Abstract

In the times of dynamically developing regenerative medicine, more and more attention is focused on the use of natural polymers. This is due to their high biocompatibility and biodegradability without the production of toxic compounds, which means that they do not hurt humans and the natural environment. Chitosan and its derivatives are polymers made most often from the shells of crustaceans and are biodegradable and biocompatible. Some of them have antibacterial or metal-chelating properties. This review article presents the development of biomaterials based on chitosan and its derivatives used in regenerative medicine, such as a dressing or graft of soft tissues or bones. Various examples of preparations based on chitosan and its derivatives in the form of gels, films, and 3D structures and crosslinking products with another polymer are discussed herein. This article summarizes the latest advances in medicine with the use of biomaterials based on chitosan and its derivatives and provides perspectives on future research activities.

1. Introduction

Tissue engineering is focused on the creation of tissues to repair or replace diseased or damaged organs. Recently, natural polymers have become of increasing interest due to rapidly developing medical applications. This is due to their biodegradability and non-toxicity. They also mimic tissue structure better than synthetic polymers due to their physicochemical similarity. The development of new products based on tissue-mimicking biopolymers that are more robust, non-toxic, and biodegradable is a key issue that will guarantee rapid growth in the development of tissue engineering. Biomimetic natural polymers and hybrid polymer materials have the advantage of combining desired functions with tailored morphology and superior chemical and physical stability. These polymeric materials aim to cover all aspects of the subject, including, for instance, the design of hybrid materials, films, gel, sponge, nanocomposites, and hydrogels, without forgetting studies of structure–property relationships, production of materials with precise structural control and advanced properties, and applications of bioinspired polymers for various fields including tissue engineering, drug delivery systems, or wound dressings [1,2,3,4].

The main problems of the resulting materials made from single polymers are insufficient mechanical properties and too rapid biodegradability. Therefore, mixtures of polymers and the use of a cell-free tissue matrix started to be used. Silk fibroin [5,6,7], collagen [8,9], hyaluronate [10,11], or gelatin [12] were used for this purpose. The materials obtained should be biodegradable and the biodegradation products must be non-toxic and removed from the body without any effect on other tissues. Furthermore, the materials should support cell adhesion, migration, and proliferation through appropriate porosity, pore size, and their appropriate combination. The physicochemical and mechanical properties should be as similar as possible to those of the tissue to be replaced and should be strong enough to allow its implantation during surgery [13,14]. These materials can take the form of thin films, hydrogels, membranes, 3D structures, fibers, and nanofibers.

Herein, we reviewed various examples of chitosan-based biomaterials, mixed with other polymers and cross-linked with chemical agents, in biomedical applications based on previous research.

2. Chitosan and Its Derivatives

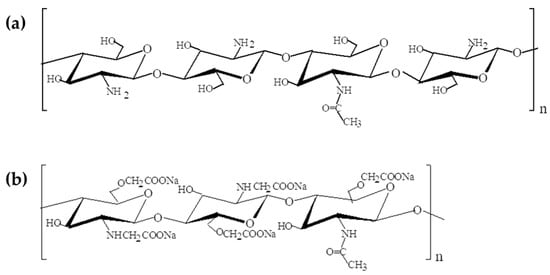

Chitosan (CS) (poly(β-(1,4)-2-amino-2-deoxy-D-glucopyranose) is a natural polymer obtained by partial deacetylation of chitin in an alkaline medium (Figure 1). Chitin was produced from the exoskeletons of crustaceans. Chitosan also occurs naturally in the cell walls of some fungi. Chitosan is a polymer with a degree of deacetylation of at least 60%. The polymer’s molecular weight and the degree of deacetylation determine its properties such as biodegradability, biocompatibility, viscosity, hydrophilicity, and antibacterial or antifungal properties. The major disadvantage of chitosan is its lack of solubility in water [15,16,17,18,19,20,21].

Figure 1.

Structures of chitosan (a) and carboxymethyl chitosan (b).

The most important properties are shown in Figure 2. Chitosan is the only naturally occurring polysaccharide classified as a cationic polyelectrolyte, which allows it to interact with different types of molecules. The polymer’s positive charge is responsible for its antibacterial properties, attaching to the negatively charged cell membrane of various microorganisms [14,21].

Figure 2.

Chitosan properties.

Carboxymethyl chitosan (CMC) is a chitosan derivative in which the carboxymethyl group is attached to either an amino group or a hydroxyl group (Figure 1).

This chitosan derivative is water soluble and this is one of the main reasons for the increased interest in this polymer by researchers. It can be obtained in many types: N-carboxymethyl chitosan N,N-carboxymethyl chitosan, N,O-carboxymethyl chitosan, and O-carboxymethyl chitosan. During the substitution reaction, the listed types of derivatives or their mixtures can be obtained [22,23]. CMC is characterized by high viscosity, biocompatibility, and biodegradability, and is non-toxic. It also has antimicrobial activity, with O-carboxymethyl chitosan showing greater activity due to the more abundant presence of amino groups. Carboxymethyl chitosan shows improved physicochemical and biological properties relative to chitosan. The properties of CMC are influenced by the average molecular weight, degree of deacetylation, and degree of substitution. In addition, CMC has antioxidant activity, antibacterial or antifungal properties, and the ability to chelate metals [22,23,24,25,26]

Chitosan acetate is obtained by reaction with acetic acid in an aqueous–ethanol environment. It is water soluble and its solution is more stable than chitosan dissolved in acetic acid, while retaining the physicochemical and biological properties of chitosan. It exhibits stronger antimicrobial activity against Gram-positive bacteria than against Gram-negative bacteria. It is used as a dressing material (Chitopack C®) and a hemostat (Hemcon Bandage®) approved by the FDA [27].

There are other chitosan derivatives such as sulfopropylchitosan, O-quaternary ammonium salt of chitosan, N-succinylchitosan, and others [28,29].

3. Chitosan and Its Derivatives in Medicine

Due to its properties, chitosan and its derivatives can be used in the production of dressing materials, in the manufacture of drugs as a controlled-release active substance carrier, or in tissue engineering involving soft tissues, nerves, cartilage, bones, or arteries. Studies on the use of chitosan are summarized in Table 1 and studies on its derivatives are in Table 2.

Table 1.

Application of chitosan-based materials in tissue engineering.

Table 2.

Applications of chitosan-derivative-based materials in tissue engineering.

