Relationship between Dough Properties and Baking Performance of Panned Bread: The Function of Maltodextrins and Natural Gums

Abstract

:1. Introduction

2. Results and Discussion

2.1. Pasting Properties

2.2. Textural Properties of Flour Mixes

2.3. Dough Mixing Properties

2.4. Wheat Flour Dough Extensibility

2.5. Solvent Retention Capacity (SRC)

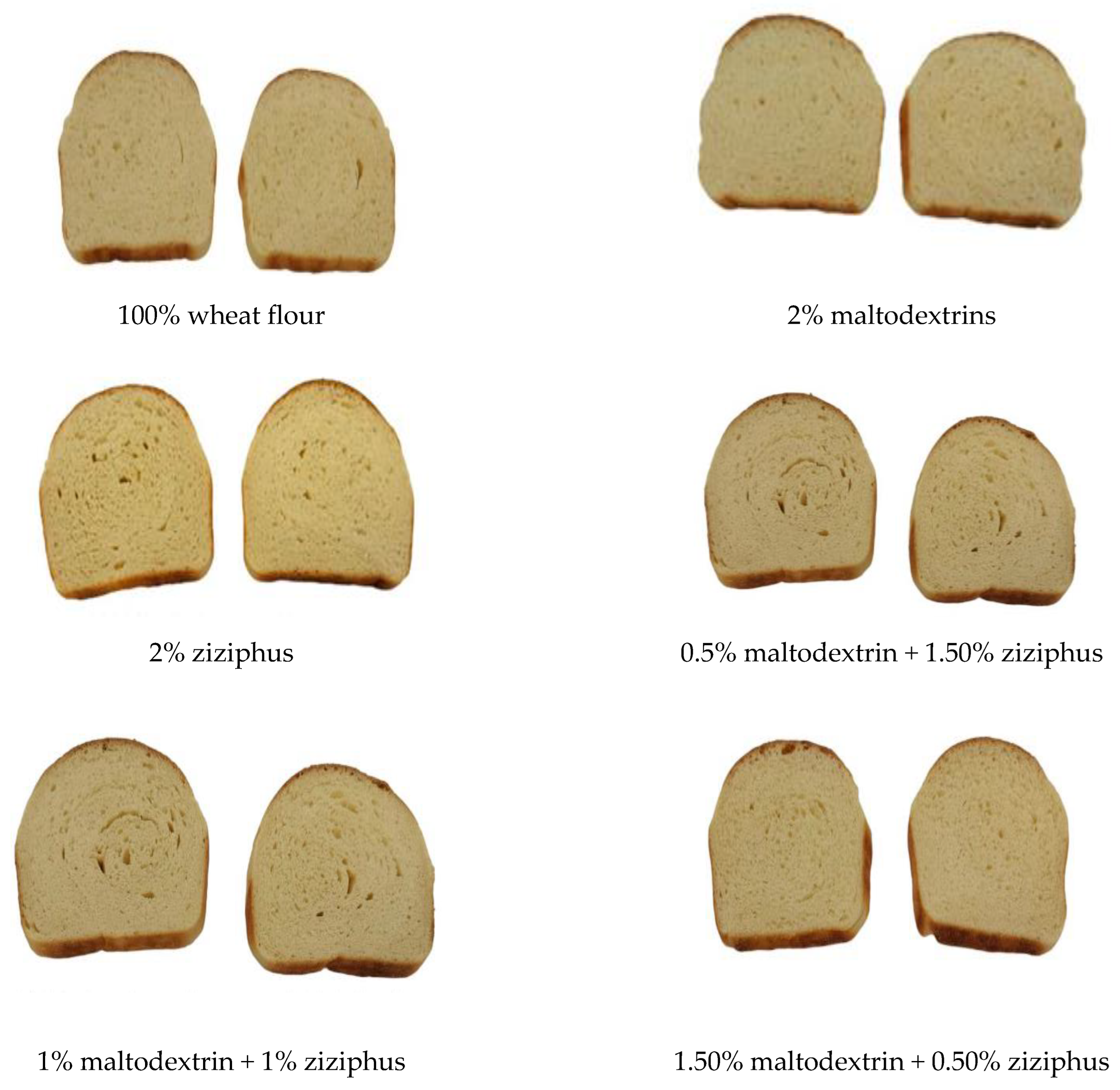

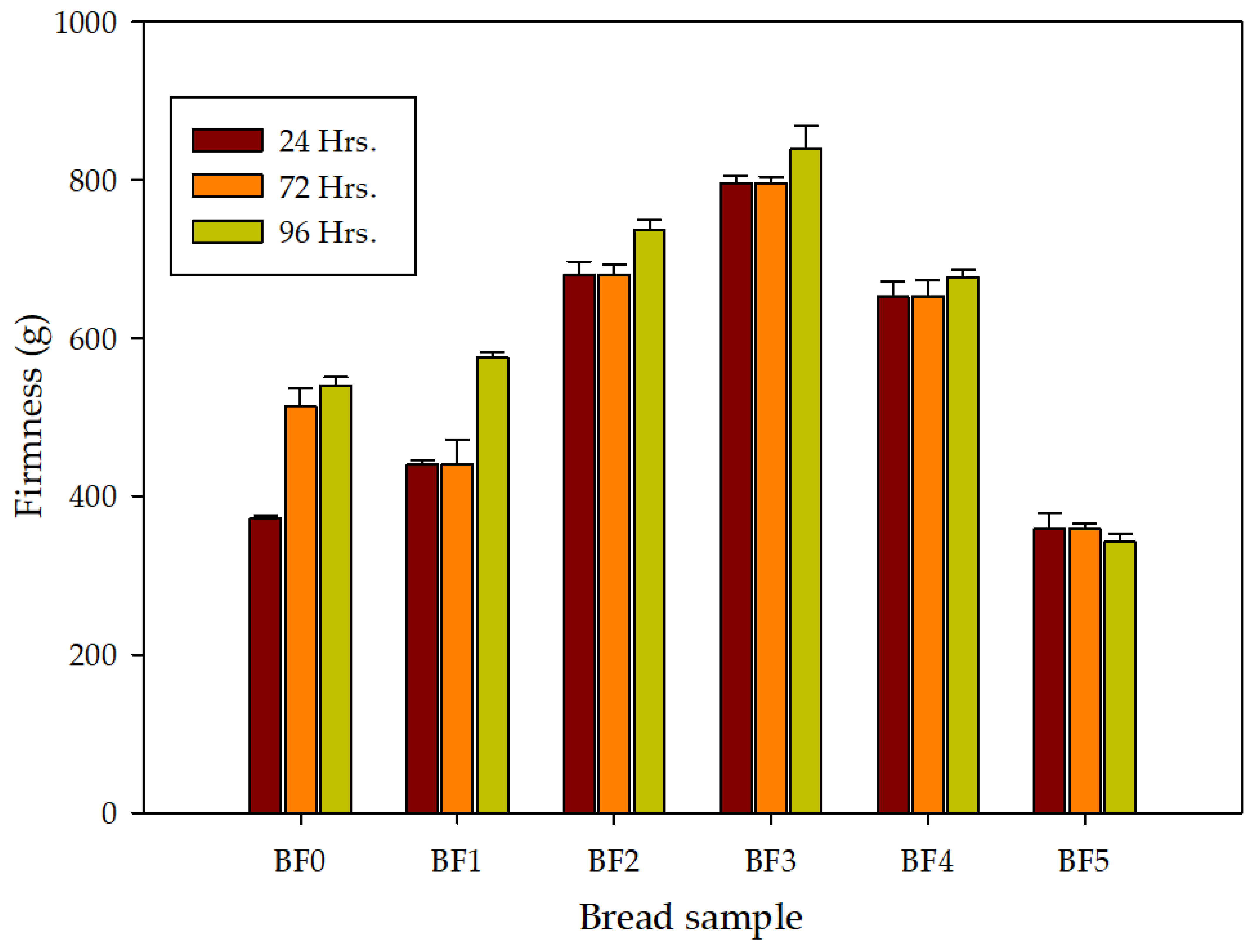

