Surface-Treated Recycling Fibers from Wind Turbine Blades as Reinforcement for Waste Phosphogypsum

Abstract

1. Introduction

2. Experimental Procedure

2.1. Materials

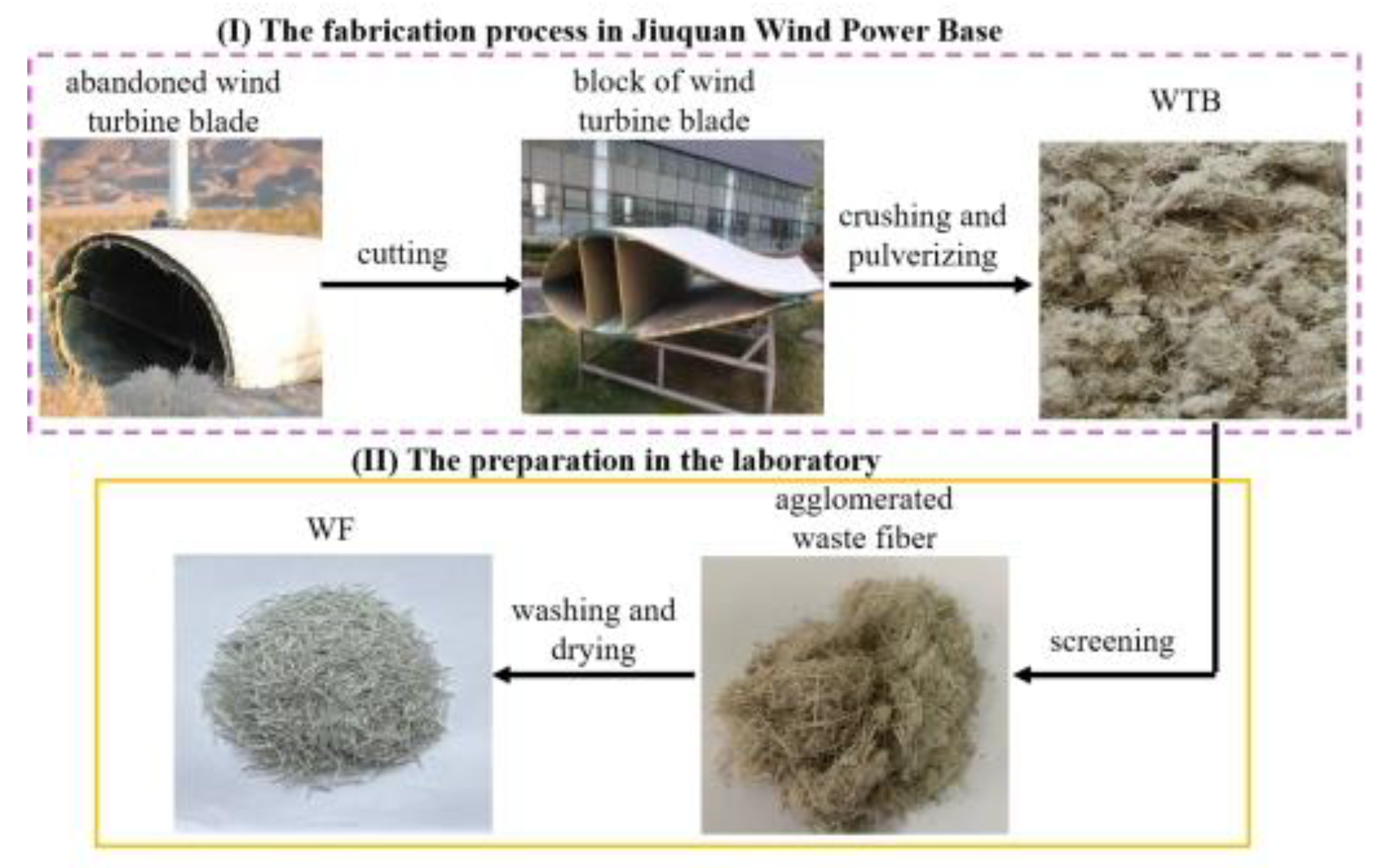

2.2. The Waste Glass Fibers

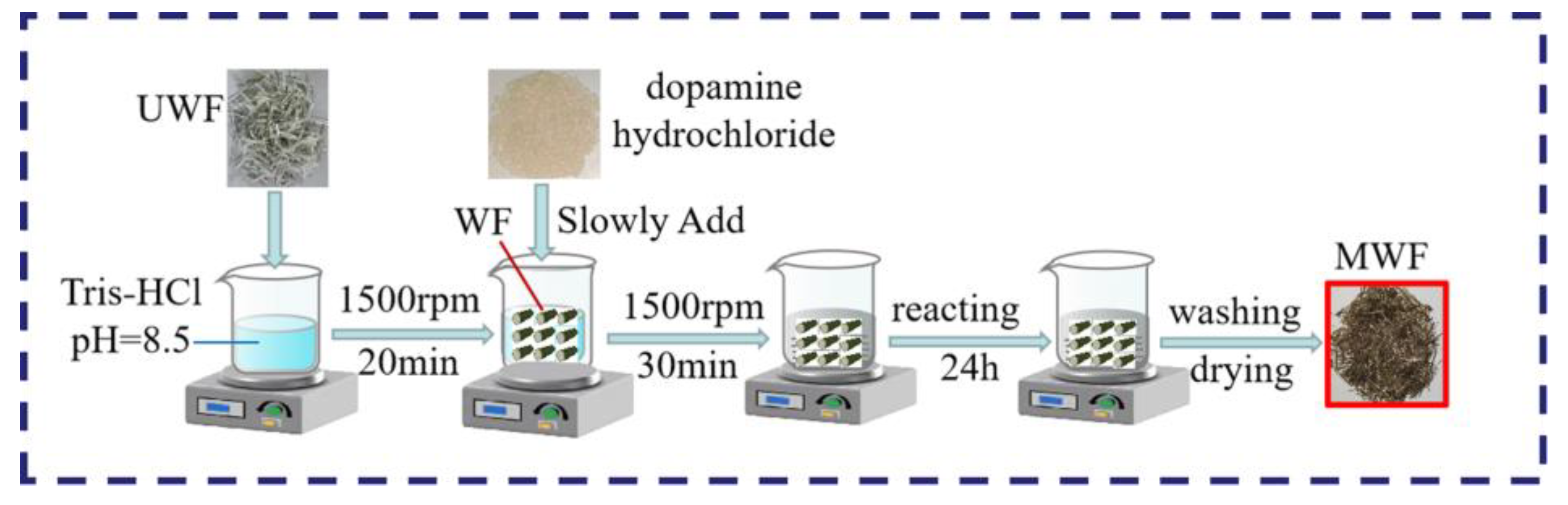

2.3. Surface Treatment of the WFs

2.4. Characterization of the Waste Glass Fibers

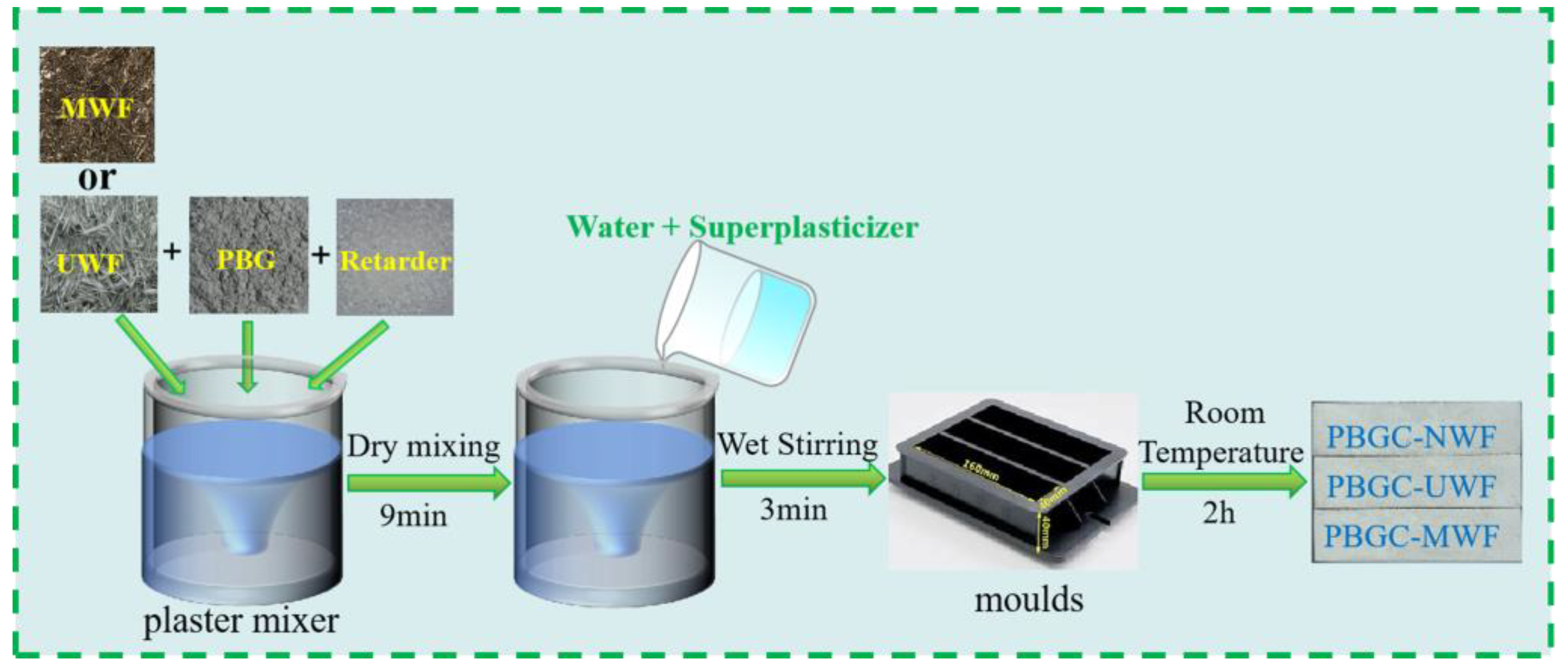

2.5. Properties Analysis of the PBGC

3. Results and Discussion

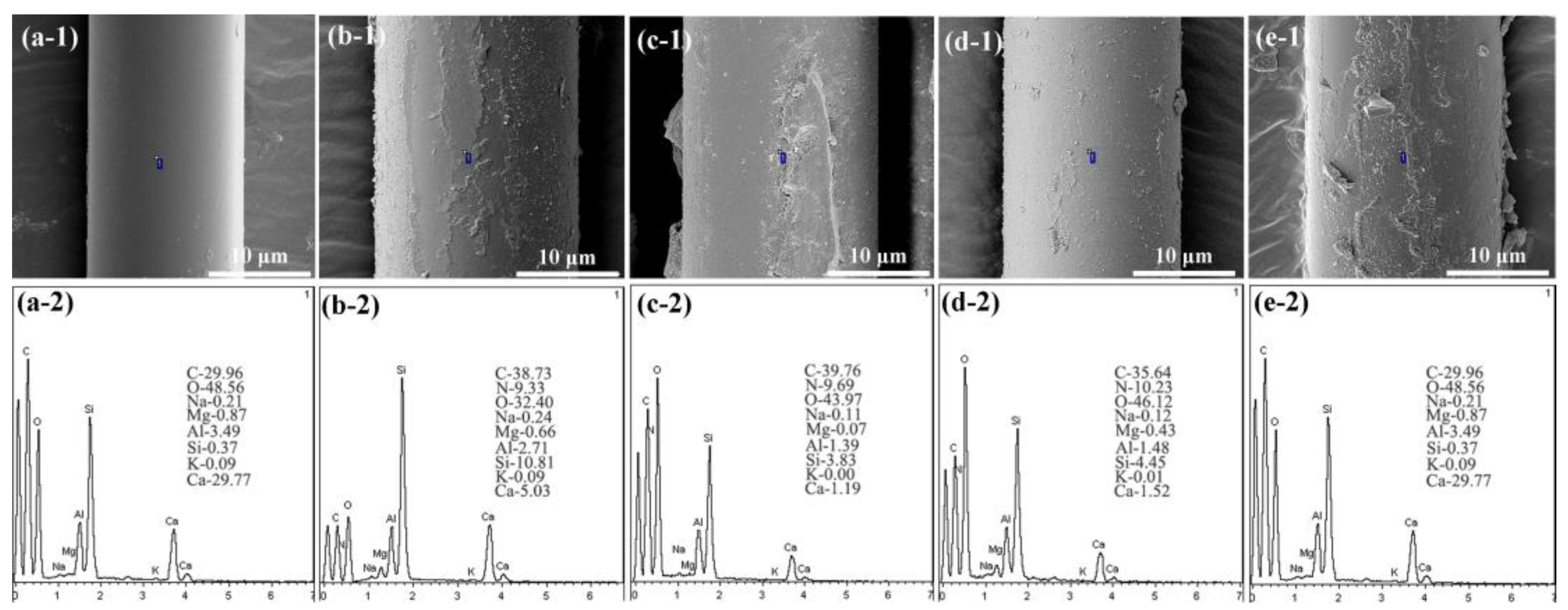

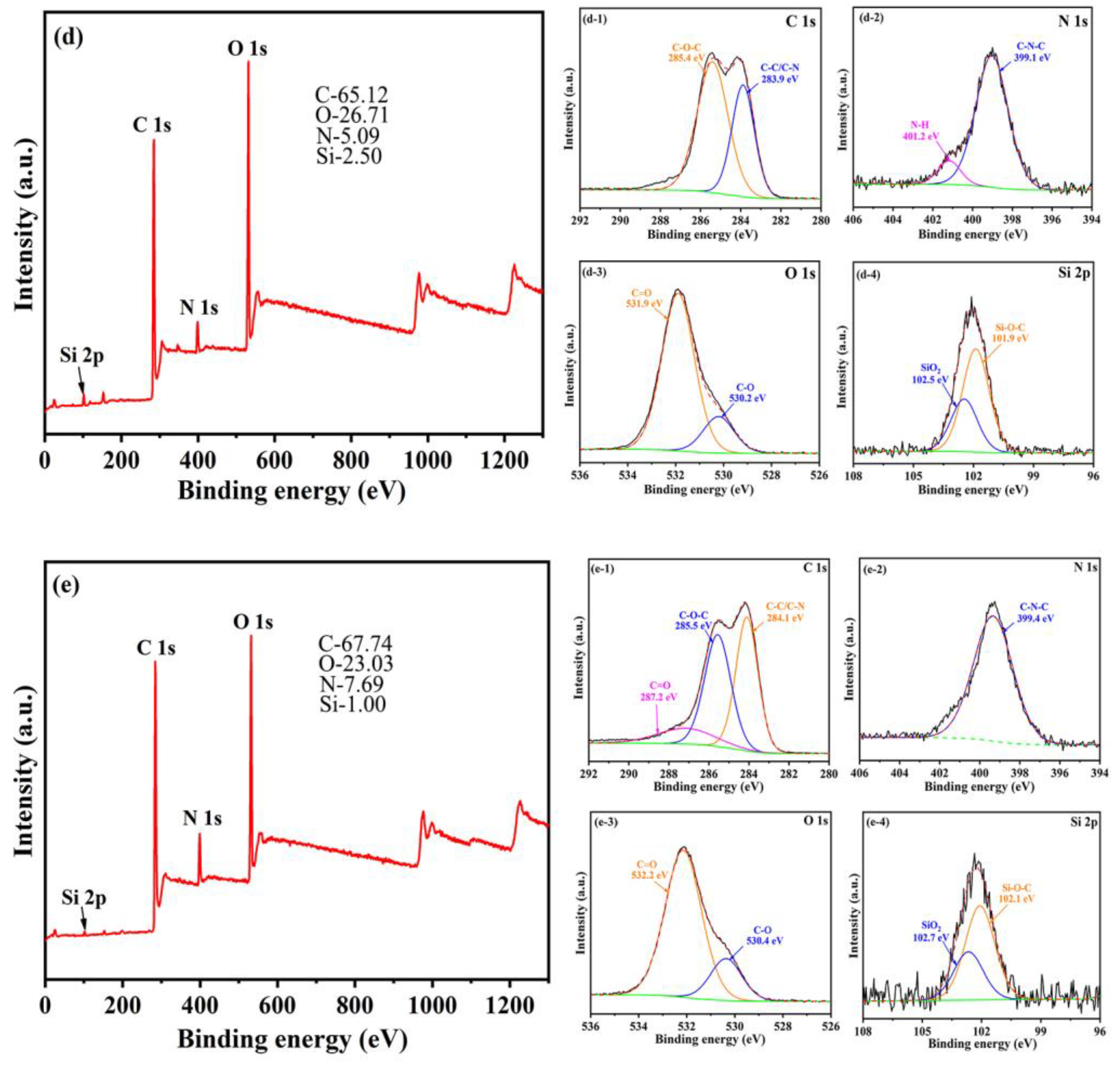

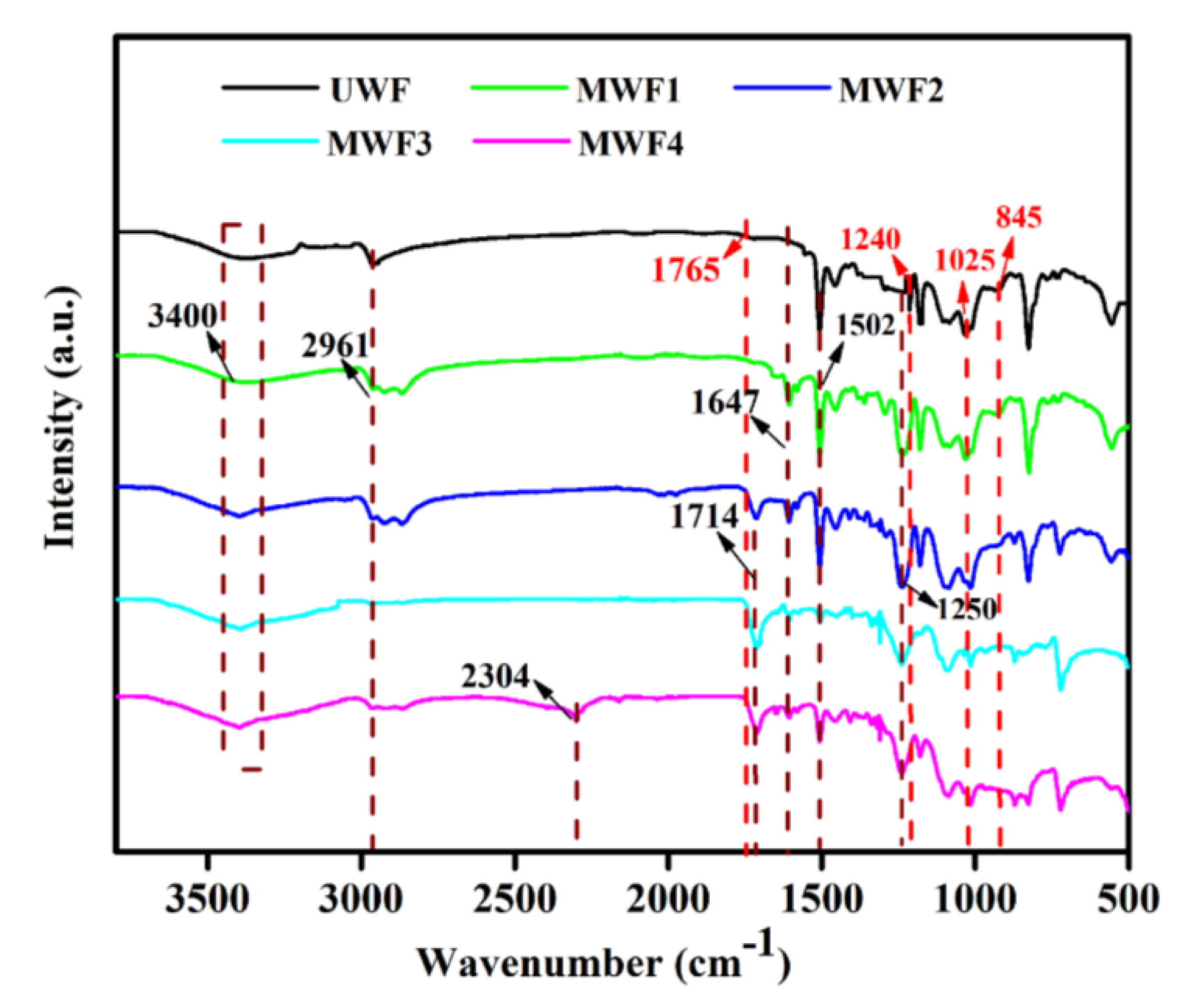

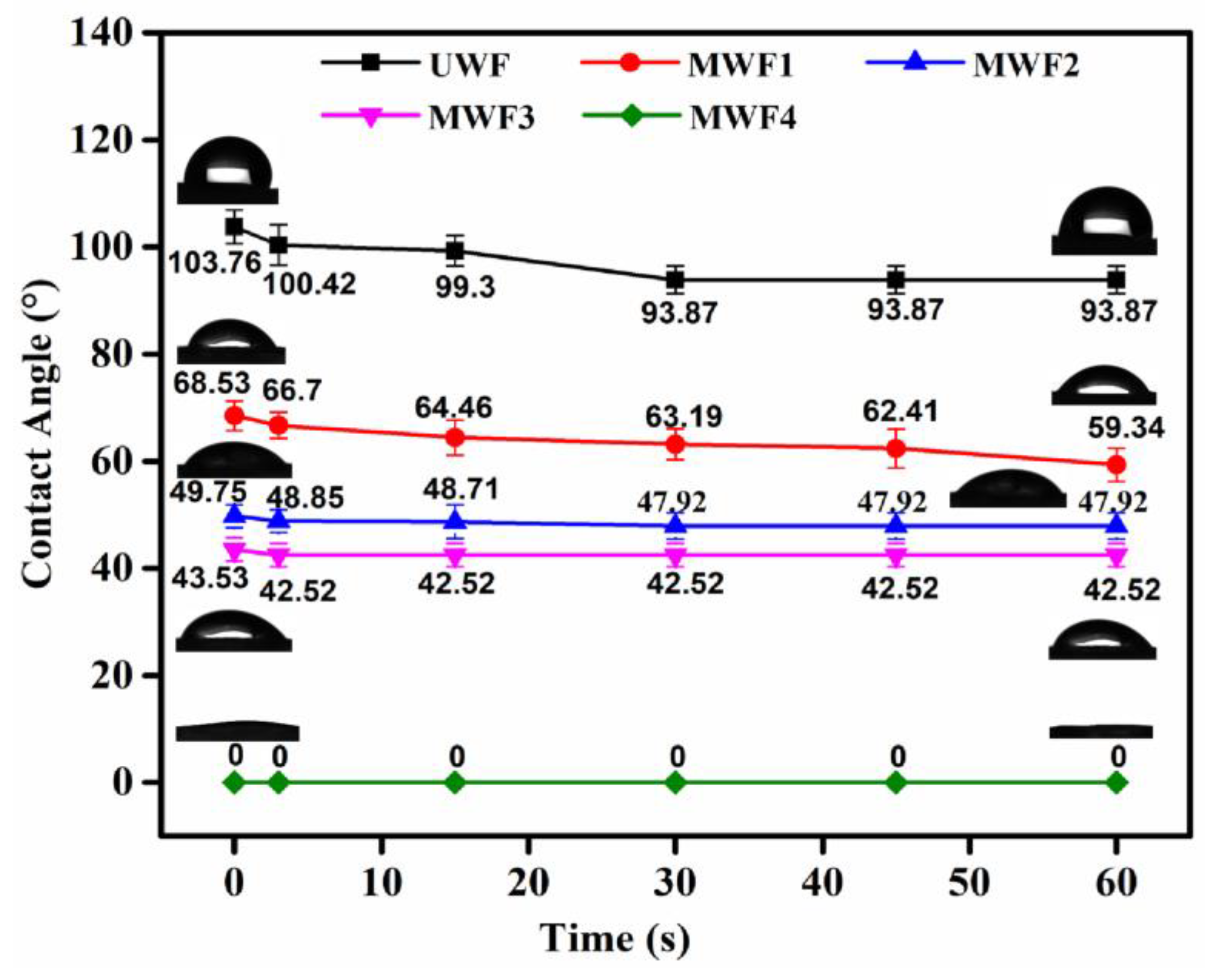

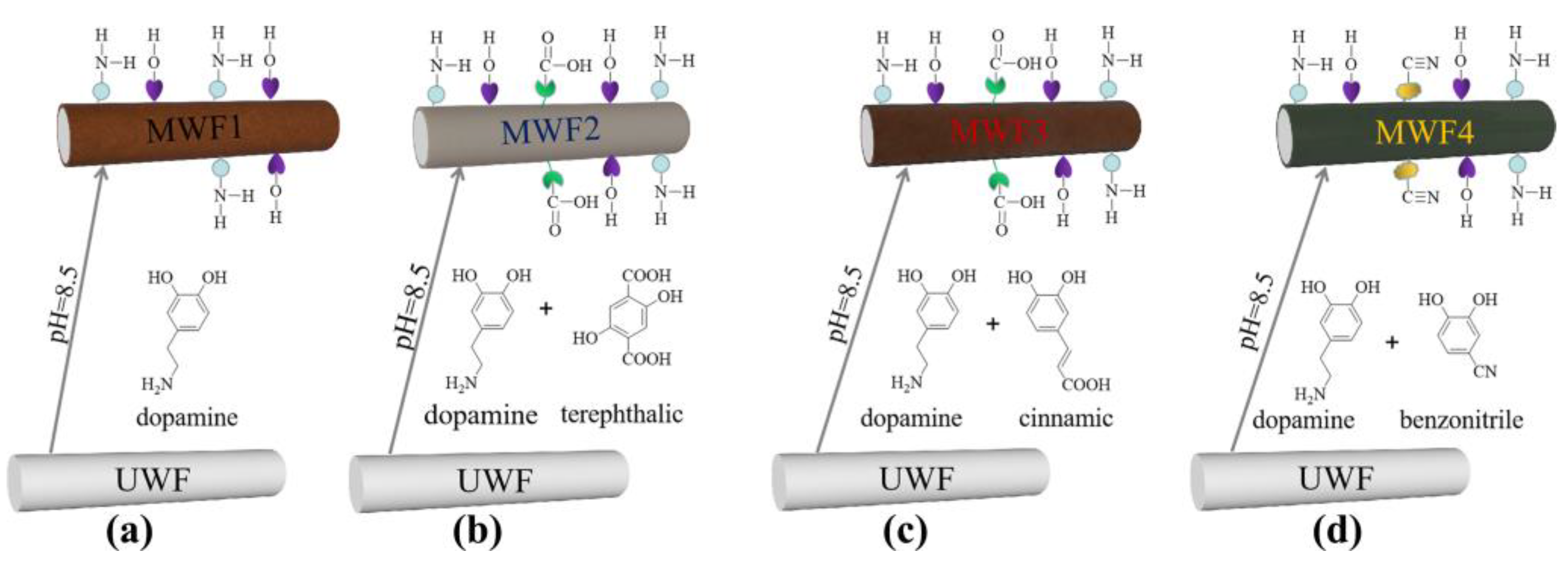

3.1. Characterization of All the WFs

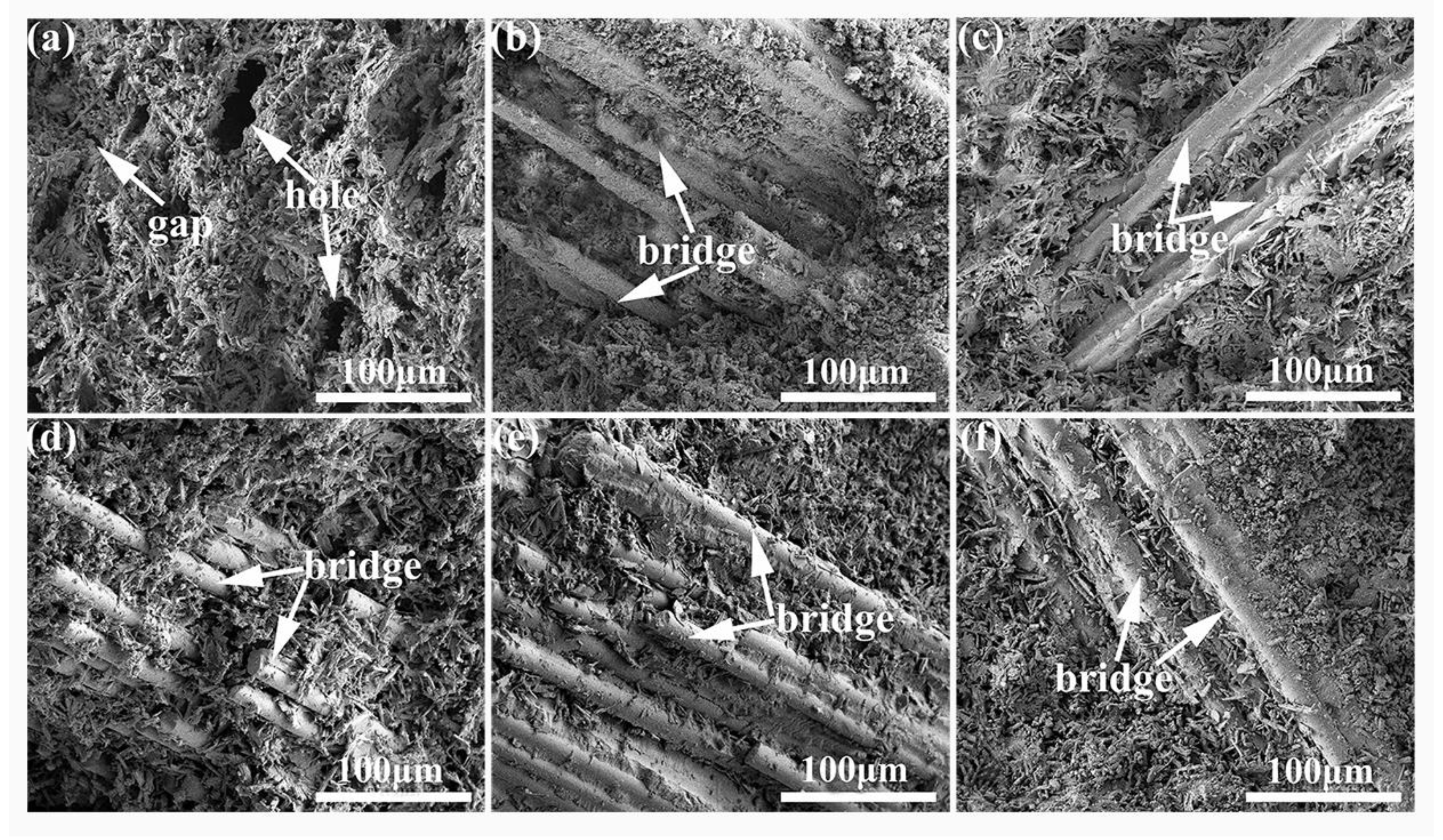

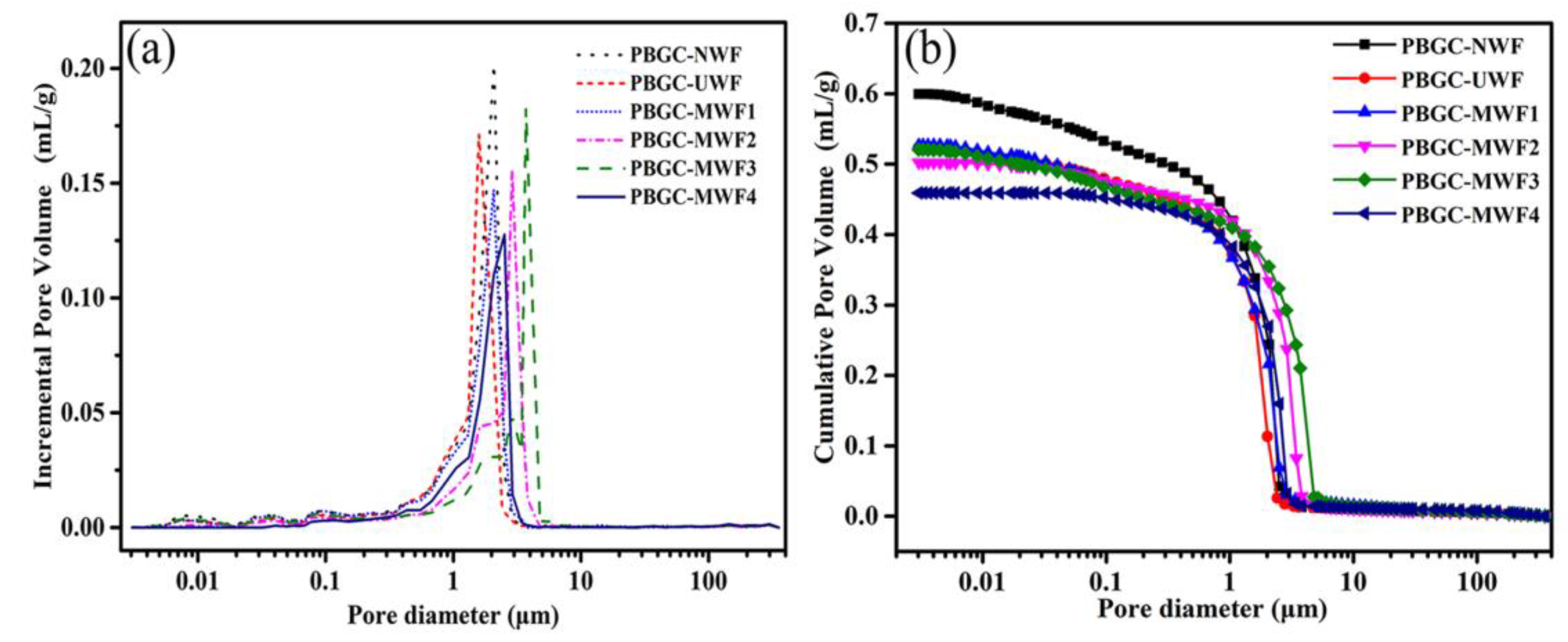

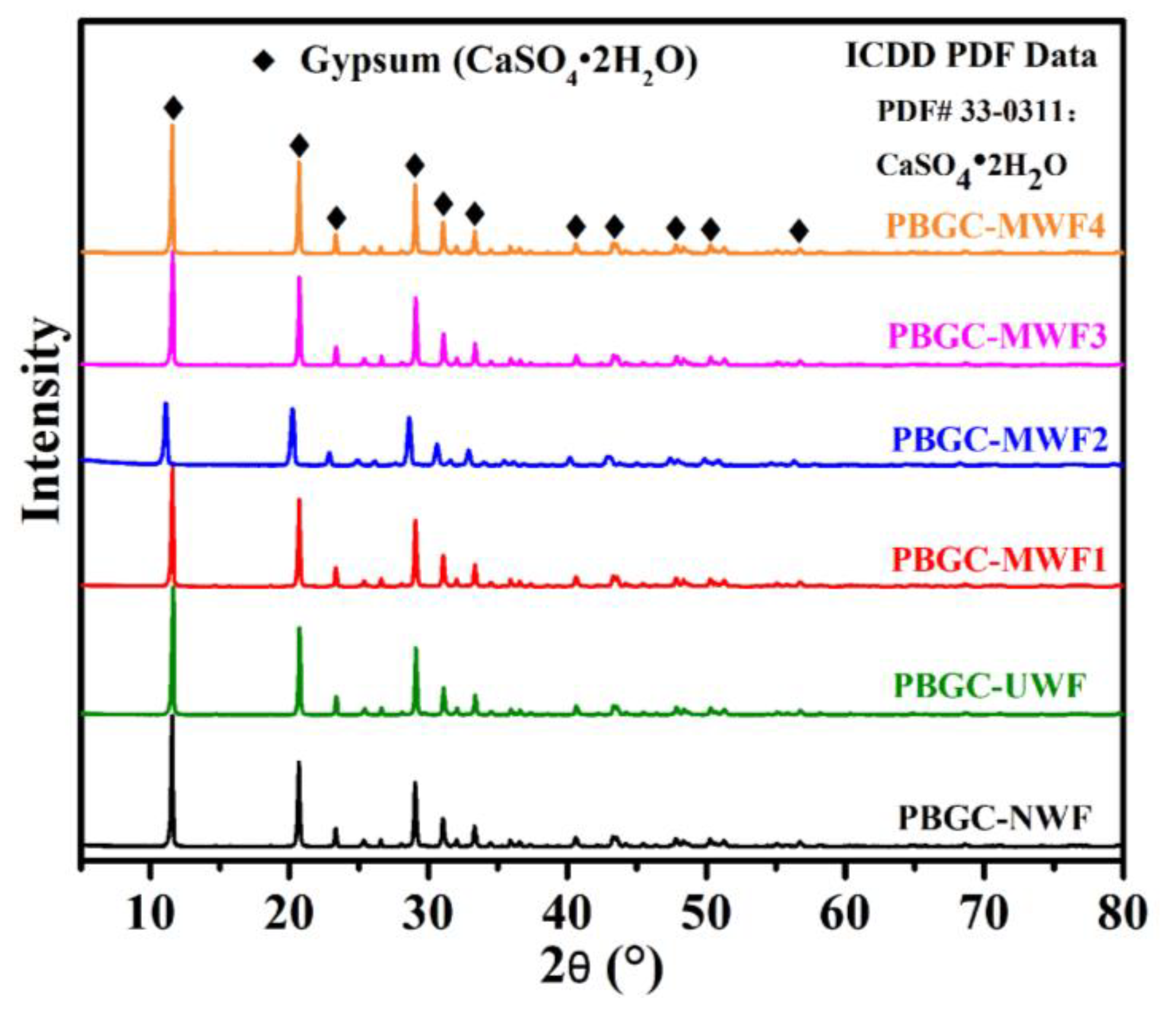

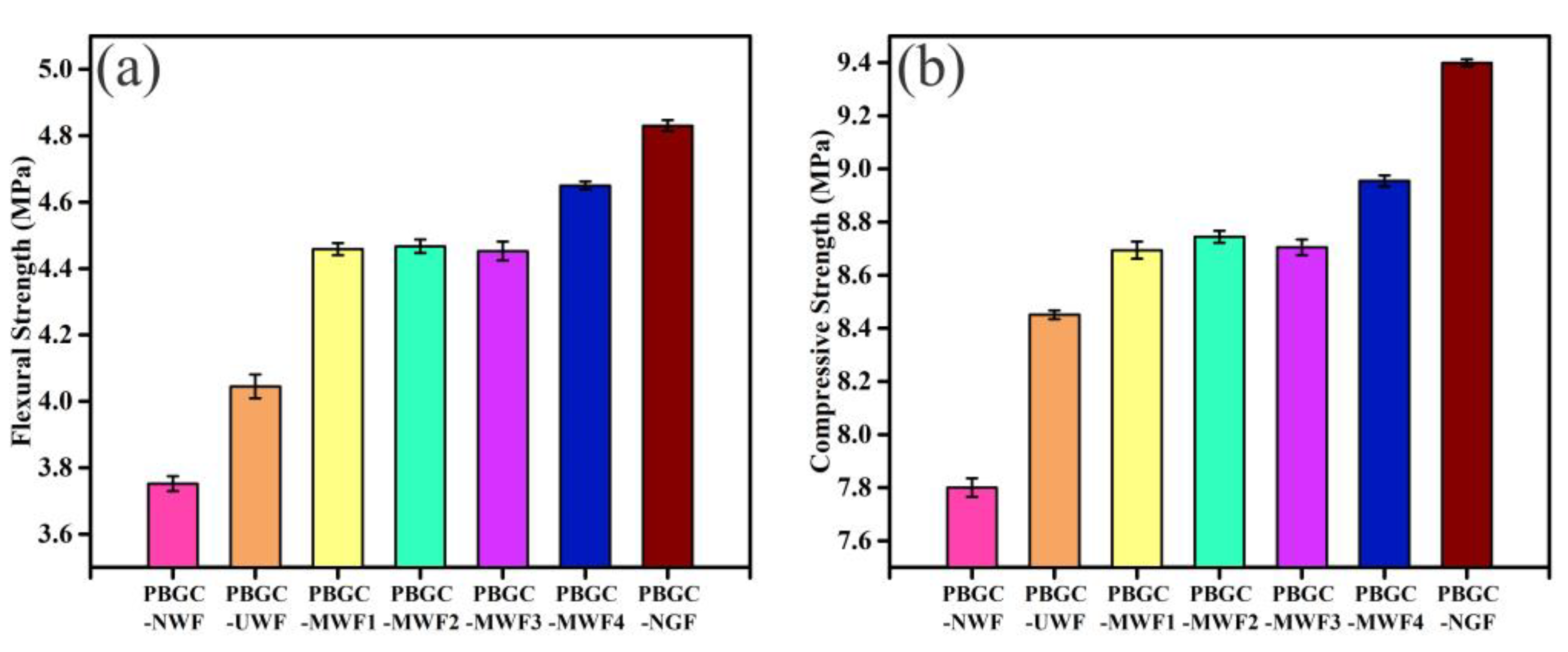

