L-Rhamnose and Phenolic Esters-Based Monocatenar and Bolaform Amphiphiles: Eco-Compatible Synthesis and Determination of Their Antioxidant, Eliciting and Cytotoxic Properties

Abstract

1. Introduction

2. Results and Discussion

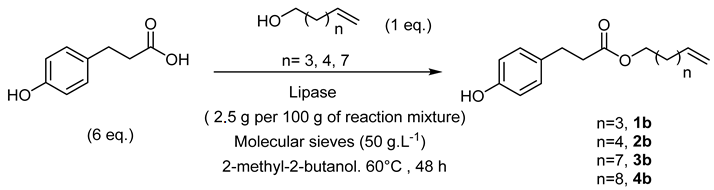

2.1. Synthesis

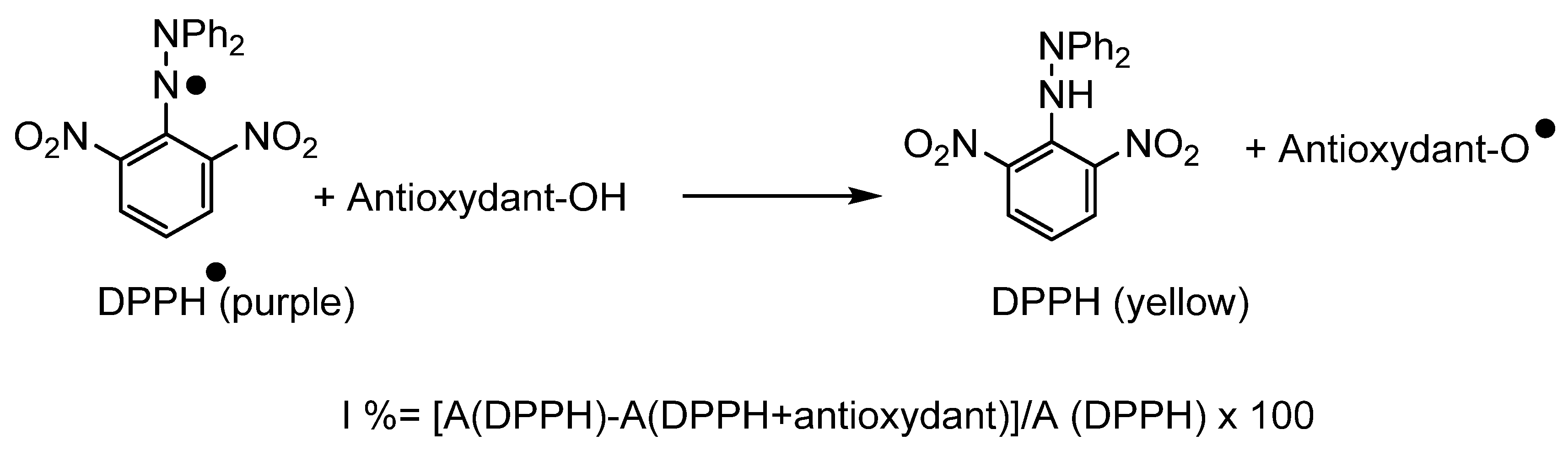

2.2. Antioxidant Properties

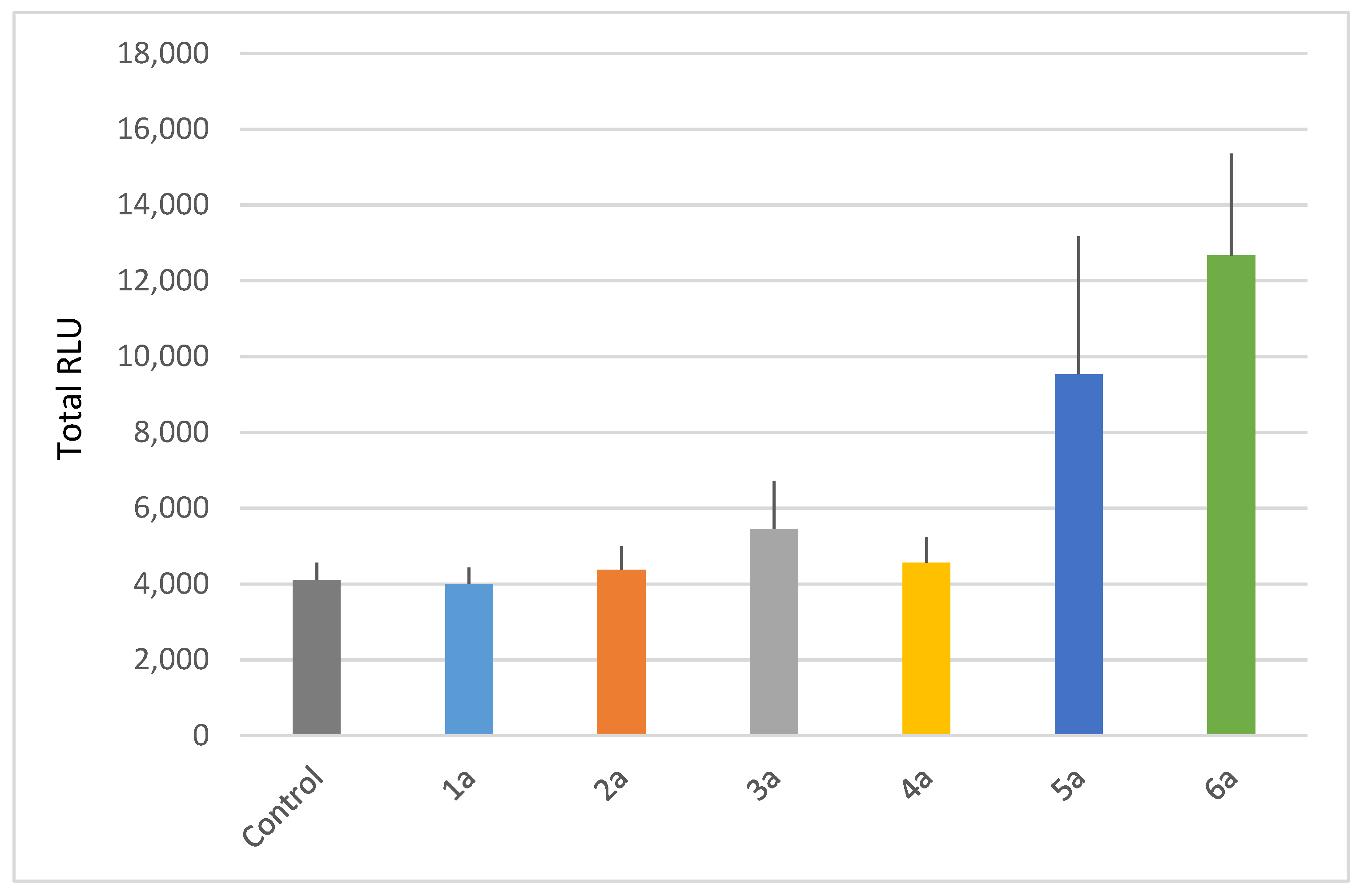

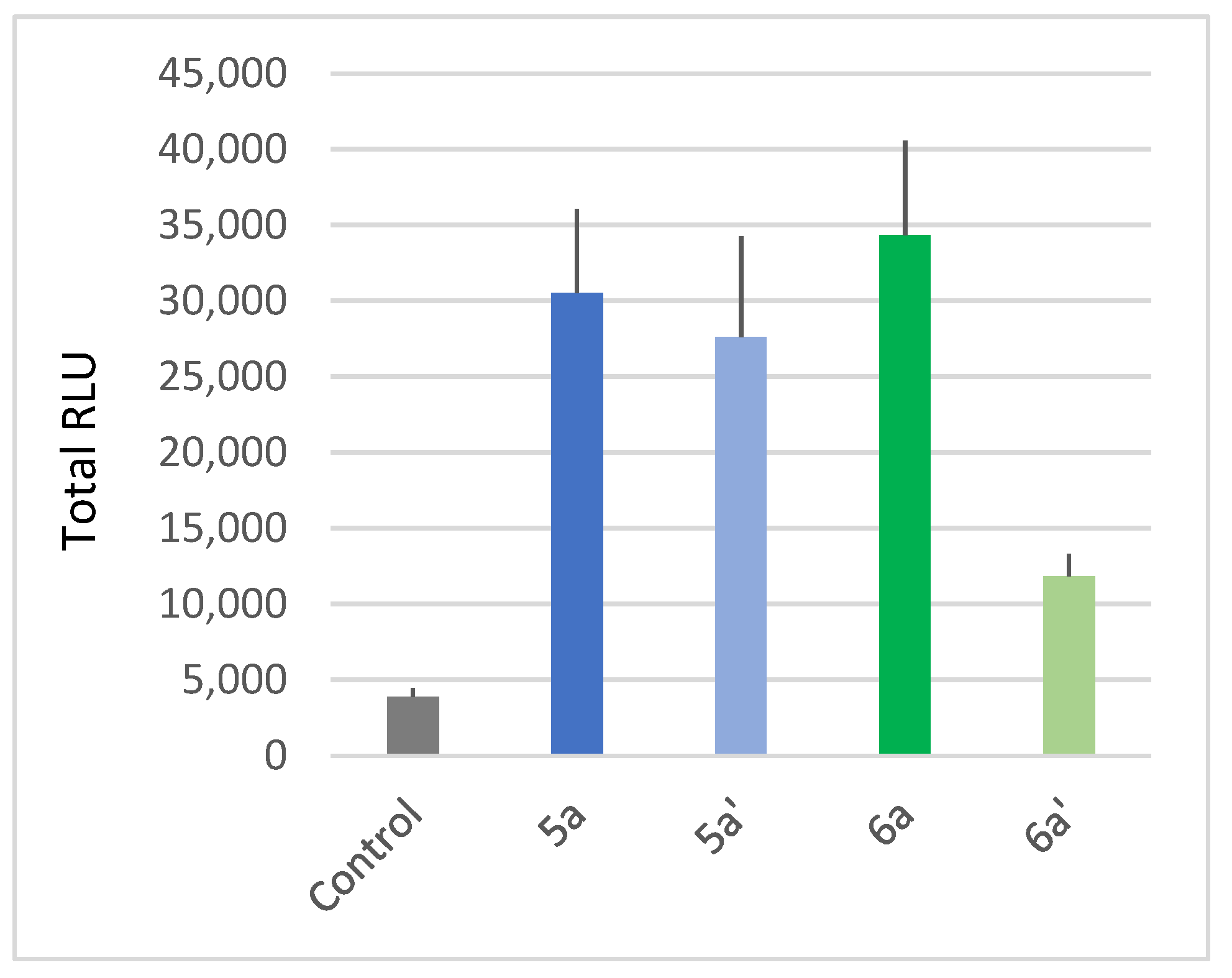

