Comparison of Phenolic Profile of Balsamic Vinegars Determined Using Liquid and Gas Chromatography Coupled with Mass Spectrometry

Abstract

:1. Introduction

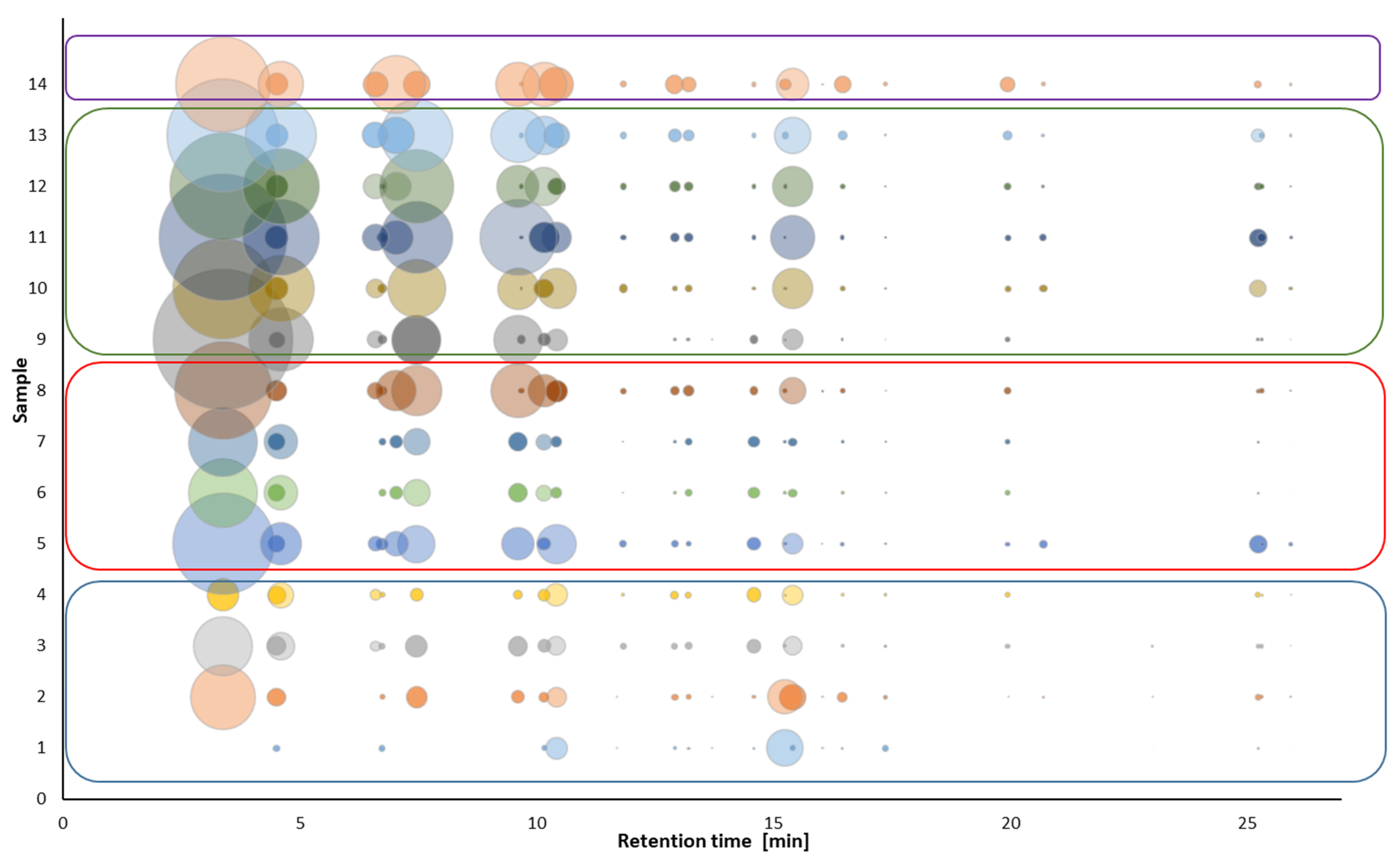

2. Results

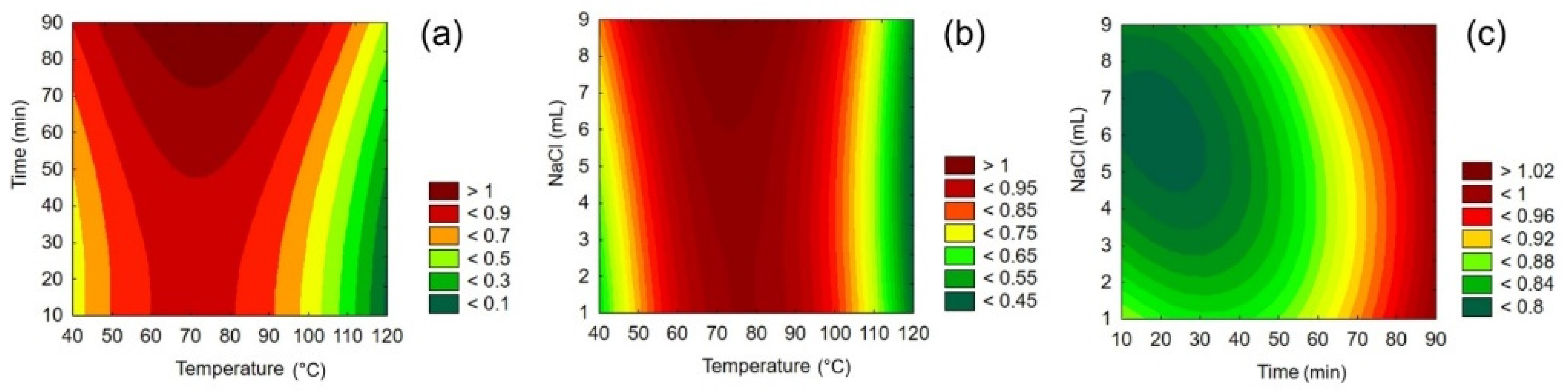

2.1. Selection and Optimization of Extraction Techniques for GC Analysis

2.2. Optimization of HPLC-MS/MS Conditions

3. Discussion

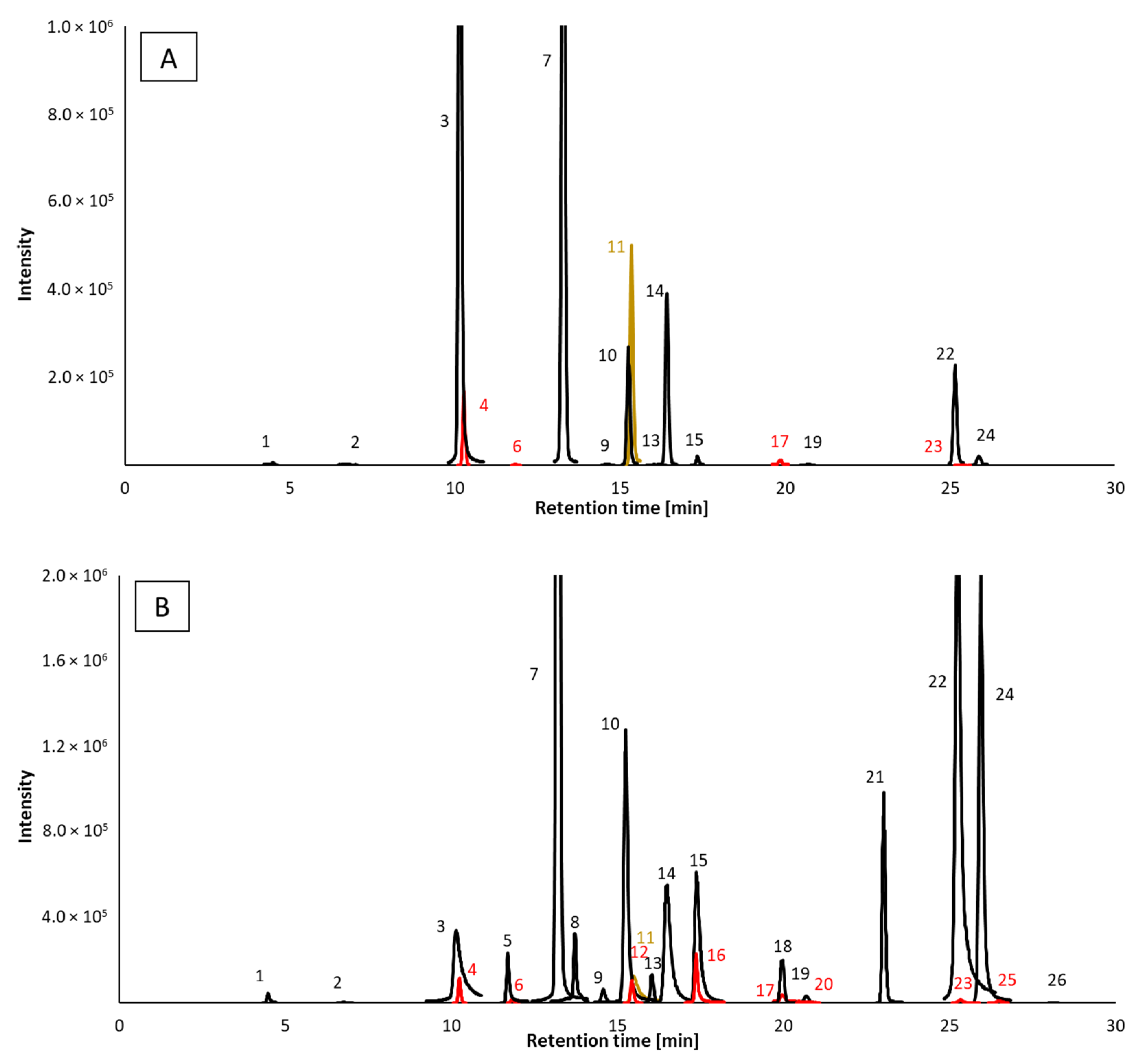

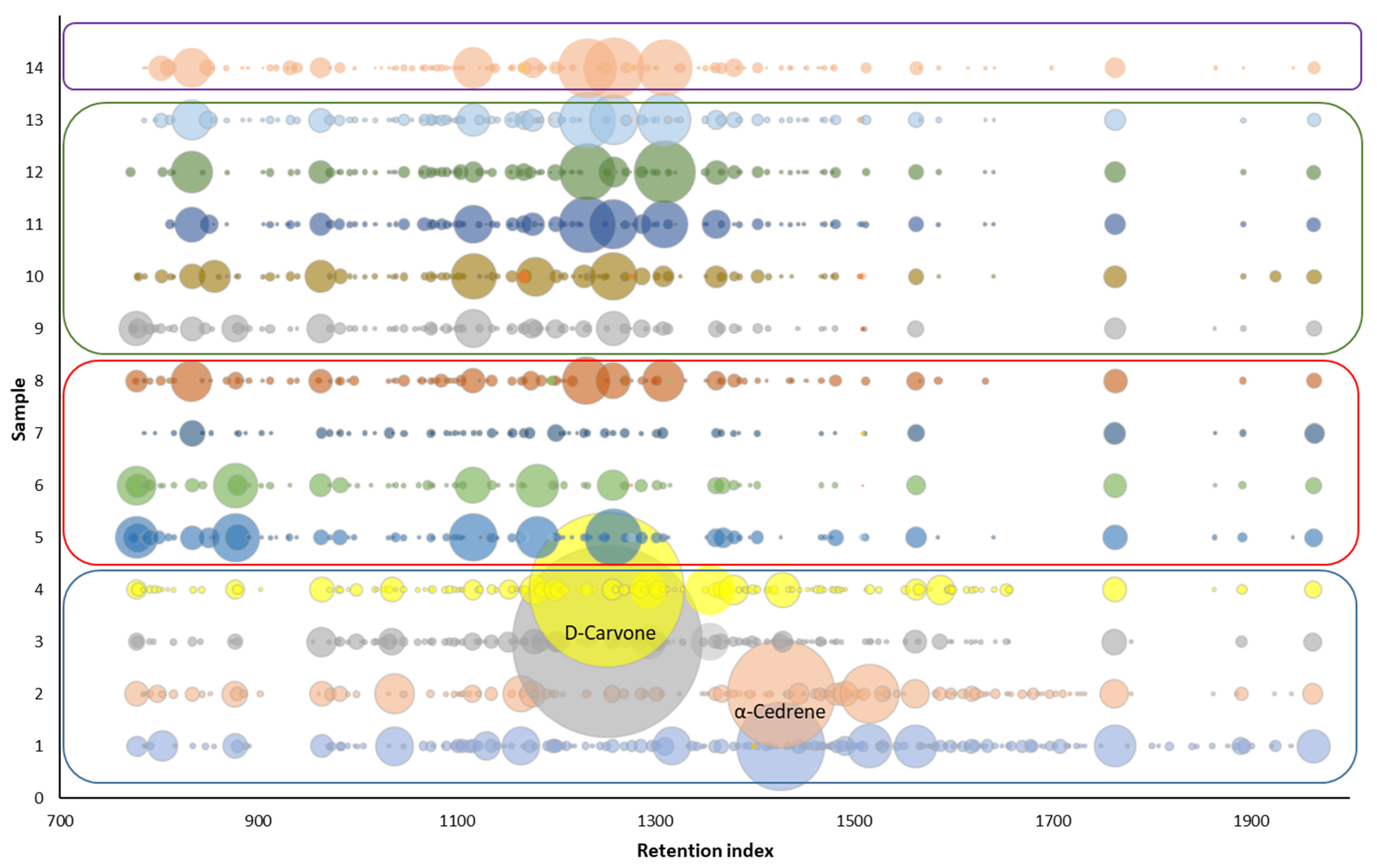

3.1. Gas Chromatography

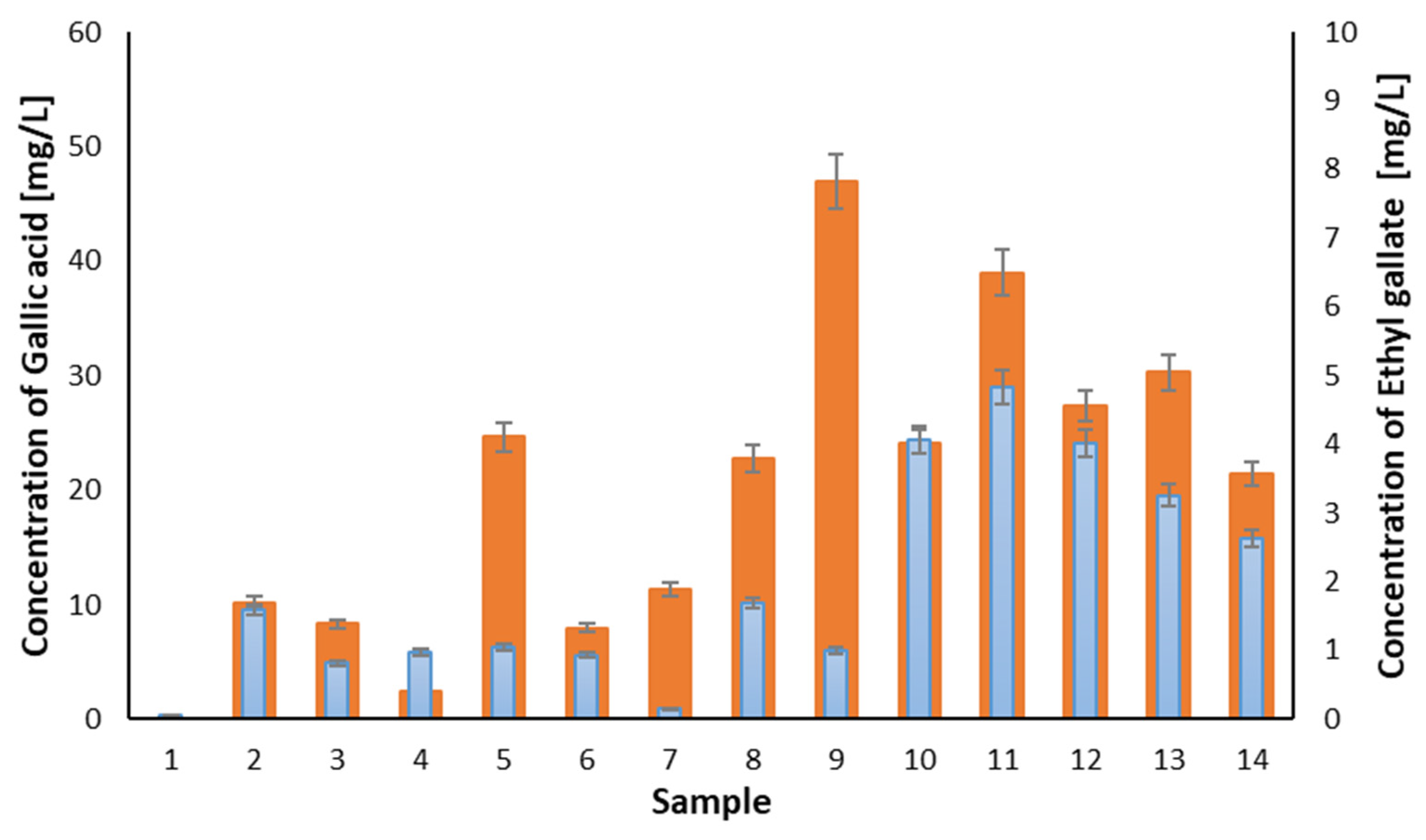

3.2. Liquid Chromatography

4. Materials and Methods

4.1. Chemical and Reagents

4.2. Samples

4.3. Gas Chromatography

4.3.1. Selection of Extraction Technique

Sample Preparation before Extraction

Static Headspace Extraction

