Comparative Study on Volatile Compounds and Taste Components of Different Durian Cultivars Based on GC-MS, UHPLC, HPAEC-PAD, E-Tongue and E-Nose

Abstract

1. Introduction

2. Results and Discussion

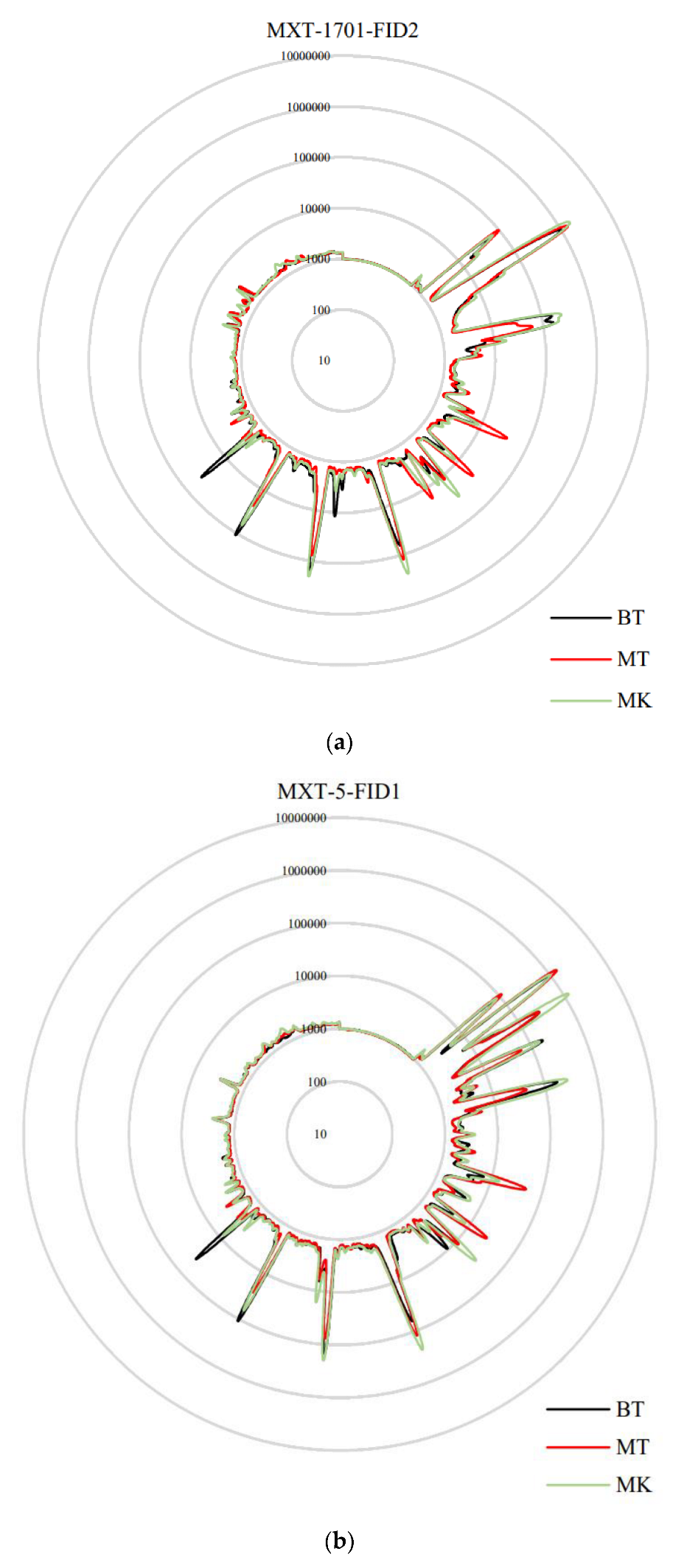

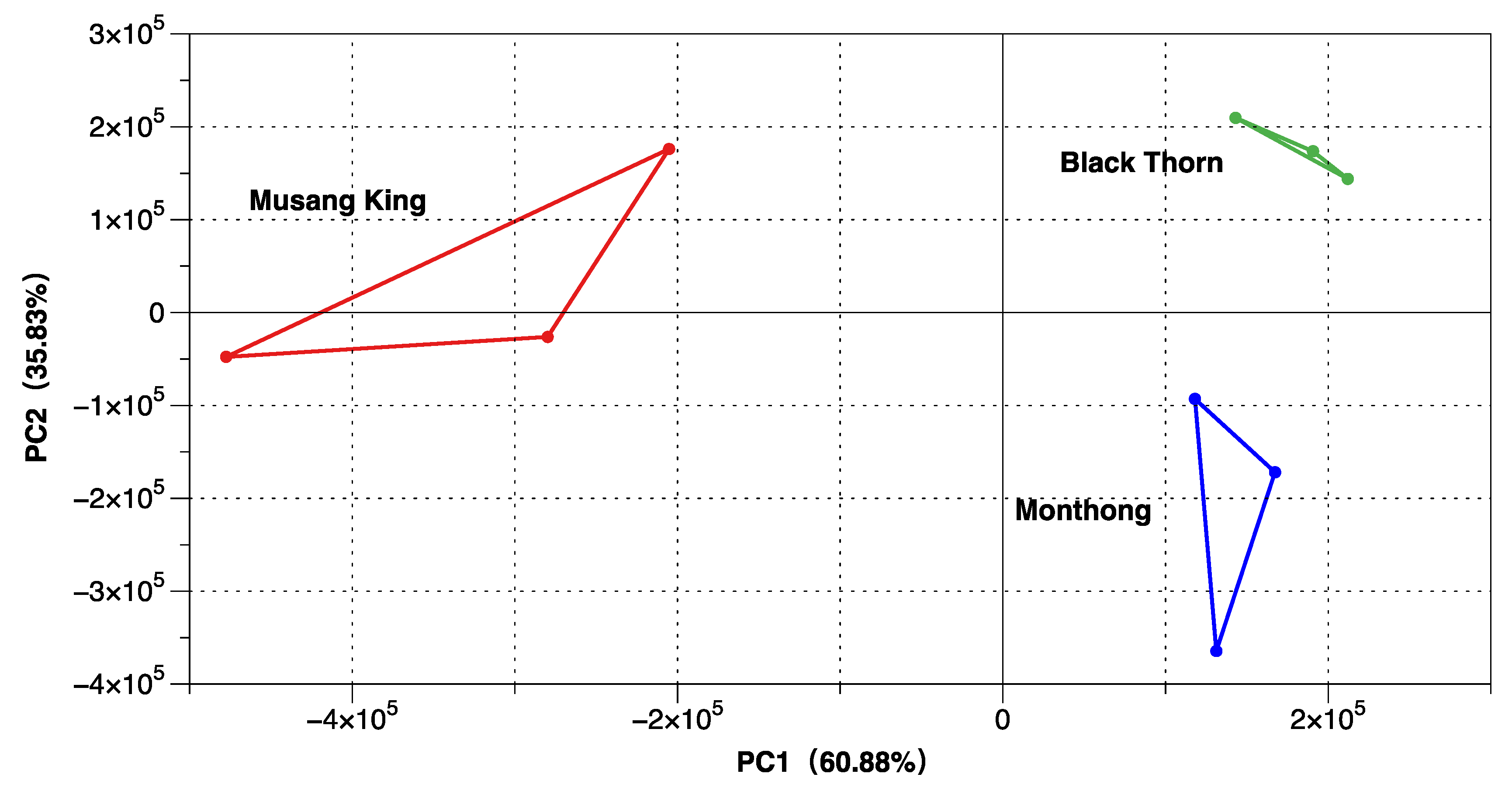

2.1. Volatile Organic Compounds (VOCs)

2.2. Sugars, Organic Acids and Amino Acids of Durian Fruits

2.3. E-Nose and E-Tongue Analyses

3. Materials and Methods

3.1. Materials

3.2. Chemicals

3.3. Determination of Volatile Organic Compounds

3.4. Determination of Sugar Contents

3.5. Determination of Organic Acid Contents

3.6. Determination of Free Amino Acids Contents

3.7. E-Tongue Analysis

3.8. Electronic Nose Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Pinsorn, P.; Oikawa, A.; Watanabe, M.; Sasaki, R.; Ngamchuachit, P.; Hoefgen, R.; Saito, K.; Sirikantaramas, S. Metabolic variation in the pulps of two durian cultivars: Unraveling the metabolites that contribute to the flavor. Food Chem. 2018, 268, 118–125. [Google Scholar] [CrossRef] [PubMed]

- Rueangrit, P.; Jatuporn, C.; Suvanvihok, V.; Wanaset, A. Forecasting Production and Export of Thailand’s Durian Fruit: An Empirical Study using the Box–Jenkins Approach. Humanit. Soc. Sci. Lett. 2020, 8, 430–437. [Google Scholar] [CrossRef]

- Tan, X.Y.; Misran, A.; Cheong, K.W.; Daim, L.D.J.; Ding, P.; Dek, M.S.P. Postharvest quality indices of different durian clones at ripening stage and their volatile organic compounds. Sci. Hortic. 2020, 264, 109169. [Google Scholar] [CrossRef]

- Oladokun, O.; James, S.; Cowley, T.; Dehrmann, F.; Smart, K.; Hort, J.; Cook, D. Perceived bitterness character of beer in relation to hop variety and the impact of hop aroma. Food Chem. 2017, 230, 215–224. [Google Scholar] [CrossRef]

