A Systematic Review on Biomass Treatment Using Microwave-Assisted Pyrolysis under PRISMA Guidelines

Abstract

1. Introduction

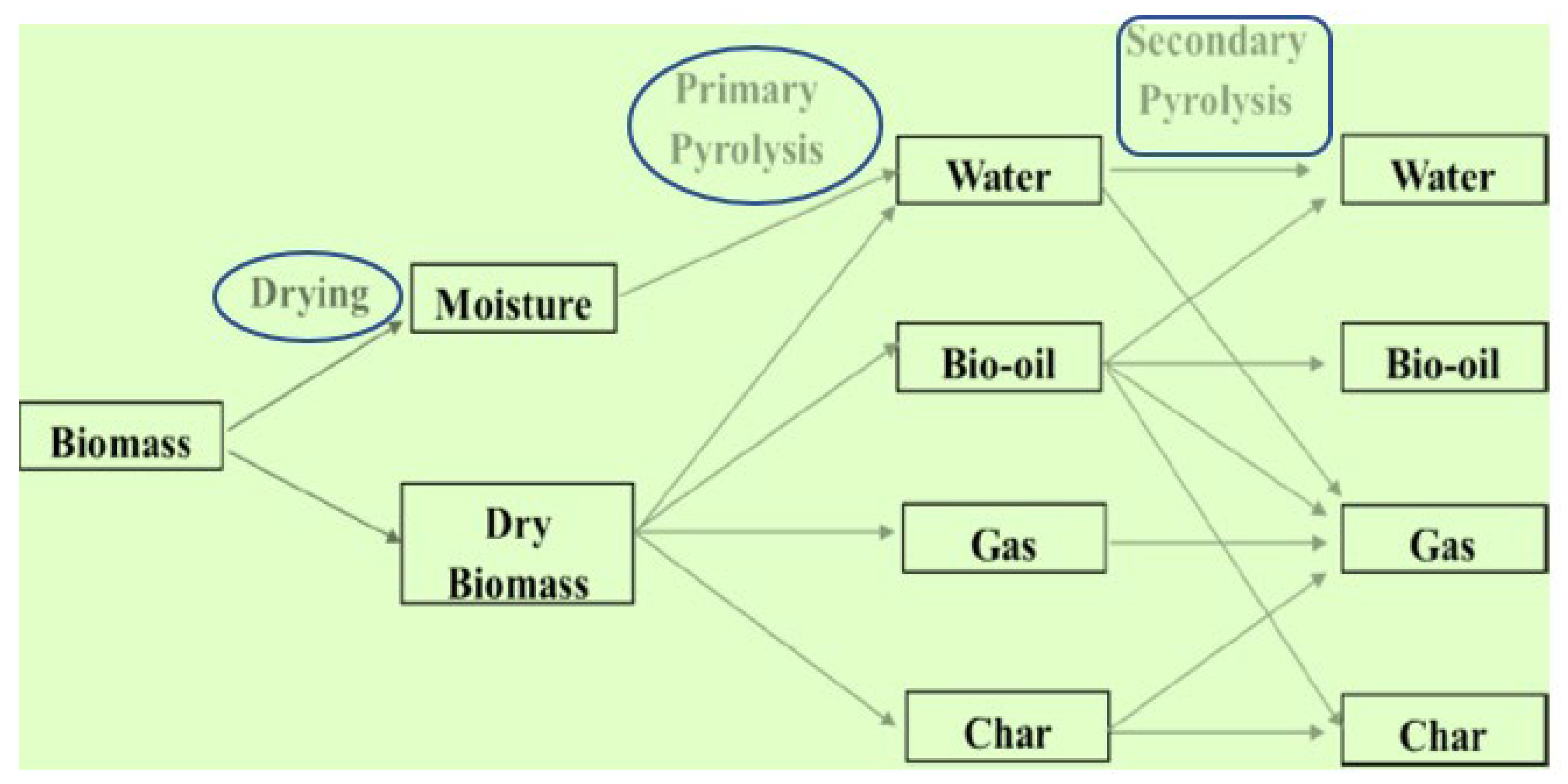

2. Pyrolysis Process

Biomass Pretreatment for Pyrolysis

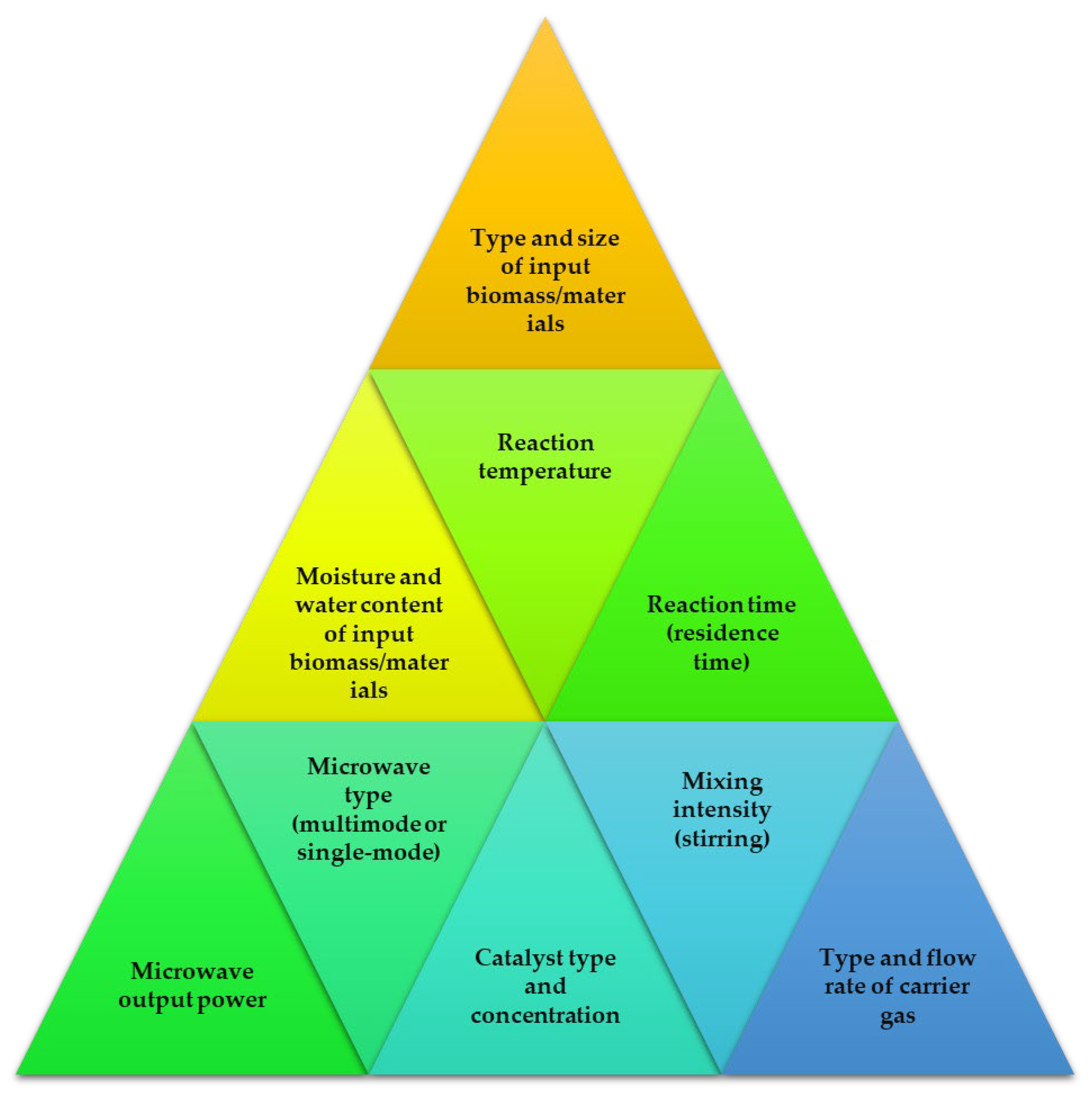

3. Microwave-Assisted Pyrolysis

Application and Limitation

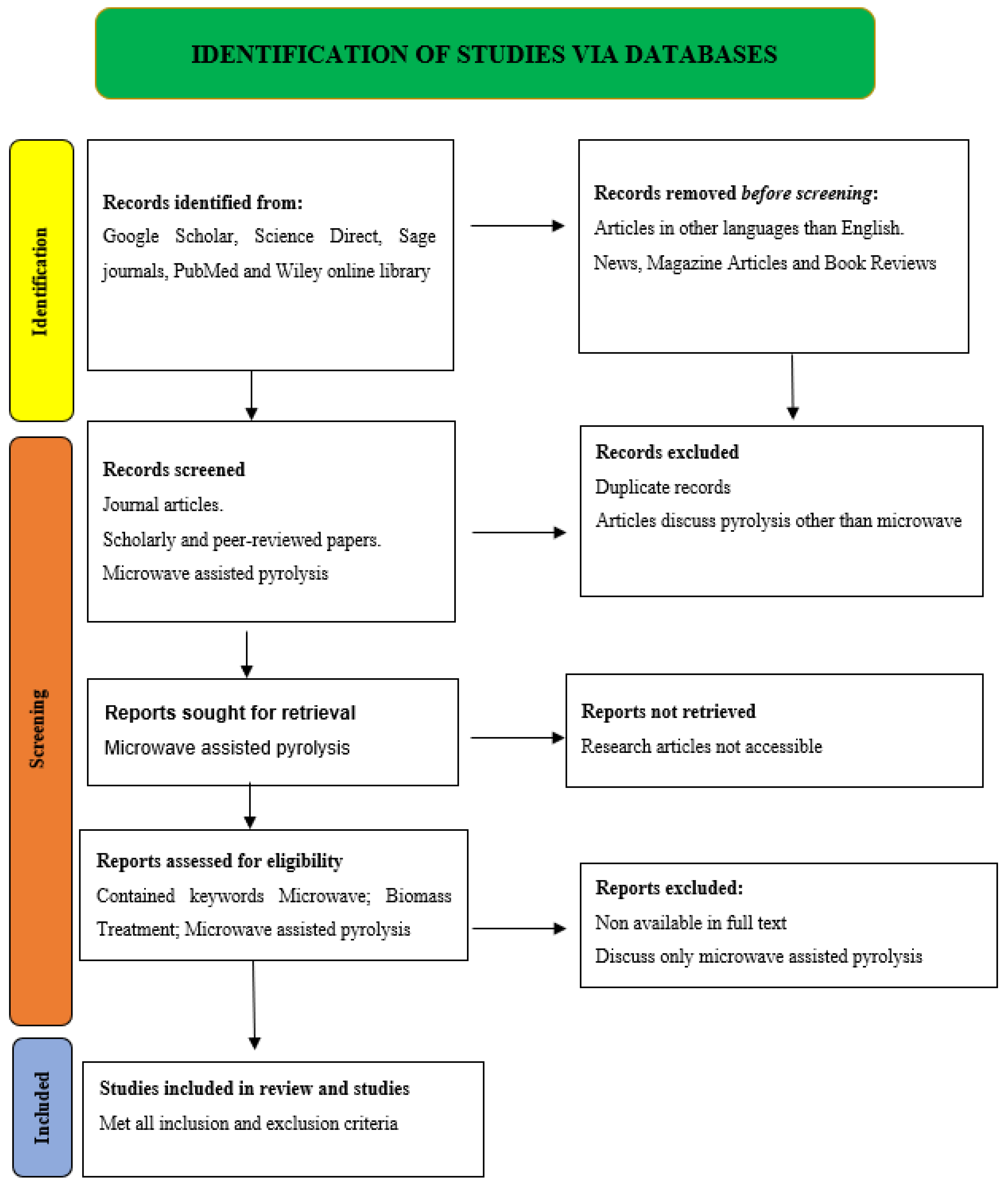

4. Systematic Literature Review

- (1)

- Data sources: Google Scholar, Science Direct, Sage journals, PubMed, and Wiley online library databases are used with the following titles and keywords: microwave-assisted pyrolysis, biomass, pyrolysis processes, microwave processes, etc.

- (2)

- Article screening: the chosen databases include duplicate, irrelevant, full-text unavailable, and non-English entries. These are deleted from identifiable records.

- (3)

- Article inclusion: The investigation included papers on microwave-assisted pyrolysis, biomass, pyrolysis processes, and microwave processes.

5. Conclusions and Future Work Suggestions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Zadeh, Z.E.; Abdulkhani, A.O.; Saha, B. Recent Insights into lignocellulosic biomass pyrolysis: A critical review on pretreatment, characterization, and products upgrading. Processes 2020, 8, 799. [Google Scholar] [CrossRef]

- Ethaib, S.; Omar, R.; Kamal, S.M.; Biak, D.A. Microwave-assisted pretreatment of lignocellulosic biomass: A review. J. Eng. Sci. Technol. 2015, 2, 97–109. [Google Scholar]

- Ethaib, S. Solid waste situation in Thi-Qar governorate. IOP Conf. Ser. Mater. Sci. Eng. 2019, 584, 012023. [Google Scholar]

- Ethaib, S.; Omar, R.; Mustapa Kamal, S.M.; Awang Biak, D.R. Comparison of sodium hydroxide and sodium bicarbonate pretreatment methods for characteristic and enzymatic hydrolysis of sago palm bark. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1, 1–11. [Google Scholar] [CrossRef]

- Erabee, I.K.; Ethaib, S. Performane of Activated Carbon Adsorption in Removing of Organic Pollutants from River Water. Int. J. Eng. Technol. 2018, 7, 356–358. [Google Scholar] [CrossRef]

- Jung, W.; Savithri, D.; Sharma-Shivappa, R.; Kolar, P. Changes in lignin chemistry of switchgrass due to delignification by sodium hydroxide pretreatment. Energies 2018, 11, 376. [Google Scholar] [CrossRef]

