Biomaterials and Their Potentialities as Additives in Bitumen Technology: A Review

Abstract

1. Introduction

- (a)

- Direct alternative (75–100% bitumen substitute);

- (b)

- Bitumen extender (10–75% bitumen substitute);

- (c)

- Bitumen modifier (<10% bitumen substitute).

2. Bio-Oils

| Fatty Acids (% of Total Fatty Acids) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Oil Type | Palmitic Acid | Palmitoleic Acid | Stearic Acid | Oleic Acid | Linoleic Acid | γ Linolenic Acid | Lauric Acid | Myristic Acid | Heneicosanoic Acid | Cis-11-Eicosenoic Acid | |

| Waste Cooking | Oil | 38.35 | <0.3 | 4.33 | 43.67 | 11.39 | 0.29 | 0.34 | 1.03 | 0.08 | 0.16 |

| Sunflower | 5.2 | 0.1 | 3.7 | 33.7 | 56.5 | 0.0 | 0.02 | 0.09 | <0.4 | <0.2 | |

| Groundnut | 11.2 | 0.0 | 3.6 | 41.1 | 35.5 | 0.1 | <0.1 | <0.1 | <0.1 | <0.1 | |

| Soybean | 10.1 | 0.0 | 4.3 | 22.3 | 53.7 | 8.1 | <0.2 | <0.2 | <0.2 | <0.2 | |

| Cottonseed | 23.0 | 0.0 | 2.3 | 15.6 | 55.6 | 0.3 | <0.5 | <0.5 | <0.5 | <0.5 | |

| Maize | 11.6 | 0.0 | 2.5 | 38.7 | 44.7 | 1.4 | <0.2 | <0.2 | <0.2 | <0.2 | |

| Olive | 13.8 | 1.4 | 2.8 | 71.6 | 9.0 | 1.0 | 0.0 | 0.0 | <0.2 | <0.2 | |

| Palm | 44.8 | 0.0 | 4.6 | 38.9 | 9.5 | 0.4 | 0.4 | 0.5 | 0.2 | 0.2 | |

| Rapeseed | 4.6 | 0.3 | 1.7 | 60.1 | 21.4 | 11.4 | 0.0 | 0.0 | <2.0 | <3.0 | |

| Linseed | 5.6 | 0.0 | 3.2 | 17.7 | 15.7 | 57.8 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Sesame | 9.6 | 0.2 | 6.7 | 41.1 | 41.2 | 0.7 | 0.0 | 0.0 | <0.3 | <0.3 | |

| Cashew nut | 11.6 | 0.3 | 8.9 | 61.5 | 17.1 | 0.0 | <0.2 | <0.2 | <0.2 | <0.2 | |

| Niger seed | 8.8 | 0.0 | 6.8 | 7.5 | 76.7 | 0.0 | <0.1 | <0.1 | <0.1 | <0.1 | |

| Nigella seed | 11.4 | 0.0 | 2.9 | 21.9 | 60.8 | 0.0 | <1.0 | <1.0 | <1.0 | <0.5 | |

| Perilla seed | 6.4 | 0.0 | 1.6 | 13.8 | 15.5 | 62.6 | <0.1 | <0.1 | 0.0 | 0.0 | |

3. Biopolymers

- (a)

- Synthetic biopolymers (are degraded via hydrolysis or oxidation);

- (b)

- Natural biopolymers (are degraded enzymatically).