- Niimi, J.; Eddy, A.I.; Overington, A.R.; Heenan, S.P.; Silcock, P.; Bremer, P.J.; Delahunty, C.M. Aroma–taste interactions between a model cheese aroma and five basic tastes in solution. Food Qual. Prefer. 2014, 31, 1–9. [Google Scholar] [CrossRef]

- Li, J.-X.; Schieberle, P.; Steinhaus, M. Characterization of the Major Odor-Active Compounds in Thai Durian (Durio zibethinus L. ‘Monthong’) by Aroma Extract Dilution Analysis and Headspace Gas Chromatography-Olfactometry. J. Agric. Food Chem. 2012, 60, 11253–11262. [Google Scholar] [CrossRef]

- Li, J.-X.; Schieberle, P.; Steinhaus, M. Insights into the Key Compounds of Durian (Durio zibethinus L. ‘Monthong’) Pulp Odor by Odorant Quantitation and Aroma Simulation Experiments. J. Agric. Food Chem. 2017, 65, 639–647. [Google Scholar] [CrossRef]

- Lin, H.; Li, S.; Xu, C.; Pang, M.; Wang, S. Simultaneous determination of galactose, glucose, lactose and galactooligosaccharides in galactooligosaccharides raw materials by high-performance anion-exchange chromatography with pulsed amperometric detection. Food Chem. 2018, 263, 29–36. [Google Scholar] [CrossRef]

- Yang, L.; Zhai, Y.; Chen, X.; Zhang, Z.; Gong, X.; Zhou, D.; Kong, J.; Zhang, W.; Zhang, Q.; Niu, C.; et al. Rapid identification of chemical compositions in callicarpa kwangtungensis Chun by ultra-high-performance liquid chromatography with Q Exactive hybrid quadrupole orbitrap high-resolution accurate mass spectrometry. J. Sep. Sci. 2020, 43, 2487–2494. [Google Scholar] [CrossRef]

- Aschariyaphotha, W.; Wongs-Aree, C.; Bodhipadma, K.; Noichinda, S. Fruit Volatile Fingerprints Characterized among Four Commercial Cultivars of Thai Durian (Durio zibethinus). J. Food Qual. 2021, 2021, 1383927. [Google Scholar] [CrossRef]

- Tiitinen, K.; Hakala, M.; Kallio, H. Headspace volatiles from frozen berries of sea buckthorn (Hippophaë rhamnoides L.) varieties. Eur. Food Res. Technol. 2006, 223, 455–460. [Google Scholar] [CrossRef]

- Lee, Y.-Y.; Jeong, M.-C.; Jang, H.W. Determination of volatile compounds by headspace-solid phase microextraction-gas chromatography/mass spectrometry: Quality evaluation of Fuji apple. Anal. Sci. Technol. 2017, 30, 68–74. [Google Scholar] [CrossRef][Green Version]

- Chin, S.; Nazimah, S.; Quek, S.-Y.; Man, Y.C.; Rahman, R.A.; Hashim, D.M. Analysis of volatile compounds from Malaysian durians (Durio zibethinus) using headspace SPME coupled to fast GC-MS. J. Food Compos. Anal. 2007, 20, 31–44. [Google Scholar] [CrossRef]

- Clark, S.; Winter, C.K. Diacetyl in Foods: A Review of Safety and Sensory Characteristics. Compr. Rev. Food Sci. Food Saf. 2015, 14, 634–643. [Google Scholar] [CrossRef]

- Besada, C.; Sanchez, G.; Salvador, A.; Granell, A. Volatile compounds associated to the loss of astringency in persimmon fruit revealed by untargeted GC–MS analysis. Metabolomics 2012, 9, 157–172. [Google Scholar] [CrossRef]

- Gong, D.; Bi, Y.; Li, S.; Li, Y.; Wang, Y. Trichothecium roseum infection promotes ripening of harvested muskmelon fruits and induces the release of specific volatile compound. J. Plant Pathol. 2019, 101, 529–538. [Google Scholar] [CrossRef]

- Song, H.S.; Phi, N.T.L.; Sawamura, M. Volatile Profile of the Peel Oil of Kiyomi (Citrus unshiu Marcov. x C. sinensis Osbeck), A New Hybrid Sweet Citrus Fruit. J. Essent. Oil Res. 2009, 21, 26–30. [Google Scholar] [CrossRef]

- Mattheis, J.P.; Fellman, J.K. Preharvest factors influencing flavor of fresh fruit and vegetables. Postharvest Biol. Technol. 1999, 15, 227–232. [Google Scholar] [CrossRef]

