The Progress on Magnetic Material Thin Films Prepared Using Polymer-Assisted Deposition

Abstract

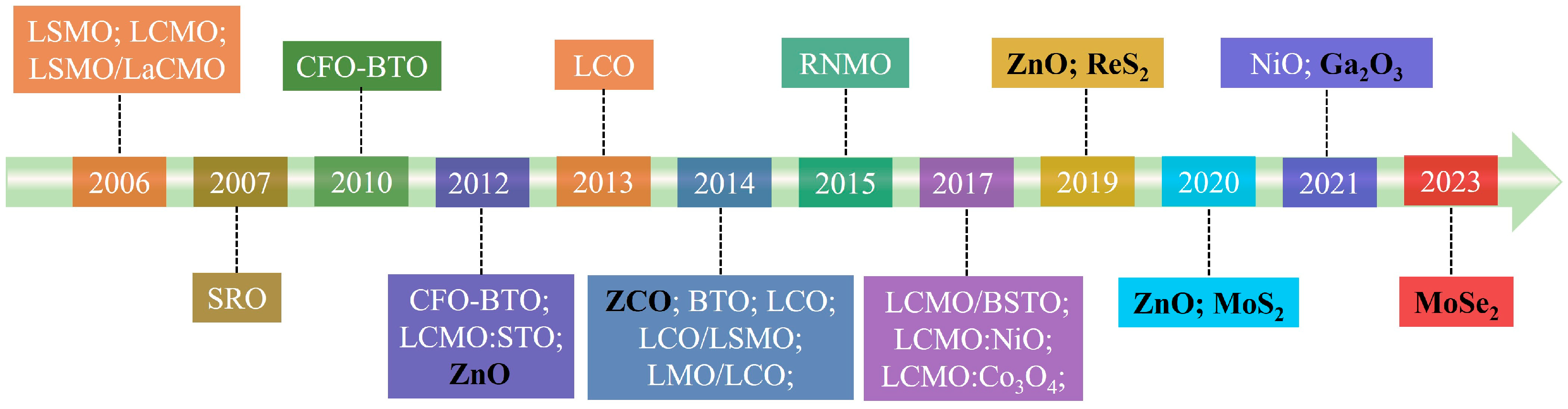

1. Introduction

2. Polymer-Assisted Deposition (PAD)

2.1. Main Processing Steps

2.2. Advantages

3. Traditional Oxide-Based Magnetic Semiconductor Thin Films

3.1. ZnO

3.2. Ga2O3

3.3. SrRuO3 (SRO)

3.4. Perovskite

3.4.1. LaCoO3 (LCO)

3.4.2. LaMnO3 (LMO)

3.4.3. Y3Fe5O12 (YIG)

4. Layered Material Thin Films

4.1. MoS2

4.2. MoSe2

4.3. ReS2

5. Atomically Thin Non-Layered Materials

5.1. NiO

Thickness-Dependent RTFM

6. Origin of Ferromagnetism in PAD-Grown Materials

7. Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jia, Q.X.; McCleskey, T.M.; Burrell, A.K.; Lin, Y.; Collis, G.E.; Wang, H.; Li, A.D.Q.; Foltyn, S.R. Polymer-assisted deposition of metal-oxide films. Nat. Mater. 2004, 3, 529. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Ma, L.; Wang, X.; Wang, X.; Yao, J.; Yi, Q.; Tang, R.; Zou, G. Sub-nanometer thick wafer-size NiO films with room-temperature ferromagnetic behavior. Angew. Chem. Int. Ed. 2021, 60, 25020–25027. [Google Scholar] [CrossRef] [PubMed]

- Ren, H.; Zhang, L.; Xiang, G. Web buckle-mediated room-temperature ferromagnetism in strained MoS2 thin films. Appl. Phys. Lett. 2020, 116, 012401. [Google Scholar] [CrossRef]

- Ren, H.; Xiang, G.; Lu, J.; Zhang, X.; Zhang, L. Biaxial strain-mediated room temperature ferromagnetism of ReS2 web buckles. Adv. Electron. Mater. 2019, 5, 1900814. [Google Scholar] [CrossRef]

- Ren, H.; Xiong, Z.; Wang, E.; Yuan, Z.; Sun, Y.; Zhu, K.; Wang, B.; Wang, X.; Ding, H.; Liu, P.; et al. Watching dynamic self-assembly of web buckles in strained MoS2 thin films. ACS Nano 2019, 13, 3106–3116. [Google Scholar] [CrossRef]

- Wang, H.; Xu, W.; Richins, S.; Liaw, K.; Yan, L.; Zhou, M.; Luo, H. Polymer-assisted approach to LaCo1−xNixO3 network nanostructures as bifunctional oxygen electrocatalysts. Electrochim. Acta 2019, 296, 945–953. [Google Scholar] [CrossRef]

- Ali, M.N.; Garcia, M.A.; Parsons-Moss, T.; Nitsche, H. Polymer-assisted deposition of homogeneous metal oxide films to produce nuclear targets. Nat. Protoc. 2010, 5, 1440–1446. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, H.; Hawley, M.E.; Foltyn, S.R.; Jia, Q.X.; Collis, G.E.; Burrell, A.K.; McCleskey, T.M. Epitaxial growth of Eu2O3 thin films on LaAlO3 substrates by polymer-assisted deposition. Appl. Phys. Lett. 2004, 85, 3426–3428. [Google Scholar] [CrossRef]

- Garcia, M.A.; Ali, M.N.; Chang, N.N.; Parsons-Moss, T.; Ashby, P.D.; Gates, J.M.; Stavsetra, L.; Gregorich, K.E.; Nitsche, H. Metal oxide targets produced by the polymer-assisted deposition method. Nucl. Instrum. Methods Phys. Res. Sect. A 2010, 613, 396–400. [Google Scholar] [CrossRef]

- Shukla, P.; Minogue, E.M.; McCleskey, T.M.; Jia, Q.X.; Lin, Y.; Lu, P.; Burrell, A.K. Conformal coating of nanoscale features of microporous Anodisc (TM) membranes with zirconium and titanium oxides. Chem. Commun. 2006, 8, 847–849. [Google Scholar] [CrossRef]

- Yi, Q.; Dai, X.; Zhao, J.; Sun, Y.; Lou, Y.; Su, X.; Li, Q.; Sun, B.; Zheng, H.; Shen, M.; et al. Enhanced mechanical strength and electrical conductivity of carbon-nanotube/TiC hybrid fibers. Nanoscale 2013, 5, 6923–6927. [Google Scholar] [CrossRef]

- Cao, Y.; Dai, X.; Zhang, K.; Wang, H.; Zou, G. One-step aqueous solution route toward depositing transparent carbon film onto different quartize substrate. Mater. Lett. 2016, 185, 135–138. [Google Scholar] [CrossRef]

- Zou, G.; Jain, M.; Zhou, H.; Luo, H.; Baily, S.A.; Civale, L.; Bauer, E.; McCleskey, T.M.; Burrell, A.K.; Jia, Q. Ultrathin epitaxial superconducting niobium nitride films grown by a chemical solution technique. Chem. Commun. 2008, 45, 6022–6024. [Google Scholar] [CrossRef]

- Zou, G.; Luo, H.; Zhang, Y.; Xiong, J.; Wei, Q.; Zhuo, M.; Zhai, J.; Wang, H.; Williams, D.; Li, N.; et al. A chemical solution approach for superconducting and hard epitaxial NbC film. Chem. Commun. 2010, 46, 7837–7839. [Google Scholar] [CrossRef]

- Zhang, Y.; Haberkorn, N.; Ronning, F.; Wang, H.; Mara, N.A.; Zhuo, M.; Chen, L.; Lee, J.H.; Blackmore, K.J.; Bauer, E.; et al. Epitaxial superconducting delta-MoN films grown by a chemical solution method. J. Am. Chem. Soc. 2011, 133, 20735–20737. [Google Scholar] [CrossRef]

- Dai, X.; Wu, J.; Qian, Z.C.; Wang, H.Y.; Jian, J.; Cao, Y.J.; Rummeli, M.H.; Yi, Q.H.; Liu, H.Y.; Zou, G.F. Ultra-smooth glassy graphene thin films for flexible transparent circuits. Sci. Adv. 2016, 2, e1601574. [Google Scholar] [CrossRef]

- Chen, L.; Xu, W.; Liu, W.; Han, S.; Cao, P.; Fang, M.; Zhu, D.; Lu, Y. Polymer-assisted deposition of gallium oxide for thin-film transistor applications. ACS Appl. Mater. Interfaces 2019, 11, 29078–29085. [Google Scholar] [CrossRef]

