Innovative Freeze-Dried Snacks with Sodium Alginate and Fruit Pomace (Only Apple or Only Chokeberry) Obtained within the Framework of Sustainable Production

Abstract

:1. Introduction

2. Results and Discussion

2.1. The Dry Matter Content and Water Activity of Freeze-Dried Bars with Fruit Pomace

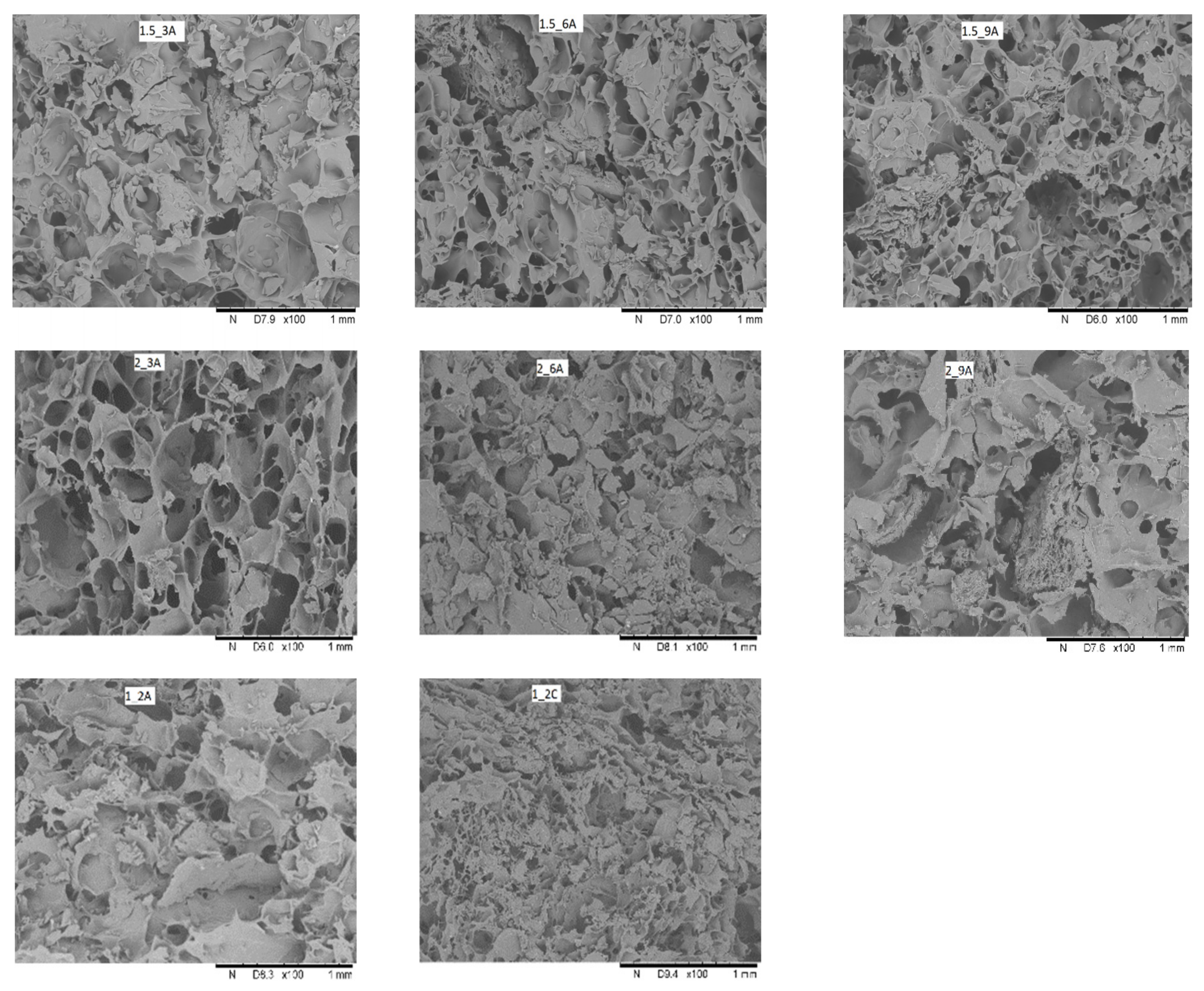

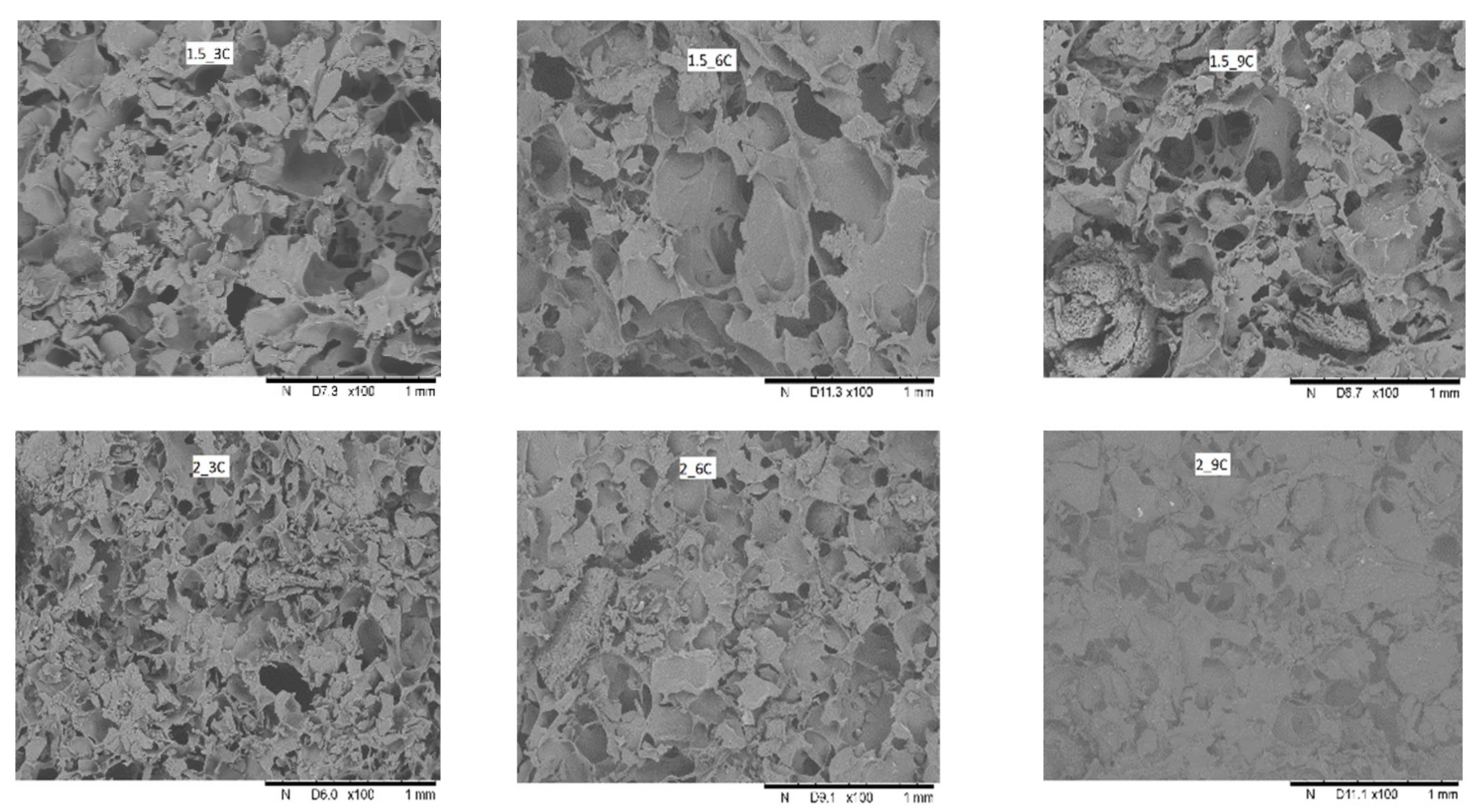

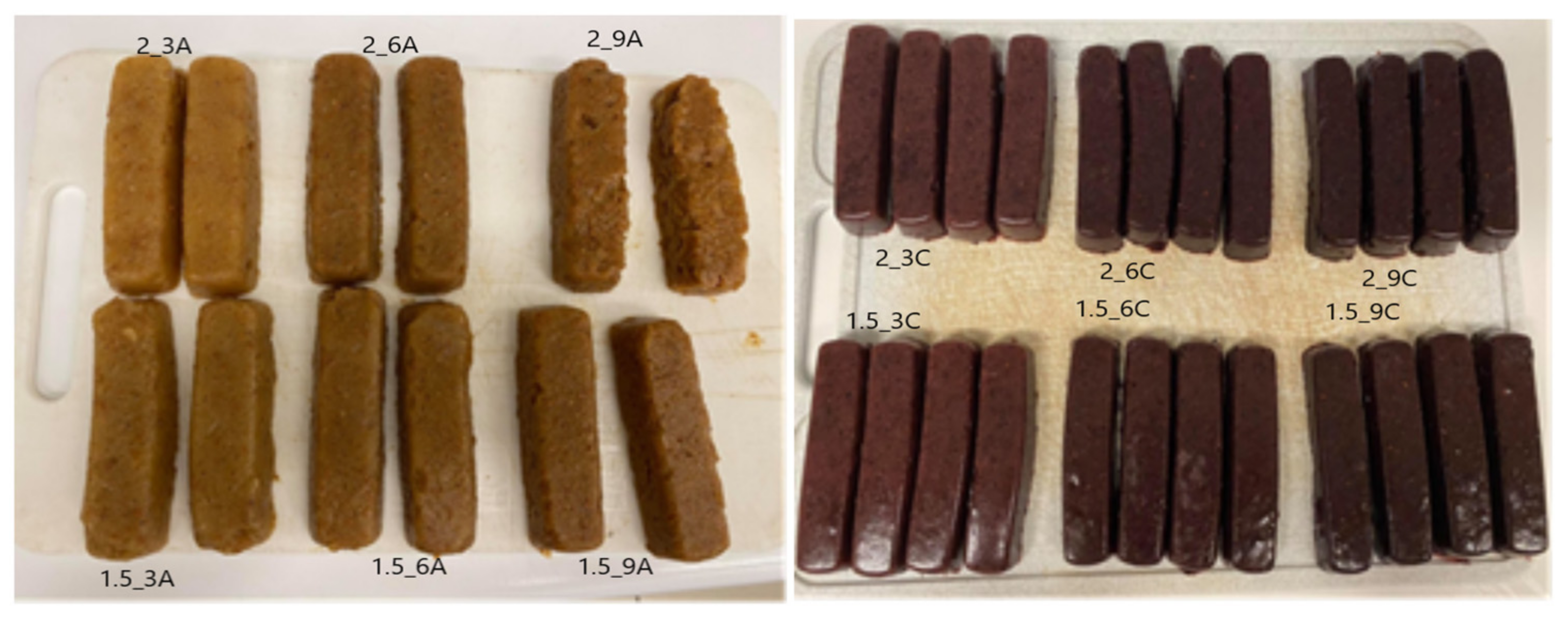

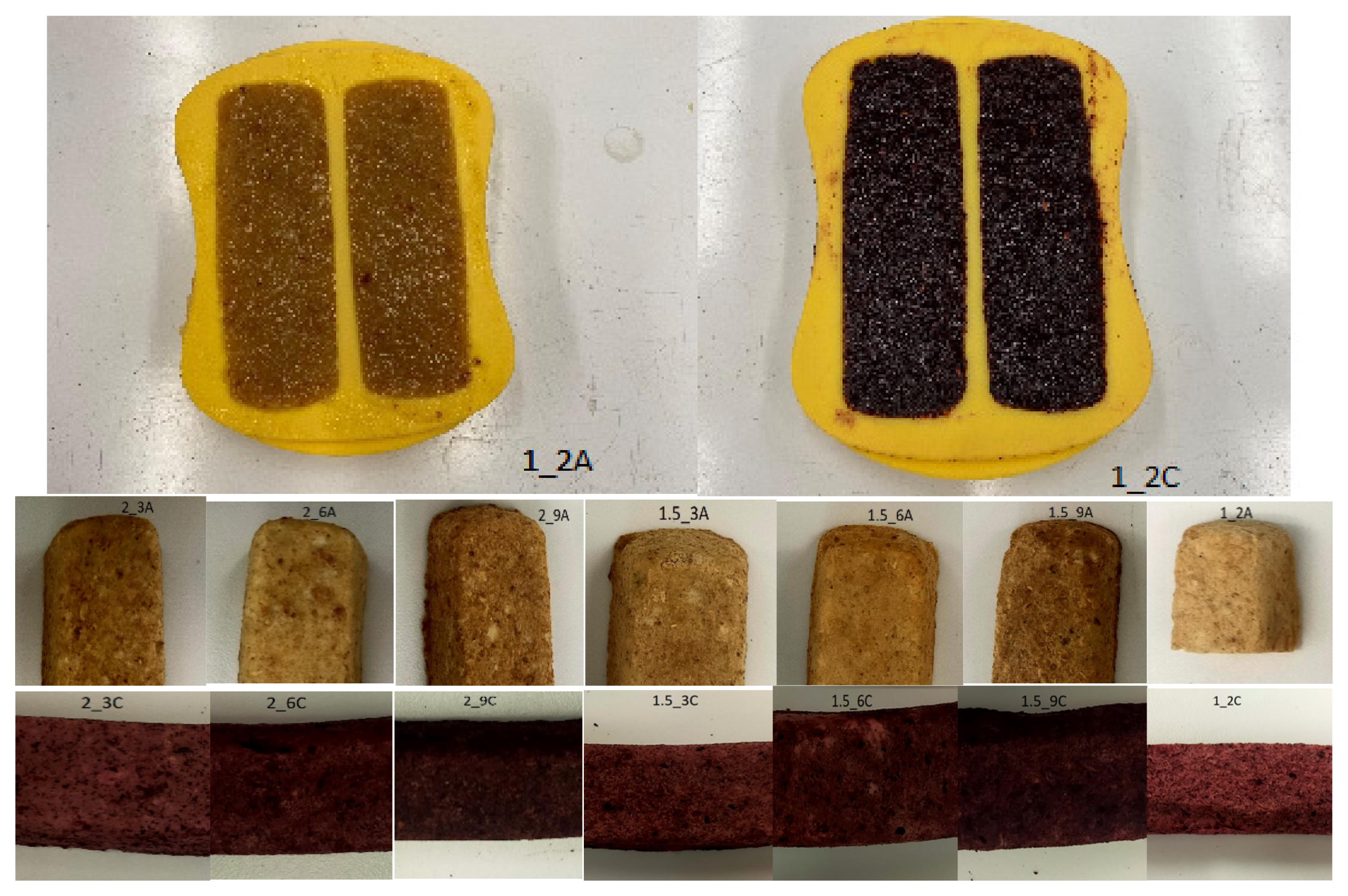