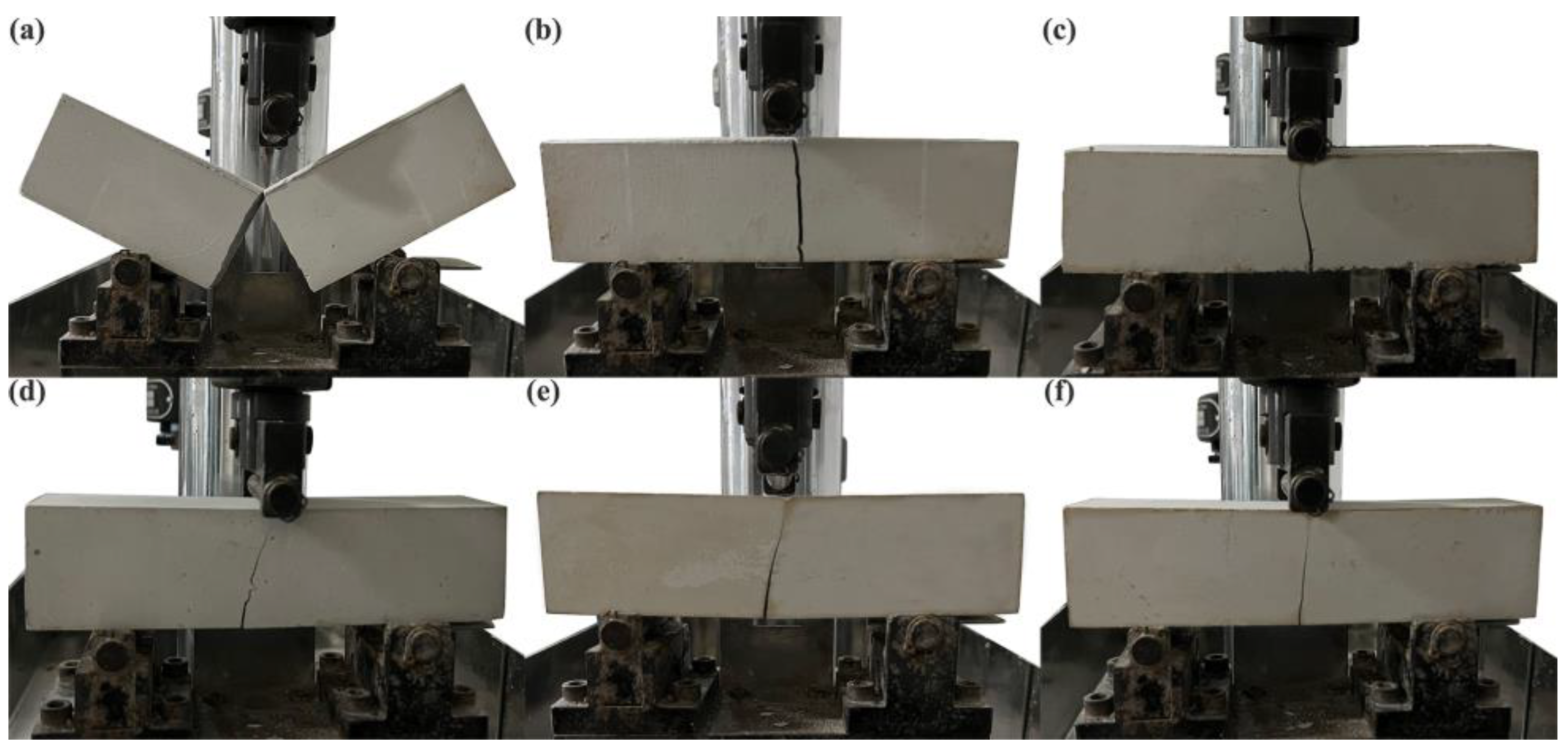

3.2. Microstructure and Mechanical Properties of the PBGCs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Delaney, E.L.; McKinley, J.M.; Megarry, W.; Graham, C.; Leahy, P.G.; Bank, L.C.; Gentry, R. An Integrated Geospatial Approach for Repurposing Wind Turbine Blades. Resour. Conserv. Recycl. 2021, 170, 105601. [Google Scholar] [CrossRef]

- Msigwa, G.; Ighalo, J.O.; Yap, P.S. Considerations on environmental, economic, and energy impacts of wind energy generation: Projections towards sustainability initiatives. Sci. Total Environ. 2022, 849, 157755. [Google Scholar] [CrossRef] [PubMed]

- Roga, S.; Bardhan, S.; Dubey, S.K. Recent technology and challenges of wind energy generation: A review. Sustain. Energy Technol. Assess. 2022, 52, 102239. [Google Scholar] [CrossRef]