- Yi, Q.; Wu, J.; Zhao, J.; Wang, H.; Hu, J.; Dai, X.; Zou, G. Tuning bandgap of P-type Cu2Zn(Sn, Ge)(S, Se)4 semiconductor thin films via aqueous polymer-assisted deposition. ACS Appl. Mater. Interfaces 2017, 9, 1602–1608. [Google Scholar] [CrossRef]

- Xu, H.; Han, X.; Dai, X.; Liu, W.; Wu, J.; Zhu, J.; Kim, D.; Zou, G.; Sablon, K.A.; Sergeev, A.; et al. High detectivity and transparent few-layer MoS2 /glassy-graphene heterostructure photodetectors. Adv. Mater. 2018, 30, 1706561. [Google Scholar] [CrossRef]

- Ren, H.; Liu, Y.; Zhang, L.; Liu, K. Synthesis, properties, and applications of large-scale two-dimensional materials by polymer-assisted deposition. J. Semicond. 2019, 40, 061003. [Google Scholar] [CrossRef]

- Ren, H.; Xiang, G. Morphology-dependent room-temperature ferromagnetism in undoped ZnO nanostructures. Nanomaterials 2021, 11, 3199. [Google Scholar] [CrossRef] [PubMed]

- Ren, H.; Xiang, G. Strain-modulated magnetism in MoS2. Nanomaterials 2022, 12, 1929. [Google Scholar] [CrossRef]

- Wang, E.; Chen, Z.; Shi, R.; Xiong, Z.; Xin, Z.; Wang, B.; Guo, J.; Peng, R.; Wu, Y.; Li, C.; et al. Humidity-controlled dynamic engineering of buckling dimensionality in MoS2 thin films. ACS Nano 2022, 16, 14157–14167. [Google Scholar] [CrossRef] [PubMed]

- Ren, H.; Xiang, G. Recent Progress in Research on Ferromagnetic Rhenium Disulfide. Nanomaterials 2022, 12, 3451. [Google Scholar] [CrossRef] [PubMed]

- Zhong, J.; Zhang, X.; He, W.; Gong, D.; Lan, M.; Dai, X.; Peng, Y.; Xiang, G. Large-scale fabrication and Mo vacancy-induced robust room-temperature ferromagnetism of MoSe2 thin films. Nanoscale 2023, 15, 6844–6852. [Google Scholar] [CrossRef]

- Zhu, J.T.; Wu, J.; Sun, Y.H.; Huang, J.W.; Xia, Y.F.; Wang, H.; Wang, H.B.; Wang, Y.; Yia, Q.H.; Zou, G.F. Thickness-dependent bandgap tunable molybdenum disulfide films for optoelectronics. RSC Adv. 2016, 6, 110604–110609. [Google Scholar] [CrossRef]

- Liu, H.; Shi, L.; Guo, Y.; Zhou, S.; Zhao, J.; Wang, C.; He, L.; Li, Y. Nature of ferromagnetic ordered state in LaCoO3 epitaxial nano-thin film on LaAlO3 substrate. J. Alloy Compd. 2014, 594, 158–164. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Liu, H.F.; Xie, R.S.; Ma, G.H.; Huo, J.C.; Wang, H.B. Controllable factors affecting the epitaxial quality of LaCoO3 films grown by polymer-assisted deposition. Bull. Mater. Sci. 2018, 41, 37. [Google Scholar] [CrossRef]

- Ren, H.; Xiang, G.; Gu, G.; Zhang, X. Enhancement of ferromagnetism of ZnO:Co nanocrystals by post-annealing treatment: The role of oxygen interstitials and zinc vacancies. Mater. Lett. 2014, 122, 256–260. [Google Scholar] [CrossRef]

- Jain, M.; Li, Y.; Hundley, M.F.; Hawley, M.; Maiorov, B.; Campbell, I.H.; Civale, L.; Jia, Q.X.; Shukla, P.; Burrell, A.K.; et al. Magnetoresistance in polymer-assisted deposited Sr- and Ca-doped lanthanum manganite films. App. Phys. Lett. 2006, 88, 232510. [Google Scholar] [CrossRef]

- Jain, M.; Shukla, P.; Li, Y.; Hundley, M.F.; Wang, H.; Foltyn, S.R.; Burrell, A.K.; McCleskey, T.M.; Jia, Q. Manipulating magnetoresistance near room temperature in La0.67Sr0.33MnO3/La0.67Ca0.33MnO3 films prepared by polymer assisted deposition. Adv. Mater. 2006, 18, 2695–2698. [Google Scholar] [CrossRef]

- Luo, H.; Yang, H.; Bally, S.A.; Ugurlu, O.; Jain, M.; Hawley, M.E.; McCleskey, T.M.; Burrell, A.K.; Bauer, E.; Civale, L.; et al. Self-assembled epitaxial nanocomposite BaTiO3-NiFe2O4 films prepared by polymer-assisted deposition. J. Am. Chem. Soc. 2007, 129, 14132–14133. [Google Scholar] [CrossRef]

- Luo, H.M.; Jain, M.; Baily, S.A.; McCleskey, T.M.; Burrell, A.K.; Bauer, E.; DePaula, R.F.; Dowden, P.C.; Civale, L.; Jia, Q.X. Structural and ferromagnetic properties of epitaxial SrRuO3 thin films obtained by polymer-assisted deposition. J. Phys. Chem. B 2007, 111, 7497–7500. [Google Scholar] [CrossRef]

- Luo, H.; Lin, Y.; Wang, H.; Baily, S.A.; Lee, J.H.; Hawley, M.E.; McCleskey, T.M.; Burrell, A.K.; Bauer, E.; Civale, L.; et al. Amorphous silica nanoparticles embedded in epitaxial SrTiO3 and CoFe2O4 matrices. Angew. Chem. Int. Ed. 2008, 47, 5768–5771. [Google Scholar] [CrossRef]

- Liang, W.; Li, Z.; Bi, Z.; Nan, T.; Du, H.; Nan, C.; Chen, C.; Jia, Q.; Lin, Y. Role of the interface on the magnetoelectric properties of BaTiO3 thin films deposited on polycrystalline Ni foils. J. Mater. Chem. C 2014, 2, 708–714. [Google Scholar] [CrossRef]

- Mos, R.B.; Petrisor, T., Jr.; Nasui, M.; Calleja, A.; Puig, T.; Ciontea, L.; Petrisor, T. Enhanced structural and morphological properties of Gd-doped CeO2 thin films obtained by polymer-assisted deposition. Mater. Lett. 2014, 124, 306–309. [Google Scholar] [CrossRef]

- Zhou, M.; Li, Y.; Jeon, I.; Yi, Q.; Zhu, X.; Tang, X.; Wang, H.; Fei, L.; Sun, Y.; Deng, S.; et al. Enhancement of low-field magnetoresistance in self-assembled epitaxial La0.67Ca0.33MnO3:NiO and La0.67Ca0.33MnO3:Co3O4 composite films via polymer-assisted deposition. Sci. Rep. 2016, 6, 26390. [Google Scholar] [CrossRef]

- Yan, L.H.; Liang, W.Z.; Liu, S.H.; Huang, W.; Lin, Y. Multiferroic BaTiO3-CoFe2O4 nano composite thin films grown by polymer-assisted deposition. Integr. Ferroelectr. 2011, 131, 82–88. [Google Scholar] [CrossRef]

- Chuai, Y.; Wang, X.; Zheng, C.; Zhang, Y.; Shen, H.; Wang, Y. Highly infrared-transparent and p-type conductive CuSc(1−x)Sn(x)O2 thin films and a p-CuScO2: Sn/n-ZnO heterojunction fabricated by the polymer-assisted deposition method. RSC Adv. 2016, 6, 31726–31731. [Google Scholar] [CrossRef]

- Lucas, I.; Manuel Vila-Fungueirino, J.; Jimenez-Cavero, P.; Rivas-Murias, B.; Magen, C.; Morellon, L.; Rivadulla, F. Tunnel conduction in epitaxial bilayers of ferromagnetic LaCoO3/La2/3Sr1/3MnO3 deposited by a chemical solution method. ACS Appl. Mater. Interfaces 2014, 6, 21279–21285. [Google Scholar] [CrossRef]

- Manuel Vila-Fungueirino, J.; Rivas-Murias, B.; Rivadulla, F. Strong interfacial magnetic coupling in epitaxial bilayers of LaCoO3/LaMnO3 prepared by chemical solution deposition. Thin Solid Films 2014, 553, 81–84. [Google Scholar] [CrossRef]

- Manuel Vila-Fungueirino, J.; Rivas-Murias, B.; Rodriguez-Gonzalez, B.; Rivadulla, F. Interface magnetic coupling in epitaxial bilayers of La0.92MnO3/LaCoO3 prepared by polymer-assisted deposition. Chem. Mater. 2014, 26, 1480–1484. [Google Scholar] [CrossRef]