3.1. Synthetic Biopolymers

3.2. Natural Biopolymers

3.2.1. Polysaccharides

Natural Fibres

Chitosan

Starch

Alginates

3.2.2. Natural Rubber

4. Waxes

5. Nanomaterials

5.1. Biochar

5.2. Nanoclay

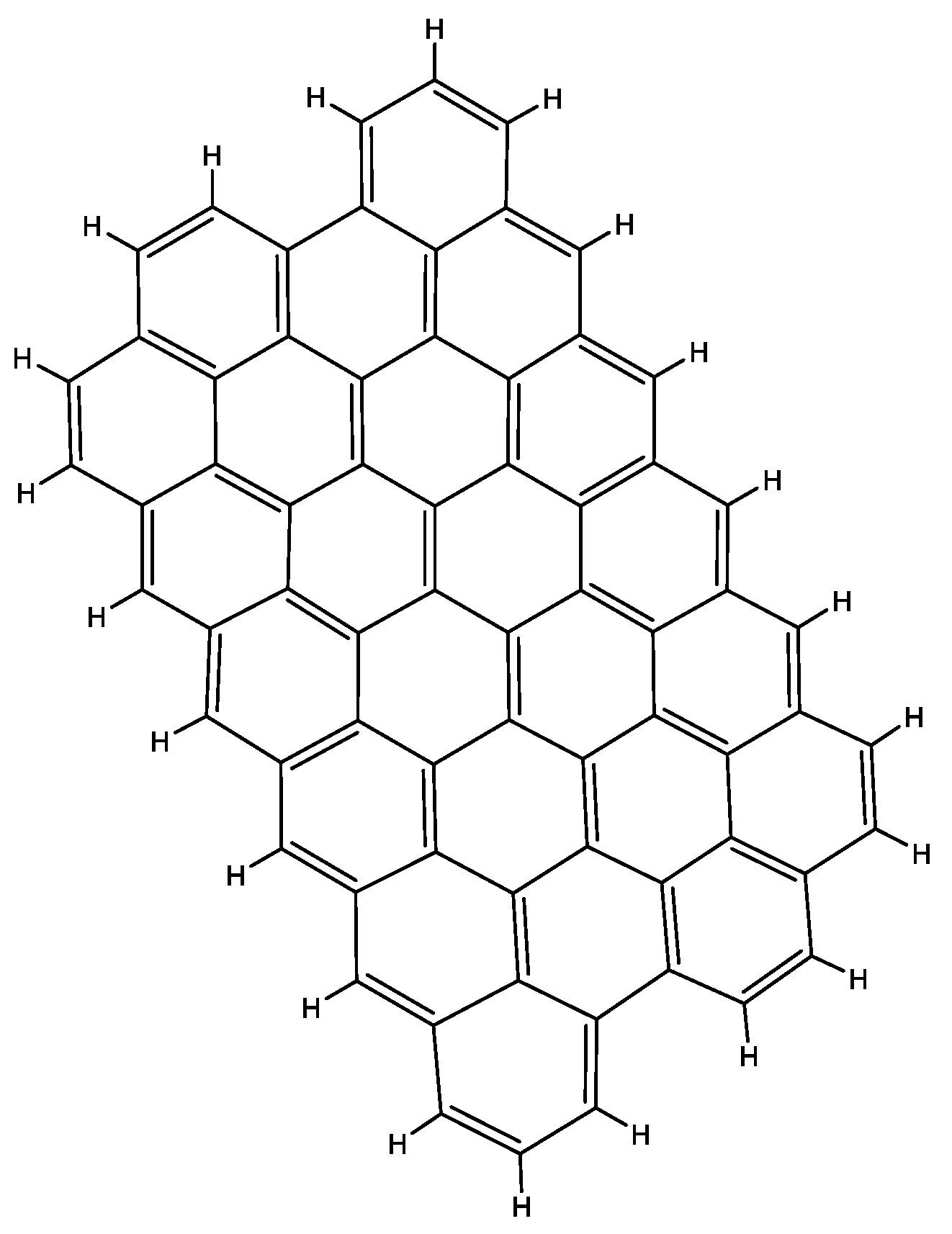

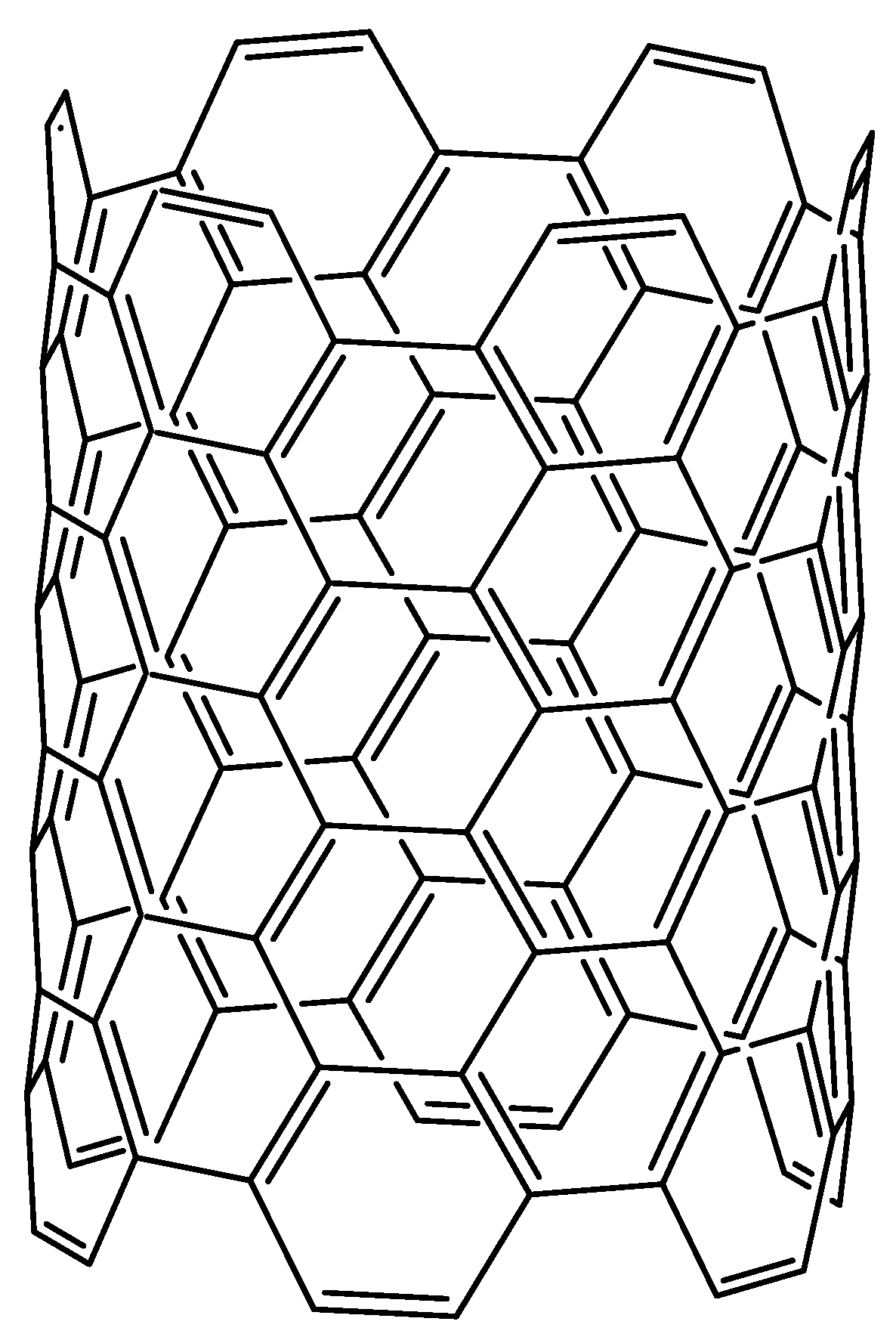

5.3. Graphite, Graphene and Their Oxides

5.4. Nanosilica

5.5. Carbon Nanotubes

6. Other Waste-Derived Biomaterials

7. Conclusions

- Bio-oils obtained are in general very useful biodegradable surfactants and asphalt additives due to their ability to induce oxypolymerization reactions via crosslinking of their structural units in bituminous mixes, thereby increasing the tensile strength of the mixes.

- Biopolymers occur in different forms, with polysaccharides being the most common source of biomaterials in this category. Polysaccharides are already widely used in the asphalt industry and are very functional in improving bitumen in various ways depending on the chemical composition of the polysaccharide. Bioelastomers such as natural rubber are also very good biomaterial additives for bituminous mixes due to crystallization phenomenon of cooled rubber in asphalt.

- Natural waxes are viscosity modifiers which enhance workability of asphalt mixes and in some cases improve adhesion between bitumen and aggregates.

- Nanomaterials from natural sources are excellent asphalt modifiers due to their ability to form nanostructures within the asphalt conglomerate.

- Waste-derived materials, apart from promoting recycling in a very utilitarian way, also bring about the improvement of the bitumen’s mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fini, E.H.; Khodaii, A.; Hajikarimi, P. Fractional viscoelastic study of low temperature characteristics of biomodified asphalt binders. J. Mater. Civ. Eng. 2016, 28, 04016078. [Google Scholar] [CrossRef]

- Aziz, M.M.A.; Rahman, M.T.; Hainin, M.R.; Bakar, W.A.W.A. An overview on alternative binders for flexible pavement. Construct. Build. Mater. 2015, 84, 315–319. [Google Scholar] [CrossRef]

- Vinod, A.; Sanjay, M.R.; Suchart, S.; Jyotishkumar, P. Renewable and sustainable biobased materials: An assessment on biofibers, biofilms, biopolymers and biocomposites. J. Clean. Prod. 2020, 258, 120978. [Google Scholar] [CrossRef]

- Hill, B.; Oldham, D.; Behnia, B.; Fini, E.H.; Buttlar, W.G.; Reis, H. Evaluation of low temperature viscoelastic properties and fracture behavior of bio-asphalt mixtures. Int. J. Pavement Eng. 2016, 19, 362–369. [Google Scholar] [CrossRef]

