonic waveguides. Plasmonics 2019, 14, 1863–1870. [Google Scholar] [CrossRef]

| Device | Voc (V) | Jsc (mA cm−2) | FF (%) | PCE (%) |

|---|---|---|---|---|

| Device A | 0.55 ± 0.02 | 10.12 ± 0.3 | 34.03 ± 0.1 | 1.89 ± 0.06 |

| Device B | 0.54 ± 0.03 | 10.39 ± 0.4 | 45.39 ± 0.2 | 2.54 ± 0.13 |

| Device C | 0.61 ± 0.03 | 10.43 ± 0.5 | 48.21 ± 0.2 | 3.07 ± 0.12 |

| Device D | 0.66 ± 0.03 | 10.66 ± 0.5 | 46.71 ± 0.2 | 3.29 ± 0.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, C.; Ling, Z.; Qu, M.; Cao, C.; Chen, G.; Shi, W.; Wei, B. Enhanced Performance of Flexible Organic Photovoltaics Based on MoS2 Micro-Nano Array. Molecules 2023, 28, 813. https://doi.org/10.3390/molecules28020813

Peng C, Ling Z, Qu M, Cao C, Chen G, Shi W, Wei B. Enhanced Performance of Flexible Organic Photovoltaics Based on MoS2 Micro-Nano Array. Molecules. 2023; 28(2):813. https://doi.org/10.3390/molecules28020813

Chicago/Turabian StylePeng, Cuiyun, Zhitian Ling, Minghao Qu, Chenhui Cao, Guo Chen, Wei Shi, and Bin Wei. 2023. "Enhanced Performance of Flexible Organic Photovoltaics Based on MoS2 Micro-Nano Array" Molecules 28, no. 2: 813. https://doi.org/10.3390/molecules28020813

APA StylePeng, C., Ling, Z., Qu, M., Cao, C., Chen, G., Shi, W., & Wei, B. (2023). Enhanced Performance of Flexible Organic Photovoltaics Based on MoS2 Micro-Nano Array. Molecules, 28(2), 813. https://doi.org/10.3390/molecules28020813