- Ren, H.; Xiang, G.; Luo, J.; Yang, D.; Zhang, X. Direct catalyst-free self-assembly of large area of horizontal ferromagnetic ZnO nanowire arrays. Mater. Lett. 2019, 234, 384–387. [Google Scholar] [CrossRef]

- Luo, J.; Ren, H.; Zhang, X.; Xiang, G. Fabrication of vertically aligned ferromagnetic ZnO nanopillar arrays on sapphire substrates by polymer-assisted deposition. AIP Adv. 2020, 10, 015337. [Google Scholar] [CrossRef]

- Deng, Y.; Zhou, J.; Wu, D.; Du, Y.; Zhang, M.; Wang, D.; Yu, H.; Tang, S.; Du, Y. Three-dimensional phases-connectivity and strong magnetoelectric response of self-assembled feather-like CoFe2O4-BaTiO3 nanostructures. Chem. Phys. Lett. 2010, 496, 301–305. [Google Scholar] [CrossRef]

- Deng, Y.; Wu, D.; Du, Y. Enhanced Magnetoelectricity and Large Phonon Abnormality of Feather-Like CoFe2O4-BaTiO3 Nanostructures. In Advanced Materials Research; Trans Tech Publications: Bach, Switzerland, 2012; Volume 560–561, pp. 761–765. [Google Scholar]

- Burrell, A.K.; McCleskey, T.M.; Jia, Q.X. Polymer assisted deposition. Chem. Commun. 2008, 11, 1271–1277. [Google Scholar] [CrossRef]

- Burrell, A.K.; McCleskey, T.M.; Shukla, P.; Wang, H.; Durakiewicz, T.; Moore, D.P.; Olson, C.G.; Joyce, J.J.; Jia, Q. Controlling oxidation states in uranium oxides through epitaxial stabilization. Adv. Mater. 2007, 19, 3559–3563. [Google Scholar] [CrossRef]

- Luo, H.; Jain, M.; McCleskey, T.M.; Bauer, E.; Burrell, A.K.; Jia, Q. Optical and structural properties of single phase epitaxial p-type transparent oxide thin films. Adv. Mater. 2007, 19, 3604–3607. [Google Scholar] [CrossRef]

- Fei, L.; Zhu, L.; Cheng, X.; Wang, H.; Baber, S.M.; Hill, J.; Lin, Q.; Xu, Y.; Deng, S.; Luo, H. Structure and magnetotransport properties of epitaxial nanocomposite La0.67Ca0.33MnO3:SrTiO3 thin films grown by a chemical solution approach. Appl. Phys. Lett. 2012, 100, 082403. [Google Scholar] [CrossRef]

- Lin, Y.; Lee, J.-S.; Wang, H.; Li, Y.; Foltyn, S.R.; Jia, Q.X.; Collis, G.E.; Burrell, A.K.; McCleskey, T.M. Structural and dielectric properties of epitaxial Ba1−xSrxTiO3 films grown on LaAlO3 substrates by polymer-assisted deposition. Appl. Phys. Lett. 2004, 85, 5007–5009. [Google Scholar] [CrossRef]

- Pan, S.Y.; Shi, L.; Zhao, J.Y.; Xie, C.Z.; Zhou, S.M.; Li, Y. Tuning the magnetic and transport properties of La0.8Ca0.2MnO3 films by Ba0.8Sr0.2TiO3 intercalated layers grown with polymer-assisted deposition. Appl. Phys. Lett. 2017, 110, 231602. [Google Scholar] [CrossRef]

- Zou, G.F.; Zhao, J.; Luo, H.M.; McCleskey, T.M.; Burrell, A.K.; Jia, Q.X. Polymer-assisted-deposition: A chemical solution route for a wide range of materials. Chem. Soc. Rev. 2013, 42, 439–449. [Google Scholar] [CrossRef]

- McCleskey, T.M.; Shi, P.; Bauer, E.; Highland, M.J.; Eastman, J.A.; Bi, Z.X.; Fuoss, P.H.; Baldo, P.M.; Ren, W.; Scott, B.L.; et al. Nucleation and growth of epitaxial metal-oxide films based on polymer-assisted deposition. Chem. Soc. Rev. 2014, 43, 2141–2146. [Google Scholar] [CrossRef]

- Luo, H.; Lin, Y.; Wang, H.; Lee, J.H.; Suvorova, N.A.; Mueller, A.H.; Burrell, A.K.; McCleskey, T.M.; Bauer, E.; Usov, I.O.; et al. A chemical solution approach to epitaxial metal nitride thin films. Adv. Mater. 2009, 21, 193–197. [Google Scholar] [CrossRef]

- Luo, H.; Wang, H.; Zou, G.; Bauer, E.; McCleskey, T.M.; Burrell, A.K.; Jia, Q. A review of epitaxial metal-nitride films by polymer-assisted deposition. Trans. Electr. Electron. Mater. 2010, 11, 54–60. [Google Scholar] [CrossRef]

- Luo, H.; Zou, G.; Wang, H.; Lee, J.H.; Lin, Y.; Peng, H.; Lin, Q.; Deng, S.; Bauer, E.; McCleskey, T.M.; et al. Controlling crystal structure and oxidation state in molybdenum nitrides through epitaxial stabilization. J. Phys. Chem. C 2011, 115, 17880–17883. [Google Scholar] [CrossRef]

- Zou, G.; Wang, H.; Mara, N.; Luo, H.; Li, N.; Di, Z.; Bauer, E.; Wang, Y.; McCleskey, T.; Burrell, A.; et al. Chemical solution deposition of epitaxial carbide films. J. Am. Chem. Soc. 2010, 132, 2516–2517. [Google Scholar] [CrossRef]

- Zou, G.F.; Luo, H.M.; Ronning, F.; Sun, B.Q.; McCleskey, T.M.; Burrell, A.K.; Bauer, E.; Jia, Q.X. Facile chemical solution deposition of high-mobility epitaxial germanium films on silicon. Angew. Chem. Int. Ed. 2010, 49, 1782–1785. [Google Scholar] [CrossRef]

- Du, W.; Yu, P.; Zhu, J.; Li, C.; Xu, H.; Zou, J.; Wu, C.; Wen, Q.; Ji, H.; Liu, T.; et al. An ultrathin MoSe2 photodetector with near-perfect absorption. Nanotechnology 2020, 31, 225201. [Google Scholar] [CrossRef]

- Klein, D.R.; MacNeill, D.; Lado, J.L.; Soriano, D.; Navarro-Moratalla, E.; Watanabe, K.; Taniguchi, T.; Manni, S.; Canfield, P.; Fernández-Rossier, J.; et al. Probing magnetism in 2D van der Waals crystalline insulators via electron tunneling. Science 2018, 360, 1218–1222. [Google Scholar] [CrossRef]

- Huang, B.; Clark, G.; Navarro-Moratalla, E.; Klein, D.R.; Cheng, R.; Seyler, K.L.; Zhong, D.; Schmidgall, E.; McGuire, M.A.; Cobden, D.H.; et al. Layer-dependent ferromagnetism in a van der Waals crystal down to the monolayer limit. Nature 2017, 546, 270–273. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Shi, L.; Zhou, S.; Zhao, J.; Guo, Y.; Wang, C.; He, L. Simple polymer assisted deposition and strain-induced ferromagnetism of LaCoO3 epitaxial thin films. Surf. Coat. Tech. 2013, 226, 108–112. [Google Scholar] [CrossRef]

- Yin, X.; Wang, Y.; Jacobs, R.; Shi, Y.; Szlufarska, I.; Morgan, D.; Wang, X. Massive vacancy concentration yields strong room-temperature ferromagnetism in two-dimensional ZnO. Nano Lett. 2019, 19, 7085–7092. [Google Scholar] [CrossRef] [PubMed]

- Fuchs, D.; Arac, E.; Pinta, C.; Schuppler, S.; Schneider, R.; von Lohneysen, H.V. Tuning the magnetic properties of LaCoO3 thin films by epitaxial strain. Phys. Rev. B 2008, 77, 014434. [Google Scholar] [CrossRef]

- Zhai, J.Y.; Zhang, Y.Y.; Zou, G.F.; Xiong, J.; Yan, L.; Zuo, M.J.; Shi, P.; Jia, Q.X. Strain controlled epitaxial multiferroic BiFeO3 thin film deposited by polymer assisted deposition. Abstr. Pap. Am. Chem. Soc. 2011, 241, 1. [Google Scholar]

- Rivadulla, F.; Bi, Z.X.; Bauer, E.; Rivas-Murias, B.; Vila-Fungueirino, J.M.; Jia, Q.X. Strain-induced ferromagnetism and magnetoresistance in epitaxial thin films of LaCoO3 prepared by polymer-assisted deposition. Chem. Mater. 2013, 25, 55–58. [Google Scholar] [CrossRef]

