Effect of Steam on Carbonation of CaO in Ca-Looping

Abstract

1. Introduction

2. Results and Discussion

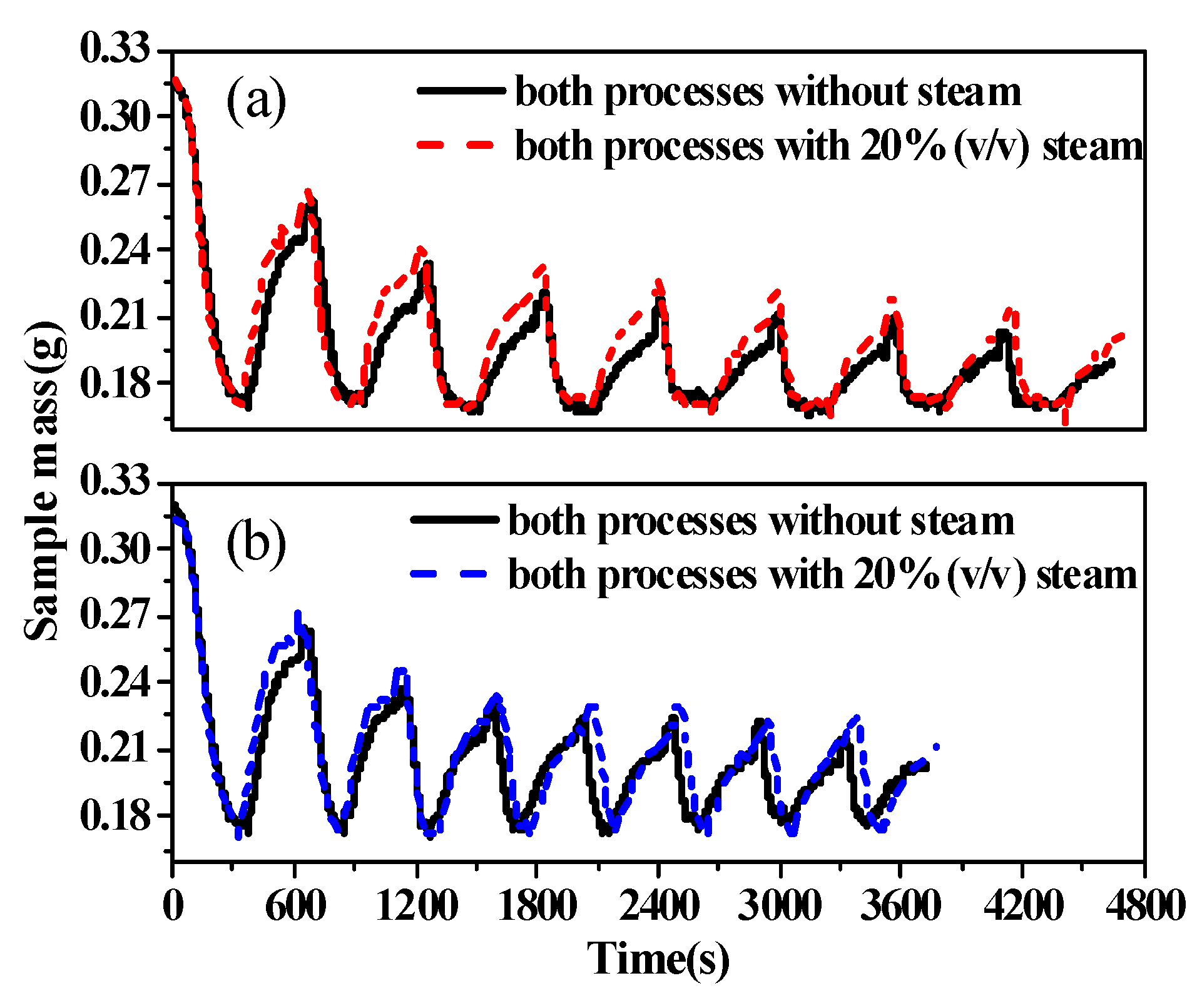

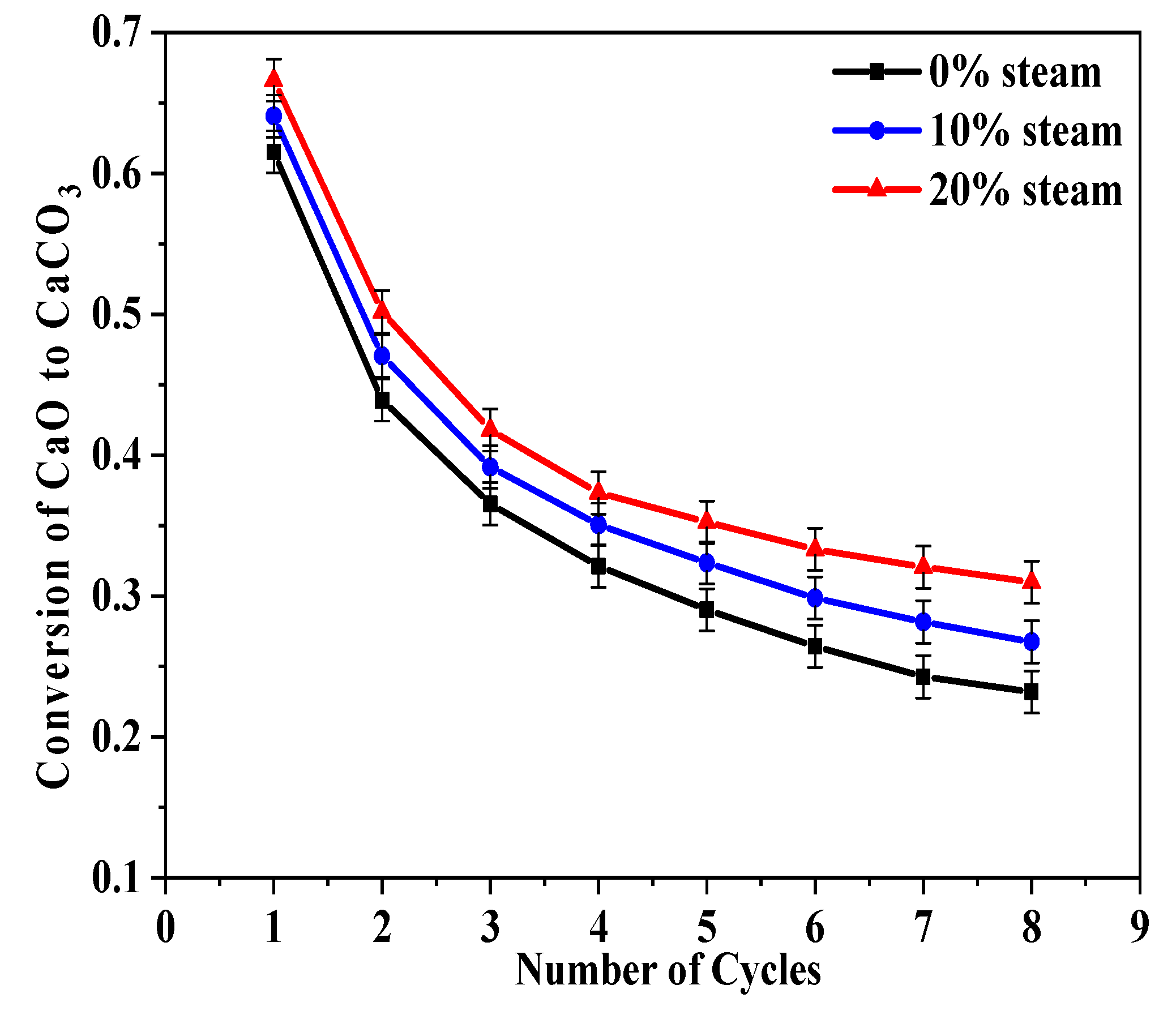

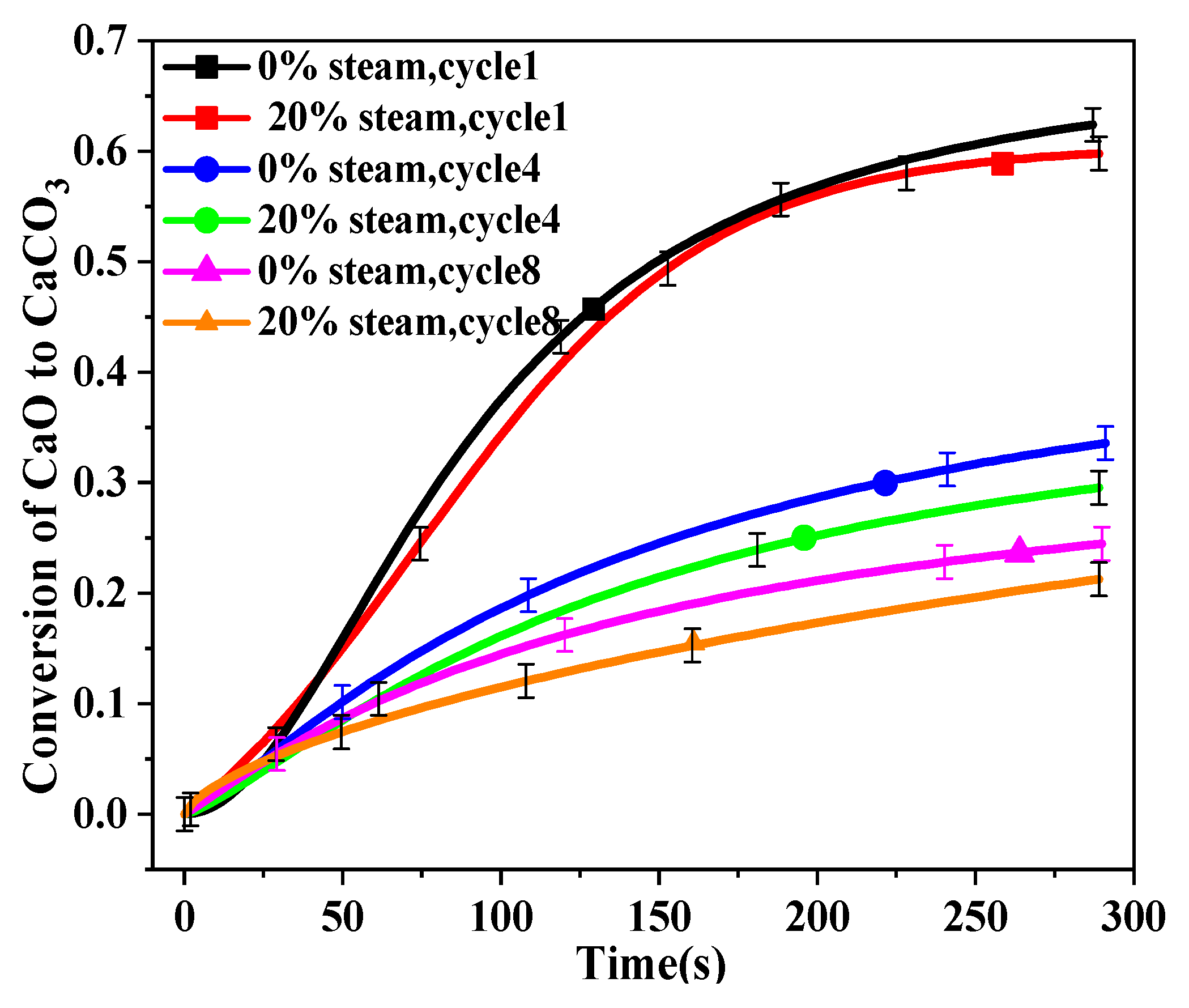

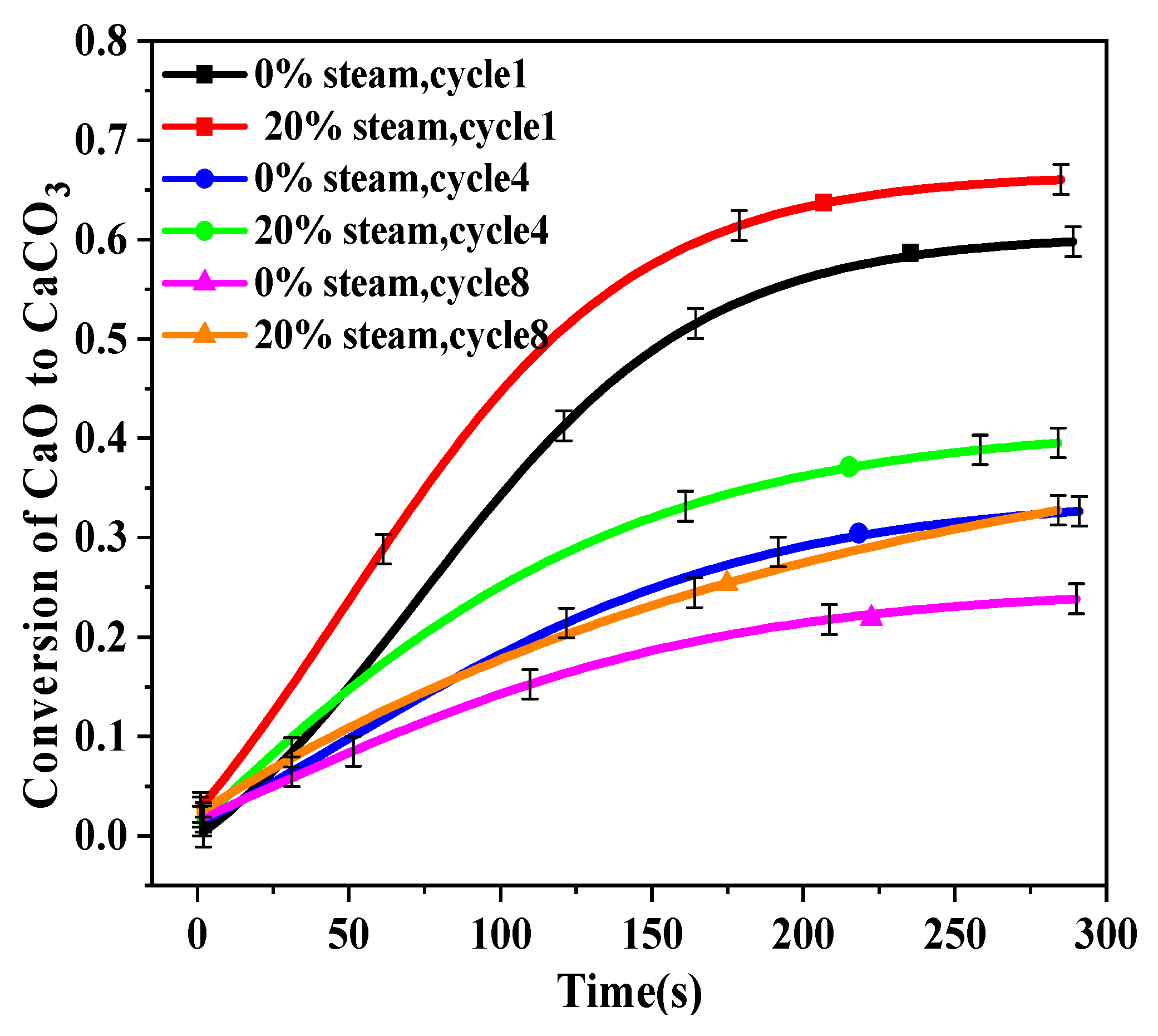

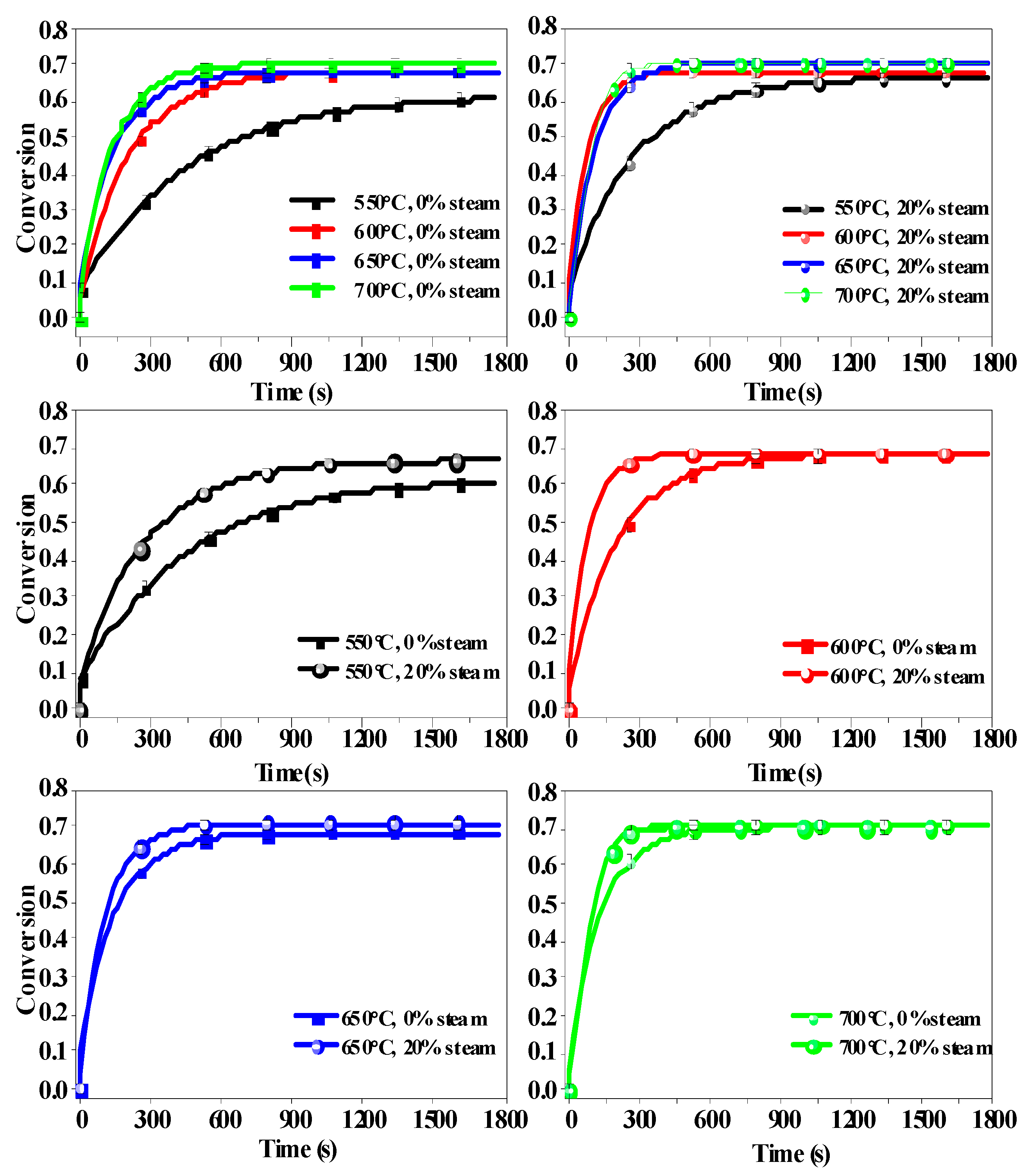

2.1. Effects of Steam during Both Calcination and Carbonation

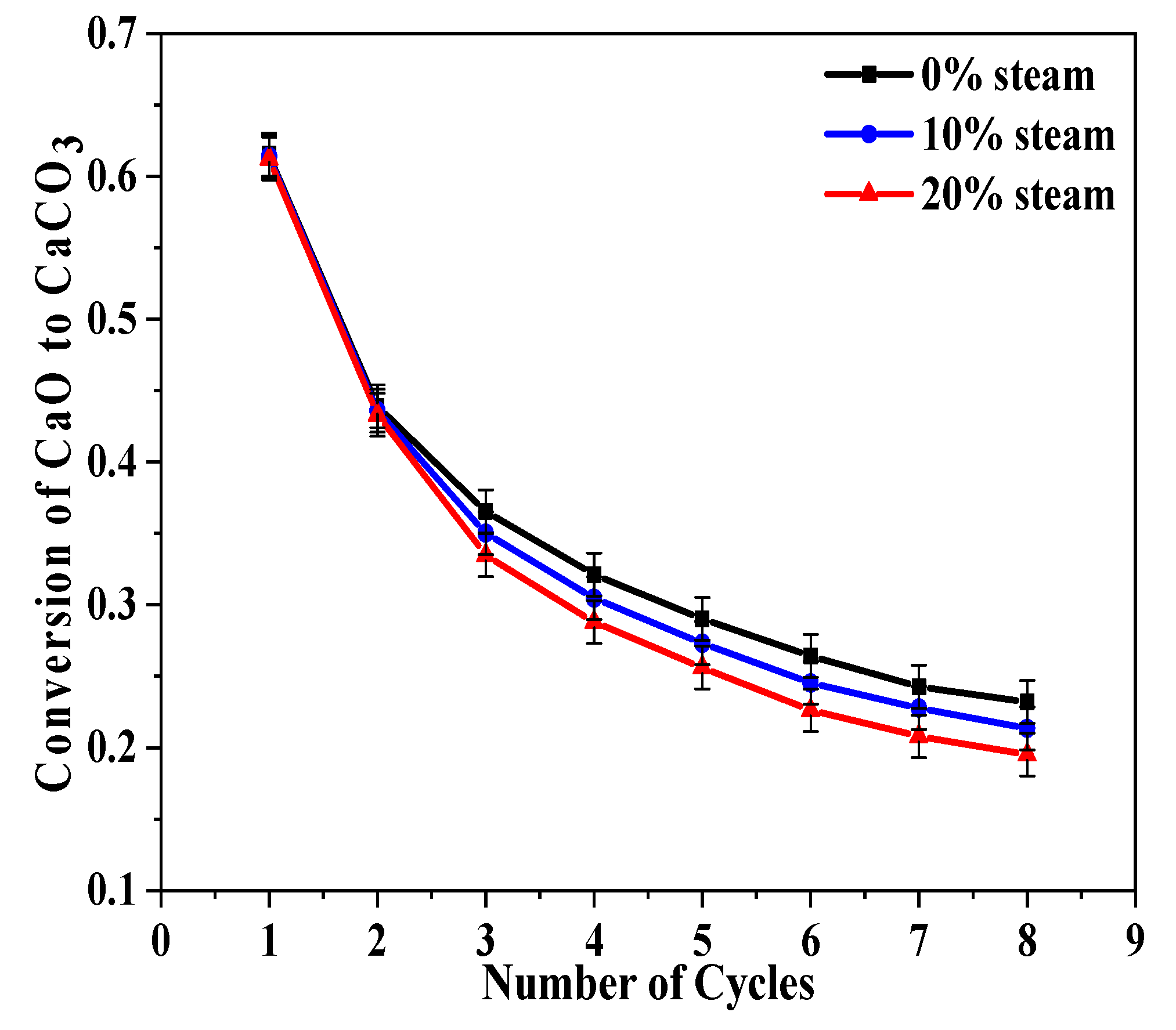

2.2. Steam Addition during Calcination or Carbonation

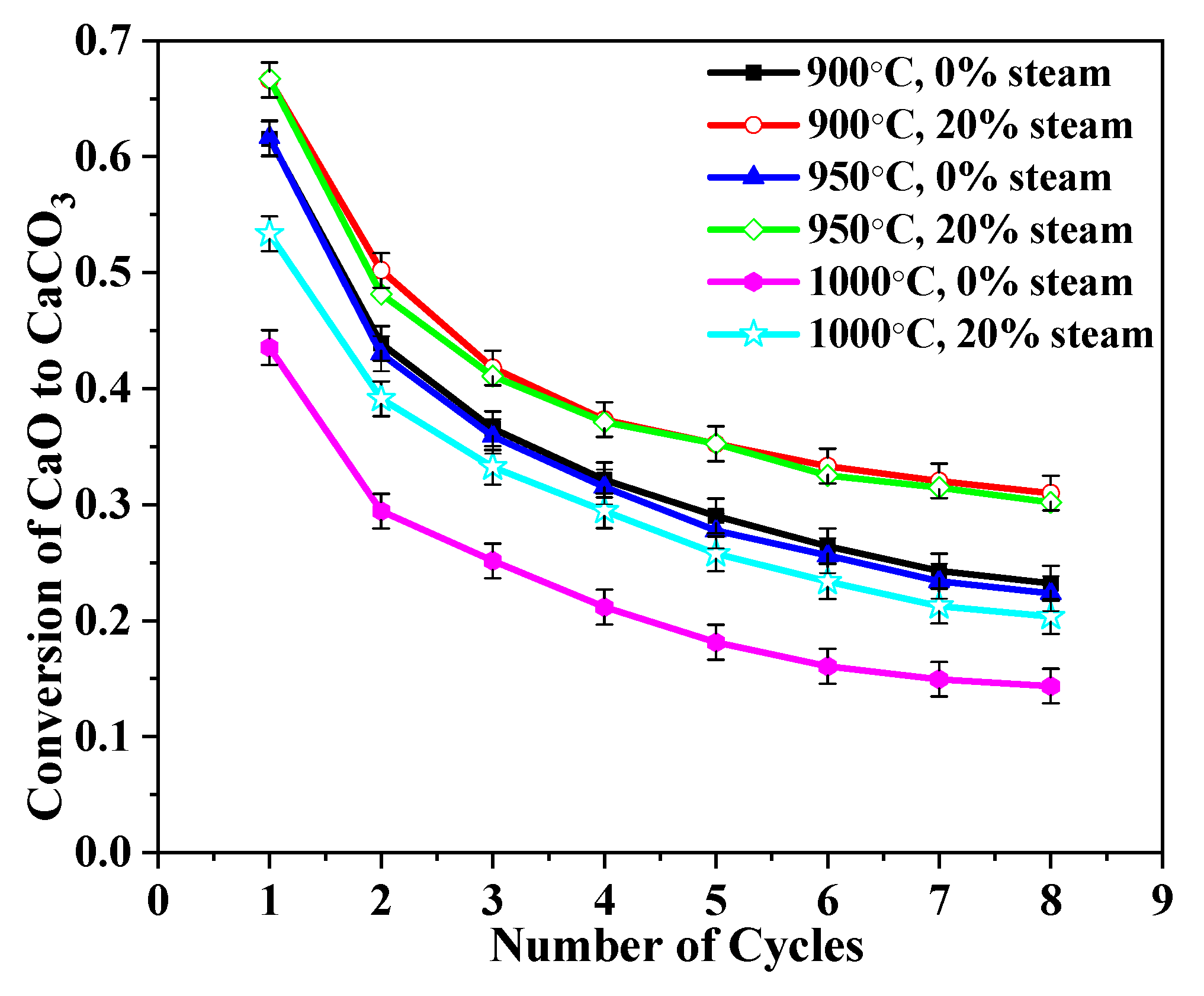

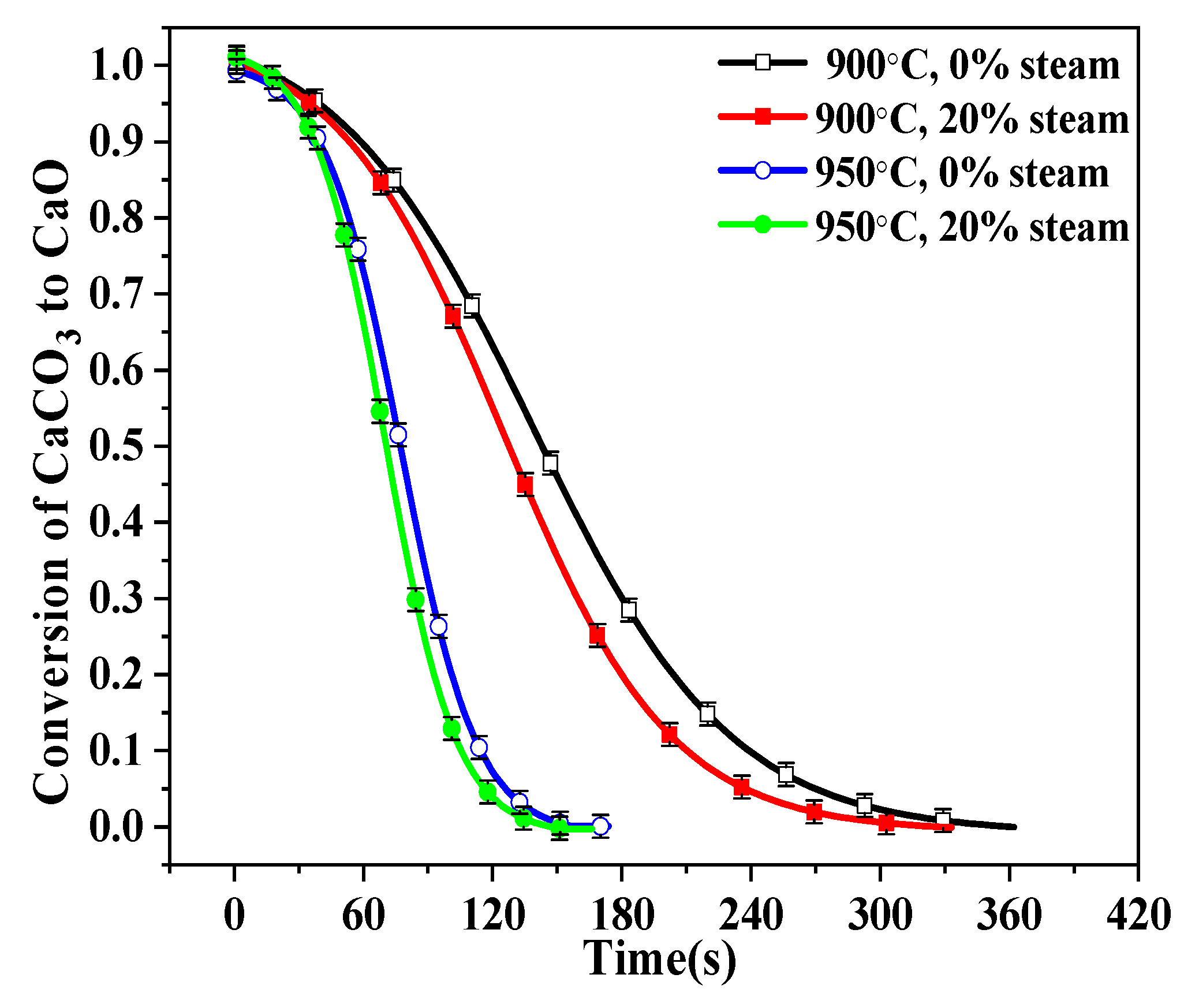

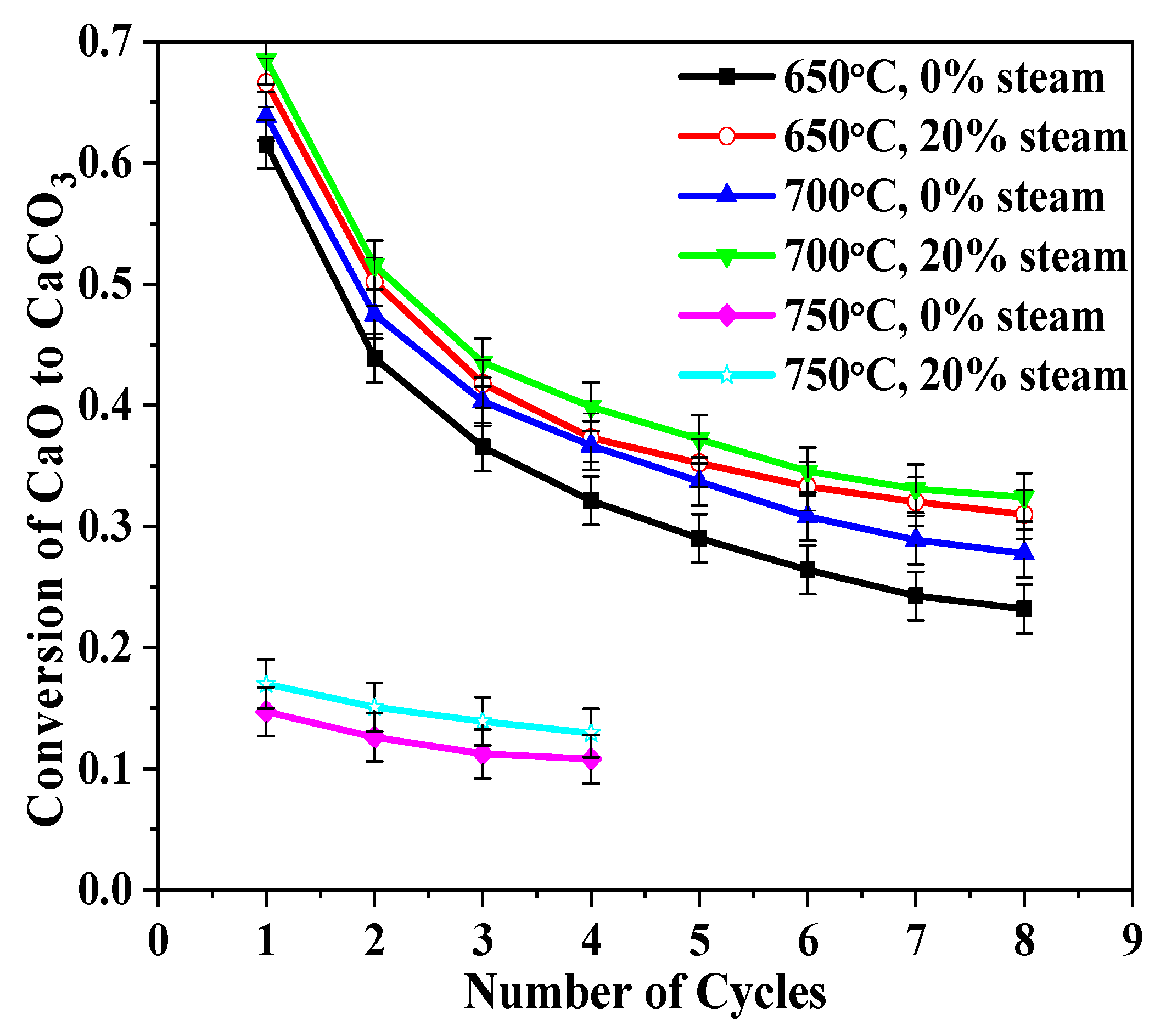

2.3. Reaction Temperature

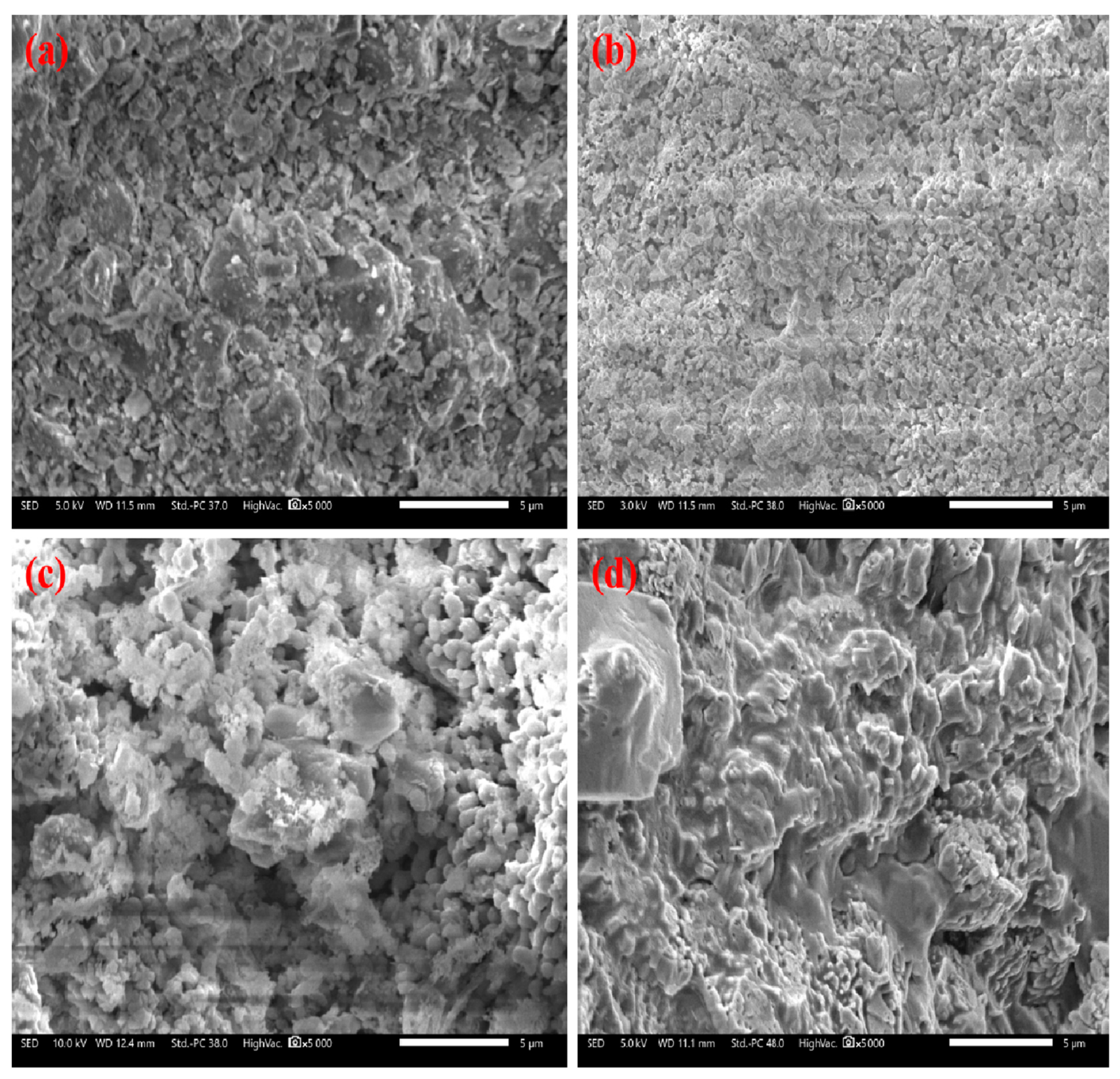

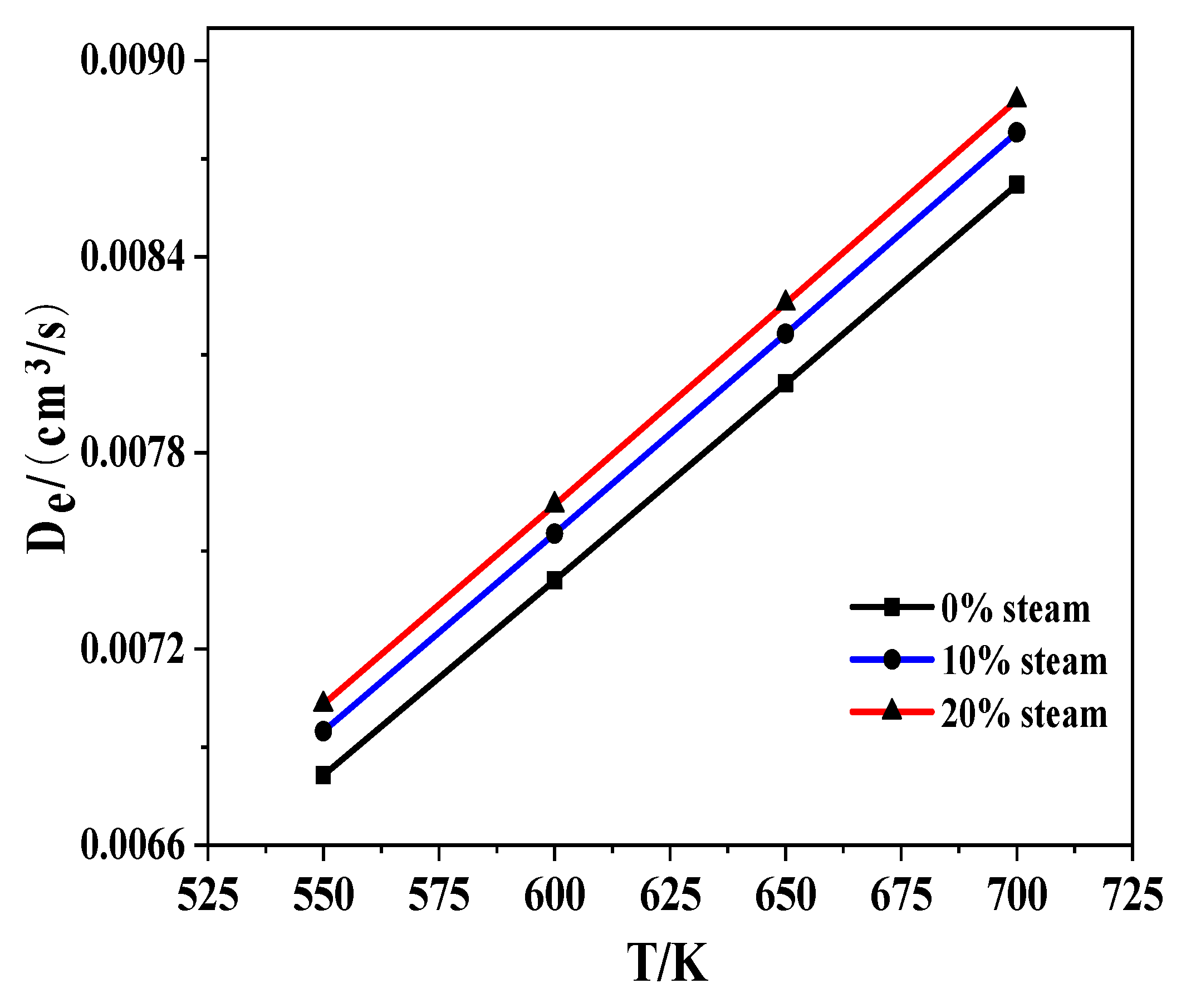

2.4. Pore Structure of CaO in Looping and Gas Diffusion Coefficient

