Pickering Emulsions Stabilized with Curcumin-Based Solid Dispersion Particles as Mayonnaise-like Food Sauce Alternatives

Abstract

:1. Introduction

2. Results and Discussion

2.1. Characterization of the Particles

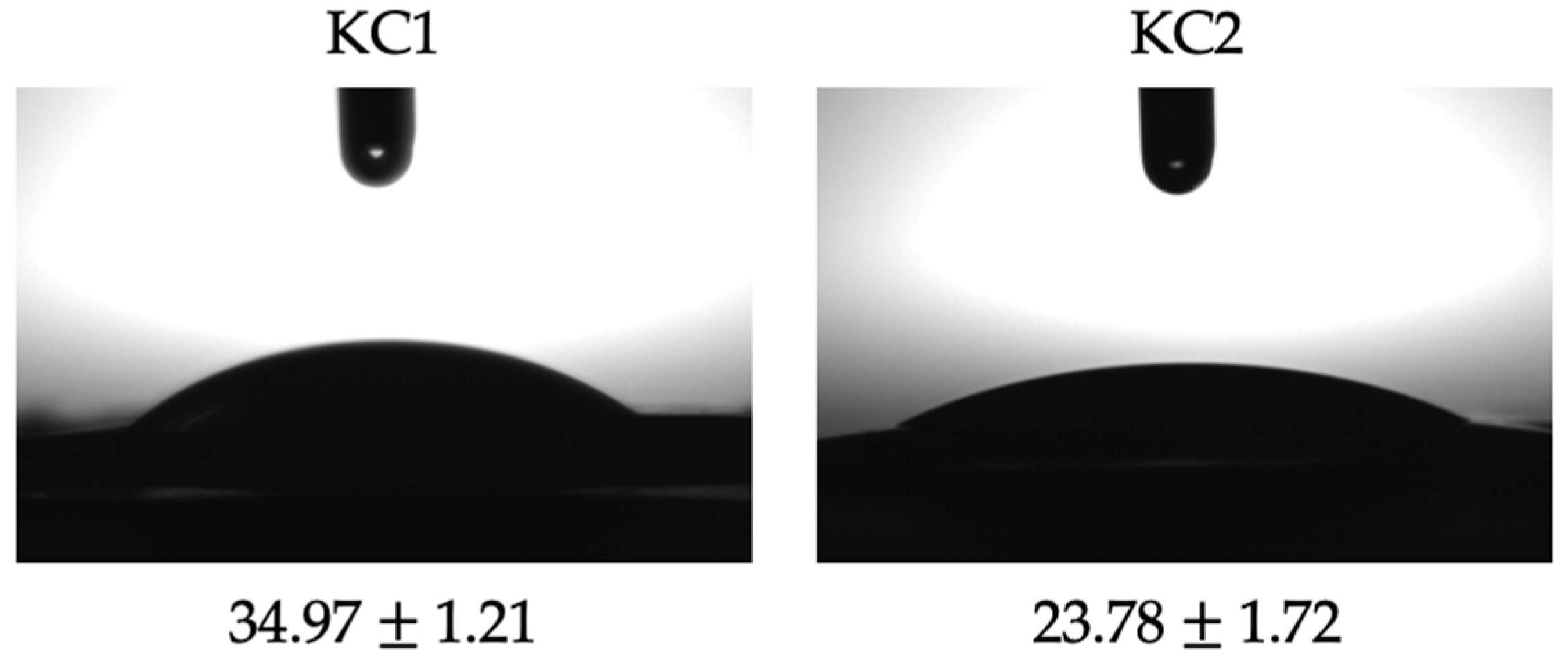

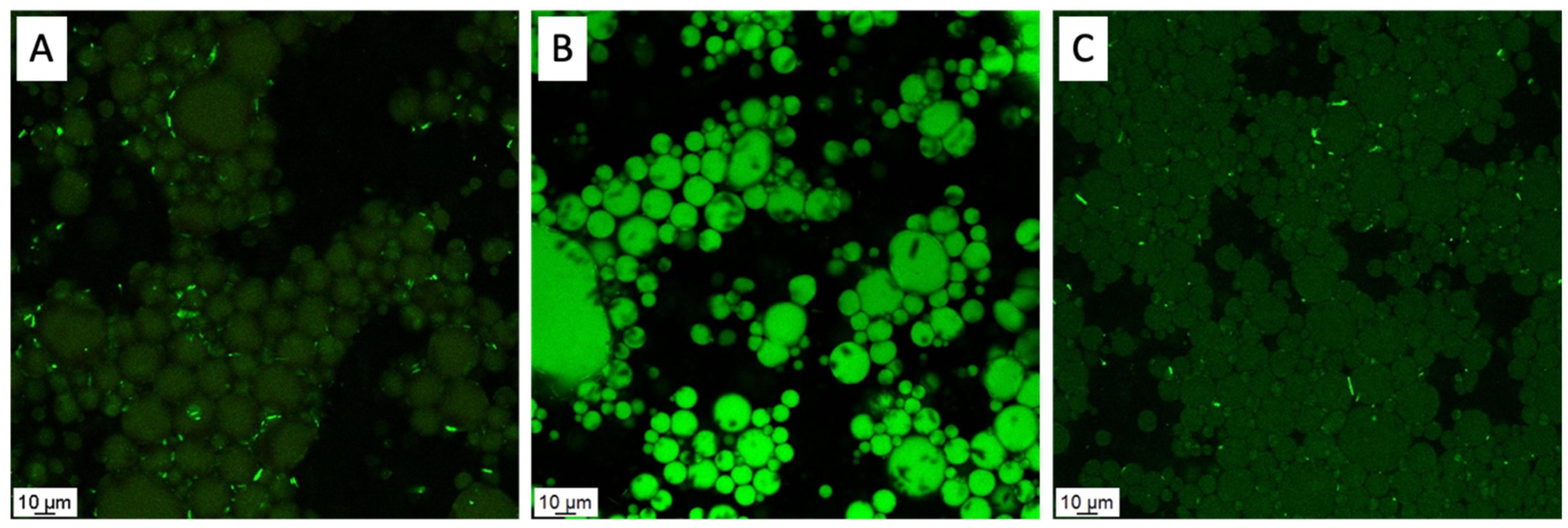