- Xie, C.Z.; Shi, L.; Zhao, J.Y.; Zhou, S.M.; Li, Y.; Yuan, X.Y. Spin-phonon coupling in R2CoMnO6 (R=Pr, Nd, Sm) thin films under biaxial compressive strain. J. Appl. Phys. 2016, 120, 155302. [Google Scholar] [CrossRef]

- Liu, H.; Fan, J.; Qian, F.; Ji, Y.; Rahman, A.; Tang, R.; Zhang, L.; Ling, L.; Zhu, Y.; Yang, H. Two-dimensional magnetic interplay in the tensile-strained LaCoO3 thin films. Phys. Chem. Chem. Phys. 2021, 23, 4912–4918. [Google Scholar] [CrossRef]

- Chen, R.; Luo, F.; Liu, Y.; Song, Y.; Dong, Y.; Wu, S.; Cao, J.; Yang, F.; N’Diaye, A.; Shafer, P.; et al. Tunable room-temperature ferromagnetism in Co-doped two-dimensional van der Waals ZnO. Nat. Commun. 2021, 12, 3952. [Google Scholar] [CrossRef]

- Ren, H.; Xiang, G.; Gu, G.; Zhang, X.; Wang, W.; Zhang, P.; Wang, B.; Cao, X. Zinc vacancy-induced room-temperature ferromagnetism in undoped ZnO thin films. J. Nanomater. 2012, 2012, 295358. [Google Scholar] [CrossRef]

- Wang, L.; Chepiga, N.; Ki, D.K.; Li, L.; Li, F.; Zhu, W.; Kato, Y.; Ovchinnikova, O.S.; Mila, F.; Martin, I.; et al. Controlling the topological sector of magnetic solitons in exfoliated Cr1/3NbS2 crystals. Phys. Rev. Lett. 2017, 118, 257203. [Google Scholar] [CrossRef]

- Miyadai, T.; Kikuchi, K.; Kondo, H.; Sakka, S.; Arai, M.; Ishikawa, Y. Magnetic properties of Cr1/3NbS2. Jpn. J. Appl. Phys 1983, 52, 1394–1401. [Google Scholar] [CrossRef]

- Zhang, C.; Yuan, Y.; Wang, M.; Li, P.; Zhang, J.; Wen, Y.; Zhou, S.; Zhang, X.X. Critical behavior of intercalated quasi-van der Waals ferromagnet Fe0.26TaS2. Phys. Rev. Mater. 2019, 3, 114403. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, J.; Liu, C.; Zhang, S.; Yuan, Y.; Li, P.; Wen, Y.; Jiang, Z.; Zhou, B.; Lei, Y.; et al. Chiral helimagnetism and one-dimensional magnetic solitons in a Cr-intercalated transition metal dichalcogenide. Adv. Mater. 2021, 33, 2101131. [Google Scholar] [CrossRef]

- Deng, Y.; Zhou, J.; Wu, D.; Yu, H.; Du, Y. Microstructure, growth mechanism, magnetoelectricity, and raman scattering of featherlike CoFe2O4-BaTiO3 nanostructures. Jpn. J. Appl. Phys. 2012, 51, 11PG05. [Google Scholar] [CrossRef]

- Xie, C.; Shi, L.; Zhou, S.; Zhao, J.; Liu, H.; Li, Y.; Yao, D. Structural characteristics, magnetic properties of Re2NiMnO6 (Re = La, Pr, Nd, Sm, Y) thin films on (001) LaAlO3 by simple polymer assisted deposition. Surf. Coat. Tech. 2015, 277, 222–226. [Google Scholar] [CrossRef]

- Lucas, I.; Jiménez-Cavero, P.; Vila-Fungueiriño, J.M.; Magén, C.; Sangiao, S.; de Teresa, J.M.; Morellón, L.; Rivadulla, F. Chemical solution synthesis and ferromagnetic resonance of epitaxial thin films of yttrium iron garnet. Phys. Rev. Mater. 2017, 1, 074407. [Google Scholar] [CrossRef]

- Gillman, E.S.; Costello, D.; Moreno, M.; Raspopin, A.; Kasica, R.; Chen, L. Polymer-assisted conformal coating of TiO2 thin films. J. Appl. Phys. 2010, 108, 044310. [Google Scholar] [CrossRef]

- Dietl, T.; Ohno, H.; Matsukura, F.; Cibert, J.; Ferrand, D. Zener model description of ferromagnetism in zinc-blende magnetic semiconductors. Science 2000, 287, 1019–1022. [Google Scholar] [CrossRef]

- Gu, G.X.; Xiang, G.; Luo, J.; Ren, H.T.; Lan, M.; He, D.W.; Zhang, X. Magnetism in transition-metal-doped ZnO: A first-principles study. J. Appl. Phys. 2012, 112, 023913. [Google Scholar] [CrossRef]

- Zhang, G.H.; Deng, X.Y.; Xue, H.; Xiang, G. Engineering of electronic and optical properties of ZnO thin films via Cu doping. Chin. Phys. B 2013, 22, 047803. [Google Scholar] [CrossRef]

- Banerjee, S.; Mandal, M.; Gayathri, N.; Sardar, M. Enhancement of ferromagnetism upon thermal annealing in pure ZnO. Appl. Phys. Lett. 2007, 91, 182501. [Google Scholar] [CrossRef]

- Sundaresan, A.; Bhargavi, R.; Rangarajan, N.; Siddesh, U.; Rao, C.N.R. Ferromagnetism as a universal feature of nanoparticles of the otherwise nonmagnetic oxides. Phys. Rev. B 2006, 74, 161306. [Google Scholar] [CrossRef]

- Wu, K.; Xu, X.G.; Yang, H.L.; Zhang, J.L.; Miao, J.; Jiang, Y. Effect of annealing atmosphere on magnetic properties of pure ZnO and Na: ZnO films. Rare Metals 2012, 31, 27–30. [Google Scholar] [CrossRef]

- Chaboy, J.; Boada, R.; Piquer, C.; Laguna-Marco, M.A.; García-Hernández, M.; Carmona, N.; Llopis, J.; Ruíz-González, M.L.; González-Calbet, J.; Fernández, J.F.; et al. Evidence of intrinsic magnetism in capped ZnO nanoparticles. Phys. Rev. B 2010, 82, 064411. [Google Scholar] [CrossRef]

- Hong, N.H.; Sakai, J.; Brizé, V. Observation of ferromagnetism at room temperature in ZnO thin films. J. Phys. Condens. Matter 2007, 19, 036219. [Google Scholar] [CrossRef]

- Zhao, C.; Huang, Y.; Abiade, J.T. Ferromagnetic ZnO nanoparticles prepared by pulsed laser deposition in liquid. Mater. Lett. 2012, 85, 164–167. [Google Scholar] [CrossRef]

- Phan, T.L.; Zhang, Y.D.; Yang, D.S.; Nghia, N.X.; Thanh, T.D.; Yu, S.C. Defect-induced ferromagnetism in ZnO nanoparticles prepared by mechanical milling. Appl. Phys. Lett. 2013, 102, 072408. [Google Scholar] [CrossRef]

- Lemine, O.M. Induced room-temperature ferromagnetism in un-doped nanocrystalline metal oxide powders obtained by mechanical milling: A review. J. Supercond. Nov. Magn. 2017, 30, 271–274. [Google Scholar] [CrossRef]

- Taniguchi, T.; Yamaguchi, K.; Shigeta, A.; Matsuda, Y.; Hayami, S.; Shimizu, T.; Matsui, T.; Yamazaki, T.; Funatstu, A.; Makinose, Y.; et al. Enhanced and engineered d0 ferromagnetism in molecularly-thin zinc oxide nanosheets. Adv. Funct. Mater. 2013, 23, 3140–3145. [Google Scholar] [CrossRef]

- Podila, R.; Queen, W.; Nath, A.; Arantes, J.T.; Schoenhalz, A.L.; Fazzio, A.; Dalpian, G.M.; He, J.; Hwu, S.J.; Skove, M.J.; et al. Origin of FM ordering in pristine micro- and nanostructured ZnO. Nano Lett. 2010, 10, 1383–1386. [Google Scholar] [CrossRef]

- Lin, Y.; Xie, J.; Wang, H.; Li, Y.; Chavez, C.; Lee, S.Y.; Foltyn, S.R.; Crooker, S.A.; Burrell, A.K.; McCleskey, T.M.; et al. Green luminescent zinc oxide films prepared by polymer-assisted deposition with rapid thermal process. Thin Solid Films 2005, 492, 101–104. [Google Scholar] [CrossRef]