- Gupta, R.; Yadav, G.; Kumar, G.; Yadav, A.; Saini, J.K.; Kuhad, R.C. Second generation bioethanol production: The state of art. In Sustainable Approaches for Biofuels Production Technologies; Springer: Cham, Switzerland, 2019; pp. 121–146. [Google Scholar]

- Maj, G.; Najda, A.; Klimek, K.; Balant, S. Estimation of Energy and Emissions Properties of Waste from Various Species of Mint in the Herbal Products Industry. Energies 2020, 13, 55. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Atabani, A.E.; Mahlia, T.M.I.; Masjuki, H.H.; Badruddin, I.A.; Mekhilef, S. A review on prospect of Jatropha curcas for biodiesel in Indonesia. Renew. Sustain. Energy Rev. 2011, 15, 3733–3756. [Google Scholar] [CrossRef]

- Enweremadu, C.C.; Mbarawa, M.M. Technical aspects of production and analysis of biodiesel from used cooking oil—A review. Renew. Sustain. Energy Rev. 2009, 13, 2205–2224. [Google Scholar] [CrossRef]

- Demirbas, A. Recent advances in biomass conversion technologies. Energy Educ. Sci. Technol. 2000, 6, 19–40. [Google Scholar]

- International Energy Agency. World Energy Outlook 2010; International Energy Agency: Paris, France, 2010. [Google Scholar]

- U.S. Energy Information Administration (EIA). Annual Energy Outlook 2011; U.S. Energy Information Administration (EIA): Washington, DC, USA, 2011.

- Davis, S.C.; Diegel, S.W.; Boundy, R.G. Transportation Energy Data Book, 30th ed.; Noyes Pubns: Norwich, NY, USA, 2011. [Google Scholar]

- Atabani, A.E.; Silitonga, A.S.; Badruddin, I.A.; Mahlia, T.M.I.; Masjuki, H.H.; Mekhilef, S. A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renew. Sustain. Energy Rev. 2012, 16, 2070–2093. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. International Energy Outlook 2011; U.S. Energy Information Administration: Washington, DC, USA, 2011.

- Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H. A review on emissions and mitigation strategies for road transport in Malaysia. Renew. Sustain. Energy Rev. 2011, 15, 3516–3522. [Google Scholar] [CrossRef]

- Fridleifsson, I.B. Geothermal energy for the benefit of the people. Renew. Sustain. Energy Rev. 2001, 5, 299–312. [Google Scholar] [CrossRef]

- Thirugnanasambandam, M.; Iniyan, S.; Goic, R. A review of solar thermal technologies. Renew. Sustain. Energy Rev. 2010, 14, 312–322. [Google Scholar] [CrossRef]

- Joselin Herbert, G.M.; Iniyan, S.; Sreevalsan, E.; Rajapandian, S. A review of wind energy technologies. Renew. Sustain. Energy Rev. 2007, 11, 1117–1145. [Google Scholar] [CrossRef]

- Montes, G.M.; Del Mar Serrano López, M.; Del Carmen Rubio Gámez, M.; Ondina, A.M. An overview of renewable energy in Spain. The small hydro-power case. Renew. Sustain. Energy Rev. 2005, 9, 521–534. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Renewable Energy. Available online: http://www.eere.energy.gov/topics/renewable_energy.html (accessed on 20 July 2012).

- Dincer, I. Renewable energy and sustainable development: A crucial review. Renew. Sustain. Energy Rev. 2000, 4, 157–175. [Google Scholar] [CrossRef]

- Psaltis, P.; Komilis, D. Environmental and economic assessment of the use of biodrying before thermal treatment of municipal solid waste. Waste Manag. 2019, 83, 95–103. [Google Scholar] [CrossRef]

- Kar, T.; Keles, S. Environmental impacts of biomass combustion for heating and electricity generation. J. Eng. Res. Appl. Sci. 2016, 5, 458–465. [Google Scholar]

- Andrade, L.A.; Batista, F.R.X.; Lira, T.S.; Barrozo, M.A.S.; Vieira, L.G.M. haracterization and product formation during the catalytic and non-catalytic pyrolysis of the green microalgae Chlamydomonas reinhardtii. Renew. Energy 2018, 119, 731–740. [Google Scholar] [CrossRef]

- Wu, C.; Budarin, V.L.; Gronnow, M.J.; De Bruyn, M.; Onwudili, J.A.; Clark, J.H.; Williams, P.T. Conventional and microwave-assisted pyrolysis of biomass under different heating rates. J. Anal. Appl. Pyrolysis 2014, 107, 276–283. [Google Scholar] [CrossRef]

- Ethaib, S.; Omar, R.; Mazlina, M.; Radiah, A.; Syafiie, S.; Harun, M.Y. Effect of microwave-assisted acid or alkali pretreatment on sugar release from Dragon fruit foliage. Int. Food Res. J. 2016, 23, S149–S154. [Google Scholar]

- Ethaib, S.; Omar, R.; Mazlina, M.K.S.; Radiah, A.B.D.; Syafiie, S. Microwave-assisted dilute acid pretreatment and enzymatic hydrolysis of sago palm bark. BioResources 2016, 11, 5687–5702. [Google Scholar] [CrossRef]

- Li, X.; Li, K.; Geng, C.; El Mashad, H.; Li, H.; Yin, W. An economic analysis of rice straw microwave pyrolysis for hydrogen-rich fuel gas. RSC Adv. 2017, 7, 53396–53400. [Google Scholar] [CrossRef]

- Rahimi, M.A.; Omar, R.; Ethaib, S.; Mazlina, M.S.; Biak, D.A.; Aisyah, R.N. Microwave-assisted extraction of lipid from fish waste. IOP Conf. Ser. Mater. Sci. Eng. 2017, 206, 012096. [Google Scholar]

- Ethaib, S.; Omar, R.; Mazlina, M.K.S.; Radiah, A.B.D.; Syafiie, S. Development of a hybrid PSO–ANN model for estimating glucose and xylose yields for microwave-assisted pretreatment and the enzymatic hydrolysis of lignocellulosic biomass. Neural Comput. Appl. 2018, 30, 1111–1121. [Google Scholar] [CrossRef]

- Fernández Díez, Y.; Arenillas de la Puente, A.; Menéndez Díaz, J.Á. Microwave heating applied to pyrolysis. In Advances in Induction and Microwave Heating of Mineral and Organic Materials; InTech: London, UK, 2011. [Google Scholar]

- Ravikumar, C.; Kumar, P.S.; Subhashni, S.K.; Tejaswini, P.V.; Varshini, V. Microwave assisted fast pyrolysis of corn cob, corn stover, saw dust and rice straw: Experimental investigation on bio-oil yield and high heating values. Sustain. Mater. Technol. 2017, 11, 19–27. [Google Scholar] [CrossRef]

