Effect of the Addition of Graphene Flakes on the Physical and Biological Properties of Composite Paints

Abstract

:1. Introduction

2. Results

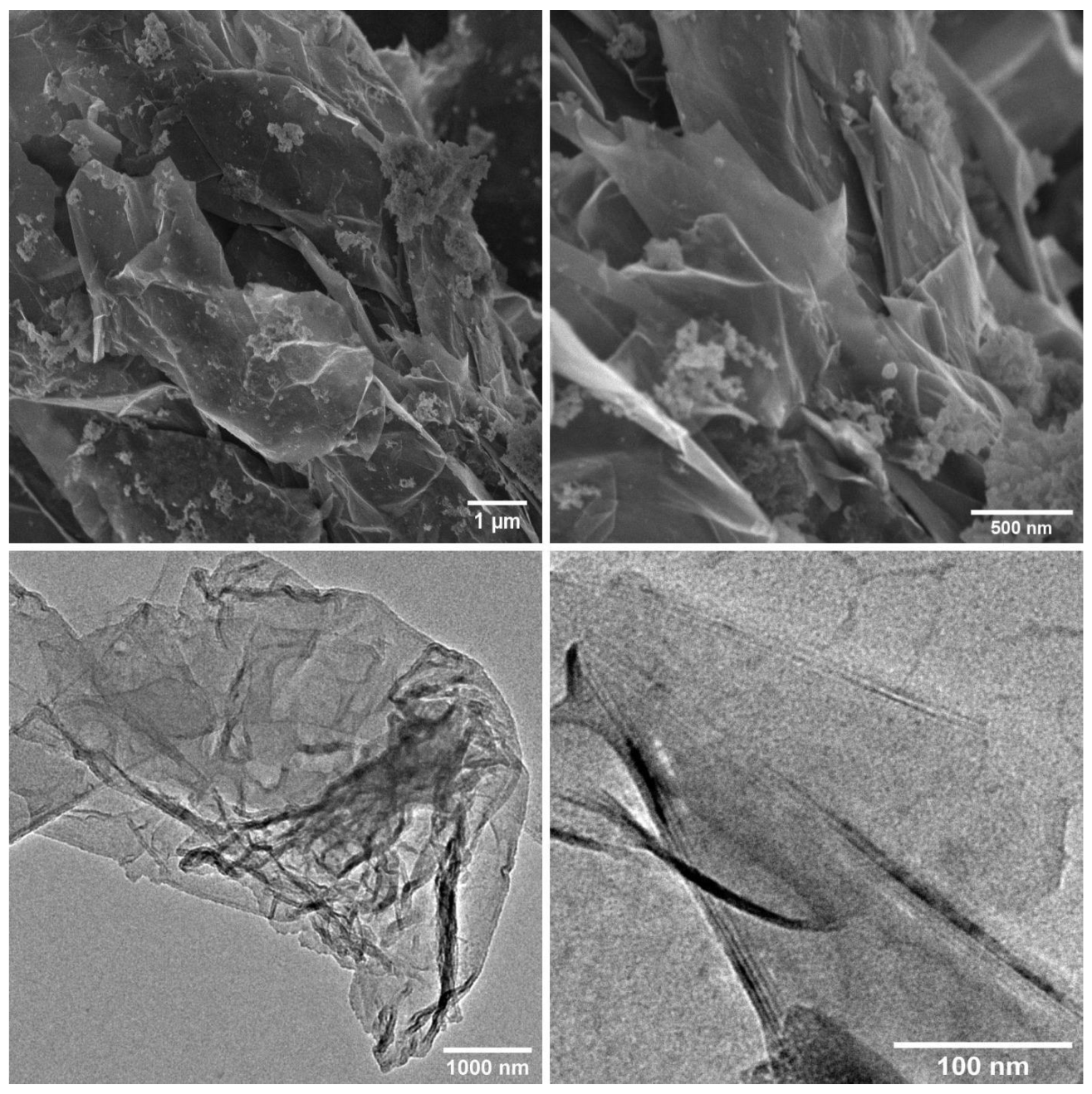

2.1. Structure and Morphology of Graphene Flakes (XRD, Raman and FTIR Spectroscopy, SEM, TEM)

2.2. Physical Properties of the Composites

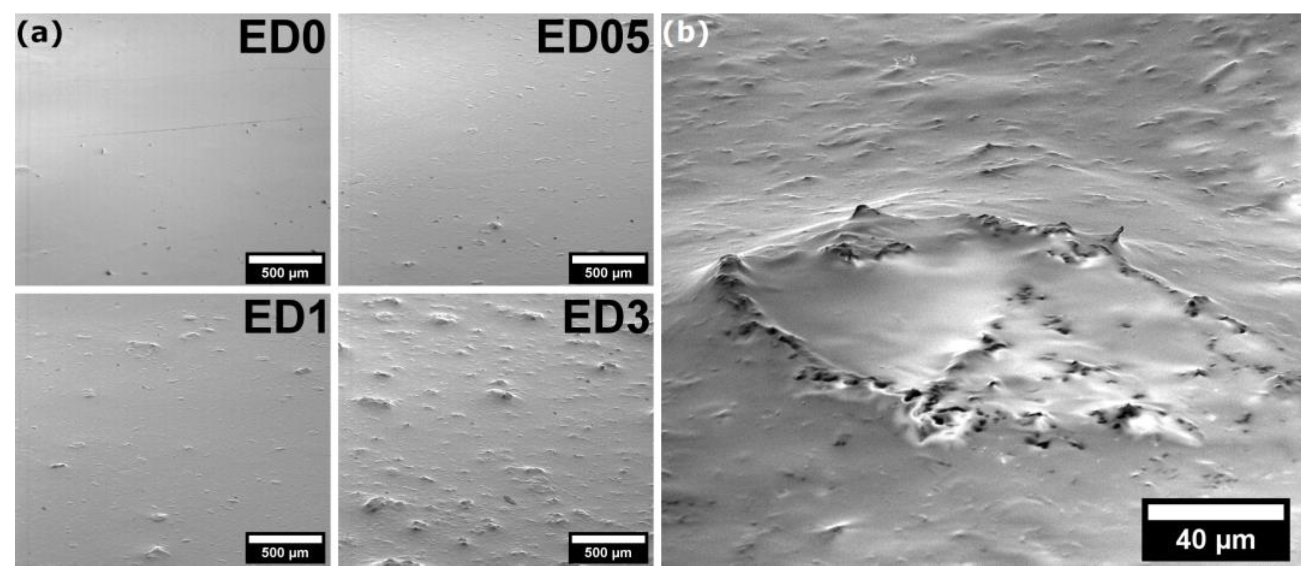

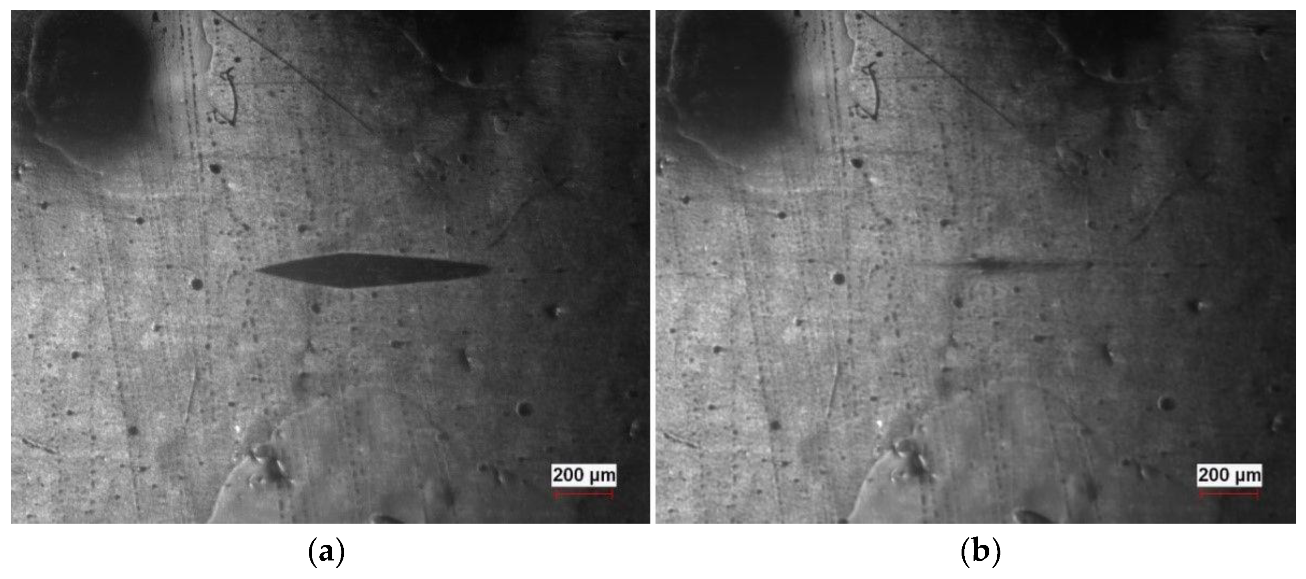

2.2.1. Morphology of Composite Paints’ Surface

