In Situ Low-Temperature Carbonization Capping of LiFePO4 with Coke for Enhanced Lithium Battery Performance

Abstract

1. Introduction

2. Results and Discussion

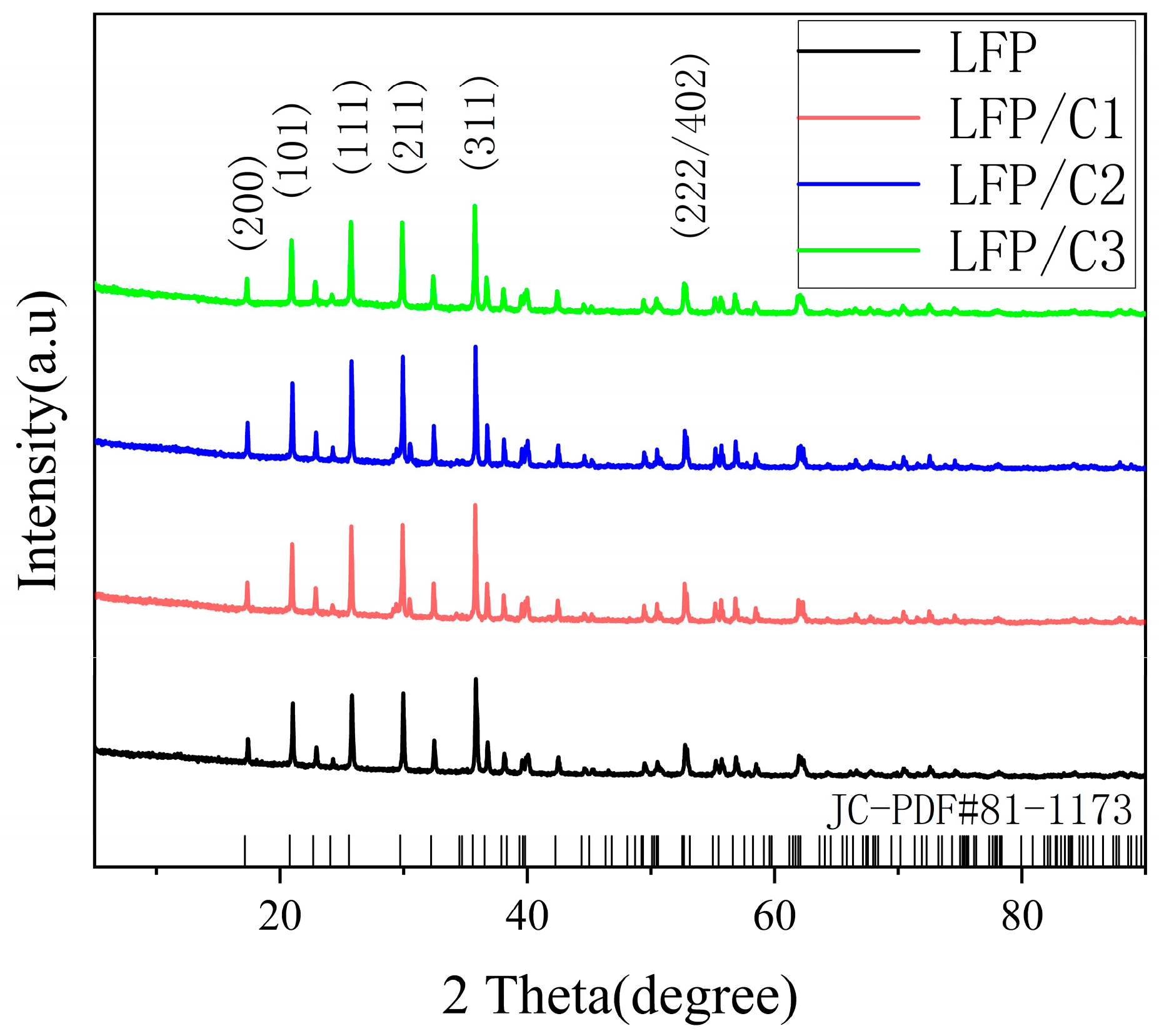

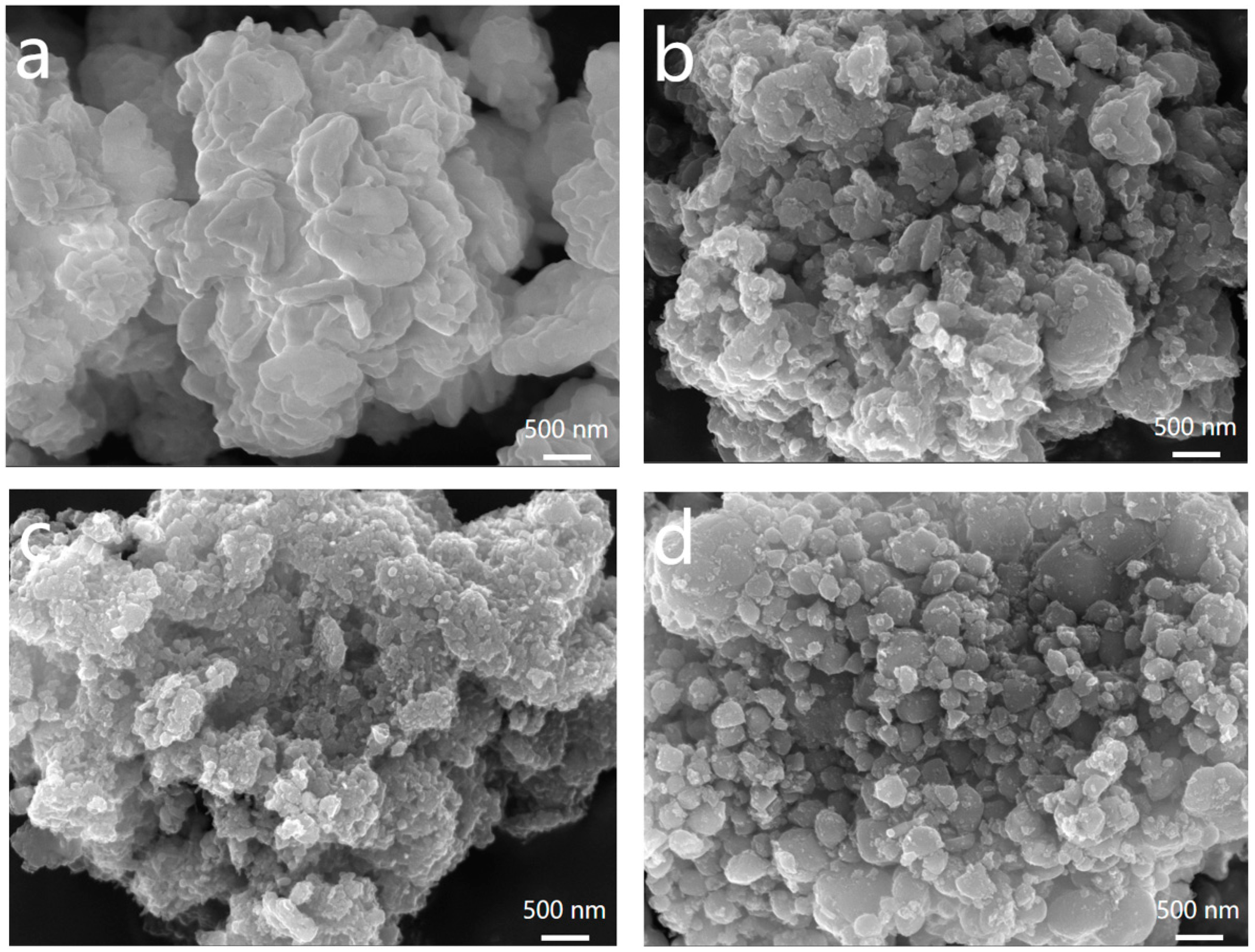

2.1. Material Structure and Morphology Characterization Testing

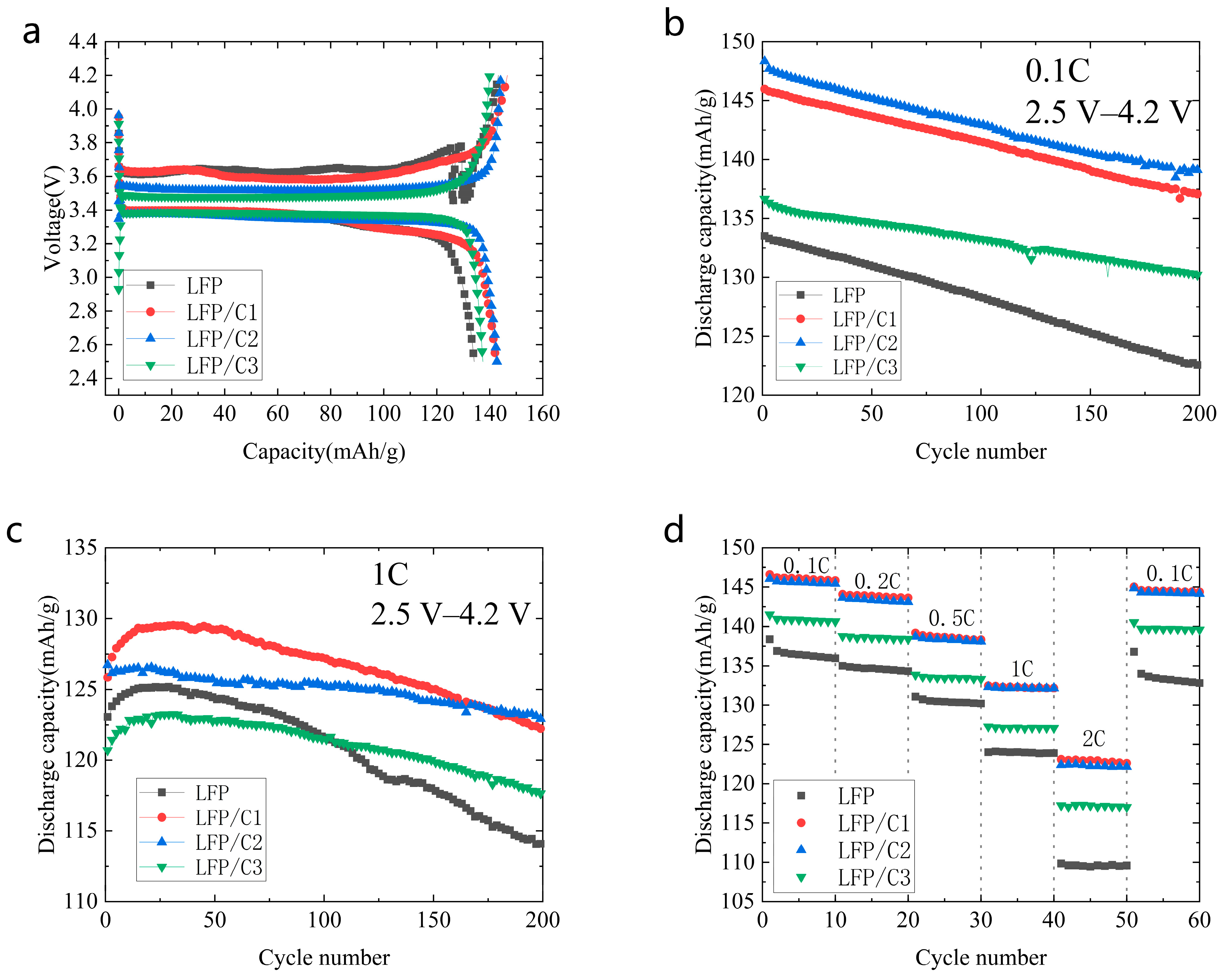

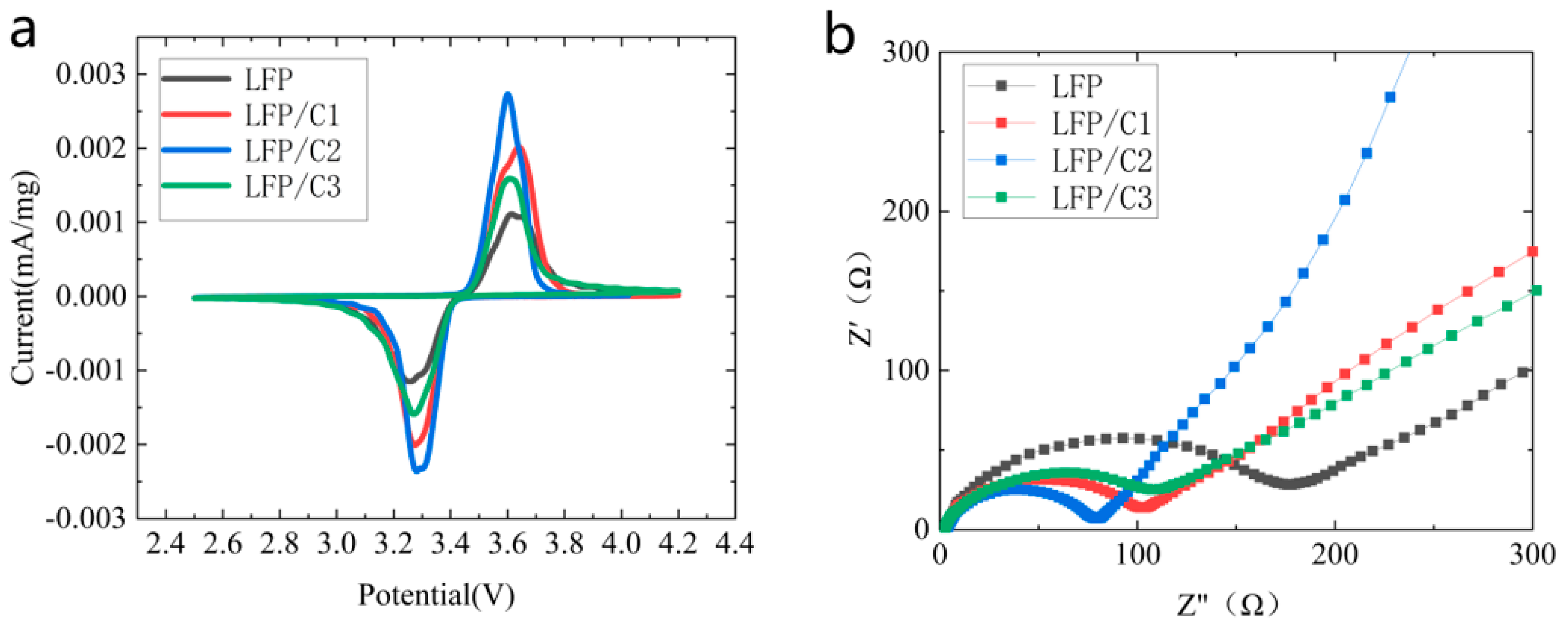

2.2. Electrochemical Performance Testing

3. Experiment

3.1. Materials Applied for the Experiment

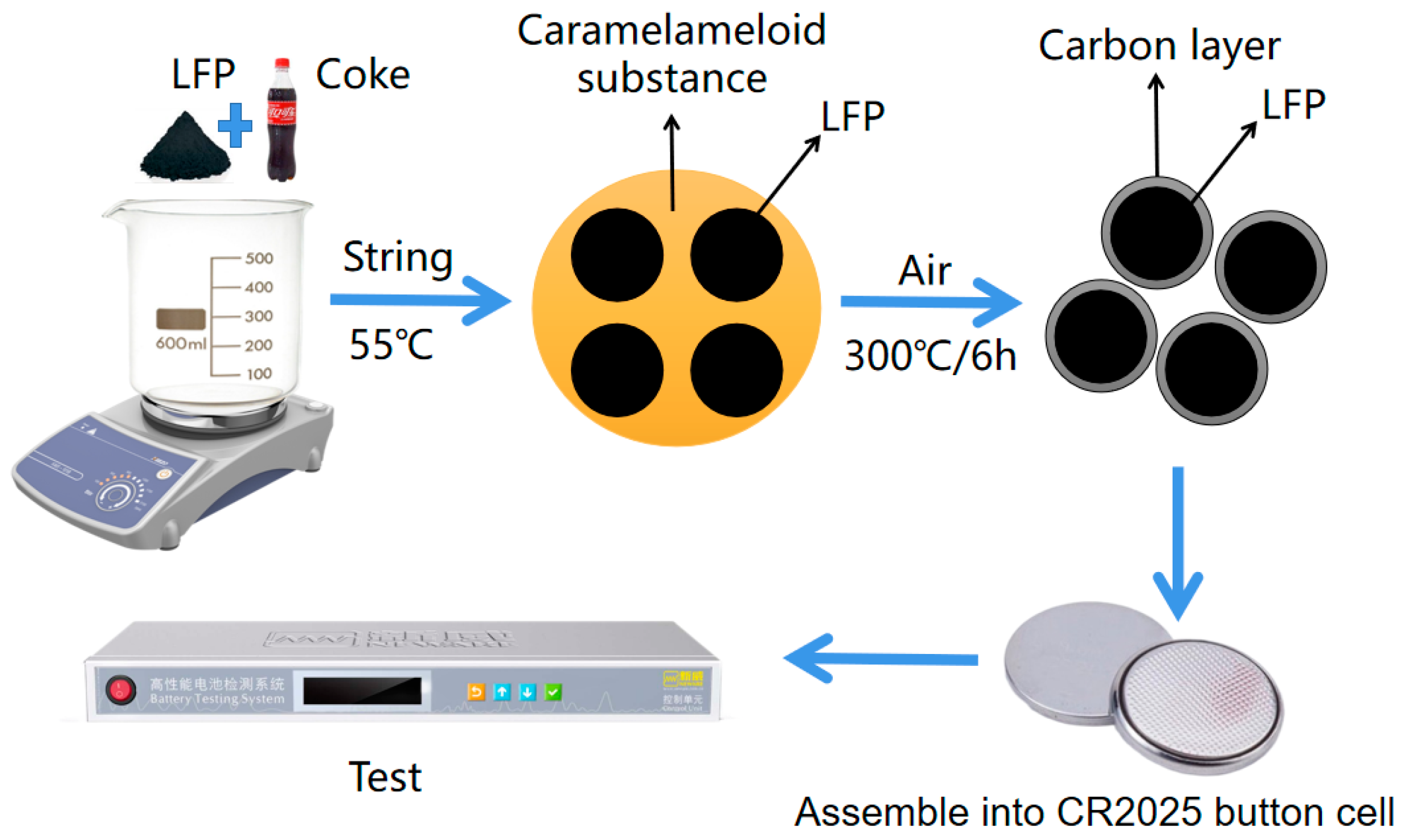