3. Experiment

3.1. Sample Preparation

3.2. Experimental Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Stocker, T.F.; Quin, D. IPCC 2013: Climate Change 2013—The Physical Science Basis. In Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- Norbarzad, M.J.; Tahmasebpoor, M.; Heidari, M.; Pevida, C. Theoretical and experimental study on the fluidity performance of hard-to-fluidize carbon nanotubes-based CO2 capture sorbents. Front. Chem. Sci. Eng. 2022, 16, 1460–1475. [Google Scholar] [CrossRef]

- Troya, J.A.; Jiménez, P.S.E.; Perejón, A.; Moreno, V.; Valverde, J.M.; Maqueda, P.A.P. Kinetics and cyclability of limestone (CaCO3) in presence of steam during calcination in the CaL scheme for thermochemical energy storage. Chem. Eng. J. 2021, 417, 129194. [Google Scholar] [CrossRef]

- Han, R.; Wang, Y.; Xing, S.; Pang, C.; Hao, Y.; Song, C.; Liu, Q. Progress in reducing calcination reaction temperature of Calcium-Looping CO2 capture technology: A critical review. Chem. Eng. J. 2022, 450, 137952. [Google Scholar] [CrossRef]

- Chen, J.; Duan, L.; Sun, S. Review on the development of sorbents for calcium looping. Energy Fuels 2020, 34, 7806–7836. [Google Scholar] [CrossRef]

- Imani, M.; TPeridas, G.; Mordick Schmidt, B. Improvement in cyclic CO2 capture performance and fluidization behavior of eggshell-derived CaCO3 particles modified with acetic acid used in calcium looping process. J. CO2 Util. 2022, 65, 102207. [Google Scholar] [CrossRef]