2.6. Bread Color, Volume and Firmness Evaluation

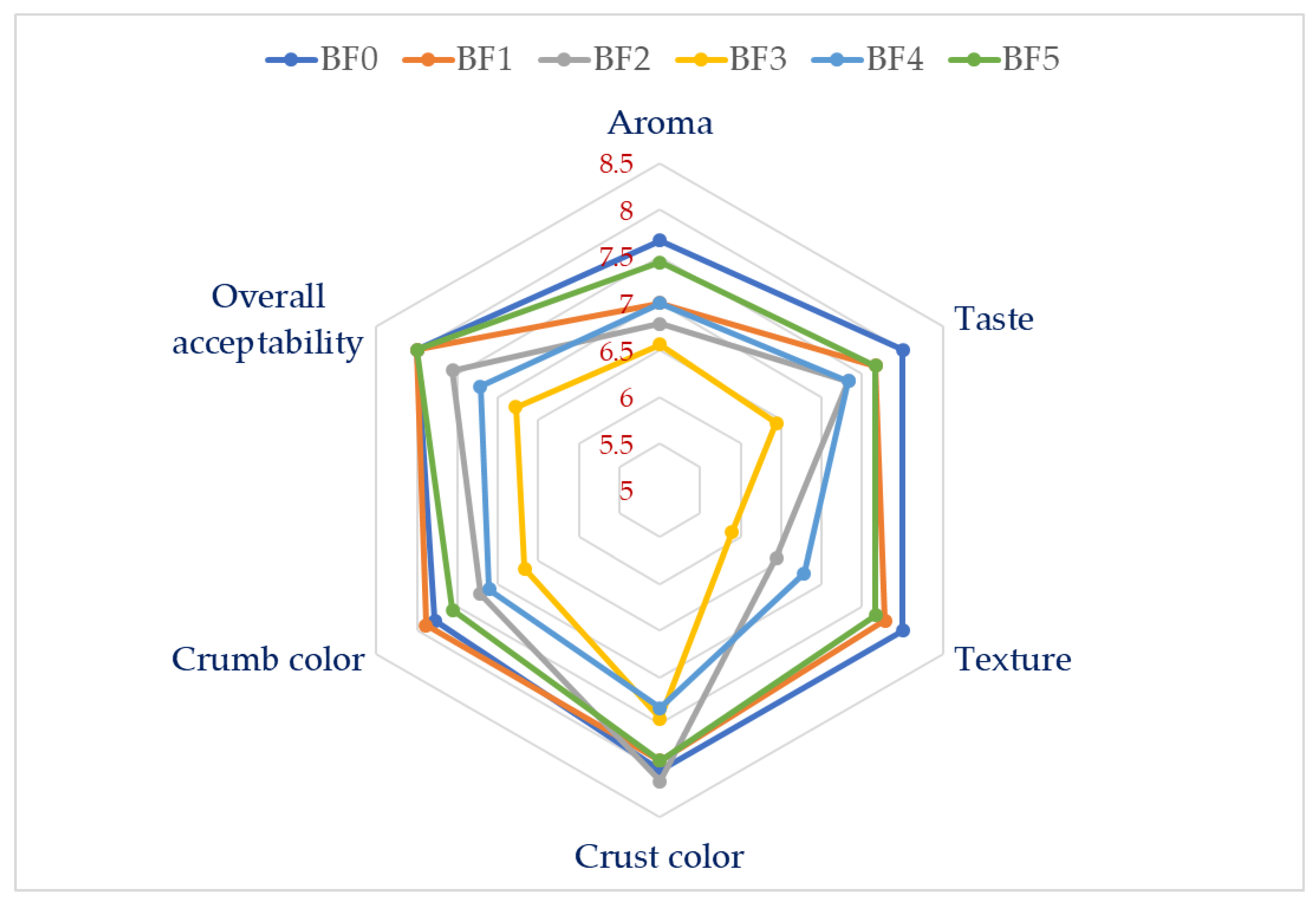

2.7. Bread Sensory Evaluation

3. Materials and Methods

3.1. Materials

3.2. Methods

3.2.1. Ziziphus Gum Extraction

3.2.2. Preparation of Flour Mixes

3.2.3. Solvent Retention Capacity (SRC)

3.2.4. Pasting Behavior of Flour Mixes

3.2.5. Gel Texture

3.2.6. Dough Mixing Properties Using DoughLab

3.2.7. Dough Extensibility

3.2.8. Bread Baking Procedures

3.2.9. Bread Firmness after Storage

3.2.10. Crumb Color of Bread

3.2.11. Sensory Evaluation of Breads

3.2.12. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Collar, C.; Andreu, P.; Martınez, J.; Armero, E. Optimization of hydrocolloid addition to improve wheat bread dough functionality: A response surface methodology study. Food Hydrocoll. 1999, 13, 467–475. [Google Scholar] [CrossRef]