The team of Fangsong Zhang et al. [30] used two chemical agents, glutaraldehyde, genipin, and a physical agent, ultraviolet light, to crosslink nerve extracellular matrix/chitosan scaffolds. Scaffolds cross-linked with genipin were characterized by higher porosity and regular structure in contrast to scaffolds cross-linked with glutaraldehyde and UV. The degree of crosslinking for genipin-crosslinked and glutaraldehyde-crosslinked scaffolds were similar to each other. Genipin-crosslinked scaffolds had the lowest degree of cytotoxicity and the highest histocompatibility, with good mechanical properties.

Another team, Jie Xu et al. [31], prepared a scaffold based on decellularized extracellular matrix, gelatin, and chitosan cross-linked EDC/NHS. The resulting scaffolds were characterized by a high modulus of elasticity and biodegradability. The obtained scaffolds are not cytotoxic and provided a good substrate for cell proliferation. The scaffolds were also characterized by antibacterial properties (E. Coli, S. Aureus). The scaffolds obtained could be used in skin tissue engineering.

A scaffold for use in muscle tissue engineering is a project by the team of Weiguang Zhao et al. [32]. They used genipin as a crosslinking agent and electrospun cellulose acetate nanofibers that were incorporated into a chitosan/fibroin silk cryogel scaffold. The resulting scaffolds were characterized by larger pores and roughness than the cryogel scaffold itself. They are also a good substrate for smooth muscle cell proliferation, which showed a higher potential for the expression of genes related to muscle contraction. They also exhibit good mechanical properties.

Scaffold for use in cartilage tissue engineering is a study by Christian E. G. Garcia et al. [33]. The properties of chitosan in two forms were compared: thin film and electrospinning scaffold chitosan/poly (ethylene oxide) (PEO). PEO of two different molecular weights was used and different weight ratios of Cs/PEO were applied. Some of the materials obtained were neutralized in order to compare the effect of neutralization on the properties of the scaffolds. The scaffolds after neutralization were characterized by better adhesion of chondrocyte cells and better proliferation; the worst properties were characterized by the chitosan film.

Nihui Zhang and her team [65] used genipin solutions with different concentrations (2.5%, 5%, 10%, and 15%) to produce carboxymethyl chitosan hydrogels. Analysis of HSFs cell proliferation and adhesion showed that the best cell adhesion and proliferation were obtained for the hydrogel with the highest amount of genipin, and the worst for the hydrogel with the lowest proportion of genipin. The best properties for promoting wound healing and reducing the appearance of scars in vivo tests were obtained for the hydrogel carboxymethyl chitosan/genipin 5% (v/v). This was confirmed by an in vivo test using female rats. With the additional contribution of aloe vera gel, wound healing results improved even further. In conclusion, genipin-crosslinked chitosan hydrogels are promising candidates for use as a dressing to accelerate wound healing.

Yalei Liu et al. [66] used polyvinyl alcohol, carboxymethyl chitosan, silver nanoparticles, and borax as a crosslinking agent to produce a hydrogel. The resulting hydrogel, due to its dual crosslinking (hydrogen bonds and borate ester bonds), has self-healing properties and is characterized by good mechanical properties. It also exhibits antibacterial properties, as confirmed by a test with E.coli and S. aureus bacteria. A cytotoxicity test was also performed using L929 cells, which showed that the resulting scaffolds were non-toxic.

Guozhu Chang et al. [67] produced a carboxymethyl chitosan/carboxymethyl cellulose hydrogel using heparin and glutaraldehyde as a crosslinking agent. This allowed the fabrication of a self-healing hydrogel. It is biocompatible with cells and its ability to release drugs has also been studied. An in vivo study was also performed on rats with diabetes, where its effect on accelerating open wound healing was confirmed. It can be concluded that the resulting hydrogel has the potential to be used as a material to accelerate diabetic wound healing.

To form antimicrobial scaffolds, A. Mishra’s team [68] used carboxymethyl chitosan, zinc, and genipin. Carboxymethyl chitosan/genipin/Zn scaffolds were obtained. Wet compression analysis showed that the carboxymethyl chitosan/genipin/Zn scaffold was more robust than the non-cross-linked scaffold. Degradation testing was carried out under enzymatic and non-enzymatic conditions. The resulting scaffold also showed good stability. An adhesion and proliferation test was performed using dental pulp stem cells; in addition, a biocompatibility test against red blood cells was performed, which confirmed its good biological properties. An antibacterial test was also performed (Pseudomonas aeruginosa ATCC 25619, S. aureus ATCC 9144, S. aureus ATCC 25923, and Staphylococcus epidermidis ATCC 155). No biofilm formed on the surface of the scaffold carboxymethyl chitosan/genipin/Zn. In conclusion, scaffold carboxymethyl chitosan/genipin/Zn can find application in dental tissue engineering due to its antibacterial properties.

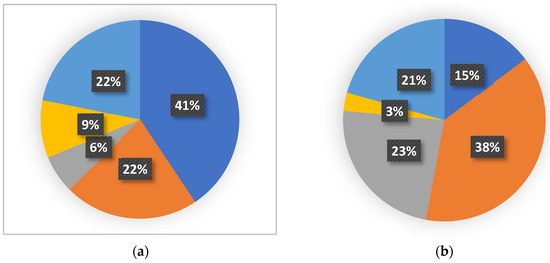

Summarizing the data overview on the use of chitosan and its derivatives in tissue engineering (Figure 3a,b), it can be written that the most research on chitosan-based materials concerned bone tissue engineering and the least concerned dental tissue engineering. For materials based on chitosan derivatives, the greatest interest in use was in skin tissue engineering and the least in tissue engineering applications.

Figure 3.

Applications of chitosan (a) and its derivatives (b) in tissue engineering. Skin tissue engineering (dark blue), bone tissue engineering (orange), cartilage tissue engineering (grey), dental tissue engineering (yellow), and other tissue engineering and unclassified tissue engineering (light blue).

4. Conclusions

The use of chitosan and its derivatives in medicine offers a huge opportunity in the further development of regenerative medicine. The use of different forms of polymers such as films, hydrogel scaffolds, or the use of strongly developing ways of producing materials such as electrospinning and 3D printing open another door to the medicine of the future. Owing to continuous development, we are able to produce biomaterials that mimic the structure, morphology, and function of various organs such as blood vessels, nerves, soft tissues, or bones. Further research using other solvents, new mixtures, or using a different cross-linking agent may bring us even closer to a perfectly mimicking tissue biomaterial. A constant challenge is to produce in the spirit of green production and ecology in a closed loop using natural polymers where their extraction will not adversely affect the environment.