- Liu, P.; Meng, F.; Barlow, C.Y. Wind turbine blade end-of-life options: An economic comparison. Resour. Conserv. Recycl. 2022, 180, 106202. [Google Scholar] [CrossRef]

- Ramírez, F.J.; Honrubia-Escribano, R.V.R.; Pérez-Barroso, A.; Gómez-Lázaro, E. Assessment of different end-of-life strategies for wind power plants under uncertainty. Energy Convers. Manag. 2022, 270, 116158. [Google Scholar] [CrossRef]

- Chen, Y.S.; Cai, G.T.; Zheng, L.X.; Zhang, Y.T.; Qi, X.L.; Ke, S.J.; Gao, L.Q.; Bai, R.X.; Liu, G. Modeling waste generation and end-of-life management of wind power development in Guangdong China until 2050. Resour. Conserv. Recycl. 2021, 169, 105533. [Google Scholar] [CrossRef]

- Lefeuvre, A.; Garnier, S.; Jacquemin, L.; Pillain, B.; Sonnemann, G. Anticipating in-use stocks of carbon fiber reinforced polymers and related waste generated by the wind power sector until 2050. Resour. Conserv. Recycl. 2019, 141, 30–39. [Google Scholar] [CrossRef]

- Volk, R.; Stallkamp, C.; Herbst, M.; Frank, S. Regional rotor blade waste quantification in Germany until 2040. Resour. Conserv. Recycl. 2021, 172, 105667. [Google Scholar] [CrossRef]

- Heng, H.; Meng, F.; McKechnie, J. Wind turbine blade wastes and the environmental impacts in Canada. Waste Manag. 2021, 133, 59–70. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades. Compos. Part B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fiber reinforced polymers: A review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Mishnaevsky, L. Repair of wind turbine blades: Review of methods and related computational mechanics problems. Renew. Energy 2019, 140, 828–839. [Google Scholar] [CrossRef]

- Oliveira, P.S.; Antunes, M.L.P.; Cruz, N.C.D.; Rangel, E.C.; Azevedo, A.R.G.; Durrant, S.F. Use of waste collected from wind turbine blade production as an eco-friendly ingredient in mortars for civil construction. J. Clean. Prod. 2020, 274, 122948. [Google Scholar] [CrossRef]