- Lazaridou, A.; Duta, D.; Papageorgiou, M.; Belc, N.; Biliaderis, C.G. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Linlaud, N.; Puppo, M.; Ferrero, C. Effect of hydrocolloids on water absorption of wheat flour and farinograph and textural characteristics of dough. Cereal Chem. 2009, 86, 376–382. [Google Scholar] [CrossRef]

- Das, L.; Raychaudhuri, U.; Chakraborty, R. Effects of hydrocolloids as texture improver in coriander bread. J. Food Sci. Technol. 2015, 52, 3671–3680. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bárcenas, M.E.; Rosell, C.M. Different approaches for increasing the shelf life of partially baked bread: Low temperatures and hydrocolloid addition. Food Chem. 2007, 100, 1594–1601. [Google Scholar] [CrossRef]

- Davidou, S.; Le Meste, M.; Debever, E.; Bekaert, D. A contribution to the study of staling of white bread: Effect of water and hydrocolloid. Food Hydrocoll. 1996, 10, 375–383. [Google Scholar] [CrossRef]

- Rosell, C.M.; Rojas, J.A.; De Barber, C.B. Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocoll. 2001, 15, 75–81. [Google Scholar] [CrossRef]

- Shittu, T.A.; Aminu, R.A.; Abulude, E.O. Functional effects of xanthan gum on composite cassava-wheat dough and bread. Food Hydrocoll. 2009, 23, 2254–2260. [Google Scholar] [CrossRef]

- Rojas, J.A.; Rosell, C.M.; De Barber, C.B. Pasting properties of different wheat flour-hydrocolloid systems. Food Hydrocoll. 1999, 13, 27–33. [Google Scholar] [CrossRef]

- Delfanian, M.; Esmaeilzadeh Kenari, R.; Sahari, M.A. Utilization of Jujube fruit (Ziziphus mauritiana Lam.) extracts as natural antioxidants in stability of frying oil. Int. J. Food Prop. 2016, 19, 789–801. [Google Scholar] [CrossRef]

- Obeed, R.; Harhash, M.; Abdel-Mawgood, A. Fruit properties and genetic diversity of five ber (Ziziphus mauritiana Lamk.) cultivars. Pak. J. Biol. Sci. 2008, 11, 888–893. [Google Scholar] [CrossRef] [Green Version]

- Muchuweti, M.; Zenda, G.; Ndhlala, A.R.; Kasiyamhuru, A. Sugars, organic acid and phenolic compounds of Ziziphus mauritiana fruit. Eur. Food Res. Technol. 2005, 221, 570–574. [Google Scholar] [CrossRef]

- Ray, P.; Chatterjee, S.; Saha, P. Screening of polysaccharides from fruit pulp of Ziziphus mauritiana L. and Artocarpus heterophyllus L. as natural mucoadhesives. Future J. Pharm. Sci. 2021, 7, 1–10. [Google Scholar] [CrossRef]

- Lee, H.B.; Kim, S.Y. Studies on the changes of chemical components of dried jujube (Zizyphus jujuba Miller) during storage. Korean J. Agric. Sci. 1988, 15, 95–113. [Google Scholar]

- Alamri, M.S.; Mohamed, A.A.; Hussain, S.; Ibraheem, M.A.; Qasem, A.A.A.; Shamlan, G.; Hakeem, M.J.; Ababtain, I.A. Functionality of Cordia and Ziziphus Gums with Respect to the Dough Properties and Baking Performance of Stored Pan Bread and Sponge Cakes. Foods 2022, 11, 460. [Google Scholar] [CrossRef]

- Mohamed, A.; Hussain, S.; Alamri, M.S.; Ibraheem, M.A.; Qasem, A.A.A.; Ababtain, I.A. Physicochemical Properties of Starch Binary Mixtures with Cordia and Ziziphus Gums. Processes 2022, 10, 180. [Google Scholar] [CrossRef]

- Wang, Y.J.; Wang, L. Structures and properties of commercial maltodextrins from corn, potato, and rice starches. Starch-Stärke 2000, 52, 296–304. [Google Scholar] [CrossRef]