Author Contributions

Conceptualization, M.S. and K.L.; data curation M.S.; writing—original draft preparation, M.S.; writing—review and editing, M.S. and K.L.; visualization, M.S. and K.L.; supervision, K.L.; project administration, M.S. and K.L.; funding acquisition, K.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This work is supported by Grants4NCUStudents, Excellence Initiative – Research University, (Grant IDUB- 4101.00000070), 2022–2023 and Young Scientist Grant, Dean of the Faculty of Chemistry NCU, 2021–2022.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhao, X.; He, X.; Hou, A.; Cheng, C.; Wang, X.; Yue, Y.; Wu, Z.; Wu, H.; Liu, B.; Li, H.; et al. Growth of Cu2O Nanoparticles on Two-Dimensional Zr–Ferrocene–Metal–Organic Framework Nanosheets for Photothermally Enhanced Chemodynamic Antibacterial Therapy. Inorg. Chem. 2022, 61, 9328–9338. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Wang, Y.; Peng, F.; Meng, F.; Zha, J.; Ma, L.; Du, Y.; Peng, N.; Ma, L.; Zhang, Q.; et al. Intercalation-Activated Layered MoO3 Nanobelts as Biodegradable Nanozymes for Tumor-Specific Photo-Enhanced Catalytic Therapy. Angew. Chem. Int. Ed. 2022, 61, e202115939. [Google Scholar] [CrossRef]

- Qin, L.; Liang, F.; Li, Y.; Wu, J.; Guan, S.; Wu, M.; Xie, S.; Luo, M.; Ma, D. A 2D Porous Zinc-Organic Framework Platform for Loading of 5-Fluorouracil. Inorganics 2022, 10, 202. [Google Scholar] [CrossRef]

- Hu, T.; Gu, Z.; Williams, G.R.; Strimaite, M.; Zha, J.; Zhou, Z.; Zhang, X.; Tan, C.; Liang, R. Layered Double Hydroxide-Based Nanomaterials for Biomedical Applications. Chem. Soc. Rev. 2022, 51, 6126–6176. [Google Scholar] [CrossRef]

- Tu, D.D.; Chung, Y.G.; Gil, E.S.; Seth, A.; Franck, D.; Cristofaro, V.; Sullivan, M.P.; Di Vizio, D.; Gomez, P.; Adam, R.M.; et al. Bladder Tissue Regeneration Using Acellular Bi-Layer Silk Scaffolds in a Large Animal Model of Augmentation Cystoplasty. Biomaterials 2013, 34, 8681–8689. [Google Scholar] [CrossRef]

- Xiao, S.; Wang, P.; Zhao, J.; Ling, Z.; An, Z.; Fu, Z.; Fu, W.; Zhang, X. Bi-Layer Silk Fibroin Skeleton and Bladder Acellular Matrix Hydrogel Encapsulating Adipose-Derived Stem Cells for Bladder Reconstruction. Biomater. Sci. 2021, 9, 6169–6182. [Google Scholar] [CrossRef]

- Cao, N.; Song, L.; Liu, W.; Fan, S.; Jiang, D.; Mu, J.; Gu, B.; Xu, Y.; Zhang, Y.; Huang, J. Prevascularized Bladder Acellular Matrix Hydrogel/Silk Fibroin Composite Scaffolds Promote the Regeneration of Urethra in a Rabbit Model. Biomed. Mater. 2018, 14, 015002. [Google Scholar] [CrossRef]

- Gasanz, C.; Raventós, C.; Temprana-Salvador, J.; Esteves, M.; Fonseca, C.; de Torres, I.; Morote, J. Use of an Acellular Collagen–Elastin Matrix to Support Bladder Regeneration in a Porcine Model of Peritoneocystoplasty. Cent. Eur. J. Urol. 2018, 71, 353. [Google Scholar] [CrossRef]

- Shi, C.; Chen, W.; Chen, B.; Shan, T.; Jia, W.; Hou, X.; Li, L.; Ye, G.; Dai, J. Bladder Regeneration in a Canine Model Using a Bladder Acellular Matrix Loaded with a Collagen-Binding BFGF. Biomater. Sci. 2017, 5, 2427–2436. [Google Scholar] [CrossRef]

- Jalali, S.; Fereidoni, M.; Shahri, N.M.; Lari, R. Effect of Swim Bladder Matrix Treated with Hyaluronic Acid on Wound Healing: An Animal Model Evaluation. J. Wound Care 2019, 28, 206–213. [Google Scholar] [CrossRef]

- Su, Z.; Ma, H.; Wu, Z.; Zeng, H.; Li, Z.; Wang, Y.; Liu, G.; Xu, B.; Lin, Y.; Zhang, P.; et al. Enhancement of Skin Wound Healing with Decellularized Scaffolds Loaded with Hyaluronic Acid and Epidermal Growth Factor. Mater. Sci. Eng. C 2014, 44, 440–448. [Google Scholar] [CrossRef] [PubMed]

- Mathapati, S.; Bishi, D.K.; Venugopal, J.R.; Cherian, K.M.; Guhathakurta, S.; Ramakrishna, S.; Verma, R.S. Nanofibers Coated on Acellular Tissue-Engineered Bovine Pericardium Supports Differentiation of Mesenchymal Stem Cells into Endothelial Cells for Tissue Engineering. Nanomedicine 2014, 9, 623–634. [Google Scholar] [CrossRef] [PubMed]

- Dolcimascolo, A.; Calabrese, G.; Conoci, S.; Parenti, R. Innovative Biomaterials for Tissue Engineering. In Biomaterial-Supported Tissue Reconstruction or Regeneration; Barbeck, M., Jung, O., Smeets, R., Koržinskas, T., Eds.; IntechOpen: London, UK, 2019; ISBN 978-1-83880-377-3. [Google Scholar]

- Rodríguez-Vázquez, M.; Vega-Ruiz, B.; Ramos-Zúñiga, R.; Saldaña-Koppel, D.A.; Quiñones-Olvera, L.F. Chitosan and Its Potential Use as a Scaffold for Tissue Engineering in Regenerative Medicine. BioMed Res. Int. 2015, 2015, 821279. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Onyeri, S.; Siewe, M.; Moshfeghian, A.; Madihally, S.V. In Vitro Characterization of Chitosan–Gelatin Scaffolds for Tissue Engineering. Biomaterials 2005, 26, 7616–7627. [Google Scholar] [CrossRef] [PubMed]

