Evaluation of VOCs Emitted from Biomass Combustion in a Small CHP Plant: Difference between Dry and Wet Poplar Woodchips

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biomass Characterization

2.2. Experimental TGA Analysis

2.3. Experimental Combustion Tests

2.4. Sampling and Analysis of VOCs

2.5. Statistical Analysis

3. Results and Discussion

3.1. Biomass Characterization

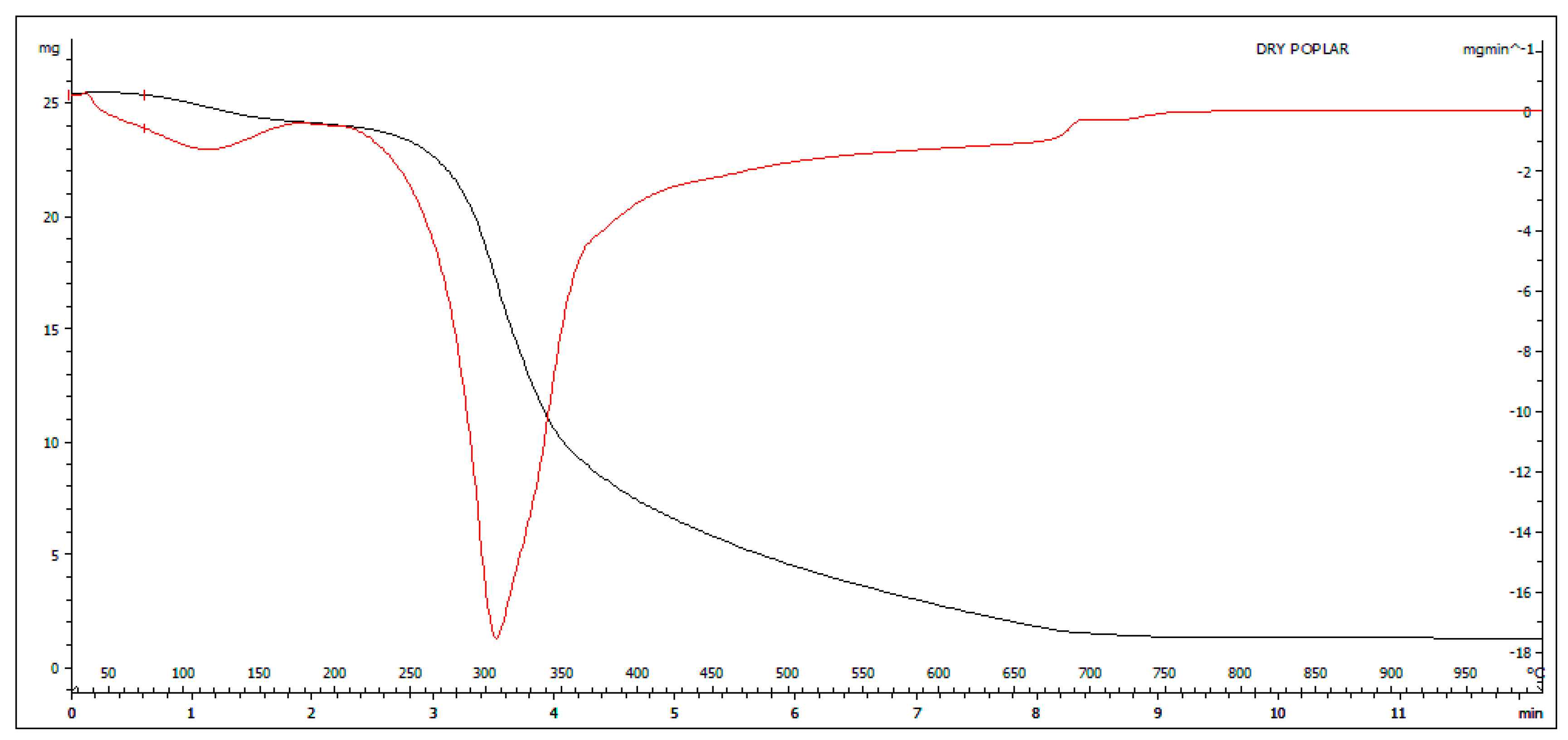

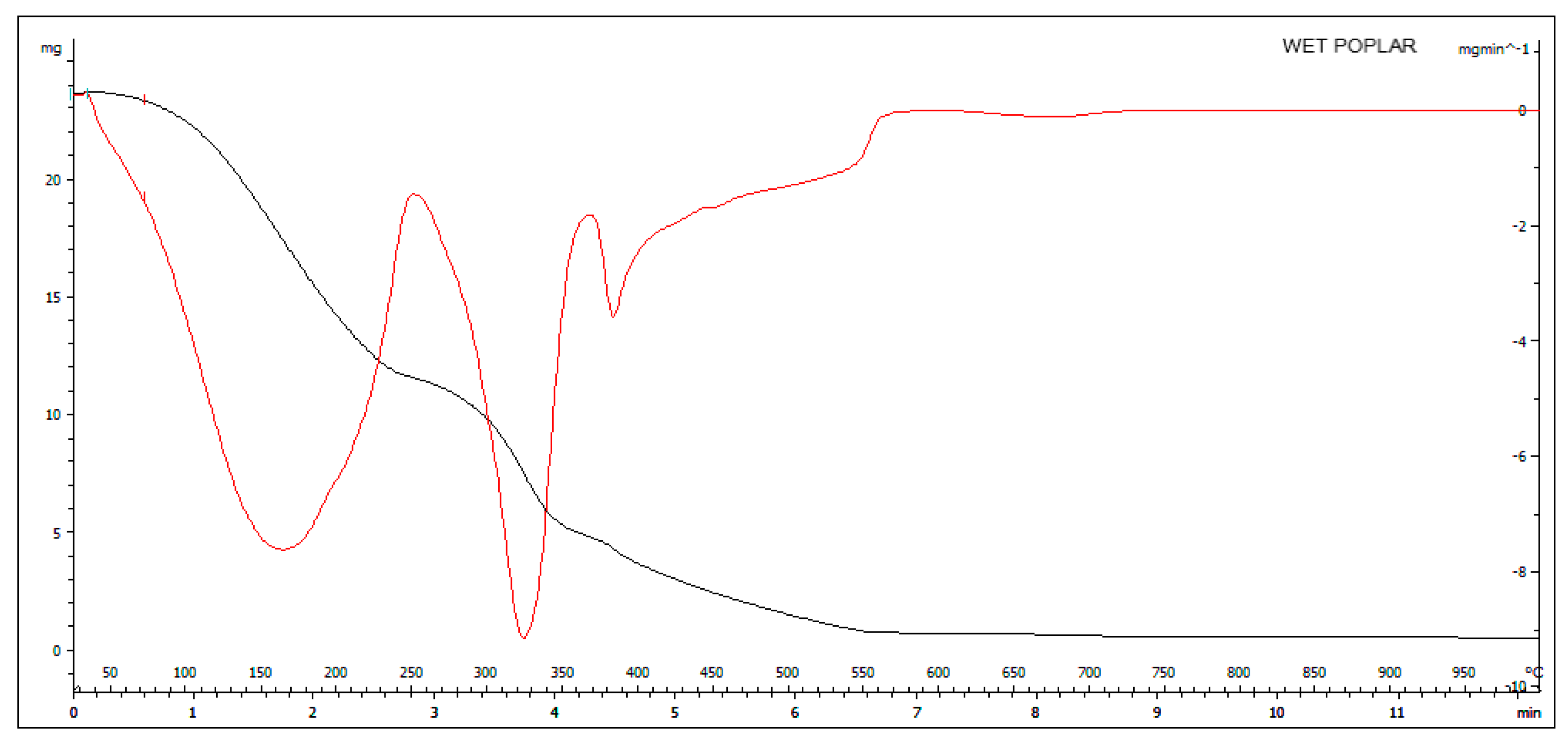