- Jones, D.A.; Lelyveld, T.P.; Mavrofidis, S.D.; Kingman, S.W.; Miles, N.J. Microwave heating applications in environmental engineering—A review. Resour. Conserv. Recycl. 2002, 34, 75–90. [Google Scholar] [CrossRef]

- Lam, S.S.; Russell, A.D.; Lee, C.L.; Chase, H.A. Microwave-heated pyrolysis of waste automotive engine oil: Influence of operation parameters on the yield, composition, and fuel properties of pyrolysis oil. Fuel 2012, 92, 327–339. [Google Scholar] [CrossRef]

- Huang, Y.F.; Shih, C.H.; Chiueh, P.T.; Lo, S.L. Microwave co-pyrolysis of sewage sludge and rice straw. Energy 2015, 87, 638–644. [Google Scholar] [CrossRef]

- Shang, H.; Lu, R.R.; Shang, L.; Zhang, W.H. Effect of additives on the microwave-assisted pyrolysis of sawdust. Fuel Process. Technol. 2015, 131, 167–174. [Google Scholar] [CrossRef]

- Beneroso, D.; Bermúdez, J.M.; Arenillas, A.; Menéndez, J.A. Influence of the microwave absorbent and moisture content on the microwave pyrolysis of an organic municipal solid waste. J. Anal. Appl. Pyrolysis 2014, 105, 234–240. [Google Scholar] [CrossRef]

- Kong, S.H.; Lam, S.S.; Yek, P.N.Y.; Liew, R.K.; Ma, N.L.; Osman, M.S.; Wong, C.C. Self-purging microwave pyrolysis: An innovative approach to convert oil palm shell into carbon-rich biochar for methylene blue adsorption. J. Chem. Technol. Biotechnol. 2019, 94, 1397–1405. [Google Scholar] [CrossRef]

- Luo, H.; Bao, L.; Kong, L.; Sun, Y. Low temperature microwave-assisted pyrolysis of wood sawdust for phenolic rich compounds: Kinetics and dielectric properties analysis. Bioresour. Technol. 2017, 238, 109–115. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Matharu, A.S. Thermochemical Valorization of Paper Deinking Residue through Microwave-Assisted Pyrolysis. In Waste Biorefinery; Elsevier: Amsterdam, The Netherlands, 2018; pp. 671–692. [Google Scholar]

- Rosi, L.; Bartoli, M.; Frediani, M. Microwave assisted pyrolysis of halogenated plastics recovered from waste computers. Waste Manag. 2018, 73, 511–522. [Google Scholar] [CrossRef] [PubMed]

- Mokhtar, N.M.; Ethaib, S.; Omar, R. Effects of microwave absorbers on the products of microwave pyrolysis of oily sludge. J. Eng. Sci. Technol. 2018, 13, 3313–3330. [Google Scholar]

- Zhou, J.; Liu, S.; Zhou, N.; Fan, L.; Zhang, Y.; Peng, P.; Chen, P. Development and application of a continuous fast microwave pyrolysis system for sewage sludge utilization. Bioresour. Technol. 2018, 256, 295–301. [Google Scholar] [CrossRef]

- Fan, J.; Shuttleworth, P.S.; Gronnow, M.; Breeden, S.W.; Clark, J.H.; Macquarrie, D.J.; Budarin, V.L. Influence of density on microwave pyrolysis of cellulose. ACS Sustain. Chem. Eng. 2018, 6, 2916–2920. [Google Scholar] [CrossRef]

- Parvez, A.M.; Wu, T.; Afzal, M.T.; Mareta, S.; He, T.; Zhai, M. Conventional and microwave-assisted pyrolysis of gumwood: A comparison study using thermodynamic evaluation and hydrogen production. Fuel Process. Technol. 2019, 184, 1–11. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, Z.; Tian, X.; Dai, L.; Jiang, L.; Zhang, S.; Ruan, R. Production of bio-oil from agricultural waste by using a continuous fast microwave pyrolysis system. Bioresour. Technol. 2018, 269, 162–168. [Google Scholar] [CrossRef]

- Hasan, M.H.; Mahlia, T.M.I.; Nur, H. A review on energy scenario and sustainable energy in Indonesia. Renew. Sustain. Energy Rev. 2012, 16, 2316–2328. [Google Scholar] [CrossRef]

- Yuksel, I.; Kaygusuz, K. Renewable energy sources for clean and sustainable energy policies in Turkey. Renew. Sustain. Energy Rev. 2011, 15, 4132–4144. [Google Scholar] [CrossRef]

- Berndes, G.; Hoogwijk, M.; van den Broek, R. The contribution of biomass in the future global energy supply: A review of 17 studies. Biomass Bioenergy 2003, 25, 1–28. [Google Scholar] [CrossRef]

- Hall, D.O. Biomass energy in industrialised countries—A view of the future. For. Ecol. Manag. 1997, 91, 17–45. [Google Scholar] [CrossRef]

- Guehenneux, G.; Baussand, P.; Brothier, M.; Poletiko, C.; Boissonnet, G. Energy production from biomass pyrolysis: A new coefficient of pyrolytic valorisation. Fuel 2005, 84, 733–739. [Google Scholar] [CrossRef]

- Börjesson, P.; Berglund, M. Environmental systems analysis of biogas systemsPart I: Fuel-cycle emissions. Biomass Bioenergy 2006, 30, 469–485. [Google Scholar] [CrossRef]

- Chung, K.H.; Kim, J.; Lee, K.Y. Biodiesel production by transesterification of duck tallow with methanol on alkali catalysts. Biomass Bioenergy 2009, 33, 155–158. [Google Scholar] [CrossRef]

- Bilgen, S.; Keleş, S.; Kaygusuz, A.; Sarı, A.; Kaygusuz, K. Global warming and renewable energy sources for sustainable development: A case study in Turkey. Renew. Sustain. Energy Rev. 2008, 12, 372–396. [Google Scholar] [CrossRef]

- Hashim, H.; Ho, W.S. Renewable energy policies and initiatives for a sustainable energy future in Malaysia. Renew. Sustain. Energy Rev. 2011, 15, 4780–4787. [Google Scholar] [CrossRef]

- Martinot, E.; Chaurey, A.; Lew, D.; Moreira, J.R.; Wamukonya, N. Renewable energy markets in developing countries. Annu. Rev. Energy Environ. 2002, 27, 309–348. [Google Scholar] [CrossRef]

- Dodic, S.N.; Vasiljevic, T.Z.; Maric, R.M.; Kosanovic, A.J.R.; Dodic, J.M.; Popov, S.D. Possibilities of application of waste wood biomass as an energy source in Vojvodina. Renew. Sustain. Energy Rev. 2012, 16, 2355–2360. [Google Scholar] [CrossRef]

- Dominguez, A.; Menéndez, J.A.; Fernandez, Y.; Pis, J.J.; Nabais, J.V.; Carrott, P.J.M.; Carrott, M.R. Conventional and microwave induced pyrolysis of coffee hulls for the production of a hydrogen rich fuel gas. J. Anal. Appl. Pyrolysis 2007, 79, 128–135. [Google Scholar] [CrossRef]