Headspace Solid-Phase Microextraction

4.3.2. Headspace Solid-Phase Microextraction Technique—Optimization

4.3.3. Gas Chromatography Conditions

4.4. Liquid Chromatography

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Ho, C.T. Phenolic Compounds in Food. In Phenolic Compounds in Food and Their Effects on Health II; Huang, M.T., Ho, C.T., Lee, C.Y., Eds.; American Chemical Society: Washington, DC, USA, 1992; pp. 2–7. [Google Scholar]

- Tomás-Barberán, F.A.; Espín, J.C. Phenolic compounds and related enzymes as determinants of quality in fruits a vegetables. J. Sci. Food Agric. 2001, 81, 853–876. [Google Scholar] [CrossRef]

- Scalbert, A.; Williamson, G. Dietary Intake and Bioavailability of Polyphenols. J. Nutr. 2000, 130, 2073–2085. [Google Scholar] [CrossRef]

- Buonocore, G.; Perrone, S.; Tataranno, M.L. Oxygen toxicity: Chemistry and biology of reactive oxygen species. Semin. Fetal Neonatal Med. 2010, 15, 186–190. [Google Scholar] [CrossRef]

- Shahidi, F. Natural Antioxidants: An Overview. In Natural Antioxidants: Chemistry, Health Effects and Applications; Shahidi, F., Ed.; The American Oil Chemists Society: Urbana, IL, USA, 1997. [Google Scholar]

- Soleas, G.J.; Grass, L.; Josephy, P.D.; Goldberg, D.M.; Diamais, E.P. A comparison of the anticarcinogenic properties of four red wine polyphenols. Clin. Biochem. 2002, 35, 119–124. [Google Scholar] [CrossRef]

- Bernátová, I.; Pechánová, O.; Babál, P.; Kyselá, S.; Stvrtina, S.; Ariantsitohaina, R. Wine polyphenols improve cardiovascular remodeling and vascular function in NO-deficient hypertension. Am. J. Physiol. Heart Circ. Physiol. 