2.3. Plant-Eliciting Properties

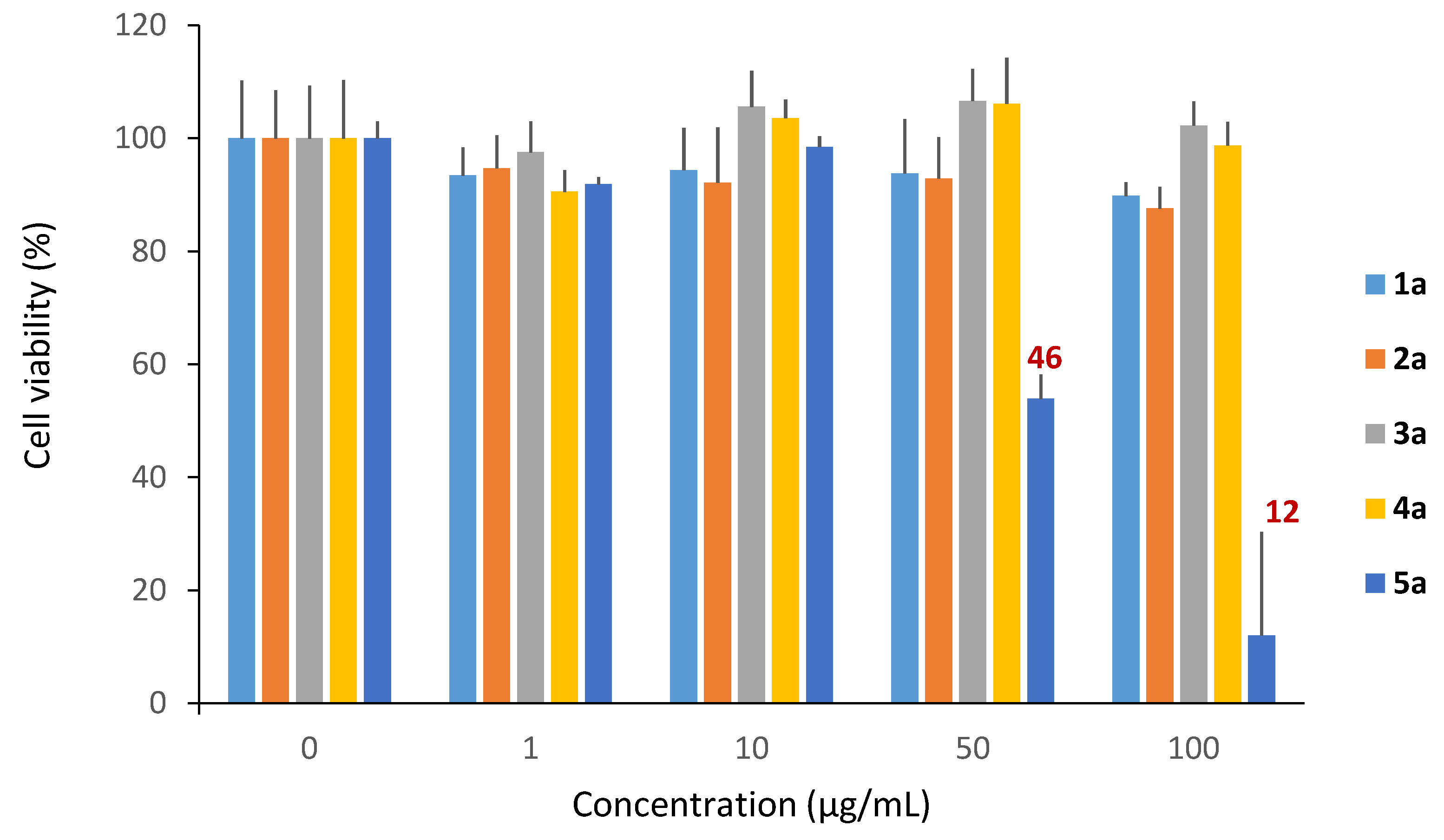

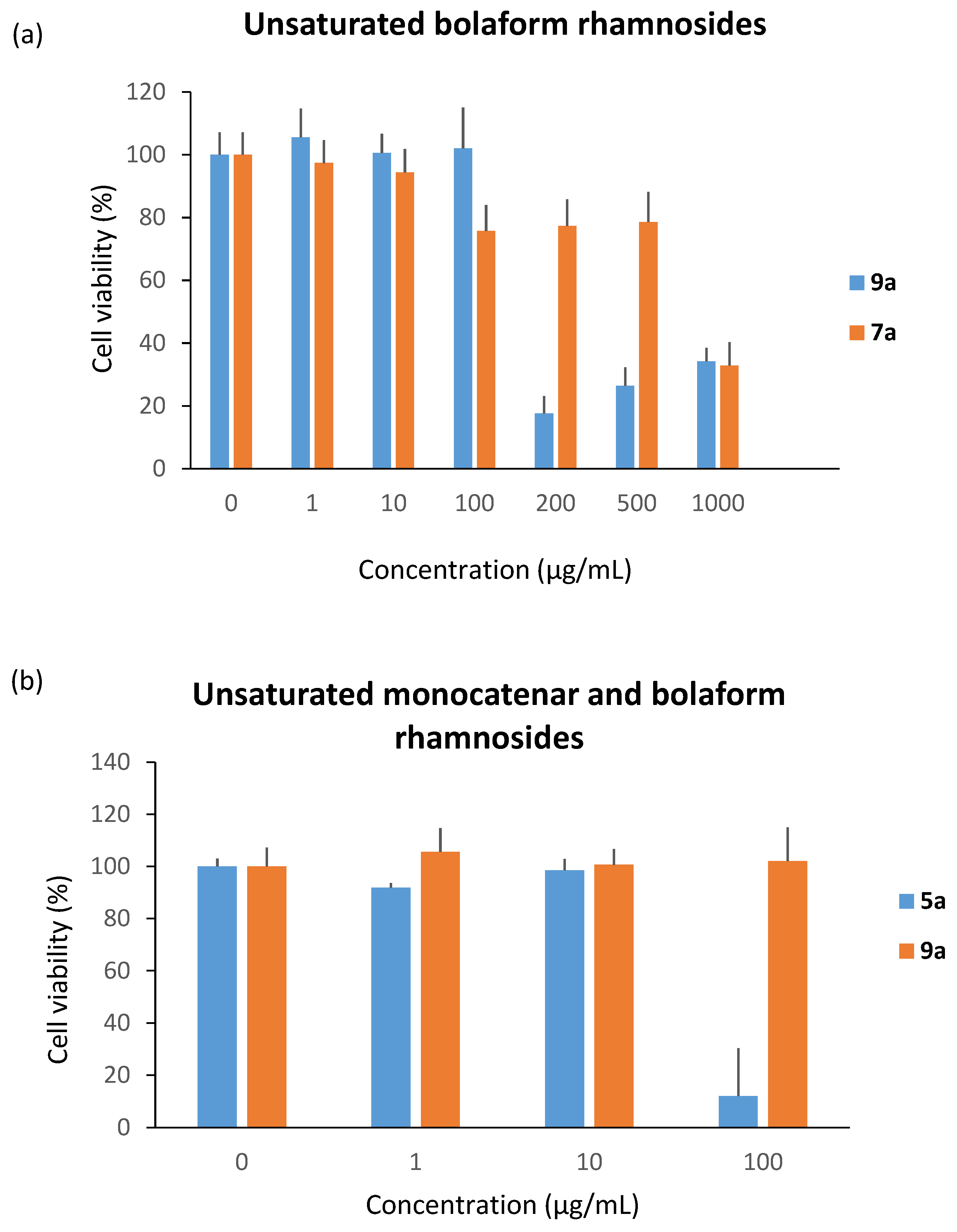

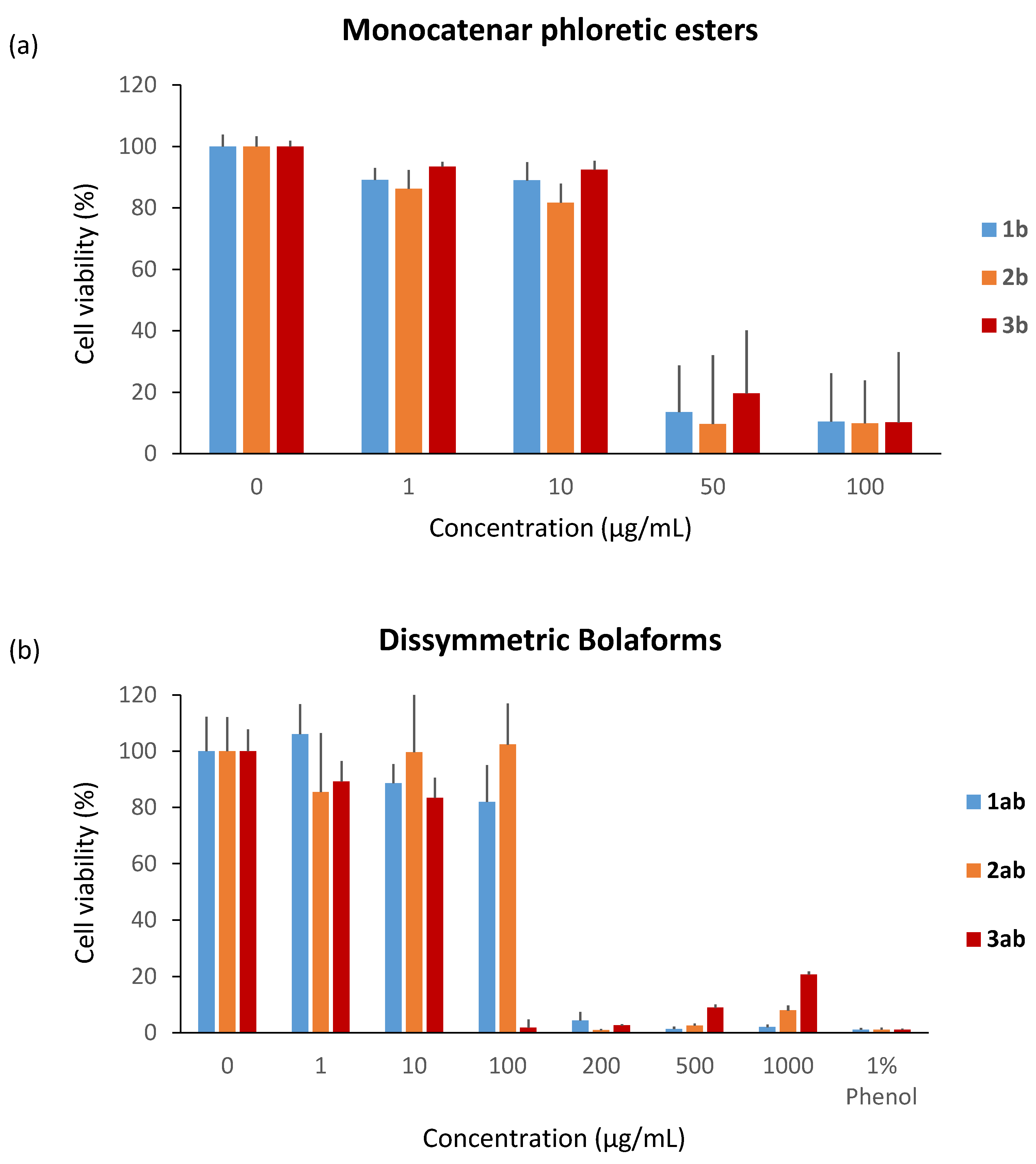

2.4. Cytotoxicity Evaluation

3. Experimental

3.1. Cytotoxicity and Plant-Eliciting Activities

3.2. General Procedure for the Preparation of Rhamnosides under Microwave Activation with Tetrahydrofuran (THF) or 2-Methyltetrahydrofuran (2-MeTHF) as a Solvent

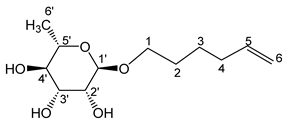