- Baturkin, D.; Hisseine, O.A.; Masmoudi, R.; Arezki, T.H.; Massicotte, L. Valorization of recycled FRP materials from wind turbine blades in concrete. Resour. Conserv. Recycl. 2021, 174, 105807. [Google Scholar] [CrossRef]

- Chen, X.M.; Gao, J.M.; Zhao, Y.S. Investigation on the hydration of hemihydrate phosphogypsum after post treatment. Constr. Build. Mater. 2019, 229, 116864. [Google Scholar] [CrossRef]

- Li, X.B.; Zhang, Q. Dehydration behaviour and impurity change of phosphogypsum during calcination. Constr. Build. Mater. 2021, 311, 125328. [Google Scholar] [CrossRef]

- Moreira, R.H.; Queiroga, F.S.; Paiva, H.A.; Medina, N.H.; Fontana, G.; Guazzelli, M.A. Extraction of natural radionuclides in TENORM waste phosphogypsum. J. Environ. Chem. Eng. 2018, 6, 6664–6668. [Google Scholar] [CrossRef]

- Rashad, A.M. Phosphogypsum as a construction material. J. Clean. Prod. 2017, 166, 732–743. [Google Scholar] [CrossRef]

- Xiang, J.C.; Qiu, J.P.; Zheng, P.K.; Sun, X.G.; Zhao, Y.L.; Gu, X.W. Usage of biowashing to remove impurities and heavy metals in raw phosphogypsum and calcined phosphogypsum for cement paste preparation. Chem. Eng. J. 2023, 451, 138594. [Google Scholar] [CrossRef]

- Wu, F.H.; Ren, Y.C.; Qu, G.F.; Liu, S.; Chen, B.J.; Liu, X.X.; Zhao, C.Y.; Li, J.Y. Utilization path of bulk industrial solid waste: A review on the multi-directional resource utilization path of phosphogypsum. J. Environ. Manag. 2022, 313, 114957. [Google Scholar] [CrossRef]

- Nizevičienė, D.; Vaičiukynienė, D.; Michalik, B.; Bonczyk, M.; Vaitkevičius, V.; Jusas., V. The treatment of phosphogypsum with zeolite to use it in binding material. Constr. Build. Mater. 2018, 180, 134–142. [Google Scholar] [CrossRef]

- Bouchair, A. Steady state theoretical model of fired clay hollow bricks for enhanced external wall thermal insulation. Build. Environ. 2008, 43, 1603–1618. [Google Scholar] [CrossRef]

- Sheng, D.D.C.V.; Ramegowda, N.S.; Guna, V.; Reddy, N. Groundnut shell and coir reinforced hybrid bio composites as alternative to gypsum ceiling tiles. J. Build. Eng. 2022, 57, 104892. [Google Scholar] [CrossRef]

- Bebana, M.V.; Ziat, K.; Semlal, N.; Saidi, M. Modeling compressive strength of Moroccan fly ash-phosphogypsum geopolymer bricks. SN Appl. Sci. 2019, 12, 1666. [Google Scholar] [CrossRef]

- Li, X.Q.; Yu, T.Y.; Park, S.J.; Kim, Y.H. Reinforcing effects of gypsum composite with basalt fiber and diatomite for improvement of high-temperature endurance. Constr. Build. Mater. 2022, 325, 126762. [Google Scholar] [CrossRef]