- Yi, J.B.; Lim, C.C.; Xing, G.Z.; Fan, H.M.; Van, L.H.; Huang, S.L.; Yang, K.S.; Huang, X.L.; Qin, X.B.; Wang, B.Y.; et al. Ferromagnetism in dilute magnetic semiconductors through defect engineering: Li-doped ZnO. Phys. Rev. Lett. 2010, 104, 137201. [Google Scholar] [CrossRef]

- Zhan, P.; Wang, W.; Xie, Z.; Li, Z.; Zhang, Z.; Zhang, P.; Wang, B.; Cao, X. Substrate effect on the room-temperature ferromagnetism in un-doped ZnO films. Appl. Phys. Lett. 2012, 101, 031913. [Google Scholar] [CrossRef]

- Dai, X.; Zheng, Q.; Zhang, X.; Wang, Y.; Ren, H.; Xiang, G. High performance photoresponse of transparent β-Ga2O3 film prepared by polymer-assisted deposition. Mater. Lett. 2021, 284, 128912. [Google Scholar] [CrossRef]

- Dai, X.; Zhang, X.; Xiang, G. Polymer-assisted deposition and room-temperature ferromagnetism of amorphous Mn-doped gallium oxide films. Scripta Mater. 2022, 220, 114919. [Google Scholar] [CrossRef]

- Dai, X.; Zhang, X.; Xiang, G. Mechanism-based tuning of room-temperature ferromagnetism in Mn-doped β-Ga2O3 by annealing atmosphere. J. Am. Ceram. 2022, 106, 374–380. [Google Scholar] [CrossRef]

- Takahashi, K.S.; Sawa, A.; Ishii, Y.; Akoh, H.; Kawasaki, M.; Tokura, Y. Inverse tunnel magnetoresistance in all-perovskite junctions of La0.7Sr0.3MnO3/SrTiO3/SrRuO3. Phys. Rev. B 2003, 67, 094413. [Google Scholar] [CrossRef]

- Jia, Q.X.; Chu, F.; Adams, C.D.; Wu, X.D.; Hawley, M.; Cho, J.H.; Findikoglu, A.T.; Foltyn, S.R.; Smith, J.L.; Mitchell, T.E. Characteristics of conductive SrRuO3 thin films with different microstructures. J. Mater. Res. 1996, 11, 2263–2268. [Google Scholar] [CrossRef]

- Zhang, J.X.; Long, C.; Hui, C.; Bao, M.R.; Zhao, J.Y.; Liu, X.G.; Zhao, A.D.; Choi, Y.S.; Hua, Z.; Padraic, S.; et al. The exceedingly strong two-dimensional ferromagnetism in bi-atomic layer SrRuO3 with a critical conduction transition. Nano Res. 2022, 15, 7584–7589. [Google Scholar] [CrossRef]

- Suzuki, H.; Miwa, Y.; Miyazaki, H.; Takahashi, M.; Ota, T. Chemical solution deposition of conductive SrRuO3 thin film on Si substrate. Ceram. Int. 2004, 30, 1357–1360. [Google Scholar] [CrossRef]

- Seveno, R.; Braud, A.; Gundel, H.W. Elaboration of strontium ruthenium oxide thin films on metal substrates by chemical solution deposition. Thin Solid Films 2005, 493, 124–128. [Google Scholar] [CrossRef]

- Sefrioui, Z.; Arias, D.; Navacerrada, M.A.; Varela, M.; Loos, G.; Lucía, M.; Santamaría, J.; Sánchez-Quesada, F.; López de la Torre, M.A. Metal–insulator transition in SrRuO3 induced by ion irradiation. Appl. Phys. Lett. 1998, 73, 3375–3377. [Google Scholar] [CrossRef]

- Wang, L.M.; Horng, H.E.; Yang, H.C. Anomalous magnetotransport in SrRuO3 films: A crossover from Fermi-liquid to non-Fermi-liquid behavior. Phys. Rev. B 2004, 70, 014433. [Google Scholar] [CrossRef]

- Jiang, J.C.; Pan, X.Q. Microstructure and growth mechanism of epitaxial SrRuO3 thin films on (001) LaAlO3 substrates. J. Appl. Phys. 2001, 89, 6365–6369. [Google Scholar] [CrossRef]

- Toyota, D.; Ohkubo, I.; Kumigashira, H.; Oshima, M.; Ohnishi, T.; Lippmaa, M.; Kawasaki, M.; Koinuma, H. Ferromagnetism stabilization of ultrathin SrRuO3 films: Thickness-dependent physical properties. J. Appl. Phys. 2006, 99, 08N505. [Google Scholar] [CrossRef]

- Lee, H.C.; Tsai, D.S. Metalorganic chemical vapor deposition of SrRuO3 thin film and its characterization. J. Mater. Sci. 2003, 38, 2633–2638. [Google Scholar] [CrossRef]

- Sumi, A.; Takahashi, K.; Yokoyama, S.; Morioka, H.; Funakubo, H.; Yoshimoto, M. Metalorganic chemical vapor deposition of atomically flat SrRuO3 films on stepped SrTiO3 substrates. Appl. Phys. Lett. 2005, 87, 052112. [Google Scholar] [CrossRef]

- Raccah, P.M.; Goodenough, J.B. First-order localized-electron collective-electron transition in LaCoO3. Phys. Rev. 1967, 155, 932–943. [Google Scholar] [CrossRef]

- Señarís-Rodríguez, M.A.; Goodenough, J.B. LaCoO3 Revisited. J. Solid State Chem. 1995, 116, 224–231. [Google Scholar] [CrossRef]

- Rafael, R.; Andrés, C.-G.; Emmanuele, C.; Francisco, G. Strain engineering in semiconducting two-dimensional crystals. J. Phys. Condens. Matter 2015, 27, 313201. [Google Scholar]

- Sun, Y.F.; Liu, K. Strain engineering in functional 2-dimensional materials. J. Appl. Phys. 2019, 125, 082402. [Google Scholar] [CrossRef]

- Miao, F.; Liang, S.-J.; Cheng, B. Straintronics with van der Waals materials. Npj Quantum Mater. 2021, 6, 59. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, C.; Liang, S.-J.; Ma, Z.; Xu, K.; Liu, X.; Zhang, L.; Admasu, A.S.; Cheong, S.-W.; Wang, L.; et al. Strain-sensitive magnetization reversal of a van der Waals magnet. Adv. Mater. 2020, 32, 2004533. [Google Scholar] [CrossRef]

- Higo, T.; Kondou, K.; Nomoto, T.; Shiga, M.; Sakamoto, S.; Chen, X.; Nishio-Hamane, D.; Arita, R.; Otani, Y.; Miwa, S.; et al. Perpendicular full switching of chiral antiferromagnetic order by current. Nature 2022, 607, 474–479. [Google Scholar] [CrossRef]

- Hu, L.; Zhou, J.; Hou, Z.P.; Su, W.T.; Yang, B.Z.; Li, L.W.; Yan, M. Polymer-buried van der Waals magnets for promising wearable room-temperature spintronics. Mater. Horiz. 2021, 8, 3306–3314. [Google Scholar] [CrossRef]

- Amani, M.; Chin, M.L.; Mazzoni, A.L.; Burke, R.A.; Najmaei, S.; Ajayan, P.M.; Lou, J.; Dubey, M. Growth-substrate induced performance degradation in chemically synthesized monolayer MoS2 field effect transistors. Appl. Phys. Lett. 2014, 104, 203506. [Google Scholar] [CrossRef]

- Zhang, C.; Li, M.Y.; Tersoff, J.; Han, Y.; Su, Y.; Li, L.J.; Muller, D.A.; Shih, C.K. Strain distributions and their influence on electronic structures of WSe2–MoS2 laterally strained heterojunctions. Nat. Nanotechnol. 2018, 13, 152–158. [Google Scholar] [CrossRef]

- Chae, W.H.; Cain, J.D.; Hanson, E.D.; Murthy, A.A.; Dravid, V.P. Substrate-induced strain and charge doping in CVD-grown monolayer MoS2. Appl. Phys. Lett. 2017, 111, 143106. [Google Scholar] [CrossRef]

- Yu, Y.; Jung, G.S.; Liu, C.; Lin, Y.-C.; Rouleau, C.M.; Yoon, M.; Eres, G.; Duscher, G.; Xiao, K.; Irle, S.; et al. Strain-induced growth of twisted bilayers during the coalescence of monolayer MoS2 crystals. ACS Nano 2021, 15, 4504–4517. [Google Scholar] [CrossRef]

- Taghinejad, H.; Eftekhar, A.A.; Campbell, P.M.; Beatty, B.; Taghinejad, M.; Zhou, Y.; Perini, C.J.; Moradinejad, H.; Henderson, W.E.; Woods, E.V.; et al. Strain relaxation via formation of cracks in compositionally modulated two-dimensional semiconductor alloys. Npj. 2D Mater. Appl. 2018, 2, 10. [Google Scholar] [CrossRef]