- Peridas, G.; Mordick Schmidt, B. The role of carbon capture and storage in the race to carbon neutrality. Electr. J. 2021, 34, 106996. [Google Scholar] [CrossRef]

- Heidari, M.; Tahmasebpoor, M.; Mousavi, S.B.; Pevida, C. CO2 capture activity of a novel CaO adsorbent stabilized with (ZrO2+Al2O3+CeO2)-based additive under mild and realistic calcium looping conditions. J. CO2 Util. 2021, 53, 101747. [Google Scholar] [CrossRef]

- Mousavi, S.B.; Heidari, M.; Rahmani, F.; Sene, R.A.; Clough, P.T.; Ozmen, S. Highly robust ZrO2-stabilized CaO nanoadsorbent prepared via a facile one-pot MWCNT-template method for CO2 capture under realistic calcium looping conditions. J. Clean. Prod. 2023, 384, 135579. [Google Scholar] [CrossRef]

- Shimizu, T.; Hirama, T.; Hosoda, H.; Kitano, K.; Inagaki, M.; Tejima, K. A Twin Fluid-Bed Reactor for Removal of CO2 from Combustion Processes. Chem. Eng. Res. Des. 1999, 77, 62–68. [Google Scholar] [CrossRef]

- Moreno, J.; Hornberger, M.; Schmid, M.; Scheffknecht, G. Oxy-Fuel Combustion of Hard Coal, Wheat Straw and Solid Recovered Fuel in a 200 kWth Calcium Looping CFB Calciner. Energies 2021, 14, 2162. [Google Scholar] [CrossRef]

- Xu, H.; Shi, B. Design and System Evaluation of Mixed Waste Plastic Gasification Process Based on Integrated Gasification Combined Cycle System. Processes 2022, 10, 499. [Google Scholar] [CrossRef]

- Heidari, M.; Tahmasebpoor, M.; Antzaras, A.; Lemonidou, A.A. CO2 capture and flfluidity performance of CaO-based sorbents: Effect of Zr, Al