2.2. Evaluation of the Effective Role of KC1 and KC2 as Pickering Stabilizers

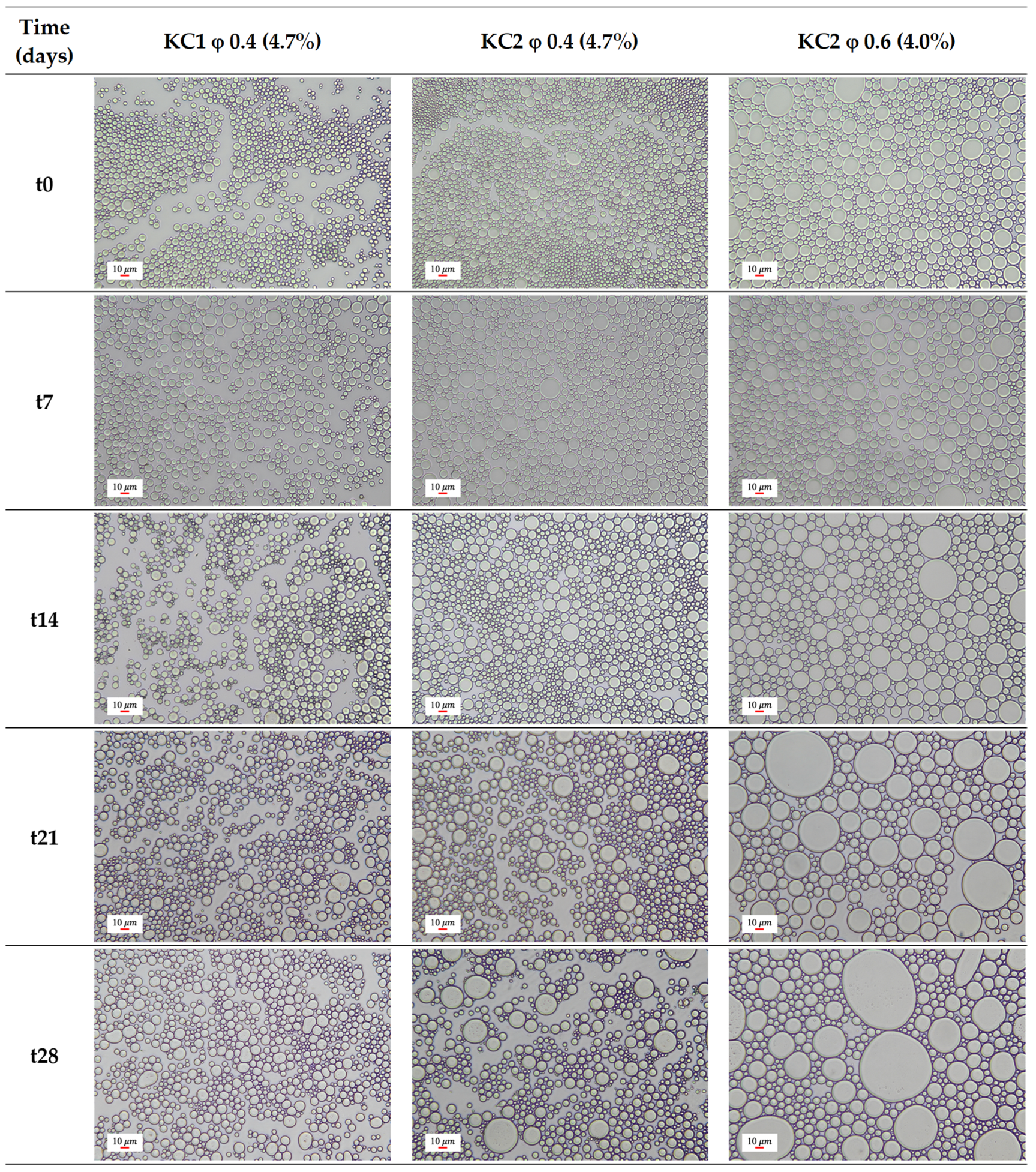

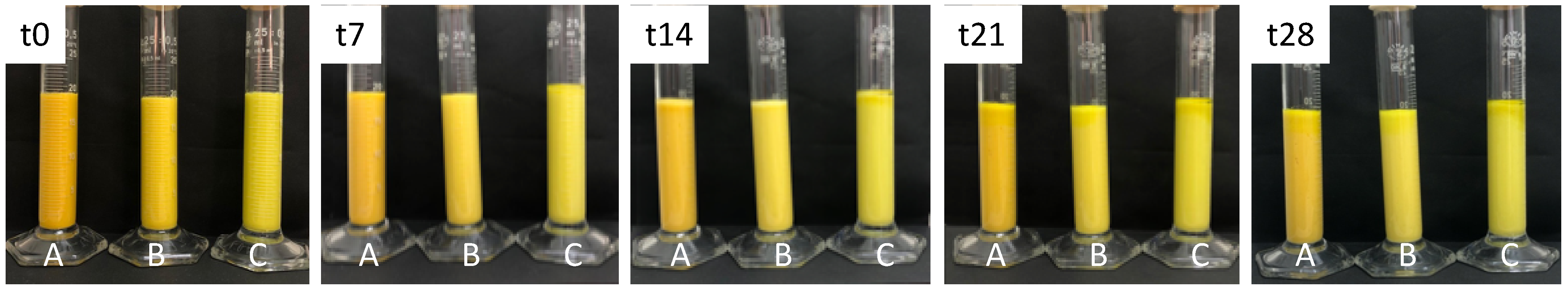

2.3. Emulsion Stability

2.4. Comparative Study with Commercial Products

3. Materials and Methods

3.1. Materials

3.2. Preparation of the Particles

3.3. Preparation of the Emulsions

3.4. Characterization of the Particles

3.5. Characterization of the Emulsions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Berton-Carabin, C.C.; Schroën, K. Pickering emulsions for food applications: Background, trends, and challenges. Annu. Rev. Food Sci. Technol. 2015, 6, 263–297. [Google Scholar] [CrossRef] [PubMed]