- Lee, P.; Tan, R.; Yu, B.; Curran, P.; Liu, S. Sugars, organic acids, and phenolic acids of exotic seasonable tropical fruits. Nutr. Food Sci. 2013, 43, 267–276. [Google Scholar] [CrossRef]

- Gomez, M.; Lajolo, F.; Cordenunsi, B. Evolution of Soluble Sugars during Ripening of Papaya Fruit and its Relation to Sweet Taste. J. Food Sci. 2002, 67, 442–447. [Google Scholar] [CrossRef]

- Cordenunsi, B.R.; Lajolo, F.M. Starch Breakdown during Banana Ripening: Sucrose Synthase and Sucrose Phosphate Synthase. J. Agric. Food Chem. 1995, 43, 347–351. [Google Scholar] [CrossRef]

- Liu, J.; Guo, S.; He, H.; Zhang, H.; Gong, G.; Ren, Y.; Xu, Y. Dynamic characteristics of sugar accumulation and related enzyme activities in sweet and non-sweet watermelon fruits. Acta Physiol. Plant. 2013, 35, 3213–3222. [Google Scholar] [CrossRef]

- Walker, R.P.; Famiani, F. Organic acids in fruits: Metabolism, functions and contents. Hortic. Rev. 2018, 45, 371–430. [Google Scholar]

- Voon, Y.; Hamid, N.S.A.; Rusul, G.; Osman, A.; Quek, S.-Y. Characterisation of Malaysian durian (Durio zibethinus Murr.) cultivars: Relationship of physicochemical and flavour properties with sensory properties. Food Chem. 2007, 103, 1217–1227. [Google Scholar] [CrossRef]

- Junge, J.Y.; Bertelsen, A.S.; Mielby, L.A.; Zeng, Y.; Sun, Y.-X.; Byrne, D.V.; Kidmose, U. Taste Interactions between Sweetness of Sucrose and Sourness of Citric and Tartaric Acid among Chinese and Danish Consumers. Foods 2020, 9, 1425. [Google Scholar] [CrossRef]

- Belgis, M.; Wijaya, C.H.; Apriyantono, A.; Kusbiantoro, B.; Yuliana, N.D. Volatiles and aroma characterization of several lai (Durio kutejensis) and durian (Durio zibethinus) cultivars grown in Indonesia. Sci. Hortic. 2017, 220, 291–298. [Google Scholar] [CrossRef]

- Albertini, M.-V.; Carcouet, E.; Pailly, O.; Gambotti, C.; Luro, F.; Berti, L. Changes in Organic Acids and Sugars during Early Stages of Development of Acidic and Acidless Citrus Fruit. J. Agric. Food Chem. 2006, 54, 8335–8339. [Google Scholar] [CrossRef]

- Campbell, C.; Koch, K. Sugar/acid composition and development of sweet and tart carambola fruit. J. Am. Soc. Hortic. Sci. 1989, 114, 455–457. [Google Scholar]

- Tieman, D.; Taylor, M.; Schauer, N.; Fernie, A.R.; Hanson, A.D.; Klee, H.J. Tomato aromatic amino acid decarboxylases participate in synthesis of the flavor volatiles 2-phenylethanol and 2-phenylacetaldehyde. Proc. Natl. Acad. Sci. USA 2006, 103, 8287–8292. [Google Scholar] [CrossRef]

- Shiraishi, M.; Fujishima, H.; Chijiwa, H. Evaluation of table grape genetic resources for sugar, organic acid, and amino acid composition of berries. Euphytica 2009, 174, 1–13. [Google Scholar] [CrossRef]

- Jiang, W.-D.; Wu, P.; Tang, R.-J.; Liu, Y.; Kuang, S.-Y.; Jiang, J.; Tang, L.; Tang, W.-N.; Zhang, Y.-A.; Zhou, X.-Q.; et al. Nutritive values, flavor amino acids, healthcare fatty acids and flesh quality improved by manganese referring to up-regulating the antioxidant capacity and signaling molecules TOR and Nrf2 in the muscle of fish. Food Res. Int. 2016, 89 Pt 1 Pt 1, 670–678. [Google Scholar] [CrossRef]

- Fischer, N.S.; Steinhaus, M. Identification of an Important Odorant Precursor in Durian: First Evidence of Ethionine in Plants. J. Agric. Food Chem. 2020, 68, 10397–10402. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Yu, J.; Pei, F.; Mariga, A.M.; Ma, N.; Fang, Y.; Hu, Q. Effect of hot air drying on volatile compounds of Flammulina velutipes detected by HS-SPME–GC–MS and electronic nose. Food Chem. 2016, 196, 860–866. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Wang, J.; Li, D.; Wang, M. Electronic tongue coupled with physicochemical analysis for the recognition of orange beverages. J. Food Qual. 2012, 35, 429–441. [Google Scholar] [CrossRef]