2002, 282, 942–948. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barnaba, C.; Dellacassa, E.; Nicolini, G.; Nardin, T.; Malacarne, M.; Larcher, R. Identification and quantification of 56 targeted phenols in wines, spirits, and vinegars by online solid-phase extraction—Ultrahigh-performance liquid chromatography—Quadrupole-orbitrap mass spectrometry. J. Chromatogr. A 2015, 1423, 124–135. [Google Scholar] [CrossRef] [PubMed]

- European Council Regulation (EC) 813/2000 of 17 April 2000 Supplementing the Annex to Commission Regulation (EC) No 1107/96 on the Registration of Geographical Indications and Designations of Origin under the Procedure Laid down in Article 17 of Regulation (EEC) No 2081/92. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32000R0813 (accessed on 10 January 2022).

- Giudici, P.; Gullo, M.; Solieri, L. Traditional Balsamic Vinegar. In Vinegars of the World, 1st ed.; Solieri, L., Giudici, P., Eds.; Springer: Milano, Italy, 2009; pp. 157–177. [Google Scholar]

- Caligiani, A.; Silva, G.; Palla, G. Determination of 2,3-Butanediol a 2-Hydroxybutanone Stereoisomers in Batteries of Traditional Balsamic Vinegar. J. Agric. Food Chem. 2007, 55, 7810–7815. [Google Scholar] [CrossRef] [PubMed]

- European Commission Regulation (EC) 583/2009 of 3 July 2009 Entering a Name in the Register of Protected Designations of Origin and Protected Geographical Indications [Aceto Balsamico di Modena (PGI)]. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32009R0583 (accessed on 10 January 2022).