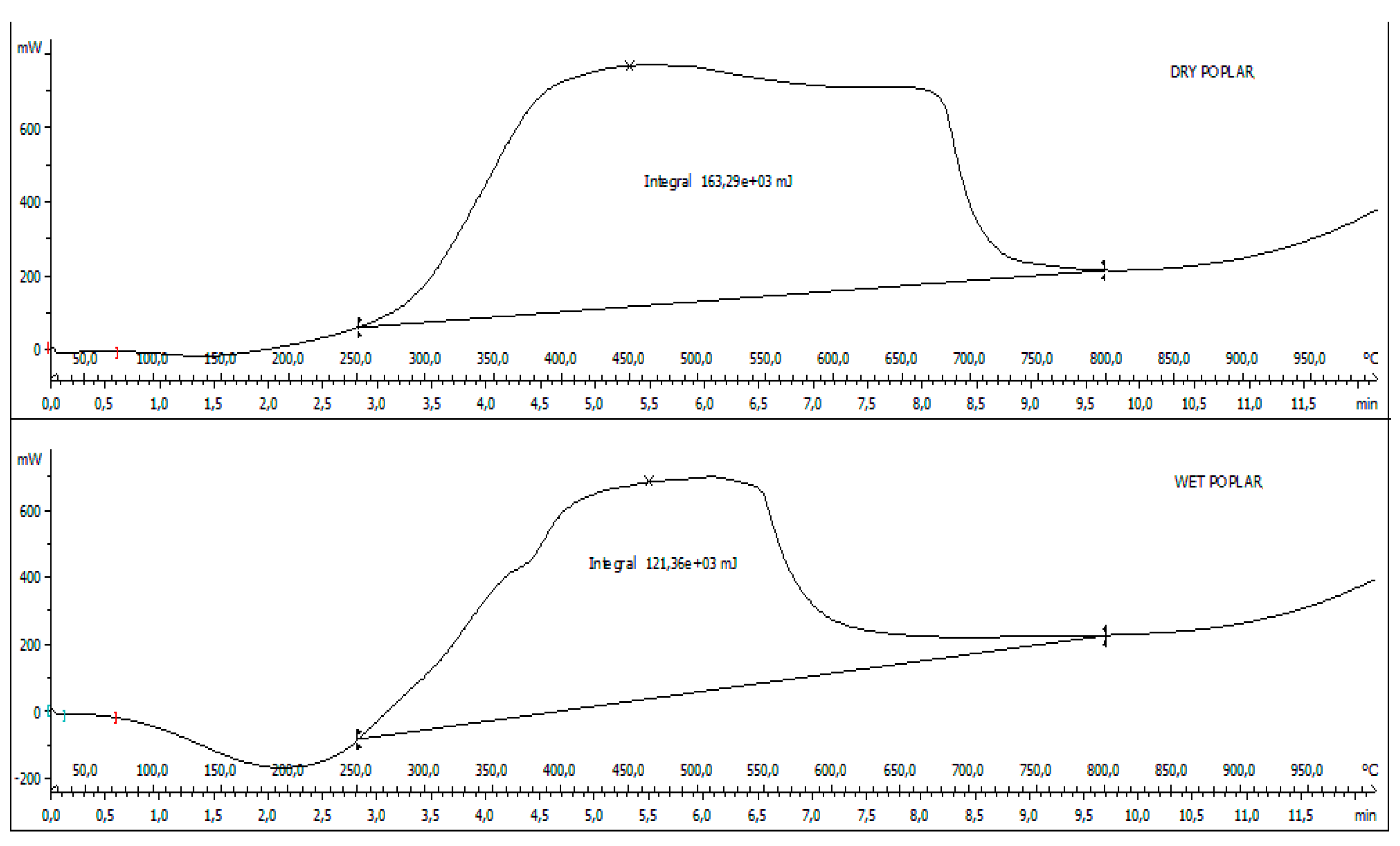

3.2. TGA Analysis

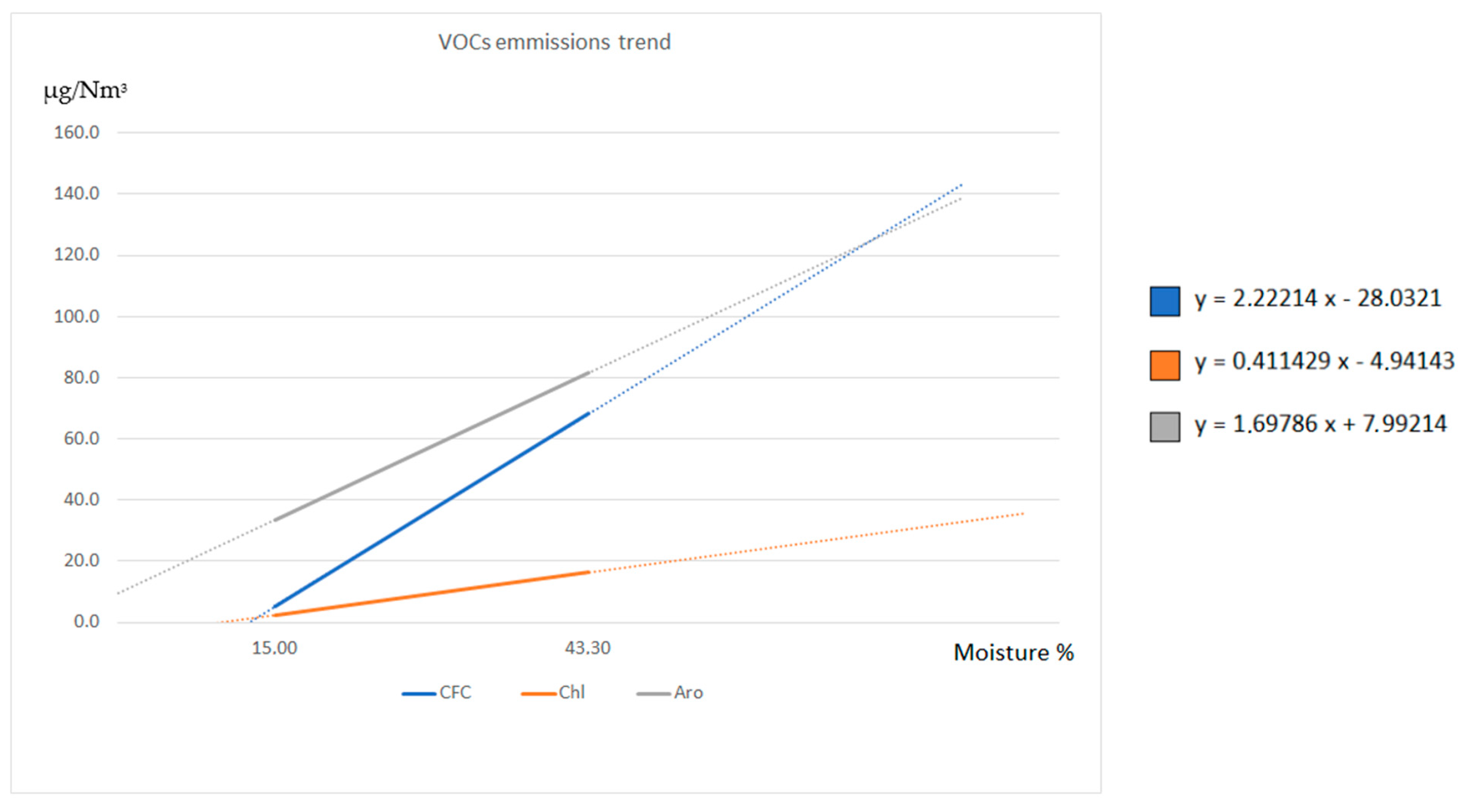

3.3. VOCs in Emission

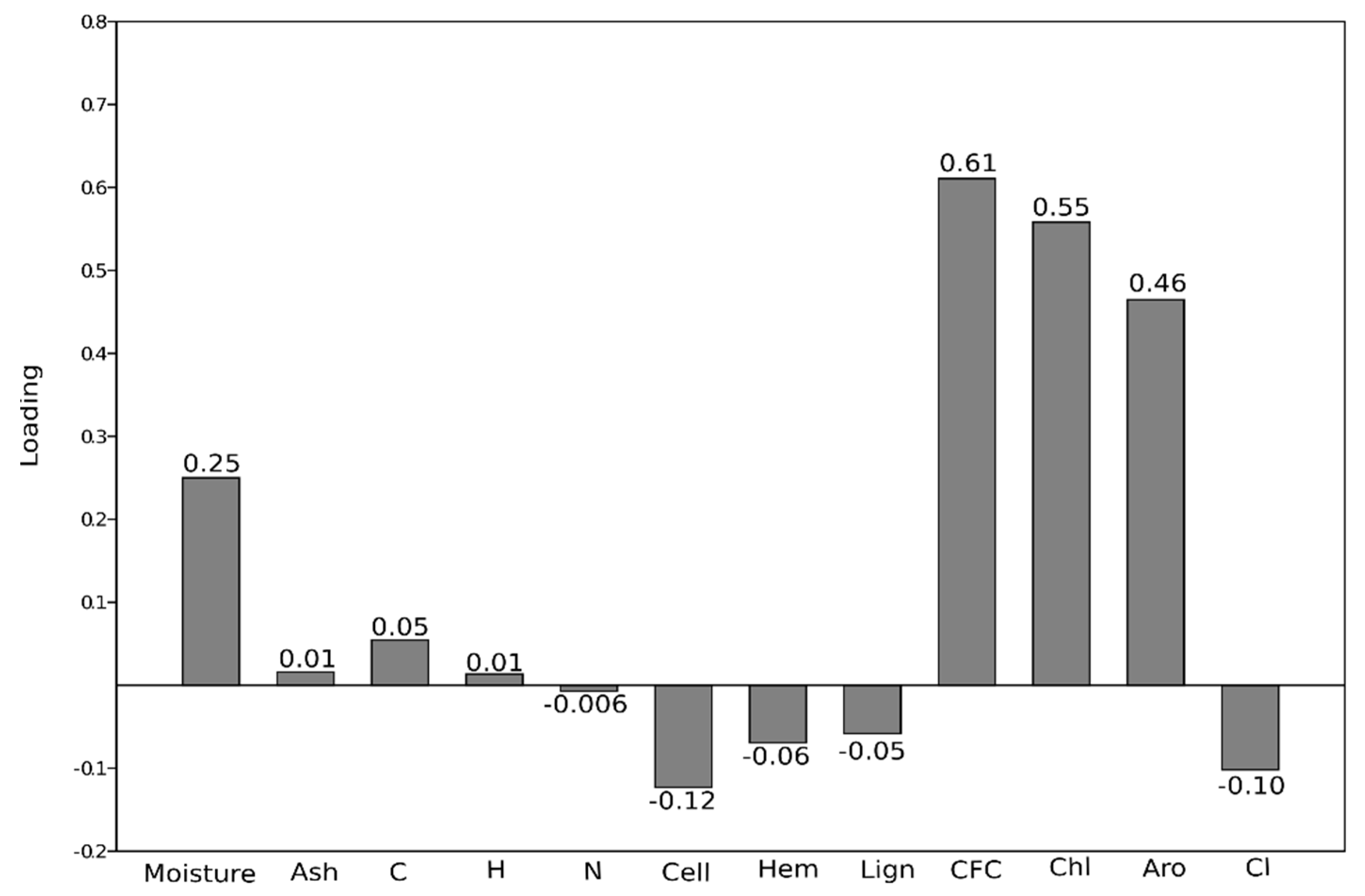

3.4. Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Pastorello, C.; Caserini, S.; Galante, S.; Dilara, P.; Galletti, F. Importance of activity data for improving the residential wood combustion emission inventory at regional level. Atmos. Environ. 2011, 45, 2869–2876. [Google Scholar] [CrossRef]