- Sun, D.; Sun, G.; Du, Y.; Zhu, X.; Lu, T.; Pang, Q.; Shi, S.; Dai, Z. Evaluation of optimized bio-asphalt containing high content waste cooking oil residues. Fuel 2017, 202, 529–540. [Google Scholar] [CrossRef]

- Mohan, D.; Pittman, C.U.; Steele, P.H. Pyrolysis of wood/biomass for bio-oil: A critical review. Energy Fuel. 2006, 20, 848e889. [Google Scholar] [CrossRef]

- Xue, Y.; Wu, S.; Cai, J.; Zhou, M.; Zha, J. Effects of two biomass ashes on asphalt binder: Dynamic shear rheological characteristic analysis. Constr. Build. Mater. 2014, 56, 7–15. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.M.; Napiah, M.B.; Sutanto, M.H.; Alaloul, W.S.; Usman, A. A systematic review of bio-asphalt for flexible pavement applications: Coherent taxonomy, motivations, challenges and future directions. J. Clean. Prod. 2020, 249, 119357. [Google Scholar] [CrossRef]

- Abd El-latief, R.A.E. Asphalt modified with Biomaterials as Eco-friendly and sustainable modifiers. In Modified Asphalt; InTech Open: Rijeka, Croatia, 2018. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.P.; Dai, Q.L. Performance evaluation of asphalt binder modified by bio-oil generated from waste wood resources. Int. J. Pavement Res. Technol. 2013, 6, 431–439. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; You, Z.; Mohd Hasan, M.; Lei, Y.; Irfan, M. Rheological behavior and sensitivity of wood-derived bio-oil modified asphalt binders. Appl. Sci. 2018, 8, 919. [Google Scholar] [CrossRef]

- Fini, E.H.; Hosseinnezhad, S.; Oldham, D.J.; Chailleux, E.; Gaudefroy, V. Source dependency of rheological and surface characteristics of bio-modified asphalts, Road Mater. Pavement Des. 2017, 18, 408–424. [Google Scholar] [CrossRef]

- Oliviero Rossi, C.; Caputo, P.; Loise, V.; Miriello, D.; Teltayev, B.; Angelico, R. Role of a food-grade additive in the high temperature performance of modified bitumens. Colloids and Surfaces A: Physicochem. Eng. Asp. 2017, 532, 618–624. [Google Scholar] [CrossRef]

- Krol, J.B.; Kowalski, K.J.; Niczke, L.; Radziszewski, P. Effect of bitumen fluxing using a bio-origin additive. Constr. Build. Mater. 2016, 114, 194–203. [Google Scholar] [CrossRef]

- Malinowski, S.; Wróbel, M.; Bandura, L.; Woszuk, A.; Franus, W. Use of New Green Bitumen Modifier for Asphalt Mixtures Recycling. Materials 2022, 15, 6070. [Google Scholar] [CrossRef]

- Mallawarachchi, D.R.; Amarasinghe, A.D.; Prashantha, M.A. Suitability of Chitosan as an emulsifier for bitumen emulsions and its behaviour as an additive to bitumen emulsion. Constr. Build. Mater. 2016, 102, 1–6. [Google Scholar] [CrossRef]

- Caputo, P.; Calandra, P.; Loise, V.; Le Pera, A.; Putz, A.-M.; Abe, A.A.; Madeo, L.; Teltayev, B.; Luprano, M.L.; Alfè, M.; et al. When Physical Chemistry Meets Circular Economy to Solve Environmental Issues: How the ReScA Project Aims at Using Waste Pyrolysis Products to Improve and Rejuvenate Bitumens. Sustainability 2022, 14, 5790. [Google Scholar] [CrossRef]

- Desseaux, S.; dos Santos, S.; Geiger, T.; Tingaut, P.; Zimmermann, T.; Partl, M.; Poulikakos, L. Improved mechanical properties of bitumen modified with acetylated cellulose fibers. Compos. Part B 2018, 140, 139–144. [Google Scholar] [CrossRef]

- Abe, A.A.; Oliviero Rossi, C.; Caputo, P.; De Santo, M.P.; Godbert, N.; Aiello, I. Spicy Bitumen: Curcumin Effects on the Rheological and Adhesion Properties of Asphalt. Materials 2021, 14, 1622. [Google Scholar] [CrossRef]

- Sigwarth, T.; Büchner, J.; Wistuba, M.P. Bio-Degradable Wax to Modify Asphalt Binder for Warm Mix Asphalt. Sustainability 2022, 14, 10219. [Google Scholar] [CrossRef]

- Perez, I.; Pasandin, A.R.; Pais, J.C.; Pereira, A.A.P. Use of lignin biopolymer from industrial waste as bitumen extender for asphalt mixture. J. Clean. Prod. 2019, 220, 87–98. [Google Scholar] [CrossRef]

- Calandra, P.; Caschera, D.; Turco Liveri, V.; Lombardo, D. How self-assembly of amphiphilic molecules can generate complexity in the nanoscale. Colloids Surf. A Physicochem. Eng. Asp. 2015, 484, 164–183. [Google Scholar] [CrossRef]

- Calandra, P.; Longo, A.; Ruggirello, A.; Turco Liveri, V. Physico-Chemical Investigation of the State of Cyanamide Confined in AOT and Lecithin Reversed Micelles. J. Phys. Chem. B 2004, 108, 8260–8268. [Google Scholar] [CrossRef]

- Calandra, P.; Giordano, C.; Ruggirello, A.; Turco Liveri, V. Physicochemical investigation of acrylamide solubilization in sodium bis(2-ethylhexyl) sulfosuccinate and lecithin reversed micelles. J. Colloid Interface Sci. 2004, 277, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Calandra, P.; Di Marco, G.; Ruggirello, A.; Turco Liveri, V. Physico-chemical investigation of nanostructures in liquid phases: Nickel chloride ionic clusters confined in sodium bis(2-ethylhexyl) sulfosuccinate reverse micelles. J. Colloid Interface Sci. 2009, 336, 176–182. [Google Scholar] [CrossRef]

- Calandra, P.; Longo, A.; Turco Liveri, V. Preparation and Characterisation of Na2S and ZnSO4 Nanoparticles in Water/AOT/n-Heptane Microemulsions. Coll. Pol. Sci. 2001, 279, 1112–1117. [Google Scholar] [CrossRef]

- Calandra, P.; Lombardo, D.; Pistone, A.; Turco Liveri, V.; Trusso, S. Structural and optical properties of novel surfactant-coated Yb@TiO2 nanoparticles. J. Nanoparticle Res. 2011, 13, 5833–5839. [Google Scholar] [CrossRef]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef]

- Calandra, P. On the physico-chemical basis of self-nanosegregation giving magnetically-induced birefringence in dibutyl phosphate/bis(2-ethylhexyl) amine systems. J. Mol. Liq. 2020, 310, 113186. [Google Scholar] [CrossRef]