- Wang, Y.-J.; Jane, J. Correlation between glass transition temperature and starch retrogradation in the presence of sugars and maltodextrins. Cereal Chem. 1994, 71, 527–531. [Google Scholar]

- Pycia, K.; Gryszkin, A.; Berski, W.; Juszczak, L. The influence of chemically modified potato maltodextrins on stability and rheological properties of model oil-in-water emulsions. Polymers 2018, 10, 67. [Google Scholar] [CrossRef] [Green Version]

- Smits, A.; Kruiskamp, P.; Van Soest, J.; Vliegenthart, J. The influence of various small plasticisers and malto-oligosaccharides on the retrogradation of (partly) gelatinised starch. Carbohydr. Polym. 2003, 51, 417–424. [Google Scholar] [CrossRef] [Green Version]

- Defloor, I.; Delcour, J.A. Impact of maltodextrins and antistaling enzymes on the differential scanning calorimetry staling endotherm of baked bread doughs. J. Agric. Food Chem. 1999, 47, 737–741. [Google Scholar] [CrossRef] [PubMed]

- Palacios, H.R.; Schwarz, P.B.; D’Appolonia, B.L. Effect of α-amylases from different sources on the retrogradation and recrystallization of concentrated wheat starch gels: Relationship to bread staling. J. Agric. Food Chem. 2004, 52, 5978–5986. [Google Scholar] [CrossRef] [PubMed]

- Vedantam, S.K.; Sagili, J.L.; Dikkala, P.K.; Sridhar, K. Functional, thermal, pasting, and rheological properties of gluten-free maize composite flour: Effect of moth bean flour and hydrocolloid addition. J. Food Process. Preserv. 2021, 45, e16104. [Google Scholar] [CrossRef]

- Alamri, M.; Mohamed, A.; Hussain, S.; Xu, J. Effect of okra extract on properties of wheat, corn and rice starches. J. Food Agric. Environ. 2012, 10, 217–222. [Google Scholar]

- Sudhakar, V.; Singhal, R.S.; Kulkarni, P.R. Studies on starch-hydrocolloid interactions: Effect of salts. Food Chem. 1995, 53, 405–408. [Google Scholar] [CrossRef]

- Alloncle, M.; Lefebvre, J.; Llamas, G.; Doublier, J. A rheological characterization of cereal starch-galactomannan mixtures. Cereal Chem. 1989, 66, 90–93. [Google Scholar]

- Alam, F.; Siddiqui, A.; Lutfi, Z.; Hasnain, A. Effect of different hydrocolloids on gelatinization behaviour of hard wheat flour. Trakia J. Sci. 2009, 7, 1–6. [Google Scholar]

- Katsuta, K.; Nishimura, A.; Miura, M. Effects of saccharides on stabilities of rice starch gels. 2. Oligosaccharides. Food Hydrocoll. 1992, 6, 399–408. [Google Scholar] [CrossRef]

- Luo, D.; Li, Y.; Xu, B.; Ren, G.; Li, P.; Li, X.; Han, S.; Liu, J. Effects of inulin with different degree of polymerization on gelatinization and retrogradation of wheat starch. Food Chem. 2017, 229, 35–43. [Google Scholar] [CrossRef]

- Yildiz, Ö.; Yurt, B.; Baştürk, A.; Toker, Ö.S.; Yilmaz, M.T.; Karaman, S.; Dağlıoğlu, O. Pasting properties, texture profile and stress–relaxation behavior of wheat starch/dietary fiber systems. Food Res. Int. 2013, 53, 278–290. [Google Scholar] [CrossRef]

- Simsek, S. Application of xanthan gum for reducing syruping in refrigerated doughs. Food Hydrocoll. 2009, 23, 2354–2358. [Google Scholar] [CrossRef]

- Teng, Y.; Liu, C.; Bai, J.; Liang, J. Mixing, tensile and pasting properties of wheat flour mixed with raw and enzyme treated rice bran. J. Food Sci. Technol. 2015, 52, 3014–3021. [Google Scholar] [CrossRef] [Green Version]

- Gaines, C. Collaborative study of methods for solvent retention capacity profiles (AACC Method 56-11). Cereal Foods World 2000, 45, 303–306. [Google Scholar]