- Shan, F.; Lin, Q.; Zhou, K.; Wu, Y.; Fu, W.; Zhang, P.; Song, L.; Shao, C.; Yi, B. An experimental study of ignition and combustion of single biomass pellets in air and oxy-fuel. Fuel 2017, 188, 277–284. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Gallucci, F.; Salerno, M.; Guerriero, E.; Amalfi, M.; Palmieri, F. Research facility assessment for biomass combustion in moving grate furnaces. WASET Int. J. Chem. Mol. Eng 2017, 4, 603–610. [Google Scholar]

- Tao, J.; Hou, L.; Li, J.; Yan, B.; Chen, G.; Cheng, Z.; Lin, F.; Ma, W.; Crittenden, J.C. Biomass combustion: Environmental impact of various precombustion processes. J. Clean. Prod. 2020, 261, 121217. [Google Scholar] [CrossRef]

- Proto, A.R.; Palma, A.; Paris, E.; Papandrea, S.F.; Vincenti, B.; Carnevale, M.; Guerriero, E.; Bonofiglio, R.; Gallucci, F. Assessment of wood chip combustion and emission behavior of different agricultural biomasses. Fuel 2021, 289, 119758. [Google Scholar] [CrossRef]

- Johansson, L.S.; Tullin, C.; Leckner, B.; Sjövall, P. Particle emissions from biomass combustion in small combustors. Biomass Bioenergy 2003, 25, 435–446. [Google Scholar] [CrossRef]

- Nussbaumer, T. Combustion and Co-combustion of Biomass: Fundamentals, Technologies, and Primary Measures for Emission Reduction. Energy Fuels 2003, 17, 1510–1521. [Google Scholar] [CrossRef]