- Dai, L.; Sun, C.; Wei, Y.; Mao, L.; Gao, Y. Characterization of Pickering emulsion gels stabilized by zein/gum arabic complex colloidal nanoparticles. Food Hydrocoll. 2018, 74, 239–248. [Google Scholar] [CrossRef]

- Xia, T.; Xue, C.; Wei, Z. Physicochemical characteristics, applications and research trends of edible Pickering emulsions. Trends Food Sci. Technol. 2021, 107, 1–15. [Google Scholar] [CrossRef]

- Albert, C.; Beladjine, M.; Tsapis, N.; Fattal, E.; Agnely, F.; Huang, N. Pickering emulsions: Preparation processes, key parameters governing their properties and potential for pharmaceutical applications. J. Control. Release 2019, 309, 302–332. [Google Scholar] [CrossRef] [PubMed]

- Harman, C.L.G.; Patel, M.A.; Guldin, S.; Davies, G.L. Recent developments in Pickering emulsions for biomedical applications. Curr. Opin. Colloid Interface Sci. 2019, 39, 173–189. [Google Scholar] [CrossRef]

- Niroula, A.; Gamot, T.D.; Ooi, C.W.; Dhital, S. Biomolecule-based pickering food emulsions: Intrinsic components of food matrix, recent trends and prospects. Food Hydrocoll. 2021, 112, 106303. [Google Scholar] [CrossRef]

- Gonzalez Ortiz, D.; Pochat-Bohatier, C.; Cambedouzou, J.; Bechelany, M.; Miele, P. Current trends in Pickering emulsions: Particle morphology and applications. Engineering 2020, 6, 468–482. [Google Scholar] [CrossRef]

- Chevalier, Y.; Bolzinger, M.A. Emulsions stabilized with solid nanoparticles: Pickering emulsions. Colloids Surf. A Physicochem. Eng. Asp. 2013, 439, 23–34. [Google Scholar] [CrossRef]

- Yang, Y.; Jiao, Q.; Wang, L.; Zhang, Y.; Jiang, B.; Li, D.; Feng, Z.; Liu, C. Preparation and evaluation of a novel high internal phase Pickering emulsion based on whey protein isolate nanofibrils derived by hydrothermal method. Food Hydrocoll. 2022, 123, 107180. [Google Scholar] [CrossRef]

- Li, B.; Konecke, S.; Wegiel, L.A.; Taylor, L.S.; Edgar, K.J. Both solubility and chemical stability of curcumin are enhanced by solid dispersion in cellulose derivative matrices. Carbohydr. Polym. 2013, 98, 1108–1116. [Google Scholar] [CrossRef] [PubMed]

- Leimann, V.F.; Gonçalves, O.H.; Sorita, G.D.; Rezende, S.; Bona, E.; Fernandes, I.P.M.; Ferreira, I.C.F.R.; Barreiro, M.F. Heat and pH stable curcumin-based hydrophylic colorants obtained by the solid dispersion technology assisted by spray-drying. Chem. Eng. Sci. 2019, 205, 248–258. [Google Scholar] [CrossRef] [Green Version]

- Gangurde, A.B.; Kundaikar, H.S.; Javeer, S.D.; Jaiswar, D.R.; Degani, M.S.; Amin, P.D. Enhanced solubility and dissolution of curcumin by a hydrophilic polymer solid dispersion and its insilico molecular modeling studies. J. Drug Deliv. Sci. Technol. 2015, 29, 226–237. [Google Scholar] [CrossRef]

- Araiza-Calahorra, A.; Akhtar, M.; Sarkar, A. Recent advances in emulsion-based delivery approaches for curcumin: From encapsulation to bioaccessibility. Trends Food Sci. Technol. 2018, 71, 155–169. [Google Scholar] [CrossRef]