3.2. Synthesis of LFP/C

3.3. Preparation of Cathode Materials and Battery Assembly

3.4. Characterization of Materials

3.5. Electrochemical Performance Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Deng, W.; Xu, Y.; Zhang, X.; Li, C.; Liu, Y.; Xiang, K.; Chen, H. (NH4)2Co2V10O28·16H2O/(NH4)2V10O25·8H2O heterostructure as cathode for high-performance aqueous Zn-ion batteries. J. Alloy. Compd. 2022, 903, 163824. [Google Scholar] [CrossRef]

- Li, D.; Guo, H.; Jiang, S.; Zeng, G.; Zhou, W.; Li, Z. Microstructures and electrochemical performances of TiO2-coated Mg-Zr co-doped NCM as a cathode material for lithium-ion batteries with high power and long circular life. New J. Chem. 2021, 45, 19446–19455. [Google Scholar] [CrossRef]

- Zhou, W.; Zeng, G.; Jin, H.; Jiang, S.; Huang, M.; Zhang, C.; Chen, H. Bio-Template Synthesis of V2O3@Carbonized Dictyophora Composites for Advanced Aqueous Zinc-Ion Batteries. Molecules 2023, 28, 2147. [Google Scholar] [CrossRef]

- Goodenough, J.B. Electrochemical energy storage in a sustainable modern society. Energy Environ. Sci. 2014, 7, 14–18. [Google Scholar] [CrossRef]

