Antioxidant, Antimicrobial, and Metabolomic Characterization of Blanched Pomegranate Peel Extracts: Effect of Cultivar

Abstract

:1. Introduction

2. Results

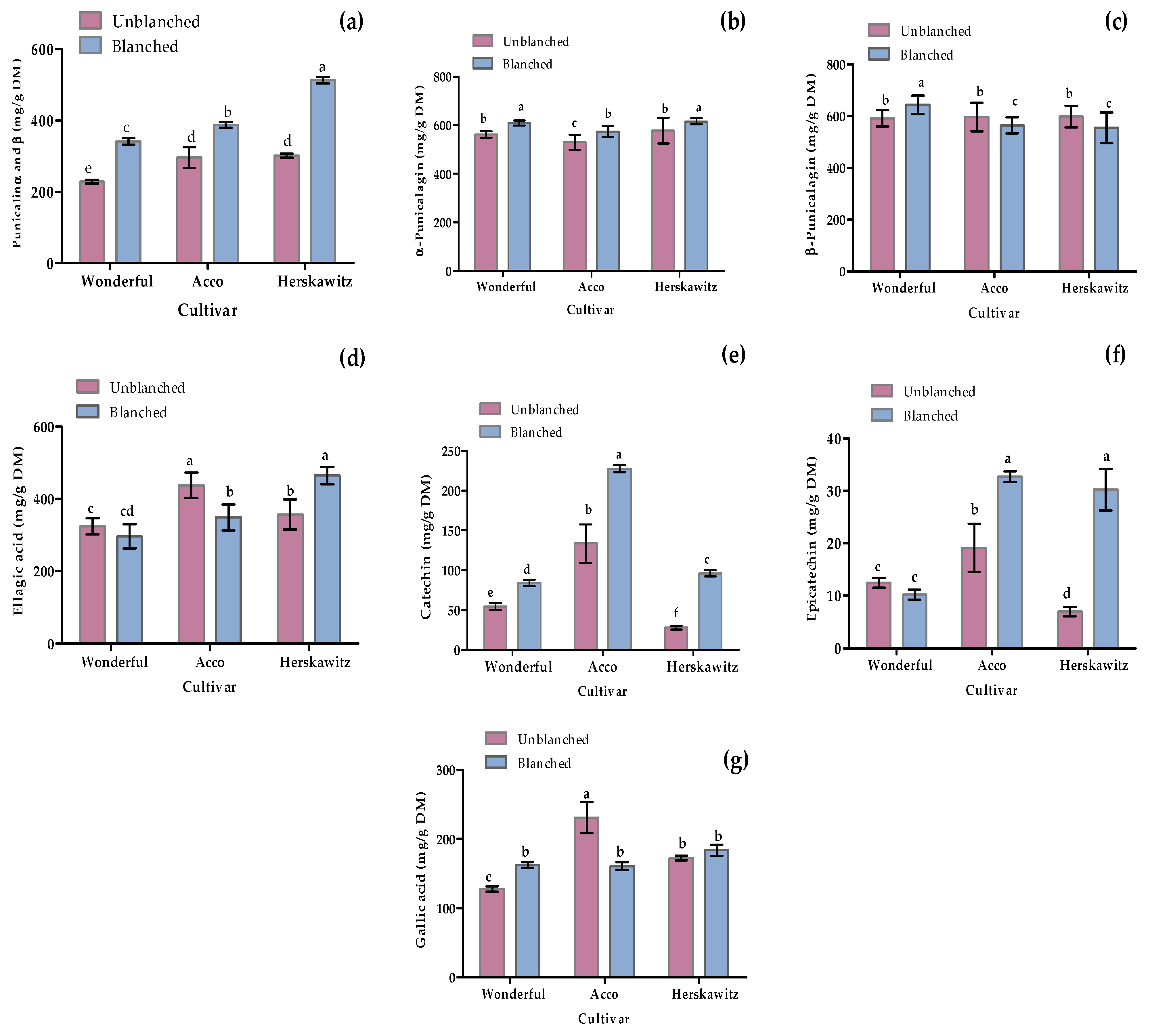

2.1. Polyphenol Analysis and Antioxidant Activity

2.2. Polyphenol Oxidase (PPO) and Peroxidase (POD) Enzyme Activities

2.3. Antibacterial Activity

2.4. Comparative Metabolomics of Cultivar

2.4.1. Tentative Identification of Metabolites

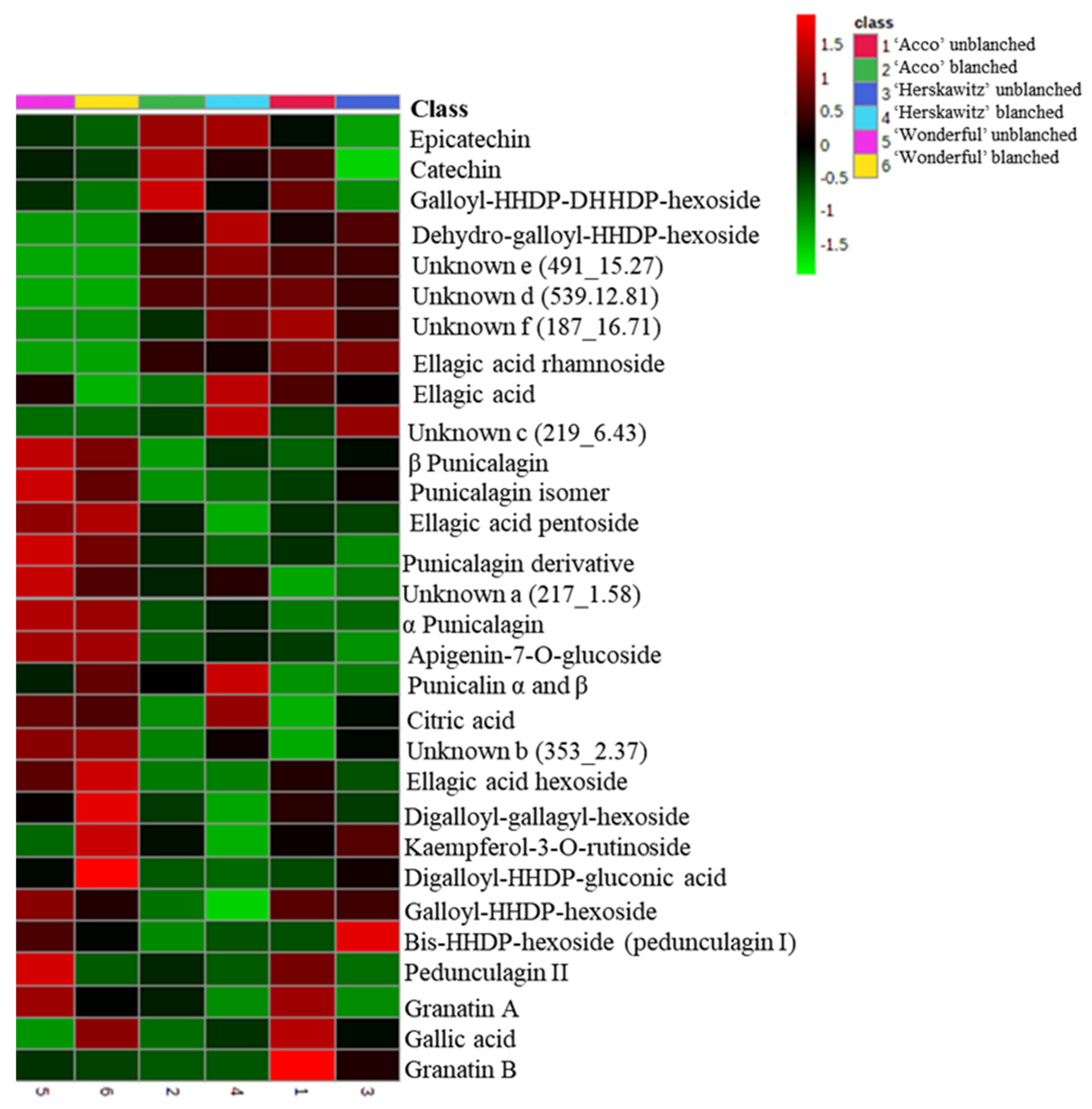

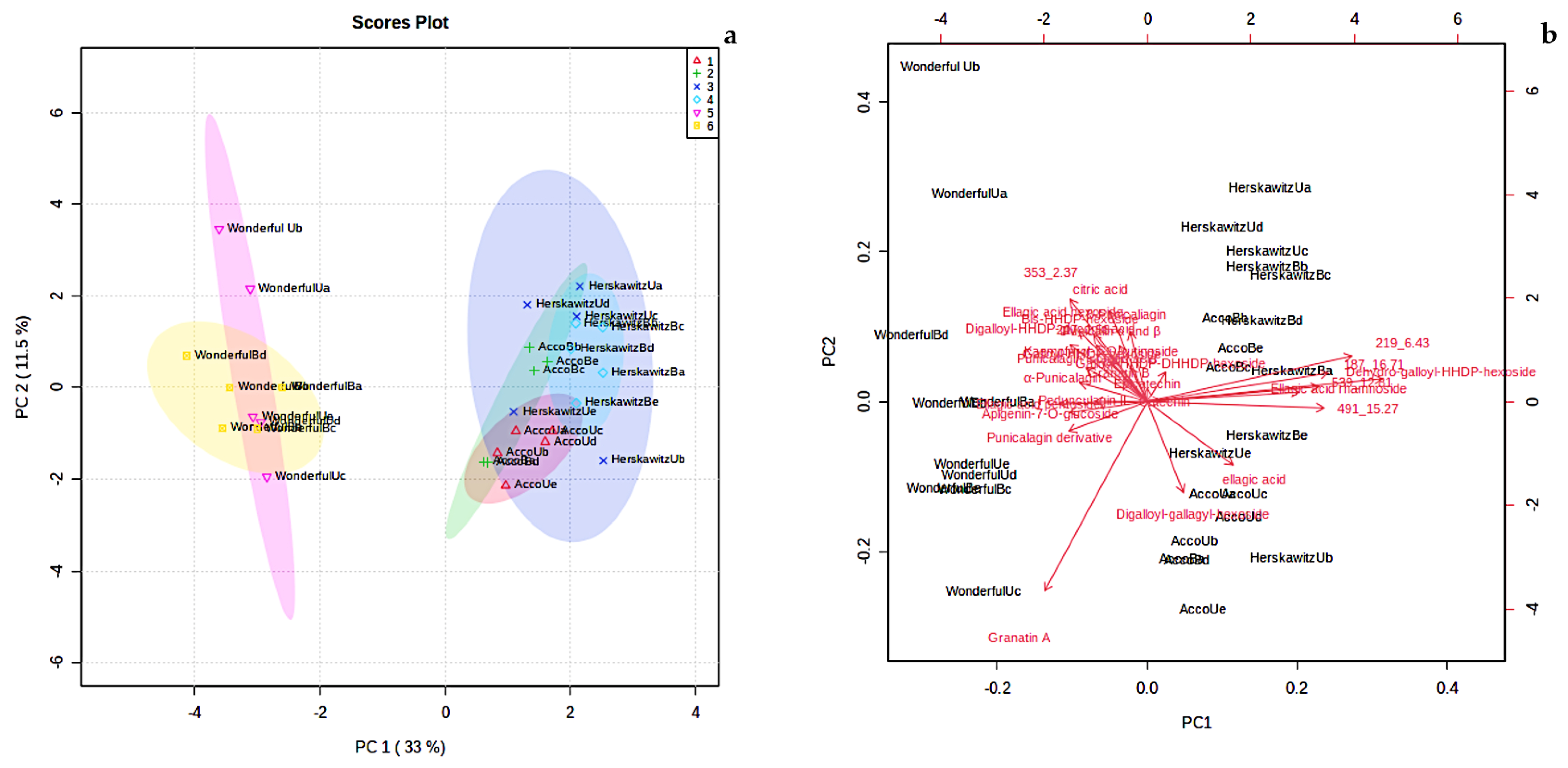

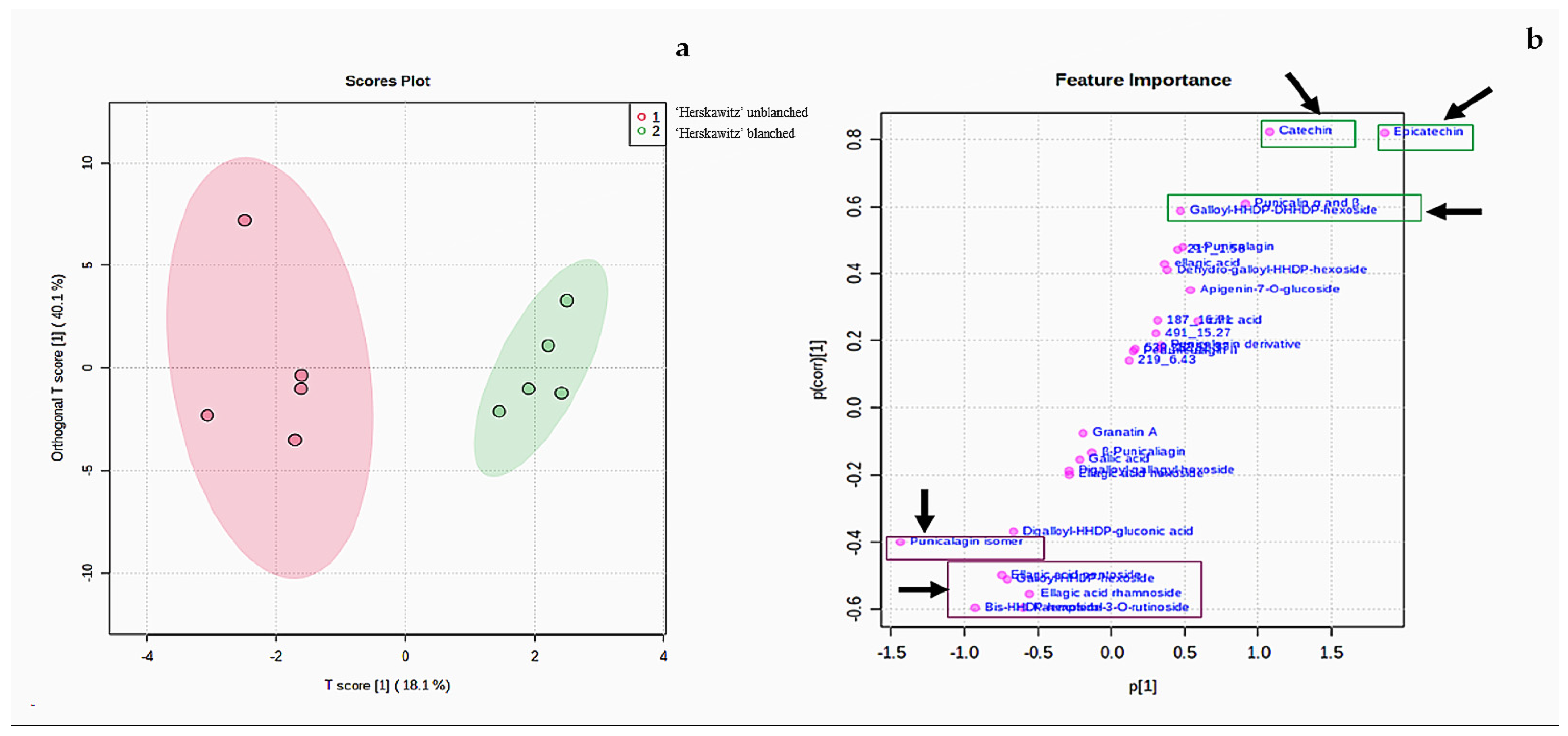

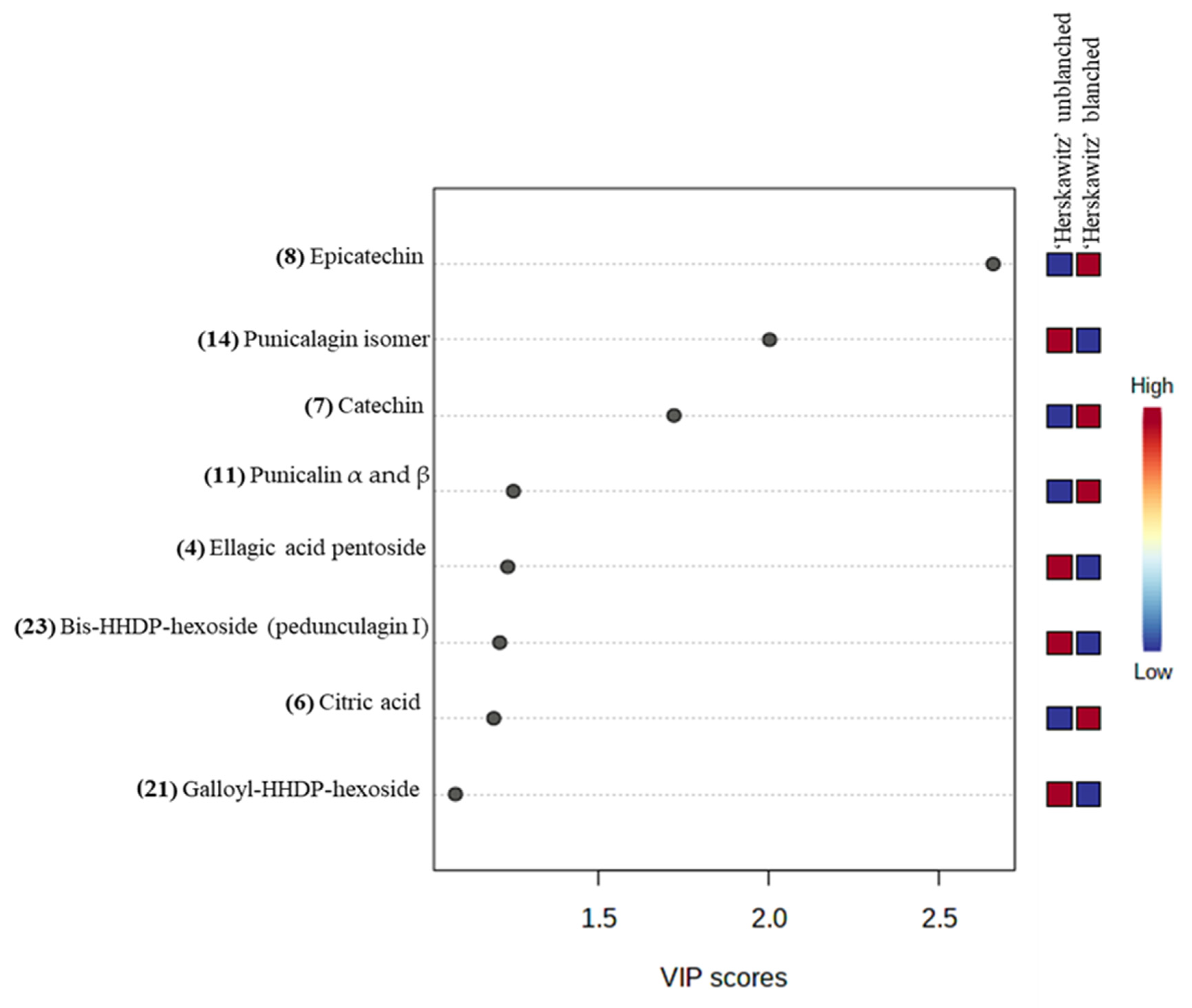

2.4.2. Chemotype Differences

2.5. Correlation Matrix

3. Discussion

4. Materials and Methods

4.1. Plant Collection and Blanching Pre-Treatment

4.2. Peel Drying Procedure

4.3. Ultrasound-Assisted Solvent Extraction

4.4. Polyphenol Analysis

Determination of Extract Yield, Total Phenolic Content, Total Tannin Content, Total Flavonoid Content, and Total Anthocyanin Content