- Calandra, P.; Turco Liveri, V.; Riello, P.; Freris, I.; Mandanici, A. Self-assembly in surfactant-based liquid mixtures: Octanoic acid/Bis(2-ethylhexyl) amine systems. J. Colloid Interface Sci. 2012, 367, 280–285. [Google Scholar] [CrossRef]

- Calandra, P.; Mandanici, A.; Turco Liveri, V. Self-assembly in surfactant-based mixtures driven by acid–base reactions: Bis(2-ethylhexyl) phosphoric acid–n-octylamine systems. RSC Adv. 2013, 3, 5148. [Google Scholar] [CrossRef]

- Calandra, P.; Mandanici, A.; Turco Liveri, V.; Pochylski, M.; Aliotta, F. Emerging dynamics in surfactant-based liquid mixtures: Octanoic acid/bis(2-ethylhexyl) amine systems. J. Chem. Phys. 2012, 136, 064515. [Google Scholar] [CrossRef] [PubMed]

- Calandra, P.; Nicotera, I.; Oliviero Rossi, C.; Turco Liveri, V. Dynamical properties of self-assembled surfactant-based mixtures: Triggering of 1D anomalous diffusion in bis(2-ethylhexyl) phosphoric acid/n-octylamine systems. Langmuir 2013, 29, 14848–14854. [Google Scholar] [CrossRef] [PubMed]

- Calandra, P.; Caponetti, E.; Chillura Martino, D.; D’Angelo, P.; Minore, A.; Turco Liveri, V. FT-IR and Dielectric study of water/AOT liquid crystals. J. Mol. Struct. 2000, 522, 165–178. [Google Scholar] [CrossRef]

- Gevert, B.S.; Otterstedt, J.E. Upgrading of directly liquefied biomass to transportation fuels hydroprocessing. Biomass 1987, 13, 105–115. [Google Scholar] [CrossRef]

- Ancheyta, J.; Speigh, J.G. Hydroprocessing of Heavy Oils and Residua; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, F.; Zhang, Y.; Zhao, L.; Chen, J.; Cao, L.; Gao, J.; Xu, C. Properties and utilization of waste tire pyrolysis oil: A mini review. Fuel Process. Technol. 2021, 211, 106582. [Google Scholar] [CrossRef]

- Abe, A.A.; Oliviero Rossi, C.; Eskandarsefat, S.; Porto, M.; Loise, V.; Venturini, L.; Caputo, P. Reclaimed asphalt recycling agents: Looking into the blueprint of their mechanisms of action. Constr. Build. Mater. 2023, 363, 129843. [Google Scholar] [CrossRef]

- Chiu, C.T.; Hsu, T.H.; Yang, W.F. Life cycle assessment on using recycled materials for rehabilitating asphalt pavements. In Resources, Conservation & Recycling; Elsevier: Amsterdam, The Netherlands, 2008; Volume 52, pp. 545–556. [Google Scholar] [CrossRef]

- Machado, H.; Cristino, A.F.; Orišková, S.; Galhano dos Santos, R. Bio-Oil: The Next-Generation Source of Chemicals. Reactions 2022, 3, 118–137. [Google Scholar] [CrossRef]

- Oasmaa, A.; Kuoppala, E.; Elliott, D.C. Development of the Basis for an Analytical Protocol for Feeds and Products of Bio-oil Hydrotreatment. Energy Fuels 2012, 26, 2454–2460. [Google Scholar] [CrossRef]

- Uchoa, A.F.J.; Rocha, W.D.; Feitosa, J.P.M.; Nogueira, R.L.; De Brito, D.H.A.; Soares, J.B.; Soares, S.D. Bio-based palm oil as an additive for asphalt binder: Chemical characterization and rheological properties. Constr. Build. Mater. 2021, 285, 122883. [Google Scholar] [CrossRef]

- Rasman, M.; Abdul Hassan, N.; Hainin, M.R.; Putra Jaya, R.; Yaacob, H.; Shukry, N.A.M.; Mohd Ezree Abdullah, M.E.; Kamaruddin, N.H.M. Engineering properties of bitumen modified with bio-oil. MATEC Web Conf. 2018, 250, 02003. [Google Scholar] [CrossRef]

- Yadykova, A.Y.; Ilyin, S.O. Rheological and adhesive properties of nanocomposite bitumen binders based on hydrophilic or hydrophobic silica and modified with bio-oil. Constr. Build. Mater. 2022, 342, 127946. [Google Scholar] [CrossRef]

- Nogueira, R.L.; Soares, J.B.; Soares, S.D. Rheological evaluation of cotton seed oil fatty amides as a rejuvenating agent for RAP oxidized asphalts. Constr. Build. Mater. 2019, 223, 1145–1153. [Google Scholar] [CrossRef]

- Kamal-Eldin, A.; Andersson, R. A multivariate study of the correlation between tocopherol content and fatty acid composition in vegetable oils. J. Am. Oil Chem. Soc. 1997, 74, 375–380. [Google Scholar] [CrossRef]

- Asli, H.; Ahmadinia, E.; Zargar, M.; Karim, M.R. Investigation on physical properties of waste cooking oil—rejuvenated bitumen binder. Constr. Build. Mater. 2012, 37, 398–405. [Google Scholar] [CrossRef]

- Orsavova, J.; Misurcova, L.; Ambrosova, J.B.; Vicha, R.; Mlcek, J. Fatty Acids Composition of Vegetable Oils and Its Contribution to Dietary Energy Intake and Dependence of Cardiovascular Mortality on Dietary Intake of Fatty Acids. Int. J. Mol. Sci. 2015, 16, 12871–12890. [Google Scholar] [CrossRef]

- Caputo, P.; Porto, M.; Calandra, P.; De Santo, M.P.; Oliviero Rossi, C. Effect of epoxidized soybean oil on mechanical properties of bitumen and aged bitumen. Mol. Cryst. Liq. Cryst. 2018, 675, 68–74. [Google Scholar] [CrossRef]

- Mallégol, J.; Gonon, L.; Commereuc, S.; Verney, V. Thermal (DSC) and chemical (iodometric titration) methods for peroxides measurements in order to monitor drying extent of alkyd resins. Prog. Org. Coat. 2001, 41, 171–176. [Google Scholar] [CrossRef]

- Vinay Sharma, P.P. Kundu, Addition polymers from natural oils—A review. Polym. Sci. 2006, 31, 983–1008. [Google Scholar] [CrossRef]

- Le, J.L.; Marasteanu, M.; Hendrickson, R. A Mechanistic Design Approach for Graphite Nanoplatelet (GNP) Reinforced Asphalt Mixtures for Low-Temperature Applications. In Minnesota Department of Transportation Research Services & Library Research Report; Minnesota Department of Transportation: Saint Paul, MN, USA, 2018. Available online: http://mndot.gov/research/reports/2018/201802.pdf (accessed on 27 October 2022).