- Wang, Y.-Q.; Hu, L.-P.; Liu, G.-M.; Zhang, D.-S.; He, H.-J. Evaluation of the Nutritional Quality of Chinese Kale (Brassica alboglabra Bailey) Using UHPLC-Quadrupole-Orbitrap MS/MS-Based Metabolomics. Molecules 2017, 22, 1262. [Google Scholar] [CrossRef]

- Han, J.; Gagnon, S.; Eckle, T.; Borchers, C.H. Metabolomic analysis of key central carbon metabolism carboxylic acids as their 3-nitrophenylhydrazones by UPLC/ESI-MS. Electrophoresis 2013, 34, 2891–2900. [Google Scholar] [CrossRef]

- Mayer, H.K.; Fiechter, G. Application of UHPLC for the determination of free amino acids in different cheese varieties. Anal. Bioanal. Chem. 2013, 405, 8053–8061. [Google Scholar] [CrossRef]

- Feng, P.; Gao, M.; Burgher, A.; Zhou, T.H.; Pramuk, K. A nine-country study of the protein content and amino acid composition of mature human milk. Food Nutr. Res. 2016, 60, 31042. [Google Scholar] [CrossRef]

- Kaspar, H.; Dettmer, K.; Gronwald, W.; Oefner, P.J. Advances in amino acid analysis. Anal. Bioanal. Chem. 2009, 393, 445–452. [Google Scholar] [CrossRef]

- Zhu, D.; Ren, X.; Wei, L.; Cao, X.; Ge, Y.; Liu, H.; Li, J. Collaborative analysis on difference of apple fruits flavour using electronic nose and electronic tongue. Sci. Hortic. 2020, 260, 108879. [Google Scholar] [CrossRef]

- Niu, Y.; Zhang, J.; Xiao, Z.; Zhu, J. Evaluation of the Perceptual Interactions Between Higher Alcohols and Off-Odor Acids in Laimao Baijiu by sigma-tau Plot and Partition Coefficient. J. Agric. Food Chem. 2020, 68, 14938–14949. [Google Scholar] [CrossRef]

| No. | Compound | CAS | RI | Identification c | Concentration (μg/kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| HP-Innowax a | DB-5 b | Black Thorn | RSD d (%) | Monthong | RSD (%) | Musang King | RSD (%) | ||||

| 1 | ethyl mercaptan | 75-08-1 | 756 | <600 | St RI MS | 364.17 | 12.80 | 1617.98 | 13.63 | 3125.34 | 7.76 |

| 2 | propyl mercaptan | 107-03-9 | 835 | <600 | St RI MS | 174.28 | 13.99 | - | - | 218.54 | 9.92 |

| 3 | ethyl methyl sulfide | 624-89-5 | 856 | 612 | St RI MS | - | - | - | - | 2389.15 | 9.11 |

| 4 | ethyl acetate | 141-78-6 | 873 | <600 | St RI MS | - | - | 1722.75 | 1.53 | - | - |

| 5 | ethyl propionate | 105-37-3 | 950 | 681 | St RI MS | 61.43 | 12.48 | - | - | - | - |

| 6 | ethyl isobutyrate | 97-62-1 | 962 | 740 | St RI MS | - | - | 1014.01 | 3.51 | 341.15 | 6.90 |

| 7 | diacetyl | 431-03-8 | 988 | <600 | St RI MS | - | - | 2075.81 | 2.05 | 1537.33 | 9.54 |

| 8 | 2-pentanone | 107-87-9 | 988 | 662 | St RI MS | - | - | 74.65 | 10.80 | - | - |

| 9 | methyl 2-methyl butyrate | 868-57-5 | 1009 | 762 | St RI MS | 146.05 | 4.21 | 468.65 | 2.76 | 964.96 | 1.81 |

| 10 | ethyl butyrate | 105-54-4 | 1021 | 785 | St RI MS | - | - | 559.80 | 13.00 | - | - |

| 11 | propyl alcohol | 71-23-8 | 1038 | <600 | St RI MS | 1012.22 | 6.32 | 2456.31 | 13.88 | 3739.34 | 5.41 |

| 12 | ethyl 2-methyl butyrate | 7452-79-1 | 1053 | 834 | St RI MS | 1722.95 | 8.10 | 11,680.31 | 5.26 | 14,484.20 | 11.36 |

| 13 | dipropyl sulfide | 111-47-7 | 1076 | 879 | St RI MS | - | - | - | - | 20.85 | 6.60 |

| 14 | S-ethyl thioacetate | 625-60-5 | 1095 | 755 | St RI MS | - | - | - | - | 74.39 | 10.03 |