- Tsai, W.T.; Lee, M.K.; Chang, Y.M. Fast pyrolysis of rice straw, sugarcane bagasse and coconut shell in an induction-heating reactor. J. Anal. Appl. Pyrolysis 2006, 76, 230–237. [Google Scholar] [CrossRef]

- Shie, J.-L.; Tsou, F.-J.; Lin, K.-L.; Chang, C.-Y. Bioenergy and products from thermal pyrolysis of rice straw using plasma torch. Bioresour. Technol. 2010, 101, 761–768. [Google Scholar] [CrossRef] [PubMed]

- Uzun, B.B.; Apaydin-Varol, E.; Ateş, F.; Ozbay, N.; Putun, A.E. Synthetic fuel production from tea waste: Characterisation of bio-oil and bio-char. Fuel 2010, 89, 176–184. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, B.; Chen, X.; Bai, Z.; Zhang, H. Studies on pyrolysis of wheat straw residues from ethanol production by solid-state fermentation. J. Anal. Appl. Pyrolysis 2008, 81, 243–246. [Google Scholar] [CrossRef]

- De Wild, P.J.; Huijgen, W.J.J.; Heeres, H.J. Pyrolysis of wheat straw-derived organosolv lignin. J. Anal. Appl. Pyrolysis 2012, 93, 95–103. [Google Scholar] [CrossRef]

- Rumphorst, M.P.; Ringel, H.D. Pyrolysis of sewage sludge and use of pyrolysis coke. J. Anal. Appl. Pyrolysis 1994, 28, 137–155. [Google Scholar] [CrossRef]

- Fonts, I.; Azuara, M.; Gea, G.; Murillo, M.B. Study of the pyrolysis liquids obtained from different sewage sludge. J. Anal. Appl. Pyrolysis 2009, 85, 184–191. [Google Scholar] [CrossRef]

- Fonts, I.; Gea, G.; Azuara, M.; Ábrego, J.; Arauzo, J. Sewage sludge pyrolysis for liquid production: A review. Renew. Sustain. Energy Rev. 2012, 16, 2781–2805. [Google Scholar] [CrossRef]

- Nourreddine, M. Recycling of auto shredder residue. J. Hazard. Mater. 2007, 139, 481–490. [Google Scholar] [CrossRef]

- Decker, S.R.; Sheehan, J.; Dayton, D.C.; Bozell, J.J.; Adney, W.S.; Hames, B.; Thomas, S.R.; Bain, R.L.; Czernik, S.; Zhang, M.; et al. Biomass conversion. In Kent and Riegel’s Handbook of Industrial Chemistry and Biotechnology; Kent, J.A., Ed.; Springer: Boston, MA, USA, 2007; pp. 1499–1548. [Google Scholar]

- Faaij, A. Modern biomass conversion technologies. Mitig. Adapt. Strateg. Glob. Change 2006, 11, 335–367. [Google Scholar] [CrossRef]

- Ethaib, S.; Omar, R.; Siti Mazlina, M.K.; Dayang Radiah, A.B. Evaluation of the interactive effect pretreatment parameters via three types of microwave-assisted pretreatment and enzymatic hydrolysis on sugar yield. Processes 2020, 8, 787. [Google Scholar] [CrossRef]

- Saadi, W.; Rodríguez-Sánchez, S.; Ruiz, B.; Souissi-Najar, S.; Ouederni, A.; Fuente, E. Pyrolysis technologies for pomegranate (Punica granatum L.) peel wastes. Prospects in the bioenergy sector. Renew. Energy 2019, 136, 373–382. [Google Scholar] [CrossRef]

- Demirbas, A. Partial hydrogenation effect of moisture contents on the combustion oils from biomass pyrolysis. Energy Sources Part A Recovery Util. Environ. Eff. 2008, 30, 508–515. [Google Scholar] [CrossRef]

- Staš, M.; Chudoba, J.; Kubička, D.; Blažek, J.; Pospíšil, M. Petroleomic characterization of pyrolysis bio-oils: A review. Energy Fuels 2017, 31, 10283–10299. [Google Scholar] [CrossRef]

- Vitasari, C.R.; Meindersma, G.W.; De Haan, A.B. Water extraction of pyrolysis oil: The first step for the recovery of renewable chemicals. Bioresour. Technol. 2011, 102, 7204–7210. [Google Scholar] [CrossRef]

- Kappler, G.; de Souza, D.M.; Moraes, C.A.M.; Modolo, R.C.E.; Brehm, F.A.; Wander, P.R.; da Cruz Tarelho, L.A. Conversion of Lignocellulosic Biomass through Pyrolysis to Promote a Sustainable Value Chain for brazilian agribusiness. In Lignocellulosic Biorefining Technologies; John Wiley & Sons: Hoboken, NJ, USA, 2020; pp. 265–283. [Google Scholar]

- Foong, S.Y.; Liew, R.K.; Yang, Y.; Cheng, Y.W.; Yek, P.N.Y.; Mahari, W.A.W.; Aghbashlo, M. Valorization of biomass waste to engineered activated biochar by microwave pyrolysis: Progress, challenges, and future directions. Chem. Eng. J. 2020, 389, 124401. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Kumar, P.S.; Varjani, S.J.; Saravanan, A. Advances in production and application of biochar from lignocellulosic feedstocks for remediation of environmental pollutants. Bioresour. Technol. 2019, 292, 122030. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 2012, 38, 68–94. [Google Scholar] [CrossRef]

- Khole, P.R.; Shukla, S. Bio-oil production through biomass pyrolysis and upgrading research. Int. J. Agric. Eng. 2018, 11, 257–263. [Google Scholar] [CrossRef]

- Qureshi, K.M.; Lup, A.N.K.; Khan, S.; Abnisa, F.; Daud, W.M.A.W. A technical review on semi-continuous and continuous pyrolysis process of biomass to bio-oil. J. Anal. Appl. Pyrolysis 2018, 131, 52–75. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Zhu, X.F.; Zhang, L.Q.; Zhu, X.F. Preparation and characterization of microemulsion fuels from diesel and model compound of walnut shell pyrolysis oil. Fuel 2019, 243, 478–484. [Google Scholar] [CrossRef]

- Yan, R.; Yang, H.; Chin, T.; Liang, D.T.; Chen, H.; Zheng, C. Influence of temperature on the distribution of gaseous products from pyrolyzing palm oil wastes. Combust. Flame 2005, 142, 24–32. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Liang, D.T.; Zheng, C. Pyrolysis of palm oil wastes for enhanced production of hydrogen rich gases. Fuel Process. Technol. 2006, 87, 935–942. [Google Scholar] [CrossRef]

- Klass, D. Biomass for Renewable Energy, Fuel and Chemicals; Academic Press: London, UK, 1998. [Google Scholar]

- Thormann, L.; de Oro, P.P. Fuels from Pyrolysis. In Biokerosene; Springer: Berlin/Heidelberg, Germany, 2018; pp. 575–605. [Google Scholar]