- Mattia, G. Balsamic vinegar of Modena: From product to market value: Competitive strategy of a typical Italian product. Br. Food J. 2004, 106, 722–745. [Google Scholar] [CrossRef]

- Liu, Q.; Tang, G.Y.; Zhao, C.N.; Gan, R.Y.; Li, H.B. Antioxidant Activities, Phenolic Profiles, and Organic Acid Contents of Fruit Vinegars. Antioxidants 2019, 8, 78. [Google Scholar] [CrossRef] [Green Version]

- Bakir, S.; Devecioglu, D.; Kayacan, S.; Toydemir, G.; Karbancioglu-Guler, F.; Capanoglu, E. Investigating the antioxidant and antimicrobial activities of different vinegars. Eur. Food Res. Technol. 2017, 243, 2083–2094. [Google Scholar] [CrossRef]

- Natera, R.; Castro, R.; Hernáez, M.J.; García-Barroso, C. Chemometric Studies of Vinegars from Different Raw Materials and Processes of Production. J. Agric. Food Chem. 2003, 51, 3345–3351. [Google Scholar] [CrossRef] [PubMed]

- Cerezo, A.B.; Tesfaye, W.; Soria-Díaz, M.E.; Torija, M.J.; Mateo, E.; Garcia-Parrilla, M.C.; Troncoso, A.M. Effect of wood on the phenolic profile and sensory properties of wine vinegars during ageing. J. Food Compos. Anal. 2010, 23, 175–184. [Google Scholar] [CrossRef]

- Cacciola, F.; Farnetti, S.; Dugo, P.; Marriott, P.J.; Mondello, L. Comprehensive two-dimensional liquid chromatography for polyphenol analysis in foodstuffs. J. Sep. Sci. 2017, 40, 7–24. [Google Scholar] [CrossRef] [PubMed]

- Cacciola, F.; Rigano, F.; Dugo, P.; Mondello, L. Comprehensive two-dimensional liquid chromatography as a powerful tool for the analysis of food and food products. TrAC Trends Anal. Chem. 2020, 127, 115894. [Google Scholar] [CrossRef]

- Kalili, K.M.; Vestner, J.; Stander, M.A.; de Villiers, A. Toward Unraveling Grape Tannin Composition: Application of Online Hydrophilic Interaction Chromatography × Reversed-Phase Liquid Chromatography–Time-of-Flight Mass Spectrometry for Grape Seed Analysis. Anal. Chem. 2013, 85, 9107–9115. [Google Scholar] [CrossRef] [PubMed]

- Montero, L.; Saez, V.; von Baer, D.; Cifuentes, A.; Herrero, M. Profiling of Vitis vinifera L. canes (poly)phenolic compounds using comprehensive two-dimensional liquid chromatography. J. Chromatogr. A 2018, 1536, 205–215. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wicht, K.; Baert, M.; Muller, M.; Bandini, E.; Schipperges, S.; von Doehren, N.; Desmet, G.; Lynen, F. Comprehensive two-dimensional temperature-responsive × reversed phase liquid chromatography for the analysis of wine phenolics. Talanta 2022, 236, 122889. [Google Scholar] [CrossRef] [PubMed]

- Cacciola, F.; Jandera, P.; Hajdu, Z.; Cesla, P.; Mondello, L. Comprehensive two-dimensional liquid chromatography with parallel gradients for separation of phenolic and flavone antioxidants. J. Chromatogr. A 2007, 1149, 73–87. [Google Scholar] [CrossRef] [PubMed]

- Plessi, M.; Bertelli, D.; Miglietta, F. Extraction and identification by GC-MS of phenolic acids in traditional balsamic vinegar from Modena. J. Food Comp. Anal. 2006, 19, 49–54. [Google Scholar] [CrossRef]

- Sinanoglou, V.; Zoumpoulakis, P.; Fotakis, C.; Kalogeropoulos, N.; Sakellari, A.; Karavoltsos, S.; Strati, I. On the Characterization and Correlation of Compositional, Antioxidant and Colour Profile of Common and Balsamic Vinegars. Antioxidants 2018, 7, 139. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arigo, A.; Česla, P.; Šilarová, P.; Calabro, M.L.; Česlová, L. Development of extraction method for characterization of free and bonded polyphenols in barley (Hordeum vulgare L.) grown in Czech Republic using liquid chromatography-tandem mass spectrometry. Food Chem. 2018, 245, 829–837. [Google Scholar] [CrossRef] [PubMed]

- Durán Guerrero, E.; Chinnici, F.; Natali, N.; Marín, R.N.; Riponi, C. Solid-phase extraction method for determination of volatile compounds in traditional balsamic vinegar. J. Sep. Sci. 2008, 31, 3030–3036. [Google Scholar] [CrossRef] [PubMed]