- Mcdonald, J.D.; Zielinska, B.; Fujita, E.M.; Sagebiel, J.C.; Chow, J.C.; Watson, J.G. Fine particle and gaseous emission rates from residential wood combustion. Environ. Sci. Technol. 2000, 34, 2080–2091. [Google Scholar] [CrossRef]

- Tissari, J.; Hytönen, K.; Lyyränen, J.; Jokiniemi, J. A novel field measurement method for determining fine particle and gas emissions from residential wood combustion. Atmos. Environ. 2007, 41, 8330–8344. [Google Scholar] [CrossRef]

- Tissari, J.; Lyyränen, J.; Hytönen, K.; Sippula, O.; Tapper, U.; Frey, A.; Saarnio, K.; Pennanen, A.S.; Hillamo, R.; Salonen, R.O.; et al. Fine particle and gaseous emissions from normal and smouldering wood combustion in a conventional masonry heater. Atmos. Environ. 2008, 42, 7862–7873. [Google Scholar] [CrossRef]

- Chen, L.W.A.; Verburg, P.; Shackelford, A.; Zhu, D.; Susfalk, R.; Chow, J.C.; Watson, J.G. Moisture effects on carbon and nitrogen emission from burning of wildland biomass. Atmos. Chem. Phys. 2010, 10, 6617–6625. [Google Scholar] [CrossRef] [Green Version]

- Gallucci, F.; Pari, L.; Longo, L.; Carnevale, M.; Santangelo, E.; Colantoni, A.; Paolini, V.; Guerriero, E.; Tonolo, A. Assessment of Organic Micropollutants (Pcdd/fs and Pcbs) from Biomass Combustion in a Small Chp Facility. Available online: https://dspace.unitus.it/handle/2067/30488?&locale=it (accessed on 29 December 2021).

- Demirbas, A. Hazardous emissions from combustion of biomass. Energy Sources Part A Recover. Util. Environ. Eff. 2008, 30, 170–178. [Google Scholar] [CrossRef]

- Yan, Y.; Yang, C.; Peng, L.; Li, R.; Bai, H. Emission characteristics of volatile organic compounds from coal-, coal gangue-, and biomass-fired power plants in China. Atmos. Environ. 2016, 143, 261–269. [Google Scholar] [CrossRef]

- Tsai, W.T. Fate of chloromethanes in the atmospheric environment: Implications for human health, ozone formation and depletion, and global warming impacts. Toxics 2017, 5, 23. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, J.; Li, C.; Ristovski, Z.; Milic, A.; Gu, Y.; Islam, M.S.; Wang, S.; Hao, J.; Zhang, H.; He, C.; et al. A review of biomass burning: Emissions and impacts on air quality, health and climate in China. Sci. Total Environ. 2017, 579, 1000–1034. [Google Scholar] [CrossRef] [Green Version]

- Kroll, J.H.; Seinfeld, J.H. Chemistry of secondary organic aerosol: Formation and evolution of low-volatility organics in the atmosphere. Atmos. Environ. 2008, 42, 3593–3624. [Google Scholar] [CrossRef]

- Ciccioli, P.; Brancaleoni, E.; Frattoni, M.; Cecinato, A.; Pinciarelli, L. Determination of volatile organic compounds (VOC) emitted from biomass burning of Mediterranean vegetation species by GC-MS. Anal. Lett. 2001, 34, 937–955. [Google Scholar] [CrossRef]

- Evtyugina, M.; Alves, C.; Calvo, A.; Nunes, T.; Tarelho, L.; Duarte, M.; Prozil, S.O.; Evtuguin, D.V.; Pio, C. VOC emissions from residential combustion of Southern and mid-European woods. Atmos. Environ. 2014, 83, 90–98. [Google Scholar] [CrossRef]

- Engling, G.; Carrico, C.M.; Kreidenweis, S.M.; Collett, J.L.; Day, D.E.; Malm, W.C.; Lincoln, E.; Min Hao, W.; Iinuma, Y.; Herrmann, H. Determination of levoglucosan in biomass combustion aerosol by high-performance anion-exchange chromatography with pulsed amperometric detection. Atmos. Environ. 2006, 40, 299–311. [Google Scholar] [CrossRef]

- Geng, C.; Yang, W.; Sun, X.; Wang, X.; Bai, Z.; Zhang, X. Emission factors, ozone and secondary organic aerosol formation potential of volatile organic compounds emitted from industrial biomass boilers. J. Environ. Sci. (China) 2019, 83, 64–72. [Google Scholar] [CrossRef]

