Manipulation of Morphology, Particle Size of Barium Sulfate and the Interacting Mechanism of Methyl Glycine Diacetic Acid

Abstract

1. Introduction

2. Results and Discussion

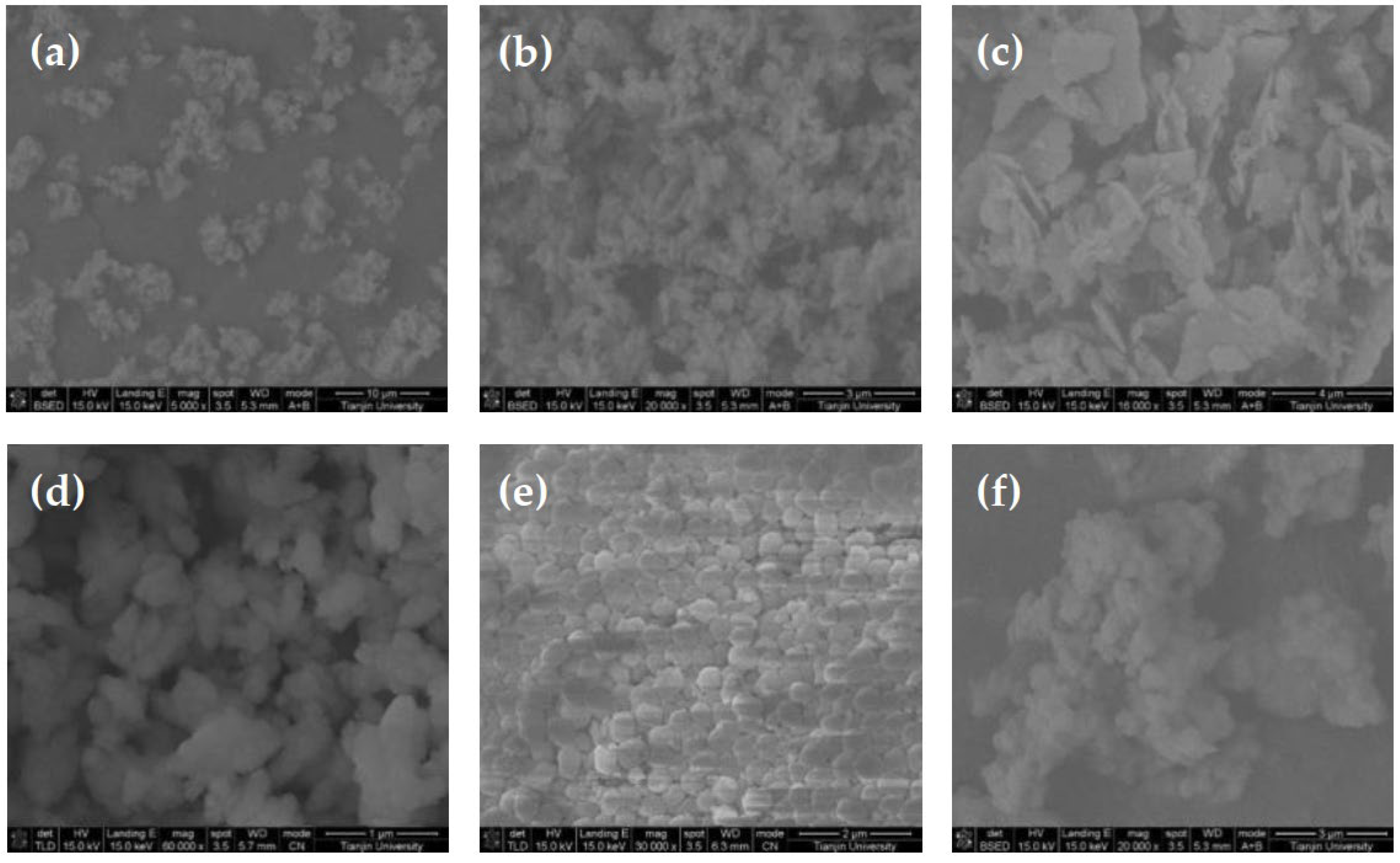

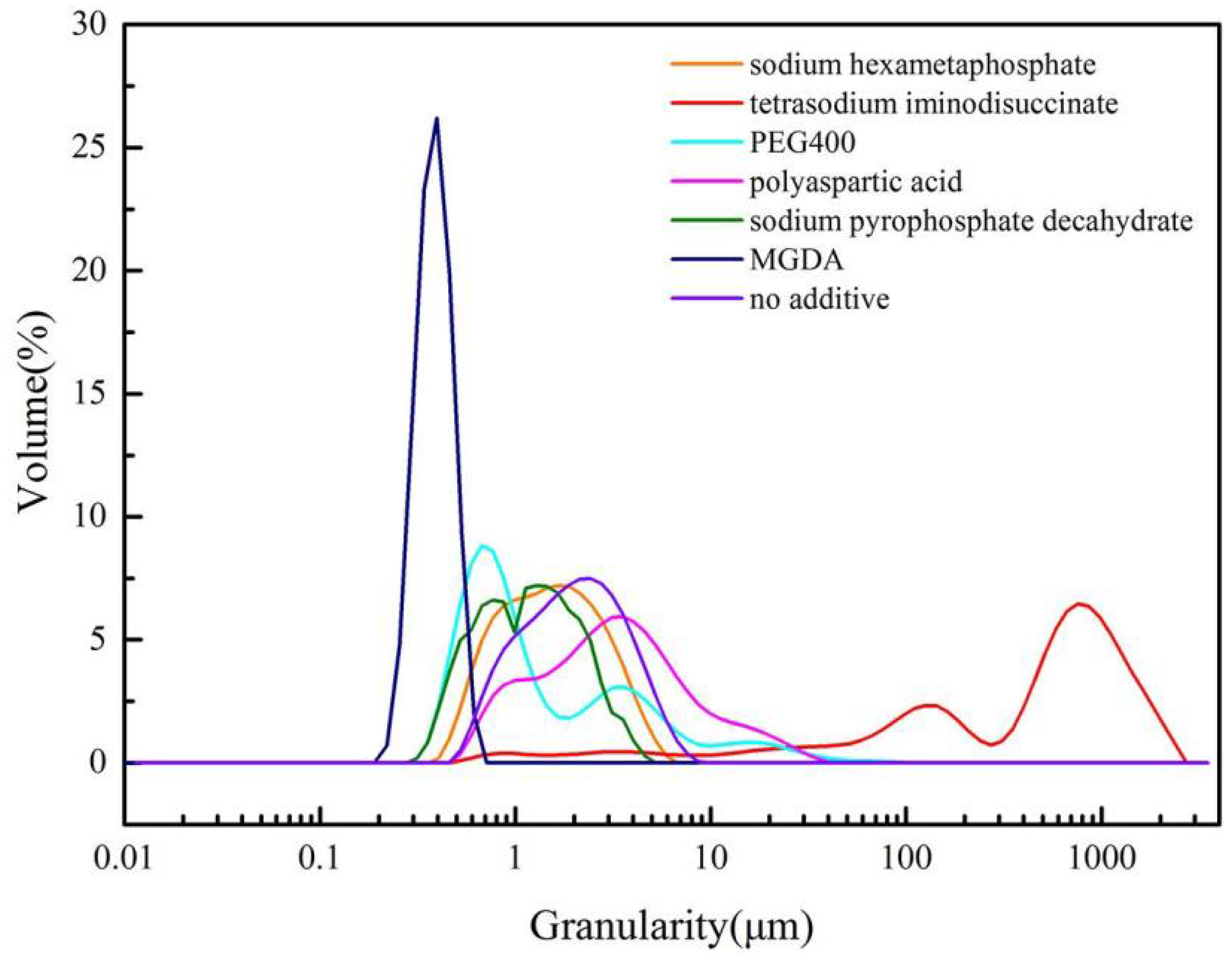

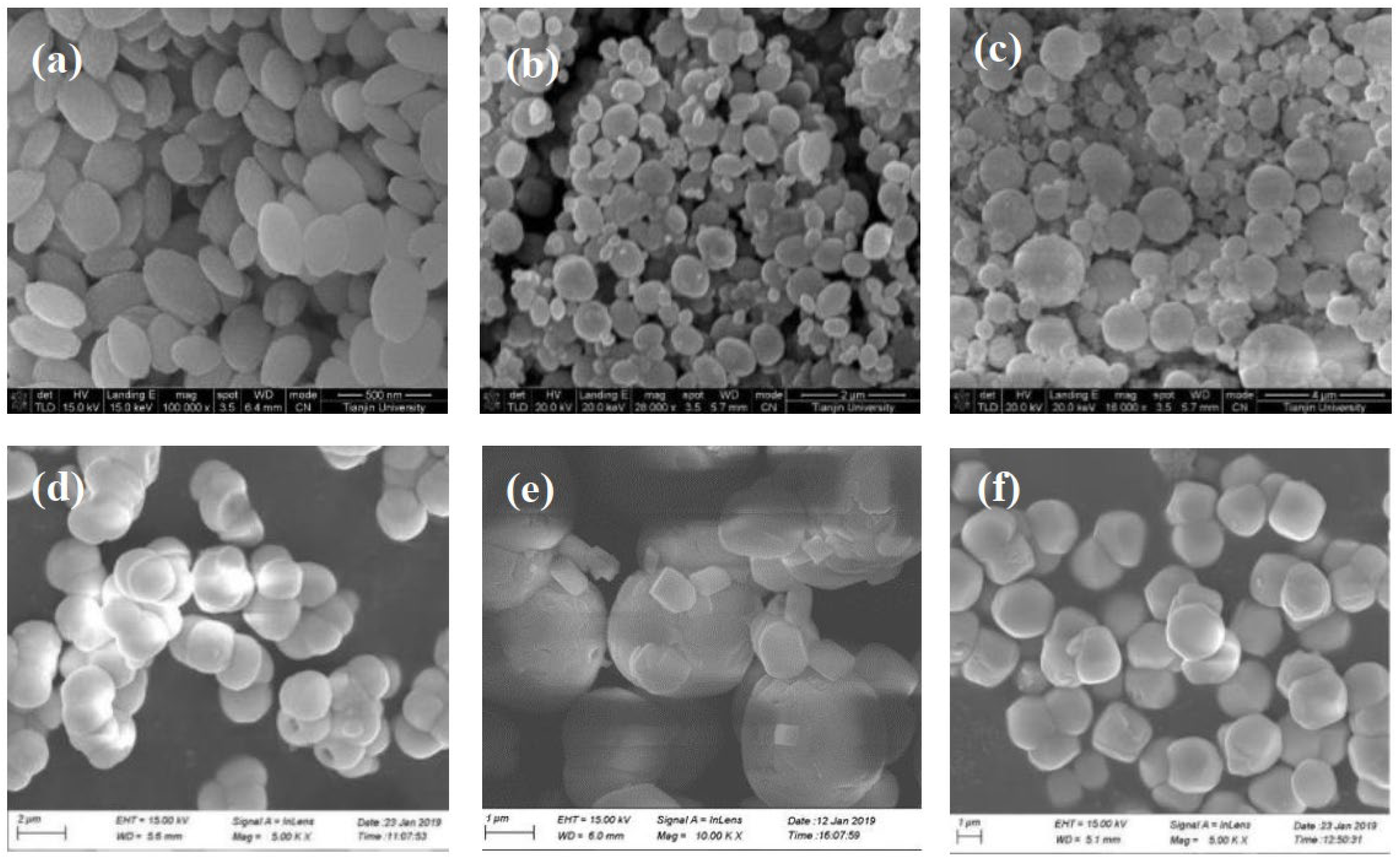

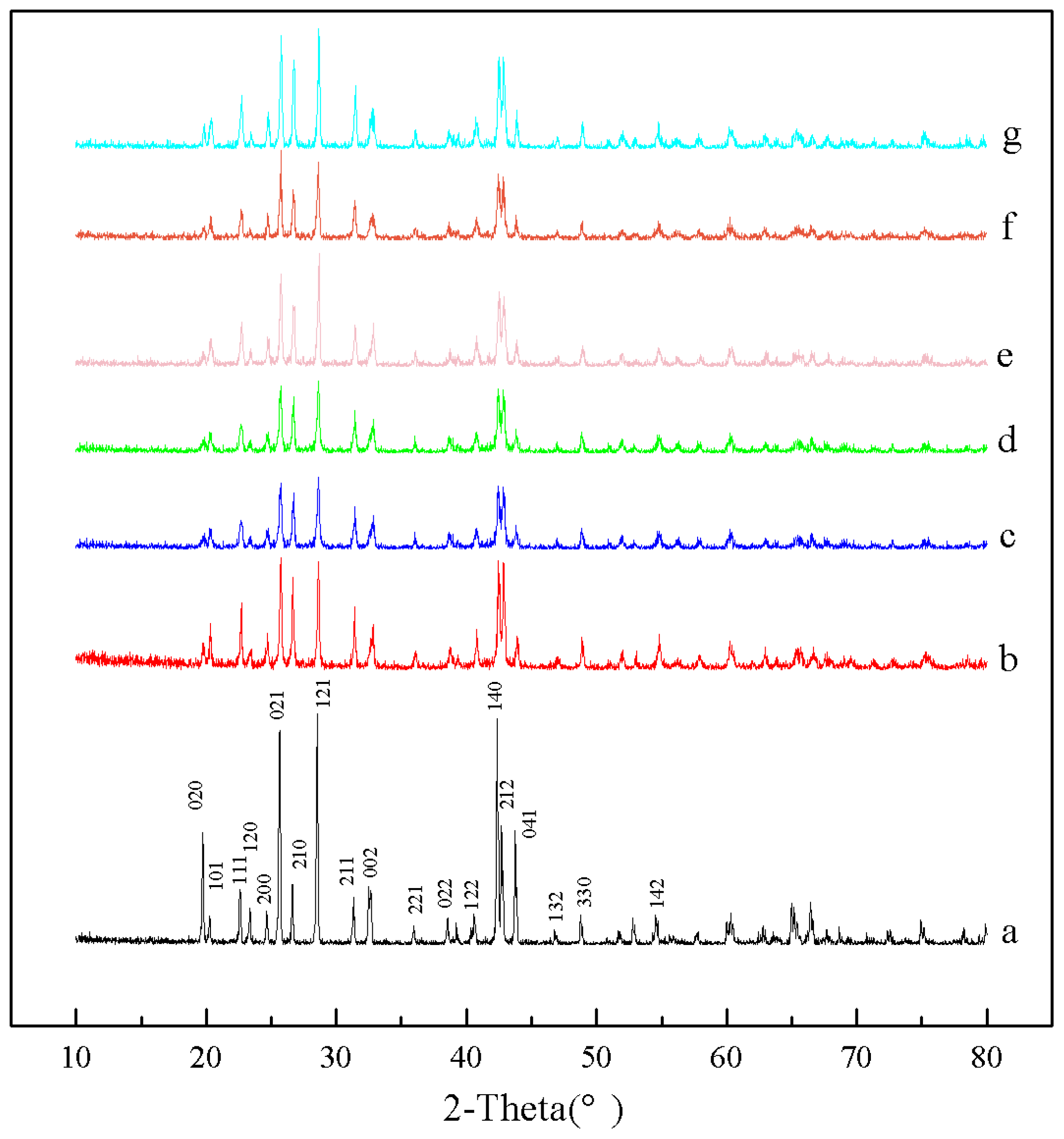

2.1. Effect of Additives on Morphology and Particle Size of Barium Sulfate

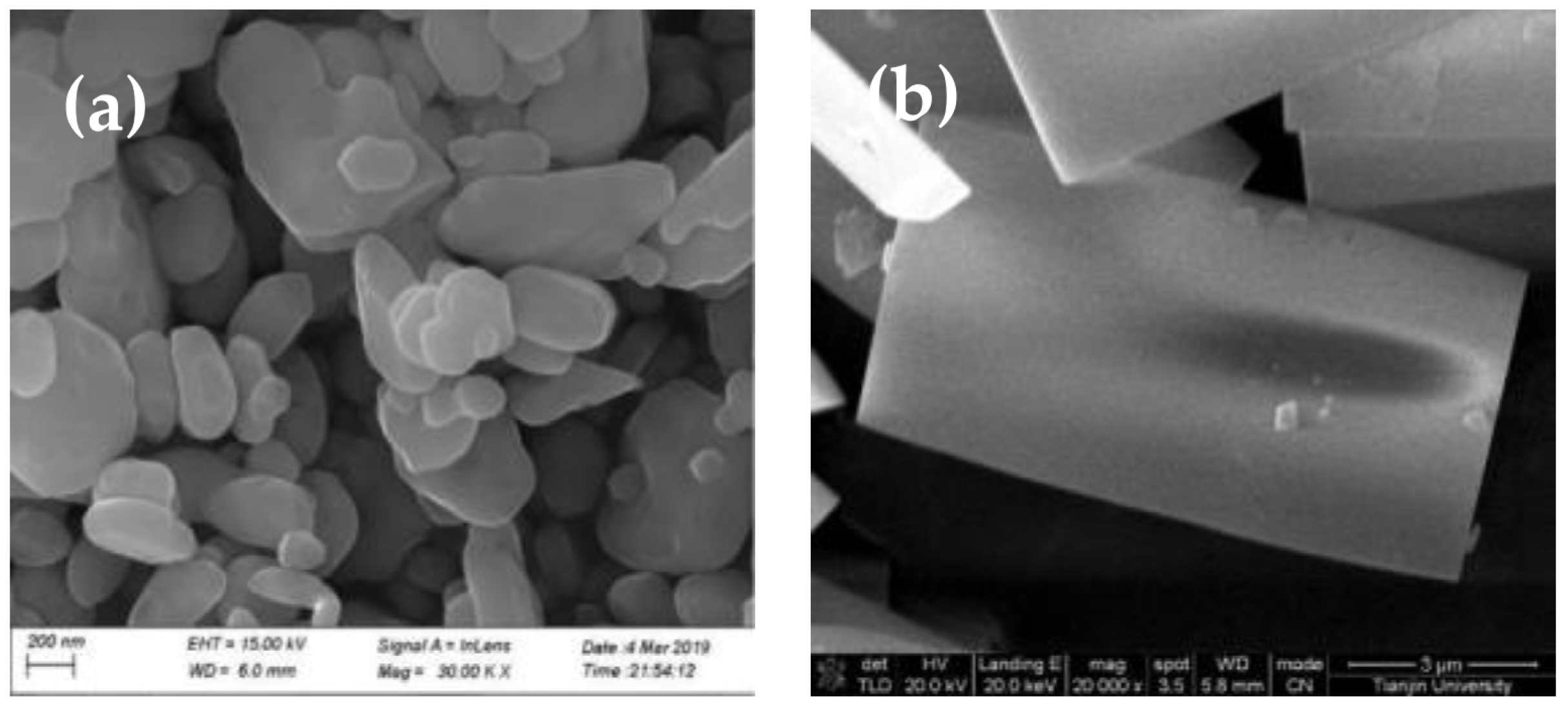

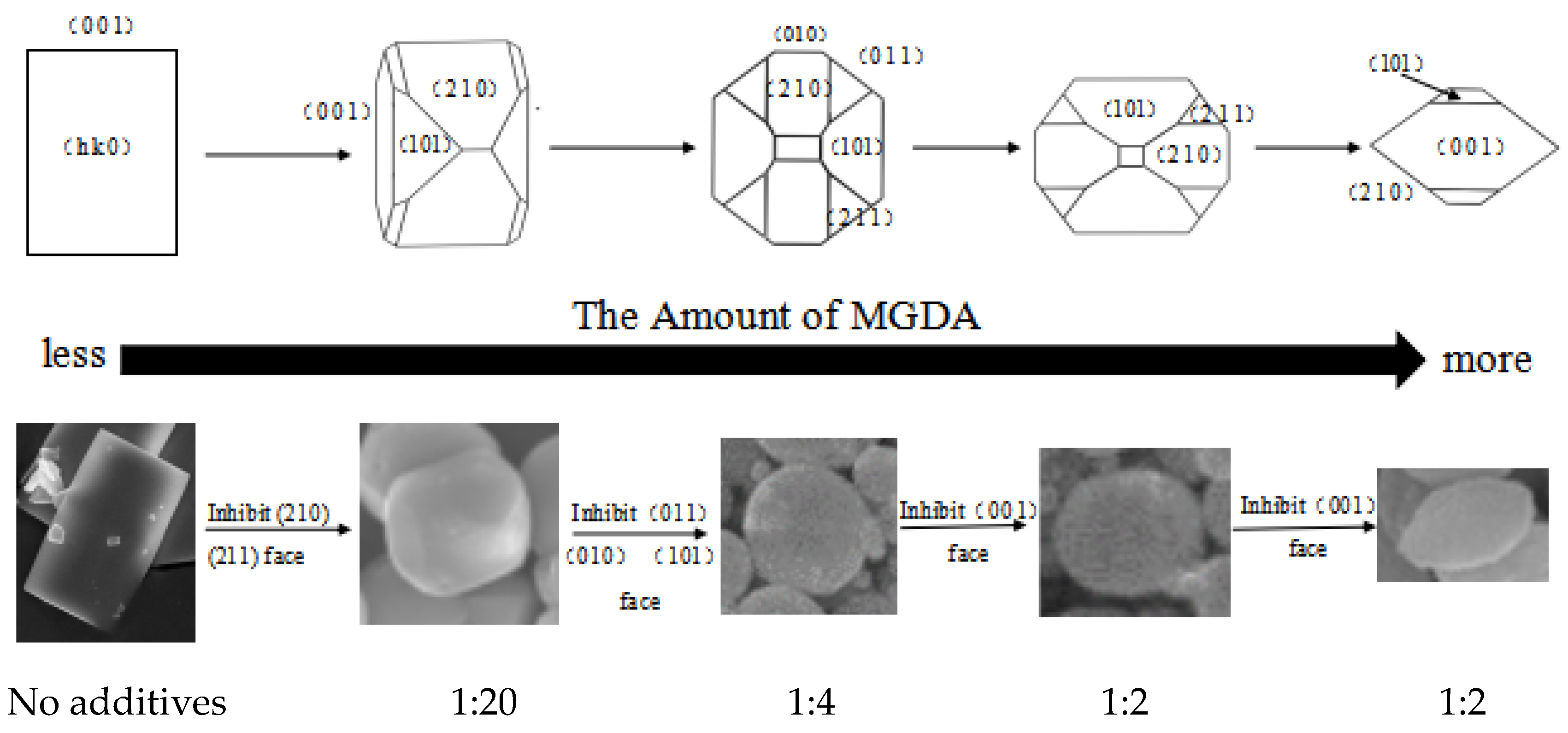

2.2. Effect of Dosage of MGDA on Morphology and Particle Size of Barium Sulfate

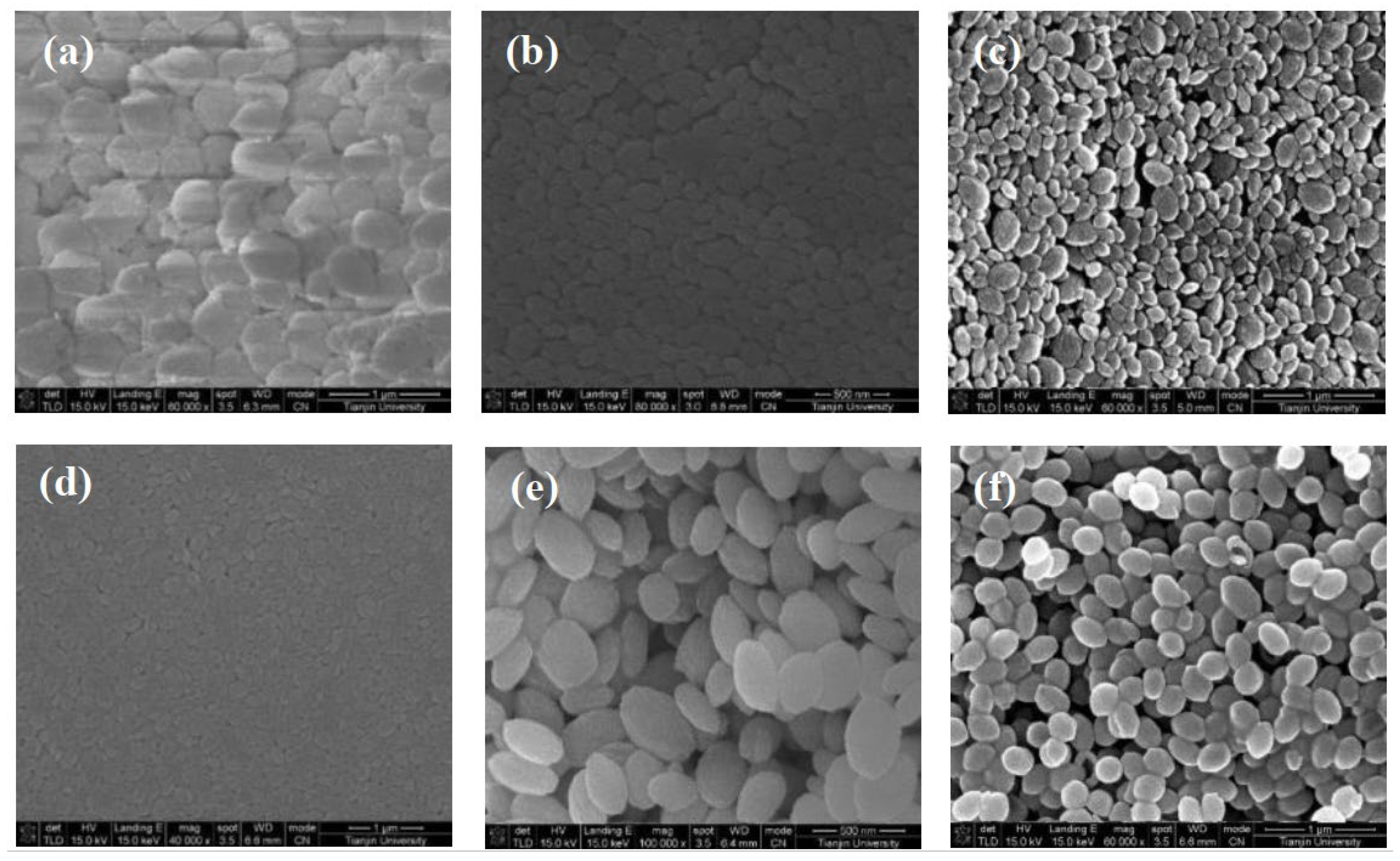

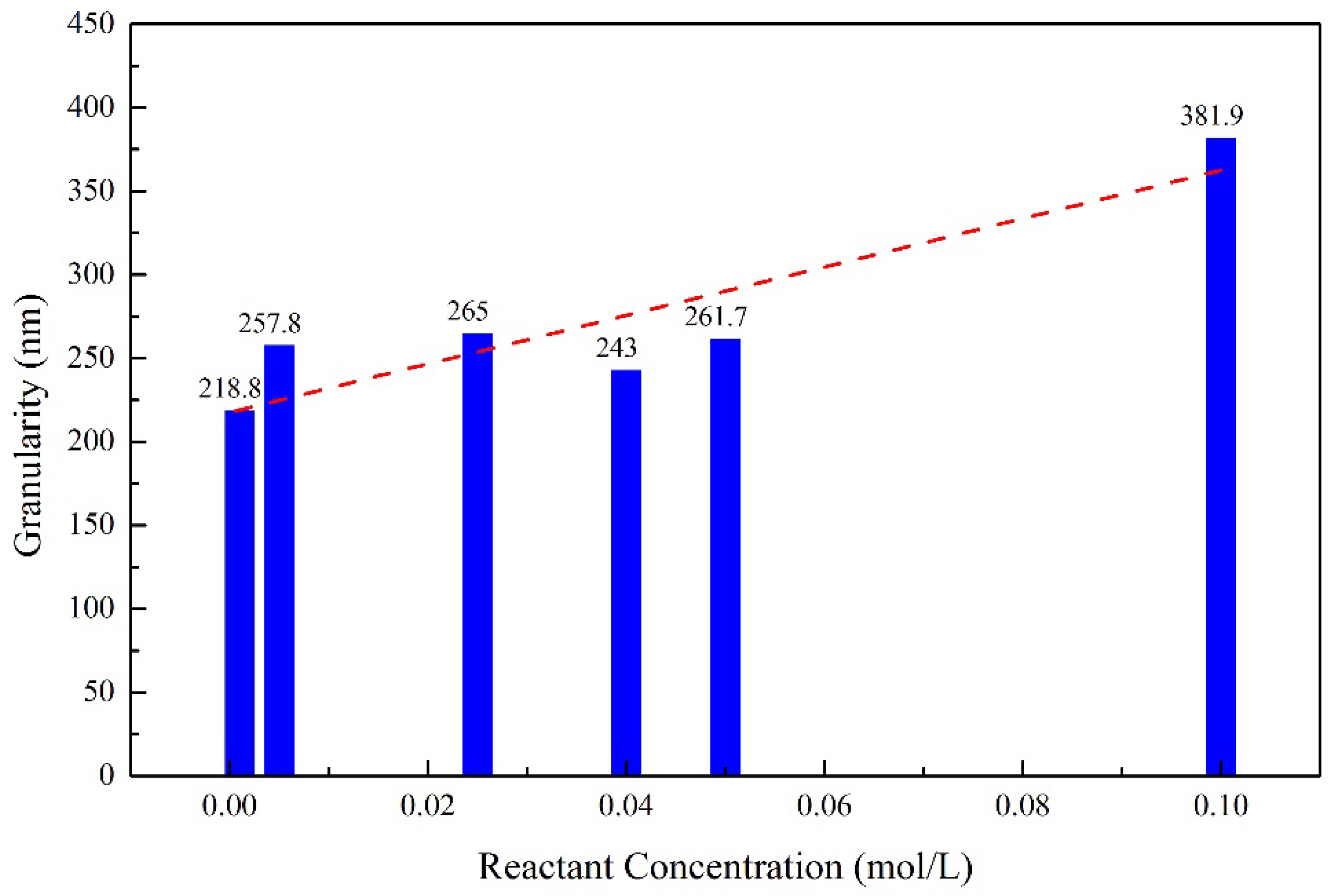