2.2. The Structure of Freeze-Dried Bars with Fruit Pomace

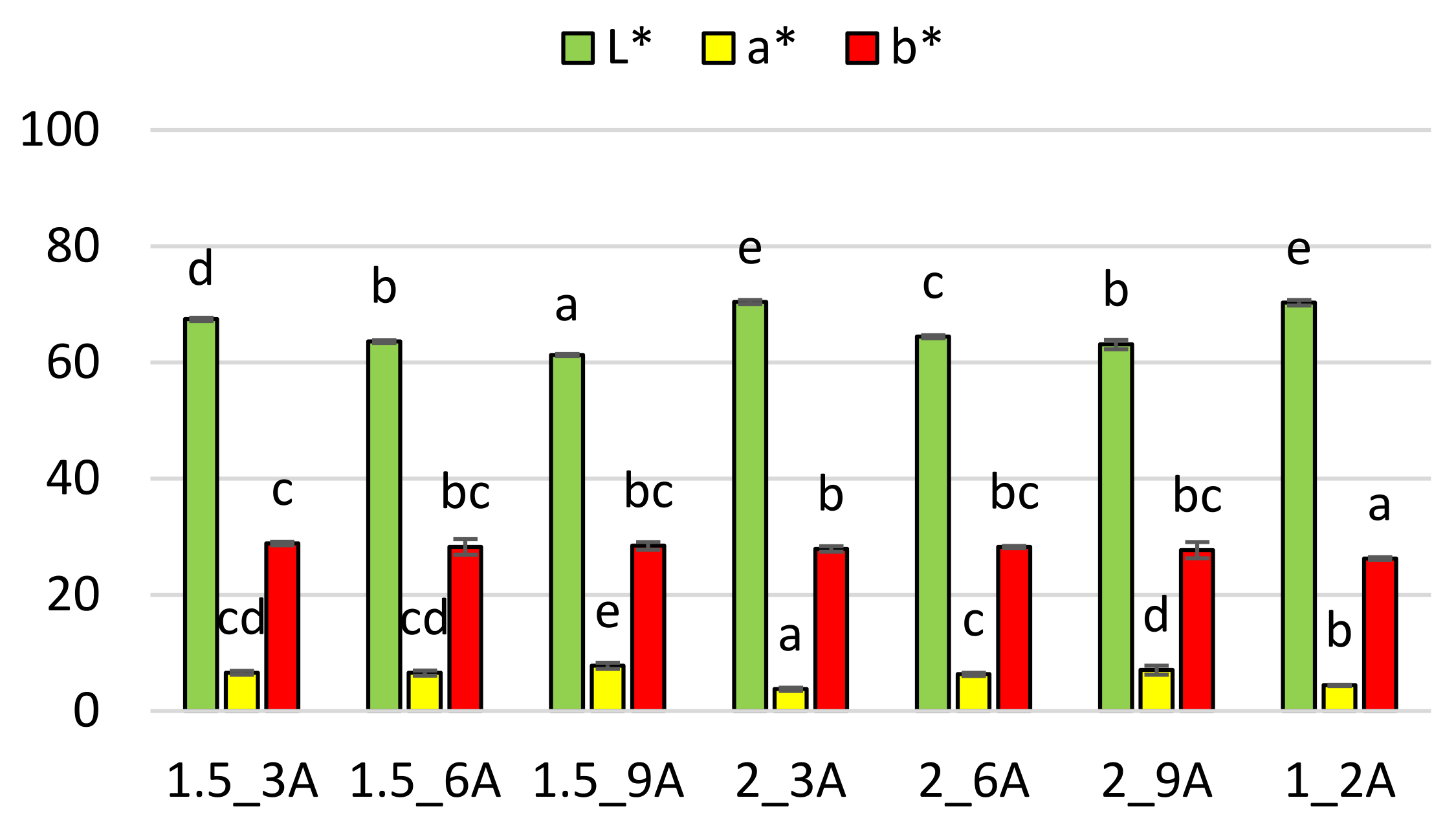

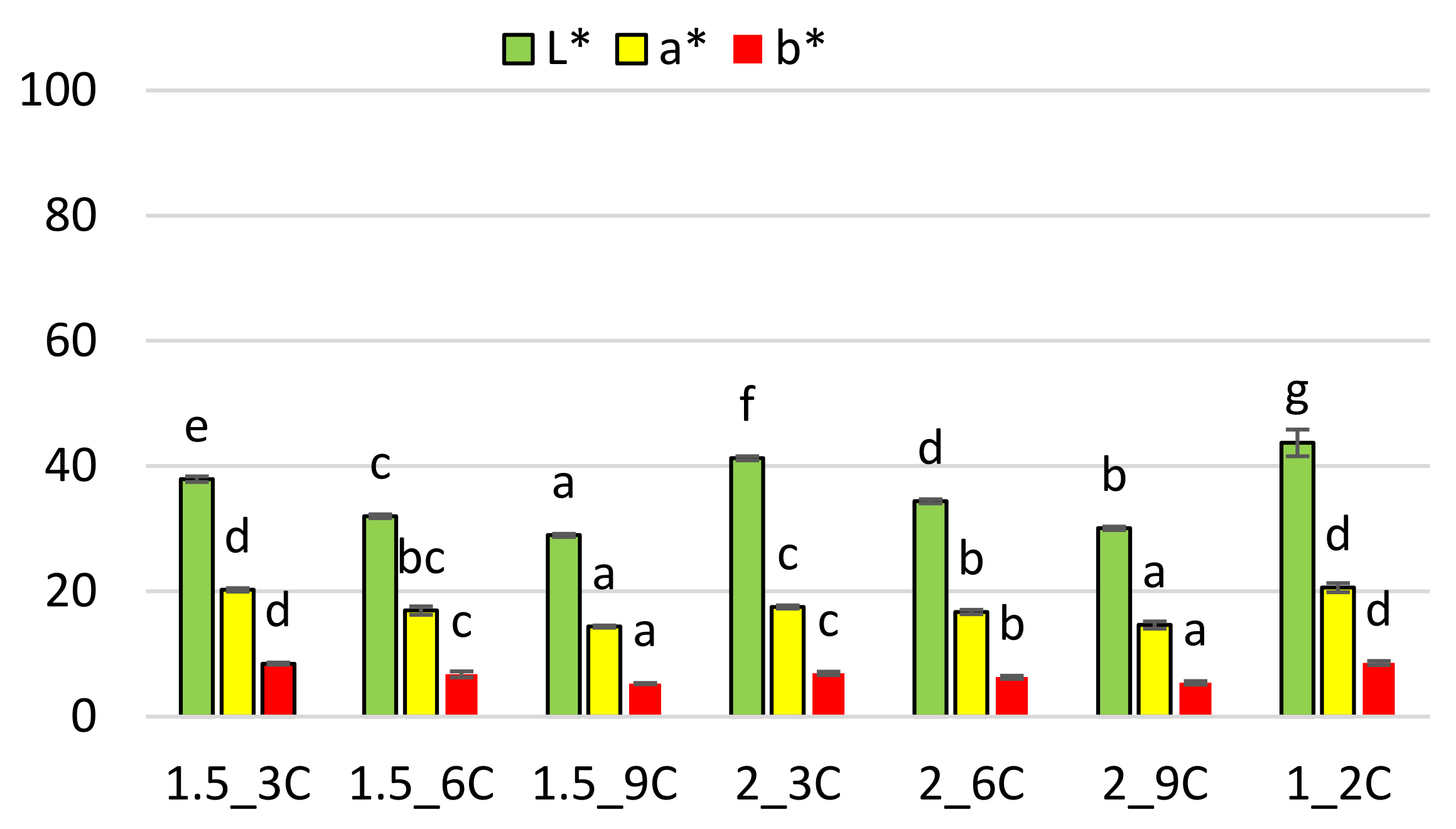

2.3. The Colour of Freeze-Dried Bars with Fruit Pomace

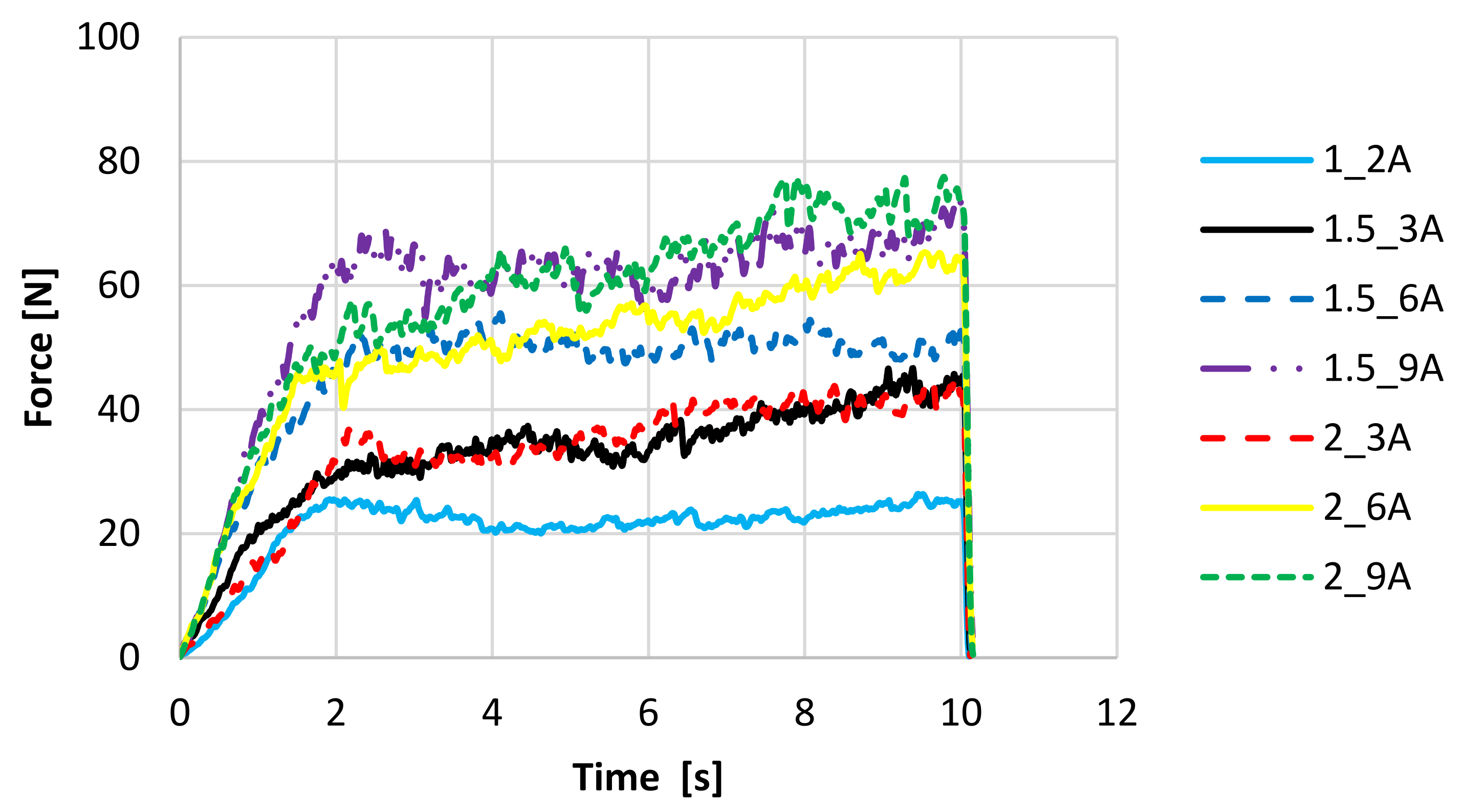

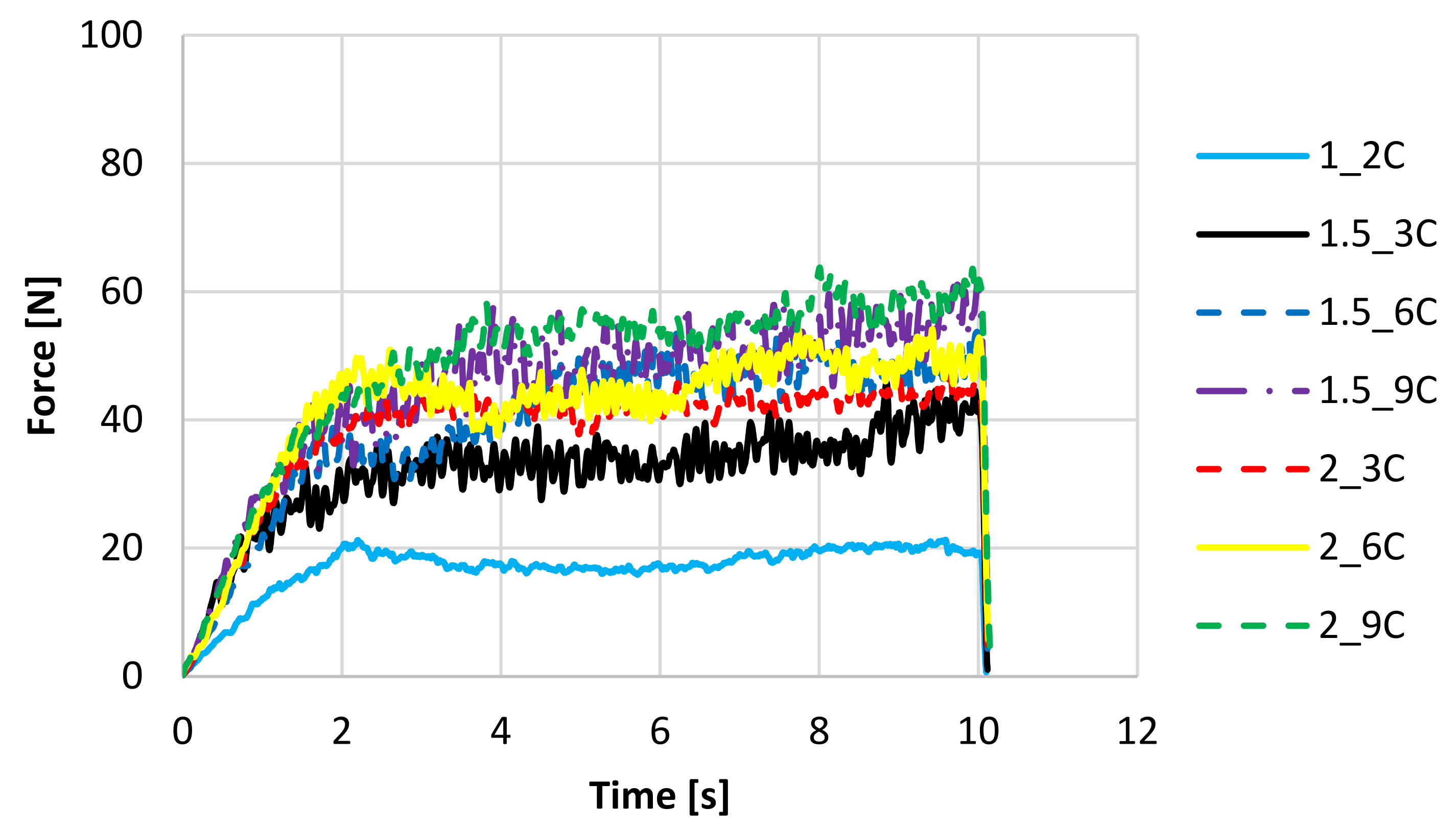

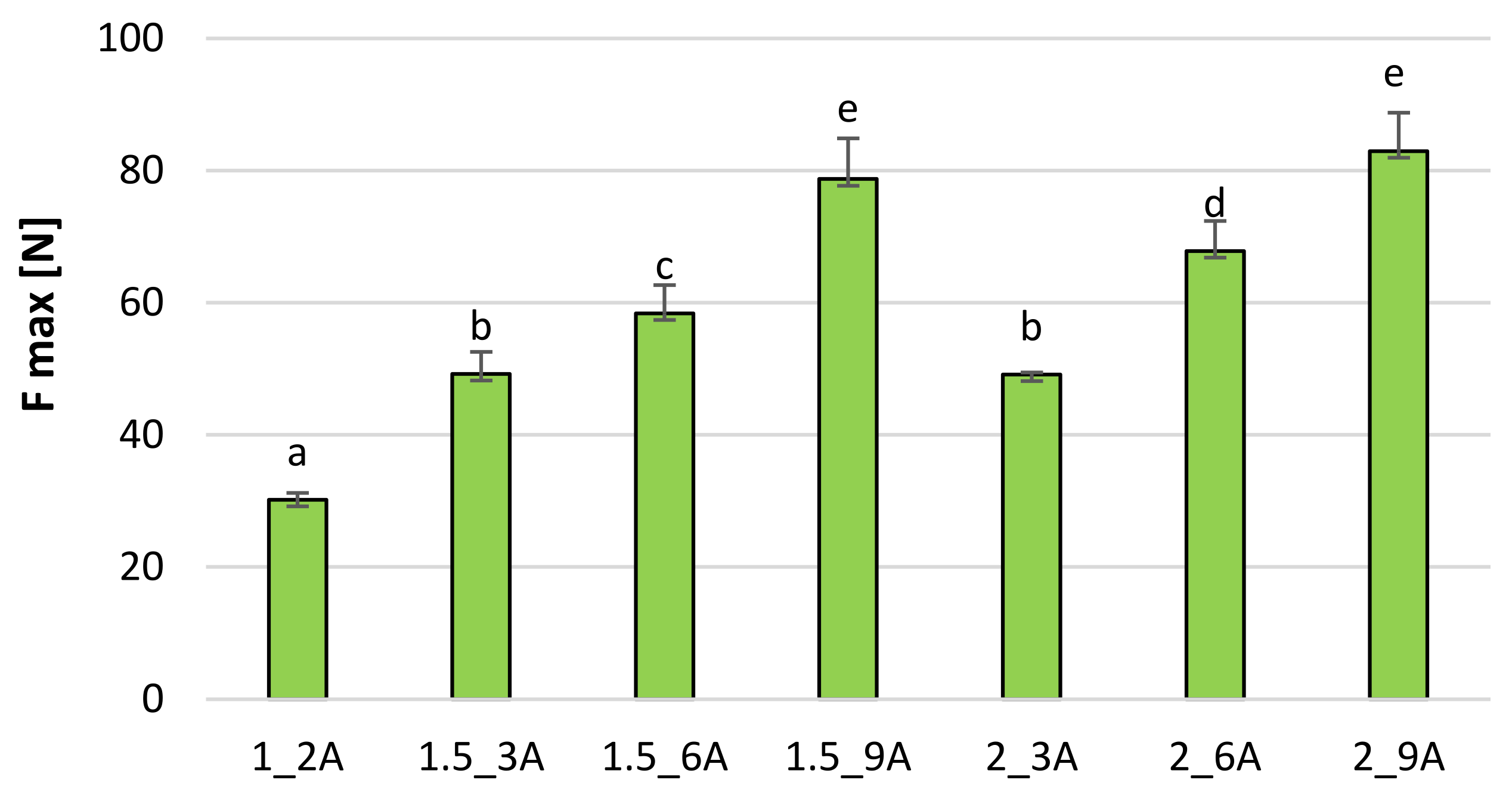

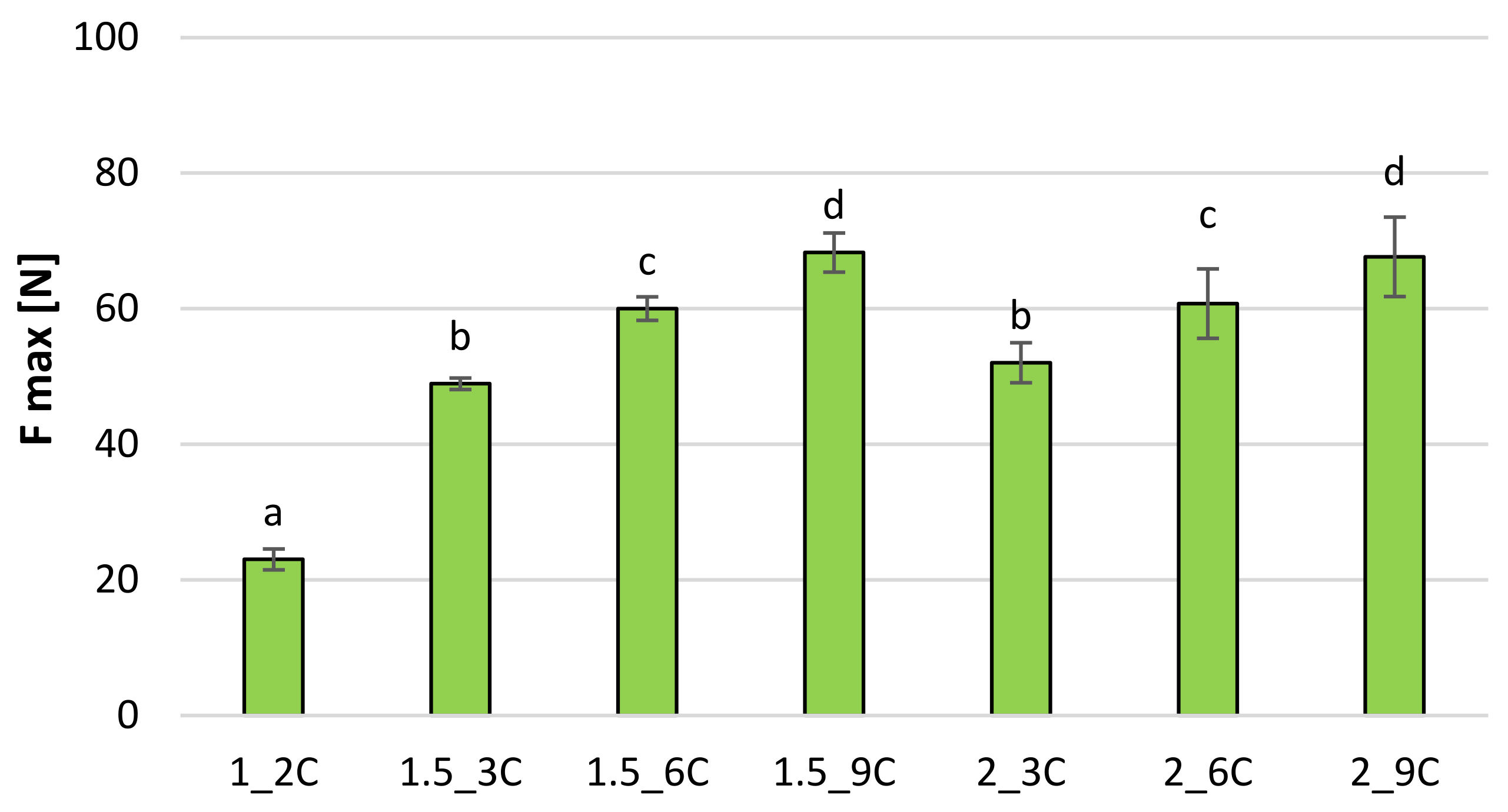

2.4. The Mechanical Properties of Freeze-Dried Bars with Fruit Pomace

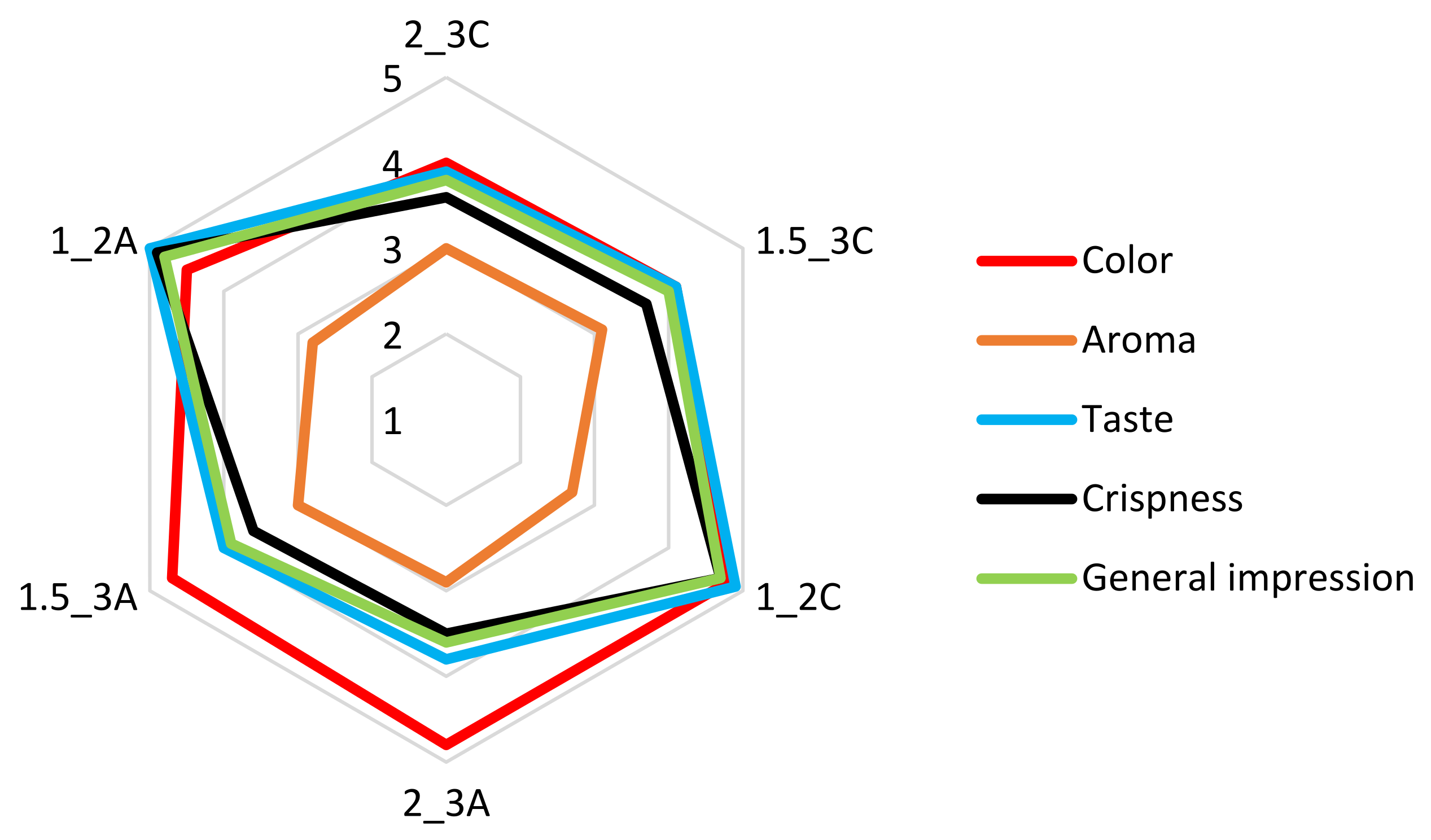