- Tang, Q.; Xie, X.; Li, C.; Zhen, B.; Cai, X.; Zhang, G.; Zhou, C.; Wang, L. Medium-chain triglyceride/water Pickering emulsion stabilized by phosphatidylcholine-kaolinite for encapsulation and controlled release of curcumin. Colloids Surf. B Biointerfaces 2019, 183, 110414. [Google Scholar] [CrossRef] [PubMed]

- Tao, S.; Guan, X.; Li, Y.; Jiang, H.; Gong, S.; Ngai, T. All-natural oil-in-water high internal phase Pickering emulsions featuring interfacial bilayer stabilization. J. Colloid Interface Sci. 2022, 607, 1491–1499. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Jiao, B.; Meng, S.; Fu, W.; Faisal, S.; Li, X.; Liu, H.; Wang, Q. Edible mayonnaise-like Pickering emulsion stabilized by pea protein isolate microgels: Effect of food ingredients in commercial mayonnaise recipe. Food Chem. 2021, 376, 131866. [Google Scholar] [CrossRef]

- Market Analysis Report. Vegan Sauces, Dressings & Spreads Market Size, Share & Trends Analysis Report by Product (Sauces, Dressings, Spreads), by Distribution Channel (Online, Offline), by Region, and Segment Forecasts, 2020–2027; Grand View Research, Inc.: San Francisco, CA, USA, 2020. [Google Scholar]

- Low, L.E.; Siva, S.P.; Ho, Y.K.; Chan, E.S.; Tey, B.T. Recent advances of characterization techniques for the formation, physical properties and stability of Pickering emulsion. Adv. Colloid Interface Sci. 2020, 277, 102117. [Google Scholar] [CrossRef] [PubMed]

- Gharsallaoui, A.; Roudaut, G.; Chambin, O.; Voilley, A.; Saurel, R. Applications of spray-drying in microencapsulation of food ingredients: An overview. Food Res. Int. 2007, 40, 1107–1121. [Google Scholar] [CrossRef]

- Wu, J.; Ma, G.H. Recent studies of Pickering emulsions: Particles make the difference. Small 2016, 12, 4633–4648. [Google Scholar] [CrossRef] [PubMed]

- Constant, P.B.L.; Stringheta, P.C.; Sandi, D. Corantes alimentícios. Bol. Cent. Pesqui. Process. Aliment. 2002, 20, 203–220. [Google Scholar] [CrossRef]

- Chen, L.; Ao, F.; Ge, X.; Shen, W. Food-grade pickering emulsions: Preparation, stabilization and applications. Molecules 2020, 25, 3202. [Google Scholar] [CrossRef] [PubMed]

- Azfaralariff, A.; Farahfaiqah, F.; Joe, L.S.; Fazry, S.; Mohamed, M.; Nazar, M.F.; Lazim, A.M. Sago starch nanocrystal-stabilized Pickering emulsions: Stability and rheological behavior. Int. J. Biol. Macromol. 2021, 182, 197–206. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Zheng, S.; Zhao, C.; Liu, M.; Zhang, Z.; Xu, W.; Luo, D.; Shah, B.R. Stability, microstructural and rheological properties of Pickering emulsion stabilized by xanthan gum/lysozyme nanoparticles coupled with xanthan gum. Int. J. Biol. Macromol. 2020, 165, 2387–2394. [Google Scholar] [CrossRef] [PubMed]

- Krebs, T.; Ershov, D.; Schroen, C.G.P.H.; Boom, R.M. Coalescence and compression in centrifuged emulsions studied with in situ optical microscopy. Soft Matter 2013, 9, 4026–4035. [Google Scholar] [CrossRef]

- Wulandari, A.; Sunarti, T.C.; Fahma, F.; Enomae, T. The potential of bioactives as biosensors for detection of pH. IOP Conf. Ser. Earth Environ. Sci. 2020, 460, 12034. [Google Scholar] [CrossRef]

- Song, X.; Zheng, F.; Ma, F.; Kang, H.; Ren, H. The physical and oxidative stabilities of Pickering emulsion stabilized by starch particle and small molecular surfactant. Food Chem. 2020, 303, 125391. [Google Scholar] [CrossRef] [PubMed]