- Porto, M.; Angelico, R.; Caputo, P.; Abe, A.A.; Teltayev, B.; Rossi, C.O. The Structure of Bitumen: Conceptual Models and Experimental Evidences. Materials 2022, 15, 905. [Google Scholar] [CrossRef]

- Katti, D.S.; Lakshmi, S.; Langer, R.; Laurencin, C.T. Toxicity, biodegradation and elimination of polyanhydrides. Adv. Drug Deliv. Rev 2002, 54, 933–961. [Google Scholar] [CrossRef]

- Vroman, I.; Tighzert, L. Biodegradable Polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Nair, L.; Laurencin, C.T. Biodegradable polymers as biomaterials. Prog. Polym. Sci. 2007, 32, 762–798. [Google Scholar] [CrossRef]

- Chandra, R.; Rustgi, R. Biodegradable polymers. Progr. Polym. Sci. 1998, 23, 1273–1335. [Google Scholar] [CrossRef]

- Samir, A.; Ashour, F.H.; Abdel Hakim, A.A.; Bassyouni, M. Recent advances in Biodegradable polymers for sustainable applications. NPJ Mater. Degrad. 2022, 6, 68. [Google Scholar] [CrossRef]

- Liu, M.; Ferry, M.A.; Davidson, R.R.; Glover, C.J.; Bullin, J.A. Oxygen uptake as correlated to carbonyl growth in aged asphalt and corbett fractions. Ind. Eng. Chem. Res. 1998, 37, 4669–4694. [Google Scholar] [CrossRef]

- Ouyang, C.; Wang, S.; Zhang, Y.; Zhang, Y. Improving the aging resistance of styrenebutadiene- styrene tri-block copolymer modified asphalt by addition of antioxidants. Polym. Degrad. Stab. 2006, 91, 795–804. [Google Scholar] [CrossRef]

- Boerjan, W.; Ralph, J.; Baucher, M. Lignin biosynthesis. Annu. Rev. Plant Biol. 2003, 54, 519–546. [Google Scholar] [CrossRef]

- Porto, M.; Caputo, P.; Loise, V.; De Filpo, G.; Oliviero Rossi, C.; Calandra, P. Polysaccharide-reinforced bitumens: Specificities and Universality of Rheological behaviour. Appl. Sci. 2019, 9, 5564. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Fangueiro, S.; Rana, S.R.M.E. Natural fibres: Advances in science and technology towards industrial applications. In Science to Market; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 9789401775137. OCLC 938890984. [Google Scholar]

- Oda, S.; Fernandes, J.L.; Ildefonso, J.S. Analysis of use of natural fibers and asphalt rubber binder in discontinuous asphalt mixtures. Constr. Build. Mater. 2012, 26, 13–20. [Google Scholar] [CrossRef]

- Kundal, A.; Goel, A. A Study of Bituminous Mixes with Natural Fibre (Sisal Fibre) by Experiment. Int. J. Civ. Eng. Technol. 2019, 10, 1565–1573. [Google Scholar]

- Oyedepo, O.J.; Olukanni, E.O.; Alalade, A.; Amoko, A.; Oluwadare, G.; Ayanda, O. Evaluation of the Strength Properties of Asphalt Concrete using Natural Fibres as Reinforcing Additives. Niger. J. Technol. Dev. 2021, 18, 302–311. [Google Scholar] [CrossRef]

- Muniandy, R.; Huat, B.B.K. Laboratory Diameteral Fatigue Performance of Stone Matrix Asphalt with Cellulose Oil Palm Fiber. Am. J. Appl. Sci. 2006, 3, 2005–2010. [Google Scholar] [CrossRef]

- Paramita, P. Influence of Natural Fibers as Additive on Characteristics of Stone Mastic Asphalt. IOP Conf. Ser. Mater. Sci. Eng. 2020, 970, 012021. [Google Scholar] [CrossRef]

- Bonica, C.; Toraldo, E.; Andena, L.; Marano, C.; Mariani, E. The effects of fibers on the performance of bituminous mastics for road pavements. Compos. Part B 2016, 95, 76–81. [Google Scholar] [CrossRef]

- Abiola, O.S.; Kupolati, W.K.; Sadiku, E.R.; Ndambuki, J.M. Utilisation of natural fibre as modifier in bituminous mixes: A review. Constr. Build. Mater. 2014, 54, 305–312. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Malcolm Brown, R.; Saxena, I.M. Cellulose: Molecular and structural biology. In Selected Articles on the Synthesis, Structure, and Applications of Cellulose; Springer: Dordrecht, The Netherlands, 2007; ISBN 9781402053801. OCLC 187314758. [Google Scholar]

- Rowell, R.M.; Young, R.A.; Rowell, J.K. Paper and Composites from Agro-Based Resources; CRC Lewis Publishers: Boca Raton, FL, USA, 1997. [Google Scholar]

- Kumar, P.; Sikdar, P.K.; Bose, S.; Chandra, S. Use of jute fibre in stone matrix asphalt. Road Mater Pav. Des. 2004, 5, 239–249. [Google Scholar] [CrossRef]

- Narayan, P. Laboratory investigations on stone matrix asphalt using sisal fibre for Indian roads. In BTech; National Institute of Technology: Rourkela, India, 2010. [Google Scholar]

- Delgado, H.; Arnaud, L. Investigation of the fatigue properties of asphalt mixtures reinforced with natural fibres. In Proceedings of the 5th International Conference Bituminous Mixtures and Pavements, Thessaloniki, Greece, 1–3 June 2011; ISBN 9789609992206. [Google Scholar]

- Luo, D.; Khater, A.; Yue, Y.; Abdelsalam, M.; Zhang, Z.; Li, Y.; Li, J.; Iseley, D.T. The performance of asphalt mixtures modified with lignin fiber and glass fiber: A review. Constr. Build. Mater. 2019, 209, 377–387. [Google Scholar] [CrossRef]

- Yao, H.; Wang, Y.; Liu, J.; Xu, M.; Ma, P.; Ji, J.; You, Z. Review on Applications of Lignin in Pavement Engineering: A Recent Survey. Front. Mater. 2022, 8, 803524. [Google Scholar] [CrossRef]

- Shi, C.; Zhu, Y.; Ran, X.; Wang, M.; Su, Y.; Cheng, T. Therapeutic potential of chitosan and its derivatives in regenerative medicine. J. Surg Res. 2006, 133, 185–192. [Google Scholar] [CrossRef]

- Liu, H.; Wang, C.; Zou, S.; Wei, Z.; Tong, Z. Simple, Reversible Emulsion System Switched by pH on the Basis of Chitosan without Any Hydrophobic Modification. Langmuir 2012, 28, 11017–11024. [Google Scholar] [CrossRef] [PubMed]