- Zhang, Q.; Liang, Q.J.; Liao, Q.L.; Yi, F.; Zheng, X.; Ma, M.; Gao, F.; Zhang, Y. Service Behavior of Multifunctional Triboelectric Nanogenerators. Adv. Mater. 2017, 29, 1606703. [Google Scholar] [CrossRef] [PubMed]

- Yuan, M.M.; Xu, R.H.; Yao, Y.C. Research progress on surface carbon coating modification of LiFePO4 as cathode material for lithium-ion batteries. Mater. Guide 2020, 19, 34. [Google Scholar]

- Feng, X.H.; Sun, J.; He, J.H. Research progress on modification of lithium iron phosphate cathode materials. Energy Storage Sci. Technol. 2022, 11, 20. [Google Scholar]

- Ramasubramanian, B.; Sundarrajan, S.; Chellappan, V.; Reddy, M.V.; Ramakrishna, S.; Zaghib, K. Recent Development in Carbon-LiFePO4 Cathodes for Lithium-Ion Batteries: A Mini Review. Batteries 2022, 8, 133. [Google Scholar] [CrossRef]

- Gao, C.; Zhou, J.; Liu, G.; Wang, L. Synthesis of F-doped LiFePO4/C cathode materials for high performance lithium-ion batteries using co-precipitation method with hydrofluoric acid source. J. Alloys Compd. 2017, 727, 501–513. [Google Scholar] [CrossRef]

