A Novel Approach by Spark Plasma Sintering to the Improvement of Mechanical Properties of Titanium Carbonitride-Reinforced Alumina Ceramics

Abstract

1. Introduction

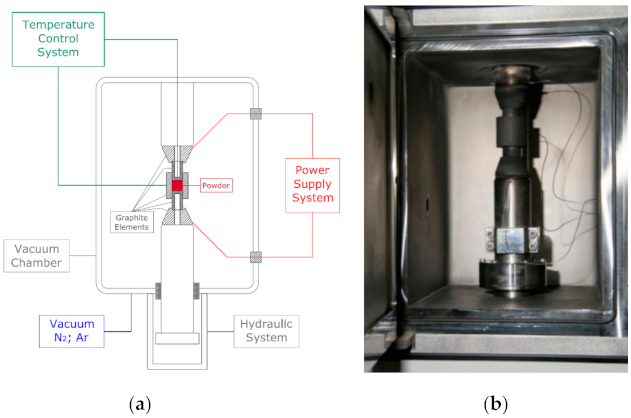

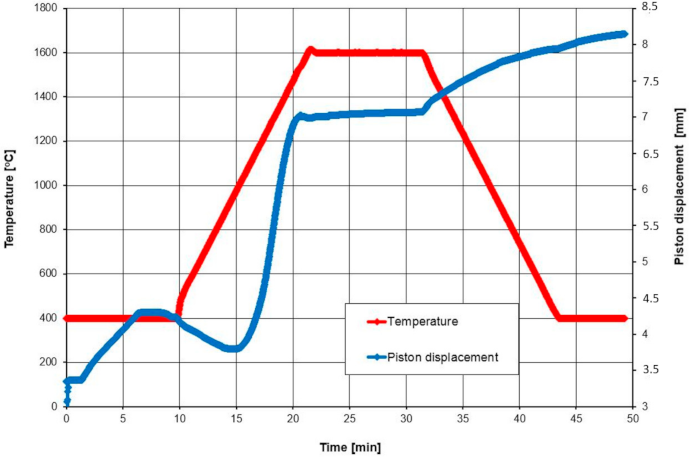

2. Materials and Methods

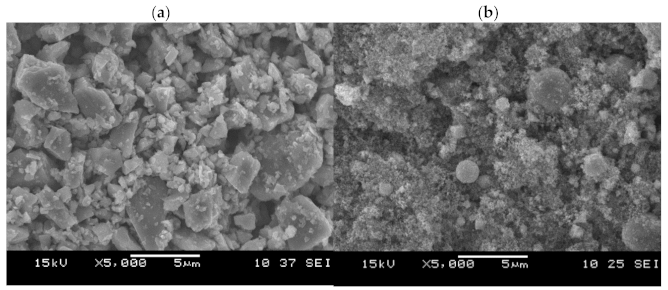

2.1. Materials

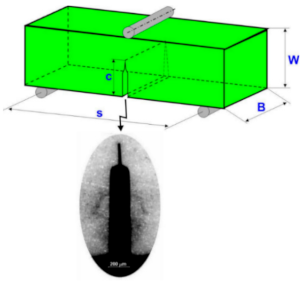

2.2. Characterization Techniques

3. Results and Discussion

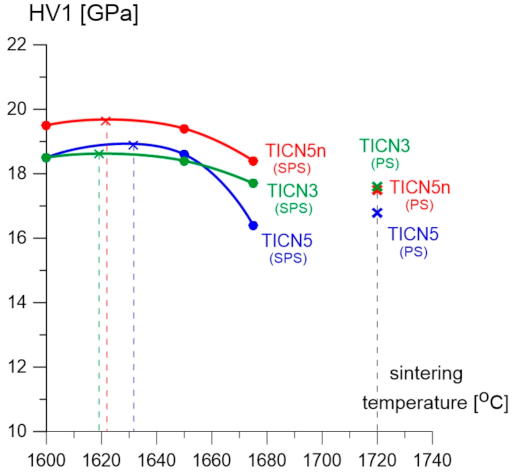

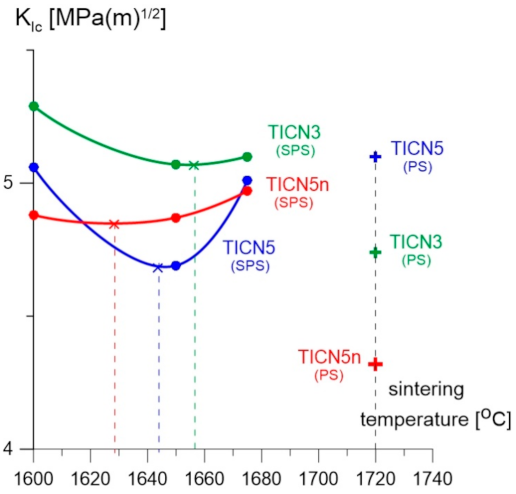

3.1. Mechanical and Physical Properties

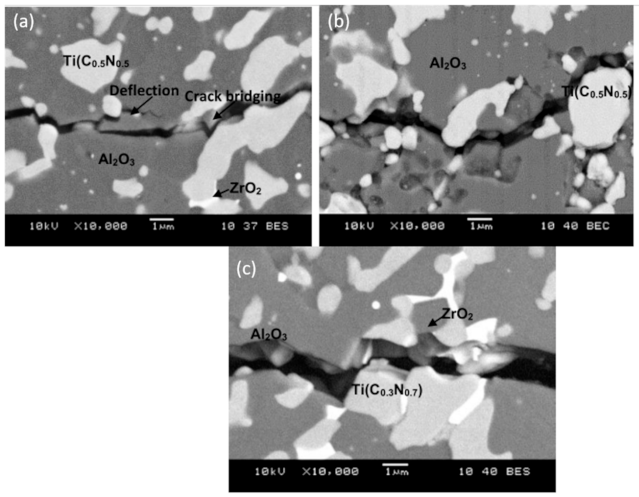

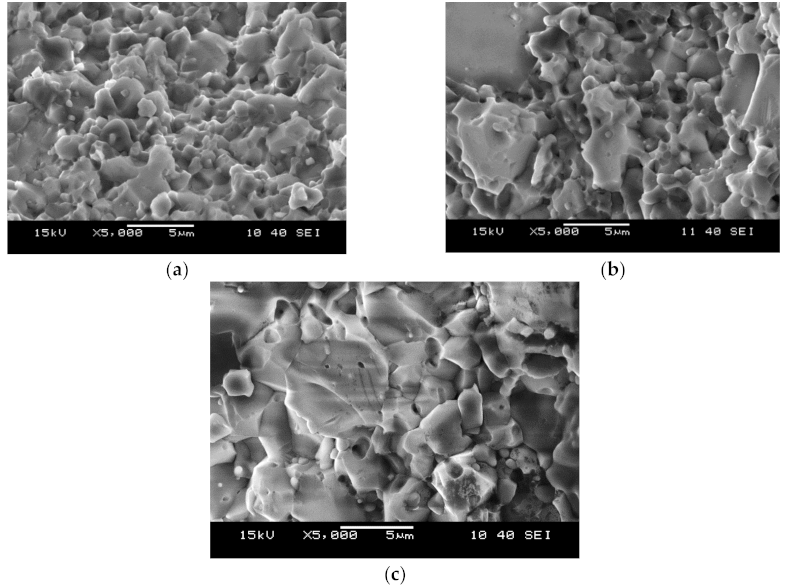

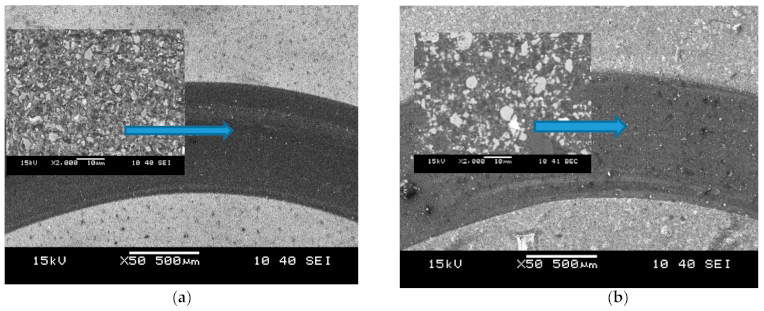

3.2. Microstructural Observations

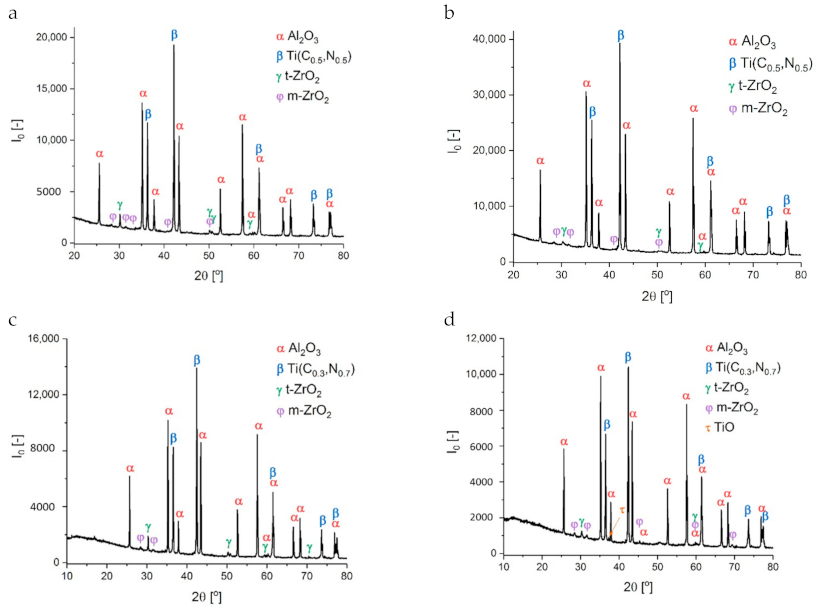

3.3. X-ray Diffraction Analysis

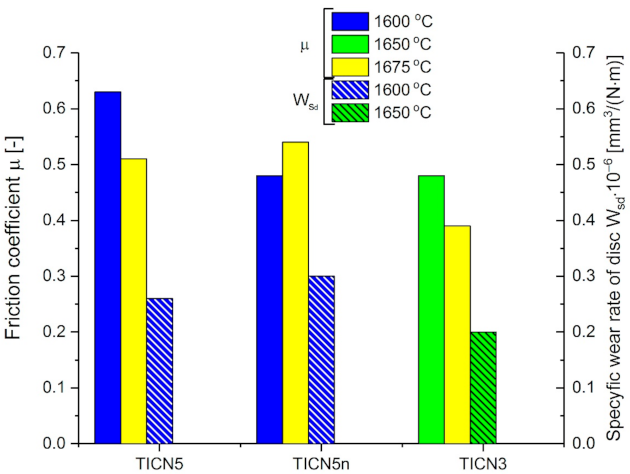

3.4. Tribological Properties

4. Conclusions

- Ti(C,N)-reinforced alumina-zirconia composites with different ratios of C to N in titanium carbonitride solid solution, such as Ti(C0.3,N0.7) (C:N = 30:70) and