- Payet, L.; Terentjev, E.M. Emulsification and Stabilization Mechanisms of O/W Emulsions in the Presence of Chitosan. Langmuir 2008, 24, 12247–12252. [Google Scholar] [CrossRef] [PubMed]

- Chapelle, C.; David, G.; Caillol, S.; Negrell, C.; Catrouillet, S.; Desroches le Foll, M.; Azéma, N. Surfactant properties of chemically modified chitooligosaccharides and their potential application in bituminous emulsions. Colloids Surf. A Physicochem. Eng. Asp. 2021, 628, 127327. [Google Scholar] [CrossRef]

- Yukuta, T.; Akira, I.; Masatoshi, K. Developments of biodegradable plastics containing polycaprolactone and/or starch. Polym. Mater. Sci. Eng. 1990, 63, 742–749. [Google Scholar]

- Jiang, L.; Zhang, J. 7 Biodegradable and Biobased Polymers. In Applied Plastics Engineering Handbook; Elsevier Inc.: Oxford, UK, 2017; pp. 127–143. [Google Scholar] [CrossRef]

- Kumar, S.; Thakur, K.S. Bioplastics-classification, production and their potential food applications. J. Hill Agric. 2017, 8, 118–129. [Google Scholar] [CrossRef]

- Fredriksson, H.; Silverio, J.; Andersson, R.; Eliasson, A.C.; Aman, P. The influence of amylase and amylopectine characteristics on gelatinization and retrogradation properties of different starches. Carbohyd. Polym. 1998, 35, 119–134. [Google Scholar] [CrossRef]

- Ratnayake, W.S.; Hoover, R.; Shahidi, F.; Perera, C.; Jane, J. Composition, molecular structure and physicochemical properties of starches from four field pea cultivars. Food Chem. 2001, 74, 189–202. [Google Scholar] [CrossRef]

- Angellier, H.; Molina, B.S.; Lebrun, L.; Dufresne, A. Processing and structural properties of waxy maize starch nanocrystals reinforced natural rubber. Macromolecules 2005, 28, 3783–3792. [Google Scholar] [CrossRef]

- Martin, O.; Schwach, E.; Averous, L.; Couturier, Y. Properties of biodegradable multilayer films based on plasticized wheat starch. Starch 2001, 53, 372–380. [Google Scholar] [CrossRef]

- Imam, S.H.; Gordon, S.H.; Shogren, R.L.; Greene, R.V. Biodegradation of starch-poly (β-hydroxybutyrate-co-valerate) composites in municipal activated sludge. J. Envir. Polym. Degr. 1995, 3, 205–213. [Google Scholar] [CrossRef]

- Myllarinen, P.; Buleon, A.; Lahtinen, R.; Forssell, P. The crystallinity of amylose and amylopectin films. Carbohydr. Polym. 2002, 48, 41–48. [Google Scholar] [CrossRef]

- Iwaura, R.; Komba, S. Modification of Asphalt by Starch-derived Supramolecular Fibres: A simple way to tune flow resistance. ACS Sustain. Chem. Eng. 2022, 10, 7447–7452. [Google Scholar] [CrossRef]

- Al-Hadidy, A.; Tan, Y.; Ayman, T.H. Starch as a modifier for asphalt paving materials. Constr. Build. Mater. 2010, 25, 14–20. [Google Scholar] [CrossRef]

- Jack, F.R.; Iwo, E.O. Dynamic Modulus and Fatigue Life of Corn Starch Modified Bitumen in Asphalt Concrete Pavement. Int. J. Res. Eng. Sci. (IJRES) 2022, 10, 292–303. [Google Scholar]

- Augst, A.D.; Kong, H.J.; Mooney, D.J. Alginate hydrogels as biomaterials. Macromol. Biosci. 2006, 6, 623–633. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Liu, X.; Tabakovic, A.; Schlangen, E. Investigation of the Potential Use of Calcium Alginate Capsules for Self-Healing in Porous Asphalt Concrete. Materials 2019, 12, 168. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Tabakovic, A.; Liu, X.; Schlangen, E. Calcium alginate capsules encapsulating rejuvenator as healing system for asphalt mastic. Constr. Build. Mater. 2018, 169, 379–387. [Google Scholar] [CrossRef]

- Arayapranee, W. Rubber Abrasion Resistance. Abrasion Resist. Mater. 2012, 8, 147–166. [Google Scholar] [CrossRef]

- Abdulrahman, S.; Hainin, M.R.; Satar, M.K.I.; Hassan, N.A.; Al Saffar, Z.H. Review on the potentials of natural rubber in bitumen modification. IOP Conf. Ser. Earth Environ. Sci. 2020, 476, 012067. [Google Scholar] [CrossRef]

- Ismail, H.; Salmah, M.N. Dynamic Vulcanization of Rubberwood-filled Polypropylene/Natural Rubber Blends. Polym. Testing. 2001, 20, 819–823. [Google Scholar] [CrossRef]

- Swetha, D.V.; Rani, K.D. Effect of Natural Rubber on the Properties of Bitumen and Bituminious Mixes. Int. J. Civ. Eng. Technol. 2014, 5, 9–21. [Google Scholar]

- Ikeda, Y.; Kato, A.; Kohjiya, S.; Nakajima, Y. Basic science of rubber. In Rubber Science; Springer: Singapore, 2018; p. 19e53. [Google Scholar] [CrossRef]

- Greve, H. Rubber, 2. Natural. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2000; p. 14. [Google Scholar] [CrossRef]

- Fernando, M.J.; Nadarajah, M. Use of natural rubber latex in road construction. Rubber Res. Inst. Malaya 1969, 22, 430–440. [Google Scholar]

- Wen, Y.; Wang, Y.; Zhao, K.; Sumalee, A. The Use of Natural Rubber Latex as a Renewable and Sustainable Modifier of Asphalt Binder. Int. J. Pavement Eng. 2017, 18, 547–559. [Google Scholar] [CrossRef]

- Tantatherdtam, R. Reinforcement of natural rubber latex by nanosize montmorillonite clay. In Dissertation Abstracts International; Pennsylvania State University: University Park, PA, USA, 2003; Volume 64-10, p. 124, Publication Number: AAI3109979; ISBN 9780496575190. [Google Scholar]

- Okieimen, F.E.; Akinlabi, A.K. Processing Characteristics and Physicomechanical Properties of Natural Rubber and Liquid Natural Rubber Blends. J. Appl. Polym. Sci. 2002, 85, 1070–1076. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.; Yussof, N.I.M.; Napiah, M.; Sutanto, M. A review of using Natural Rubber in the modification of bitumen and Asphalt mixtures used for road construction. J. Teknol. Sci. Eng. 2019, 81, 81–88. [Google Scholar] [CrossRef]