2.2.2. Micro-Hardness and Elasticity

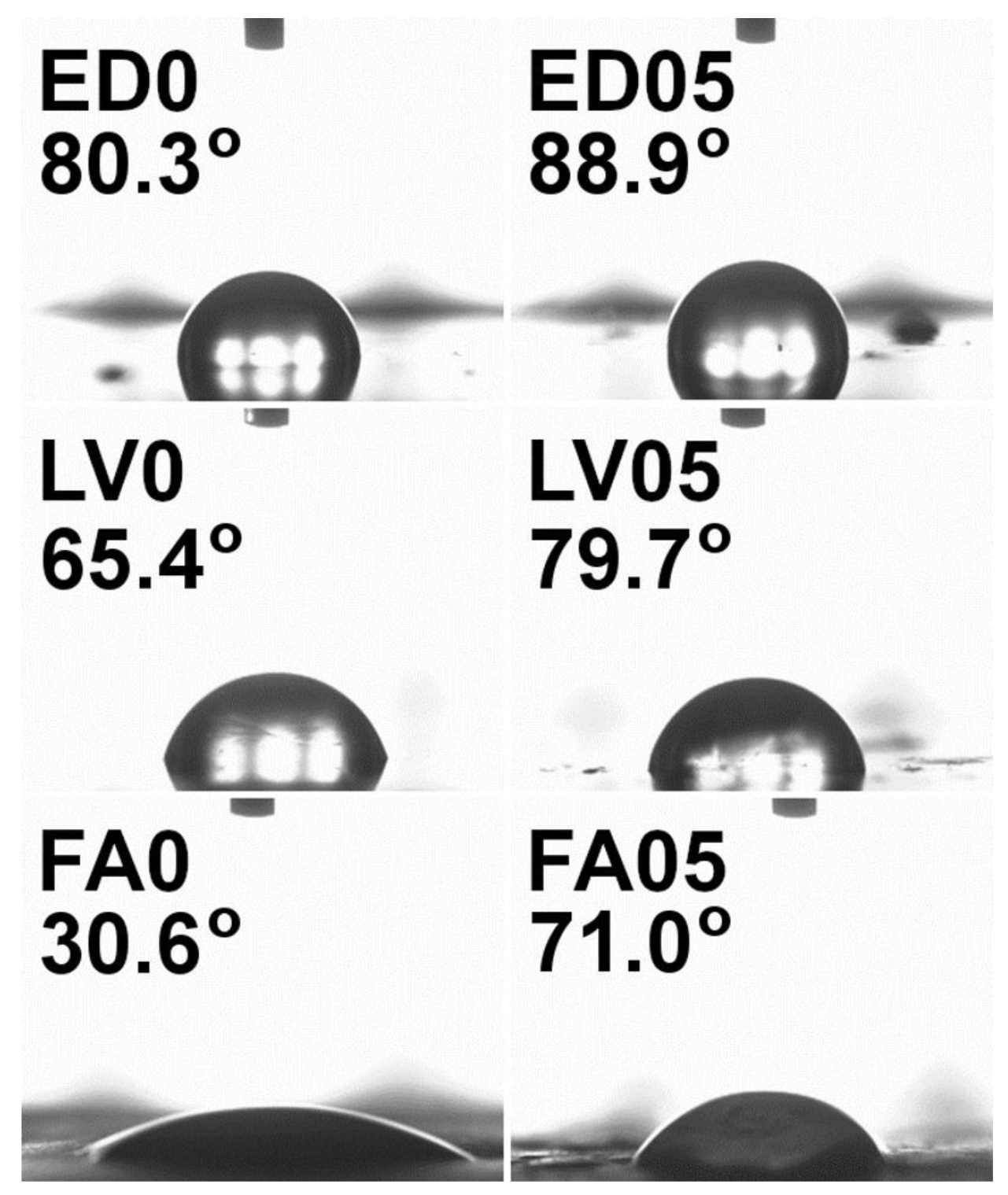

2.2.3. Wettability

2.2.4. Biological Properties of the Composites

3. Discussion

4. Materials and Methods

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Jiang, J.-W.; Wang, J.-S.; Li, B. Young’s Modulus of Graphene: A Molecular Dynamics Study. Phys. Rev. B 2009, 80, 113405. [Google Scholar] [CrossRef]

- Paszkiewicz, S. Synergiczny Efekt Poprawy Przewodnictwa Elektrycznego w Hybrydowych Nanokompozytach Polimerowych z Udziałem Nanocząstek Węglowych 1D i 2D. Inżynieria Mater. 2015, 1, 10–13. [Google Scholar] [CrossRef]

- Sukumaran, L. A Study of Graphene. Int. J. Educ. Manag. Eng. 2014, 4, 9–14. [Google Scholar] [CrossRef]

- Taqi-Uddeen Safian, M.; Umar, K.; Nasir, M.; Ibrahim, M. Synthesis and Scalability of Graphene and Its Derivatives: A Journey towards Sustainable and Commercial Material. J. Clean. Prod. 2021, 318, 128603. [Google Scholar] [CrossRef]