- Sencadas, V.; Correia, D.M.; Ribeiro, C.; Moreira, S.; Botelho, G.; Gómez Ribelles, J.L.; Lanceros-Mendez, S. Physical-Chemical Properties of Cross-Linked Chitosan Electrospun Fiber Mats. Polym. Test. 2012, 31, 1062–1069. [Google Scholar] [CrossRef]

- Muxika, A.; Etxabide, A.; Uranga, J.; Guerrero, P.; de la Caba, K. Chitosan as a Bioactive Polymer: Processing, Properties and Applications. Int. J. Biol. Macromol. 2017, 105, 1358–1368. [Google Scholar] [CrossRef]

- Aguilar, A.; Zein, N.; Harmouch, E.; Hafdi, B.; Bornert, F.; Offner, D.; Clauss, F.; Fioretti, F.; Huck, O.; Benkirane-Jessel, N.; et al. Application of Chitosan in Bone and Dental Engineering. Molecules 2019, 24, 3009. [Google Scholar] [CrossRef]

- Baranwal, A.; Kumar, A.; Priyadharshini, A.; Oggu, G.S.; Bhatnagar, I.; Srivastava, A.; Chandra, P. Chitosan: An Undisputed Bio-Fabrication Material for Tissue Engineering and Bio-Sensing Applications. Int. J. Biol. Macromol. 2018, 110, 110–123. [Google Scholar] [CrossRef]

- El Knidri, H.; Belaabed, R.; Addaou, A.; Laajeb, A.; Lahsini, A. Extraction, Chemical Modification and Characterization of Chitin and Chitosan. Int. J. Biol. Macromol. 2018, 120, 1181–1189. [Google Scholar] [CrossRef]

- Yang, J.; Tian, F.; Wang, Z.; Wang, Q.; Zeng, Y.-J.; Chen, S.-Q. Effect of Chitosan Molecular Weight and Deacetylation Degree on Hemostasis. J. Biomed. Mater. Res. 2008, 84B, 131–137. [Google Scholar] [CrossRef]

- Jimtaisong, A.; Saewan, N. Utilization of Carboxymethyl Chitosan in Cosmetics. Int. J. Cosmet. Sci. 2014, 36, 12–21. [Google Scholar] [CrossRef] [PubMed]

- Muzzarelli, R.A.A. Carboxymethylated Chitins and Chitosans. Carbohydr. Polym. 1988, 8, 1–21. [Google Scholar] [CrossRef]

- Mourya, V.K.; Inamdara, N.; Ashutosh Tiwari, N. Carboxymethyl Chitosan and Its Applications. Adv. Mater. Lett. 2010, 1, 11–33. [Google Scholar] [CrossRef]

- Sun, T.; Yao, Q.; Zhou, D.; Mao, F. Antioxidant Activity of N-Carboxymethyl Chitosan Oligosaccharides. Bioorg. Med. Chem. Lett. 2008, 18, 5774–5776. [Google Scholar] [CrossRef]

- Shariatinia, Z. Carboxymethyl Chitosan: Properties and Biomedical Applications. Int. J. Biol. Macromol. 2018, 120, 1406–1419. [Google Scholar] [CrossRef]

- Li, Y.; Chen, X.G.; Liu, N.; Liu, C.S.; Liu, C.G.; Meng, X.H.; Yu, L.J.; Kenendy, J.F. Physicochemical Characterization and Antibacterial Property of Chitosan Acetates. Carbohydr. Polym. 2007, 67, 227–232. [Google Scholar] [CrossRef]

- Kahya, N. Water Soluble Chitosan Derivatives and Their Biological Activities: A Review. Polym. Sci. 2019, 5, 1–16. [Google Scholar] [CrossRef]

- Kato, Y. N-Succinyl-Chitosan as a Drug Carrier: Water-Insoluble and Water-Soluble Conjugates. Biomaterials 2004, 25, 907–915. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, N.; Xu, Q.; Zhang, L.; Zhang, C.; Liu, H.; Yu, Z.; Zhou, S.; Feng, G.; Huang, F. Decellularized Nerve Extracellular Matrix/Chitosan Crosslinked by Genipin to Prepare a Moldable Nerve Repair Material. Cell Tissue Bank 2021, 22, 419–430. [Google Scholar] [CrossRef]

- Xu, J.; Fang, H.; Zheng, S.; Li, L.; Jiao, Z.; Wang, H.; Nie, Y.; Liu, T.; Song, K. A Biological Functional Hybrid Scaffold Based on Decellularized Extracellular Matrix/Gelatin/Chitosan with High Biocompatibility and Antibacterial Activity for Skin Tissue Engineering. Int. J. Biol. Macromol. 2021, 187, 840–849. [Google Scholar] [CrossRef]

- Zhao, W.; Cao, S.; Cai, H.; Wu, Y.; Pan, Q.; Lin, H.; Fang, J.; He, Y.; Deng, H.; Liu, Z. Chitosan/Silk Fibroin Biomimic Scaffolds Reinforced by Cellulose Acetate Nanofibers for Smooth Muscle Tissue Engineering. Carbohydr. Polym. 2022, 298, 120056. [Google Scholar] [CrossRef] [PubMed]

- Garcia, C.E.G.; Lardy, B.; Bossard, F.; Soltero, F.A. Chitosan based biomaterials for cartilage tissue engineering: Chondrocyte adhesion and proliferation. Food Hydrocolloids for Health 2021, 1, 100018. [Google Scholar] [CrossRef]

- Karabıyık Acar, Ö.; Bedir, S.; Kayitmazer, A.B.; Kose, G.T. Chondro-Inductive Hyaluronic Acid/Chitosan Coacervate-Based Scaffolds for Cartilage Tissue Engineering. Int. J. Biol. Macromol. 2021, 188, 300–312. [Google Scholar] [CrossRef] [PubMed]

- Asghari, F.; Rabiei Faradonbeh, D.; Malekshahi, Z.V.; Nekounam, H.; Ghaemi, B.; Yousefpoor, Y.; Ghanbari, H.; Faridi-Majidi, R. Hybrid PCL/Chitosan-PEO Nanofibrous Scaffolds Incorporated with A. Euchroma Extract for Skin Tissue Engineering Application. Carbohydr. Polym. 2022, 278, 118926. [Google Scholar] [CrossRef] [PubMed]