- Mwangi, W.W.; Lim, H.P.; Low, L.E.; Tey, B.T.; Chan, E.S. Food-grade Pickering emulsions for encapsulation and delivery of bioactives. Trends Food Sci. Technol. 2020, 100, 320–332. [Google Scholar] [CrossRef]

- Abdullah; Weiss, J.; Ahmad, T.; Zhang, C.; Zhang, H. A review of recent progress on high internal-phase Pickering emulsions in food science. Trends Food Sci. Technol. 2020, 106, 91–103. [Google Scholar] [CrossRef]

- Cui, F.; Zhao, S.; Guan, X.; McClements, D.J.; Liu, X.; Liu, F.; Ngai, T. Polysaccharide-based Pickering Emulsions: Formation, stabilization and applications. Food Hydrocoll. 2021, 119, 106812. [Google Scholar] [CrossRef]

- Xiao, J.; Li, Y.; Huang, Q. Recent advances on food-grade particles stabilized Pickering emulsions: Fabrication, characterization and research trends. Trends Food Sci. Technol. 2016, 55, 48–60. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Xu, X.M.; Guo, S.D. Rheological, texture and sensory properties of low-fat mayonnaise with different fat mimetics. LWT–Food Sci. Technol. 2007, 40, 946–954. [Google Scholar] [CrossRef]

- Rojas, V.M.; Marconi, L.F.D.C.B.; Guimarães-Inácio, A.; Leimann, F.V.; Tanamati, A.; Gozzo, Â.M.; Fuchs, R.H.B.; Barreiro, M.F.; Barros, L.; Ferreira, I.C.F.R.; et al. Formulation of mayonnaises containing PUFAs by the addition of microencapsulated chia seeds, pumpkin seeds and baru oils. Food Chem. 2019, 274, 220–227. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Olsson, V.; Håkansson, A.; Purhagen, J.; Wendin, K. The effect of emulsion intensity on selected sensory and instrumental texture properties of full-fat mayonnaise. Foods 2018, 7, 9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, T.; Yang, J.; Hua, S.; Hong, Y.; Gu, Z.; Cheng, L.; Li, Z.; Li, C. Characteristics of starch-based Pickering emulsions from the interface perspective. Trends Food Sci. Technol. 2020, 105, 334–346. [Google Scholar] [CrossRef]

- Pompili, S.; Vetuschi, A.; Gaudio, E.; Tessitore, A.; Capelli, R.; Alesse, E.; Latella, G.; Sferra, R.; Onori, P. Long-term abuse of a high-carbohydrate diet is as harmful as a high-fat diet for development and progression of liver injury in a mouse model of NAFLD/NASH. Nutrition 2020, 75–76, 110782. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.T.D.; Tran, P.H.L. Molecular interactions in solid dispersions of poorly water-soluble drugs. Pharmaceutics 2020, 12, 745. [Google Scholar] [CrossRef]

- Sharkawy, A.; Barreiro, M.F.; Rodrigues, A.E. Preparation of chitosan/gum Arabic nanoparticles and their use as novel stabilizers in oil/water Pickering emulsions. Carbohydr. Polym. 2019, 224, 115190. [Google Scholar] [CrossRef] [Green Version]

- Nikolovski, B.G.; Ilić, J.D.; Sovilj, M.N. How to formulate a stable and monodisperse water-in-oil nanoemulsion containing pumpkin seed oil: The use of multiobjective optimization. Braz. J. Chem. Eng. 2016, 33, 919–931. [Google Scholar] [CrossRef]

- Correa, R.F.; Colucci, G.; Halla, N.; Pinto, J.A.; Echart, A.S.; Blanco, S.P.; Fernandes, I.P.; Barreiro, M.F. Development of chitosan microspheres through a green dual crosslinking strategy based on tripolyphosphate and vanillin. Molecules 2021, 26, 2325. [Google Scholar] [CrossRef]