- Mathew, M.N. Natural Rubber, Biology, Cultivation and Technology; Elsevier Science: San Diego, CA, USA, 1992; ISBN 9780444597809. [Google Scholar]

- Sriring, M.; Nimpaiboon, A.; Kumarn, S.; Sirisinha, C.; Sakdapipanich, J.; Toki, S. Viscoelastic and mechanical properties of large- and small-particle natural rubber before and after vulcanization. Polym. Test. 2018, 70, 127–134. [Google Scholar] [CrossRef]

- Ansari, A.H.; Jakarni, F.M.; Muniandy, R.; Hassim, S.; Elahi, Z. Natural rubber as a renewable and sustainable bio-modifier for pavement applications: A review. J. Clean. Prod. 2021, 289, 125727. [Google Scholar] [CrossRef]

- Azahar, N.F.B.M.; Hassan, N.B.A.; Jaya, R.P.; Kadir, M.A.B.A.; Yunus, N.Z.B.M.; Mahmud, M.Z.H. An Overview on Natural Rubber Application for Asphalt Modification. Int. J. Agric. Plant 2016, 2, 212. [Google Scholar]

- Polacco, G.; Stastna, J.; Biondi, D.; Zanzotto, L. Relation between polymer architecture and nonlinear viscoelastic behavior of modified asphalts. Curr. Opin. Colloid Interface Sci. 2006, 11, 230e245. [Google Scholar] [CrossRef]

- Krishnapriya, M.G. Performance evaluation of natural rubber modified bituminous mixes. Int. J. Civil. Struct. Env. Infrastruct. Eng. Res. Dev. 2015, 5, 121–134. [Google Scholar]

- Shaffie, E.; Ahmad, J.; Arshad, A.K.; Kamarun, D.; Kamaruddin, F. Stripping Performance and Volumetric Properties Evaluation of Hot Mix Asphalt (HMA) Mix Design Using Natural Rubber Latex Polymer Modified Binder (NRMB). In CIEC; Springer: Singapore, 2015; pp. 873–884. [Google Scholar]

- Ruggles, C. The Use of Natural Rubber Latex in Modified Asphalt Road Binders in the UK. In Annual General Meeting Report; World Class Natural Rubber Solutions: Las Vegas, NV, USA, 2005; pp. 1–29. [Google Scholar]

- Riemenschneider, W.; Bolt, H.M. “Esters, Organic” Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH: Weinheim, Germany, 2005. [Google Scholar] [CrossRef]

- Wolfmeier, U.; Schmidt, H.; Heinrichs, F.L.; Michalczyk, G.; Payer, W.; Dietsche, W.; Boehlke, K.; Hohner, G.; Wildgruber, J. “Waxes” in Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH: Weinheim, Germany, 2002. [Google Scholar] [CrossRef]

- Caputo, P.; Abe, A.A.; Loise, V.; Porto, M.; Calandra, P.; Angelico, R.; Oliviero-Rossi, C. The Role of Additives in Warm Mix Asphalt Technology: An Insight into Their Mechanisms of Improving an Emerging Technology. Nanomaterials 2020, 10, 1202. [Google Scholar] [CrossRef] [PubMed]

- Rubio, M.C.; Martínez, G.; Baena, L.; Moreno, F. Warm mix asphalt: An overview. J. Clean. Prod. 2012, 24, 76–84. [Google Scholar] [CrossRef]

- Diab, A.; Sangiorgi, C.; Ghabchi, R.; Zaman, M.; Wahaballa, A.M.; Lee, Y.-H.; Chou, N.N.; He, J.; Qian, G.; Zhu, J.; et al. Warm mix asphalt (WMA) technologies: Benefits and drawbacks—A literature review. In Proceedings of the Functional Pavement Design, Delft, The Netherlands, 29 June–1 July 2016. [Google Scholar]

- Calandra, P.; Caputo, P.; De Santo, M.P.; Todaro, L.; Liveri, V.T.; Rossi, C.O. Effect of additives on the structural organization of asphaltene aggregates in bitumen. Constr. Build. Mater. 2019, 199, 288–297. [Google Scholar] [CrossRef]

- Caputo, P.; Kaljaca, H.; Porto, M.; Loise, V.; Abe, A.A.; Oliviero-Rossi, C. Waste Food Wax Additive as a Bitumen Modifier for Warm Mix Asphalt Production; Dorogi i Mosti: Kyiv, Ukraine, 2020; ISSN 2524-0994. [Google Scholar] [CrossRef]

- Nagabhushana, M.N. Right Grade of Bitumen for Flexible Pavements: Indian Perspective, NBMCW, Flexible Pavements Division, Central Road Research Institute, New Delhi, India, Infra Construction and Equipment magazine, September 2009. Available online: https://www.nbmcw.com/article-report/infrastructure-construction/roads-and-pavements/right-grade-of-bitumen-for-flexible-pavements-indian-perspective.html (accessed on 7 November 2022).

- Masri, K.A.; Nur Syafikah, S.M.Z.; Seman, M.A.; Ramadhansyah, P.J.; Yaacob, H.; Mashros, N. A review on nanomaterials as additive in asphalt binder. IOP Conf. Ser. Earth Environ. Sci. 2021, 682, 012055. [Google Scholar] [CrossRef]

- Alfè, M.; Gargiulo, V.; Porto, M.; Migliaccio, R.; Le Pera, A.; Sellaro, M.; Pellegrino, C.; Abe, A.A.; Urciuolo, M.; Caputo, P.; et al. Pyrolysis and Gasification of a Real Refuse-Derived Fuel (RDF): The Potential Use of the Products under a Circular Economy Vision. Molecules 2022, 27, 8114. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Ye, X.P.; Shu, X.; Jia, X. Utilizing bio-char as a bio-modifier for asphalt cement: A sustainable application of bio-fuel by-product. Fuel 2014, 133, 52–62. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.K.; Koh, H.J. Application of biochar from food and wood waste as green admixture for cement mortar. Sci. Total Env. 2018, 619–620, 419–435. [Google Scholar] [CrossRef]

- Taborda, E.A.; Franco, C.A.; Ruiz, M.A.; Alvarado, V.; Cortés, F.B. Experimental and Theoretical Study of Viscosity Reduction in Heavy Crude Oils by Addition of Nanoparticles. Energy Fuels 2017, 31, 1329–1338. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Structure–mechanics property relationship of waste derived biochars. Sci. Total Env. 2015, 538, 611–620. [Google Scholar] [CrossRef]

- Zhang, R.; Dai, Q.; You, Z.; Wang, H.; Peng, C. Rheological Performance of Bio-Char Modified Asphalt with Different Particle Sizes. Appl. Sci. 2018, 8, 1665. [Google Scholar] [CrossRef]