4.5. Antioxidant Activity

Determination of Radical Scavenging Activity (RSA), Ferric Ion Reducing Antioxidant Power (FRAP), and 2,2-Azino-bis(3-ethylbenzothiazoline-6-sulphonic Acid (ABTS) Antioxidant Assay

4.6. Enzyme Activity

Determination of Polyphenol Oxidase and Peroxidase Enzyme

4.7. Ultra-Performance Liquid Chromatography Mass Spectrometry

4.8. Determination of Minimum Inhibitory Concentration (MIC)

4.9. Statistical Analyses

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adetoro, A.O.; Opara, U.L.; Fawole, O.A. Effect of Blanching on Enzyme Inactivation, Physicochemical Attributes and Antioxidant Capacity of Hot-Air Dried Pomegranate (Punica granatum L.) Arils (cv. Wonderful). Processes 2021, 9, 25. [Google Scholar] [CrossRef]

- Fawole, O.A.; Makunga, N.P.; Opara, U.L. Antibacterial, antioxidant and tyrosinase-inhibition activities of pomegranate fruit peel methanolic extract. BMC Complement. Altern. Med. 2012, 12, 200. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mphahlele, R.R.; Fawole, O.A.; Makunga, N.P.; Opara, U.L. Effect of drying on the bioactive compounds, antioxidant, antibacterial and antityrosinase activities of pomegranate peel. BMC Complement. Altern. Med. 2016, 16, 143. [Google Scholar] [CrossRef] [Green Version]

- Foujdar, R.; Bera, M.B.; Chopra, H.K. Optimization of process variables of probe ultrasonic-assisted extraction of phenolic compounds from the peel of Punica granatum Var. Bhagwa and it’s chemical and bioactivity characterization. J. Food Process. Preserv. 2020, 44, e14317. [Google Scholar] [CrossRef]

- More, P.R.; Arya, S.S. Intensification of bio-actives extraction from pomegranate peel using pulsed ultrasound: Effect of factors, correlation, optimization and antioxidant bioactivities. Ultrason. Sonochem. 2021, 72, 105423. [Google Scholar] [CrossRef]