- Schmuch, R.; Wagner, R.; Horpel, G.; Placke, T.; Winter, M. Performance and cost of materials for lithium-based rechargeable automotive batteries. Nat. Energy 2018, 3, 267–278. [Google Scholar] [CrossRef]

- Wang, Q.; Peng, D.C.; Chen, Y.X.; Xia, X.; Liu, H.; He, Y.; Ma, Q. A facile surfactant-assisted self-assembly of LiFePO4/graphene composites with improved rate performance for lithium ion batteries. J. Electroanal. Chem. 2018, 818, 68–75. [Google Scholar] [CrossRef]

- Adepoju, A.A.; Williams, Q.L. High C-rate performance of LiFePO4/carbon nanofibers composite cathode for Li-ion batteries. Curr. Appl. Phys. 2020, 20, 1–4. [Google Scholar] [CrossRef]

- Du, G.D.; Zhou, Y.K.; Tian, X.; Wu, G.; Xi, Y.; Zhao, S. High-performance 3D directional porous LiFePO4/C materials synthesized by freeze casting. Appl. Surf. Sci. 2018, 453, 493–501. [Google Scholar] [CrossRef]

- Wei, X.F.; Guan, Y.B.; Zheng, X.; Zhu, Q.; Shen, J.; Qiao, N.; Zhou, S.; Xu, B. Improvement on high rate performance of LiFePO4 cathodes using graphene as a conductive agent. Appl. Surf. Sci. 2018, 440, 748–754. [Google Scholar] [CrossRef]

- Li, J.K.; Ma, Z.F. Past and Present of LiFePO4: From Fundamental Research to Industrial Applications. Chem 2019, 5, 3–6. [Google Scholar] [CrossRef]

- Ye, F.X.; Wang, J.M. Effect of carbon cladding on the performance of LiFePO4/C cathode materials. Power Technol. 2019, 43, 4. [Google Scholar]

- Ramasubramanian, B.; Reddy, M.V.; Zaghib, K.; Armand, M.; Ramakrishna, S. Growth Mechanism of Micro/Nano Metal Dendrites and Cumulative Strategies for Countering Its Impacts in Metal Ion Batteries: A Review. Nanomaterials 2021, 11, 2476. [Google Scholar] [CrossRef]

- Liu, X.Y.; Zhao, R.P.; Xia, Y.; Li, Q. Improved electrochemical performance of LiFePO4/carbon cathode for lithium-ion batteries. Ionics 2022, 28, 4579–4585. [Google Scholar] [CrossRef]

- Balo, L.; Gupta, H.; Singh, S.K.; Singh, V.K.; Tripathi, A.K.; Srivastava, N.; Tiwari, R.K.; Mishra, R.; Meghnani, D.; Singh, R. Development of gel polymer electrolyte based on LiTFSI and EMIMFSI for application in rechargeable lithium metal battery with GO-LFP and NCA cathodes. J. Solid State Electrochem. 2019, 23, 2507–2518. [Google Scholar] [CrossRef]

- Eftekhari, A. LiFePO4/C nanocomposites for lithium-ion batteries. J. Power Sources 2017, 343, 395–411. [Google Scholar] [CrossRef]

- Uddin, M.J.; Alaboina, P.K.; Cho, S.J. Nanostructured cathode materials synthesis for lithium-ion batteries. Mater. Today Energy 2017, 5, 138–157. [Google Scholar] [CrossRef]

- Raj, H.; Sil, A. Effect of carbon coating on electrochemical performance of LiFePO4 cathode material for Li-ion battery. Ionics 2018, 24, 2543–2553. [Google Scholar] [CrossRef]

- Chen, Z.L.; Zhang, Q.; Liang, Q.J. Carbon-Coatings Improve Performance of Li-Ion Battery. Nanomaterials 2022, 12, 1936. [Google Scholar] [CrossRef] [PubMed]

- Toprakci, O.; Toprakci, H.A.K.; Ji, L.; Xu, G.; Lin, Z.; Zhang, X. Carbon Nanotube-Loaded Electrospun LiFePO4/Carbon Composite Nanofibers As Stable and Binder-Free Cathodes for Rechargeable Lithium-Ion Batteries. ACS Appl. Mater. Interfaces 2012, 4, 1273–1280. [Google Scholar] [CrossRef]