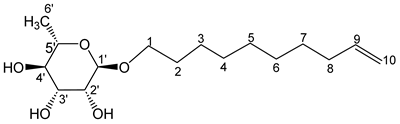

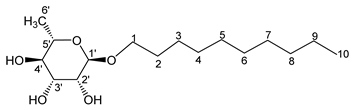

- Hex-5′-enyl-α-L-rhamnopyranoside (1a)

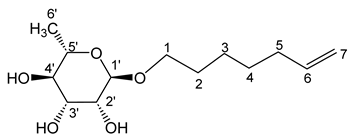

- Hept-6′-enyl-α-L-rhamnopyranoside (2a)

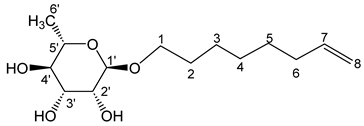

- Oct-7′-enyl-α-L-rhamnopyranoside (3a)

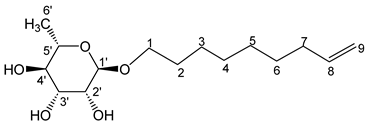

- Non-8′-enyl-α-L-rhamnopyranoside (4a)

- Dec-9′-enyl-α-L-rhamno-pyranoside (5a)

- Undec-10′-enyl-α-L-rhamnopyranoside (6a)