- Albrecht, M.; Jiang, W.; Kumi-Diaka, J.; Lansky, E.P.; Gommersall, L.M.; Patel, A.; Mansel, R.E.; Neeman, I.; Geldof, A.A.; Campbell, M.J. Pomegranate Extracts Potently Suppress Proliferation, Xenograft Growth, and Invasion of Human Prostate Cancer Cells. J. Med. Food 2004, 7, 13–15. [Google Scholar] [CrossRef]

- Deng, Y.; Li, Y.; Yang, F.; Zeng, A.; Yang, S.; Luo, Y.; Zhang, Y.; Xie, Y.; Ye, T.; Xia, Y.; et al. The extract from Punica granatum (pomegranate) peel induces apoptosis and impairs metastasis in prostate cancer cells. Biomed. Pharmacother. 2017, 93, 976–984. [Google Scholar] [CrossRef]

- Li, R.; Chen, X.G.; Jia, K.; Liu, Z.P.; Peng, H.Y. A systematic determination of polyphenols constituents and cytotoxic ability in fruit parts of pomegranates derived from five Chinese cultivars. SpringerPlus 2016, 5, 914. [Google Scholar] [CrossRef] [Green Version]

- Ruan, J.-H.; Li, J.; Adili, G.; Sun, G.-Y.; Abuduaini, M.; Abdulla, R.; Maiwulanjiang, M.; Aisa, H.A. Phenolic Compounds and Bioactivities from Pomegranate (Punica granatum L.) Peels. J. Agric. Food Chem. 2022, 70, 3678–3686. [Google Scholar] [CrossRef]

- Fischer, U.A.; Carle, R.; Kammerer, D.R. Identification and quantification of phenolic compounds from pomegranate (Punica granatum L.) peel, mesocarp, aril and differently produced juices by HPLC-DAD–ESI/MSn. Food Chem. 2011, 127, 807–821. [Google Scholar] [CrossRef]

- Nuncio-Jáuregui, N.; Nowicka, P.; Munera-Picazo, S.; Hernández, F.; Carbonell-Barrachina, Á.A.; Wojdyło, A. Identification and quantification of major derivatives of ellagic acid and antioxidant properties of thinning and ripe Spanish pomegranates. J. Funct. Foods 2015, 12, 354–364. [Google Scholar] [CrossRef]

- Singh, A.; Bajpai, V.; Kumar, S.; Sharma, K.R.; Kumar, B. Profiling of Gallic and Ellagic Acid Derivatives in Different Plant Parts of Terminalia Arjuna by HPLC-ESI-QTOF-MS/MS. Nat. Prod. Commun. 2016, 11, 239–244. [Google Scholar] [CrossRef] [Green Version]

- Kaderides, K.; Kyriakoudi, A.; Mourtzinos, I.; Goula, A.M. Potential of pomegranate peel extract as a natural additive in foods. Trends Food Sci. Technol. 2021, 115, 380–390. [Google Scholar] [CrossRef]

- Mphahlele, R.R.; Stander, M.A.; Fawole, O.A.; Opara, U.L. Effect of fruit maturity and growing location on the postharvest contents of flavonoids, phenolic acids, vitamin C and antioxidant activity of pomegranate juice (cv. Wonderful). Sci. Hortic. 2014, 179, 36–45. [Google Scholar] [CrossRef]

- Pomegranate Association of South Africa (POMASA). Pomegranate Industry Overview. Available online: http://www.hortgro.co.za/portfolio/pomegranates (accessed on 20 March 2020).

- Mphahlele, R.; Fawole, O.; Stander, M.; Opara, U.L. Preharvest and postharvest factors influencing bioactive compounds in pomegranate (Punica granatum L.)—A review. Sci. Hortic. 2014, 178, 114–123. [Google Scholar] [CrossRef]

- Tozzi, F.; Núñez-Gómez, D.; Legua, P.; Del Bubba, M.; Giordani, E.; Melgarejo, P. Qualitative and varietal characterization of pomegranate peel: High-value co-product or waste of production? Sci. Hortic. 2022, 291, 110601. [Google Scholar] [CrossRef]

- Feng, L.; Wang, C.; Yang, X.; Jiao, Q.; Yin, Y. Transcriptomics and metabolomics analyses identified key genes associated with sugar and acid metabolism in sweet and sour pomegranate cultivars during the developmental period. Plant Physiol. Biochem. 2022, 181, 12–22. [Google Scholar] [CrossRef]

- Zhao, X.; Shen, Y.; Yan, M.; Yuan, Z. Flavonoid profiles in peels and arils of pomegranate cultivars. J. Food Meas. Charact. 2021, 16, 880–890. [Google Scholar] [CrossRef]

- Zhao, X.; Yuan, Z.; Fang, Y.; Yin, Y.; Feng, L. Characterization and evaluation of major anthocyanins in pomegranate (Punica granatum L.) peel of different cultivars and their development phases. Eur. Food Res. Technol. 2013, 236, 109–117. [Google Scholar] [CrossRef]

- Saad, H.; Bouhtoury, F.C.-E.; Pizzi, A.; Rode, K.; Charrier, B.; Ayed, N. Characterization of pomegranate peels tannin extractives. Ind. Crop. Prod. 2012, 40, 239–246. [Google Scholar] [CrossRef]

- Magangana, T.P.; Makunga, N.P.; Fawole, O.A.; Opara, U.L. Processing Factors Affecting the Phytochemical and Nutritional Properties of Pomegranate (Punica granatum L.) Peel Waste: A Review. Molecules 2020, 25, 4690. [Google Scholar] [CrossRef]

- Xiang, Q.; Li, M.; Wen, J.; Ren, F.; Yang, Z.; Jiang, X.; Chen, Y. The bioactivity and applications of pomegranate peel extract: A review. J. Food Biochem. 2022, e14105. [Google Scholar] [CrossRef]

- Jerome, R.E.; Dwivedi, M.; Rifna, E. Microwave vacuum drying of pomegranate peel: Evaluation of specific energy consumption and quality attributes by response surface methodology and artificial neural network. J. Food Process. Preserv. 2022, 46, e16325. [Google Scholar] [CrossRef]

- Šavikin, K.; Nastić, N.; Janković, T.; Bigović, D.; Miličević, B.; Vidović, S.; Menković, N.; Vladić, J. Effect of Type and Concentration of Carrier Material on the Encapsulation of Pomegranate Peel Using Spray Drying Method. Foods 2021, 10, 1968. [Google Scholar] [CrossRef]

- Rifna, E.J.; Dwivedi, M. Optimization and validation of microwave–vacuum drying process variables for recovery of quality attribute and phytochemical properties in pomegranate peels (Punica granatum L. cv. Kabul). J. Food Meas. Charact. 2021, 15, 4446–4464. [Google Scholar] [CrossRef]

- Xiao, H.-W.; Pan, Z.; Deng, L.-Z.; El Mashad, H.; Yang, X.-H.; Mujumdar, A.S.; Gao, Z.-J.; Zhang, Q. Recent developments and trends in thermal blanching—A comprehensive review. Inf. Process. Agric. 2017, 4, 101–127. [Google Scholar] [CrossRef]

