Adding Mealworm (Tenebrio molitor L.) Powder to Wheat Bread: Effects on Physicochemical, Sensory and Microbiological Qualities of the End-Product

Abstract

:1. Introduction

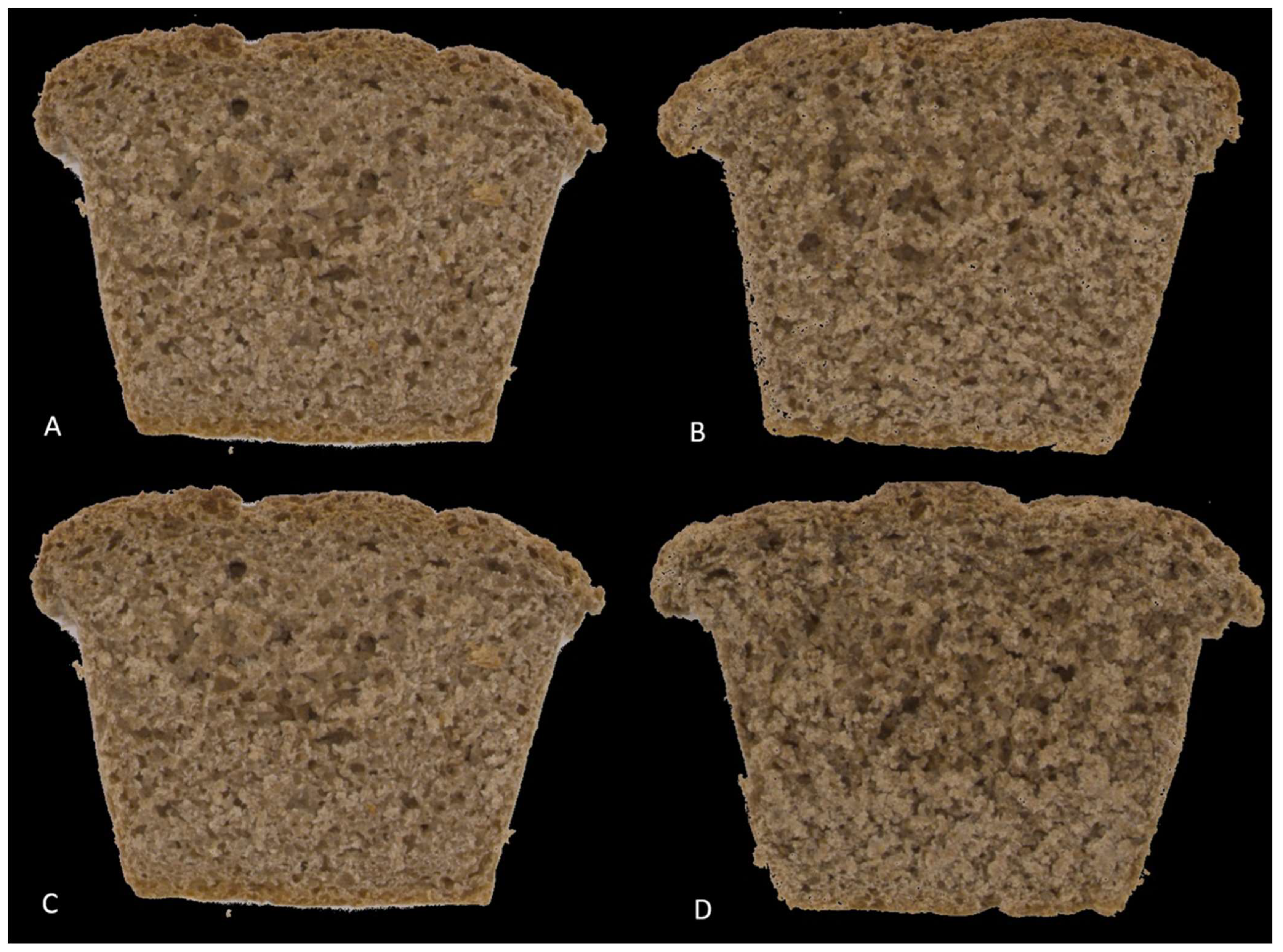

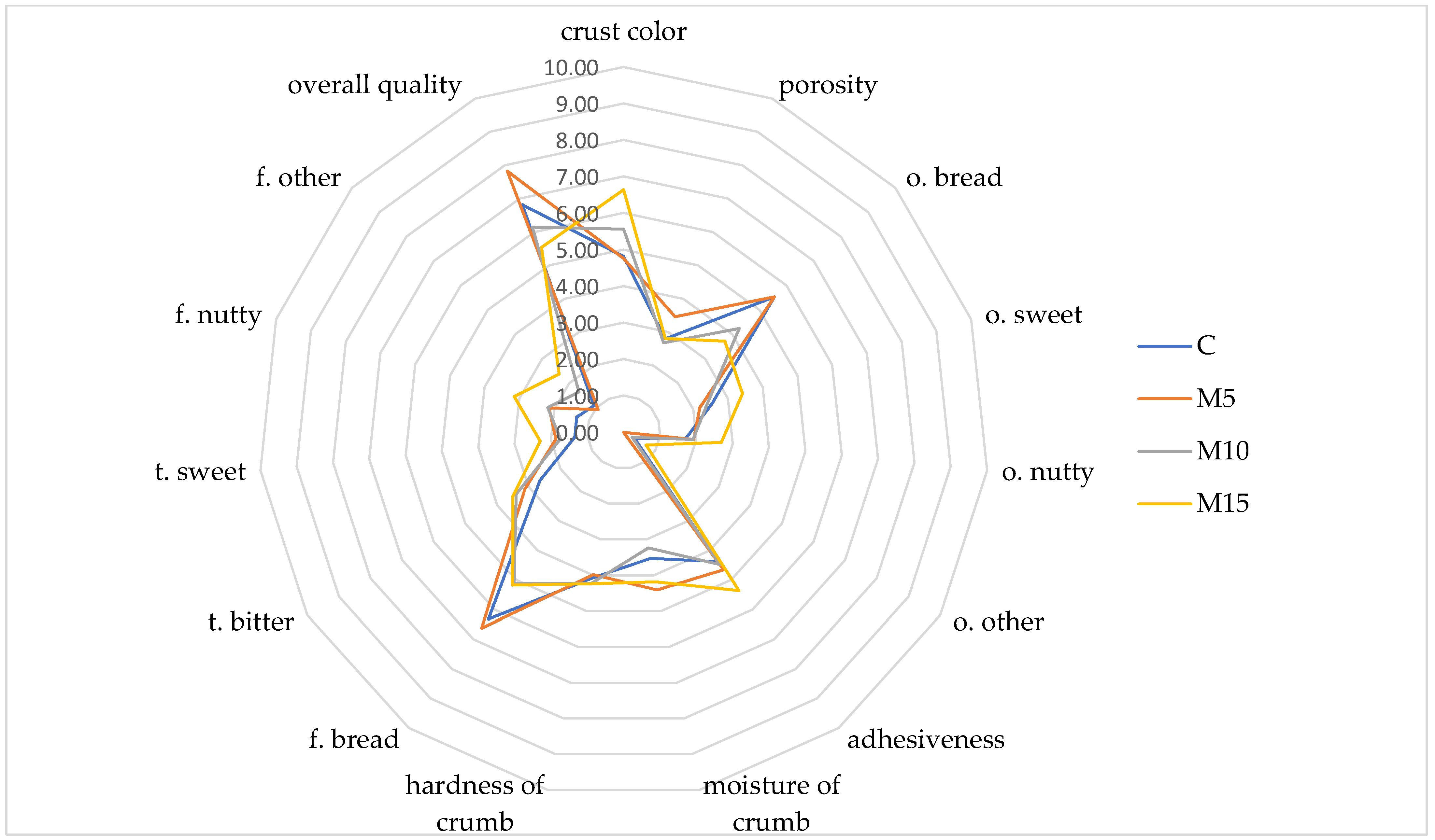

2. Results and Discussion

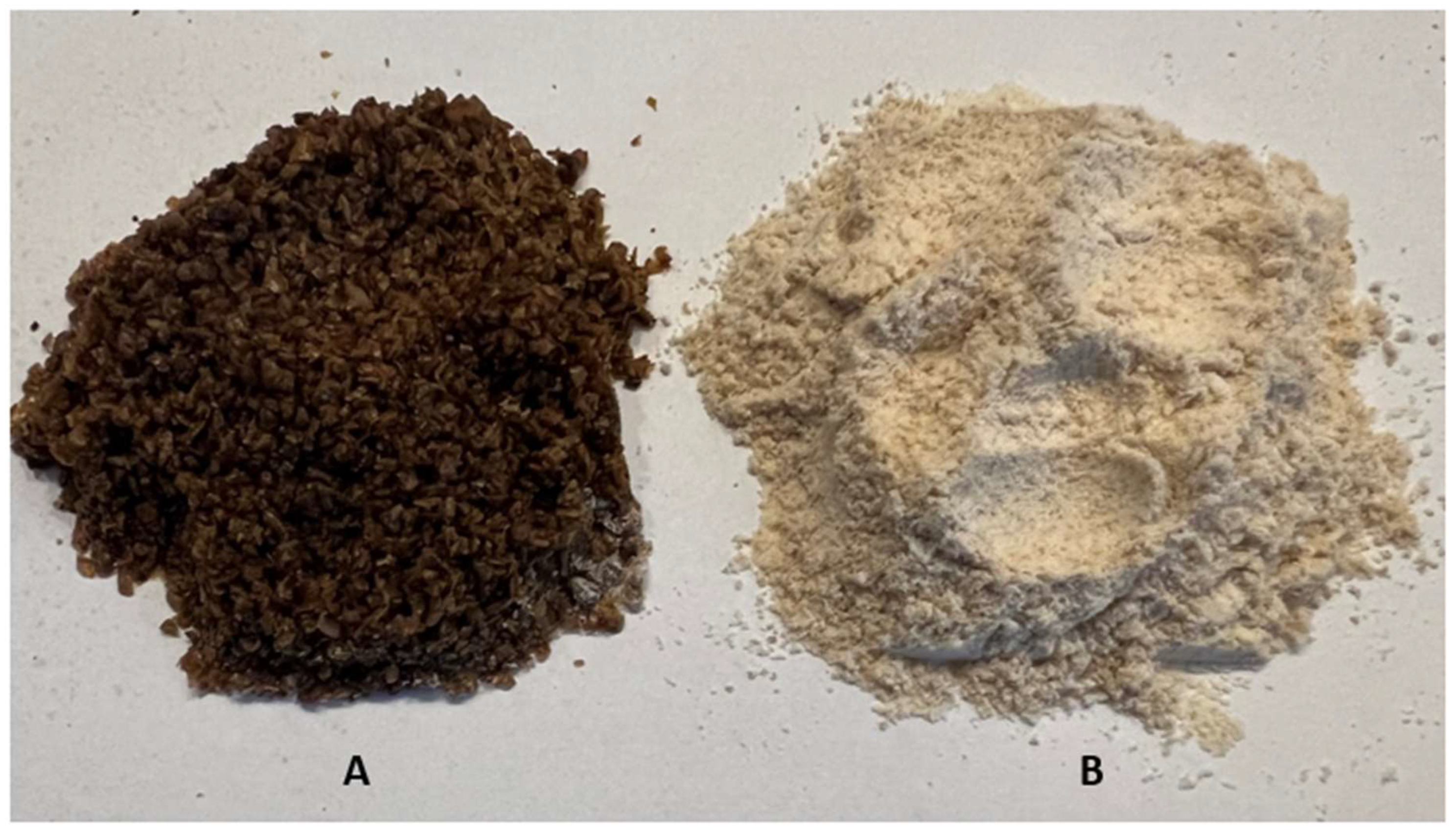

2.1. Physicochemical Properties of Mealworm Powder and Wheat Flour

2.2. Designing of the Mealworm Bread

2.3. Assessment of Quality Parameters of Designed Mealworm Bread

2.4. Microbiological Analysis

3. Materials and Methods

3.1. Nutritional Value, Physicochemical Properties of Wheat Flour and Mealworm Powder

3.2. Bread Preparation

3.3. Color, Density and Hardness Measurement

3.4. Proximate Composition

3.5. Microbiological Analysis

3.6. Sensory Analysis

3.7. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Halloran, A.; Vantomme, P. The Contribution of Insects to FoodSecurity, Livelihoods and the Environment. 2013. Available online: www.fao.org/forestry/edibleinsects/en/ (accessed on 17 June 2022).

- European Union Regulations (EU) 2021/882 Authorizing the Placing on the Market of Dried Tenebrio molitor Larva as a Novel Food. Available online: (https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32021R0882) (accessed on 17 June 2022).