3.3. General Procedure for the Preparation of Rhamnosides under Microwave Activation with γ-Valerolactone as Solvent

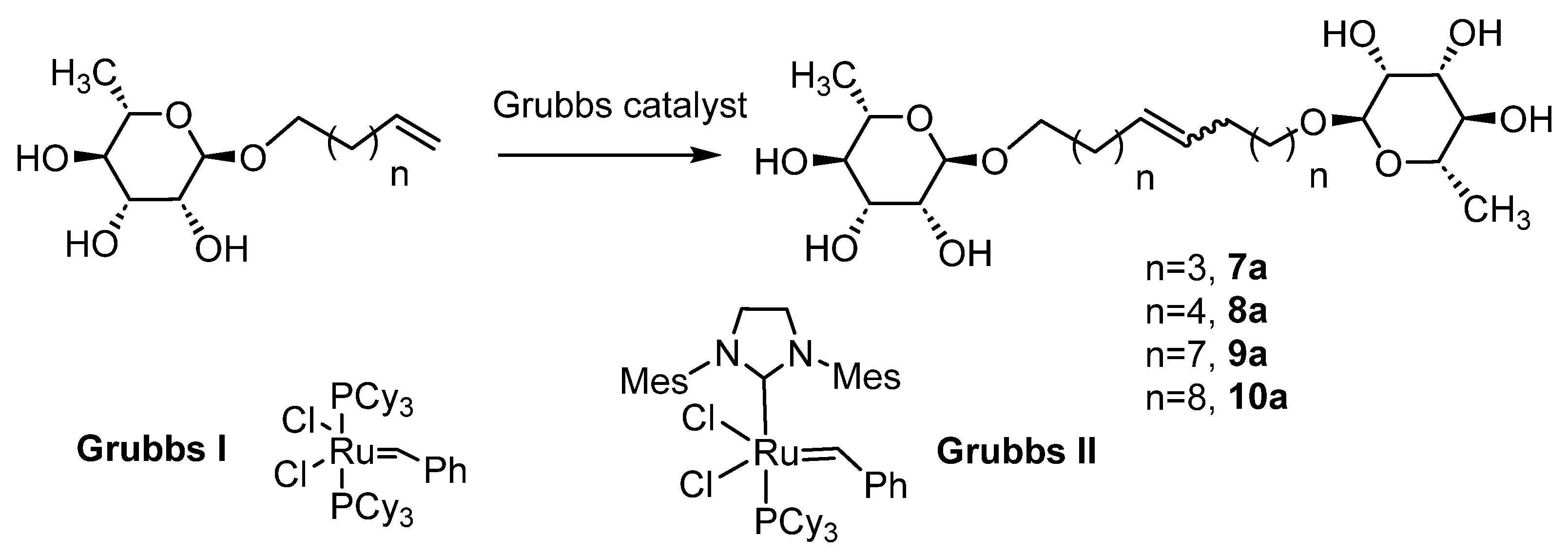

3.4. General Procedure for the Preparation of Rhamnoside-Based Boloamphiphiles under Microwave Activation

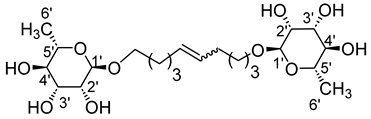

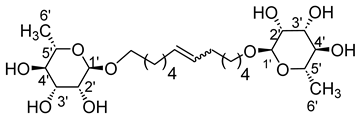

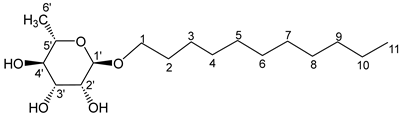

- 1′,10′-bis-dec-5′-eny-L-rhamnopyranoside (7a)

- 1′,12′-bis-dodec-6′-enyl-l-rhamnopyranoside (8a)

- 1′,18′-bis-octadec-9′-enyl-l-rhamnopyranoside (9a)

- 1′,20′-bis-eicosa-10′-enyl-l-rhamnopyranoside (10a)

3.5. General Procedure for the Hydrogenation of Monocatenar Unsaturated Rhamnosides

- Decyl-α-l-rhamno-pyranoside (5a’)

- Undecyl-α-L-rhamnopyranoside (6a′)

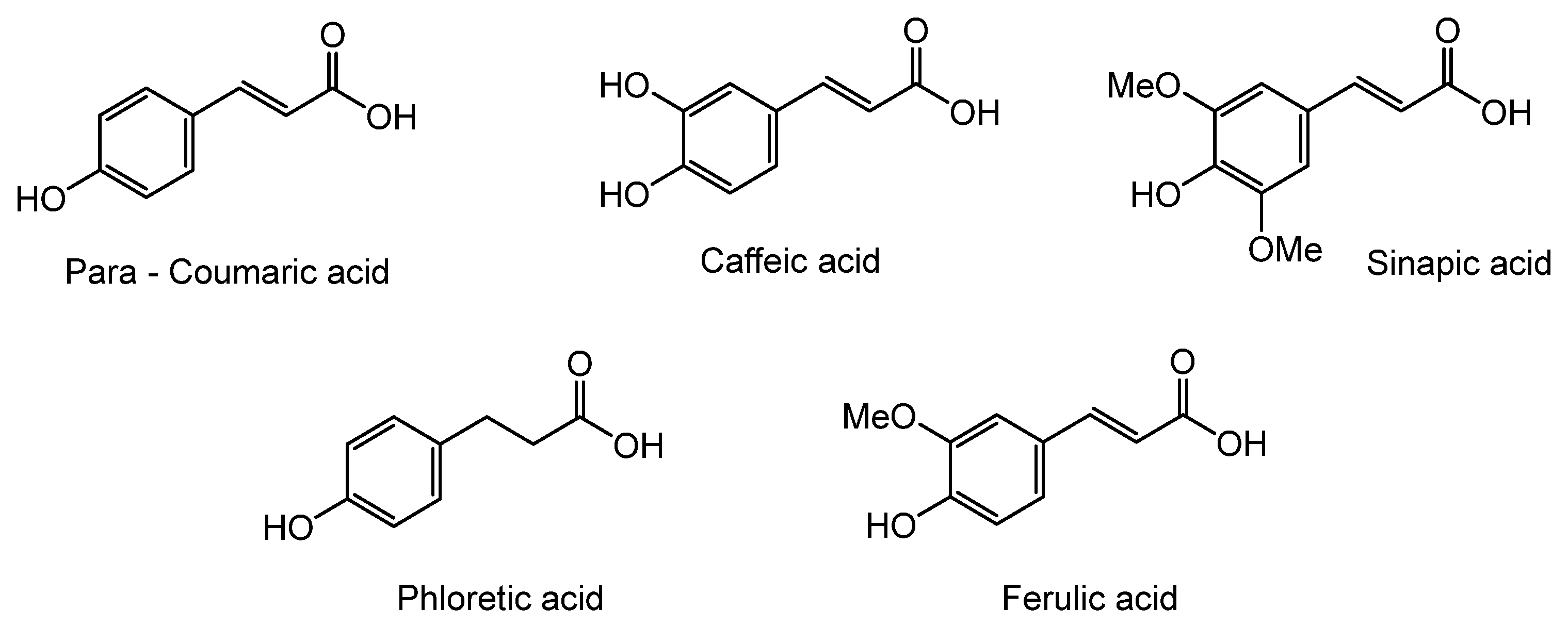

3.6. General Procedure for the Preparation of Monocatenar Esters Derived from Phenolic Acids

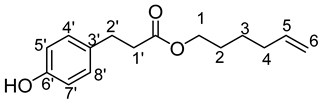

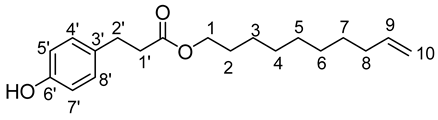

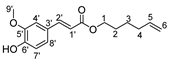

- Hex-5′-enyl-3-(4-hydroxyphenyl)propionic (1b)

- Hept-6′-enyl-3-(4-hydroxyphenyl)propionic (2b)

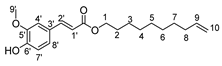

- Dec-9′-enyl-3-(4-hydroxyphenyl)propionic (3b)

- Undec-10′-enyl-3-(4-hydroxyphenyl)propionic (4b)

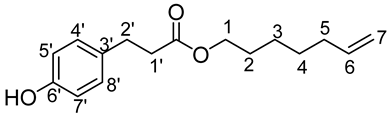

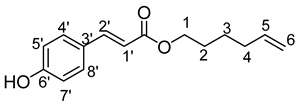

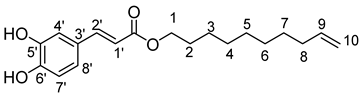

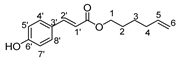

- Hex-5′-enyl-3-(4-hydroxyphenyl)prop-2-enoic (5b)

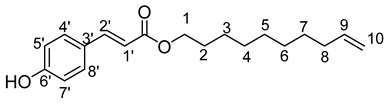

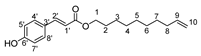

- Dec-9′-enyl-3-(4-hydroxyphenyl)prop-2-enoïc (6b)

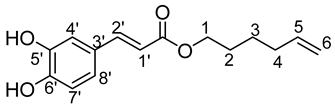

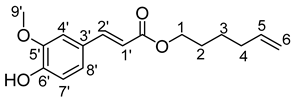

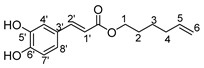

- Hex-5′-enyl-3-(3,5-dihydroxyphenyl)prop-2-enoic (7b)