- Nurhuda, H.H.; Maskat, M.Y.; Mamot, S.; Afiq, J.; Aminah, A. Effect of blanching on enzyme and antioxidant activities of rambutan (Nephelium lappaceum) peel. Int. Food Res. J. 2013, 20, 1725–1730. [Google Scholar]

- Ben Zid, M.; Dhuique-Mayer, C.; Bellagha, S.; Sanier, C.; Collignan, A.; Servent, A.; Dornier, M. Effects of Blanching on Flavanones and Microstructure of Citrus aurantium Peels. Food Bioprocess Technol. 2015, 8, 2246–2255. [Google Scholar] [CrossRef]

- Hughey, C.A.; Janusziewicz, R.; Minardi, C.S.; Phung, J.; Huffman, B.A.; Reyes, L.; Wilcox, B.E.; Prakash, A. Distribution of almond polyphenols in blanch water and skins as a function of blanching time and temperature. Food Chem. 2012, 131, 1165–1173. [Google Scholar] [CrossRef]

- Geerkens, C.H.; Nagel, A.; Just, K.M.; Miller-Rostek, P.; Kammerer, D.R.; Schweiggert, R.M.; Carle, R. Mango pectin quality as influenced by cultivar, ripeness, peel particle size, blanching, drying, and irradiation. Food Hydrocoll. 2015, 51, 241–251. [Google Scholar] [CrossRef]

- Deylami, M.Z.; Rahman, R.A.; Tan, C.P.; Bakar, J.; Olusegun, L. Effect of blanching on enzyme activity, color changes, anthocyanin stability and extractability of mangosteen pericarp: A kinetic study. J. Food Eng. 2016, 178, 12–19. [Google Scholar] [CrossRef]

- Deng, L.-Z.; Yang, X.-H.; Mujumdar, A.S.; Zhao, J.-H.; Wang, D.; Zhang, Q.; Wang, J.; Gao, Z.-J.; Xiao, H.-W. Red pepper (Capsicum annuum L.) drying: Effects of different drying methods on drying kinetics, physicochemical properties, antioxidant capacity, and microstructure. Dry. Technol. 2018, 36, 893–907. [Google Scholar] [CrossRef]

- Mai, T.H.A.; Tran, T.T.T.; Le, V.V.M. Protection of antioxidants in pitaya (Hylocereus undatus) peel: Effects of blanching conditions on polyphenoloxidase, peroxidase and antioxidant activities. Food Sci. Technol. 2022, 42, e112921. [Google Scholar] [CrossRef]

- Magangana, T.P.; Makunga, N.P.; Grange, C.; Stander, M.A.; Fawole, O.A.; Opara, U.L. Blanching pre-treatment promotes high yields, bioactive compounds, antioxidants, enzyme inactivation and antibacterial activity of ‘Wonderful’ pomegranate peel extracts at three different harvest maturities. Antioxidants 2021, 10, 1119. [Google Scholar] [CrossRef]

- John, K.M.; Bhagwat, A.A.; Luthria, D.L. Swarm motility inhibitory and antioxidant activities of pomegranate peel processed under three drying conditions. Food Chem. 2017, 235, 145–153. [Google Scholar] [CrossRef]

- He, L.; Xu, H.; Liu, X.; He, W.; Yuan, F.; Hou, Z.; Gao, Y. Identification of phenolic compounds from pomegranate (Punica granatum L.) seed residues and investigation into their antioxidant capacities by HPLC–ABTS+ assay. Food Res. Int. 2011, 44, 1161–1167. [Google Scholar] [CrossRef]

- Abid, M.; Yaich, H.; Cheikhrouhou, S.; Khemakhem, I.; Bouaziz, M.; Attia, H.; Ayadi, M.A. Antioxidant properties and phenolic profile characterization by LC–MS/MS of selected Tunisian pomegranate peels. J. Food Sci. Technol. 2017, 54, 2890–2901. [Google Scholar] [CrossRef]

- Mena, P.; Calani, L.; Dall’Asta, C.; Galaverna, G.; García-Viguera, C.; Bruni, R.; Crozier, A.; Del Rio, D. Rapid and Comprehensive Evaluation of (Poly)phenolic Compounds in Pomegranate (Punica granatum L.) Juice by UHPLC-MSn. Molecules 2012, 17, 14821–14840. [Google Scholar] [CrossRef] [Green Version]

- Masike, K.; De Villiers, A.J.; Hoffman, E.W.; Stander, M.A. Application of Metabolomics Tools to Determine Possible Biomarker Metabolites Linked to Leaf Blackening in Protea. J. Agric. Food Chem. 2020, 68, 12595–12605. [Google Scholar] [CrossRef]

- Henderson, I.R.; Salt, D.E. Natural genetic variation and hybridization in plants. J. Exp. Bot. 2017, 68, 5415–5417. [Google Scholar] [CrossRef] [Green Version]

- Nasrabadi, M.; Ramezanian, A.; Eshghi, S.; Kamgar-Haghighi, A.A.; Vazifeshenas, M.R.; Valero, D. Biochemical changes and winter hardiness in pomegranate (Punica granatum L.) trees grown under deficit irrigation. Sci. Hortic. 2019, 251, 39–47. [Google Scholar] [CrossRef]

- Bhandari, H.R.; Bhanu, A.N.; Srivastava, K.; Singh, M.N.; Shreya, H.A. Assessment of Genetic Diversity in Crop Plants—An Overview. Adv. Plants Agric. Res. 2017, 7, 279–286. [Google Scholar] [CrossRef]

- Adiba, A.; Razouk, R.; Charafi, J.; Haddioui, A.; Hamdani, A. Assessment of water stress tolerance in eleven pomegranate cultivars based on agronomic traits. Agric. Water Manag. 2021, 243, 106419. [Google Scholar] [CrossRef]

- Magangana, T.P.; Makunga, N.P.; Fawole, O.A.; Opara, U.L. Effect of Solvent Extraction and Blanching Pre-Treatment on Peel Extracts. Process. J. 2021, 9, 1012. [Google Scholar] [CrossRef]

- Liu, Y.; Kong, K.W.; Wu, D.-T.; Liu, H.-Y.; Li, H.-B.; Zhang, J.-R.; Gan, R.-Y. Pomegranate peel-derived punicalagin: Ultrasonic-assisted extraction, purification, and its α-glucosidase inhibitory mechanism. Food Chem. 2022, 374, 131635. [Google Scholar] [CrossRef]

- Bhatt, S.; Gupta, M. Exploration of soluble dietary fiber extraction technique for enhancing physicochemical and structural properties of mango and pomegranate peel. Biomass Convers. Biorefinery 2022, 1–16. [Google Scholar] [CrossRef]

- Rashid, R.; Masoodi, F.A.; Wani, S.M.; Manzoor, S.; Gull, A. Ultrasound assisted extraction of bioactive compounds from pomegranate peel, their nanoencapsulation and application for improvement in shelf life extension of edible oils. Food Chem. 2022, 385, 132608. [Google Scholar] [CrossRef]

- Wang, Z.; Pan, Z.; Ma, H.; Atungulu, G.G. Extract of Phenolics from Pomegranate Peels. Open Food Sci. J. 2011, 5, 17–25. [Google Scholar] [CrossRef]

- Bustamante, A.; Hinojosa, A.; Robert, P.; Escalona, V. Extraction and microencapsulation of bioactive compounds from pomegranate (Punica granatum var. Wonderful) residues. Int. J. Food Sci. Technol. 2017, 52, 1452–1462. [Google Scholar] [CrossRef]