- Cerone, N.; Zimbardi, F.; Villone, A.; Strjiugas, N.; Kiyikci, E.G. Gasification of wood and torrefied wood with air, oxygen, and steam in a fixed-bed pilot plant. Energy Fuels 2016, 30, 4034–4043. [Google Scholar] [CrossRef]

- Lidström, P.; Tierney, J.; Wathey, B.; Westman, J. Microwave assisted organic synthesis—A review. Tetrahedron 2001, 57, 9225–9283. [Google Scholar] [CrossRef]

- Kappe, C.O.; Stadler, A.; Dallinger, D. Microwaves in Organic and Medicinal Chemistry; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Nascimento, U.M.; Azevedo, E.B. Microwaves and their coupling to advanced oxidation processes: Enhanced performance in pollutants degradation. J. Environ. Sci. Health Part A 2013, 48, 1056–1072. [Google Scholar] [CrossRef]

- World Commission on Environment and Development. Our Common Future; Oxford University Press: Melbourne, Australia, 1990. [Google Scholar]

- Kreith, F.; Krumdieck, S.; Kreider, J.F. Principles of Sustainable Energy; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2010. [Google Scholar]

- International Biochar Initiative (IBI). Available online: http://www.biochar-international.org/ (accessed on 14 February 2012).

- Zhao, X.; Wang, M.; Liu, H.; Li, L.; Ma, C.; Song, Z. A microwave reactor for characterization of pyrolyzed biomass. Bioresour. Technol. 2012, 104, 673–678. [Google Scholar] [CrossRef]

- Hu, Z.; Ma, X.; Chen, C. A study on experimental characteristic of microwaveassisted pyrolysis of microalgae. Bioresour. Technol. 2012, 107, 487–493. [Google Scholar] [CrossRef]

- Ren, S.; Lei, H.; Wang, L.; Bu, Q.; Chen, S.; Wu, J.; Julson, J.; Ruan, R. Biofuel production and kinetics analysis for microwave pyrolysis of Douglas fir sawdust pellet. J. Anal. Appl. Pyrolysis 2012, 94, 163–169. [Google Scholar] [CrossRef]

- Chen, M.Q.; Wang, J.; Zhang, M.X.; Chen, M.G.; Zhu, X.F.; Min, F.F.; Tan, Z.C. Catalytic effects of eight inorganic additives on pyrolysis of pine wood sawdust by microwave heating. J. Anal. Appl. Pyrolysis 2008, 82, 145–150. [Google Scholar] [CrossRef]

- Omar, R.; Idris, A.; Yunus, R.; Khalid, K.; Aida Isma, M.I. Characterization of empty fruit bunch for microwave-assisted pyrolysis. Fuel 2011, 90, 1536–1544. [Google Scholar] [CrossRef]

- Hussain, Z.; Khan, K.M.; Basheer, N.; Hussain, K. Co-liquefaction of Makarwal coal and waste polystyrene by microwave–metal interaction pyrolysis in copper coil reactor. J. Anal. Appl. Pyrolysis 2011, 90, 53–55. [Google Scholar] [CrossRef]

- Tian, Y.; Zuo, W.; Ren, Z.; Chen, D. Estimation of a novel method to produce biooil from sewage sludge by microwave pyrolysis with the consideration of efficiency and safety. Bioresour. Technol. 2011, 102, 2053–2061. [Google Scholar] [CrossRef]

- Du, J.; Liu, P.; Liu, Z.-H.; Sun, D.-G.; Tao, C.-Y. Fast pyrolysis of biomass for bio-oil with ionic liquid and microwave irradiation. J. Fuel Chem. Technol. 2010, 38, 554–559. [Google Scholar] [CrossRef]

- Zeng, X.; Fu, D.; Sheng, H.; Xie, S.; Li, X.; Hu, Q.; Zou, J. Growth and morphology of carbon nanostructures by microwave-assisted pyrolysis of methane. Phys. E Low-Dimens. Syst. Nanostruct. 2010, 42, 2103–2108. [Google Scholar] [CrossRef]

- Huang, Y.F.; Kuan, W.H.; Lo, S.L.; Lin, C.F. Hydrogen-rich fuel gas from rice straw via microwave-induced pyrolysis. Bioresour. Technol. 2010, 101, 1968–1973. [Google Scholar] [CrossRef]

- Fu, D.; Zeng, X.; Zou, J.; Li, L.; Li, X.; Deng, F. In situ synthesis and photoluminescence of SiC nanowires by microwave-assisted pyrolysis of methane. J. Alloys Compd. 2009, 486, 406–409. [Google Scholar] [CrossRef]

- Andersson, M.; Knutson Wedel, M.; Forsgren, C.; Christéen, J. Microwave assisted pyrolysis of residual fractions of waste electrical and electronics equipment. Miner. Eng. 2012, 29, 105–111. [Google Scholar] [CrossRef]

- Chemat, F.; Poux, M. Microwave assisted pyrolysis of urea supported on graphite under solvent-free conditions. Tetrahedron Lett. 2001, 42, 3693–3695. [Google Scholar] [CrossRef]

- Salema, A.A.; Ani, F.N. Microwave induced pyrolysis of oil palm biomass. Bioresour. Technol. 2011, 102, 3388–3395. [Google Scholar] [CrossRef]

- Lei, H.; Ren, S.; Wang, L.; Bu, Q.; Julson, J.; Holladay, J.; Ruan, R. Microwave pyrolysis of distillers dried grain with solubles (DDGS) for biofuel production. Bioresour. Technol. 2011, 102, 6208–6213. [Google Scholar] [CrossRef] [PubMed]

- Wan, Y.; Chen, P.; Zhang, B.; Yang, C.; Liu, Y.; Lin, X.; Ruan, R. Microwave-assisted pyrolysis of biomass: Catalysts to improve product selectivity. J. Anal. Appl. Pyrolysis 2009, 86, 161–167. [Google Scholar] [CrossRef]

- Du, Z.; Li, Y.; Wang, X.; Wan, Y.; Chen, Q.; Wang, C.; Lin, X.; Liu, Y.; Chen, P.; Ruan, R. Microwave-assisted pyrolysis of microalgae for biofuel production. Bioresour. Technol. 2011, 102, 4890–4896. [Google Scholar] [CrossRef] [PubMed]

- Bu, Q.; Lei, H.; Ren, S.; Wang, L.; Holladay, J.; Zhang, Q.; Tang, J.; Ruan, R. Phenol and phenolics from lignocellulosic biomass by catalytic microwave pyrolysis. Bioresour. Technol. 2011, 102, 7004–7007. [Google Scholar] [CrossRef]

- Lam, S.S.; Russell, A.D.; Lee, C.L.; Lam, S.K.; Chase, H.A. Production of hydrogen and light hydrocarbons as a potential gaseous fuel from microwave-heated pyrolysis of waste automotive engine oil. Int. J. Hydrogen Energy 2012, 37, 5011–5021. [Google Scholar] [CrossRef]