2.3. Effect of Concentration of Reactants on the Morphology of Barium Sulfate

2.4. Effect of pH Value on the Morphology of Barium Sulfate

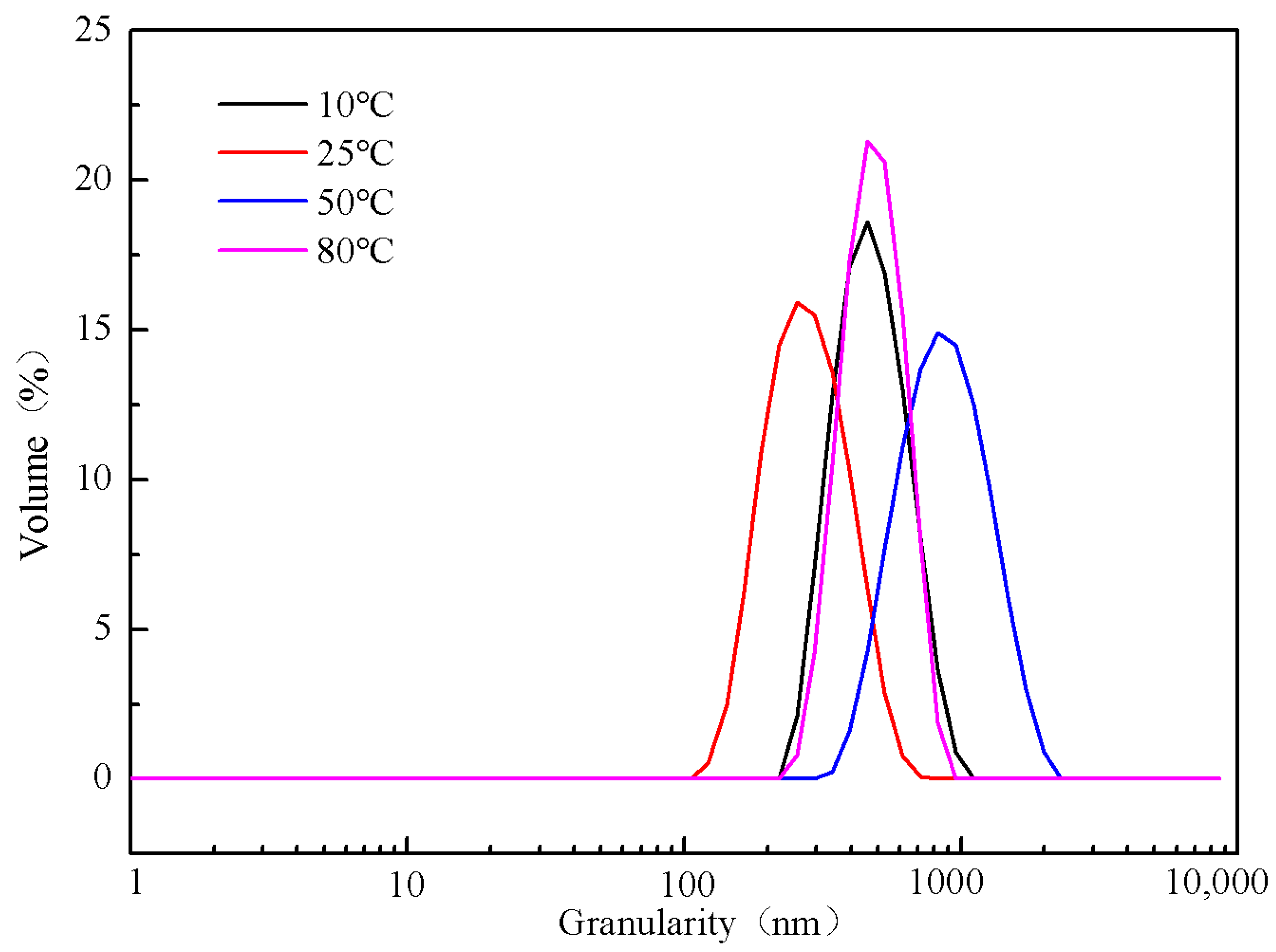

2.5. Effect of Temperature on the Morphology and Particle Size of Barium Sulfate

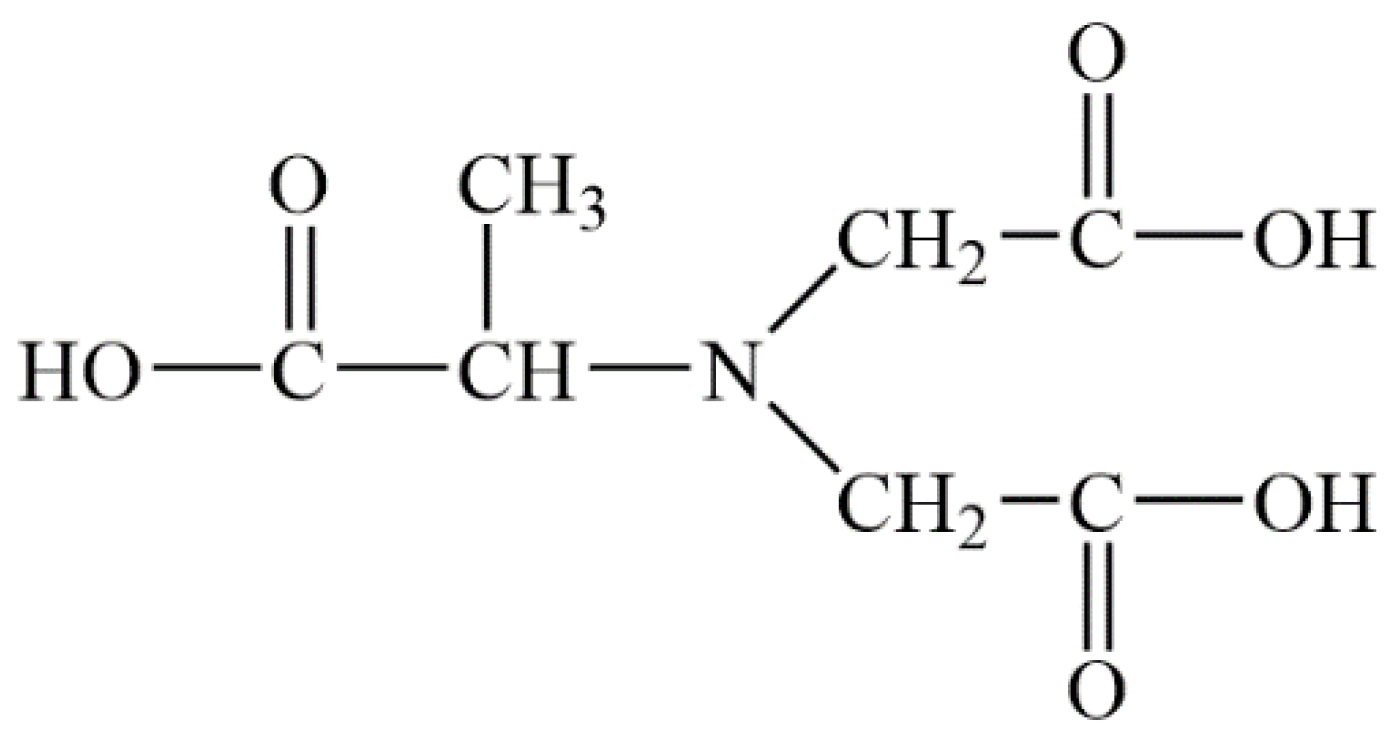

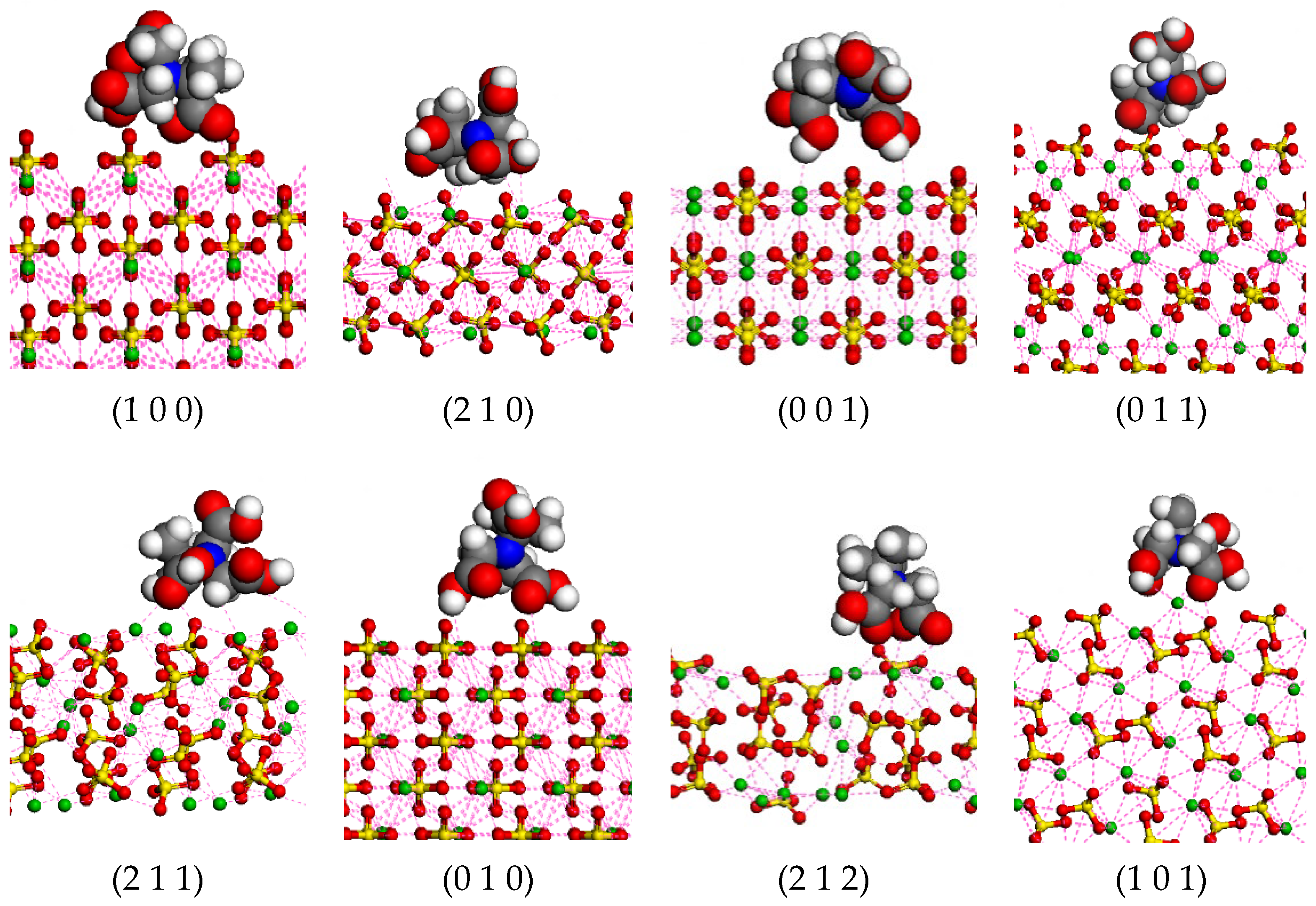

2.6. Molecular Mechanism of the Effect of MGDA on the Morphology and Particle Size of Barium Sulfate

3. Experimental

3.1. Materials

3.2. Crystallization Experiment of Barium Sulfate

3.3. Characterization of Barium Sulfate

3.3.1. Scanning Electron Microscopy (SEM)

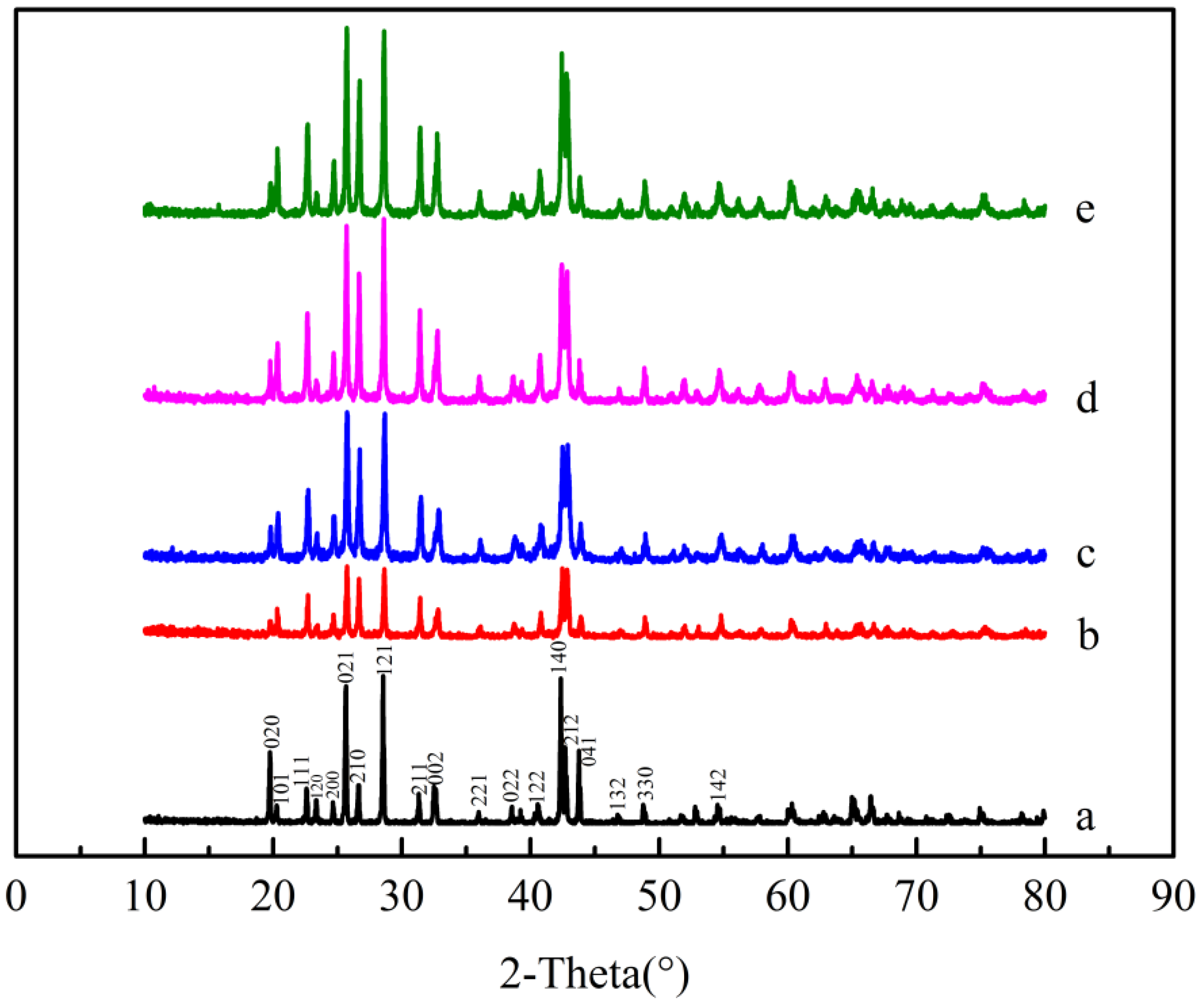

3.3.2. X-ray Powder Diffraction