- Yavari Maroufi, L.; Ghorbani, M. Injectable Chitosan-Quince Seed Gum Hydrogels Encapsulated with Curcumin Loaded-Halloysite Nanotubes Designed for Tissue Engineering Application. Int. J. Biol. Macromol. 2021, 177, 485–494. [Google Scholar] [CrossRef] [PubMed]

- Sadeghianmaryan, A.; Naghieh, S.; Alizadeh Sardroud, H.; Yazdanpanah, Z.; Afzal Soltani, Y.; Sernaglia, J.; Chen, X. Extrusion-Based Printing of Chitosan Scaffolds and Their in Vitro Characterization for Cartilage Tissue Engineering. Int. J. Biol. Macromol. 2020, 164, 3179–3192. [Google Scholar] [CrossRef]

- Ma, P.; Wu, W.; Wei, Y.; Ren, L.; Lin, S.; Wu, J. Biomimetic Gelatin/Chitosan/Polyvinyl Alcohol/Nano-Hydroxyapatite Scaffolds for Bone Tissue Engineering. Mater. Des. 2021, 207, 109865. [Google Scholar] [CrossRef]

- Amiryaghoubi, N.; Noroozi Pesyan, N.; Fathi, M.; Omidi, Y. The Design of Polycaprolactone-Polyurethane/Chitosan Composite for Bone Tissue Engineering. Colloids Surf. A Physicochem. Eng. Asp. 2022, 634, 127895. [Google Scholar] [CrossRef]

- Sanchez, A.G.; Prokhorov, E.; Luna-Barcenas, G.; Hernández-Vargas, J.; Román-Doval, R.; Mendoza, S.; Rojas-Chávez, H. Chitosan-Hydroxyapatite-MWCNTs Nanocomposite Patch for Bone Tissue Engineering Applications. Mater. Today Commun. 2021, 28, 102615. [Google Scholar] [CrossRef]

- Shirzaei Sani, I.; Rezaei, M.; Baradar Khoshfetrat, A.; Razzaghi, D. Preparation and Characterization of Polycaprolactone/Chitosan-g-Polycaprolactone/Hydroxyapatite Electrospun Nanocomposite Scaffolds for Bone Tissue Engineering. Int. J. Biol. Macromol. 2021, 182, 1638–1649. [Google Scholar] [CrossRef]

- Hu, J.; Wang, Z.; Miszuk, J.M.; Zhu, M.; Lansakara, T.I.; Tivanski, A.V.; Banas, J.A.; Sun, H. Vanillin-Bioglass Cross-Linked 3D Porous Chitosan Scaffolds with Strong Osteopromotive and Antibacterial Abilities for Bone Tissue Engineering. Carbohydr. Polym. 2021, 271, 118440. [Google Scholar] [CrossRef] [PubMed]

- Scalera, F.; Monteduro, A.G.; Maruccio, G.; Blasi, L.; Gervaso, F.; Mazzotta, E.; Malitesta, C.; Piccirillo, C. Sustainable Chitosan-Based Electrical Responsive Scaffolds for Tissue Engineering Applications. Sustain. Mater. Technol. 2021, 28, e00260. [Google Scholar] [CrossRef]

- Mirmusavi, M.H.; Ahmadian, M.; Karbasi, S. Polycaprolactone-Chitosan/Multi-Walled Carbon Nanotube: A Highly Strengthened Electrospun Nanocomposite Scaffold for Cartilage Tissue Engineering. Int. J. Biol. Macromol. 2022, 209, 1801–1814. [Google Scholar] [CrossRef] [PubMed]

- Esmaeili, J.; Jadbabaee, S.; Far, F.M.; Lukolayeh, M.E.; Kırboğa, K.K.; Rezaei, F.S.; Barati, A. Decellularized Alstroemeria Flower Stem Modified with Chitosan for Tissue Engineering Purposes: A Cellulose/Chitosan Scaffold. Int. J. Biol. Macromol. 2022, 204, 321–332. [Google Scholar] [CrossRef] [PubMed]

- Ali, H.U.; Iqbal, D.N.; Iqbal, M.; Ezzine, S.; Arshad, A.; Zeeshan, R.; Chaudhry, A.A.; Alshawwa, S.Z.; Nazir, A.; Khan, A.F. HPMC Crosslinked Chitosan/Hydroxyapatite Scaffolds Containing Lemongrass Oil for Potential Bone Tissue Engineering Applications. Arab. J. Chem. 2022, 15, 103850. [Google Scholar] [CrossRef]

- Wasupalli, G.K.; Verma, D. Thermosensitive Injectable Hydrogel Based on Chitosan-Polygalacturonic Acid Polyelectrolyte Complexes for Bone Tissue Engineering. Carbohydr. Polym. 2022, 294, 119769. [Google Scholar] [CrossRef]

- Sacco, P.; Borgogna, M.; Travan, A.; Marsich, E.; Paoletti, S.; Asaro, F.; Grassi, M.; Donati, I. Polysaccharide-Based Networks from Homogeneous Chitosan-Tripolyphosphate Hydrogels: Synthesis and Characterization. Biomacromolecules 2014, 15, 3396–3405. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, K.; Du, L.; Cheng, Z.; Zhang, T.; Ding, J.; Li, W.; Xu, B.; Zhu, M. Construction of Chitosan Scaffolds with Controllable Microchannel for Tissue Engineering and Regenerative Medicine. Mater. Sci. Eng. C 2021, 126, 112178. [Google Scholar] [CrossRef]

- Baysan, G.; Colpankan Gunes, O.; Akokay, P.; Husemoglu, R.B.; Ertugruloglu, P.; Ziylan Albayrak, A.; Cecen, B.; Havitcioglu, H. Loofah-Chitosan and Poly (−3-Hydroxybutyrate-Co-3-Hydroxyvalerate) (PHBV) Based Hydrogel Scaffolds for Meniscus Tissue Engineering Applications. Int. J. Biol. Macromol. 2022, 221, 1171–1183. [Google Scholar] [CrossRef]

- Ali, A.; Hasan, A.; Negi, Y.S. Effect of Carbon Based Fillers on Xylan/Chitosan/Nano-HAp Composite Matrix for Bone Tissue Engineering Application. Int. J. Biol. Macromol. 2022, 197, 1–11. [Google Scholar] [CrossRef]