- Bu, Q.; Lei, H.; Ren, S.; Wang, L.; Zhang, Q.; Tang, J.; Ruan, R. Production of phenols and biofuels by catalytic microwave pyrolysis of lignocellulosic biomass. Bioresour. Technol. 2012, 108, 274–279. [Google Scholar] [CrossRef]

- Lam, S.S.; Russell, A.D.; Chase, H.A. Pyrolysis using microwave heating: A sustainable process for recycling used car engine oil. Ind. Eng. Chem. Res. 2010, 49, 10845–10851. [Google Scholar] [CrossRef]

- Lin, Q.; Chen, G.; Liu, Y. Scale-up of microwave heating process for the production of bio-oil from sewage sludge. J. Anal. Appl. Pyrolysis 2012, 94, 114–119. [Google Scholar] [CrossRef]

- Huang, Y.F.; Kuan, W.H.; Lo, S.L.; Lin, C.F. Total recovery of resources and energy from rice straw using microwave-induced pyrolysis. Bioresour. Technol. 2008, 99, 8252–8258. [Google Scholar] [CrossRef]

- Salema, A.A.; Ani, F.N. Microwave-assisted pyrolysis of oil palm shell biomass using an overhead stirrer. J. Anal. Appl. Pyrolysis 2012, 96, 162–172. [Google Scholar] [CrossRef]

- Moen, J.; Yang, C.; Zhang, B.; Lei, H.; Hennessy, K.; Wan, Y.; Le, Z.; Liu, Y.; Chen, P.; Ruan, R. Catalytic microwave assisted pyrolysis of aspen. Int. J. Agric. Biol. Eng. 2009, 2, 70–75. [Google Scholar]

- Yu, F.; Ruan, R.; Steele, P. Microwave pyrolysis of corn stover. Trans. Am. Soc. Agric. Biol. Eng. 2009, 52, 1595–1601. [Google Scholar]

- Salema, A.A.; Ani, F.N. Microwave pyrolysis of oil palm fibers. J. Mek. 2010, 30, 77–86. [Google Scholar]

- Ludlow-Palafox, C.; Chase, H.A. Microwave-induced pyrolysis of plastic wastes. Ind. Eng. Chem. Res. 2001, 40, 4749–4756. [Google Scholar] [CrossRef]

- Lei, H.; Ren, S.; Julson, J. The effects of reaction temperature and time and particle size of corn stover on microwave pyrolysis. Energy Fuels 2009, 23, 3254–3261. [Google Scholar] [CrossRef]

- Fernandez, Y.; Arenillas, A.; Bermúdez, J.M.; Menendez, J.A. Comparative study of conventional and microwave-assisted pyrolysis, steam and dry reforming of glycerol for syngas production, using a carbonaceous catalyst. J. Anal. Appl. Pyrolysis 2010, 88, 155–159. [Google Scholar] [CrossRef]

- Duan, X.-H.; Srinivasakannan, C.; Peng, J.-H.; Zhang, L.-B.; Zhang, Z.-Y. Comparison of activated carbon prepared from Jatropha hull by conventional heating and microwave heating. Biomass Bioenergy 2011, 35, 3920–3926. [Google Scholar]

| PT (Type) | RT (s) | HR (°C/s) | Te (°C) | VR (s) |

|---|---|---|---|---|

| slow | >290 | 0.10–10 | 400–900 | ≤550 |

| fast | 0.50 to 10 | 10–200 | 450–850 | 0.5–10 |

| flash | <1 | >1000 | 600–1200 | <0.5 |

| Studies | Research Target | Biomass Input | Product Output | Microwave Power | Microwave Frequency | Study Findings |

|---|---|---|---|---|---|---|

| Zhao et al. [95] | Investigated the effect of temperature on the MAP of biomass | wheat straw | fuels and chemicals | 3000 W | 2.45 GHz | It was found that the temperature has a significant impact on the performance of MAP. |

| Hu et al. [96] | Investigated the effect of microwave power level and catalysts on the products | solid residue (Chlorella vulgaris) | bio-oil | 3750 W | 2.45 GHz | Using Cac as a catalyst yielded the best results for solid residue, and raising the microwave power level improved gas generation. |

| Ren et al. [97] | Examined the influence of reaction time and temperature | Douglas fir sawdust pellet | syngas, bio-oil, and charcoal | 700 W | 2450 MHz | It was discovered that increasing the reaction time and temperature increased the yield of volatiles. |

| Chen et al. [98] | Examined the catalytic effects of eight distinct inorganic additives | pine wood sawdust | Acetol formation | 300–800 W | 2.45 GHz | It was determined that each of the eight additives increased the output of the solid portion, whereas the yield of the gaseous and liquid products remained relatively unchanged. |

| Omar et al. [99] | Examined the characterization of oil palm empty fruit bunch (EFB) | Biomass (OP-EFB) | bio-oil | 800 W | 2450 MHz | Based on the results, EFB has tremendous potential as a raw material for microwave pyrolysis since its fuel and chemical qualities are on par with those of other biomass feedstock. |

| Hussain et al. [100] | Investigated the microwave–copper interaction of waste polystyrene and Makarwal coal co-pyrolysis at high temperature | waste polystyrene and Makarwal coal | acetylene and sulfur | 3 kW | 2450 MHz | The quantity of oil produced was observed to be greater than the amount of water. |

| Tian et al. [101]. | The authors attempted to establish a relationship between the mass balance of the products and microwave exit power. | sewage sludge | bio-oil | 400–600 W | 2.45 GHz | At 400 W microwave exit power for 6 min, the highest bio-oil output (49.8%), highest calorific value (35.5 MJ/kg), and lowest density (929 kg/m3) were all achieved. |

| Du et al. [102] | Examined microwave exit power (160 W to 800 W), microwave heating time (up to 25 min), and catalyst dosage (0.0 to 0.5 catalyst/biomass ratio) | rice straw and sawdust | bio-oil | 160–800 W | 2.45 GHz | After 20 min of microwave irradiation (for both catalysts), it was found that the yields of bio-oil from rice straw stabilized. |

| Zeng et al. [103] | Evaluated the effect of MAP on the growth and morphology of biomass in the absence of a catalyst | methane | carbon nanostructures | 700 W | 2.45 GHz | The findings revealed that MAP is a novel and promising method for synthesizing carbon nanostructures. |

| Huang et al. [104] | Examined the effect of microwave heating on pyrolysis | rice straw | H2-rich fuel gas | 3000 W | 2.45 GHz | It was found that the hotspots generated by microwave ovens could be utilized for H2 production. |

| Fu et al. [105] | Investigated the effects of reaction conditions, such as the concentration and temperature of the reaction gas | methane | Syngas | 0.7 KW | 2450 MHz | It concluded that a nanowire of high purity could be synthesized using this novel method. |

| Andersson et al. [106] | Analyzed six distinct fractions of discarded electrical and electronic equipment | six different fractions of waste | Bio-oil and syngas | 3 KW | 2.45 GHz | This method was discovered to be effective at transforming wastes into more valuable substances. |