2.5. The Organoleptic Evaluation of Freeze-Dried Bars with Fruit Pomace

3. Materials and Methods

3.1. Material

Characteristics of Ingredients

- Golden Delicious apples from one production batch purchased in November 2020 constituted the basic raw material for obtaining freeze-dried food products. The fruits had been stored at the temperature of about 4 °C until the tests were carried out. Apple pulp served as the basic ingredient of the bars. Some of the apples were used for obtaining apple juice.

- In order to enrich the taste of snacks and to use by-products from fruit and vegetable processing, dried chokeberry or apple pomace were used after having been purchased from Greenherb Company (Wysoka, Poland) in 2021.

- Sodium alginate (Agnex, Białystok, Poland) and calcium lactate (Hortimex, Konin, Poland) were used as binders to initiate gelation.

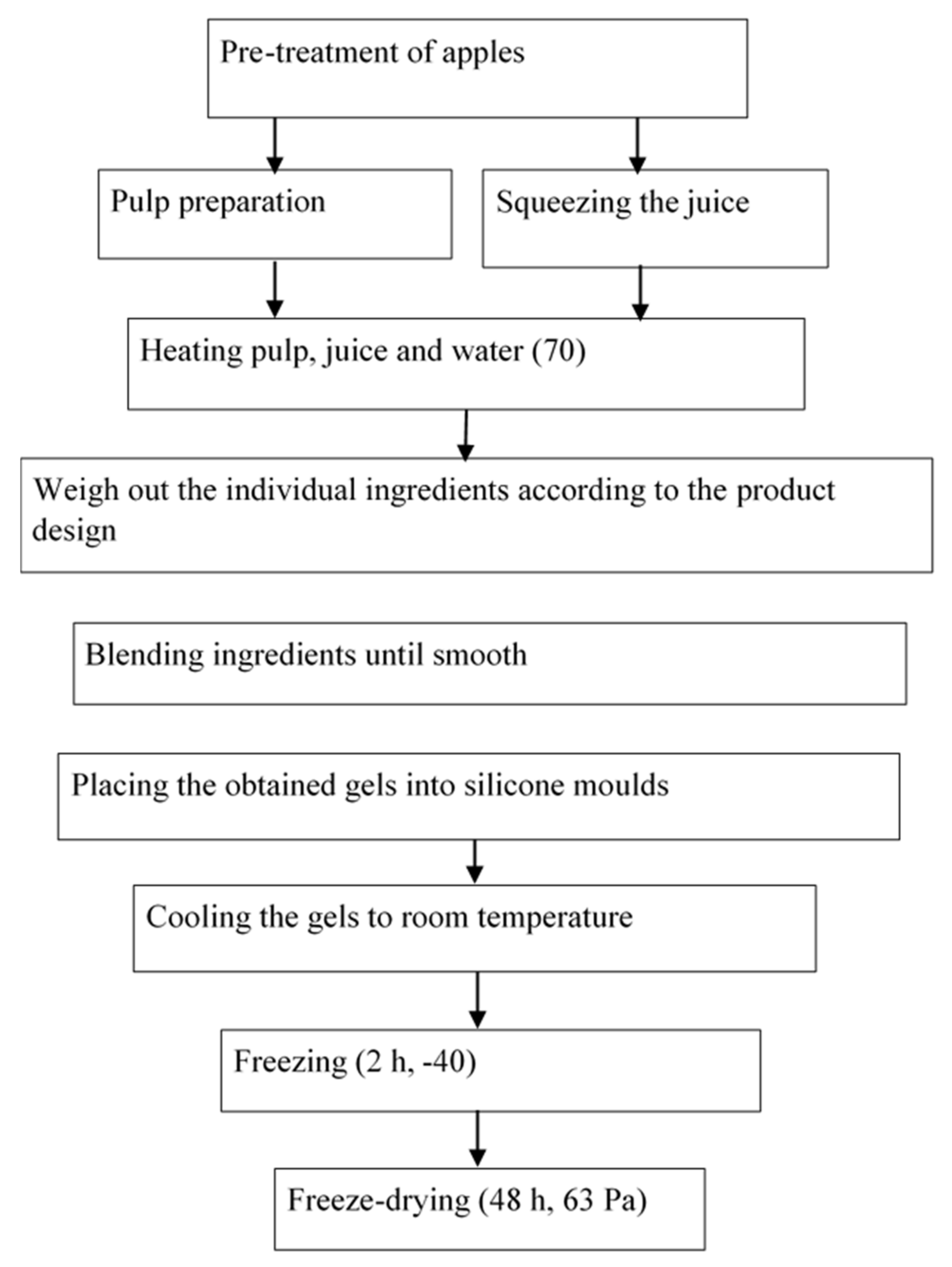

3.2. Methodology

3.2.1. Technological Methods

Preparation of Bars

Freeze-Drying

3.2.2. Analytical Methods

Determination of Physical Properties of Obtained Snacks

- s.s—dry matter content [%],

- w1—the mass of the empty vessel [g],

- w2—weight of the sample dish before drying [g],

- w3—weight of the sample dish after drying [g].

- a*—red colour coefficient [dimensionless value]

- b*—yellow colour coefficient [dimensionless value]

Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Płachciak, A. The idea of sustainable development—A principle of justice. Annales 2009, 12, 197–204. [Google Scholar]

- Tiwari, B.K.; Norton, T.; Holden, N.M. Introduction. In Sustainable Food Processing; Tiwari, B.K., Norton, T., Holden, N.M., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2014; pp. 1–7. [Google Scholar]

- Fruit and Vegetables Market—Production, Processing (IERiGŻ Analysis). Available online: www.sadyogrody.pl (accessed on 20 January 2020).