- Herrero, M.; Havlík, P.; Valin, H.; Notenbaert, A.; Rufino, M.C.; Thornton, P.K.; Blümmel, M.; Weiss, F.; Grace, D.; Obersteiner, M. Biomass use, production, feed efficiencies, and greenhouse gas emissions from global livestock systems. Proc. Natl. Acad. Sci. USA 2013, 110, 20888–20893. [Google Scholar] [CrossRef] [PubMed]

- Dreyer, M.; Hörtenhuber, S.; Zollitsch, W.; Jäger, H.; Schaden, L.M.; Gronauer, A.; Kral, I. Environmental life cycle assessment of yellow mealworm (Tenebrio molitor) production for human consumption in Austria—A comparison of mealworm and broiler as protein source. Int. J. Life Cycle Assess. 2021, 26, 2232–2247. [Google Scholar] [CrossRef]

- Orkusz, A. Edible Insects versus Meat—Nutritional Comparison: Knowledge of Their Composition Is the Key to Good Health. Nutrients 2021, 13, 1207. [Google Scholar] [CrossRef]

- Zielińska, E.; Baraniak, B.; Karaś, M.; Rybczyńska, K.; Jakubczyk, A. Selected species of edible insects as a source of nutrient composition. Food Res. Int. 2015, 77, 460–466. [Google Scholar] [CrossRef]

- Akhtar, Y.; Isman, M.B. Insects as an Alternative Protein Source. In Proteins in Food Processing; Yada, R.Y., Ed.; Woodhead Publishing: Sawston, UK, 2018; pp. 263–288. [Google Scholar]

- Chen, X.; Feng, Y.; Zhang, H.; Chen, Z. Review of the nutritive value of edible insects. In Forest Insects as Food: Humans Bite Back. Proceeding of the A Workshop on Asia-Pacific Resources and Their Potential for Development, Chiang Mai, Thailand, 19–21 February 2008; Durst, P.B., Ed.; FAO: Bangkok, Thailand, 2010; pp. 85–92. [Google Scholar]

- Finke, M.D. Nutrient Composition of Bee Brood and its Potential as Human Food. Ecol. Food Nutr. 2007, 44, 257–270. [Google Scholar] [CrossRef]

- Mlcek, J.; Rop, O.; Borkovcova, M.; Bednarova, M. A Comprehensive Look at the Possibilities of Edible Insects as Food in Europe—A Review. Polish J. Food Nutr. Sci. 2014, 64, 147–157. [Google Scholar] [CrossRef]

- Bußler, S.; Rumpold, B.A.; Jander, E.; Rawel, H.M.; Schlüter, O.K. Recovery and techno-functionality of flours and proteins from two edible insect species: Meal worm (Tenebrio molitor) and black soldier fly (Hermetia illucens) larvae. Heliyon 2016, 2, e00218. [Google Scholar] [CrossRef]

- Schösler, H.; de Boer, J.; Boersema, J.J. Can we cut out the meat of the dish? Constructing consumer-oriented pathways towards meat substitution. Appetite 2012, 58, 39–47. [Google Scholar] [CrossRef]

- Hartmann, C.; Siegrist, M. Short Communication. Food Qual. Prefer. 2016, 51, 118–122. [Google Scholar] [CrossRef]

- Tan, H.S.G.; van den Berg, E.; Stieger, M. The influence of product preparation, familiarity and individual traits on the consumer acceptance of insects as food. Food Qual. Prefer. 2016, 52, 222–231. [Google Scholar] [CrossRef]

- Zielińska, E.; Pankiewicz, U.; Kowalczewski, P.L.; Singh, A.P.; Kitts, D. Nutritional, physiochemical, and antioxidative characteristics of shortcake biscuits enriched with Tenebrio molitor flour. Molecules 2020, 25, 5629. [Google Scholar] [CrossRef] [PubMed]

- Cappelli, A.; Oliva, N.; Bonaccorsi, G.; Lorini, C.; Cini, E. Assessment of the rheological properties and bread characteristics obtained by innovative protein sources (Cicer arietinum, Acheta domesticus, Tenebrio molitor): Novel food or potential improvers for wheat flour? LWT 2020, 118, 108867. [Google Scholar] [CrossRef]

- Choi, Y.S.; Kim, T.K.; Choi, H.D.; Park, J.D.; Sung, J.M.; Jeon, K.H.; Paik, H.D.; Kim, Y.B. Optimization of Replacing Pork Meat with Yellow Worm (Tenebrio molitor L.) for Frankfurters. Korean J. food Sci. Anim. Resour. 2017, 37, 617–625. [Google Scholar] [CrossRef]