- Guttieri, M.J.; Becker, C.; Souza, E.J. Application of wheat meal solvent retention capacity tests within soft wheat breeding populations. Cereal Chem. 2004, 81, 261–266. [Google Scholar] [CrossRef]

- Maleki, G.; MilaNi, J.M. Effect of guar gum, xanthan gum, CMC and HPMC on dough rhealogy and physical properties of Barbari bread. Food Sci. Technol. Res. 2013, 19, 353–358. [Google Scholar] [CrossRef] [Green Version]

- Bell, D.A. Methylcellulose as a structure enhancer in bread baking. Cereal Foods World 1990, 35, 1001–1006. [Google Scholar]

- Filipčev, B.; Lević, L.; Bodroža-Solarov, M.; Mišljenović, N.; Koprivica, G. Quality characteristics and antioxidant properties of breads supplemented with sugar beet molasses-based ingredients. Int. J. Food Prop. 2010, 13, 1035–1053. [Google Scholar] [CrossRef]

- AACC. Approved Methods of the American Association of Cereal Chemists; Amer Assn of Cereal Chemists: Saint Paul, MI, USA, 2000; Volume 1. [Google Scholar]

- Sharma, P.; Gujral, H.S. Cookie making behavior of wheat–barley flour blends and effects on antioxidant properties. LWT-Food Sci. Technol. 2014, 55, 301–307. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Singh, N. Some properties of corn starches II: Physicochemical, gelatinization, retrogradation, pasting and gel textural properties. Food Chem. 2007, 101, 1499–1507. [Google Scholar] [CrossRef]

- Dangi, P.; Chaudhary, N.; Khatkar, B. Rheological and microstructural characteristics of low molecular weight glutenin subunits of commercial wheats. Food Chem. 2019, 297, 124989. [Google Scholar] [CrossRef]

- Al-Saleh, A.; Brennan, C.S. Bread wheat quality: Some physical, chemical and rheological characteristics of Syrian and English bread wheat samples. Foods 2012, 1, 3–17. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alamri, M.S. Okra-gum fortified bread: Formulation and quality. J. Food Sci. Technol. 2014, 51, 2370–2381. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hussain, S.; Alamri, M.S.; Mohamed, A.A.; Ibraheem, M.A.; Qasem, A.A.A.; Shamlan, G.; Ababtain, I.A. Exploring the Role of Acacia (Acacia seyal) and Cactus (Opuntia ficus-indica) Gums on the Dough Performance and Quality Attributes of Breads and Cakes. Foods 2022, 11, 1208. [Google Scholar] [CrossRef] [PubMed]

| Mixes | PV (cP) | BD (cP) | FV (cP) | SB (cP) | PT (°C) |

|---|---|---|---|---|---|

| * BF | 2694.00 ± 22.72 a | 983.67 ± 88.23 a | 3105.67 ± 42.10 a | 1395.33 ± 67.53 a | 70.48 ± 0.94 b |

| BF1 | 2522.33 ± 11.55 c | 969.00 ± 15.72 a | 2929.00 ± 12.29 d | 1375.67 ± 17.79 a | 81.32 ± 8.98 a |

| BF2 | 2609.67 ± 36.46 b | 1043.33 ± 17.62 a | 2990.33 ± 31.79 b | 1424.00 ± 21.17 a | 67.17 ± 0.46 b |

| BF3 | 2576.67 ± 12.10 bc | 1013.33 ± 51.98 a | 2943.33 ± 17.01 cd | 1380.00 ± 50.41 a | 67.37 ± 0.54 b |

| BF4 | 2574.00 ± 50.71 bc | 962.00 ± 78.58 a | 2975.33 ± 14.74 bc | 1363.33 ± 81.40 a | 68.27 ± 0.89 b |

| BF5 | 2569.33 ± 24.58 bc | 1007.33 ± 26.01 a | 2964.67 ± 6.81 bcd | 1402.67 ± 8.39 a | 67.70 ± 0.05 b |

| Hardness (g) | Gumminess (g) | Chewiness (g) | Springiness (mm) | Cohesiveness | Adhesiveness (mJ) | |

|---|---|---|---|---|---|---|

| * BF | 85.00 ± 7.55 a | 45.51 ± 2.36 a | 516.43 ± 149.84 a | 11.27 ± 2.71 a | 0.54 ± 0.02 a | 0.73 ± 0.47 a |