- Rodrigues, N.; Casal, S.; Pinho, T.; Cruz, R.; Baptista, P.; Martín, H.; Asensio, M.C.; António, S.M.; José, M.P.; Pereira, A. Olive oil characteristics of eleven cultivars produced in a high—Density grove in Valladolid province (Spain). Eur. Food Res. Technol. 2021, 247, 3113–3122. [Google Scholar] [CrossRef]

- Roriz, C.L.; Heleno, S.A.; Carocho, M.; Rodrigues, P.; Pinela, J.; Dias, M.I.; Fernandes, I.P.; Barreiro, M.F.; Morales, P.; Barros, L.; et al. Betacyanins from Gomphrena globosa L. flowers: Incorporation in cookies as natural colouring agents. Food Chem. 2020, 329, 127178. [Google Scholar] [CrossRef] [PubMed]

| Sample | Particle Size in Volume | Particle Size in Number | ||||

|---|---|---|---|---|---|---|

| D10 (µm) | D50 (µm) | D90 (µm) | D10 (µm) | D50 (µm) | D90 (µm) | |

| KC1 | 0.56 ± 0.00 | 3.29 ± 0.02 | 164 ± 1.69 | 0.37 ± 0.00 | 0.48 ± 0.00 | 0.69 ± 0.00 |

| KC2 | 0.53 ± 0.00 | 2.39 ± 0.01 | 70.2 ± 2.26 | 0.37 ± 0.00 | 0.48 ± 0.00 | 0.69 ± 0.00 |

| Sample | L* | a* | b* | RGB Color |

|---|---|---|---|---|

| KC1 | 85.57 ± 0.02 | 6.69 ± 0.02 | 93.95 ± 0.02 | |

| KC2 | 88.21 ± 0.03 | 0.77 ± 0.02 | 97.70 ± 0.00 |

| Average Size of Droplets (µm) | |||

|---|---|---|---|

| Time (Days) | KC1 φ 0.4 (4.7%) | KC2 φ 0.4 (4.7%) | KC2 φ 0.6 (4.0%) |

| t0 | 5.93 ± 2.66 | 6.56 ± 3.04 | 10.73 ± 4.80 |

| t7 | 6.03 ± 2.77 | 6.66 ± 3.51 | 14.22 ± 6.31 |

| t14 | 6.18 ± 1.61 | 7.34 ± 3.54 | 20.06 ± 5.78 |

| t21 | 6.68 ± 2.00 | 8.06 ± 4.02 | 29.19 ± 15.15 |

| t28 | 7.68 ± 1.92 | 8.95 ± 5.32 | 35.10 ± 14.69 |

| Sample | L* | a* | b* | RGB Color | pH | Oxidative Stability (h) |

|---|---|---|---|---|---|---|

| KC1 φ 0.4 (4.7%) | 80.13 | 1.74 | 72.87 | 4.62 ± 0.02 | 24.28 | |

| KC2 φ 0.4 (4.7%) | 84.42 | −6.40 | 71.58 | 4.55 ± 0.04 | 27.98 | |

| KC2 φ 0.6 (4.0%) | 81.18 | −15.61 | 70.42 | 3.70 ± 0.03 | 20.32 | |

| Traditional mayonnaise | 93.02 | −1.61 | 18.15 | 3.61 ± 0.02 | 0.34 | |

| Light mayonnaise | 92.66 | −2.52 | 25.18 | 3.42 ± 0.07 | 0.72 |

| Sample |

Time

(min) |

Firmness

(g) |

Consistency

(g·s) |

Cohesiveness

(g) |

Work of Cohesion

(g·s) |

|---|---|---|---|---|---|

| Traditional mayonnaise | 0 | 395.37± 0.94 a | 946.25± 61.99 a | (−) 219.57 ± 19.38 bc | (−) 3.52 ± 0.96 a |

| 10 | 369.8 ± 44.83 a | 563.88 ± 489.83 a | (−) 239.21 ± 4.79 c | (−) 42.39 ± 38.64 ab | |

| Light mayonnaise | 0 | 374.30 ± 13.20 a | 865.54 ± 48.07 a | (−) 204.30 ± 0.26 bc | (−) 1052.84 ± 315.56 c |