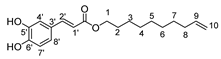

- Dec-9′-enyl-3-(4-hydroxyphenyl)prop-2-enoic (8b)

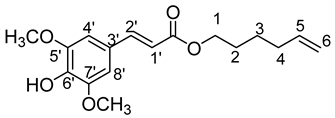

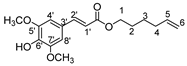

- Hex-5′-enyl-3-(3,5-dimethoxy-4-hydroxyphenyl)prop-2-enoic (9b)

- Hex-5′-enyl-3-(4-hydroxy-3-méthoxyphényl)prop-2-enoïc (10b)

- Dec-9′-enyl-3-enyl-3-(4-hydroxy-3-méthoxyphényl)prop-2-enoïc (11b)

3.7. General Procedure for the Preparation of the Fatty Ester-Based Bolaamphiphiles under Microwave Activation

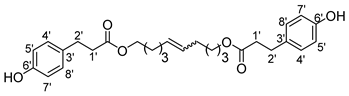

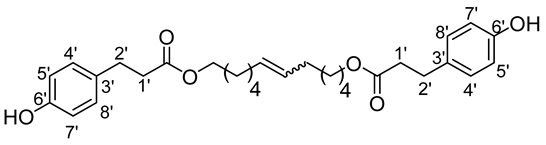

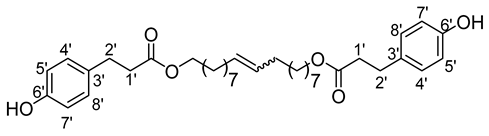

- 1′,10′-bis-dec-5′-enyl-3-(4-hydroxyphenyl)propionic ester (12b)

- 1′,12′-bis-dodec-6′-enyl-3-(4-hydroxyphenyl)propionic ester (13b)

- 1′,18′-bis-octadec-9′-enyl-3-(4-hydroxyphenyl)propionic ester (14b)

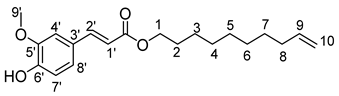

- 1′,10′-bis-dec-5′-enyl-3-(4-hydroxyphenyl)prop-2-enoic (15b)

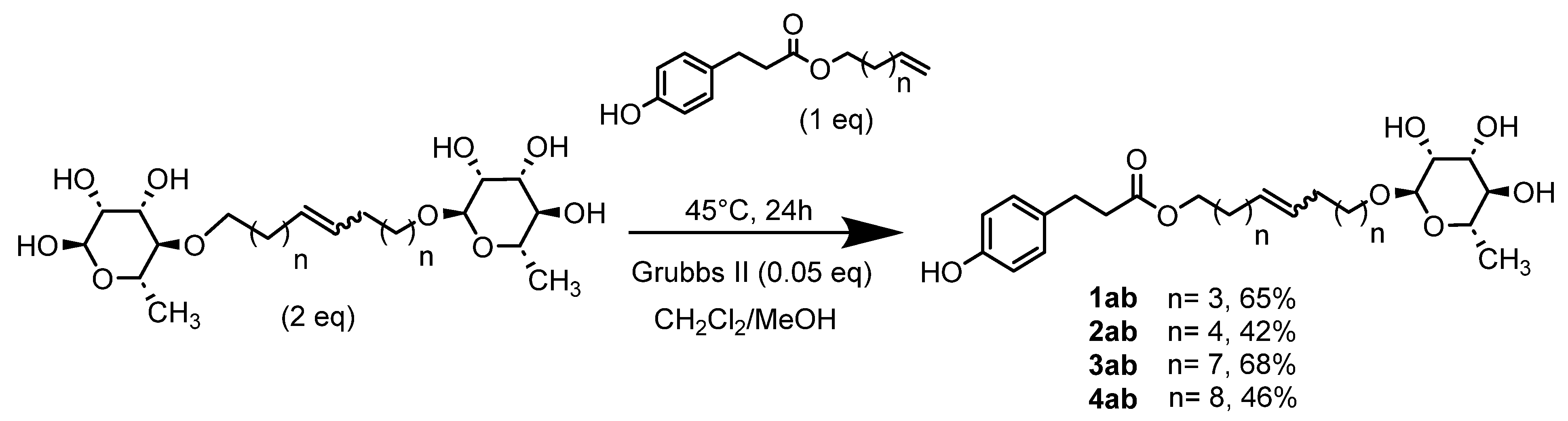

3.8. General Procedure for the Preparation of the Unsymmetrical Fatty Ester- and Rhamnoside-Based Bolaamphiphiles by Classic Heating

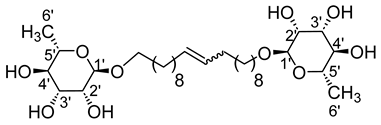

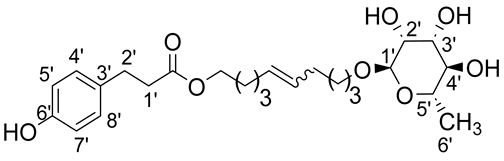

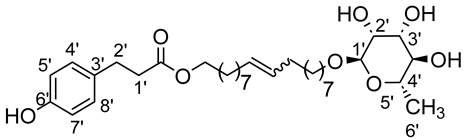

- 1′,10′-bis-dec-5′-enyl-3-(4-hydroxyphenyl)propionicacid–α–L-rhamnopyranoside (1ab)

- 1′,12′-bis-dodec-6′-enyl-3-(4-hydroxyphenyl)propionicacid–α–l-rhamnopyranoside (2ab)

- 1′,18′-bis-dodec-9′-enyl-3-(4-hydroxyphenyl)propionicacid–α–l-rhamnopyranoside (3ab)

- 1′,20′-bis-eicosa-10′-enyl-3-(4-hydroxyphenyl)propionicacid–α–l-rhamnopyranoside (4ab)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

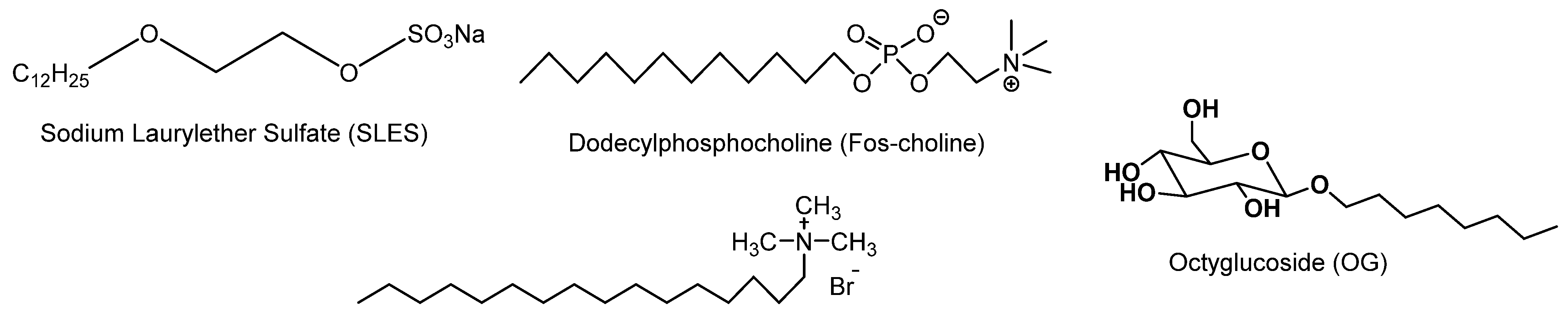

- Ash, I.; Ash, M. Encyclopedia of Surfactants; Chemical Pub. Co.: New York, NY, USA, 1983. [Google Scholar]

- Gonçalves, R.A.; Holmberg, K.; Lindman, B. Cationic surfactants: A review. J. Mol. Liq. 2023, 375, 121335–121346. [Google Scholar] [CrossRef]

- Sarkar, R.; Pal, A.; Rakshit, A.; Saha, B. Properties and applications of amphoteric surfactant: A concise review. J. Surfactants Deterg. 2021, 24, 709–730. [Google Scholar] [CrossRef]

- Singh, N.; Sharma, L. Synthesis of carbohydrate derived non-ionic gemini surfactants and study of their micellar and reverse micellar behavior—A review. Lett. Org. Chem. 2019, 16, 607–614. [Google Scholar] [CrossRef]

- Zhou, M.; Li, S.; Zhang, Z.; Wang, C.; Luo, G.; Zhao, J. Progress in the Synthesis of Zwitterionic Gemini Surfactants. J. Surfactants Deterg. 2017, 20, 1243–12541. [Google Scholar] [CrossRef]