- Kauling, A.P.; Seefeldt, A.T.; Pisoni, D.P.; Pradeep, R.C.; Bentini, R.; Oliveira, R.V.B.; Novoselov, K.S.; Castro Neto, A.H. The Worldwide Graphene Flake Production. Adv. Mater. 2018, 30, e1803784. [Google Scholar] [CrossRef] [PubMed]

- Ye, Z.; Wu, P.; Wang, H.; Jiang, S.; Huang, M.; Lei, D.; Wu, F. Multimode Tunable Terahertz Absorber Based on a Quarter Graphene Disk Structure. Results Phys. 2023, 48, 106420. [Google Scholar] [CrossRef]

- Tang, B.; Guo, Z.; Jin, G. Polarization-Controlled and Symmetry-Dependent Multiple Plasmon-Induced Transparency in Graphene-Based Metasurfaces. Opt. Express 2022, 30, 35554–35566. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Cai, P.; Wen, Q.; Chen, H.; Tang, Y.; Yi, Z.; Wei, K.; Li, G.; Tang, B.; Yi, Y. Graphene Multi-Frequency Broadband and Ultra-Broadband Terahertz Absorber Based on Surface Plasmon Resonance. Electronics 2023, 12, 2655. [Google Scholar] [CrossRef]

- Shahdeo, D.; Roberts, A.; Abbineni, N.; Gandhi, S. Graphene Based Sensors. Compr. Anal. Chem. 2020, 91, 175–199. [Google Scholar] [CrossRef]

- Wu, J.; Feng, S.; Li, Z.; Tao, K.; Chu, J.; Miao, J.; Norford, L.K. Boosted Sensitivity of Graphene Gas Sensor via Nanoporous Thin Film Structures. Sens. Actuators B Chem. 2018, 255, 1805–1813. [Google Scholar] [CrossRef]

- Taheri, B.; Nia, N.Y.; Agresti, A.; Pescetelli, S.; Ciceroni, C.; Del Rio Castillo, A.E.; Cinà, L.; Bellani, S.; Bonaccorso, F.; Di Carlo, A. Graphene-Engineered Automated Sprayed Mesoscopic Structure for Perovskite Device Scaling-Up. 2D Mater. 2018, 5, 045034. [Google Scholar] [CrossRef]

- Moh, T.S.Y.; Ting, T.W.; Lau, A.H.Y. Graphene Nanoparticles (GNP) Nanofluids as Key Cooling Media on a Flat Solar Panel through Micro-Sized Channels. Energy Rep. 2020, 6, 282–286. [Google Scholar] [CrossRef]

- Ghamkhari, A.; Abbaspour-Ravasjani, S.; Talebi, M.; Hamishehkar, H.; Hamblin, M.R. Development of a Graphene Oxide-Poly Lactide Nanocomposite as a Smart Drug Delivery System. Int. J. Biol. Macromol. 2021, 169, 521–531. [Google Scholar] [CrossRef] [PubMed]

- Farsinia, F.; Goharshadi, E.K.; Ramezanian, N.; Sangatash, M.M.; Moghayedi, M. Antimicrobial Waterborne Acrylic Paint by the Additive of Graphene Nanosheets/Silver Nanocomposite. Mater. Chem. Phys. 2023, 297, 127355. [Google Scholar] [CrossRef]

- Li, L.; Cui, Y.; Zhang, Z.; Tu, P.; Gong, H.; Li, P. Preparation of Graphene/Fe3O4 Composite Varnish with Excellent Corrosion-Resistant and Electromagnetic Shielding Properties. Ceram. Int. 2020, 46, 22876–22882. [Google Scholar] [CrossRef]

- Kamboj, S.; Thakur, A. Applications of Graphene-Based Composites—A Review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Mates, J.E.; Bayer, I.S.; Salerno, M.; Carroll, P.J.; Jiang, Z.; Liu, L.; Megaridis, C.M. Durable and Flexible Graphene Composites Based on Artists’ Paint for Conductive Paper Applications. Carbon N. Y. 2015, 87, 163–174. [Google Scholar] [CrossRef]

- Ye, Y.; Chen, H.; Zou, Y.; Zhao, H. Study on Self-Healing and Corrosion Resistance Behaviors of Functionalized Carbon Dot-Intercalated Graphene-Based Waterborne Epoxy Coating. J. Mater. Sci. Technol. 2021, 67, 226–236. [Google Scholar] [CrossRef]

- Cui, G.; Zhang, C.; Wang, A.; Zhou, X.; Xing, X.; Liu, J.; Li, Z.; Chen, Q.; Lu, Q. Research Progress on Self-Healing Polymer/Graphene Anticorrosion Coatings. Prog. Org. Coat. 2021, 155, 106231. [Google Scholar] [CrossRef]

- Ashfaq, M.Y.; Al-Ghouti, M.A.; Zouari, N. Investigating the Effect of Polymer-Modified Graphene Oxide Coating on RO Membrane Fouling. J. Water Process. Eng. 2022, 49, 103164. [Google Scholar] [CrossRef]