- Narmatha, C.P.; Khaleel, B.S.; Sugantha, K.V. Multifunctional Organic and Inorganic Hybrid Bionanocomposite of Chitosan/Poly(Vinyl Alcohol)/Nanobioactive Glass/Nanocellulose for Bone Tissue Engineering. J. Mech. Behav. Biomed. Mater. 2022, 135, 105427. [Google Scholar] [CrossRef]

- Phatchayawat, P.P.; Khamkeaw, A.; Yodmuang, S.; Phisalaphong, M. 3D Bacterial Cellulose-Chitosan-Alginate-Gelatin Hydrogel Scaffold for Cartilage Tissue Engineering. Biochem. Eng. J. 2022, 184, 108476. [Google Scholar] [CrossRef]

- Christy, P.N.; Basha, S.K.; Kumari, V.S. Nano Zinc Oxide and Nano Bioactive Glass Reinforced Chitosan/Poly(Vinyl Alcohol) Scaffolds for Bone Tissue Engineering Application. Mater. Today Commun. 2022, 31, 103429. [Google Scholar] [CrossRef]

- Leite, M.L.; Anselmi, C.; Soares, I.P.M.; Manso, A.P.; Hebling, J.; Carvalho, R.M.; de Souza Costa, C.A. Calcium Silicate-Coated Porous Chitosan Scaffold as a Cell-Free Tissue Engineering System for Direct Pulp Capping. Dent. Mater. 2022, 38, 1763–1776. [Google Scholar] [CrossRef]

- Shamekhi, M.A.; Mirzadeh, H.; Mahdavi, H.; Rabiee, A.; Mohebbi-Kalhori, D.; Baghaban Eslaminejad, M. Graphene Oxide Containing Chitosan Scaffolds for Cartilage Tissue Engineering. Int. J. Biol. Macromol. 2019, 127, 396–405. [Google Scholar] [CrossRef]

- Kashi, M.; Baghbani, F.; Moztarzadeh, F.; Mobasheri, H.; Kowsari, E. Green Synthesis of Degradable Conductive Thermosensitive Oligopyrrole/Chitosan Hydrogel Intended for Cartilage Tissue Engineering. Int. J. Biol. Macromol. 2018, 107, 1567–1575. [Google Scholar] [CrossRef]

- Vishwanath, V.; Pramanik, K.; Biswas, A. Optimization and Evaluation of Silk Fibroin-Chitosan Freeze-Dried Porous Scaffolds for Cartilage Tissue Engineering Application. J. Biomater. Sci. Polym. Ed. 2016, 27, 657–674. [Google Scholar] [CrossRef]

- Kar, S.; Kaur, T.; Thirugnanam, A. Microwave-Assisted Synthesis of Porous Chitosan–Modified Montmorillonite–Hydroxyapatite Composite Scaffolds. Int. J. Biol. Macromol. 2016, 82, 628–636. [Google Scholar] [CrossRef]

- Tithito, T.; Suntornsaratoon, P.; Charoenphandhu, N.; Thongbunchoo, J.; Krishnamra, N.; Tang, I.M.; Pon-On, W. Fabrication of Biocomposite Scaffolds Made with Modified Hydroxyapatite Inclusion of Chitosan-Grafted-Poly(Methyl Methacrylate) for Bone Tissue Engineering. Biomed. Mater. 2019, 14, 025013. [Google Scholar] [CrossRef]

- Fiqrianti, I.; Widiyanti, P.; Manaf, M.; Savira, C.; Cahyani, N.; Bella, F. Poly-L-Lactic Acid (PLLA)-Chitosan-Collagen Electrospun Tube for Vascular Graft Application. JFB 2018, 9, 32. [Google Scholar] [CrossRef]

- Pezeshki-Modaress, M.; Zandi, M.; Rajabi, S. Tailoring the Gelatin/Chitosan Electrospun Scaffold for Application in Skin Tissue Engineering: An in Vitro Study. Prog. Biomater. 2018, 7, 207–218. [Google Scholar] [CrossRef] [PubMed]

- Jafari, A.; Hassanajili, S.; Azarpira, N.; Bagher Karimi, M.; Geramizadeh, B. Development of Thermal-Crosslinkable Chitosan/Maleic Terminated Polyethylene Glycol Hydrogels for Full Thickness Wound Healing: In Vitro and in Vivo Evaluation. Eur. Polym. J. 2019, 118, 113–127. [Google Scholar] [CrossRef]

- Madni, A.; Khan, R.; Ikram, M.; Naz, S.S.; Khan, T.; Wahid, F. Fabrication and Characterization of Chitosan–Vitamin C–Lactic Acid Composite Membrane for Potential Skin Tissue Engineering. Int. J. Polym. Sci. 2019, 2019, 4362395. [Google Scholar] [CrossRef]

- Zhang, N.; Gao, T.; Wang, Y.; Liu, J.; Zhang, J.; Yao, R.; Wu, F. Modulating Cationicity of Chitosan Hydrogel to Prevent Hypertrophic Scar Formation during Wound Healing. Int. J. Biol. Macromol. 2020, 154, 835–843. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Mao, J.; Guo, Z.; Hu, Y.; Wang, S. Polyvinyl Alcohol/Carboxymethyl Chitosan Hydrogel Loaded with Silver Nanoparticles Exhibited Antibacterial and Self-Healing Properties. Int. J. Biol. Macromol. 2022, 220, 211–222. [Google Scholar] [CrossRef]

- Chang, G.; Dang, Q.; Liu, C.; Wang, X.; Song, H.; Gao, H.; Sun, H.; Zhang, B.; Cha, D. Carboxymethyl Chitosan and Carboxymethyl Cellulose Based Self-Healing Hydrogel for Accelerating Diabetic Wound Healing. Carbohydr. Polym. 2022, 292, 119687. [Google Scholar] [CrossRef]

- Mishra, A.H.; Mishra, D. Evidences of Biomimetic and Nonantibiotic Characteristics of the Zinc–Carboxymethyl Chitosan–Genipin Organometallic Complex and Its Biocompatibility Aspects. Biomacromolecules 2020, 21, 688–700. [Google Scholar] [CrossRef]

- Liu, J.; Yang, B.; Li, M.; Li, J.; Wan, Y. Enhanced Dual Network Hydrogels Consisting of Thiolated Chitosan and Silk Fibroin for Cartilage Tissue Engineering. Carbohydr. Polym. 2020, 227, 115335. [Google Scholar] [CrossRef]