- Wichrowska, D.; Żary-Sikorska, E. Health-promoting properties of apple press cake. Inżynieria Apar. Chem. 2015, 54, 286–287. [Google Scholar]

- Tarko, T.; Duda-Chodak, A.; Bebak, A. Biological activity of selected fruit and vegetable pomaces. Żywność Nauka Technol. Jakość 2012, 4, 55–65. [Google Scholar] [CrossRef]

- Krishnaswamy, K.; Vali, H.; Orsat, V. Value-adding to grape waste: Green synthesis of gold nanoparticles. J. Food Eng. 2014, 142, 210–220. [Google Scholar] [CrossRef]

- Kowalska, H.; Lenart, A.; Marzec, A.; Ciurzyńska, A.; Cichowska, J.; Czajkowska, K.; Wojnowski, M.; Hankus, M. Development of sustainable processing technologies for converting by-products into healthy, added value ingredients and food products. Postępy Tech. Przetwórstwa Spożywczego 2015, 2, 119–125. [Google Scholar]

- Rana, S.; Gupta, S.; Rana, A.; Bhushan, S. Functional properties, phenolic constituents and antioxidant potential of industrial apple pomace for utilization as active food ingredient. Food Sci. Hum. Wellness 2015, 4, 180–187. [Google Scholar] [CrossRef] [Green Version]

- Skinner, R.C.; Gigliotti, J.C.; Ku, K.; Tou, J.C. A comprehensive analysis of the composition, health benefits, and safety of apple pomace. Nutr. Rev. 2018, 76, 893–909. [Google Scholar] [CrossRef] [PubMed]

- Lyu, F.; Luiz, S.F.; Azeredo, D.R.P.; Cruz, A.G.; Ajlouni, S.; Ranadheera, C.S. Apple pomace as a functional and healthy ingredient in food products: A review. Processes 2020, 8, 319. [Google Scholar] [CrossRef] [Green Version]

- Pawlak, S.; Sielicka, M. Wpływ Rozpuszczalnika Zastosowanego do Ekstrakcji na Oznaczoną Zawartość Związków Fenolowych i Aktywność Przeciwutleniającą Wytłoków z Aronii. Zagospodarowanie Ubocznych Produktów Przemysłu Spożywczego; Górecka, W.D., Pospiech, E., Eds.; Uniwersytet Przyrodniczy w Poznaniu: Poznań, Poland, 2016; pp. 25–35. [Google Scholar]

- Fronc, A.; Nawirska, A. The waste from vegetable and fruit processing—Possibilities of using. Ochr. Sr. 1994, 2, 31–32. [Google Scholar]

- Grasso, S. Extruded snacks from industrial by-products: A review. Trends Food Sci. Technol. 2020, 99, 284–294. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Cieśluk, P.; Barwińska, M.; Marczak, W.; Ordyniak, A.; Lenart, A.; Janowicz, M. Eating Habits and Sustainable Food Production in the development of innovative “healthy” snacks. Sustainability 2019, 11, 2800. [Google Scholar] [CrossRef] [Green Version]

- Kowalska, H.; Czajkowska, K.; Cichowska, J.; Lenart, A. What’s new in biopotential of fruit and vegetable by-products applied in the food processing industry. Trends Food Sci. Technol. 2017, 67, 150–159. [Google Scholar] [CrossRef]

- Majerska, J.; Michalska, A.; Fiegiel, A. A review of new directions in managing fruit and vegetable processing byproducts. Trends Food Sci. Technol. 2019, 88, 207–219. [Google Scholar] [CrossRef]

- Orrego, C.E.; Salgado, N.; Botero, C.A. Developments and trends in fruit bar production and characterization. Crit. Rev. Food Sci. Nutr. 2013, 54, 84–97. [Google Scholar] [CrossRef] [PubMed]

- Gronowska-Senger, A.; Drywień, M.; Hamułka, J.; Wawrzyniak, A. Oznaczanie zawartości wody i suchej masy w wybranych produktach spożywczych. In Analiza Żywności Zbiór Ćwiczeń; Gronowska-Senger, A., Ed.; Wydawnictwo SGGW: Warszawa, Poland, 2018; pp. 13–20. [Google Scholar]

- Marciniak-Łukasiak, K.; Żbikowska, A.; Kačániová, M. Ocena jakości batonów zbożowych z dodatkiem wybranych surowców odpadowych przemysłu owocowego. In Proceedings of the Surowce Pochodzenia Zwierzęcego Jako Źródło Składników Bioaktywnych: XIII Konferencja Naukowa z Cyklu Żywność XXI Wieku, Żywność a Składniki Bioaktywne”, Kraków, Poland, 24–25 September 2018; Słupski, J., Tarko, T., Drożdż, I., Eds.; Oddział Małopolski Polskiego Towarzystwa Technologów Żywności: Kraków, Poland, 2018; pp. 143–153. [Google Scholar]

- Karwacka, M.; Gumkowska, M.; Rybak, K.; Ciurzyńska, A.; Janowicz, M. Impact of sodium alginate and dried apple pomace powder as a carrier agent on the properties of freeze-dried vegetable snacks. Pol. J. Food Nutr. Sci. 2021, 71, 451–461. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Marczak, W.; Lenart, A.; Janowicz, M. Production of innovative freeze-dried vegetable snack with hydrocolloids in terms of technological process and carbon footprint calculation. Food Hydrocoll. 2020, 108, 105993. [Google Scholar] [CrossRef]

- Gaidhani, K.A.; Harwalkar, M.; Bhambere, D.; Nirgude, P.S. Lyophilization/freeze drying—A review. World J. Pharm. Res. 2015, 8, 516–543. [Google Scholar]

- Pałacha, Z.; Markiewicz, M. Water activity of choosen food-stuff groups. Postępy Tech. Przetwórstwa Spożywczego 2011, 2, 24–29. [Google Scholar]

- Grzegory, P.; Piotrowski, D. Effect of drying method on selected properties of dried fruits and vegetables. Przemysł Ferment. Owocowo-Warzywny 2013, 57, 5–6. [Google Scholar]

- Gondek, E.; Gauze, J.; Jakubczyk, E.; Janczar-Smuga, M.; Nowak, D.; Stasiak, M.; Kamińska-Dwórznicka, A.; Samborska, K. The high-fibre vegetable and cereal based snacks—Analysis of selected physical and functional properties. Zesz. Probl. Postępów Nauk. Rol. 2017, 590, 15–27. [Google Scholar]

- Tapia, M.S.; Alzamora, S.M.; Chirife, J. Effects of water activity (aw) on microbial stability as a hurdle in food preservation. In Water Activity in Foods: Fundamentals and Applications; Wiley-Blackwell: Hoboken, NJ, USA, 2020; Chapter 14; pp. 323–355. [Google Scholar]

- Karwacka, M.; Ciurzyńska, A.; Galus, S.; Janowicz, M. Freeze-dried snacks obtained from frozen vegetable by-products and apple pomace—Selected properties, energy consumption and carbon footprint. Innov. Food Sci. Emerg. Technol. 2022, 77, 102949. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Mieszkowska, A.; Olsiński, I.; Lenart, A. The effect of composition and aeration on selected physical and sensory properties of freeze-dried hydrocolloid gels. Food Hydrocoll. 2017, 67, 94–103. [Google Scholar] [CrossRef]

- Silva-Espinoza, M.A.; Camacho, M.M.; Martínez-Navarrete, N. Use of different biopolymers as carriers for purposes of obtaining a freeze-dried orange snack. LWT 2020, 127, 109415. [Google Scholar] [CrossRef]

- Valentina, V.; Pratiwi, A.R.; Hsiao, P.Y.; Tseng, H.T.; Hsieh, J.F.; Chen, C.C. Sensorial characterization of foods before and after freeze-drying. Austin J. Nutr. Food Sci. 2016, 1, 1–5. [Google Scholar]

- Ciurzyńska, A.; Lenart, A. Effect of aerated structure on selected properties of freeze-dried hydrocolloids gels. Int. Agrophys. 2016, 30, 9–17. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Lenart, A. Wybrane właściwości fizyczne liofilizowanych galaretek truskawkowych. Zesz. Probl. Postępów Nauk. Rol. 2010, 553, 31–39. [Google Scholar]

- Konrade, D.; Klava, D.; Gramatina, I. Cereal crispbread improvement with dietary fibre from apple by-products. CBU Int. Conf. Proc. 2017, 5, 1143–1148. [Google Scholar] [CrossRef] [Green Version]

- PN-ISO 4121:1998; Analiza Sensoryczna. Metodologia. Ocena Produktów Żywnościowych Przy Użyciu Metod Skalowania. Polish Committee for Standardization: Warsaw, Poland, 2013.