- Zheng, Z.; Liao, C.; Xia, Y.; Chai, W.; Xie, C.; Zhang, W.; Liu, Y. Facile Fabrication of Robust, Biomimetic and Superhydrophobic Polymer/Graphene-Based Coatings with Self-Cleaning, Oil-Water Separation, Anti-Icing and Corrosion Resistance Properties. Colloids Surf. A Physicochem. Eng. Asp. 2021, 627, 127164. [Google Scholar] [CrossRef]

- Mandal, P.; Ghosh, S.K.; Grewal, H.S. Graphene Oxide Coated Aluminium as an Efficient Antibacterial Surface. Environ. Technol. Innov. 2022, 28, 102591. [Google Scholar] [CrossRef]

- Ding, R.; Li, W.; Wang, X.; Gui, T.; Li, B.; Han, P.; Tian, H.; Liu, A.; Wang, X.; Liu, X.; et al. A Brief Review of Corrosion Protective Films and Coatings Based on Graphene and Graphene Oxide. J. Alloys Compd. 2018, 764, 1039–1055. [Google Scholar] [CrossRef]

- Nayak, P.K.; Hsu, C.J.; Wang, S.C.; Sung, J.C.; Huang, J.L. Graphene Coated Ni Films: A Protective Coating. Thin Solid Films 2013, 529, 312–316. [Google Scholar] [CrossRef]

- Ren, S.; Cui, M.; Liu, C.; Wang, L. A Comprehensive Review on Ultrathin, Multi-Functionalized, and Smart Graphene and Graphene-Based Composite Protective Coatings. Corros. Sci. 2023, 212, 110939. [Google Scholar] [CrossRef]

- Nine, M.J.; Cole, M.A.; Tran, D.N.H.; Losic, D. Graphene: A Multipurpose Material for Protective Coatings. J. Mater. Chem. A 2015, 3, 12580–12602. [Google Scholar] [CrossRef]

- Nuraje, N.; Khan, S.I.; Misak, H.; Asmatulu, R.; Jafari, H.; Velasco, J.I. The Addition of Graphene to Polymer Coatings for Improved Weathering. ISRN Polym. Sci. 2013, 2013, 514617. [Google Scholar] [CrossRef]

- Qiu, Y.; Wang, Z.; Owens, A.C.E.; Kulaots, I.; Chen, Y.; Kane, A.B.; Hurt, R.H. Antioxidant Chemistry of Graphene-Based Materials and Its Role in Oxidation Protection Technology. Nanoscale 2014, 6, 11744–11755. [Google Scholar] [CrossRef] [PubMed]

- Fu, P.; Teri, G.-L.; Chao, X.-L.; Li, J.; Li, Y.-H.; Yang, H. Modified Graphene-FEVE Composite Coatings: Application in the Repair of Ancient Architectural Color Paintings. Coatings 2020, 10, 1162. [Google Scholar] [CrossRef]

- Krishnamurthy, A.; Gadhamshetty, V.; Mukherjee, R.; Natarajan, B.; Eksik, O.; Shojaee, S.A.; Lucca, D.A.; Ren, W.; Cheng, H.-M.; Koratkar, N. Superiority of Graphene over Polymer Coatings for Prevention of Microbially Induced Corrosion. Sci. Rep. 2015, 5, 13858. [Google Scholar] [CrossRef]

- Wojucki, M.; Nasiłowska, B.; Bombalska, A.; Djas, M.; Babul, T. Wpływ Tlenku Grafenu i Zredukowanego Tlenku Grafenu Na Wybrane Właściwości Strukturalne Wodorozcieńczalnej Żywicy Akrylowej. Inżynieria Powierzchni 2018, 24, 55–59. [Google Scholar] [CrossRef]

- Calovi, M.; Rossi, S.; Deflorian, F.; Dirè, S.; Ceccato, R. Effect of Functionalized Graphene Oxide Concentration on the Corrosion Resistance Properties Provided by Cataphoretic Acrylic Coatings. Mater. Chem. Phys. 2020, 239, 121984. [Google Scholar] [CrossRef]

- Monetta, T.; Acquesta, A.; Bellucci, F. Graphene/Epoxy Coating as Multifunctional Material for Aircraft Structures. Aerospace 2015, 2, 423–434. [Google Scholar] [CrossRef]

- Nine, M.J.; Cole, M.A.; Johnson, L.; Tran, D.N.H.; Losic, D. Robust Superhydrophobic Graphene-Based Composite Coatings with Self-Cleaning and Corrosion Barrier Properties. ACS Appl. Mater. Interfaces 2015, 7, 28482–28493. [Google Scholar] [CrossRef]

- Zhu, X.; Ni, Z.; Dong, L.; Yang, Z.; Cheng, L.; Zhou, X.; Xing, Y.; Wen, J.; Chen, M. In-Situ Modulation of Interactions between Polyaniline and Graphene Oxide Films to Develop Waterborne Epoxy Anticorrosion Coatings. Prog. Org. Coat. 2019, 133, 106–116. [Google Scholar] [CrossRef]

- Graphenstone Global. Available online: https://www.graphenstone.com/ (accessed on 12 May 2023).