- Chinnici, F.; Durán Guerrero, E.; Sonni, F.; Natali, N.; Marín, R.N.; Riponi, C. Gas Chromatography−Mass Spectrometry (GC−MS) Characterization of Volatile Compounds in Quality Vinegars with Protected European Geographical Indication. J. Agric. Food Chem. 2009, 57, 4784–4792. [Google Scholar] [CrossRef]

- Zeppa, G.; Giordano, M.; Gerbi, V.; Meglioli, G. Characterisation of volatile compounds in three acetification batteries used for the production of Aceto Balsamico Tradizionale di Reggio Emilia. Ital. J. Food Sci. 2002, 14, 247–266. [Google Scholar]

- Guerrero, E.D.; Marín, R.N.; Mejías, R.C.; Barroso, C.G. Stir bar sorptive extraction of volatile compounds in vinegar: Validation study and comparison with solid phase microextraction. J. Chromatogr. A 2007, 1167, 18–26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marrufo-Curtido, A.; Cejudo-Bastante, M.J.; Durán-Guerrero, E.; Castro-Mejías, R.; Natera Marín, R.; Chinnici, F.; García-Barroso, C. Characterization and differentiation of high quality vinegars by stir bar sorptive extraction coupled to gas chromatography-mass spectrometry (SBSE–GC–MS). Food Sci. Technol. 2012, 47, 332–341. [Google Scholar] [CrossRef]

- Alissandrakis, E.; Tarantilis, P.A.; Harizanis, P.C.; Polissiou, M. Comparison of the Volatile Composition in Thyme Honeys from Several Origins in Greece. J. Agric. Food Chem. 2007, 55, 8152–8157. [Google Scholar] [CrossRef]

- Sterckx, F.L.; Missiaen, J.; Saison, D.; Delvaux, F.R. Contribution of monophenols to beer flavour based on flavour thresholds, interactions and recombination experiments. Food Chem. 2011, 126, 1679–1685. [Google Scholar] [CrossRef]

- Morcia, C.; Tumino, G.; Ghizzoni, R.; Terzi, V. Carvone (Mentha spicata L.) Oils. In Essential Oils in Food Preservation, Flavor and Safety; Academic Press: Amsterdam, The Netherlands, 2016; pp. 309–316. [Google Scholar]

- Adams, R.P. Cedar Wood Oil—Analyses and Properties. In Essential Oils and Waxes; Linskens, H.F., Jackon, J.F., Eds.; Springer: Berlin/Heidelberg, Germany, 1991; pp. 159–173. [Google Scholar]

- Food and Drugs. Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?FR=172.515 (accessed on 10 January 2022).

- Deng, W.W.; Wang, R.; Yang, T.; Jiang, L.; Zhang, Z.-Z. Functional Characterization of Salicylic Acid Carboxyl Methyltransferase from Camellia sinensis, Providing the Aroma Compound of Methyl Salicylate during the Withering Process of White Tea. J. Agric. Food Chem. 2017, 65, 11036–11045. [Google Scholar] [CrossRef]

- Chatonnet, P.; Dubourdie, D.; Boidron, J.N.; Pons, M. The origin of ethylphenols in wines. J. Sci. Food Agric. 1992, 60, 165–178. [Google Scholar] [CrossRef]

- Pineiro, Z.; Cantos-Villar, E.; Palma, M.; Puertas, B. Direct Liquid Chromatography Method for the Simultaneous Quantification of Hydroxytyrosol and Tyrosol in Red Wines. J. Agric. Food Chem. 2011, 59, 11683–11689. [Google Scholar] [CrossRef] [PubMed]

- Burri, J.; Graf, M.; Lambelet, P.; Löliger, J. Vanillin: More than a flavouring agent—A potent antioxidant. J. Sci. Food Agric. 1989, 48, 49–56. [Google Scholar] [CrossRef]