- Dhindsa, K.S.; Mandal, B.P.; Bazzi, K.; Lin, M.; Nazri, M.; Nazri, G.; Naik, V.; Garg, V.; Oliveira, A.; Vaishnava, P.; et al. Enhanced electrochemical performance of graphene modified LiFePO4 cathode material for lithium ion batteries. Solid State Ion. 2013, 253, 94–100. [Google Scholar] [CrossRef]

- Jang, S.K.; Kim, J.M.; Yun, Y.H.; Chung, H.T. Optimizing a new synthesis route for LiFePO4/C composites. J. Ceram. Process. Res. 2009, 10, 95–101. [Google Scholar]

- Liu, Y.W.; Zhang, W.; Jiang, J.N. Synthesis, Structure and Electrochemical Performance of LiFePO4/C. Asian J. Chem. 2013, 25, 831–834. [Google Scholar] [CrossRef]

- Wu, M.; Choi, S.; Kang, Y.; Jung, H.-K. One-Step Microwave Synthesis of Hierarchical Structured LiFePO4 Using Citric Acid. Bull. Korean Chem. Soc. 2014, 35, 2901–2905. [Google Scholar] [CrossRef][Green Version]

- Wang, Y.G.; Wang, Y.R.; Hosono, E.J.; Wang, K.; Zhou, H. The design of a LiFePO4/carbon nanocomposite with a core-shell structure and its synthesis by an in situ polymerization restriction method. Angew. Chem. Int. Ed. 2008, 47, 7461–7465. [Google Scholar] [CrossRef]

- Park, K.S.; Schougaard, S.B.; Goodenough, J.B. Conducting-polymer/iron-redox-couple composite cathodes for lithium secondary batteries. Adv. Mater. 2007, 19, 848. [Google Scholar] [CrossRef]

- Yin, X.G. Synthesis of Lithium Iron Phosphate by In Situ Polymerization-Carbon Thermal Reduction and Its Electrochemical Properties; Central South University: Changsha, China, 2010. [Google Scholar]

- Franger, S.; Le, C.F.; Bourbon, C.; Rouault, H. LiFePO4 synthesis routes for enhanced electrochemical performance. Electrochem. Solid State Lett. 2002, 5, A231–A233. [Google Scholar] [CrossRef]

- Hsu, K.F.; Tsay, S.Y.; Hwang, B.J. Physical and electrochemical properties of LiFePO4/carbon composite synthesized at various pyrolysis periods. J. Power Sources 2005, 146, 529–533. [Google Scholar] [CrossRef]

- Zhao, T.L.; Chen, S.; Li, L.; Zhang, X.; Chen, R.; Belharouak, I.; Wu, F.; Amine, K. Synthesis, characterization, and electrochemistry of cathode material Li Li0.2Co0.13Ni0.13Mn0.54 O−2 using organic chelating agents for lithium-ion batteries. J. Power Sources 2013, 228, 206–213. [Google Scholar] [CrossRef]

- Mi, C.H.; Zhao, X.B.; Cao, G.S.; Tu, J.P. In situ synthesis and properties of carbon-coated LiFePO4 as Li-ion battery cathodes. J. Electrochem. Soc. 2005, 152, A483–A487. [Google Scholar] [CrossRef]

- Ma, Q.X.; Chen, Z.J.; Zhong, S.W.; Meng, J.; Lai, F.; Li, Z.; Cheng, C.; Zhang, L.; Liu, T. Na-substitution induced oxygen vacancy achieving high transition metal capacity in commercial Li-rich cathode. Nano Energy 2021, 81, 105622. [Google Scholar] [CrossRef]

- Zhu, W.; Zhang, J.C.; Luo, J.W.; Zeng, C.; Su, H.; Zhang, J.; Liu, R.; Hu, E.; Liu, Y.; Liu, W.; et al. Ultrafast Non-Equilibrium Synthesis of Cathode Materials for Li-Ion Batteries. Adv. Mater. 2023, 35, e2208974. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Liu, B.S.; Li, F. Effect of doped NCA process on the performance of lithium-ion battery cathode. J. Guangxi Univ. Sci. Technol. 2022, 33, 10. [Google Scholar] [CrossRef]

- Liu, H.W.; Tang, D.G. The low cost synthesis of nanoparticles LiFePO4/C composite for lithium rechargeable batteries. Solid State Ion. 2008, 179, 1897–1901. [Google Scholar] [CrossRef]

- Chen, R.R.; Wu, Y.X.; Kong, X.Y. Monodisperse porous LiFePO4/C microspheres derived by microwave-assisted hydrothermal process combined with carbothermal reduction for high power lithium-ion batteries. J. Power Sources 2014, 258, 246–252. [Google Scholar] [CrossRef]