- Gan, X.; Zhang, W. Application of biochar from crop straw in asphalt modification. PLoS ONE 2021, 16, e0247390. [Google Scholar] [CrossRef] [PubMed]

- Loise, V.; Caputo, P.; Porto, M.; Calandra, P.; Angelico, R.; Oliviero Rossi, C. A Review on Bitumen Rejuvenation: Mechanisms, Materials, Methods and Perspectives. Appl. Sci. 2019, 9, 4316. [Google Scholar] [CrossRef]

- Huang, W.; Guo, Y.; Zheng, Y.; Ding, Q.; Sun, C.; Yu, J.; Zhu, M.; Yu, H. Chemical and rheological characteristics of rejuvenated bitumen with typical regeneration agents. Constr. Build. Mater. 2021, 273, 121525. [Google Scholar] [CrossRef]

- Crucho, J.; Picado-Santos, L.; Neves, J.; Capitao, S.D. A Review of Nanomaterials’ Effect on Mechanical Performance and Aging of Asphalt Mixtures. Appl. Sci. 2019, 9, 3657. [Google Scholar] [CrossRef]

- Thomas, B.; Maria, H.J.; George, G.; Thomas, S.; Unnikrishnan, N.V.; Joseph, K. A novel green approach for the preparation of high-performance nitrile butadiene rubber-pristine graphene nanocomposites. Compos. Part B 2019, 175, 107174. [Google Scholar] [CrossRef]

- Karatzas, S. Applications of Nanomaterials in Pavement Engineering: A Review. In Proceedings of the 10th International Conference on Construction in the 21st Century (CITC-10), Colombo, Sri Lanka, 2–4 July 2018. [Google Scholar]

- Zhu, J.; Zhang, K.; Liu, K.; Shi, X. Performance of hot and warm mix asphalt mixtures enhanced by nano-sized graphene oxide. Constr. Build. Mater. 2019, 217, 273–282. [Google Scholar] [CrossRef]

- Mukhtar, A.; Luo, X.; Lü, C.; Wang, J.; Huang, Z. Improving mechanics behavior of hot mix asphalt using graphene-oxide. Constr. Build. Mater. 2020, 254, 119261. [Google Scholar] [CrossRef]

- Norhasri, M.S.M.; Hamidah, M.S.; Fadzil, A.M. Applications of using nano material in concrete: A. review. Constr. Build. Mater. 2017, 133, 91–97. [Google Scholar] [CrossRef]

- Dhawo, I.A.; Nur, I.M.Y.; Jiantao, W.; Quan, L.; Shaban, I.A. The effects of nano silica particles on the physical properties and storage stability of polymer- modified bitumen. J. Civ. Eng. Res. 2015, 5, 11–16. [Google Scholar]

- Yao, H.; You, Z.; Li, L.; Lee, C.H.; Wingard, D.; Yap, Y.K.; Shi, X.; Wei, S. Rheological properties and chemical bonding of asphalt modified with nanosilica. J. Mater. Civ. Eng. 2012, 25, 1619–1630. [Google Scholar] [CrossRef]

- Mahmoud, E.; Aboelkasim, D. Characteristics of asphalt binder and mixture containing nanosilica. Int. J. Pavement Res. Technol. 2017, 10, 148–157. [Google Scholar] [CrossRef]

- Lara-Romero, J.; Campos-García, J.; Dasgupta-Schubert, N.; Borjas-García, S.; Tiwari, D.K.; Paraguay-Delgado, F.; Jiménez-Sandoval, S.; Alonso-Nuñez, G.; Gómez-Romero, M.; Lindig-Cisneros, R.; et al. Biological effects of carbon nanotubes generated in forest wildfire ecosystems rich in resinous trees on native plants. PeerJ. 2017, 15, e3658. [Google Scholar] [CrossRef] [PubMed]

- Vysotskaya, M.; Shekhovtsova, S. Nanotubes as a modifier polymer modified binder and asphalt concrete. In International Conference on Structural, Mechanical and Materials Engineering ICSMME; Atlantis Press: Paris, France, 2015; pp. 177–179. [Google Scholar]

- Urkhanova, L.; Shestakov, N.; Semeno, A.; Smirnyagina, N.; Semenova, I. Improving the quality of asphalt coating with carbon nanomodifiers. In PCM; IOP Publishing: Bristol, UK, 2015; pp. 1–8. [Google Scholar]

- Galooyak, S.S.; Palassi, M.; Farahani, H.Z.; Goli, A. Effect of carbon nanotube on the rheological properties of bitumen. Pet. Coal 2015, 57, 556–564. [Google Scholar]

- Akbari, A.; Motlagh, A.K.; Mirzaei, E.; Omidi, B.F. Bitumen modification using carbon nanotubes. World Appl. Sci. J. 2012, 18, 594–599. [Google Scholar]

- Caputo, P.; Porto, M.; Loise, V.; Abe, A.; Teltayev, B.; Calandra, P.; Oliviero-Rossi, C. How Organic Waste Improves Bitumen’s Characteristics. Eurasian Chem. -Technol. J. 2021, 23, 227–233. [Google Scholar] [CrossRef]

- Calandra, P.; Quaranta, S.; Figueira, B.A.M.; Caputo, P.; Porto, M.; Oliviero-Rossi, C. Mining wastes to improve bitumen performances: An example of circular economy. J. Colloid Interface Sci. 2022, 614, 277–287. [Google Scholar] [CrossRef]

| Component | Bio-Oil % Composition |

|---|---|

| Carbon (wt%) | 50–60 |

| Hydrogen (wt%) | 6–7 |

| Oxygen (wt%) | 35–40 |

| Nitrogen (wt%) | <0.4 |

| Sulphur (wt%) | <0.05 |

| Water (wt%) | 20–30 |

| Solids (wt%) | 0.01–0.1 |

| Ash (wt%) | 0.01–0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abe, A.A.; Oliviero Rossi, C.; Caputo, P. Biomaterials and Their Potentialities as Additives in Bitumen Technology: A Review. Molecules 2022, 27, 8826. https://doi.org/10.3390/molecules27248826

Abe AA, Oliviero Rossi C, Caputo P. Biomaterials and Their Potentialities as Additives in Bitumen Technology: A Review. Molecules. 2022; 27(24):8826. https://doi.org/10.3390/molecules27248826

Chicago/Turabian StyleAbe, Abraham A., Cesare Oliviero Rossi, and Paolino Caputo. 2022. "Biomaterials and Their Potentialities as Additives in Bitumen Technology: A Review" Molecules 27, no. 24: 8826. https://doi.org/10.3390/molecules27248826

APA StyleAbe, A. A., Oliviero Rossi, C., & Caputo, P. (2022). Biomaterials and Their Potentialities as Additives in Bitumen Technology: A Review. Molecules, 27(24), 8826. https://doi.org/10.3390/molecules27248826