3.3.3. Malvern Zetasizer Nano ZS

3.4. Molecular Simulation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Abbreviation | Full name |

| MGDA | methyl glycine diacetic acid |

| EDTA | ethylenediaminetetraacetic acid |

| NTMP | nitrilotrimethylenephosphonate |

| MNDP | N-methylnitrilodimethylenephosphonate |

| NTA | nitrilotriacetic acid |

| SEM | scanning electron microscopy |

| PSD | particle size distribution |

| XRD | X-ray diffraction |

References

- Akyol, E.; Cedimagar, M.A. Size and morphology controlled synthesis of barium sulfate. Cryst. Res. Technol. 2016, 51, 393–399. [Google Scholar] [CrossRef]

- Ramaswamya, V.; Vimalathithana, R.M.; Ponnusamy, V. Preparation of barium sulphate nanocrystals in ethanol-water mixed solvents. J. Ceram. Process. Res. 2011, 12, 173–175. [Google Scholar]

- Uchida, M.; Sue, A.; Yoshioka, T.; Okuwaki, A. Hydrothermal synthesis of needle-like barium sulfate using a barium(II)-EDTA chelate precursor and sulfate ions. J. Mater. Sci. Lett. 2000, 19, 1373–1374. [Google Scholar] [CrossRef]

- Yang, S.P.; Yang, J.N.; Zhu, J.B. Progress on the application of ultra-fine barium sulfate in the polymeric composite. New Chem. Mater. 2017, 45, 16–18. [Google Scholar]

- Ardizzones, S.; Ragaini, V.; Vercelli, B. SO42−/ZrO2 catalysts for the esterification of benzonic acid to methylbenzoate. Catal. Lett. 1999, 62, 59–65. [Google Scholar] [CrossRef]