Ti(C0.5,N0.5) (C:N = 50:50), were tested to improve their mechanical properties. The effect of the Ti(C0.5,N0.5)n powder of nanoscale size on the mechanical properties of the tested composites compared to composites with Ti(C0.5,N0.5) powder of microscale size was analysed.

- The composite with the addition of Ti(C0.5,N0.5) powder of nanoscale size exhibited the highest Vickers hardness (over 19.0 GPa), and its fracture toughness was 5.0 MPa·m1/2.

- It was found that slightly higher values (above 5.0 MPa·m1/2) of fracture toughness were achieved by a composite with C:N = 30:70 ratio in the Ti(C0.3,N0.7) solid solution. There was only a 2–7% difference in KIC compared to composites with the addition of Ti(C0.5,N0.5).

- The Vickers hardness values decreased slightly with increasing sintering temperature. The difference in the Vickers hardness values between the tested composites measured at the lowest (1600 °C) and the highest (1675 °C) temperature ranged from 5% to 10%.

- The fracture toughness of the composites sintered at a temperature of 1720 °C by PS revealed lower values when compared to those sintered at the highest temperature (1675 °C) using the SPS method.

- The phases of Al2O3, Ti(C,N), and ZrO2 in the monoclinic and tetragonal form were revealed during X-ray diffraction analysis of the tested composites. The partial polymorphic transformation of monoclinic ZrO2(m) into tetragonal ZrO2(t) in the tested composites was observed. The most intense transformation was observed in Al2O3/ZrO2/Ti(C0.5,N0.5) composites. The percentage of Ti(C0.5,N0.5) solid solution in the tested composites was in the range of 23.9 to 30.0 wt %.

- The sintering temperature used in this test had an effect on the friction coefficient. The highest value of the friction coefficient (0.63) was exhibited in a composite with Ti(C0.5, N0.5) powder of micrometric size sintered by SPS at a temperature of 1600 °C. The lowest friction coefficient (0.39) and specific wear rate of the disk (0.2 × 10−6) was attained by the composite with the addition of Ti(C0.3,N0.7) to the alumina-zirconia matrix.