- Smarzyński, K.; Sarbak, P.; Musiał, S.; Jezowski, P.; Piatek, M.; Kowalczewski, P.T. Nutritional analysis and evaluation of the consumer acceptance of pork pâté enriched with cricket powder-preliminary study. Open Agric. 2019, 4, 159–163. [Google Scholar] [CrossRef]

- Delicato, C.; Schouteten, J.J.; Dewettinck, K.; Gellynck, X.; Tzompa-Sosa, D.A. Consumers’ perception of bakery products with insect fat as partial butter replacement. Food Qual. Prefer. 2020, 79, 103755. [Google Scholar] [CrossRef]

- Vantomme, P.; Halloran, A. The Contribution of Insects to Food Security, Livelihoods and the Environment. FAO. Available online: https://www.fao.org/documents/card/es/c/c499eb3c-58dc-52dc-ac64-5f2ff88dce8f/ (accessed on 17 June 2022).

- Homann, A.M.; Ayieko, M.A.; Konyole, S.O.; Roos, N. Acceptability of biscuits containing 10% cricket (Acheta domesticus) compared to milk biscuits among 5-10-year-old Kenyan schoolchildren. J. Insects Food Feed 2017, 3, 95–103. [Google Scholar] [CrossRef]

- González, C.M.; Garzón, R.; Rosell, C.M. Insects as ingredients for bakery goods. A comparison study of H. illucens, A. domestica and T. molitor flours. Innov. Food Sci. Emerg. Technol. 2019, 51, 205–210. [Google Scholar] [CrossRef]

- Biró, B.; Sipos, M.A.; Kovács, A.; Badak-Kerti, K.; Pásztor-Huszár, K.; Gere, A. Cricket-enriched oat biscuit: Technological analysis and sensory evaluation. Food 2020, 9, 1561. [Google Scholar] [CrossRef]

- García-Segovia, P.; Igual, M.; Noguerol, A.T.; Martínez-Monzó, J. Use of insects and pea powder as alternative protein and mineral sources in extruded snacks. Eur. Food Res. Technol. 2020, 246, 703–712. [Google Scholar] [CrossRef]

- Kim, H.W.; Setyabrata, D.; Lee, Y.J.; Jones, O.G.; Kim, Y.H.B. Pre-treated mealworm larvae and silkworm pupae as a novel protein ingredient in emulsion sausages. Innov. Food Sci. Emerg. Technol. 2016, 38, 116–123. [Google Scholar] [CrossRef]

- Megido, R.C.; Gierts, C.; Blecker, C.; Brostaux, Y.; Haubruge, É.T.; Alabi, T.; Francis, F. Consumer acceptance of insect-based alternative meat products in Western countries. Food Qual. Prefer. 2016, 52, 237–243. [Google Scholar] [CrossRef]

- Roncolini, A.; Milanović, V.; Cardinali, F.; Osimani, A.; Garofalo, C.; Sabbatini, R.; Clementi, F.; Pasquini, M.; Mozzon, M.; Foligni, R.; et al. Protein fortification with mealworm (Tenebrio molitor L.) powder: Effect on textural, microbiological, nutritional and sensory features of bread. PLoS ONE 2019, 14, 0211747. [Google Scholar] [CrossRef] [PubMed]

- da Silva Lucas, A.J.; de Oliveira, L.M.; da Rocha, M.; Prentice, C. Edible insects: An alternative of nutritional, functional and bioactive compounds. Food Chem. 2020, 311, 126022. [Google Scholar] [CrossRef] [PubMed]

- Jonas-Levi, A.; Martinez, J.J.I. The high level of protein content reported in insects for food and feed is overestimated. J. Food Compos. Anal. 2017, 62, 184–188. [Google Scholar] [CrossRef]

- de Oliveira, L.M.; da Silva Lucas, A.J.; Cadaval, C.L.; Mellado, M.S. Bread enriched with flour from cinereous cockroach (Nauphoeta cinerea). Innov. Food Sci. Emerg. Technol. 2017, 44, 30–35. [Google Scholar] [CrossRef]

- Khuenpet, K.; Pakasap, C.; Vatthanakul, S.; Kitthawee, S. Effect of larval-stage mealworm (Tenebrio molitor) powder on qualities of bread. Int. J. Agric. Technol. 2020, 16, 283–296. [Google Scholar]

- Çabuk, B. Influence of grasshopper (Locusta Migratoria) and mealworm (Tenebrio Molitor) powders on the quality characteristics of protein rich muffins: Nutritional, physicochemical, textural and sensory aspects. J. Food Meas. Charact. 2021, 15, 3862–3872. [Google Scholar] [CrossRef]