- Yu, J.G.; Liu, S.W.; Cheng, B. Effects of PSMA additive on morphology of barite particles. J. Cryst. Growth 2005, 275, 572–579. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, B.; Li, X.H.; Yin, Z.L.; Guo, X.Y. Synthesis and surface properties of submicron barium sulfate particles. Appl. Surf. Sci. 2011, 258, 24–29. [Google Scholar] [CrossRef]

- Qi, Q.; Sun, Q.; Zhang, J.; Yan, J.; Pan, F.Z.; Sheng, W.J. Process in preparation and research of ultrafine precipitated barium sulfate. Inorg. Chem. Ind. 2018, 50, 15–20. [Google Scholar]

- Ke, Z.; Bai, Y.P. Improve the gas harrier property of PET film with montmorillonite by in situ interlayer polymerization. Mater. Lett. 2005, 59, 3348–3351. [Google Scholar] [CrossRef]

- Jiao, Q.S. Research progress on micromorphology of precipitated barium sulfate particles. Coal Chem. Ind. 2021, 44, 138–141. [Google Scholar]

- Jones, F.; Stanley, A.; Oliveira, A.; Rohl, A.L.; Reyhani, M.M.; Parkinson, G.M.; Ogden, M.I. The role of phosphonate speciation on the inhibition of barium sulfate precipitation. J. Cryst. Growth 2003, 249, 584–593. [Google Scholar] [CrossRef]

- Jones, F.; Oliveira, A.; Rohl, A.L.; Ogdena, M.I.; Parkinsona, G.M. Understanding the mechanism by which nitrilotriacetic acid interacts with precipitating barium sulfate. CrystEngComm 2006, 8, 869–876. [Google Scholar] [CrossRef]

- Jones, F.; Richmond, W.R.; Rohl, A.L. Molecular modeling of phosphonate molecules onto barium sulfate terraced surfaces. The J. Phys. Chem. B 2006, 110, 7414–7424. [Google Scholar] [CrossRef]

- Jones, F.; Jones, P.; Ogden, M.I.; Richmond, W.R.; Rohl, A.L.; Saunders, M. The interaction of EDTA with barium sulfate. J. Colloid Interface Sci. 2007, 316, 553–561. [Google Scholar] [CrossRef] [PubMed]

- Edward, C.; Muzaffer, M.; Adeolu, M.; Micah, E.; Oluseyi, D.; Travis, C.; Taiwo, O.O.; Chinenye, N.; Kadir, A. Effect of additives on the crystal morphology of amino acids: A theoretical and experimental study. J. Phys. Chem. C 2016, 120, 14749–14757. [Google Scholar]