- Sharayei, P.; Azarpazhooh, E.; Zomorodi, S.; Ramaswamy, H.S. Ultrasound assisted extraction of bioactive compounds from pomegranate (Punica granatum L.) peel. LWT 2019, 101, 342–350. [Google Scholar] [CrossRef]

- Malviya, S.; Arvind; Jha, A.; Hettiarachchy, N. Antioxidant and antibacterial potential of pomegranate peel extracts. J. Food Sci. Technol. 2014, 51, 4132–4137. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lansky, E.P.; Newman, R.A. Punica granatum (pomegranate) and its potential for prevention and treatment of inflammation and cancer. J. Ethnopharmacol. 2007, 109, 177–206. [Google Scholar] [CrossRef] [PubMed]

- Akhtar, S.; Ismail, T.; Fraternale, D.; Sestili, P. Pomegranate peel and peel extracts: Chemistry and food features. Food Chem. 2015, 174, 417–425. [Google Scholar] [CrossRef] [PubMed]

- Al-Zoreky, N.S. Antimicrobial activity of pomegranate (Punica granatum L.) fruit peels. Int. J. Food Microbiol. 2009, 134, 244–248. [Google Scholar] [CrossRef]

- Kharchoufi, S.; Licciardello, F.; Siracusa, L.; Muratore, G.; Hamdi, M.; Restuccia, C. Antimicrobial and antioxidant features of ‘Gabsi’ pomegranate peel extracts. Ind. Crop. Prod. 2018, 111, 345–352. [Google Scholar] [CrossRef]

- Endo, E.H.; Nakamura, C.V.; Prado, B.; Filho, D. Potent antifungal activity of extracts and pure compound isolated from pomegranate peels and synergism with fluconazole against Candida albicans. Res. Microbiol. 2010, 161, 534–540. [Google Scholar] [CrossRef]

- Sun, S.; Huang, S.; Shi, Y.; Shao, Y.; Qiu, J.; Sedjoah, R.-A.; Yan, Z.; Ding, L.; Zou, D.; Xin, Z. Extraction, isolation, characterization and antimicrobial activities of non-extractable polyphenols from pomegranate peel. Food Chem. 2021, 351, 129232. [Google Scholar] [CrossRef]

- Ratcliffe, B.; Rungapamestry, V.; Duncan, A.J. Effect of cooking brassica vegetables on the subsequent hydrolysis and metabolic fate of glucosinolates. Proc. Nutr. Soc. 2007, 66, 69–81. [Google Scholar]

- Sung, D.; Kaplan, F.; Lee, K.; Guy, C.L. Acquired tolerance to temperature extremes. Trends Plant Sci. 2003, 8, 179–187. [Google Scholar] [CrossRef]

- Duarte, Y.; Chaux, A.; Lopez, N.; Largo, E.; Ramírez, C.; Nuñez, H.; Simpson, R.; Vega, O. Effects of Blanching and Hot Air Drying Conditions on the Physicochemical and Technological Properties of Yellow Passion Fruit (Passiflora edulis Var. Flavicarpa) by-Products. J. Food Process Eng. 2017, 40, e12425. [Google Scholar] [CrossRef]

- Chung, Y.C.; Chiang, B.H.; Wei, J.H.; Wang, C.K.; Chen, P.C.; Hsu, C.K. Effects of blanching, drying and extraction processes on the antioxidant activity of yam (Dioscorea alata). Int. J. Food Sci. Technol. 2008, 43, 859–864. [Google Scholar] [CrossRef]

- Heras-Ramírez, M.E.; Quintero-Ramos, A.; Torres-Muñoz, J.V.; Salas-Muñoz, E. Effect of Blanching and Drying Temperature on Polyphenolic Compound Stability and Antioxidant Capacity of Apple Pomace. Food Bioprocess Technol. 2012, 5, 2201–2210. [Google Scholar] [CrossRef]

- Kaseke, T.; Fawole, O.A.; Mokwena, L.; Opara, U.L. Effect of cultivar and blanching of pomegranate seeds on physicochemical properties, nutritional qualities and antioxidant capacity of extracted oil. J. Food Meas. Charact. 2020, 15, 93–106. [Google Scholar] [CrossRef]

- Rosidi, N.A.S.; Abdul, G.; Yaacob, A.; Yusof, N. Effect of Blanching and Drying Temperatures on Physicochemical Properties of Red Dragon Fruit (Hylocereus polyrhizus) Peel Powder. J. Agrobiotechnol. 2021, 12, 62–73. [Google Scholar] [CrossRef]

- Kieu, V.T.D.; Viet, P.X. Effect of alum and blanching time on the naringin and hardness of grapefruit peel waste. Adv. Food Nutr. Res. 2021, 4, 19–22. [Google Scholar]

- Fawole, O.A.; Opara, U.L. Effects of maturity status on biochemical content, polyphenol composition and antioxidant capacity of pomegranate fruit arils (cv. ‘Bhagwa’). South Afr. J. Bot. 2013, 85, 23–31. [Google Scholar] [CrossRef] [Green Version]

- Joint FAO/IAEA Division of Nuclear Techniques in Food and Agriculture. Quantification of Tannins in Tree Foliage. Laboratory Manual. 2000. Available online: https://inis.iaea.org/search/search.aspx?orig_q=RN:33048138 (accessed on 21 April 2021).

- Yang, J.; Martinson, T.E.; Liu, R.H. Phytochemical profiles and antioxidant activities of wine grapes. Food Chem. 2009, 116, 332–339. [Google Scholar] [CrossRef]

- Wrolstad, R.E. Color and Pigment Analyses in Fruit Products; Agricultural Experiment Station, Oregon State University: Corvallis, OR, USA, 1993. [Google Scholar]

- Karioti, A.; Hadjipavlou-Litina, D.; Mensah, M.L.K.; Fleischer, T.C.; Skaltsa, H. Composition and Antioxidant Activity of the Essential Oils of Xylopia aethiopica (Dun) A. Rich. (Annonaceae) Leaves, Stem Bark, Root Bark, and Fresh and Dried Fruits, Growing in Ghana. J. Agric. Food Chem. 2004, 52, 8094–8098. [Google Scholar] [CrossRef]

- Benzie, I.F.F.; Strain, J.J. Determination of optimal extraction conditions for phenolic compounds from: Pistacia atlantica leaves using the response surface methodology. Anal. Methods 2016, 8, 6107–6114. [Google Scholar] [CrossRef]

- Chirinos, R.; Pedreschi, R.; Rogez, H.; Larondelle, Y.; Campos, D. Phenolic compound contents and antioxidant activity in plants with nutritional and/or medicinal properties from the Peruvian Andean region. Ind. Crop. Prod. 2013, 47, 145–152. [Google Scholar] [CrossRef]

- González, E.M.; de Ancos, B.; Cano, M.P. Partial Characterization of Polyphenol Oxidase Activity in Raspberry Fruits. J. Agric. Food Chem. 1999, 47, 4068–4072. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meighani, H.; Ghasemnezhad, M.; Bakshi, D. Evaluation of Biochemical Composition and Enzyme Activities in Browned Arils of Pomegranate Fruits. Int. J. Hortic. Sci. Technol. 2014, 1, 53–65. [Google Scholar] [CrossRef]