- Garciá-Segovia, P.; Igual, M.; Martínez-Monzó, J. Physicochemical Properties and Consumer Acceptance of Bread Enriched with Alternative Proteins. Foods 2020, 9, 933. [Google Scholar] [CrossRef]

- Bellary, A.N.; Indiramma, A.R.; Prakash, M.; Baskaran, R.; Rastogi, N.K. Anthocyanin infused watermelon rind and its stability during storage. Innov. Food Sci. Emerg. Technol. 2016, 33, 554–562. [Google Scholar] [CrossRef]

- Kowalski, S.; Mikulec, A.; Mickowska, B.; Skotnicka, M.; Mazurek, A. Wheat bread supplementation with various edible insect flours. Influence of chemical composition on nutritional and technological aspects. LWT 2022, 159, 113220. [Google Scholar] [CrossRef]

- Bukkens, S.G.F. Insects in the human diet: Nutritional aspects. In Ecological Implications of Minilivestock (Role of Rodents, Frogs, Snails, and Insects for Sustainable Development); Paoletti, M.G., Ed.; Science Publiscers Inc.: Enfield, NH, USA, 2005; pp. 545–577. [Google Scholar]

- Ekpo, K.E.; Onigbinde, A.O. Nutritional potentials of the larva of Rhynchophorus phoenicis (F). Pak. J. Nutr. 2005, 4, 287–290. [Google Scholar] [CrossRef]

- Finke, M.D. Complete nutrient composition of commercially raised invertebrates used as food for insectivores. Zoo Biol. 2002, 21, 269–285. [Google Scholar] [CrossRef]

- Rumpold, B.A.; Schlüter, O.K. Nutritional composition and safety aspects of edible insects. Mol. Nutr. Food Res. 2013, 57, 802–823. [Google Scholar] [CrossRef] [PubMed]

- Haber, M.; Mishyna, M.; Martinez, J.J.I.; Benjamin, O. The influence of grasshopper (Schistocerca gregaria) powder enrichment on bread nutritional and sensorial properties. LWT-Food Sci. Technol. 2019, 115, 108395. [Google Scholar] [CrossRef]

- Mafu, A.; Ketnawa, S.; Phongthai, S.; Schönlechner, R.; Rawdkuen, S. Whole Wheat Bread Enriched with Cricket Powder as an Alternative Protein. Foods 2022, 11, 2142. [Google Scholar] [CrossRef]

- Curti, E.; Carini, E.; Diantom, A.; Vittadini, E. The use of potato fibre to improve bread physicochemical properties during storage. Food Chem. 2016, 195, 64–70. [Google Scholar] [CrossRef]

- Li, X.; Fei, T.; Wang, Y.; Zhao, Y.; Pan, Y.; Li, D. Wheat Starch with Low Retrogradation Properties Produced by Modification of the GtfB Enzyme 4,6-α-Glucanotransferase from Streptococcus thermophilus. J. Agric. Food Chem. 2018, 66, 3891–3898. [Google Scholar] [CrossRef]

- Fik, M. Czerstwienie pieczywa i sposoby przedłużania jego świeżości. Żywność Nauka Technol. Jakość 2004, 11, 5–22. [Google Scholar]

- Gerez, C.L.; Torino, M.I.; Rollán, G.; Font de Valdez, G. Prevention of bread mould spoilage by using lactic acid bacteria with antifungal properties. Food Control. 2009, 20, 144–148. [Google Scholar] [CrossRef]

- Sahan, Y.A. Effect of Prunus laurocerasus L. (Cherry laurel) leaf extracts on growth of bread spoilage fungi. Bulg. J. Agric. Sci. 2011, 17, 83–92. [Google Scholar]

- Zhang, G.; Tu, J.; Sadiq, F.A.; Zhang, W.; Wang, W. Prevalence, Genetic Diversity, and Technological Functions of the Lactobacillus sanfranciscensis in Sourdough: A Review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1209–1226. [Google Scholar] [CrossRef] [PubMed]

- Quattrini, M.; Liang, N.; Fortina, M.G.; Xiang, S.; Curtis, J.M.; Gänzle, M. Exploiting synergies of sourdough and antifungal organic acids to delay fungal spoilage of bread. Int. J. Food Microbiol. 2019, 302, 8–14. [Google Scholar] [CrossRef]