- Janarthanan, G.; Tran, H.N.; Cha, E.; Lee, C.; Das, D.; Noh, I. 3D Printable and Injectable Lactoferrin-Loaded Carboxymethyl Cellulose-Glycol Chitosan Hydrogels for Tissue Engineering Applications. Mater. Sci. Eng. C 2020, 113, 111008. [Google Scholar] [CrossRef]

- Li, T.; Song, X.; Weng, C.; Wang, X.; Gu, L.; Gong, X.; Wei, Q.; Duan, X.; Yang, L.; Chen, C. Silk Fibroin/Carboxymethyl Chitosan Hydrogel with Tunable Biomechanical Properties Has Application Potential as Cartilage Scaffold. Int. J. Biol. Macromol. 2019, 137, 382–391. [Google Scholar] [CrossRef]

- Rui, Q.; Gao, J.; Yin, Z.-Z.; Li, J.; Cai, W.; Wu, D.; Kong, Y. A Biodegradable PH and Glutathione Dual-Triggered Drug Delivery System Based on Mesoporous Silica, Carboxymethyl Chitosan and Oxidized Pullulan. Int. J. Biol. Macromol. 2022, 224, 1294–1302. [Google Scholar] [CrossRef] [PubMed]

- Yao, S.; Chen, S.; Wang, R.; Zhang, K.; Lin, X.; Mai, S. Antibacterial Activity and Bonding Performance of Carboxymethyl Chitosan–Containing Dental Adhesive System. Int. J. Adhes. Adhes. 2022, 119, 103269. [Google Scholar] [CrossRef]

- Yin, H.; Song, P.; Chen, X.; Huang, Q.; Huang, H. A Self-Healing Hydrogel Based on Oxidized Microcrystalline Cellulose and Carboxymethyl Chitosan as Wound Dressing Material. Int. J. Biol. Macromol. 2022, 221, 1606–1617. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Chen, Y.; Han, J.; Mo, J.; Dong, P.; Zhuo, Y.; Feng, Y. Biocompatiable Silk Fibroin/Carboxymethyl Chitosan/Strontium Substituted Hydroxyapatite/Cellulose Nanocrystal Composite Scaffolds for Bone Tissue Engineering. Int. J. Biol. Macromol. 2019, 136, 1247–1257. [Google Scholar] [CrossRef]

- Kashyap, P.K.; Chauhan, S.; Negi, Y.S.; Goel, N.K.; Rattan, S. Biocompatible Carboxymethyl Chitosan-Modified Glass Ionomer Cement with Enhanced Mechanical and Anti-Bacterial Properties. Int. J. Biol. Macromol. 2022, 223, 1506–1520. [Google Scholar] [CrossRef]

- Xu, C.; Guan, S.; Wang, S.; Gong, W.; Liu, T.; Ma, X.; Sun, C. Biodegradable and Electroconductive Poly(3,4-Ethylenedioxythiophene)/Carboxymethyl Chitosan Hydrogels for Neural Tissue Engineering. Mater. Sci. Eng. C 2018, 84, 32–43. [Google Scholar] [CrossRef]

- Hao, Y.; Zhao, W.; Zhang, H.; Zheng, W.; Zhou, Q. Carboxymethyl Chitosan-Based Hydrogels Containing Fibroblast Growth Factors for Triggering Diabetic Wound Healing. Carbohydr. Polym. 2022, 287, 119336. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, Y.; Tao, H.; Jin, L.; Wan, Z.; Dai, F.; Xiang, W.; Deng, H. Carboxymethyl Chitosan/Sodium Alginate-Based Micron-Fibers Fabricated by Emulsion Electrospinning for Periosteal Tissue Engineering. Mater. Des. 2020, 194, 108849. [Google Scholar] [CrossRef]

- Liu, T.; Feng, Z.; Li, Z.; Lin, Z.; Chen, L.; Li, B.; Chen, Z.; Wu, Z.; Zeng, J.; Zhang, J.; et al. Carboxymethyl Chitosan/Sodium Alginate Hydrogels with Polydopamine Coatings as Promising Dressings for Eliminating Biofilm and Multidrug-Resistant Bacteria Induced Wound Healing. Int. J. Biol. Macromol. 2022, in press. [Google Scholar] [CrossRef]

- Osorio Echavarría, J.; Gómez Vanegas, N.A.; Orozco, C.P.O. Chitosan/Carboxymethyl Cellulose Wound Dressings Supplemented with Biologically Synthesized Silver Nanoparticles from the Ligninolytic Fungus Anamorphous Bjerkandera Sp. R1. Heliyon 2022, 8, e10258. [Google Scholar] [CrossRef]

- Maji, S.; Agarwal, T.; Das, J.; Maiti, T.K. Development of Gelatin/Carboxymethyl Chitosan/Nano-Hydroxyapatite Composite 3D Macroporous Scaffold for Bone Tissue Engineering Applications. Carbohydr. Polym. 2018, 189, 115–125. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.-T.; Lu, T.-W.; Chen, C.-H.; Lu, K.-Y.; Mi, F.-L. Development of Nanocomposite Scaffolds Based on Biomineralization of N,O-Carboxymethyl Chitosan/Fucoidan Conjugates for Bone Tissue Engineering. Int. J. Biol. Macromol. 2018, 120, 2335–2345. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Liu, J.; Lu, D.-Q.; Chen, L.; Yang, R.; Liu, D.; Zhang, B. Diselenide-Crosslinked Carboxymethyl Chitosan Nanoparticles for Doxorubicin Delivery: Preparation and in Vivo Evaluation. Carbohydr. Polym. 2022, 292, 119699. [Google Scholar] [CrossRef] [PubMed]

- Medeiros Borsagli, F.G.L.; de Souza, A.J.M.; Paiva, A.E. Ecofriendly Multifunctional Thiolated Carboxymethyl Chitosan-Based 3D Scaffolds with Luminescent Properties for Skin Repair and Theragnostic of Tissue Regeneration. Int. J. Biol. Macromol. 2020, 165, 3051–3064. [Google Scholar] [CrossRef] [PubMed]

- Murugan, E.; Akshata, C.R.; Ilangovan, R.; Mohan, M. Evaluation of Quaternization Effect on Chitosan-HAP Composite for Bone Tissue Engineering Application. Colloids Surf. B Biointerfaces 2022, 218, 112767. [Google Scholar] [CrossRef]