- Damez, C.; Bouquillon, S.; Harakat, D.; Hénin, F.; Muzart, J.; Pezron, I.; Komunjer, L. Alkenyl and alkenoyl amphiphilic derivatives of D-xylose and their surfactant properties. Carbohydr. Res. 2007, 342, 154–163. [Google Scholar] [CrossRef]

- Zakharova, L.Y.; Pashirova, T.N.; Doktorovova, S.; Fernandes, A.R.; Sanchez-Lopez, E.; Silva, A.M.; Souto, S.B. Cationic surfactants: Self-assembly, structure-activity correlation and their biological applications. Int. J. Mol. Sci. 2019, 20, 5534. [Google Scholar] [CrossRef] [PubMed]

- Montesinos, E.; Badosa, E.; Pla, M.; Montesinos, L.; Bonaterra, A. Biocontrol of Plant Disease: Recent Advances and Prospects in Plant Protection; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2022; pp. 121–147. [Google Scholar]

- Kumar, A.; Singh, S.K.; Kant, C.; Verma, H.; Kumar, D.; Singh, P.P.; Modi, A.; Droby, S.; Kesawat, M.S.; Alavilli, H.; et al. Microbial biosurfactant: A new frontier for sustainable agriculture and pharmaceutical industries. Antioxidants 2021, 10, 1472. [Google Scholar] [CrossRef]

- Bajpai, D.; Tyagi, V.K. Laundry detergents: An overview. J. Oleo Sci. 2007, 56, 327–340. [Google Scholar] [CrossRef]

- Mijaljica, D.; Spada, F.; Harrison, I.P. Skin Cleansing without or with Compromise: Soaps and Syndets. Molecules 2022, 27, 2010. [Google Scholar] [CrossRef]

- Andree, H.; Hessel, J.F.; Meine, G.; Middelhauve, B.; Schmid, K. Alkyl Polyglycosides, Technology, Properties and Applications; Hill, K., Von Rybinski, W., Stoll, G., Eds.; VCH Publishers Inc.: New York, NY, USA, 1996; pp. 99–130. [Google Scholar]

- Naveen, K.; Rashmi, T. Characteristic and Application of Anionic Dimeric Surfactants: A Review. Tenside Surfactants Deterg. 2019, 56, 172–179. [Google Scholar]

- Abe, M.; Schechter, D.; Schechter, R.S.; Wade, H.; Weerasooriya, U.; Yiv, S. Microemulsion formation with branched tail polyoxyethylene sulfonate surfactants. J. Colloid Interface Sci. 1986, 114, 342–356. [Google Scholar] [CrossRef]

- Sunwoo, C.K.; Wade, W.H. Optimal Surfactant Structures for Cosurfactant-Free Microemulston Systems I. C16 and C14 Guerbet Alcohol Hydrophobes. J. Dispersion Sci. Technol. 1992, 13, 491–514. [Google Scholar] [CrossRef]

- Sanchez, J.; del Valle, M. Determination of Anionic Surfactants Employing Potentiometric Sensors-A Review. Crit. Rev. Anal.Chem. 2005, 35, 15–29. [Google Scholar] [CrossRef]

- Kaler, E.W.; Herrington, K.L.; Murthy, A.K.; Zasadzinski, J.A. Phase Behavior and Structures of Mixtures of Anionic and Cationic Surfactants. J. Phys. Chem. 1992, 96, 6698–6707. [Google Scholar] [CrossRef]

- Ahmady, A.R.; Hosseinzadeh, P.; Solouk, A.; Akbari, S.; Szulc, A.M.; Brycki, B.E. Cationic gemini surfactant properties, its potential as a promising bioapplication candidate, and strategies for improving its biocompatibility: A review. Adv. Colloid Interface Sci. 2022, 299, 102581–102609. [Google Scholar] [CrossRef]

- Jesus, C.F.; Alves, A.A.S.; Fiuza, S.M.; Murtinho, D.; Antunes, F.E. Mini-review: Synthetic methods for the production of cationic sugar-based surfactants. J. Mol. Liq. 2021, 342, 117389–117398. [Google Scholar] [CrossRef]

- Holmberg, K. Handbook of Applied Surface and Colloid Chemistry; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2002. [Google Scholar]

- Benvegnu, T.; Sassi, J.F. Oligomannuronates from Seaweeds as Renewable Sources for the Development of Green Surfactants. Top. Curr. Chem. 2010, 294, 143–164. [Google Scholar]

- Farn, R.J. Chemistry and Technology of Surfactants; Wiley—Blackwell: Hoboken, NY, USA, 2008. [Google Scholar]

- Hoffmann, B.; Platz, G. Phase and aggregation behaviour of alkylglycosides. Curr. Opin. Colloid Interface Sci. 2010, 6, 171–177. [Google Scholar] [CrossRef]

- Jérôme, F.; Marinkovic, S.; Estrine, B. Transglycosylation: A Key Reaction to Access Alkylpolyglycosides from Lignocellulosic Biomass. ChemSusChem 2018, 11, 1395–1409. [Google Scholar] [CrossRef]

- Geetha, D.; Tyagi, R. Alkyl Poly Glucosides (APGs) Surfactants and Their Properties: A Review. Tenside Surf. Det. 2012, 49, 417–427. [Google Scholar] [CrossRef]

- Roy, S.; Maiti, K.; Moulik, S.P.; Ghosh, R. Synthesis of C14- and C16-carbon chain containing mannitol diester and diether based non-ionic amphiphiles and studies of their Langmuir monolayer films at the air/water interface. Colloids Surf. A Physicochem. Eng. Asp. 2011, 377, 349–355. [Google Scholar] [CrossRef]

- Mulligan, C.N. Recent advances in the environmental applications of biosurfactants. Curr. Opin. Colloid Interface Sci. 2009, 14, 372–378. [Google Scholar] [CrossRef]

- Deleu, M.; Paquot, M. From renewable vegetables resources to microorganisms: New trends in surfactants. C. R. Chim. 2004, 7, 641–646. [Google Scholar] [CrossRef]

- Lin, S.C. Biosurfactants: Recent advances. J. Chem. Technol. Biotechnol. 1996, 66, 109–120. [Google Scholar] [CrossRef]

- Lang, S. Biological amphiphiles (microbial biosurfactants). Curr. Opin. Colloid Interface Sci. 2002, 7, 12–20. [Google Scholar] [CrossRef]

- Gatard, S.; Nasir, M.N.; Deleu, M.; Klai, N.; Legrand, V.; Bouquillon, S. Bolaamphiphiles Derived from Alkenyl L-Rhamnosides and Alkenyl D-Xylosides: Importance of the Hydrophilic Head. Molecules 2013, 18, 6101–6112. [Google Scholar] [CrossRef] [PubMed]

- Nasir, M.N.; Crowet, J.M.; Lins, L.; Obounou Akong, F.; Haudrechy, A.; Bouquillon, S.; Deleu, M. Interactions of sugar-based bolaamphiphiles with biomimetic systems of plasma membranes. Biochimie 2016, 130, 23–32. [Google Scholar] [CrossRef]

- Corma, A.; Hamid, S.B.A.; Iborra, S.; Velty, A. Surfactants from Biomass: A Two-Step Cascade Reaction for the Synthesis of Sorbitol Fatty Acid Esters Using Solid Acid Catalysts. ChemSusChem 2008, 1, 85–90. [Google Scholar] [CrossRef]

- Angyal, S.J. Complexes of Metal Cations with Carbohydrates in Solution. Adv. Carbohydr. Chem. Biochem. 1989, 47, 1–43. [Google Scholar]

- Garelli-Calvet, R.; Brisset, F.; Godefroy, L.; Lattes, A. Alkyldiamides à Double tête de Sucre ou Dérivé de Sucre Comme Composés Amphiphiles. Brevet Européen N° 0 541 467 A2, 7 May 1993. FR 9113851. [Google Scholar]

- Satgé, C.; Granet, R.; Verneuil, B.; Champavier, Y.; Krausz, P. Synthesis and properties of new bolaform and macrocyclic galactose-based surfactants obtained by olefin metathesis. Carbohydr. Res. 2004, 339, 1243–1254. [Google Scholar] [CrossRef]

- Dzulkefly, K.; Khoh, H.F.; Ahmad, F.B.H.; Adlie Ahmad, S.; Lim, W.H. Solvent-free esterification process for the synthesis of glucose bolaform surfactants. Orient. J. Chem. 2010, 26, 747–752. [Google Scholar]