- Jin, J.; Nguyen, T.T.H.; Humayun, S.; Park, S.H.; Oh, H.; Lim, S.; Mok, I.K.; Li, Y.; Pal, K.; Kim, D. Characteristics of sourdough bread fermented with Pediococcus pentosaceus and Saccharomyces cerevisiae and its bio-preservative effect against Aspergillus flavus. Food Chem. 2021, 345, 128787. [Google Scholar] [CrossRef] [PubMed]

- Rana, J.; Paul, J. Consumer behavior and purchase intention for organic food: A review and research agenda. J. Retail. Consum. Serv. 2017, 38, 157–165. [Google Scholar] [CrossRef]

- Sagar, N.A.; Pareek, S. Fortification of multigrain flour with onion skin powder as a natural preservative: Effect on quality and shelf life of the bread. Food Biosci. 2021, 41, 100992. [Google Scholar] [CrossRef]

- Bernaert, N.; Debonne, E.; De Leyn, I.; Van Droogenbroeck, B.; Van Bockstaele, F. Incorporation of leek powder (Allium ampeloprasum var. porrum) in wheat bread: Technological implications, shelf life and sensory evaluation. LWT 2022, 153, 112517. [Google Scholar] [CrossRef]

- Ravimannan, N.; Sevvel, P.; Saarutharshan, S. Study on fungi associated with spoilage of bread. Int. J. Adv. Res. Biol. Sci. 2016, 3, 165–167. [Google Scholar]

- ISO 4833-1:2013-12/A1:2022-06; Microbiology of the Food Chain. Horizontal Method for the Enumeration of Microorganisms. Part 1: Colony Count at 30 °C by the Pour Plate Technique. Amendment 1: Clarification of Scope (ISO 4833-1:2013/Amd 1:2022). ISO: Geneva, Switzerland, 2013. Available online: https://www.iso.org/standard/53728.html (accessed on 5 February 2022).

- ISO 21527-2:2008; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Yeasts and Moulds—Part 2: Colony Count Technique in Products with Water Activity Less than or Equal to 0.95. ISO: Geneva, Switzerland, 2008. Available online: https://www.iso.org/standard/38275.html (accessed on 5 February 2022).

- EN ISO 4121:2003; Sensory Analysis. Guidelines for the Use of Quantitative Response Scales. ISO: Geneva, Switzerland, 2003.

- EN ISO 8586:2012; Sensory Analysis. General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. ISO: Geneva, Switzerland, 2012.

- EN ISO 8589:2010; Sensory Analysis. General Guidance for the Design of Test Rooms. ISO: Geneva, Switzerland, 2010.

| Physicochemical Properties | Mealworm Powder | Wheat Flour |

|---|---|---|

| pH | 6.95 ± 0.02 b | 6.78 ± 0.13 a |

| Fat absorption capacity [g oil/g powder] | 0.40 ± 0.20 a | 0.26 ± 0.05 a |

| Water holding capacity [g water/g powder] | 1.63 ± 0.57 a | 1.47 ± 0.14 a |

| aw | 0.33 ± 0.00 a | 0.44 ± 0.00 b |

| L* | 32.65 ± 1.02 a | 80.48 ± 1.34 b |

| a* | 5.84 ± 0.04 b | 4.73 ± 0.48 a |

| b* | 25.31 ± 0.21 b | 21.54 ± 0.98 a |

| Ingredients [%] | ||||||

|---|---|---|---|---|---|---|

| Samples | Wheat Flour | Mealworm Powder | Freeze-Dried Yeasts | Sugar | Salt | Water |

| C | 58.7 | 0.0 | 0.8 | 0.7 | 0.7 | 39.2 |

| M5 | 55.8 | 2.0 | ||||

| M10 | 52.9 | 5.9 | ||||

| M15 | 49.9 | 8.9 | ||||

| C | M5 | M10 | M15 | |

|---|---|---|---|---|

| L* | 44.87 ± 1.03 d | 43.10 ± 0.85 c | 41.11 ± 1.45 b | 40.07 ± 0.43 a |

| a* | 6.23 ± 0.43 b | 6.12 ± 0.12 ab | 6.21 ± 0.11 b | 6.00 ± 0.26 a |

| b* | 27.93 ± 0.59 c | 27.89 ± 0.39 c | 27.30 ± 0.18 b | 26.92 ± 0.59 a |

| ΔE | - | 2.27 ± 0.12 | 4.00 ± 0.56 | 4.50 ± 0.78 |

| BI | 13.90 ± 0.14 a | 14.26 ± 0.17 b | 15.04 ± 0.01 c | 14.97 ± 0.33 c |

| Density [g/cm3] | 0.43 ± 0.02 a | 0.39 ± 0.01 a | 0.36 ± 0.00 a | 0.36 ± 0.01 a |