| Chemat and Poux [107] | Examined the effect of microwave heating on pyrolysis | urea | cyanuric acid | 2 KW | 2450 MHz | The reaction rates of heterogeneous pyrolysis were significantly accelerated. |

| Salema and Ani [108] | Examined the effect of microwave heating on pyrolysis | oil palm shell and fibers | bio-oil | 1000 W | 2.45 GHz | Large biomass particle sizes can be utilized in microwave reactors, resulting in cost reductions for grinding and moisture removal. |

| Lei et al. [109] | The effect of critical reaction conditions, including reaction time, temperature, and microwave exit power, was investigated and analyzed through response surface methodology (RSM). | dried grain | bio-oil | 900 W | 2450 MHz | The most effective reaction conditions for microwave pyrolysis of DDGS are reaction time and temperature. |

| Wan et al. [110] | Reactions to various catalysts were analyzed | dry corn stover and aspen wood pellets | bio-oil | 875 W | 2450 MHz | It was discovered that the catalysts may serve as an MA to accelerate the heating process. |

| Du et al. [111] | Examined the effect of microwave power on pyrolysis | Chlorella sp. | bio-oil compounds | 1.25 kW | 2.45 GHz | From 500 W to 1250 W, gas output increased by 12%, creating bio-oil molecules similar to fossil fuels including crude oil, gasoline, and diesel. |

| Lam et al. [36] | Examined the effectiveness of MAP on waste products | waste automotive engine oil | bio-oil compounds | 5 kW | 2450 MHz | MAP has great potential for recycling wastes like waste oils. |

| Bu et al. [112] | Microwave pyrolysis was used with Cac as the catalyst. | lignocellulose biomass | Phenolic products | 700 W | 2450 MHz | The upgraded phenol may be utilized as fuel or as a feedstock for bio-based phenols. |

| Lam et al. [113] | Explored the microwave pyrolysis of automobile engine oil to learn about the properties of the incondensable gaseous produced | engine oil | hydrocarbon energy | (5 kW) | 2450 MHz | Microwave irradiation with carbon bed aid strengthened the production of useful gases as an alternative source of hydrogen or hydrocarbon energy from waste oil. |

| Quan et al. [114] | Investigated biofuels with high concentrations of phenol and phenolics | biomass feedstock | phenol | 700 W | 2.45 GHz | Cac was observed to substantially increase volatile yields. |

| Lam et al. [115] | Discussed the thermal cracking (pyrolysis) of used automobile engines | engine oils | metal contaminants | 3 KW | 2450 MHz | MAP is a promising method for treating residues such as engine lubricants. |

| Lin et al. [116] | This study investigated the impact of reaction parameters and chemical additives on the yield and quality of bio-oil produced. | sewage sludge | bio-oil | 8.8 kW | 2.45 GHz | Maximum bio-oil yield (30.4%) was obtained at a microwave exit power of 8.8 kW and a final pyrolysis temperature of 500 °C. |

| Huang et al. [117] | Examined the effect of microwave power on pyrolysis | rice straw | flue gas | 2 kW | 2.45 GHz | Lower microwave power would be suitable when the particle size is small. |

| Salema and Ani [118] | Explored the use of an overhead stirrer in a MAP reactor | Biomass (OPS) | bio-char | 1000 W | 2.45 GHz | Mechanical stirrers can achieve higher microwave pyrolysis temperatures, enhance heat transfer rate, remove hot spot phenomena, and reduce time and energy for complete pyrolysis. However, size and design must be maintained to prevent interference from electromagnetic waves. |

| Moen et al. [119] | Examined the effect of catalyst on pyrolysis | Aspen hardwood pellets | bio-oil | 800 W | 2.45 GHz | The maximum yields of gas (35.57%), char (32.01%), heavy oil (12.93%), and light oil (10.68%) were obtained with nitrates, without catalyst, metaloxides, and chlorides, respectively. |

| Yu et al. [120] | Examined the effect of microwave power on pyrolysis | corn stover | charcoal | 900 W | 2.45 GHz | Increasing the microwave input power from 300 W to 900 W increased the output of gas and bio-oil while decreasing the yield of charcoal. |

| Salema and Ani [121] | Examined the effect of MAP to produce quality products | OPS/OPF | bio-oil | 1000 W | 2.45 GHz | MAP can be used to convert waste materials such as OPS/OPF into bio-oil and other quality byproducts. |

| Palafox and Chase [122] | High-density polyethylene and aluminum/polymer laminates in a semi-batch-scale microwave reactor was evaluated. | polyethylene and aluminum/polymer laminates | Clean aluminum along with hydrocarbons | 5 kW | 2450 MHz | Toothpaste tubing was used as an example of a laminated material to be treated with the MAP. The experiment proved that the process has excellent potential for the treatment of plastic wastes such as toothpaste. |

| Hanwu Lei et al. [123] | Examined the effects of particle size (0.5–4 mm), reaction time (4–22 min), and temperature (515–615 °C) on microwave pyrolysis | corn stover | bio-oil | 700 W | 2450 MHz | Large biomass materials can undergo using MAP technology and generate useful products. |

| Fernandez at al. [124] | Examined the effect of MAP to produce quality products against a conventional heating method | glycerol | syngas | 1 KW | 2.45 GHz | The results demonstrated that microwave-assisted heating produced higher gas yields (converted from glycerol) with a high syngas content and a higher H2/Co ratio compared to conventional heating method. |

| Xin-hui et al. [125] | Steam and CO2 were used as activation agents for the pyrolysis process. | Jatropha hull | activated carbon | 3 kW | 2.45 GHz | Microwave heating increased the production yield (double) using CO2 as the activation agent. This made the process more economical, although the porosity of carbon was in the same order of magnitude. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Syed, N.R.; Zhang, B.; Mwenya, S.; Aldeen, A.S. A Systematic Review on Biomass Treatment Using Microwave-Assisted Pyrolysis under PRISMA Guidelines. Molecules 2023, 28, 5551. https://doi.org/10.3390/molecules28145551

Syed NR, Zhang B, Mwenya S, Aldeen AS. A Systematic Review on Biomass Treatment Using Microwave-Assisted Pyrolysis under PRISMA Guidelines. Molecules. 2023; 28(14):5551. https://doi.org/10.3390/molecules28145551

Chicago/Turabian StyleSyed, Neyha Rubab, Bo Zhang, Stephen Mwenya, and Awsan Shujaa Aldeen. 2023. "A Systematic Review on Biomass Treatment Using Microwave-Assisted Pyrolysis under PRISMA Guidelines" Molecules 28, no. 14: 5551. https://doi.org/10.3390/molecules28145551

APA StyleSyed, N. R., Zhang, B., Mwenya, S., & Aldeen, A. S. (2023). A Systematic Review on Biomass Treatment Using Microwave-Assisted Pyrolysis under PRISMA Guidelines. Molecules, 28(14), 5551. https://doi.org/10.3390/molecules28145551