- Obounou Akong, F.; Bouquillon, S. Efficient syntheses of bolaform surfactants from L-rhamnose and/or 3-(4-hydroxyphenyl)propionic acid. Green Chem. 2015, 17, 3290–3300. [Google Scholar] [CrossRef]

- Stuerga, D. Microwave-material interaction and dielectric properties, key ingredients for mastery of chemical microwave process. In Microwave in Organic Synthesis, 2nd ed.; Loupy, A., Ed.; CiteSeer: Princeton, NJ, USA, 2006; pp. 1–61. [Google Scholar]

- Luzuriaga-Loaiza, W.P.; Schellenberger, R.; De Gaetano, Y.; Obounou Akong, F.; Villaume, S.; Crouzet, J.; Haudrechy, A.; Baillieul, F.; Clément, C.; Lins, L.; et al. Synthetic Rhamnolipid Bolaforms trigger an innate immune response in Arabidopsis thaliana. Sci. Rep. 2018, 8, 8534–8547. [Google Scholar] [CrossRef] [PubMed]

- Perreux, L.; Loupy, A. A tentative rationalisation of microwave effects in organic synthesis according to the reaction medium, and mechanistic considerations. Tetrahedron 2001, 57, 9199–9223. [Google Scholar] [CrossRef]

- Bornaghi, F.L.; Poulsen, S.A. Microwave-accelerated Fischer glycosylation. Tetrahedron Lett. 2005, 46, 3485–3488. [Google Scholar] [CrossRef]

- Kerkel, F.; Markiewicz, M.; Stolte, S.; Müller, C.; Kunz, W. The green platform molecule gamma-valerolactone—Ecotoxicity, biodegradability, solvent properties, and potential applications. Green Chem. 2021, 23, 2962–2976. [Google Scholar] [CrossRef]

- Dutta, S.; Yu, I.K.M.; Tsang, D.C.W.; Hau Ng, Y.; Sik Ok, Y.; Sherwood, J.; Clark, J.H. Green synthesis of gamma-valerolactone (GVL) through hydrogenation of biomass-derived levulinic acid using non-noble metal catalysts. Chem. Eng. J. 2019, 372, 992–1006. [Google Scholar] [CrossRef]

- Snoussi, M.; Trabelsi, N.; Dehmeni, A.; Benzekri, R.; Bouslama, L.; Hajlaoui, B.; Al-sieni, A.; Papetti, A. Phytochemical analysis, antimicrobial and antioxidant activities of Allium roseum var. odoratissimum (Desf.) Coss extracts. Ind. Crops Prod. 2016, 89, 533–542. [Google Scholar] [CrossRef]

- Selka, A.; Moutombi, F.J.N.; Jean-François, J.; Touaibia, M. Hydroxycinnamic Acids and Their Related Synthetic Analogs: An Update of Pharmacological Activities. Mini Rev. Med. Chem. 2022, 22, 1516–1544. [Google Scholar] [CrossRef]

- Abazari, M.F.; Nasiri, N.; Karizi, S.Z.; Nejati, F.; Haghiaminjan, H.; Norouzi, S.; Piri, P.; Estakhr, L.; Faradonbeh, D.R.; Kohandani, M.; et al. An updated review of various medicinal applications of p-coumaric acid: From antioxidative and anti-inflammatory properties to effects on cell cycle and proliferation. Mini Rev. Med. Chem. 2021, 21, 2187–2201. [Google Scholar] [CrossRef]

- Kaur, J.; Kaur, R. p-Coumaric Acid: A Naturally Occurring Chemical with Potential Therapeutic Applications. Curr. Org. Chem. 2022, 26, 1333–1349. [Google Scholar] [CrossRef]

- Antonopoulou, I.; Sapountzaki, E.; Rova, U.; Christakopoulos, P. Ferulic Acid From Plant Biomass: A Phytochemical With Promising Antiviral Properties. Front. Nutr. 2022, 8, 777576. [Google Scholar] [CrossRef] [PubMed]

- Suárez-Escobedo, L.; Gotor-Fernández, V. Solvent role in the lipase-catalysed esterification of cinnamic acid and derivatives. Optimisation of the biotransformation conditions. Tetrahedron 2021, 8112, 131873–131879. [Google Scholar] [CrossRef]

- Chen, H.C.; Twu, Y.K.; Chang, C.M.J.; Liu, Y.C.; Shieh, C.J. Optimized synthesis of lipase-catalyzed octyl caffeate by Novozym® 435. Ind. Crops Prod. 2010, 32, 522–526. [Google Scholar] [CrossRef]

- Kotha, S.; Dipak, M.K. Strategies and tactics in olefin metathesis. Tetrahedron 2012, 68, 397–421. [Google Scholar] [CrossRef]

- Connon, S.J.; Blechert, S. Recent developments in olefin cross-metathesis. Angew. Chem. Int. Ed. 2003, 42, 1900–1923. [Google Scholar] [CrossRef]

- López-Alarcón, C.; Denicola, A. Evaluating the antioxidant capacity of natural products: A review on chemical and cellular-based assays. Anal. Chim. Acta 2013, 763, 1–10. [Google Scholar] [CrossRef]

- Munteanu, I.G.; Apetrei, C. Analytical Methods Used in Determining Antioxidant Activity: A Review. Int. J. Mol. Sci. 2021, 22, 3380. [Google Scholar] [CrossRef]

- Ilyasov, I.R.; Beloborodov, V.L.; Selivanova, I.A.; Terekhov, R.P. ABTS/PP Decolorization Assay of Antioxidant Capacity Reaction Pathways. Int. J. Mol. Sci. 2020, 21, 1131–1158. [Google Scholar] [CrossRef]

- Moussaoui, A.L.; Jawhari, F.Z.; Almehdi, A.M.; Elmsellem, H.; Benbrahim, K.F.; Bousta, D.; Bari, A. Antibacterial, antifungal and antioxidant activity of total polyphenols of Withania frutescens L. Bioorg. Chem. 2019, 93, 103337–103346. [Google Scholar] [CrossRef]

- Sakurai, S.; Kawakami, Y.; Kuroki, M.; Gotoh, H. Structure/antioxidant activity (oxygen radical absorbance capacity) relationships of phenolic compounds. Struct. Chem. 2022, 33, 1055–1062. [Google Scholar] [CrossRef]

- Zheng, Y.; Karimi-Maleh, H.; Fu, L. Evaluation of Antioxidants Using Electrochemical Sensors: A Bibliometric Analysis. Sensors 2022, 22, 3238. [Google Scholar] [CrossRef] [PubMed]

- Chaillou, L.L.; Nazareno, M.A. New Method to Determine Antioxidant Activity of Polyphenols. J. Agric. Food Chem. 2006, 54, 8397–8402. [Google Scholar] [CrossRef] [PubMed]

- Blaser, H.U.; Malan, C.; Pugin, B.; Spindler, F.; Steiner, H.; Studer, M. Selective Hydrogenation for Fine Chemicals: Recent Trends and New Developments. Adv. Synth. Catal. 2003, 345, 103–151. [Google Scholar] [CrossRef]

- Aziz, A.; Kapoor, D. Salicylic Acid: It’s Physiological Role and Interactions. Res. J. Pharm. Technol. 2018, 11, 3171–3177. [Google Scholar] [CrossRef]

- Ullah, C.; Chen, Y.H.; Ortega, M.A.; Tsai, C.J. The diversity of salicylic acid biosynthesis and defense signaling in plants: Knowledge gaps and future opportunities. Curr. Opin. Plant Biol. 2023, 72, 102349. [Google Scholar] [CrossRef] [PubMed]

- Ishiyama, I.; Shiga, M.; Sasamoto, K. A new sulfonated tetrazolium salt that produces a highly water-soluble formazan dye. Chem. Pharm. Bull. 1993, 41, 1118–1122. [Google Scholar] [CrossRef]

- Fink, S.L.; Cookson, B.T. Apoptosis, pyroptosis, and necrosis: Mechanistic description of dead and dying eukaryotic cells. Infect. Immun. 2005, 73, 1907–1916. [Google Scholar] [CrossRef]