| 10 | 361.70 ± 7.24 ab | 762.67 ± 184.49 a | (−) 211.01 ± 9.92 bc | (−) 773.27 ± 7.06 abc | |

| KC1 φ 0.4 (4.7%) | 0 | 359.29 ± 6.41 ab | 885.44 ± 15.89 a | (−) 204.04 ± 2.94 bc | (−) 1081.38 ± 289.98 c |

| 10 | 332.94 ± 0.34 abc | 787.70 ± 34.28 a | (−) 196.46 ± 1.70 abc | (−) 817.55 ± 50.21 bc | |

| KC2 φ 0.4 (4.7%) | 0 | 273.33 ± 1.06 bcd | 643.29 ± 26.07 a | (−) 180.06 ± 0.68 ab | (−) 329.26 ± 78.99 abc |

| 10 | 260.40± 8.48 cd | 581.90 ± 87.06 a | (−) 177.87 ± 8.97 ab | (−) 324.47 ± 62.52 abc | |

| KC2 φ 0.6 (4.0%) | 0 | 189.67 ± 15.87 d | 427.78 ± 0.88 a | (−) 148.62± 8.22 a | (−) 151.73 ± 3.05 ab |

| 10 | 184.77 ± 13.91 d | 465.50 ± 7.71 a | (−) 150.47 ± 9.39 a | (−) 170.48 ± 0.17 ab |

| Sample | Curcumin (% w/w, Polymer-Basis) | pH | Tween 80 (% w/w, Polymer-Basis) |

|---|---|---|---|

| KC1 | 15.00 | 4.50 | 15.00 |

| KC2 | 8.88 | 3.58 | 24.19 |

| Sample | Particle Type | PC (% w/w) | φ (v/v) |

|---|---|---|---|

| KC1 φ 0.4 (4.7%) | KC1 | 4.7 | 0.4 |

| KC2 φ 0.4 (4.7%) | KC2 | 4.7 | 0.4 |

| KC2 φ 0.6 (4.0%) | KC2 | 4.0 | 0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghirro, L.C.; Rezende, S.; Ribeiro, A.S.; Rodrigues, N.; Carocho, M.; Pereira, J.A.; Barros, L.; Demczuk, B., Jr.; Barreiro, M.-F.; Santamaria-Echart, A. Pickering Emulsions Stabilized with Curcumin-Based Solid Dispersion Particles as Mayonnaise-like Food Sauce Alternatives. Molecules 2022, 27, 1250. https://doi.org/10.3390/molecules27041250

Ghirro LC, Rezende S, Ribeiro AS, Rodrigues N, Carocho M, Pereira JA, Barros L, Demczuk B Jr., Barreiro M-F, Santamaria-Echart A. Pickering Emulsions Stabilized with Curcumin-Based Solid Dispersion Particles as Mayonnaise-like Food Sauce Alternatives. Molecules. 2022; 27(4):1250. https://doi.org/10.3390/molecules27041250

Chicago/Turabian StyleGhirro, Larissa C., Stephany Rezende, Andreia S. Ribeiro, Nuno Rodrigues, Márcio Carocho, José Alberto Pereira, Lillian Barros, Bogdan Demczuk, Jr., Maria-Filomena Barreiro, and Arantzazu Santamaria-Echart. 2022. "Pickering Emulsions Stabilized with Curcumin-Based Solid Dispersion Particles as Mayonnaise-like Food Sauce Alternatives" Molecules 27, no. 4: 1250. https://doi.org/10.3390/molecules27041250

APA StyleGhirro, L. C., Rezende, S., Ribeiro, A. S., Rodrigues, N., Carocho, M., Pereira, J. A., Barros, L., Demczuk, B., Jr., Barreiro, M.-F., & Santamaria-Echart, A. (2022). Pickering Emulsions Stabilized with Curcumin-Based Solid Dispersion Particles as Mayonnaise-like Food Sauce Alternatives. Molecules, 27(4), 1250. https://doi.org/10.3390/molecules27041250