| 15 | diethyl carbonate | 105-58-8 | 1105 | 766 | St RI MS | - | - | 564.51 | 2.67 | - | - |

| 16 | methyl (E)-2-butenoate | 623-43-8 | 1109 | 746 | St RI MS | - | - | 83.90 | 5.95 | 37.58 | 4.26 |

| 17 | ethyl valerate | 539-82-2 | 1126 | 880 | St RI MS | - | - | 163.79 | 2.88 | - | - |

| 18 | propyl 2-methyl butyrate | 37064-20-3 | 1131 | 931 | St RI MS | 1818.42 | 11.66 | 1137.25 | 8.18 | 2880.98 | 7.66 |

| 19 | ethyl methyl disulfide | 20333-39-5 | 1148 | 816 | St RI MS | 124.34 | 6.91 | 526.51 | 8.96 | 1191.53 | 6.72 |

| 20 | ethyl (Z)-crotonate | 6776-19-8 | 1150 | 754 | St RI MS | 108.13 | 6.61 | - | - | - | - |

| 21 | propyl isovalerate | 557-00-6 | 1152 | 933 | St RI MS | 43.44 | 13.13 | 146.97 | 4.65 | - | - |

| 22 | butyl alcohol | 71-36-3 | 1154 | 653 | St RI MS | - | - | 631.74 | 13.29 | 305.87 | 1.89 |

| 23 | heptanal | 111-71-7 | 1171 | 882 | St RI MS | - | - | 71.22 | 13.91 | - | - |

| 24 | (E)-methyl tiglate | 6622-76-0 | 1180 | 858 | St RI MS | 37.68 | 11.62 | 49.20 | 10.28 | - | - |

| 25 | dextro-limonene | 5989-27-5 | 1196 | 1015 | St RI MS | - | - | 72.90 | 4.52 | 40.06 | 13.11 |

| 26 | 2-methyl-1-butanol | 137-32-6 | 1201 | 725 | St RI MS | 290.26 | 12.07 | 990.66 | 3.33 | - | - |

| 27 | isoamyl alcohol | 123-51-3 | 1203 | 721 | St RI MS | - | - | 550.31 | 5.71 | 1637.92 | 5.67 |

| 28 | diethyl disulfide | 110-81-6 | 1212 | 907 | St RI MS | 17,777.04 | 3.00 | 8665.01 | 10.52 | 27,253.26 | 11.76 |

| 29 | methyl propyl disulfide | 2179-60-4 | 1221 | 917 | St RI MS | 155.98 | 9.20 | 102.43 | 7.21 | 159.36 | 5.87 |

| 30 | ethyl hexanoate | 123-66-0 | 1226 | 979 | St RI MS | 355.56 | 10.66 | 1527.06 | 4.70 | 352.27 | 5.51 |

| 31 | (E)-ethyl tiglate | 5837-78-5 | 1228 | 925 | St RI MS | 430.37 | 7.21 | - | - | 204.04 | 9.78 |

| 32 | amyl alcohol | 71-41-0 | 1239 | 750 | St RI MS | - | - | 63.27 | 6.20 | 79.48 | 10.65 |

| 33 | 1-octanal | 124-13-0 | 1281 | 984 | St RI MS | - | - | 81.84 | 8.97 | - | - |

| 34 | acetoin | 513-86-0 | 1283 | 691 | St RI MS | - | - | 1240.91 | 11.11 | 655.79 | 3.72 |

| 35 | propyl tiglate | 61692-83-9 | 1331 | 1028 | St RI MS | 262.85 | 2.32 | 74.17 | 2.99 | 28.18 | 5.02 |

| 36 | hexyl formate | 629-33-4 | 1350 | 901 | St RI MS | - | - | 264.43 | 8.94 | - | - |

| 37 | hexanol | 111-27-3 | 1363 | 851 | St RI MS | 106.54 | 3.80 | - | - | 505.16 | 2.31 |

| 38 | dipropyl disulfide | 629-19-6 | 1367 | 1101 | St RI MS | 538.15 | 11.86 | 61.25 | 4.07 | 511.46 | 2.68 |

| 39 | methyl octanoate | 111-11-5 | 1381 | 1113 | St RI MS | 53.80 | 8.18 | 110.43 | 6.70 | 43.22 | 9.04 |

| 40 | nonanal | 124-19-6 | 1392 | 1088 | St RI MS | - | - | 106.20 | 8.03 | 121.50 | 10.17 |

| 41 | hexyl 2-methyl butyrate | 10032-15-2 | 1431 | 1227 | St RI MS | 29.06 | 13.46 | - | - | - | - |

| 42 | ethyl octanoate | 106-32-1 | 1441 | 1178 | St RI MS | 265.37 | 2.84 | 860.81 | 3.19 | 173.15 | 6.34 |