- Jia, R.Q.; Wang, Q.; Feng, P. A comprehensive overview of fiber-reinforced gypsum-based composites (FRGCs) in the construction field. Compos. Part B Eng. 2021, 205, 108540. [Google Scholar] [CrossRef]

- Hua, S.D.; Wang, K.J.; Yao, X.; Xu, W.; He, Y.X. Effects of fibers on mechanical properties and freeze-thaw resistance of phosphogypsum-slag based cementitious materials. Constr. Build. Mater. 2016, 121, 290–299. [Google Scholar] [CrossRef]

- Gonçalves, R.M.; Martinho, A.; Oliveira, J.P. Evaluating the potential use of recycled glass fibers for the development of gypsum-based composites. Constr. Build. Mater. 2022, 321, 126320. [Google Scholar] [CrossRef]

- Shanmugam, L.; Feng, X.; Yang, J. Enhanced interphase between thermoplastic matrix and UHMWPE fiber sized with CNT-modified polydopamine coating. Compos. Sci. Technol. 2019, 174, 212–220. [Google Scholar] [CrossRef]

- Li, M.; Cheng, K.; Wang, C.; Lu, S. Functionalize aramid fibers with polydopamine to possess UV resistance. J. Inorg. Organomet. Polym. Mater. 2021, 31, 2791–2805. [Google Scholar] [CrossRef]

- Dreyer, D.R.; Miller, D.J.; Freeman, B.D.; Paul, D.R.; Bielawski, C.W. Elucidating the structure of poly(dopamine). Langmuir 2012, 28, 6428–6435. [Google Scholar] [CrossRef] [PubMed]

- GB/T, 3; Gypsum Plasters–Determination of Mechanical Properties. China Standard Press: Beijing, China, 1999.

- Yang, X.; Duan, L.; Ran, X. Effect of polydopamine coating on improving photostability of polyphenylene sulfide fiber. Polym. Bull. 2017, 74, 641–656. [Google Scholar] [CrossRef]

- Huang, F.; Zhang, J.; Zheng, X.Y.; Wu, Y.C.; Fu, T.F.; Easa, S.; Liu, W.D.; Qiu, R.F. Preparation and performance of autoclaved aerated concrete reinforced by dopamine-modified polyethylene terephthalate waste fiber. Constr. Build. Mater. 2022, 348, 128649. [Google Scholar] [CrossRef]

- Yu, F.; Chen, S.; Chen, Y.; Li, H.; Yang, L.; Chen, Y.; Yin, Y. Experimental and theoretical analysis of polymerization reaction process on the polydopamine membranes and its corrosion protection properties for 304 stainless steel. J. Mol. Struct. 2010, 982, 152–161. [Google Scholar] [CrossRef]

- Prakasham, R.S.; Devi, G.S.; Laxmi, K.R.; Rao, C.S. Novel synthesis of ferric impregnated silica nanoparticles and their evaluation as a matrix for enzyme immobilization. J. Phys. Chem. C 2007, 111, 3842–3847. [Google Scholar] [CrossRef]

- Choi, S.Y.; Chaudhari, S.; Shin, H.T.; Cho, K.Y.; Lee, D.; Shon, M.Y.; Nam, S.E.; Park, Y. Polydopamine-modified halloysite nanotube-incorporated polyvinyl alcohol membrane for pervaporation of water-isopropanol mixture. J. Ind. Eng. Chem. 2022, 105, 158–170. [Google Scholar] [CrossRef]

- Liu, T.; Wei, H.; Zhou, A.; Zou, D.; Jian, H. Multiscale investigation on tensile properties of ultra-high performance concrete with silane coupling agent modified steel fibers. Cem. Concr. Compos. 2020, 111, 103638. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, J.; Yang, X.; Dong, Y.; Feng, T.; Liu, J. Enhancing the PVA fiber matrix interface properties in ultra high performance concrete: An experimental and molecular dynamics study. Constr. Build. Mater. 2021, 285, 122862. [Google Scholar] [CrossRef]

- Suárez, F.; FelipeSesé, L.; Díaz, F.A.; Gálvez, J.C.; Alberti, M.G. On the fracture behaviour of fiber-reinforced gypsum using micro and macro polymer fibers. Constr. Build. Mater. 2020, 244, 118347. [Google Scholar] [CrossRef]

- Xie, L.; Zhou, Y.S.; Xiao, S.H.; Miao, X.; Murzataev, A.; Kong, D.; Wang, L.L. Research on basalt fiber reinforced phosphogypsum-based composites based on single factor test and RSM test. Constr. Build. Mater. 2022, 316, 126084. [Google Scholar] [CrossRef]

| SO3 | CaO | SiO2 | Al2O3 | SrO | MgO | Fe2O3 | P2O5 | K2O | CuO | ZrO2 |

|---|---|---|---|---|---|---|---|---|---|---|

| 54.02 | 38.99 | 2.82 | 0.21 | 0.09 | 0.07 | 0.36 | 1.16 | 0.05 | 68ppm | 73ppm |

| Sample | Water/Plaster Ratio | PBG (g) | WF(g) | Retarder (g) | Superplasticizer (g) |

|---|---|---|---|---|---|

| NWF | 0.65 | 1000 | 0 | 0.2 | 9 |

| UWF or MWF or NGF | 0.65 | 1000 | 5 | 0.2 | 9 |

| UWF or MWF or NGF | 0.65 | 1000 | 15 | 0.2 | 9 |

| UWF or MWF or NGF | 0.65 | 1000 | 20 | 0.2 | 9 |

| UWF or MWF or NGF | 0.65 | 1000 | 25 | 0.2 | 9 |

| Sample | Median Pore Diameter (μm) | Cumulative Pore Volume (mL/g) | Porosity (%) |

|---|---|---|---|

| PBGC-NWF | 1.82 | 0.601 | 58.87 |

| PBGC-UWF | 1.65 | 0.533 | 54.58 |

| PBGC-MWF1 | 1.80 | 0.527 | 51.81 |

| PBGC-MWF2 | 2.81 | 0.502 | 50.20 |

| PBGC-MWF3 | 3.24 | 0.502 | 51.38 |

| PBGC-MWF4 | 2.27 | 0.459 | 49.92 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Zhao, W.; Wang, D.; Liu, Y.; Wang, D.; Cui, N. Surface-Treated Recycling Fibers from Wind Turbine Blades as Reinforcement for Waste Phosphogypsum. Molecules 2022, 27, 8668. https://doi.org/10.3390/molecules27248668

Yang L, Zhao W, Wang D, Liu Y, Wang D, Cui N. Surface-Treated Recycling Fibers from Wind Turbine Blades as Reinforcement for Waste Phosphogypsum. Molecules. 2022; 27(24):8668. https://doi.org/10.3390/molecules27248668

Chicago/Turabian StyleYang, Lilin, Weilin Zhao, Daobei Wang, Yang Liu, Dongzhi Wang, and Na Cui. 2022. "Surface-Treated Recycling Fibers from Wind Turbine Blades as Reinforcement for Waste Phosphogypsum" Molecules 27, no. 24: 8668. https://doi.org/10.3390/molecules27248668

APA StyleYang, L., Zhao, W., Wang, D., Liu, Y., Wang, D., & Cui, N. (2022). Surface-Treated Recycling Fibers from Wind Turbine Blades as Reinforcement for Waste Phosphogypsum. Molecules, 27(24), 8668. https://doi.org/10.3390/molecules27248668