- Aragaw, B.A. Reduced Graphene Oxide-Intercalated Graphene Oxide Nano-Hybrid for Enhanced Photoelectrochemical Water Reduction. J. Nanostructure Chem. 2020, 10, 9–18. [Google Scholar] [CrossRef]

- Patterson, L. The Scherrer Formula for X-Ray Particle Size Determination. Phys. Rev. 1939, 56, 978–982. [Google Scholar] [CrossRef]

- Malard, L.M.; Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S. Raman Spectroscopy in Graphene. Phys. Rep. 2009, 473, 51–87. [Google Scholar] [CrossRef]

- Stańczyk, B.; Dobrzański, L.; Jagoda, A.; Możdżonek, M.; Natarajan, S. Graphene Obtained by Electrolytic Method on Silicon Carbide Substrates. Electron. Mater. 2014, 42, 20–25. [Google Scholar]

- Dong, X.; Wang, P.; Fang, W.; Su, C.Y.; Chen, Y.H.; Li, L.J.; Huang, W.; Chen, P. Growth of Large-Sized Graphene Thin-Films by Liquid Precursor-Based Chemical Vapor Deposition under Atmospheric Pressure. Carbon N. Y. 2011, 49, 3672–3678. [Google Scholar] [CrossRef]

- Stobinski, L.; Lesiak, B.; Malolepszy, A.; Mazurkiewicz, M.; Mierzwa, B.; Zemek, J.; Jiricek, P.; Bieloshapka, I. Graphene Oxide and Reduced Graphene Oxide Studied by the XRD, TEM and Electron Spectroscopy Methods. J. Electron Spectrosc. Relat. Phenom. 2014, 195, 145–154. [Google Scholar] [CrossRef]

- Aziz, M.; Halim, F.S.A.; Jaafar, J. Preparation and Characterization of Graphene Membrane Electrode Assembly. J. Teknol. Sci. Eng. 2014, 69, 11–14. [Google Scholar] [CrossRef]

- Lu, C.T.; Weerasinghe, A.; Maroudas, D.; Ramasubramaniam, A. A Comparison of the Elastic Properties of Graphene- and Fullerene-Reinforced Polymer Composites: The Role of Filler Morphology and Size. Sci. Rep. 2016, 6, 31735. [Google Scholar] [CrossRef]

- Tarhini, A.; Tehrani-Bagha, A.; Kazan, M.; Grady, B. The Effect of Graphene Flake Size on the Properties of Graphene-Based Polymer Composite Films. J. Appl. Polym. Sci. 2021, 138, 49821. [Google Scholar] [CrossRef]

- Monetta, T.; Acquesta, A.; Carangelo, A.; Bellucci, F. Considering the Effect of Graphene Loading in Water-Based Epoxy Coatings. J. Coat. Technol. Res. 2018, 15, 923–931. [Google Scholar] [CrossRef]

- Shih, C.J.; Strano, M.S.; Blankschtein, D. Wetting Translucency of Graphene. Nat. Mater. 2013, 12, 866–869. [Google Scholar] [CrossRef]

- Li, M.; Liu, X.; Liu, N.; Guo, Z.; Singh, P.K.; Fu, S. Effect of Surface Wettability on the Antibacterial Activity of Nanocellulose-Based Material with Quaternary Ammonium Groups. Colloids Surf. A Physicochem. Eng. Asp. 2018, 554, 122–128. [Google Scholar] [CrossRef]

- Jiao, Y.; Qian, F.; Li, Y.; Wang, G.; Saltikov, C.W.; Gralnick, J.A. Deciphering the Electron Transport Pathway for Graphene Oxide Reduction by Shewanella Oneidensis MR-1. J. Bacteriol. 2011, 193, 3662–3665. [Google Scholar] [CrossRef] [PubMed]

- Tu, Y.; Lv, M.; Xiu, P.; Huynh, T.; Zhang, M.; Castelli, M.; Liu, Z.; Huang, Q.; Fan, C.; Fang, H.; et al. Destructive Extraction of Phospholipids from Escherichia Coli Membranes by Graphene Nanosheets. Nat. Nanotechnol. 2013, 8, 594–601. [Google Scholar] [CrossRef] [PubMed]

- Akhavan, O.; Ghaderi, E. Toxicity of Graphene and Graphene Oxide Nanowalls against Bacteria. ACS Nano 2010, 4, 5731–5736. [Google Scholar] [CrossRef] [PubMed]