| 43 | diethyl trisulfide | 3600-24-6 | 1520 | 1134 | St RI MS | 2514.78 | 3.46 | 1013.71 | 13.49 | 3203.47 | 11.51 |

| 44 | 3-hydroxybutyric acid ethyl ester | 5405-41-4 | 1524 | 923 | St RI MS | - | - | 409.98 | 8.75 | 64.70 | 7.23 |

| 45 | 3,5-dimethyl-1,2,4-trithiolane | 23654-92-4 | 1599 | 1126 | St RI MS | 336.17 | 11.02 | 167.21 | 1.33 | 264.36 | 3.39 |

| 46 | beta-caryophyllene | 87-44-5 | 1605 | 1408 | St RI MS | - | - | - | - | 20.87 | 1.37 |

| 47 | ethyl decanoate | 110-38-3 | 1649 | 1380 | St RI MS | - | - | 57.82 | 7.87 | 19.08 | 11.35 |

| 48 | dipropyl trisulfide | 6028-61-1 | 1712 | 1319 | St RI MS | 49.08 | 8.33 | - | - | 37.57 | 9.64 |

| 49 | acetaldehyde diethyl mercaptal | 14252-42-7 | 2223 | 1317 | St RI MS | 343.83 | 12.56 | 20.55 | 10.32 | 889.76 | 6.23 |