- The experimental testing of the considered composites will be extended to uniaxial tension or compression loading similar to [36,37,38,39,40,41]. The corresponding numerical models will be elaborated for a description of the quasi-static and dynamic response of the analysed Al2O3/ZrO2/Ti(C,N) composites. Moreover, brittle-damage and shear-damage models and surface-based cohesive behaviour will be used to account for decohesion process of composites at interfaces [40,41,42,43,44,45,46,47,48].

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Riedel, R.; Chen, I.W. Ceramic oxides. Ceram. Sci. Technol. 2010, 2, 3–58. [Google Scholar]

- Imanaka, Y. Ceramic cutting tools. In Advanced Ceramic Technologies & Product; Springer: Tokyo, Japan, 2012; Chapter 16.2; pp. 387–389. [Google Scholar]

- Goodfellow Cambridge. Metals, Alloys, Compounds, Ceramics, Polymers, Composites, Catalogue; Goodfellow Cambridge Ltd.: Cambridge, UK, 1993. [Google Scholar]

- Tang, A.; Liu, S.; Pan, F. Novel approaches to produce Al2O3–TiC/TiCN–Fe composite powders directly from ilmenite. Proc. Nat. Sci. Mater. 2013, 3, 501–507. [Google Scholar] [CrossRef][Green Version]

- Yang, Y.; Yao, W.; Zhang, H. Phase constituents and mechanical properties of laser in-situ synthesized TiCN/TiN composite coating on Ti-6Al-4V. Surf. Coat. Technol. 2010, 205, 620–624. [Google Scholar] [CrossRef]

- Peng, Y.; Miao, H.; Peng, Z. Development of TiCN-based cermets: Mechanical properties and wear mechanism. Int. J. Refract. Met. Hard Mater. 2013, 39, 78–89. [Google Scholar] [CrossRef]

- Chevalier, J.; Gremillard, L.; Virkar, A.V.; Clarke, D.R. The tetragonal-monoclinic transformation in zirconia: Lessons learned and future trends. J. Am. Ceram. Soc. 2009, 92, 1901–1920. [Google Scholar] [CrossRef]

- Szutkowska, M.; Boniecki, M. Subcritical crack growth in zirconia-toughened alumina (ZTA) ceramics. J. Mater. Process. Technol. 2006, 175, 416–420. [Google Scholar] [CrossRef]

- Yeh, C.-W.; Chen, Y. D. Direct formation of titanium carbonitrides by SHS in nitrogen. Ceram. Int. 2005, 31, 719–729. [Google Scholar] [CrossRef]

- Zhang, S. Titanium carbonitride-based cermets: Processes and properties. Mater. Sci. Eng. A 1993, 163, 141–148. [Google Scholar] [CrossRef]

- Cardinal, S.; Malchere, A.; Garnier, V.; Fantozzi, G. Microstructure and mechanical properties of TiC-TiN based cermets for tool application. Int. J. Refract. Met. Hard Mater. 2009, 27, 521–527. [Google Scholar] [CrossRef]

- Karlsson, L.; Hultman, L.; Johansson, M.P.; Sundgren, J.E.; Ljungcrantz, H. Growth, microstructure and mechanical properties of arc evaporated TiCxN1-x (0 ≤ x ≤ 1) films. Surf. Coat. Technol. 2000, 126, 1–14. [Google Scholar] [CrossRef]

- Zhang, H.; Yan, D.; Tang, S. Preparation and properties of ultra-fine TiCN matrix cermets by vacuum microwave sintering. Rare Met. 2010, 29, 528–532. [Google Scholar] [CrossRef]

- Levi, G.; Kaplan, W.D.; Bamberger, M. Structure refinement of titanium carbonitride (TiCN). Mater. Lett. 1998, 35, 344–350. [Google Scholar] [CrossRef]

- Yin, Z.; Yuan, J.; Wang, Z.; Hu, H.; Cheng, Y.; Hu, X. Preparation and properties of an Al2O3/Ti(C,N) micro-nano-composite ceramic tool material by microwave sintering. Ceram. Int. 2016, 42, 4099–4106. [Google Scholar] [CrossRef]

- Huang, J.L.; Nayak, P.K. Strengthening alumina ceramic matrix nanocomposites using spark plasma sintering. In Advances in Ceramic Matrix Composites; Woodhead Publishing Series; Elsevier Inc.: Amsterdam, The Netherlands, 2018; pp. 231–247. [Google Scholar]

- Song, S.-X.; Wang, Z.; Shi, G.-P. Heating mechanism of spark plasma sintering. Ceram. Int. 2013, 39, 1393–1396. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Liu, Z.-F.; Lu, J.-F.; Shen, X.-B.; Wang, F.-C.; Wang, Y.-D. The sintering mechanism in spark plasma sintering—Proof of the occurrence of spark discharge. Scr. Mater. 2014, 81, 56–59. [Google Scholar] [CrossRef]