- Silva-Espinoza, M.A.; Salvador, A.; Camacho, M.D.M.; Martínez-Navarrete, N. Impact of freeze-drying conditions on the sensory perception of a freeze-dried orange snack. J. Sci. Food Agric. 2011, 101, 4585–4590. [Google Scholar] [CrossRef]

- Parra, A.F.R.; Sahagún, M.; Ribotta, P.D.; Ferrero, C.; Gómez, M. Particle size and hydration properties of dried apple pomace: Effect on dough viscoelasticity and quality of sugar-snap cookies. Food Bioprocess Technol. 2019, 12, 1083–1092. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Lenart, A.; Traczyk, W. Influence of chemical composition and structure of strawberry gels on the choosen physical properties of freeze–dried final product. Ital. J. Food Sci. 2013, 2, 149–159. [Google Scholar] [CrossRef]

- Zalewska, M.; Otreszko-Arski, A.; Zalewski, M. Wpływ suszenia konwekcyjnego i liofilizacji na barwę wybranych owoców. Apar. Badaw. Dydakt. 2016, 3, 141–145. [Google Scholar]

- Kowalska, H.; Marzec, A.; Domian, E.; Masiarz, E.; Ciurzyńska, A.; Galus, S.; Małkiewicz, A.; Lenart, A.; Kowalska, J. Physical and sensory properties of japanese quince chips obtained by osmotic dehydration in fruit juice concentrates and hybrid drying. Molecules 2020, 25, 5504. [Google Scholar] [CrossRef] [PubMed]

- Kita, A.; Górnicka, E.; Wojdyło, A.; Drożdż, W. Wpływ dodatku wytłoków rzepakowych na właściwości smażonych chrupek ziemniaczanych. Rośliny Oleiste Oilseed Crops 2012, 33, 285–294. [Google Scholar] [CrossRef]

| Sample Symbol | Apple Pomace | Chokeberry Pomace | Apple Pulp | Apple Juice | Water | Calcium Lactate | Sodium Alginate |

|---|---|---|---|---|---|---|---|

| 2_3A | 3% | - | 50% | 22.5% | 22.4% | 0.1% | 2% |

| 2_3C | - | 3% | |||||

| 2_6A | 6% | - | 50% | 21% | 20.9% | 0.1% | 2% |

| 2_6C | - | 6% | |||||

| 2_9A | 9% | - | 50% | 19.5% | 19.4% | 0.1% | 2% |

| 2_9C | - | 9% | |||||

| 1.5_3A | 3% | - | 50% | 22.7% | 22.7% | 0.1% | 2% |

| 1.5_3C | - | 3% | |||||

| 1.5_6A | 6% | - | 50% | 1.2% | 21.2% | 0.1% | 2% |

| 1.5_6C | - | 6% | |||||

| 1.5_9A | 9% | - | 50% | 19.7% | 19.7% | 0.1% | 2% |

| 1.5_9C | - | 9% | |||||

| 1_2A | 2% | - | 50% | 23.6% | 23.4% | 0.1% | 2% |

| 1_2C | - | 2% |

| Freeze-Dried Samples | Samples before Freeze-Drying | ||

|---|---|---|---|

| Sample | Average Dry Matter Content | Average Water Activity | Average Water Content |

| 1.5_3A | 98.23% ± 0.013 a,b | 0.14 ± 0.002 d | 77.12% ± 0.086 c,d |

| 1.5_6A | 98.40% ± 0.055 b,c | 0.12 ± 0.001 b | 74.74% ± 0.036 b,c |

| 1.5_9A | 98.56% ± 0.013 c | 0.099 ± 0.001 a | 71.92% ± 0.006 a |

| 2_3A | 97.99% ± 0.009 a | 0.148 ± 0.003 e | 77.26% ± 0.057 c,d |

| 2_6A | 98.07% ± 0.01 a | 0.126 ± 0.002 b | 75.00% ± 0.03 a,b |

| 2_9A | 98.17% ± 0.087 a,b | 0.102 ± 0.003 a | 71.31% ± 0.314 a |

| 1_2A | 99.46% ± 0.28 d | 0.132 ± 0.001 c | 81.07% ± 1.078 d |

| 1.5_3C | 97.11% ± 0.00 A | 0.15 ± 0.001 E | 79.572% ± 0.411 C |

| 1.5_6C | 97.90% ± 0.014 C | 0.116 ± 0.002 C | 73.178% ± 0.317 B |

| 1.5_9C | 98.04% ± 0.034 D | 0.106 ± 0.001 A | 70.98% ± 0.192 A |

| 2_3C | 97.28% ± 0.038 B | 0.159 ± 0.001 F | 76.90% ± 0.063 C |

| 2_6C | 98.00% ± 0.022 D | 0.126 ± 0.000 D | 71.65% ± 0.526 B |

| 2_9C | 98.11% ± 0.046 E | 0.112 ± 0.001 B | 70.32% ± 1.298 A |

| 1_2C | 98.29% ± 0.000 F | 0.116 ± 0.001 B,C | 78.087% ± 0.376 C |

| Sample Symbol | Samples with Chokeberry Pomace [C] | Samples with Apple Pomace [A] |

|---|---|---|

| 1.5_3 | 21.9 ± 0.33 d | 29.6 ± 0.37 c |

| 1.5_6 | 18.2 ± 0.78 b,c | 29.0 ± 1.38 b,c |

| 1.5_9 | 15.3 ± 0.18 a | 29.5 ± 0.77 c |

| 2_3 | 18.8 ± 0.35 c | 28.2 ± 0.49 b |

| 2_6 | 17.8 ± 0.43 b | 28.9 ± 0.26 b,c |

| 2_9 | 15.6 ± 0.63 a | 28.6 ± 1.54 b,c |

| 1_2 | 22.3 ± 0.81 d | 26.6 ± 0.24 a |

| Sample Symbol | ||||||

|---|---|---|---|---|---|---|

| 1_2A | 1.5_3A | 2_3A | 1_2C | 1.5_3C | 2_3C | |

| Color | ||||||

| Aroma | ||||||

| Taste | ||||||

| Crisspness | ||||||

| General impression | ||||||

| Average | 4.4 | 3.84 | 3.72 | 4.36 | 3.8 | 3.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciurzyńska, A.; Popkowicz, P.; Galus, S.; Janowicz, M. Innovative Freeze-Dried Snacks with Sodium Alginate and Fruit Pomace (Only Apple or Only Chokeberry) Obtained within the Framework of Sustainable Production. Molecules 2022, 27, 3095. https://doi.org/10.3390/molecules27103095

Ciurzyńska A, Popkowicz P, Galus S, Janowicz M. Innovative Freeze-Dried Snacks with Sodium Alginate and Fruit Pomace (Only Apple or Only Chokeberry) Obtained within the Framework of Sustainable Production. Molecules. 2022; 27(10):3095. https://doi.org/10.3390/molecules27103095

Chicago/Turabian StyleCiurzyńska, Agnieszka, Paulina Popkowicz, Sabina Galus, and Monika Janowicz. 2022. "Innovative Freeze-Dried Snacks with Sodium Alginate and Fruit Pomace (Only Apple or Only Chokeberry) Obtained within the Framework of Sustainable Production" Molecules 27, no. 10: 3095. https://doi.org/10.3390/molecules27103095

APA StyleCiurzyńska, A., Popkowicz, P., Galus, S., & Janowicz, M. (2022). Innovative Freeze-Dried Snacks with Sodium Alginate and Fruit Pomace (Only Apple or Only Chokeberry) Obtained within the Framework of Sustainable Production. Molecules, 27(10), 3095. https://doi.org/10.3390/molecules27103095