| BF1 | 77.33 ± 6.11 ab | 39.45 ± 3.42 b | 388.07 ± 35.67 b | 9.83 ± 0.06 a | 0.51 ± 0.01 ab | 0.93 ± 0.06 a |

| BF2 | 70.33 ± 1.53 bc | 34.21 ± 1.33 c | 333.05 ± 16.02 b | 9.73 ± 0.12 a | 0.49 ± 0.03 b | 1.07 ± 0.05 a |

| BF3 | 70.67 ± 2.08 bc | 34.41 ± 1.82 c | 337.51 ± 27.26 b | 9.80 ± 0.26 a | 0.49 ± 0.01 b | 0.97 ± 0.23 a |

| BF4 | 73.67 ± 4.04 bc | 37.80 ± 1.76 bc | 378.03 ± 21.86 b | 10.00 ± 0.36 a | 0.51 ± 0.01 ab | 0.90 ± 0.30 a |

| BF5 | 67.33 ± 6.11 c | 33.68 ± 3.52 c | 337.00 ± 38.27 b | 10.00 ± 0.10 a | 0.50 ± 0.02 b | 0.90 ± 0.20 a |

| WA as Is (%) | DDT (min) | Stability (min) | Softening (FU) | MTI (FU) | FQN (mm) | |

|---|---|---|---|---|---|---|

| * BF | 56.20 ± 1.21 c | 1.70 ± 0.20 c | 5.93 ± 0.98 bc | 81.67 ± 15.27 bc | 35.00 ± 5.00 b | 63.43 ± 2.65 ab |

| BF1 | 59.00 ± 0.00 a | 6.43 ± 0.65 a | 9.93 ± 0.32 a | 73.33 ± 2.88 c | 38.33 ± 5.77 b | 64.47 ± 2.30 a |

| BF2 | 59.00 ± 0.00 a | 4.33 ± 0.37 ab | 5.80 ± 0.34 c | 103.33 ± 17.55 ab | 60.00 ± 13.22 ab | 55.07 ± 4.86 c |

| BF3 | 58.00 ± 0.00 b | 4.77 ± 0.25 ab | 6.20 ± 0.34 bc | 111.67 ± 7.63 a | 66.67 ± 5.77 a | 52.43 ± 3.01 c |

| BF4 | 57.87 ± 0.11 b | 3.93 ± 1.74 abc | 6.50 ± 0.40 bc | 108.33 ± 12.58 a | 50.00 ± 21.79 ab | 56.03 ± 4.57 bc |

| BF5 | 57.20 ± 0.00 b | 3.27 ± 2.63 bc | 7.03 ± 0.87 b | 98.33 ± 10.40 ab | 35.00 ± 18.02 b | 60.03 ± 6.04 abc |

| Resistance to Extension (g) | Extensibility (mm) | |

|---|---|---|

| * BF | 78.03 ± 2.43 a | 18.78 ± 1.66 c |

| BF1 | 80.29 ± 1.48 a | 40.69 ± 4.80 ab |

| BF2 | 44.58 ± 1.29 c | 29.84 ± 5.39 b |

| BF3 | 59.73 ± 3.89 b | 39.87 ± 7.54 ab |

| BF4 | 77.88 ± 1.64 a | 42.33 ± 6.89 a |

| BF5 | 56.50 ± 2.28 b | 32.74 ± 6.85 ab |

| WRC | SuSRC | SCRC | LARC | GPI | |

|---|---|---|---|---|---|

| * BF | 76.07 ± 7.97 b | 131.51 ± 27.54 a | 97.67 ± 5.12 ab | 137.96 ± 19.08 b | 0.60 ± 0.06 b |

| BF1 | 88.00 ± 0.97 ab | 84.45 ± 9.54 b | 78.49 ± 8.60 b | 131.19 ± 2.44 b | 0.81 ± 0.03 a |

| BF2 | 87.03 ± 0.97 b | 128.29 ± 8.78 a | 114.75 ± 20.84 a | 130.55 ± 0.00 b | 0.54 ± 0.03 b |

| BF3 | 83.16 ± 0.97 a | 110.88 ± 17.94 ab | 98.63 ± 4.22 ab | 160.52 ± 12.79 ab | 0.77 ± 0.09 a |