| Attributes | Durian Cultivars | |||||

|---|---|---|---|---|---|---|

| Black Thorn | RSD a (%) | Musang King | RSD (%) | Monthong | RSD (%) | |

| Sugar (μg/mg) | ||||||

| Glucose | 10.49 | 1.1 | 34.26 | 1.90 | 30.91 | 1.46 |

| Fructose | 10.05 | 0.5 | 49.45 | 1.59 | 43.70 | 1.27 |

| Ribose | 0.69 | 5.03 | - | - | - | - |

| Sucrose | 235.34 | 0.89 | 111.53 | 1.17 | 57.26 | 0.96 |

| Maltose | 1.06 | 1.03 | 20.76 | 1.28 | 6.87 | 0.34 |

| Organic acid (ng/mg) | ||||||

| Propionic acid | 2210.56 | 4.99 | 1109.35 | 4.13 | 275.93 | 1.84 |

| Isobutyric acid | 49.83 | 1.35 | 8.18 | 1.73 | 29.48 | 1.62 |

| Butyric acid | 117.97 | 2.51 | 77.01 | 3.13 | 49.84 | 2.91 |

| Oxalic acid | 798.03 | 2.42 | 263.26 | 1.59 | 389.03 | 1.49 |

| lactic acid | 34.22 | 4.46 | 41.64 | 0.64 | 369.25 | 2.97 |

| Valeric acid | 5.17 | 4.28 | 5.36 | 0.19 | 3.23 | 2.71 |

| Isovaleric acid | 87.38 | 4.08 | 26.75 | 0.69 | 30.24 | 4.22 |

| Malonic acid | 14.45 | 2.69 | 29.83 | 1.95 | 8.40 | 0.45 |

| Hexanoic Acid | 55.52 | 3.00 | 45.53 | 0.81 | 38.58 | 0.03 |

| 4-Methylvaleric Acid | 61.59 | 0.17 | 51.66 | 4.16 | 43.26 | 2.03 |

| Fumaric acid | 260.76 | 2.06 | 444.80 | 1.17 | 281.58 | 1.40 |

| Maleic acid | 1316.30 | 3.83 | 2245.44 | 0.13 | 1420.47 | 4.87 |

| Succinic acid | 11,453.95 | 3.10 | 8442.83 | 2.79 | 4681.37 | 0.26 |

| Benzoic acid | 4.23 | 0.76 | 10.10 | 3.41 | 6.75 | 0.86 |

| Itaconic acid | 1.06 | 3.37 | 0.15 | 4.09 | 0.25 | 0.17 |

| Glutaric Acid | 94.26 | 4.58 | 103.23 | 4.61 | 58.34 | 2.30 |

| Malic acid | 3888.95 | 0.48 | 5986.80 | 2.05 | 4180.52 | 3.70 |

| Salicylic acid | 1.04 | 4.43 | 0.82 | 4.81 | 0.67 | 2.53 |

| Octanoic Acid | 27.02 | 2.87 | 30.16 | 1.14 | 35.95 | 0.79 |

| Adipic acid | 42.66 | 0.87 | 202.74 | 0.98 | 24.35 | 0.32 |

| Tartaric acid | 72.44 | 1.57 | 125.45 | 1.19 | 221.67 | 4.27 |

| Pimelic Acid | 39.89 | 2.96 | 40.51 | 3.43 | 44.09 | 0.62 |

| Shikimic Acid | 28.11 | 0.57 | 29.00 | 2.09 | 64.06 | 2.14 |

| Citric acid | 4875.13 | 2.58 | 1141.72 | 1.52 | 1897.57 | 0.55 |

| Isocitricacid | 212.97 | 0.12 | 47.38 | 5.62 | 72.81 | 3.86 |

| Quinic acid | 99.10 | 0.32 | 4.08 | 2.85 | 43.12 | 1.91 |

| Acetic acid | 2934.75 | 1.22 | 5490.22 | 4.12 | 3521.15 | 2.18 |

| Amino acids (ng/mg) | ||||||

| l-Alanine | 6451.55 | 2.45 | 3897.17 | 1.43 | 6019.09 | 3.94 |

| l-Arginine | 1526.99 | 1.55 | 1267.24 | 2.23 | 1108.34 | 1.63 |

| l-Asparagine | 65.71 | 3.62 | 39.83 | 1.97 | 42.86 | 3.73 |

| l-Aspartic acid | 6708.92 | 5.74 | 4634.31 | 2.47 | 3884.03 | 1.36 |

| l-Cystine | 87.47 | 3.61 | 104.66 | 2.29 | 63.88 | 0.66 |

| l-Glutamic acid | 3849.50 | 2.24 | 3462.46 | 0.34 | 3040.48 | 0.93 |

| l-Glutamine | 0.99 | 2.71 | 0.75 | 3.68 | 1.91 | 3.59 |

| Glycine | 1796.68 | 0.60 | 1617.87 | 0.44 | 1506.77 | 4.59 |

| l-Histidine | 615.19 | 4.47 | 520.96 | 1.53 | 460.74 | 4.86 |

| l-Isoleucine | 1186.12 | 1.83 | 1189.70 | 3.01 | 1109.90 | 1.83 |

| l-Leucine | 2156.67 | 4.03 | 2137.24 | 1.64 | 1903.56 | 2.98 |

| l-Lysine | 1614.67 | 0.26 | 1446.72 | 0.92 | 1381.04 | 2.77 |

| l-Methionine | 54.18 | 3.49 | 63.62 | 2.30 | 38.23 | 3.03 |

| l-Phenylalanine | 1454.20 | 4.51 | 1243.40 | 1.34 | 1093.01 | 1.76 |

| l-Proline | 1699.47 | 0.72 | 1499.98 | 3.21 | 1440.28 | 0.12 |

| l-Serine | 1580.29 | 1.10 | 1390.38 | 1.87 | 1305.95 | 2.57 |

| l-Threonine | 1177.47 | 2.20 | 1130.76 | 1.71 | 1016.17 | 4.58 |

| l-Tryptophan | - | - | 0.15 | 4.26 | - | - |

| l-Tyrosine | 875.93 | 3.41 | 721.99 | 2.11 | 654.02 | 4.29 |

| l-Valine | 1524.03 | 3.46 | 1454.92 | 0.31 | 1354.35 | 2.19 |

| Black Thorn | RSD a (%) | Musang King | RSD (%) | Monthong | RSD (%) | |

|---|---|---|---|---|---|---|

| Sweetness | 22.33 | 0.48 | 22.03 | 0.51 | 21.02 | 0.59 |

| Sourness | −25.04 | 2.13 | −26.26 | 2.52 | −26.39 | 2.02 |

| Umami | 10.88 | 1.02 | 11.34 | 0.81 | 11.52 | 0.69 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Z.; Niu, M.; Niu, Y. Comparative Study on Volatile Compounds and Taste Components of Different Durian Cultivars Based on GC-MS, UHPLC, HPAEC-PAD, E-Tongue and E-Nose. Molecules 2022, 27, 1264. https://doi.org/10.3390/molecules27041264

Xiao Z, Niu M, Niu Y. Comparative Study on Volatile Compounds and Taste Components of Different Durian Cultivars Based on GC-MS, UHPLC, HPAEC-PAD, E-Tongue and E-Nose. Molecules. 2022; 27(4):1264. https://doi.org/10.3390/molecules27041264

Chicago/Turabian StyleXiao, Zuobing, Minxing Niu, and Yunwei Niu. 2022. "Comparative Study on Volatile Compounds and Taste Components of Different Durian Cultivars Based on GC-MS, UHPLC, HPAEC-PAD, E-Tongue and E-Nose" Molecules 27, no. 4: 1264. https://doi.org/10.3390/molecules27041264

APA StyleXiao, Z., Niu, M., & Niu, Y. (2022). Comparative Study on Volatile Compounds and Taste Components of Different Durian Cultivars Based on GC-MS, UHPLC, HPAEC-PAD, E-Tongue and E-Nose. Molecules, 27(4), 1264. https://doi.org/10.3390/molecules27041264