- Paolinia, A.; Porredon Guarch, C.; Ramos-López, D.; de Lapuente, J.; Lascialfari, A.; Guari, Y.; Larionova, J.; Long, J.; Nano, J. Rhamnose-coated superparamagnetic iron-oxide nanoparticles: An evaluation of their in vitro cytotoxicity, genotoxicity and carcinogenicity. J. Appl. Toxicol. 2016, 36, 510–520. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, G.; Wang, H.; Cheng, C.; Zang, G.; Guo, X.; Liu, R.H. Phytochemical Profiles and Antioxidant Activities in Six Species of Ramie Leaves. PLoS ONE 2014, 9, e108140. [Google Scholar] [CrossRef]

| Entry | Alcohol | Conditions | Rhamnoside/Isolated Yields (%) after Flash Chromatography (CH2Cl2/MeOH: 9/1) |

|---|---|---|---|

| 1 | Hex-5-enol | THF, 80 °C, 48 h | 1a/19 |

| 2 | Dec-9-enol | THF, 80 °C, 48 h | 5a/10 |

| 3 | Hex-5-enol | THF, 60 °C, 48 h | 1a/5 |

| 4 | Dec-9-enol | THF, 60 °C, 48 h | 5a/5 |

| 5 | Hex-5-enol | THF, 60 °C, 48 h Addition of the catalyst 3 times | 1a/7 |

| 6 | Dec-9-enol | THF, 60 °C, 48 h Addition of the catalyst 3 times | 5a/7 |

| 7 | Hex-5-enol | Neat, 60 °C, 5 h | 1a/38 |

| 8 | Dec-9-enol | Neat, 60 °C, 5 h | 5a/40 |

| Entry | Ratios (eq.) L-Rhamnose/Hex-5-enol/PTSA | Conditions | Isolated Yields in 1a (%) (Combiflash) |

|---|---|---|---|

| 1 | 1/2/0.6 | 35 °C, 5 min, 80 W | - |

| 2 | 1/2/0.6 | 35 °C, 10 min, 80 W | 17 |

| 3 | 1/2/0.6 | 80 °C, 35 min, 60 W | 40 |

| 4 | 1/2/0.6 | 60 °C, 60 min, 60 W | 48 |

| 5 | 1/2/0.6 | 80 °C, 60 min, 60 W | 50 |

| 6 | 1/4/0.6 | 60 °C, 60 min, 60 W | 58 |

| 7 | 1/4/0.6 | 80 °C, 60 min, 60 W | 55 |

| 8 | 1/4/0.6 | 60 °C, 120 min, 60 W | 64 |

| 9 | 1/6/0.6 | 60 °C, 120 min, 60 W | 62 |

| 10 | 1/6/0.6 | 80 °C, 60 min, 60 W | 60 |

| Entry | Alcohol | Solvent (5 mL) | Rhamnoside | Isolated Yields (%) (Combiflash) |

|---|---|---|---|---|

| 1 | Hex-5-enol | THF | 1a | 64 |

| 2 | Hex-5-enol | γ-valerolactone | 1a | 66 |

| 3 | Hex-5-enol | 2-methyltetrahydrofuran | 1a | 63 |

| 4 | Hept-6-enol | THF | 2a | 60 |

| 5 | Oct-7-enol | THF | 3a | 50 |

| 6 | Non-8-enol | THF | 4a | 53 |

| 7 | Dec-9-enol | THF | 5a | 48 |

| 8 | Dec-9-enol | γ-valerolactone | 5a | 73 |

| 9 | Dec-9-enol | 2-methyltetrahydrofuran | 5a | 55 |

| 10 | Undec-10-enol | THF | 6a | 47 |

| Entry | Monocatenar Rhamnoside | Conditions | Grubbs Catalyst (0.1 eq.) | Purification | Bolaform Rhamnoside Isolated Yields (%) |

|---|---|---|---|---|---|

| 1 | 1a | CH2Cl2 | Grubbs I | Silica Chromatography | 7a 19 |

| 2 | 2a | CH2Cl2 | Grubbs I | Silica Chromatography | 8a 13 |

| 3 | 5a | CH2Cl2 | Grubbs I | Silica Chromatography | 9a 10 |

| 4 | 1a | CH2Cl2/MeOH (9/1) | Grubbs I | CombiFlash | 7a 52 |

| 5 | 2a | CH2Cl2/MeOH (9/1) | Grubbs I | CombiFlash | 8a 37 |

| 6 | 5a | CH2Cl2/MeOH (9/1) | Grubbs I | CombiFlash | 9a 31 |

| 7 | 1a | CH2Cl2/MeOH (9/1) | Grubbs II | CombiFlash | 7a 77 |

| 8 | 2a | CH2Cl2/MeOH (9/1) | Grubbs II | CombiFlash | 8a 60 |

| 9 | 5a | CH2Cl2/MeOH (9/1) | Grubbs II | CombiFlash | 9a 56 |

| 10 | 6a | CH2Cl2/MeOH (9/1) | Grubbs II | CombiFlash | 10a 32 |

| |||

|---|---|---|---|

| Compounds | Conversion of Acid (% GC) | Isolated Yields (Combiflash) % | Isolated Yields (Flash Chromatography) % |

| 1b | 97 | 95 | 12 |

| 2b | 90 | 88 | 28 |

| 3b | 97 | 96 | 46 |

| 4b | 85 | 79 | 31 |

| Starting Phenolic Acid | Compounds | Solvent | Isolated Yields (%) |

|---|---|---|---|

| p-coumaric acid |  5b | 2M2B (40 mL) | 70 |

| p-coumaric acid |  6b | 2M2B (40 mL) | 74 |

| caffeic acid |  7b | 2M2B/THF (1/2) (30 mL) | 52 |

| caffeic acid |  8b | 2M2B/THF (1/2) (30 mL) | 45 |

| ferulic acid |  10b | 2M2B (60 mL) | 52 |

| ferulic acid |  11b | 2M2B (60 mL) | 52 |

| sinapic acid |  9b | Acetone (30 mL) | 40 |

| ||

|---|---|---|

| Compound | Isolated Yields | |

| Grubbs I Catalyst | Grubbs II Catalyst | |

| 12b | 20 | 56 |

| 13b | 16 | 48 |

| 14b | 18 | 60 |

| 15b | 11 | 42 |

| Entry | Compounds | IC50 (μmol/L) |

|---|---|---|

| 1 | Vitamin C | 34 |

| 2 | 5b | 45 |

| 3 | 7b | 29 |

| 4 | 9b | 31 |

| 5 | 10b | 47 |

| 6 | 6b | 32 |

| 7 | 11b | 32 |

| 8 | 12b | 36 |

| 9 | 14b | 35 |

| 10 | 15b | 27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kordkatooli, E.; Bacha, K.; Villaume, S.; Dorey, S.; Monboisse, J.-C.; Brassart-Pasco, S.; Mbakidi, J.-P.; Bouquillon, S. L-Rhamnose and Phenolic Esters-Based Monocatenar and Bolaform Amphiphiles: Eco-Compatible Synthesis and Determination of Their Antioxidant, Eliciting and Cytotoxic Properties. Molecules 2023, 28, 5154. https://doi.org/10.3390/molecules28135154

Kordkatooli E, Bacha K, Villaume S, Dorey S, Monboisse J-C, Brassart-Pasco S, Mbakidi J-P, Bouquillon S. L-Rhamnose and Phenolic Esters-Based Monocatenar and Bolaform Amphiphiles: Eco-Compatible Synthesis and Determination of Their Antioxidant, Eliciting and Cytotoxic Properties. Molecules. 2023; 28(13):5154. https://doi.org/10.3390/molecules28135154

Chicago/Turabian StyleKordkatooli, Emad, Katia Bacha, Sandra Villaume, Stephan Dorey, Jean-Claude Monboisse, Sylvie Brassart-Pasco, Jean-Pierre Mbakidi, and Sandrine Bouquillon. 2023. "L-Rhamnose and Phenolic Esters-Based Monocatenar and Bolaform Amphiphiles: Eco-Compatible Synthesis and Determination of Their Antioxidant, Eliciting and Cytotoxic Properties" Molecules 28, no. 13: 5154. https://doi.org/10.3390/molecules28135154

APA StyleKordkatooli, E., Bacha, K., Villaume, S., Dorey, S., Monboisse, J.-C., Brassart-Pasco, S., Mbakidi, J.-P., & Bouquillon, S. (2023). L-Rhamnose and Phenolic Esters-Based Monocatenar and Bolaform Amphiphiles: Eco-Compatible Synthesis and Determination of Their Antioxidant, Eliciting and Cytotoxic Properties. Molecules, 28(13), 5154. https://doi.org/10.3390/molecules28135154