and Ce additives in tri-, bi- and mono-metallic confifigurations. Process Saf. Environ. Prot. 2020, 14, 349–365. [Google Scholar] [CrossRef]

- Heidari, M.; Mousavi, S.B.; Rahmani, F.; Clough, P.T.; Ozmen, S. The novel Carbon Nanotube-assisted development of highly porous CaZrO3-CaO xerogel with boosted sorption activity towards high-temperature cyclic CO2 capture. Energy Convers. Manag. 2022, 274, 116461. [Google Scholar] [CrossRef]

- Chen, J.; Duan, L.; Sun, S. Accurate control of cage-Like CaO hollow microspheres for enhanced CO2 capture in calcium looping via a template-assisted synthesis approach. Environ. Sci. Technol. 2019, 53, 2249–2259. [Google Scholar] [CrossRef]

- Tian, S.C.; Yan, F.; Zhang, Z.T.; Jiang, J.G. Calcium-looping reforming of methane realizes in situ CO2 utilization with improved energy efficiency. Sci. Adv. 2019, 5, eaav5077. [Google Scholar] [CrossRef] [PubMed]

- Labus, K. Comparison of the Properties of Natural Sorbents for the Calcium Looping Process. Materials 2021, 14, 548. [Google Scholar] [CrossRef]

- Wang, N.N.; Feng, Y.C.; Guo, X. Atomistic mechanisms study of the carbonation reaction of CaO for high temperature CO2 capture. Appl. Surf. Sci. 2020, 532, 147425. [Google Scholar] [CrossRef]

- Bian, Z.G.; Li, Y.J.; Zhang, C.X.; Zhao, J.L.; Wang, Z.Y.; Liu, W.Q. CaO/Ca(OH)2 heat storage performance of hollow nanostructured CaO-based material from Ca-looping cycles for CO2 capture. Fuel Process. Technol. 2021, 217, 106834. [Google Scholar] [CrossRef]