- Bicchi, C.; Cordero, C.; Liberto, E.; Sgorbini, B.; Rubiolo, P. Headspace sampling of the volatile fraction of vegetable matrices. J. Chromatogr. A 2008, 1184, 220–233. [Google Scholar] [CrossRef] [PubMed]

| Sample | Trademark | Type | Approximate Price (EUR/100 mL) |

|---|---|---|---|

| 1 | Galaxy | White balsamic vinegar | 0.7 |

| 2 | Galaxy | Balsamic vinegar | 0.6 |

| 3 | Agia Triada | Balsamic vinegar (with thyme honey) | 2.0 |

| 4 | Agia Triada | Balsamic vinegar | 1.5 |

| 5 | San Fabio | BVM | 0.3 |

| 6 | Italiamo | BVM | 0.9 |

| 7 | Italiamo | BVM | 0.8 |

| 8 | Deluxe | BVM | 1.4 |

| 9 | Giuseppe Giusti | Silver medal BVM | 11.0 |

| 10 | Giuseppe Giusti | 2 × Gold medals BVM | 15.5 |

| 11 | Giuseppe Giusti | 3 × Gold medals BVM | 23.0 |

| 12 | Giuseppe Giusti | 4 × Gold medals BVM | 35.0 |

| 13 | Giuseppe Giusti | 5 × Gold medals BVM | 53.0 |

| 14 | Acetaia Casanova | TBVM | 70.0 |

| Compound | Greek Vinegars | BVM | “Premium” BVM | TBVM | Barnaba et al. [8] | Natera et al. [16] | Liu et al. [14] |

|---|---|---|---|---|---|---|---|

| Gallic acid | 6.97 ± 4.03 | 11.61 ± 9.43 | 33.53 ± 9.33 | 21.42 ± 0.16 | 12.4 ± 11.8 | 64.50 ± 10.20 | 12.56 ± 0.86 |

| Protocatechuic acid | 1.69 ± 0.23 | 3.48 ± 1.00 | 12.06 ± 1.73 | 5.09 ± 1.42 | 6.11 ± 7.14 | 13.40 ± 29.94 | 3.29 ± 0.05 |

| Caffeic acid | 0.86 ± 0.43 | 1.52 ± 1.32 | 10.22 ± 3.21 | 1.61 ± 0.10 | 3.14 ± 3.17 | 28.70 ± 12.40 | 3.58 ± 0.14 |

| p-Coumaric acid | 0.47 ± 0.37 | 1.00 ± 1.02 | 7.09 ± 4.09 | 4.707 ± 0.69 | 2.45 ± 2.52 | 22.40 ± 33.00 | 1.97 ± 0.05 |

| Salicylic acid | 0.26 ± 0.01 | 0.63 ± 0.13 | 1.21 ± 0.45 | 1.51 ± 0.05 | 0.29 ± 0.26 | ||

| Syringic acid | n.d. | 1.90 ± 1.81 | 2.71 ± 0.57 | 8.14 ± 1.04 | 1.05 ± 1.11 | n.d. | |

| Pyrogallol | 0.80 ± 0.03 | 0.80 ± 0.23 | 1.06 ± 0.26 | 1.12 ± 0.003 | |||

| Ethyl gallate | 1.13 ± 0.41 | 0.96 ± 0.63 | 3.44 ± 1.47 | 2.63 ± 0.04 | |||

| Tyrosol | 0.99 ± 0.19 | 1.88 ± 1.52 | 1.85 ± 1.16 | 2.906 ± 0.08 | 0.27 ± 0.36 | 109.40 ± 60.10 | |

| Protocatechuic aldehyde | 0.32 ± 0.08 | 0.92 ± 1.07 | 2.10 ± 1.44 | 4.62 ± 0.07 | 6.41 ± 8.35 | 15.70 ± 2.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kašpar, M.; Bajer, T.; Bajerová, P.; Česla, P. Comparison of Phenolic Profile of Balsamic Vinegars Determined Using Liquid and Gas Chromatography Coupled with Mass Spectrometry. Molecules 2022, 27, 1356. https://doi.org/10.3390/molecules27041356

Kašpar M, Bajer T, Bajerová P, Česla P. Comparison of Phenolic Profile of Balsamic Vinegars Determined Using Liquid and Gas Chromatography Coupled with Mass Spectrometry. Molecules. 2022; 27(4):1356. https://doi.org/10.3390/molecules27041356

Chicago/Turabian StyleKašpar, Michal, Tomáš Bajer, Petra Bajerová, and Petr Česla. 2022. "Comparison of Phenolic Profile of Balsamic Vinegars Determined Using Liquid and Gas Chromatography Coupled with Mass Spectrometry" Molecules 27, no. 4: 1356. https://doi.org/10.3390/molecules27041356

APA StyleKašpar, M., Bajer, T., Bajerová, P., & Česla, P. (2022). Comparison of Phenolic Profile of Balsamic Vinegars Determined Using Liquid and Gas Chromatography Coupled with Mass Spectrometry. Molecules, 27(4), 1356. https://doi.org/10.3390/molecules27041356