- Gonçalves, C.; Alves, C.; Fernandes, A.P.; Monteiro, C.; Tarelho, L.; Evtyugina, M.; Pio, C. Organic compounds in PM2.5 emitted from fireplace and woodstove combustion of typical Portuguese wood species. Atmos. Environ. 2011, 45, 4533–4545. [Google Scholar] [CrossRef] [Green Version]

- Alves, C.; Gonçalves, C.; Fernandes, A.P.; Tarelho, L.; Pio, C. Fireplace and woodstove fine particle emissions from combustion of western Mediterranean wood types. Atmos. Res. 2011, 101, 692–700. [Google Scholar] [CrossRef]

- Alves, C.A.; Vicente, A.; Monteiro, C.; Gonçalves, C.; Evtyugina, M.; Pio, C. Emission of trace gases and organic components in smoke particles from a wildfire in a mixed-evergreen forest in Portugal. Sci. Total Environ. 2011, 409, 1466–1475. [Google Scholar] [CrossRef]

- Jia, L.; Liu, S.; Zhu, L.; Hu, J.; Wang, X. Carbon storage and density of poplars in China. J. Nanjing For. Univ. (Nat. Sci. Ed.) 2013, 56, 1. [Google Scholar]

- Chu, D.; Xue, L.; Zhang, Y.; Kang, L.; Mu, J. Surface characteristics of poplar wood with high-temperature heat treatment: Wettability and surface brittleness. BioResources 2016, 11. [Google Scholar] [CrossRef] [Green Version]

- Energy Research Centre of The Netherlands Phyllis2, Database for Biomass and Waste #2907. Available online: https://phyllis.nl/ (accessed on 10 October 2021).

- Yaman, S. Pyrolysis of biomass to produce fuels and chemical feedstocks. Energy Convers. Manag. 2004, 45, 651–671. [Google Scholar] [CrossRef]

- Strezov, V.; Moghtaderi, B.; Lucas, J.A. Computational calorimetric investigation of the reactions during thermal conversion of wood biomass. Biomass Bioenergy 2004, 27, 459–465. [Google Scholar] [CrossRef]

- EN 13284-1:2017; Stationary Source Emissions. Determination of Low Range Mass Concentration Of Dust—Part 1: Manual Gravimetric Method. 2017. Available online: https://shop.bsigroup.com/products/stationary-source-emissions-determination-of-low-range-mass-concentration-of-dust-manual-gravimetric-method-1/tracked-changes (accessed on 29 December 2021).

- Jeguirim, M.; Trouvé, G. Pyrolysis characteristics and kinetics of Arundo donax using thermogravimetric analysis. Bioresour. Technol. 2009, 100, 4026–4031. [Google Scholar] [CrossRef]

- Chen, C.; Wang, L.; Qin, Y.; Zhang, Y.; Zheng, S.; Yang, Y.; Jin, S.; Yang, X. Voc characteristics and their source apportionment in the yangtze river delta region during the g20 summit. Atmosphere 2021, 12, 928. [Google Scholar] [CrossRef]

- Garcia, D.P.; Caraschi, J.C.; Ventorim, G.; Vieira, F.H.A.; de Paula Protásio, T. Assessment of plant biomass for pellet production using multivariate statistics (PCA and HCA). Renew. Energy 2019, 139, 796–805. [Google Scholar] [CrossRef]

- Giungato, P.; Barbieri, P.; Cozzutto, S.; Licen, S. Sustainable domestic burning of residual biomasses from the Friuli Venezia Giulia region. J. Clean. Prod. 2018, 172, 3841–3850. [Google Scholar] [CrossRef]

- Barboni, T.; Pellizzaro, G.; Arca, B.; Chiaramonti, N.; Duce, P. Analysis and origins of volatile organic compounds smoke from ligno-cellulosic fuels. J. Anal. Appl. Pyrolysis 2010, 89, 60–65. [Google Scholar] [CrossRef]

- Greenberg, J.P.; Friedli, H.; Guenther, A.B.; Hanson, D.; Harley, P.; Karl, T. Volatile organic emissions from the distillation and pyrolysis of vegetation. Atmos. Chem. Phys. 2006, 6, 81–91. [Google Scholar] [CrossRef] [Green Version]