- Zhou, M.; Liao, J.; Li, G.; Yu, Z.; Xie, D.; Zhou, H.; Wang, F.; Ren, Y.; Xu, R.; Dai, Y.; et al. Expandable Carboxymethyl Chitosan/Cellulose Nanofiber Composite Sponge for Traumatic Hemostasis. Carbohydr. Polym. 2022, 294, 119805. [Google Scholar] [CrossRef]

- Yu, N.; Li, Y.; Wang, Y.; Xu, H.; Ye, F.; Fu, Q. Healing Effect of Carboxymethyl Chitosan-Plantamajoside Hydrogel on Burn Wound Skin. Burns 2022, 48, 902–914. [Google Scholar] [CrossRef]

- Ghahremanzadeh, F.; Alihosseini, F.; Semnani, D. Investigation and Comparison of New Galactosylation Methods on PCL/Chitosan Scaffolds for Enhanced Liver Tissue Engineering. Int. J. Biol. Macromol. 2021, 174, 278–288. [Google Scholar] [CrossRef]

- Shaheen, T.I.; Abdelhameed, M.F.; Zaghloul, S.; Montaser, A.S. In Vivo Assessment of the Durable, Green and in Situ Bio-Functional Cotton Fabrics Based Carboxymethyl Chitosan Nanohybrid for Wound Healing Application. Int. J. Biol. Macromol. 2022, 209, 485–497. [Google Scholar] [CrossRef]

- Liu, H.; Mao, J.; Yao, K.; Yang, G.; Cui, L.; Cao, Y. A Study on a Chitosan-Gelatin-Hyaluronic Acid Scaffold as Artificial Skin in Vitro and Its Tissue Engineering Applications. J. Biomater. Sci. Polym. Ed. 2004, 15, 25–40. [Google Scholar] [CrossRef]

- Jin, Z.; Hu, G.; Zhao, K. Mannose-Anchored Quaternized Chitosan/Thiolated Carboxymethyl Chitosan Composite NPs as Mucoadhesive Carrier for Drug Delivery. Carbohydr. Polym. 2022, 283, 119174. [Google Scholar] [CrossRef] [PubMed]

- Hasan, A.; Waibhaw, G.; Saxena, V.; Pandey, L.M. Nano-Biocomposite Scaffolds of Chitosan, Carboxymethyl Cellulose and Silver Nanoparticle Modified Cellulose Nanowhiskers for Bone Tissue Engineering Applications. Int. J. Biol. Macromol. 2018, 111, 923–934. [Google Scholar] [CrossRef] [PubMed]

- Cheng, F.; Xu, L.; Dai, J.; Yi, X.; He, J.; Li, H. N, O-Carboxymethyl Chitosan/Oxidized Cellulose Composite Sponge Containing ε-Poly-l-Lysine as a Potential Wound Dressing for the Prevention and Treatment of Postoperative Adhesion. Int. J. Biol. Macromol. 2022, 209, 2151–2164. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Gu, Z.; Li, W.; Guo, L.; Wang, L.; Guo, L.; Ma, S.; Han, B.; Chang, J. PH-Sensitive O-Carboxymethyl Chitosan/Sodium Alginate Nanohydrogel for Enhanced Oral Delivery of Insulin. Int. J. Biol. Macromol. 2022, 223, 433–445. [Google Scholar] [CrossRef]

- Sharifi, F.; Atyabi, S.M.; Norouzian, D.; Zandi, M.; Irani, S.; Bakhshi, H. Polycaprolactone/Carboxymethyl Chitosan Nanofibrous Scaffolds for Bone Tissue Engineering Application. Int. J. Biol. Macromol. 2018, 115, 243–248. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, L.; Li, H.; Xia, L.; Hu, H.; Wang, S.; Liu, C.; Chi, J.; Yang, Y.; Song, F.; et al. Preparation, Biocompatibility, and Wound Healing Effects of O-Carboxymethyl Chitosan Nonwoven Fabrics in Partial-Thickness Burn Model. Carbohydr. Polym. 2022, 280, 119032. [Google Scholar] [CrossRef]

- Yang, Y.; Campbell Ritchie, A.; Everitt, N.M. Recombinant Human Collagen/Chitosan-Based Soft Hydrogels as Biomaterials for Soft Tissue Engineering. Mater. Sci. Eng. C 2021, 121, 111846. [Google Scholar] [CrossRef]

- Shakir, M.; Jolly, R.; Khan, M.S.; Iram, N.; Sharma, T.K.; Al-Resayes, S.I. Synthesis and Characterization of a Nano-Hydroxyapatite/Chitosan/Polyethylene Glycol Nanocomposite for Bone Tissue Engineering: Nano-hydroxyapatite/chitosan/polyethylene glycol nanocomposite. Polym. Adv. Technol. 2015, 26, 41–48. [Google Scholar] [CrossRef]

- Chi, J.; Jiang, Z.; Chen, X.; Peng, Y.; Liu, W.; Han, B.; Han, B. Studies on Anti-Hepatocarcinoma Effect, Pharmacokinetics and Tissue Distribution of Carboxymethyl Chitosan Based Norcantharidin Conjugates. Carbohydr. Polym. 2019, 226, 115297. [Google Scholar] [CrossRef]

- Rao, K.M.; Sudhakar, K.; Suneetha, M.; Won, S.Y.; Han, S.S. Fungal-Derived Carboxymethyl Chitosan Blended with Polyvinyl Alcohol as Membranes for Wound Dressings. Int. J. Biol. Macromol. 2021, 190, 792–800. [Google Scholar] [CrossRef]

- Xie, M.; Zeng, Y.; Wu, H.; Wang, S.; Zhao, J. Multifunctional Carboxymethyl Chitosan/Oxidized Dextran/Sodium Alginate Hydrogels as Dressing for Hemostasis and Closure of Infected Wounds. Int. J. Biol. Macromol. 2022, 219, 1337–1350. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Lan, Y.; Guo, H.; Cheng, L.; Fan, J.; Cai, X.; Zhang, L.; Chen, R.; Zhou, H. Ophthalmic Drug-Loaded N,O-Carboxymethyl Chitosan Hydrogels: Synthesis, in Vitro and in Vivo Evaluation. Acta Pharm. Sin. 2010, 31, 1625–1634. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).