- Li, H.; Sanchez-Santolino, G.; Puebla, S.; Frisenda, R.; Al-Enizi, A.M.; Nafady, A.; D’Agosta, R.; Castellanos-Gomez, A. Strongly anisotropic strain-tunability of excitons in exfoliated ZrSe3. Adv. Mater. 2022, 34, 2103571. [Google Scholar] [CrossRef] [PubMed]

- Castellanos-Gomez, A.; Roldan, R.; Cappelluti, E.; Buscema, M.; Guinea, F.; van der Zant, H.S.J.; Steele, G.A. Local strain engineering in atomically thin MoS2. Nano Lett. 2013, 13, 5361–5366. [Google Scholar] [CrossRef] [PubMed]

- Plechinger, G.; Castellanos-Gomez, A.; Buscema, M.; van der Zant, H.S.J.; Steele, G.A.; Kuc, A.; Heine, T.; Schüller, C.; Korn, T. Control of biaxial strain in single-layer molybdenite using local thermal expansion of the substrate. 2D Mater. 2015, 2, 015006. [Google Scholar] [CrossRef]

- Solovyev, I.; Hamada, N.; Terakura, K. Crucial role of the lattice distortion in the magnetism of LaMnO3. Phys. Rev. Lett. 1996, 76, 4825–4828. [Google Scholar] [CrossRef]

- Vila-Fungueirino, J.M.; Rivas-Murias, B.; Rodriguez-Gonzalez, B.; Txoperena, O.; Ciudad, D.; Hueso, L.E.; Lazzari, M. Room-temperature ferromagnetism in thin films of Lamno3 deposited by a chemical method over large areas. ACS Appl. Mater. Interfaces 2015, 7, 5410–5414. [Google Scholar] [CrossRef]

- Vukmirović, J.; Joksović, S.; Piper, D.; Nesterović, A.; Novaković, M.; Rakić, S.; Milanović, M.; Srdić, V.V. Epitaxial growth of LaMnO3 thin films on different single crystal substrates by polymer assisted deposition. Ceram. Int. 2023, 49, 2366–2372. [Google Scholar] [CrossRef]

- Vila-Fungueiriño, J.M.; Rivas-Murias, B.; Rivadulla, F. Synthesis and magnetic properties of manganite thin films on Si by polymer assisted (PAD) and pulsed laser deposition (PLD). MRS Online Proceedings Library 2012, 1449, 19–24. [Google Scholar] [CrossRef]

- Shukla, P.; Lin, Y.; Minogue, E.M.; Burrell, A.K.; McCleskey, T.M.; Jia, Q.X.; Lu, P. Polymer assisted deposition (PAD) of thin metal films: A new technique to the preparation of metal oxides and reduced metal films. Mater. Res. Soc. Symp. Proc. 2006, 893, 183. [Google Scholar] [CrossRef]

- Dubs, C.; Surzhenko, O.; Linke, R.; Danilewsky, A.; Bruckner, U.; Dellith, J. Sub-micrometer yttrium iron garnet LPE films with low ferromagnetic resonance losses. J. Phys. D Appl. Phys. 2017, 50, 204005. [Google Scholar] [CrossRef]

- LeCraw, R.C.; Spencer, E.G.; Porter, C.S. Ferromagnetic resonance line width in yttrium iron garnet single crystals. Phys. Rev. 1958, 110, 1311–1313. [Google Scholar] [CrossRef]

- Comstock, R.L. Microwave Ferrites and Ferrimagnetics; Lax, B., Button, K.J., Eds.; McGraw-Hill: New York, NY, USA, 1963; Volume 6, pp. 392–393. [Google Scholar]

- Serga, A.A.; Chumak, A.V.; Hillebrands, B. YIG magnonics. J. Phys. D: Appl. Phus. 2010, 43, 264002. [Google Scholar] [CrossRef]

- Wang, H.L.; Du, C.H.; Hammel, P.C.; Yang, F.Y. Spin current and inverse spin Hall effect in ferromagnetic metals probed by Y3Fe5O12-based spin pumping. Appl. Phys. Lett. 2014, 104, 202405. [Google Scholar] [CrossRef]

- Barker, J.; Bauer, G.E.W. Thermal spin dynamics of yttrium iron garnet. Phys. Rev. Lett. 2016, 117, 217201. [Google Scholar] [CrossRef]

- Hahn, C.; de Loubens, G.; Klein, O.; Viret, M.; Naletov, V.V.; Ben Youssef, J. Comparative measurements of inverse spin Hall effects and magnetoresistance in YIG/Pt and YIG/Ta. Phys. Rev. B 2013, 87, 174417. [Google Scholar] [CrossRef]

- Mallmann, E.J.J.; Sombra, A.S.B.; Goes, J.C.; Fechine, P.B.A. Yttrium iron garnet: Properties and applications review. Solid State Phenom. 2013, 202, 65–96. [Google Scholar] [CrossRef]

- Pirro, P.; Brächer, T.; Chumak, A.V.; Lägel, B.; Dubs, C.; Surzhenko, O.; Görnert, P.; Leven, B.; Hillebrands, B. Spin-wave excitation and propagation in microstructured waveguides of yttrium iron garnet/Pt bilayers. Appl. Phys. Lett. 2014, 104, 012402. [Google Scholar] [CrossRef]

- Burrowes, C.; Heinrich, B.; Kardasz, B.; Montoya, E.A.; Girt, E.; Sun, Y.; Song, Y.-Y.; Wu, M. Enhanced spin pumping at yttrium iron garnet/Au interfaces. Appl. Phys. Lett. 2012, 100, 092403. [Google Scholar] [CrossRef]

- d’Allivy Kelly, O.; Anane, A.; Bernard, R.; Ben Youssef, J.; Hahn, C.; Molpeceres, A.H.; Carrétéro, C.; Jacquet, E.; Deranlot, C.; Bortolotti, P.; et al. Inverse spin Hall effect in nanometer-thick yttrium iron garnet/Pt system. Appl. Phys. Lett. 2013, 103, 082408. [Google Scholar] [CrossRef]

- Heinrich, B.; Burrowes, C.; Montoya, E.; Kardasz, B.; Girt, E.; Song, Y.-Y.; Sun, Y.; Wu, M. Spin pumping at the magnetic insulator (YIG)/normal metal (Au) interfaces. Phys. Rev. Lett. 2011, 107, 066604. [Google Scholar] [CrossRef]

- Jungfleisch, M.B.; Chumak, A.V.; Kehlberger, A.; Lauer, V.; Kim, D.H.; Onbasli, M.C.; Ross, C.A.; Kläui, M.; Hillebrands, B. Thickness and power dependence of the spin-pumping effect in Y3Fe5O12/Pt heterostructures measured by the inverse spin Hall effect. Phys. Rev. B 2015, 91, 134407. [Google Scholar] [CrossRef]

- Onbasli, M.C.; Kehlberger, A.; Kim, D.H.; Jakob, G.; Klaui, M.; Chumak, A.V.; Hillebrands, B.; Ross, C.A. Pulsed laser deposition of epitaxial yttrium iron garnet films with low gilbert damping and bulk-like magnetization. Apl Mater. 2014, 2, 106102. [Google Scholar] [CrossRef]

- Sokolov, N.S.; Fedorov, V.V.; Korovin, A.M.; Suturin, S.M.; Baranov, D.A.; Gastev, S.V.; Krichevtsov, B.B.; Maksimova, K.Y.; Grunin, A.I.; Bursian, V.E.; et al. Thin yttrium iron garnet films grown by pulsed laser deposition: Crystal structure, static, and dynamic magnetic properties. J. Appl. Phys. 2016, 119, 023903. [Google Scholar] [CrossRef]

- Sun, Y.; Chang, H.; Kabatek, M.; Song, Y.-Y.; Wang, Z.; Jantz, M.; Schneider, W.; Wu, M.; Montoya, E.; Kardasz, B.; et al. Damping in yttrium iron garnet nanoscale films capped by platinum. Phys. Rev. Lett. 2013, 111, 106601. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.Y.; Song, Y.Y.; Chang, H.C.; Kabatek, M.; Jantz, M.; Schneider, W.; Wu, M.Z.; Schultheiss, H.; Hoffmann, A. Growth and ferromagnetic resonance properties of nanometer-thick yttrium iron garnet films. Appl. Phys. Lett. 2012, 101, 152405. [Google Scholar] [CrossRef]

- Howe, B.M.; Emori, S.; Jeon, H.M.; Oxholm, T.M.; Jones, J.G.; Mahalingam, K.; Zhuang, Y.; Sun, N.X.; Brown, G.J. Pseudomorphic yttrium iron garnet thin films with low damping and inhomogeneous linewidth broadening. IEEE Magn. Lett. 2015, 6, 3500504. [Google Scholar] [CrossRef]