- Eloff, J.N. A Sensitive and Quick Microplate Method to Determine the Minimal Inhibitory Concentration of Plant Extracts for Bacteria. Planta Med. 1998, 64, 711–713. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Cultivar | Treatment | Extract Yield (%) | TPC | TTC | TFC | TAC | DPPH | FRAP | ABTS | PPO | POD |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wonderful | Unblanched | 29.46 ± 0.75 b | 10.61 ± 0.15 d | 0.76 ± 0.02 f | 1.17 ± 0.00 c | 0.07 ± 0.00 f | 243.97 ± 2.43 d | 478.04 ± 73.98 e | 718.79 ± 2.43 f | 0.40 ± 0.00 b | 3.00 ± 0.00 b |

| Blanched | 33.83 ± 1.42 a | 12.22 ± 0.08 c | 1.06 ± 0.06 e | 1.50 ± 0.00 b | 0.08 ± 0.00 e | 319.16 ± 4.20 c | 525.34 ± 15.77 d | 778.82 ± 2.43 d | 0.33 ± 0.03 c | 1.5 ± 0.00 c | |

| Acco | Unblanched | 25.57 ± 0.68 cd | 13.71 ± 0.36 b | 1.27 ± 0.05 d | 1.00 ± 0.00 d | 0.09 ± 0.00 d | 429.53 ± 3.03 c | 703.63 ± 3.20 c | 758.21 ± 6.67 e | 0.68 ± 0.03 a | 4.25 ± 0.00 a |

| Blanched | 28.96 ± 0.38 b | 15.47 ± 0.09 a | 1.70 ± 0.02 b | 1.17 ± 0.00 c | 0.11 ± 0.00 b | 585.37 ± 11.03 a | 772.15 ± 1.82 b | 869.18 ± 6.06 b | 0.28 ± 0.03 d | 3.00 ± 0.00 b | |

| Herskawitz | Unblanched | 24.32 ± 0.55 d | 13.64 ± 0.27 b | 1.39 ± 0.02 c | 1.28 ± 0.06 c | 0.10 ± 0.00 c | 442.87 ± 7.28 b | 706.06 ± 4.85 c | 846.14 ± 3.03 c | 0.48 ± 0.08 b | 4.50 ± 0.00 a |

| Blanched | 27.36 ± 0.60 bc | 15.74 ± 0.13 a | 1.92 ± 0.04 a | 1.70 ± 0.00 a | 0.15 ± 0.00 a | 567.78 ± 9.47 a | 800.05 ± 1.60 a | 915.27 ± 0.61 a | 0.25 ± 0.05 d | 3.13 ± 0.38 b |

| Cultivar | Treatment | Gram Negative | Gram Positive | ||

|---|---|---|---|---|---|

| Escherichia coli | Klebsiella pneumoniae | Staphylococcus aureus | Bacillus subtilis | ||

| Wonderful | Unblanched | 310 b | 310 c | 310 b | 310 c |

| Blanched | 160 a | 160 b | 160 a | 160 b | |

| Acco | Unblanched | 310 b | 310 c | 310 b | 160 b |

| Blanched | 160 a | 160 b | 160 a | 80 a | |

| Herskawitz | Unblanched | 310 b | 160 b | 310 b | 160 b |

| Blanched | 160 a | 80 a | 160 a | 80 a | |

| Significance level | <0.0001 | <0.0001 | <0.0001 | <0.0001 | |

| Streptomycin (µg/mL) | 1.6 | 1.6 | 0.8 | 1.6 | |

| Solvent control (70% ethanol) | - | - | - | - | |

| No. | Experimental m/z [M − H]− | Retention Time (min) | Elemental Formula | MSE Fragments | UV (nm) | Tentative Identity | ‘Wonderful’ | ‘Acco’ | ‘Herskawitz’ | References |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 169.0146 | 4.72 | C7H5O5 | 169.014, 125.025, 124.017 | 270; 259 | Gallic acid * | √ | √ | √ | Std |

| 2 | 300.9969 | 14.24 | C14H5O8 | 213.597, 137.983, 49.474 | 254; 364 | Ellagic acid * | √ | √ | √ | Std |

| 3 | 463.0539 | 11.06 | C20H15O13 | 463.053, 300.989, 165.021,114.6995 | None | Ellagic acid hexoside | √ | √ | √ | [35,36] |

| 4 | 433.0307 | 13.59 | C19H13O12 | 433.038, 303.7598, 300.995, 299.997, 201.556, 126.237 | 254; 361 | Ellagic acid pentoside | √ | √ | √ | [12,35,36] |

| 5 | 447.0945 | 16.48 | C21H19O11 | 447.074, 346.019, 327.124, 285.044, 284.025, 220.820, 143.011, 127.056, 51.022 | 230; 360 | Ellagic acid rhamnoside | × | √ | √ | [11,36] |

| 6 | 191.0198 | 2.52 | C5H7O7 | 191.0198, 173.008, 111.008,87.008, 67.017 | None | Citric acid * | √ | √ | √ | Std |

| 7 | 289.0733 | 8.31 | C15H13O6 | 289.071, 245.082, 203.072, 109.028 | None | (+)-Catechin * | √ | √ | √ | Std |

| 8 | 289.0733 | 10.19 | C15H13O6 | 289.071, 245.082, 203.072, 109.028 | None | (−)-Epicatechin * | √ | √ | √ | Std |

| 9 | 431.1906 | 11.07 | C20H20O10 | 161.041, 153.091 | 253; 361 | Apigenin-7-O-glucoside | √ | √ | √ | [12,35] |

| 10 | 593.1494 | 15.95 | C27H29O15 | 593.142, 523.421, 440.063, 316.023, 300.998, 285.033, 211.911, 125.025, 101.031, 80.779 | 275; 360 | Kaempferol-3-O-rutinoside | √ | √ | √ | [35,37] |

| 11 | 781.0506 | 4.99 | C34H21O22 | 781.022, 779.000,783.055, 784.065 | 270; 259 | Punicalin α and β * | √ | √ | √ | Std |

| 12 | 1083.0547 | 6.46 | C48H27O30 | 1083.060, 781.035, 600.986, 541.027, 300.997 | 258; 378 | α Punicalagin * | √ | √ | √ | Std |

| 13 | 1083.0558 | 7.69 | C48H27O30 | 1083.060, 781.035, 600.986, 541.027, 300.997 | 258; 378 | β Punicalagin * | √ | √ | √ | Std |

| 14 | 1083.0547 | 5.31 | C48H27O30 | 1083.060, 781.035, 600.986, 541.027, 300.997 | 258; 378 | Punicalagin isomer | √ | √ | √ | Std |

| 15 | 541.0341 | 6.44 | - | 541.027, 300.997 | 258; 378 | Punicalagin derivative | √ | √ | √ | [35,38] |

| 16 | 951.0479 | 6.83 | C52 H23O19 | 951.042, 907.087, 820.125, 783.062, 300.997, 275.021, 249.035, 102.241 | 255; 230 | Galloyl-HHDP-DHHDP-hexoside | √ | √ | √ | [12,35,38] |

| 17 | 951.071 | 12.43 | C52 H23O19 | 951.044, 933.079,915.9995, 763.081, 614.803, 464.044, 341.011, 302.006, 300.999, 273.002, 169.013, 1233.011 | 273 | Galloyl-HHDP-DHHDP-hexoside (Granatin B) | √ | √ | √ | [12,35,38] |