- Criado, Y.A.; Arias, B.; Abanades, J.C. Effect of the Carbonation Temperature on the CO2 Carrying Capacity of CaO. Ind. Eng. Chem. Res. 2018, 57, 12595–12599. [Google Scholar] [CrossRef]

- Wang, H.; Guo, S.; Liu, D.Y.; Guo, Y.Z.; Gao, D.Y.; Sun, S.Z. A dynamic study on the impacts of water vapor and impurities on limestone calcination and cao sulfurization processes in a microfluidized bed reactor analyzer. Energy Fuels 2016, 30, 4625–4634. [Google Scholar] [CrossRef]

- Guo, H.X.; Yan, S.L.; Zhao, Y.G.; Ma, X.B.; Wang, S.P. Influence of water vapor on cyclic CO2 capture performance in both carbonation and decarbonation stages for Ca-Al mixed oxide. Chem. Eng. J. 2019, 359, 542–551. [Google Scholar] [CrossRef]

- Dong, J.; Tang, Y.; Nzihou, A.; Weiss-Hortala, E. Effect of steam addition during carbonation, calcination or hydration on re-activation of CaO sorbent for CO2 capture. J. CO2 Util. 2020, 39, 101167. [Google Scholar] [CrossRef]

- Wang, C.B.; Jia, L.F.; Tan, Y.W.; Anthony, E.J. Carbonation of fly ash in oxy-fuel CFB combustion. Fuel 2008, 87, 1108–1114. [Google Scholar] [CrossRef]

- Champagne, S.; Lu, D.Y.; Macchi, A.; Symonds, R.T.; Anthiny, E.J. Influence of Steam Injection during Calcination on the Reactivity of CaO-Based Sorbent for Carbon Capture. Ind. Eng. Chem. Res. 2013, 52, 2241–2246. [Google Scholar] [CrossRef]

- Donat, F.; Florin, N.H.; Anthony, E.J.; Fennell, P.S. Influence of high-temperature steam on the reactivity of CaO sorbent for CO capture. Environ. Sci. Technol. 2012, 46, 1262–1269. [Google Scholar] [CrossRef]

- Ar, I.; Dogu, G. Calcination kinetics of high purity limestones. Chem. Eng. J. 2001, 2, 131–137. [Google Scholar] [CrossRef]

- Ramezani, M.; Tremain, P.; Doroodchi, E.; Moghtaderi, B. Determination of carbonation/calcination reaction kinetics of a limestone sorbent in low CO2 partial pressures using TGA experiments. Energy Procedia 2017, 114, 259–270. [Google Scholar] [CrossRef]

- Valverde, J.M. On the negative activation energy for limestone calcination at high temperatures nearby equilibrium. Chem. Eng. Sci. 2015, 132, 169–177. [Google Scholar] [CrossRef]

- Li, D.; Wang, Y.; Li, Z.S. Limestone Calcination Kinetics in Microfluidized Bed Thermogravimetric Analysis (MFB-TGA) for Calcium Looping. Catalysts 2022, 12, 1661. [Google Scholar] [CrossRef]

- Iliuta, I.; Radfarnia, H.R.; Iliuta, M.C. Hydrogen Production by Sorption-Enhanced Steam Glycerol Reforming: Sorption Kinetics and Reactor Simulation. AIChE J. 2013, 59, 2105–2118. [Google Scholar] [CrossRef]

- Yang, S.; Xiao, Y. Steam Catalysis in CaO Carbonation under Low Steam Partial Pressure. Ind. Eng. Chem. Res. 2008, 47, 4043–4048. [Google Scholar] [CrossRef]

- Li, Z.S.; Fan, F.; Tang, X.Y.; Cai, N.S. Effect of Temperature on the Carbonation Reaction of CaO with CO2. Energy Fuels 2012, 26, 2473–2482. [Google Scholar] [CrossRef]

- Sun, P.; Grace, J.R.; Lim, J.C.; Anthony, E. A discrete-pore-size-distribution-based gas–solid model and its application to the reaction. Chem. Eng. Sci. 2008, 63, 57–70. [Google Scholar] [CrossRef]

- Lindén, I.; Backman, P.; Brink, A. Influence of Water Vapor on Carbonation of CaO in the Temperature Range 400–550 °C. Ind. Eng. Chem. Res. 2011, 50, 14115–14120. [Google Scholar] [CrossRef]

- Silakhori, M.; Jafarian, M.; Alfonso, C.; Saw, W.; Venkataraman, M.; Lipinski, W.; Nathan, G. Effects of steam on the kinetics of calcium carbonate calcination. Chem. Eng. Sci. 2021, 246, 116987. [Google Scholar] [CrossRef]

- Yang, J.; Ma, L.P.; Liu, H.P.; Yi, W.; Keomounlath, B.; Dai, Q.X. Thermodynamics and kinetics analysis of Ca-looping for CO2 capture: Application of carbide slag. Fuel 2019, 242, 1–11. [Google Scholar] [CrossRef]

- Fedunik-Hofaman, L.; Bayon, A.; Donne, S.W. Comparative Kinetic Analysis of CaCO3/CaO Reaction System for Energy Storage and Carbon Capture. Appl. Sci. 2019, 9, 4601. [Google Scholar] [CrossRef]

| Surface Area m2/g | Pore Volume mm3/g | |||||

|---|---|---|---|---|---|---|

| 1st | 3rd | 8th | 1st | 3rd | 8th | |

| = = 0% | 8.38 | 4.45 | 3.08 | 28.28 | 11.45 | 5.65 |

| = = 20% | 7.86 | 4.24 | 3.07 | 24.12 | 11.13 | 5.32 |

| Compound | SiO2 | Al2O3 | Fe2O3 | TiO2 | P2O5 | CaO | MgO | SO3 | Na2O | K2O | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| BD (wt%) | 2.13 | 1.31 | <0.55 | <0.03 | <0.03 | 53.22 | 1.48 | <0.10 | <0.20 | 0.13 | 41.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, R.; Li, N.; Liu, Q.; Chen, S.; Liu, Q.; Zhou, X. Effect of Steam on Carbonation of CaO in Ca-Looping. Molecules 2023, 28, 4910. https://doi.org/10.3390/molecules28134910

Bai R, Li N, Liu Q, Chen S, Liu Q, Zhou X. Effect of Steam on Carbonation of CaO in Ca-Looping. Molecules. 2023; 28(13):4910. https://doi.org/10.3390/molecules28134910

Chicago/Turabian StyleBai, Ruzhan, Na Li, Quansheng Liu, Shenna Chen, Qi Liu, and Xing Zhou. 2023. "Effect of Steam on Carbonation of CaO in Ca-Looping" Molecules 28, no. 13: 4910. https://doi.org/10.3390/molecules28134910

APA StyleBai, R., Li, N., Liu, Q., Chen, S., Liu, Q., & Zhou, X. (2023). Effect of Steam on Carbonation of CaO in Ca-Looping. Molecules, 28(13), 4910. https://doi.org/10.3390/molecules28134910