| BF4 | 92.83 ± 5.39 a | 127.32 ± 15.72 a | 97.18 ± 13.06 ab | 182.76 ± 8.60 a | 0.81 ± 0.06 a |

| BF5 | 82.20 ± 0.97 a | 97.34 ± 24.03 ab | 101.21 ± 2.79 a | 154.72 ± 30.29 ab | 0.78 ± 0.13 a |

| Loaf Volume (cm3) | Loaf Weight (g) | Specific Volume (cm3/g) | |

|---|---|---|---|

| * BF | 1371.37 ± 2.19 a | 471.80 ± 2.50 c | 2.91 ± 0.02 a |

| BF1 | 1231.67 ± 1.89 c | 481.75 ± 0.45 a | 2.56 ± 0.01 d |

| BF2 | 1051.15 ± 3.56 d | 468.35 ± 1.65 d | 2.25 ± 0.01 e |

| BF3 | 901.17 ± 2.29 e | 461.25 ± 2.05 e | 1.95 ± 0.02 f |

| BF4 | 1291.88 ± 5.23 b | 479.20 ± 0.30 ab | 2.70 ± 0.01 c |

| BF5 | 1291.66 ± 11.81 b | 476.05 ± 2.65 b | 2.71 ± 0.01 b |

| L* | a* | b* | |

|---|---|---|---|

| * BF | 75.37 ± 0.98 ab | −2.85 ± 0.18 c | 14.48 ± 0.36 b |

| BF1 | 77.00 ± 1.35 a | −2.82 ± 0.10 c | 15.63 ± 0.34 ab |

| BF2 | 74.70 ± 0.56 b | −2.02 ± 0.05 ab | 16.73 ± 0.31 a |

| BF3 | 74.59 ± 0.28 b | −1.91 ± 0.22 a | 16.73 ± 0.60 a |

| BF4 | 74.58 ± 0.67 b | −2.28 ± 0.06 b | 16.07 ± 1.13 a |

| BF5 | 76.86 ± 1.00 a | −2.64 ± 0.22 c | 15.35 ± 1.12 ab |

| Mixes | Wheat Flour (%) | Maltodextrins (%) | Ziziphus Gum (%) |

|---|---|---|---|

| BF0 | 100 | - | - |

| BF1 | 98 | 2 | - |

| BF2 | 98 | - | 2 |

| BF3 | 98 | 0.5 | 1.50 |

| BF4 | 98 | 1.00 | 1.00 |

| BF5 | 98 | 1.50 | 0.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

AbuDujayn, A.A.; Mohamed, A.A.; Alamri, M.S.; Hussain, S.; Ibraheem, M.A.; Qasem, A.A.A.; Shamlan, G.; Alqahtani, N.K. Relationship between Dough Properties and Baking Performance of Panned Bread: The Function of Maltodextrins and Natural Gums. Molecules 2023, 28, 1. https://doi.org/10.3390/molecules28010001

AbuDujayn AA, Mohamed AA, Alamri MS, Hussain S, Ibraheem MA, Qasem AAA, Shamlan G, Alqahtani NK. Relationship between Dough Properties and Baking Performance of Panned Bread: The Function of Maltodextrins and Natural Gums. Molecules. 2023; 28(1):1. https://doi.org/10.3390/molecules28010001

Chicago/Turabian StyleAbuDujayn, Abdulmajeed A., Abdellatif A. Mohamed, Mohamed Saleh Alamri, Shahzad Hussain, Mohamed A. Ibraheem, Akram A. Abdo Qasem, Ghalia Shamlan, and Nashi K. Alqahtani. 2023. "Relationship between Dough Properties and Baking Performance of Panned Bread: The Function of Maltodextrins and Natural Gums" Molecules 28, no. 1: 1. https://doi.org/10.3390/molecules28010001

APA StyleAbuDujayn, A. A., Mohamed, A. A., Alamri, M. S., Hussain, S., Ibraheem, M. A., Qasem, A. A. A., Shamlan, G., & Alqahtani, N. K. (2023). Relationship between Dough Properties and Baking Performance of Panned Bread: The Function of Maltodextrins and Natural Gums. Molecules, 28(1), 1. https://doi.org/10.3390/molecules28010001