- Banasiak, A.I.; Racki, A.; Małek, M.; Chlanda, A. Flake Graphene as an Efficient Agent Governing Cellular Fate and Antimicrobial Properties of Fibrous Tissue Engineering Scaffolds—A Review. Materials 2022, 15, 5306. [Google Scholar] [CrossRef] [PubMed]

- Buccheri, M.A.; D’Angelo, D.; Scalese, S.; Spanò, S.F.; Filice, S.; Fazio, E.; Compagnini, G.; Zimbone, M.; Brundo, M.V.; Pecoraro, R.; et al. Modification of Graphene Oxide by Laser Irradiation: A New Route to Enhance Antibacterial Activity. Nanotechnology 2016, 27, 245704. [Google Scholar] [CrossRef]

- Sawangphruk, M.; Srimuk, P.; Chiochan, P.; Sangsri, T.; Siwayaprahm, P. Synthesis and Antifungal Activity of Reduced Graphene Oxide Nanosheets. Carbon N. Y. 2012, 50, 5156–5161. [Google Scholar] [CrossRef]

- Qiu, J.; Geng, H.; Wang, D.; Qian, S.; Zhu, H.; Qiao, Y.; Qian, W.; Liu, X. Layer-Number Dependent Antibacterial and Osteogenic Behaviors of Graphene Oxide Electrophoretic Deposited on Titanium. ACS Appl. Mater. Interfaces 2017, 9, 12253–12263. [Google Scholar] [CrossRef] [PubMed]

- Vanzetto, A.B.; Marocco, M.V.; de Lima, G.G.; Beltrami, L.V.R.; Zattera, A.J.; Piazza, D. Antimicrobial and Mechanical Performance of Epoxy/Graphene-Based Powder Coatings. Iran. Polym. J. 2023, 32, 1–11. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhai, D.; Xu, M.; Yao, Q.; Zhu, H.; Chang, J.; Wu, C. 3D-Printed Bioceramic Scaffolds with Antibacterial and Osteogenic Activity. Biofabrication 2017, 9, 025037. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, A.M.; Mohamad, D. Antibacterial Properties of Graphene and Its Reinforcement Effect on Compressive Properties of PMMA. Biointerface Res. Appl. Chem. 2023, 13, 393. [Google Scholar] [CrossRef]

- Huong, Q.T.T.; Nam, N.T.H.; Hai, N.D.; Dat, N.M.; Linh, N.T.T.; Tinh, N.T.; Chau, N.M.; Phuc, N.V.H.; Le Hoai Nhi, T.; Phong, M.T.; et al. Surface Modification and Antibacterial Activity Enhancement of Acrylic Fabric by Coating Silver/Graphene Oxide Nanocomposite. J. Polym. Res. 2023, 30, 1–16. [Google Scholar] [CrossRef]

- Barua, S.; Chattopadhyay, P.; Phukan, M.M.; Konwar, B.K.; Islam, J.; Karak, N. Biocompatible Hyperbranched Epoxy/Silver–Reduced Graphene Oxide–Curcumin Nanocomposite as an Advanced Antimicrobial Material. RSC Adv. 2014, 4, 47797–47805. [Google Scholar] [CrossRef]

- Grabowska, A.; Kowalczyk, J.; Tomala, R.; Ptak, M.; Małecka, M.; Wędzyńska, A.; Stefanski, M.; Stręk, W.; Głuchowski, P. Optimization of the Electrochemical Method of Obtaining Graphene Nanoplatelets (GNPs). Materials 2023, 16, 2188. [Google Scholar] [CrossRef]

| Sample | Micro-Hardness | Standard Deviation |

|---|---|---|

| HK | ||

| ED0 | 2.8 | 0.4 |

| ED05 | 1.0 | 0.1 |

| ED1 | 1.2 | 0.4 |

| ED3 | 2.4 | 0.49 |

| Sample | Contact Angle | Standard Deviation |

|---|---|---|

| ° | ||

| ED0 | 80.3 | 3.1 |

| ED05 | 88.9 | 0.8 |

| ED1 | 76.0 | 5.2 |

| ED3 | 71.4 | 3.5 |

| LV0 | 65.4 | 2.0 |

| LV05 | 79.7 | 3.4 |

| LV1 | 71.6 | 3.4 |

| LV3 | 61.1 | 4.0 |

| FA0 | 30.6 | 8.1 |

| FA05 | 71.0 | 2.2 |

| FA1 | 33.7 | 9.1 |

| FA3 | 44.8 | 14.4 |

| Sample | S. aureus | P. aeruginosa | C. albicans | |||

|---|---|---|---|---|---|---|

| Average Absorbance | Survival Rate | Average Absorbance | Survival Rate | Average Absorbance | Survival Rate | |