- Gao, F.; Tang, Z.Y. Kinetic behavior of LiFePO4/C cathode material for lithium-ion batteries. Electrochim. Acta 2008, 53, 5071–5075. [Google Scholar] [CrossRef]

- Liu, H.; Li, C.; Zhang, H.P.; Fu, L.; Wu, Y.; Wu, H. Kinetic study on LiFePO4/C nanocomposites synthesized by solid state technique. J. Power Sources 2006, 159, 717–720. [Google Scholar] [CrossRef]

- Fei, H.L.; Peng, Z.W.; Yang, Y.; Li, L.; Raji, A.-R.O.; Samuel, E.L.G.; Tour, J.M. LiFePO4 nanoparticles encapsulated in graphene nanoshells for high-performance lithium-ion battery cathodes. Chem. Commun. 2014, 50, 7117–7119. [Google Scholar] [CrossRef] [PubMed]

- Su, C.; Bu, X.D.; Xu, L.H.; Liu, J.; Zhang, C. A novel LiFePO4/graphene/carbon composite as a performance-improved cathode material for lithium-ion batteries. Electrochim. Acta 2012, 64, 190–195. [Google Scholar] [CrossRef]

- Qi, M.; Liu, Y.X.; Xu, M.; Feng, M.; Gu, J.; Liu, Y.; Wang, L. Improved electrochemical performances of carbon-coated LiFePO4 microspheres for Li-ion battery cathode. Mater. Res. Express 2019, 6, 5520. [Google Scholar] [CrossRef]

| Carbon Source | Coating Method | Specific Capacity | Cycling Stability | Ref. |

|---|---|---|---|---|

| Glucose | Carbothermal reduction | 160.7 mA·h/g (0.1 C) | 82.1% (0.1 C, 100 cycles) | [18] |

| Citric acid | Sol–gel method | 135.2 mA·h/g (1 C) | 96% (1 C, 300 cycles) | [22] |

| Glucose | Co-precipitation | 140.8 mA·h/g (0.1 C) | 87.7% (0.1 C, 50 cycles) | [16] |

| Graphene nanosheet | Chemical vapor deposition | 145 mA·h/g (0.1 C) | 95.3% (0.1 C, 1000 cycles) | [43] |

| Graphene and sucrose | Solvothermal, drying, and calcination | 163.7 mA·h/g (0.1 C) | 97% (0.1 C, 30 cycles) | [44] |

| Sucrose | Hydrothermal method and heat treatment | 128 mA·h/g (0.1 C) | No capacity fading (0.1 C, 50 cycles) | [45] |

| Coke | In situ low-temperature carbon coating | 148.35 mA·h/g (0.1 C) 126.74 mA·h/g (1 C) | 93.74% (0.1 C, 200 cycles) 97.05% (1 C, 200 cycles) | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, F.; Huang, X.; Li, Y.; Zhang, S.; He, X.; Liu, J.; Yu, Z.; Li, F.; Liu, B. In Situ Low-Temperature Carbonization Capping of LiFePO4 with Coke for Enhanced Lithium Battery Performance. Molecules 2023, 28, 6083. https://doi.org/10.3390/molecules28166083

Guo F, Huang X, Li Y, Zhang S, He X, Liu J, Yu Z, Li F, Liu B. In Situ Low-Temperature Carbonization Capping of LiFePO4 with Coke for Enhanced Lithium Battery Performance. Molecules. 2023; 28(16):6083. https://doi.org/10.3390/molecules28166083

Chicago/Turabian StyleGuo, Fei, Xiaoqi Huang, Yudong Li, Shaohui Zhang, Xiong He, Jinghua Liu, Zhiqiang Yu, Feng Li, and Baosheng Liu. 2023. "In Situ Low-Temperature Carbonization Capping of LiFePO4 with Coke for Enhanced Lithium Battery Performance" Molecules 28, no. 16: 6083. https://doi.org/10.3390/molecules28166083

APA StyleGuo, F., Huang, X., Li, Y., Zhang, S., He, X., Liu, J., Yu, Z., Li, F., & Liu, B. (2023). In Situ Low-Temperature Carbonization Capping of LiFePO4 with Coke for Enhanced Lithium Battery Performance. Molecules, 28(16), 6083. https://doi.org/10.3390/molecules28166083