- Hauser, C.; Richter, T.; Homonnay, N.; Eisenschmidt, C.; Qaid, M.; Deniz, H.; Hesse, D.; Sawicki, M.; Ebbinghaus, S.G.; Schmidt, G. Yttrium iron garnet thin films with very low damping obtained by recrystallization of amorphous material. Sci. Rep. 2016, 6, 20827. [Google Scholar] [CrossRef]

- Chang, H.C.; Li, P.; Zhang, W.; Liu, T.; Hoffmann, A.; Deng, L.J.; Wu, M.Z. Nanometer-thick yttrium iron garnet films with extremely low damping. IEEE Magn. Lett. 2014, 5, 6700104. [Google Scholar] [CrossRef]

- Klingler, S.; Maier-Flaig, H.; Dubs, C.; Surzhenko, O.; Gross, R.; Huebl, H.; Goennenwein, S.T.B.; Weiler, M. Gilbert damping of magnetostatic modes in a yttrium iron garnet sphere. Appl. Phys. Lett. 2017, 110, 092409. [Google Scholar] [CrossRef]

- Li, S.Z.; Zhang, W.; Ding, J.J.; Pearson, J.E.; Novosad, V.; Hoffmann, A. Epitaxial patterning of nanometer-thick Y3Fe5O12 films with low magnetic damping. Nanoscale 2016, 8, 388–394. [Google Scholar] [CrossRef]

- Gong, C.; Li, L.; Li, Z.L.; Ji, H.W.; Stern, A.; Xia, Y.; Cao, T.; Bao, W.; Wang, C.Z.; Wang, Y.A.; et al. Discovery of intrinsic ferromagnetism in two-dimensional van der Waals crystals. Nature 2017, 546, 265–269. [Google Scholar] [CrossRef]

- Thiel, L.; Wang, Z.; Tschudin, M.A.; Rohner, D.; Gutiérrez-Lezama, I.; Ubrig, N.; Gibertini, M.; Giannini, E.; Morpurgo, A.F.; Maletinsky, P. “Probing magnetism in 2D materials at the nanoscale with single-spin microscopy. Science 2019, 364, eaav6926. [Google Scholar] [CrossRef]

- Kim, K.; Lim, S.Y.; Lee, J.U.; Lee, S.; Kim, T.Y.; Park, K.; Jeon, G.S.; Park, C.-H.; Park, J.-G.; Cheong, H. Suppression of magnetic ordering in XXZ-type antiferromagnetic monolayer NiPS3. Nat. Commun. 2019, 10, 345. [Google Scholar] [CrossRef]

- Su, J.; Wang, M.; Liu, G.; Li, H.; Han, J.; Zhai, T. Air-Stable 2D intrinsic ferromagnetic Ta3FeS6 with four months durability. Adv. Sci. 2020, 7, 2001722. [Google Scholar] [CrossRef]

- Deng, Y.J.; Yu, Y.J.; Song, Y.C.; Zhang, J.Z.; Wang, N.Z.; Sun, Z.Y.; Yi, Y.F.; Wu, Y.Z.; Wu, S.W.; Zhu, J.Y.; et al. Gate-tunable room-temperature ferromagnetism in two-dimensional Fe3GeTe2. Nature 2018, 563, 94–99. [Google Scholar] [CrossRef]

- Giri, A.; De, C.; Kumar, M.; Pal, M.; Lee, H.H.; Kim, J.S.; Cheong, S.W.; Jeong, U. Large-area epitaxial film growth of van der Waals ferromagnetic ternary chalcogenides. Adv. Mater. 2021, 33, 2103609. [Google Scholar] [CrossRef]

- Li, B.; Xing, T.; Zhong, M.Z.; Huang, L.; Lei, N.; Zhang, J.; Li, J.B.; Wei, Z.M. A two-dimensional Fe-doped SnS2 magnetic semiconductor. Nat. Commun. 2017, 8, 1958. [Google Scholar] [CrossRef]

- Remskar, M.; Mrzel, A.; Skraba, Z.; Jesih, A.; Ceh, M.; Demsar, J.; Stadelmann, P.; Levy, F.; Mihailovic, D. Self-assembly of subnanometer-diameter single-wall MoS2 nanotubes. Science 2001, 292, 479–481. [Google Scholar] [CrossRef]

- Jaglicic, Z.; Jeromen, A.; Trontelj, Z.; Mihailovic, D.; Arcon, D.; Remskar, M.; Mrzel, A.; Dominko, R.; Gaberscek, M.; Martinez-Agudo, J.M.; et al. Magnetic properties of MoS2 nanotubes doped with lithium. Polyhedron 2003, 22, 2293–2295. [Google Scholar] [CrossRef]

- Mihailovic, D.; Jaglicic, Z.; Arcon, D.; Mrzel, A.; Zorko, A.; Remskar, M.; Kabanov, V.V.; Dominko, R.; Gaberscek, M.; Gómez-García, C.J.; et al. Unusual magnetic state in lithium-doped MoS2 nanotubes. Phys. Rev. Lett. 2003, 90, 146401. [Google Scholar] [CrossRef]

- Zhang, H.; Loh, K.P.; Sow, C.H.; Gu, H.R.; Su, X.D.; Huang, C.; Chen, Z.K. Surface modification studies of edge-oriented molybdenum sulfide nanosheets. Langmuir 2004, 20, 6914–6920. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Soon, J.M.; Loh, K.P.; Yin, J.; Ding, J.; Sullivian, M.B.; Wu, P. Magnetic molybdenum disulfide nanosheet films. Nano Lett. 2007, 7, 2370–2376. [Google Scholar] [CrossRef]

- Yagmurcukardes, M.; Bacaksiz, C.; Unsal, E.; Akbali, B.; Senger, R.T.; Sahin, H. Strain mapping in single-layer two-dimensional crystals via Raman activity. Phys. Rev. B 2018, 97, 115427. [Google Scholar] [CrossRef]

- Jie, M.; Yu, Y.Q.; Wang, L.; Zhang, X.J.; Wang, Y.M.; Shao, Z.B.; Jie, J.S. Ultrafast, broadband photodetector based on MoSe2/Silicon heterojunction with vertically standing layered structure using graphene as transparent electrode. Adv. Sci. 2016, 11, 1600018. [Google Scholar]

- Mak, K.F.; Lee, C.; Hone, J.; Shan, J.; Heinz, T.F. Atomically thin MoS2: A new direct-gap semiconductor. Phys. Rev. Lett. 2010, 105, 136805. [Google Scholar] [CrossRef]

- Zhang, Y.; Chang, T.R.; Zhou, B.; Cui, Y.T.; Yan, Y.; Liu, Z.K.; Schmitt, F.; Lee, J.; Moore, R.; Chen, Y.L.; et al. Direct observation of the transition from indirect to direct bandgap in atomically thin epitaxial MoSe2. Nat. Nano. 2014, 9, 111–115. [Google Scholar] [CrossRef]

- Sun, L.F.; Yan, J.X.; Zhan, D.; Liu, L.; Hu, H.L.; Li, H.; Tay, B.K.; Kuo, J.L.; Huang, C.C.; Hewak, D.W.; et al. Spin-orbit splitting in single-layer MoS2 revealed by triply resonant Raman scattering. Phys. Rev. Lett. 2013, 111, 126801. [Google Scholar] [CrossRef]

- Xia, B.R.; Gao, D.Q.; Liu, P.T.; Liu, Y.G.; Shi, S.P.; Tao, K. Zigzag-edge related ferromagnetism in MoSe2 nanoflakes. Phys. Chem. Chem. Phys. 2015, 17, 32505–32510. [Google Scholar] [CrossRef]

- Xia, B.R.; Wang, T.T.; Xiao, W.; Zhang, R.F.; Liu, P.T.; Ding, J.; Gao, D.Q.; Xue, D.S. Phase-transfer induced room temperature ferromagnetic behavior in 1T@2H-MoSe2 nanosheets. Sci. Rep. 2017, 7, 45307. [Google Scholar] [CrossRef]

- Xing, X.J.; Wang, X.W.; Wu, C.; Lu, Y.H.; Yan, M. Room temperature ferromagnetism and its origin for amorphous MoSe2 nanoflowers. Appl. Phys. Lett. 2018, 112, 122407. [Google Scholar] [CrossRef]

- Shimomura, Y.; Kojima, M.; Saito, S. Crystal structure of ferromagnetic nickel oxide. Jpn. J. Appl. Phys 1956, 11, 1136–1146. [Google Scholar] [CrossRef]