| Arb. Units | % | Arb. Units | % | Arb. Units | % | |

| ED0 | 0.0544 | 0.22 | 0.2440 | 11.14 | 0.3730 | 15.43 |

| ED05 | 0.0541 | 0.20 | 0.3438 | 15.70 | 0.4773 | 19.74 |

| ED1 | 0.0557 | 0.27 | 0.0768 | 3.51 | 0.5397 | 22.32 |

| ED3 | 0.0623 | 0.56 | 0.0936 | 4.27 | 0.1520 | 6.29 |

| LV0 | 0.1849 | 5.81 | 0.2330 | 10.64 | 0.3743 | 15.48 |

| LV05 | 0.0657 | 0.70 | 0.1160 | 5.30 | 0.0833 | 3.45 |

| LV1 | 0.0660 | 0.71 | 0.0927 | 4.23 | 0.0811 | 3.36 |

| LV3 | 0.0549 | 0.24 | 0.0668 | 3.05 | 0.0627 | 2.59 |

| FA0 | 0.1984 | 6.39 | 0.4810 | 21.96 | 0.6870 | 28.41 |

| FA05 | 0.2159 | 7.14 | 0.4607 | 21.03 | 1.0523 | 43.52 |

| FA1 | 0.1596 | 4.72 | 0.6103 | 27.87 | 0.8500 | 35.15 |

| FA3 | 0.1860 | 5.85 | 0.6170 | 28.17 | 0.6760 | 27.96 |

| Composite | Type of Micro-Organism | Survival Rate/Time | Proposed Mechanism | Ref. |

|---|---|---|---|---|

| Acrylic paint + Ag + rGO | E. coli S. aureus | ~5%/24 h | Interaction between Ag NPs and thiol groups in the enzyme of the bacterial cell membrane | [14] |

| Epoxy resin + rGO | E. coli | ~35%/24 h | Oxidative stresses | [56] |

| PVA + Ag@GO | E. coli | 0%/12 h | Interaction between Ag NPs and thiol groups in the enzyme of the bacterial cell membrane | [57] |

| PMMA + graphene | S. aureus | 85%/7 h | Extraction of phospholipids from bacteria cell membranes | [58] |

| Acrylic paint + Ag@GO | P. aeruginosa S. aureus | 0%/3 h | Interaction between the cell membrane and the electron-rich surface of the GO sheets | [59] |

| Epoxy Ag-rGO- curcumine | S. aureus C. albicans | 0%/12 h | Adherence of microbes to the nanocomposite surface causes microbial cell lysis | [60] |

| Acrylic paint + graphene | S. aureus P. aeruginosa C. albicans | 4.7%/24 h 21%/24 h 28%/24 h | Mechanical (direct contact of sharp edge of graphene flake with bacteria/fungi cell) | This work |

| Varnish + graphene | S. aureus P. aeruginosa C. albicans | 0.24%/24 h 3%/24 h 2.6%/24 h | Mechanical (direct contact of sharp edge of graphene flake with bacteria/fungi cell) | This work |

| Enamel + graphene | S. aureus P. aeruginosa C. albicans | 0.2%/24 h 3.5%/24 h 6.3%/24 h | Mechanical (direct contact of sharp edge of graphene flake with bacteria/fungi cell) | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartczak, N.; Kowalczyk, J.; Tomala, R.; Stefanski, M.; Szymański, D.; Ptak, M.; Stręk, W.; Szustakiewicz, K.; Kurzynowski, T.; Szczepański, Ł.; et al. Effect of the Addition of Graphene Flakes on the Physical and Biological Properties of Composite Paints. Molecules 2023, 28, 6173. https://doi.org/10.3390/molecules28166173

Bartczak N, Kowalczyk J, Tomala R, Stefanski M, Szymański D, Ptak M, Stręk W, Szustakiewicz K, Kurzynowski T, Szczepański Ł, et al. Effect of the Addition of Graphene Flakes on the Physical and Biological Properties of Composite Paints. Molecules. 2023; 28(16):6173. https://doi.org/10.3390/molecules28166173

Chicago/Turabian StyleBartczak, Natalia, Jerzy Kowalczyk, Robert Tomala, Mariusz Stefanski, Damian Szymański, Maciej Ptak, Wiesław Stręk, Konrad Szustakiewicz, Tomasz Kurzynowski, Łukasz Szczepański, and et al. 2023. "Effect of the Addition of Graphene Flakes on the Physical and Biological Properties of Composite Paints" Molecules 28, no. 16: 6173. https://doi.org/10.3390/molecules28166173

APA StyleBartczak, N., Kowalczyk, J., Tomala, R., Stefanski, M., Szymański, D., Ptak, M., Stręk, W., Szustakiewicz, K., Kurzynowski, T., Szczepański, Ł., Junka, A., Gorczyca, D., & Głuchowski, P. (2023). Effect of the Addition of Graphene Flakes on the Physical and Biological Properties of Composite Paints. Molecules, 28(16), 6173. https://doi.org/10.3390/molecules28166173