- Alén, R.; Kuoppala, E.; Oesch, P. Formation of the main degradation compound groups from wood and its components during pyrolysis. J. Anal. Appl. Pyrolysis 1996, 36, 137–148. [Google Scholar] [CrossRef]

- Faix, O.; Fortmann, I.; Bremer, J.; Meier, D. Thermal degradation products of wood: Gas chromatographic separation and mass spectrometric characterization of polysaccharide derived products. Eur. J. Wood Wood Prod. 1991, 48, 281–285. [Google Scholar] [CrossRef]

- Peters, J.; Fischer, K.; Fischer, S. Characterization of emissions from thermally modified wood and their reduction by chemical treatment. BioResources 2008, 3, 491–502. [Google Scholar]

- Roos, C.J. Biomass Drying and Dewatering for Clean Heat & Power; U.S. Departement of Energy, CHP Technical Assistance Partnerships, 2008; Available online: http://northwestchptap.org/nwchpdocs/biomassdryinganddewateringforcleanheatandpower.pdf (accessed on 29 December 2021).

- Khan, A.A.; de Jong, W.; Jansens, P.J.; Spliethoff, H. Biomass combustion in fluidized bed boilers: Potential problems and remedies. Fuel Process. Technol. 2009, 90, 21–50. [Google Scholar] [CrossRef]

- Demirbas, A. Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- Zhang, Y.; Shao, M.; Lin, Y.; Luan, S.; Mao, N.; Chen, W.; Wang, M. Emission inventory of carbonaceous pollutants from biomass burning in the Pearl River Delta Region, China. Atmos. Environ. 2013, 76, 189–199. [Google Scholar] [CrossRef]

| Parameters | Dry Poplar | Wet Poplar |

|---|---|---|

| Moisture % | 15.00 | 43.30 |

| Ash % | 1.30 | 3.12 |

| C % | 41.20 | 47.36 |

| H % | 4.05 | 5.58 |

| N % | 1.10 | 0.31 |

| HHV [MJ/kg] | 18.27 | 17.94 |

| LHV [MJ/kg] | 17.43 | 16.77 |

| Compound | Dry Poplar (μg/Nm3) | Wet Poplar (μg/Nm3) |

|---|---|---|

| Dichlorodifluoromethane | 0.10 | 0.38 |

| Chloromethane | 4.25 | 51.15 |

| Bromomethane | <LOQ | 14.55 |

| Chloroethane | <LOQ | 6.90 |

| 1,1-Dichloroethene | 1.23 | 5.85 |

| Dichloromethane | 0.95 | 1.44 |

| Benzene | 30.97 | 60.51 |

| Toluene | 6.9 | 15.46 |

| Chlorobenzene | 1.33 | 5.32 |

| p,m-Xylene | 1.10 | 6.18 |

| o-Xylene | 0.45 | 2.83 |

| Styrene | 0.47 | 1.87 |

| 1,2,4-Trimethylbenzene | <LOQ | 1.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paris, E.; Carnevale, M.; Vincenti, B.; Palma, A.; Guerriero, E.; Borello, D.; Gallucci, F. Evaluation of VOCs Emitted from Biomass Combustion in a Small CHP Plant: Difference between Dry and Wet Poplar Woodchips. Molecules 2022, 27, 955. https://doi.org/10.3390/molecules27030955

Paris E, Carnevale M, Vincenti B, Palma A, Guerriero E, Borello D, Gallucci F. Evaluation of VOCs Emitted from Biomass Combustion in a Small CHP Plant: Difference between Dry and Wet Poplar Woodchips. Molecules. 2022; 27(3):955. https://doi.org/10.3390/molecules27030955

Chicago/Turabian StyleParis, Enrico, Monica Carnevale, Beatrice Vincenti, Adriano Palma, Ettore Guerriero, Domenico Borello, and Francesco Gallucci. 2022. "Evaluation of VOCs Emitted from Biomass Combustion in a Small CHP Plant: Difference between Dry and Wet Poplar Woodchips" Molecules 27, no. 3: 955. https://doi.org/10.3390/molecules27030955

APA StyleParis, E., Carnevale, M., Vincenti, B., Palma, A., Guerriero, E., Borello, D., & Gallucci, F. (2022). Evaluation of VOCs Emitted from Biomass Combustion in a Small CHP Plant: Difference between Dry and Wet Poplar Woodchips. Molecules, 27(3), 955. https://doi.org/10.3390/molecules27030955