- Margarete, B.W.; Thomas, E. Environmental fate and microbial degradation of aminopolycarboxylic acids. FEMS Microbiol. Rev. 2001, 25, 69–106. [Google Scholar]

- Wu, L.L. Methyl glycine diacetic acid and its application in detergents. China Clean. Ind. 2015, 7, 36–40. [Google Scholar]

- Mahmoud, M.; Badr, B.G.; Abdelgawad, K.; Kamal, M.S.; Hussein, I.; Elkatatny, S.; Shawabkeh, R. Evaluation of the Reaction Kinetics of DTPA Chelating Agent and Converter with Barium Sulfate (Barite) Using Rotating Disk Apparatus. Energy Fuels 2018, 32, 9813–9821. [Google Scholar] [CrossRef]

- Chen, K.; Hou, B.H.; Wu, H.; Huang, X.; Li, F.; Xiao, Y.; Li, J.; Bao, Y.; Hao, H.H. Hollow and Solid Spherical Azithromycin Particles Prepared by Different Spherical Crystallization Technologies for Direct Tableting. Processes 2019, 7, 276. [Google Scholar] [CrossRef]

- Matteo, S.; Thomas, V.; Federico, G.; Marco, M.; Michele, P. Uncovering molecular details of urea crystal growth in the presence of additives. J. Am. Chem. Soc. 2012, 134, 17221–17233. [Google Scholar]

- Qi, R.B.; Wang, J.K.; Ye, J.X.; Hao, H.X.; Bao, Y. The solubility of cefquinome sulfate in pure and mixed solvents. Front. Chem. Sci. Eng. 2016, 10, 245–254. [Google Scholar] [CrossRef]

- Gao, J.Y.; Wang, Y.L.; Hao, H.X. Investigations on dehydration processes of trisodium citrate hydrates. Front. Chem. Sci. Eng. 2012, 6, 276–281. [Google Scholar] [CrossRef]

- OuYang, J.B.; Wang, J.K.; Wang, Y.L.; Yin, Q.X.; Hao, H.X. Thermodynamic study on dynamic water and organic vapor sorption on amorphous valnemulin hydrochloride. Front. Chem. Sci. Eng. 2015, 9, 94–104. [Google Scholar] [CrossRef]

- Gupta, A.; Singh, P.; Shivakumara, C. Synthesis of BaSO4 nanoparticles by precipitation method using sodium hexa metaphosphate as a stabilizer. Solid State Commun. 2010, 150, 386–388. [Google Scholar] [CrossRef]

- Yuan, R.S. Study on the Preparation of Nanometer Barium Sulfate by EDTA Complex Method. Master’s Thesis, North China Institute of Technology, Taiyuan, China, 2002. [Google Scholar]

- Myerson, A.S.; Jang, S.M. A comparison of binding energy and metastable zone width for adipic acid with various additives. J. Cryst. Growth 1995, 156, 459–466. [Google Scholar] [CrossRef]

- Yang, X.T.; Qian, G.; Duan, X.Z.; Zhou, X.G. Effect of impurity on the lateral crystal growth of L-alanine: A combined simulation and experimental Study. Ind. Eng. Chem. Res. 2012, 51, 14845–14849. [Google Scholar] [CrossRef]

- Ryabov, I.D.; Bershov, L.V.; Speranskiy, A.V.; Ganeev, I.G. Electron paramagnetic resonance of PO32− and SO3− radicals in anhydrite, celestite and barite: The hyperfine structure and dynamics. Phys. Chem. Miner. 1983, 10, 21–26. [Google Scholar] [CrossRef]

- Li, D.; Qi, T.; Gao, Y.Y. Crystallization of ammonium persulfate in the presence of an additive: Experimental and molecular dynamics simulation studies. Cryst. Res. Technol. 2018, 53, 1700280. [Google Scholar] [CrossRef]

- Yao, C.L.; Li, Y.F.; Wang, L.; Song, S.; Li, B.; Liu, Y.; Tao, X.T. Tuning the solution-mediated concomitant phase transformation outcome of the piroxicam monohydrate by two hydroxyl-containing additives: Hydroxypropyl cellulose and H2O. Cryst. Growth Des. 2019, 19, 583–590. [Google Scholar] [CrossRef]

| Temperature/°C | Reactant Concentration/M | pH | Molar Ratio of MGDA-3Na to BaCl2 | BaSO4 Granularity/nm |

|---|---|---|---|---|

| 25 | 0.005 | Unregulated | 1:1 | 257.8 |

| 25 | 0.005 | Unregulated | 1:2 | 355.7 |

| 25 | 0.005 | Unregulated | 1:4 | 304.5 |

| 25 | 0.005 | Unregulated | 1:8 | 5486 |

| 25 | 0.005 | Unregulated | 1:16 | 5970 |

| 25 | 0.005 | Unregulated | 1:20 | 6142 |

| Surface | Etotal (kJ/mol) | Esurface (kJ/mol) | Eadditive (kJ/mol) | Ebinding (kJ/mol) |

|---|---|---|---|---|

| (1 0 0) | 67,506.1 | 49,569.6 | 18,390.6 | −454.061 |

| (2 1 0) | 72,417.5 | 54,540.5 | 18,525.1 | −648.094 |

| (0 0 1) | 71,645.9 | 53,768.1 | 18,225.6 | −347.824 |

| (0 1 1) | 64,920.5 | 46,853.4 | 18,500.8 | −433.714 |

| (2 1 1) | 67,451.8 | 49,253.3 | 18,709.2 | −510.655 |

| (0 1 0) | 69,131.4 | 51,511.8 | 18,017.3 | −397.643 |

| (2 1 2) | 64,630.9 | 46,467.2 | 18,861.1 | −697.406 |

| (1 0 1) | 69,322.4 | 51,262.5 | 18,429.1 | −369.121 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhou, Y.; Wang, J.; Wang, N.; Bi, J.; Li, X.; Chen, K.; Hao, H. Manipulation of Morphology, Particle Size of Barium Sulfate and the Interacting Mechanism of Methyl Glycine Diacetic Acid. Molecules 2023, 28, 726. https://doi.org/10.3390/molecules28020726

Li J, Zhou Y, Wang J, Wang N, Bi J, Li X, Chen K, Hao H. Manipulation of Morphology, Particle Size of Barium Sulfate and the Interacting Mechanism of Methyl Glycine Diacetic Acid. Molecules. 2023; 28(2):726. https://doi.org/10.3390/molecules28020726

Chicago/Turabian StyleLi, Jing, Yanan Zhou, Jingkang Wang, Na Wang, Jingtao Bi, Xin Li, Kui Chen, and Hongxun Hao. 2023. "Manipulation of Morphology, Particle Size of Barium Sulfate and the Interacting Mechanism of Methyl Glycine Diacetic Acid" Molecules 28, no. 2: 726. https://doi.org/10.3390/molecules28020726

APA StyleLi, J., Zhou, Y., Wang, J., Wang, N., Bi, J., Li, X., Chen, K., & Hao, H. (2023). Manipulation of Morphology, Particle Size of Barium Sulfate and the Interacting Mechanism of Methyl Glycine Diacetic Acid. Molecules, 28(2), 726. https://doi.org/10.3390/molecules28020726