| 18 | 799.0454 | 8.34 | C34H23O23 | 799.0454, 800.0641, 802.0781 | None | Granatin A | √ | √ | √ | [10,11,35] |

| 19 | 801.0732 | 8.60 | C41H21O18 | 801.073, 781.3245 | Digalloyl-HHDP-gluconic acid (punigluconin) | √ | √ | √ | [10,35] | |

| 20 | 785.0775 | 9.37 | C34H25O22 | 785.021, 781.795, 635.099, 483.122, 419.050, 345.086, 301.995, 300.9982, 275.032, 165.021, 125.132 | 264; 370 | Digalloyl-HHDP-hexoside (Pedunculagin II) | √ | √ | √ | [11,35,36,38] |

| 21 | 633.0686 | 9.76 | C27H22O18 | 633.075, 597.082, 464.051, 301.9998, 275.0219, 125.024 | 260;360 | Galloyl-HHDP-hexoside | √ | √ | √ | [35,38,39] |

| 22 | 1085.0889 | 9.99 | C48H29O30 | 933.081, 783.088, 633.0696, 540.536, 450.989, 301.996, 300.997, 275.014, | 257; 370 | Digalloyl-gallagyl-hexoside | √ | √ | √ | [35,36,39] |

| 23 | 783.0746 | 8.83 | C34H23O22 | 783.567, 635.087, 541.022, 453.103, 392.036, 291.016, 203.0396 | 260; 370 | Bis-HHDP-hexoside (pedunculagin I) | √ | √ | √ | [35,36,38] |

| 24 | 615.0828 | 13.01 | C23H19O20 C28H24O16 | 615.056, 508.782, 324.158, 302.004, 301.000, 299.981, 190.991, 67.024 | 254; 230 | Dehydro-galloyl-HHDP-hexoside | × | √ | √ | [12,39] |

| 25 | 217.0461 | 1.58 | C12H9O4 | 217.042, 191.0211, 173.006 | None | Unknown a | √ | √ | √ | [35] |

| 26 | 353.0731 | 2.37 | C12H17O12 | 353.0742, 191.0211, 173.0062 | None | Unknown b | √ | √ | √ | [35] |

| 27 | 219.0497 | 6.43 | C8H11O7 | 123.005, 111.009, 67.010 | None | Unknown c | × | √ | √ | - |

| 28 | 539.2146 | 12.81 | C26H35O12 | 541.038, 492.1699, 405.014, 328.021, 302.001, 300.998, 222.005, 169.011, 52.256 | 254; 230 | Unknown d | × | √ | √ | - |

| 29 | 491.0756 | 15.27 | C22H19O13 | 491.085, 357.434, 328.016, 312.996, 300.9995, 297.984, 211.149, 197.990, 55.027 | None | Unknown e | √ | √ | √ | [35] |

| 30 | 187.1024 | 16.71 | C9H15O4 | 100.092, 52.055 | None | Unknown f | × | √ | √ | - |

| POD | EY | GA | Epi | FRAP | DPPH | TTC | TPC | B.s | TAC | ABTS | Pα&β | K.p | S.a | E.c | TFC | βPC | PPO | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| POD | 1 | |||||||||||||||||

| EY | −0.98 | 1 | ||||||||||||||||

| GA | 0.49 | −0.50 | 1 | |||||||||||||||

| Epi | −0.05 | −0.06 | 0.19 | 1 | ||||||||||||||

| FRAP | 0.48 | −0.59 | 0.55 | 0.70 | 1 | |||||||||||||

| DPPH | 0.28 | −0.40 | 0.40 | 0.79 | 0.97 | 1 | ||||||||||||

| TTC | 0.21 | −0.36 | 0.38 | 0.76 | 0.95 | 0.97 | 1 | |||||||||||

| TPC | 0.25 | −0.38 | 0.47 | 0.77 | 0.97 | 0.99 | 0.98 | 1 | ||||||||||

| B.s | −0.02 | 0.14 | −0.47 | −0.66 | −0.85 | −0.91 | −0.92 | −0.94 | 1 | |||||||||

| TAC | 0.16 | −0.33 | 0.29 | 0.70 | 0.85 | 0.86 | 0.95 | 0.88 | -0.78 | 1 | ||||||||

| ABTS | 0.11 | −0.27 | 0.15 | 0.61 | 0.84 | 0.89 | 0.95 | 0.89 | −0.86 | 0.92 | 1 | |||||||

| Pα&β | −0.19 | 0.02 | 0.23 | 0.72 | 0.71 | 0.78 | 0.89 | 0.82 | −0.84 | 0.93 | 0.87 | 1 | ||||||

| K.p | 0.25 | −0.09 | 0.07 | −0.36 | −0.53 | −0.63 | −0.75 | −0.66 | 0.75 | −0.76 | −0.89 | −0.84 | 1 | |||||

| S.a | 0.70 | −0.59 | 0.13 | −0.59 | −0.29 | −0.48 | −0.55 | −0.51 | 0.67 | −0.52 | −0.59 | −0.78 | 0.75 | 1 | ||||

| E.c | 0.70 | −0.59 | 0.13 | −0.59 | −0.29 | −0.48 | −0.55 | −0.51 | 0.67 | −0.52 | −0.59 | −0.78 | 0.75 | 1.00 | 1 | |||

| TFC | −0.48 | 0.33 | −0.18 | 0.15 | 0.14 | 0.22 | 0.42 | 0.28 | −0.38 | 0.60 | 0.58 | 0.74 | −0.82 | −0.66 | −0.66 | 1 | ||

| βPC | −0.61 | 0.47 | −0.36 | 0.11 | 0.07 | 0.19 | 0.36 | 0.24 | −0.39 | 0.49 | 0.57 | 0.67 | −0.86 | −0.75 | −0.75 | 0.96 | 1 | |

| PPO | 0.65 | −0.53 | 0.62 | −0.43 | −0.09 | −0.29 | −0.38 | −0.27 | 0.32 | −0.45 | −0.55 | −0.61 | 0.72 | 0.80 | 0.80 | −0.71 | −0.83 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magangana, T.P.; Makunga, N.P.; Fawole, O.A.; Stander, M.A.; Opara, U.L. Antioxidant, Antimicrobial, and Metabolomic Characterization of Blanched Pomegranate Peel Extracts: Effect of Cultivar. Molecules 2022, 27, 2979. https://doi.org/10.3390/molecules27092979

Magangana TP, Makunga NP, Fawole OA, Stander MA, Opara UL. Antioxidant, Antimicrobial, and Metabolomic Characterization of Blanched Pomegranate Peel Extracts: Effect of Cultivar. Molecules. 2022; 27(9):2979. https://doi.org/10.3390/molecules27092979

Chicago/Turabian StyleMagangana, Tandokazi Pamela, Nokwanda P. Makunga, Olaniyi Amos Fawole, Maria A. Stander, and Umezuruike Linus Opara. 2022. "Antioxidant, Antimicrobial, and Metabolomic Characterization of Blanched Pomegranate Peel Extracts: Effect of Cultivar" Molecules 27, no. 9: 2979. https://doi.org/10.3390/molecules27092979

APA StyleMagangana, T. P., Makunga, N. P., Fawole, O. A., Stander, M. A., & Opara, U. L. (2022). Antioxidant, Antimicrobial, and Metabolomic Characterization of Blanched Pomegranate Peel Extracts: Effect of Cultivar. Molecules, 27(9), 2979. https://doi.org/10.3390/molecules27092979