- Tongay, S.; Sahin, H.; Ko, C.; Luce, A.; Fan, W.; Liu, K.; Zhou, J.; Huang, Y.S.; Ho, C.H.; Yan, J.; et al. Monolayer behaviour in bulk ReS2 due to electronic and vibrational decoupling. Nat. Commun. 2014, 5, 3252. [Google Scholar] [CrossRef]

- Fujita, T.; Ito, Y.; Tan, Y.W.; Yamaguchi, H.; Hojo, D.; Hirata, A.; Voiry, D.; Chhowalla, M.; Chen, M.W. Chemically exfoliated ReS2 nanosheets. Nanoscale 2014, 6, 12458–12462. [Google Scholar] [CrossRef]

- Chenet, D.A.; Aslan, O.B.; Huang, P.Y.; Fan, C.; van der Zande, A.M.; Heinz, T.F.; Hone, J.C. In-plane anisotropy in mono- and few-layer ReS2 probed by raman spectroscopy and scanning transmission electron microscopy. Nano Lett. 2015, 15, 5667–5672. [Google Scholar] [CrossRef]

- Horzum, S.; Cakir, D.; Suh, J.; Tongay, S.; Huang, Y.S.; Ho, C.H.; Wu, J.; Sahin, H.; Peeters, F.M. Formation and stability of point defects in monolayer rhenium disulfide. Phys. Rev. B 2014, 89, 155433. [Google Scholar] [CrossRef]

- Cakir, D.; Sahin, H.; Peeters, F.M. Doping of rhenium disulfide monolayers: A systematic first principles study. Phys. Chem. Chem. Phys. 2014, 16, 16771–16779. [Google Scholar] [CrossRef]

- Loh, G.C.; Pandey, R. Robust magnetic domains in fluorinated ReS2 monolayer. Phys. Chem. Chem. Phys. 2015, 17, 18843–18853. [Google Scholar] [CrossRef]

- Zhai, P.F.; Yi, Q.H.; Jian, J.; Wang, H.Y.; Song, P.Y.; Dong, C.; Lu, X.; Sun, Y.H.; Zhao, J.; Dai, X.; et al. Transparent p-type epitaxial thin films of nickel oxide. Chem. Commun. 2014, 50, 1854–1856. [Google Scholar] [CrossRef]

- Napari, M.; Huq, T.N.; Maity, T.; Gomersall, D.; Niang, K.M.; Barthel, A.; Thompson, J.E.; Kinnunen, S.; Arstila, K.; Sajavaara, T.; et al. Antiferromagnetism and p-type conductivity of nonstoichiometric nickel oxide thin films. Infomat 2020, 2, 769–774. [Google Scholar] [CrossRef]

- Cullity, B.D.; Graham, C.D. Antiferromagnetism. In Introduction to Magnetic Materials; John Wiley & Sons: Hoboken, NJ, USA, 2008; pp. 151–173. [Google Scholar] [CrossRef]

- Nogués, J.; Sort, J.; Langlais, V.; Skumryev, V.; Suriñach, S.; Muñoz, J.S.; Baró, M.D. Exchange bias in nanostructures. Phys. Rep. 2005, 422, 65–117. [Google Scholar] [CrossRef]

- Sugiyama, I.; Shibata, N.; Wang, Z.C.; Kobayashi, S.; Yamamoto, T.; Ikuhara, Y. Ferromagnetic dislocations in antiferromagnetic NiO. Nat. Nano. 2013, 8, 266–270. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Tseng, L.T.; Li, S.; Yi, J.B. Room temperature ferromagnetic ordering of NiO films through exchange coupling. Mat. Sci. Semicon. Proc. 2015, 30, 228–232. [Google Scholar] [CrossRef]

- Kodama, R.H.; Makhlouf, S.A.; Berkowitz, A.E. Finite size effects in antiferromagnetic NiO nanoparticles. Phys. Rev. Lett. 1997, 79, 1393–1396. [Google Scholar] [CrossRef]

- Proenca, M.P.; Sousa, C.T.; Pereira, A.M.; Tavares, P.B.; Ventura, J.; Vazquez, M.; Araujo, J.P. Size and surface effects on the magnetic properties of NiO nanoparticles. Phys. Chem. Chem. Phys. 2011, 13, 9561–9567. [Google Scholar] [CrossRef] [PubMed]

- Yi, J.B.; Ding, J.; Feng, Y.P.; Peng, G.W.; Chow, G.M.; Kawazoe, Y.; Liu, B.H.; Yin, J.H.; Thongmee, S. Size-dependent magnetism and spin-glass behavior of amorphous NiO bulk, clusters, and nanocrystals: Experiments and first-principles calculations. Phys. Rev. B 2007, 76, 224402. [Google Scholar] [CrossRef]

- Feygenson, M.; Kou, A.; Kreno, L.E.; Tiano, A.L.; Patete, J.M.; Zhang, F.; Kim, M.S.; Solovyov, V.; Wong, S.S.; Aronson, M.C. Properties of highly crystalline NiO and Ni nanoparticles prepared by high-temperature oxidation and reduction. Phys. Rev. B 2010, 81, 014420. [Google Scholar] [CrossRef]

- Karthik, K.; Selvan, G.K.; Kanagaraj, M.; Arumugam, S.; Jaya, N.V. Particle size effect on the magnetic properties of NiO nanoparticles prepared by a precipitation method. J. Alloy Compd. 2011, 509, 181–184. [Google Scholar] [CrossRef]

- Anthony, K.; Burrell, T.M.M.; Jia, Q. Polymer-Assisted Deposition; Springer: Berlin/Heidelberg, Germany, 2013; pp. 141–158. [Google Scholar]

- Wang, S.; Chen, Y.; Yao, J.; Zhao, G.; Li, L.; Zou, G. Wafer-sized 2D perovskite single crystal thin film for UV photodetector. J. Mater. Chem. C 2021, 9, 6498. [Google Scholar] [CrossRef]

| Materials | Magnetic Order | Tc | Origin | Characterization Technique | Strategy |

|---|---|---|---|---|---|

| ZnO [71] | FM | >300 K | VZn | SQUID; XPS; PAS | Defect engineering |

| Zn0.97Co0.03O [29] | FM | >300 K | VZn | SQUID; XPS; PL | Defect and doping engineering |

| ZnO HZNW [43] | FM | >300 K | VZn | SQUID | Defect engineering |

| ZnO VZPA [44] | FM | >300 K | VZn | SQUID; PL | Defect engineering |

| Mn-doped Ga2O3 [97,98] | FM | ~350 K | Vo; Mn2+, Mn3+, Mn4+ | SQUID; XPS; PL | Defect and doping engineering |

| SrRuO3 [33] | FM | ~160 K | unclear | SQUID | Defect engineering |

| LaCoO3 [67] | FM | ~85 K | high-spin Co3+ | SQUID; MR | Defect and strain engineering |

| LaCoO3 [27] | FM | ~85 K | high-spin Co3+ | SQUID | Strain engineering |

| LCMO: NiO [37] | FM | ~158 K | lattice parameter | SQUID; MR | Phase engineering |

| LCMO: Co3O4 [37] | FM | ~210 K | lattice parameter | SQUID; MR | Phase engineering |

| R2CoMnO6 [68] | FM | ~183 K | chemical and biaxial compressive strain | SQUID | Strain engineering |

| R2NiMnO6 [77] | FM | ~270 K | cation disorder | SQUID | Strain engineering |

| Y3Fe5O12 [77] | FM | ~500 K | oxygen content | SQUID; FMR | Defect engineering |

| MoS2 [3] | FM | >400 K | VMo | SQUID; PL | Defect and strain engineering |

| MoSe2 [25] | FM | >400 K | VMo | SQUID; VASP; EPR | Defect engineering |

| ReS2 [4] | FM | >400 K | VRe, VReS, VReS2 | SQUID; VASP | Defect and strain engineering |

| NiO [2] | FM | ~380 K | lattice defects | PPMS; MR | Defect engineering |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, H.; Zhong, J.; Xiang, G. The Progress on Magnetic Material Thin Films Prepared Using Polymer-Assisted Deposition. Molecules 2023, 28, 5004. https://doi.org/10.3390/molecules28135004

Ren H, Zhong J, Xiang G. The Progress on Magnetic Material Thin Films Prepared Using Polymer-Assisted Deposition. Molecules. 2023; 28(13):5004. https://doi.org/10.3390/molecules28135004

Chicago/Turabian StyleRen, Hongtao, Jing Zhong, and Gang Xiang. 2023. "The Progress on Magnetic Material Thin Films Prepared Using Polymer-Assisted Deposition" Molecules 28, no. 13: 5004. https://doi.org/10.3390/molecules28135004

APA StyleRen, H., Zhong, J., & Xiang, G. (2023). The Progress on Magnetic Material Thin Films Prepared Using Polymer-Assisted Deposition. Molecules, 28(13), 5004. https://doi.org/10.3390/molecules28135004