| aw | 0.97 ± 0.00 a | 0.96 ± 0.00 a | 0.97 ± 0.00 a | 0.97 ± 0.00 a |

| Hardness [N] | 30.91 ± 1.02 b | 24.94 ± 0.90 b | 28.22 ± 1.56 b | 17.12 ± 0.76 a |

| C | M5 | M10 | M15 | |

|---|---|---|---|---|

| Protein (g) | 11.30 ± 0.12 a | 14.13 ± 0.11 b | 16.95 ± 0.16 c | 19.77 ± 0.04 d |

| Fat (g) | 2.23 ± 0.04 a | 3.07 ± 0.01 b | 3.92 ± 0.02 c | 4.77 ± 0.06 d |

| Carbohydrates (g) | 62.09 ± 0.45 d | 59.10 ± 1.89 c | 56.10 ± 0.49 b | 53.11 ± 1.05 a |

| Fiber (g) | 7.47 ± 0.87 a | 7.56 ± 0.45 a | 7.65 ± 0.61 a | 7.74 ± 0.82 a |

| Sample | Days | TVC [log CFU g−1] | Y&M [log CFU g−1] |

|---|---|---|---|

| C | 0 | 3.51 ± 0.30 a | nd |

| 2 | 7.18 ± 0.07 c | 3.58 ± 0.04 a | |

| 7 | 8.44 ± 0.29 e | 4.28 ± 0.03 d | |

| M5 | 0 | 4.17 ± 0.08 b | nd |

| 2 | 6.46 ± 0.44 d | 3.34 ± 0.06 b | |

| 7 | 8.38 ± 0.27 e | 4.24 ± 0.05 d | |

| M10 | 0 | 4.21 ± 0.19 b | nd |

| 2 | 6.46 ± 0.45 d | nd | |

| 7 | 9.17 ± 0.13 f | 4.38 ± 0.11 d | |

| M15 | 0 | 4.22 ± 0.13 b | nd |

| 2 | 7.16 ± 0.10 c | 3.35 ± 0.04 b | |

| 7 | 8.58 ± 0.30 e | 4.21 ± 0.02 d |

| Mealworm Powder | Wheat Flour | |

|---|---|---|

| Fat (g) | 21.5 | 2.30 |

| Protein (g) | 61.0 | 11.0 |

| Carbohydrates (g) | 3.4 | 63.0 |

| Fiber (g) | 6.9 | 7.60 |

| Energetic value (kcal) | 478 | 332 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gantner, M.; Król, K.; Piotrowska, A.; Sionek, B.; Sadowska, A.; Kulik, K.; Wiącek, M. Adding Mealworm (Tenebrio molitor L.) Powder to Wheat Bread: Effects on Physicochemical, Sensory and Microbiological Qualities of the End-Product. Molecules 2022, 27, 6155. https://doi.org/10.3390/molecules27196155

Gantner M, Król K, Piotrowska A, Sionek B, Sadowska A, Kulik K, Wiącek M. Adding Mealworm (Tenebrio molitor L.) Powder to Wheat Bread: Effects on Physicochemical, Sensory and Microbiological Qualities of the End-Product. Molecules. 2022; 27(19):6155. https://doi.org/10.3390/molecules27196155

Chicago/Turabian StyleGantner, Magdalena, Katarzyna Król, Anna Piotrowska, Barbara Sionek, Anna Sadowska, Klaudia Kulik, and Mateusz Wiącek. 2022. "Adding Mealworm (Tenebrio molitor L.) Powder to Wheat Bread: Effects on Physicochemical, Sensory and Microbiological Qualities of the End-Product" Molecules 27, no. 19: 6155. https://doi.org/10.3390/molecules27196155

APA StyleGantner, M., Król, K., Piotrowska, A., Sionek, B., Sadowska, A., Kulik, K., & Wiącek, M. (2022). Adding Mealworm (Tenebrio molitor L.) Powder to Wheat Bread: Effects on Physicochemical, Sensory and Microbiological Qualities of the End-Product. Molecules, 27(19), 6155. https://doi.org/10.3390/molecules27196155