- Akinribide, O.J.; Mekgwe, G.N.; Ajibola, O.O.; Obadele, B.A.; Akinwamide, S.O.; Falodun, E.O.; Olubambi, P.A. Mechanical properties of ultrafine graphite –Ti (C0.9, N0.1) solid solutions fabricated via spark plasma sintering. Procedia Manuf. 2019, 30, 411–418. [Google Scholar] [CrossRef]

- Kim, Y.W.; Lee, J.G. Pressureless sintering of alumina—Titanium carbide composites. J. Am. Ceram. Soc. 2005, 72, 1333–1337. [Google Scholar] [CrossRef]

- Zhang, H.; Yan, J.; Zhang, X.; Tang, S. Properties of titanium carbonitride matrix cermets. Int. J. Refract. Met. Hard Mater. 2006, 24, 236–239. [Google Scholar] [CrossRef]

- Szutkowska, M.; Cygan, S.; Podsiadło, M.; Laszkiewicz-Łukasik, J.; Cyboroń, J.; Kalinka, A. Properties of TiC and TiN reinforced alumina–zirconia composites sintered with spark plasma technique. Metals 2019, 9, 1220. [Google Scholar] [CrossRef]

- Klimczyk, P. SiC-based composites sintered with high pressure method. In Silicon Carbide Materials, Processing and Applications in Electronic Devices; Mukherjee, M., Ed.; IntechOpen: London, UK, 2011; Volume 13, pp. 309–334. [Google Scholar]

- Fett, T.; Munz, D. Subcritical crack growth of macrocracks in alumina with R-curve behaviour. J. Mater. Sci. 1992, 4, 958–963. [Google Scholar]

- Fett, T. An analysis of the three-point bending bar by use of the weight function method. Eng. Fract. Mech. 1991, 40, 683–686. [Google Scholar] [CrossRef]

- ISO International Standard. Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Friction and Wear Characteristics of Monolithic Ceramics by Ball-on-Disc Method; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Lengauer, W.; Scagnetto, F. Ti(C,N)-based cermets: Critical review of achievements and recent developments. Solid State Phenom. 2018, 274, 53–100. [Google Scholar] [CrossRef]

- Fang, Y.; Zhao, X.; Zhang, M.; Zhang, P.; Cheng, H.; Xue, S.; Zhang, L.; Wu, J.; Feng, S. Effect of ZrO 2 whiskers on the microstructure and mechanical properties of a Ti(C,N)-based cermet cutting tool material. Int. J. Appl. Ceram. Technol. 2019, 16, 1347–1355. [Google Scholar] [CrossRef]

- Demoly, A.; Lengauer, W.; Veitsch, C.; Rabitsch, K. Effect of submicron Ti(C,N) on the microstructure and the mechanical properties of Ti(C,N)-based cermets. Int. J. Refract. Met. Hard Mater. 2011, 29, 716–723. [Google Scholar] [CrossRef]

- Chicardi, E.; Martínez, F.J.G. Effects of boron addition on the microstructure and mechanical properties of (Ti,Ta)(C,N)-co based cermets. Metals 2019, 9, 787. [Google Scholar] [CrossRef]

- Pang, J.; Liu, Y.; Wen-Ye, J.; Hua-Tang, Z. Microwave sintering of TiCN-based cermets prepared from electroless Co-coated (Ti, W, Mo, V)CN powders. Rare Met. 2017, 6, 1–8. [Google Scholar] [CrossRef]

- Cordoba, J.M.; Snachez-Lopez, J.C.; Aviles, M.A.; Alcala, M.D.; Gotor, J. Properties of Ti(C,N) cermets synthesized by mechanically induced self-sustaining reaction. J. Eur. Ceram. Soc. 2009, 29, 1173–1182. [Google Scholar] [CrossRef]

- Yang, H.; Shang, F.; Gao, L. Microstructure and mechanical properties of gas pressure sintered Al2O3/TiCN composite. Ceram. Int. 2007, 33, 1521–1524. [Google Scholar] [CrossRef]

- Dyatlova, Y.G.; Agafonow, S.V.; Boikov, S.Y.; Ordanyan, S.S.; Rumyantsev, V.I. Tool ceramics based on Al2O3–ZrO2-TiCN composite. Powder Metall. Met. Ceram. 2011, 49, 675–681. [Google Scholar] [CrossRef]

- Gao, Z.; Zhao, J.; Zheng, G.M. Processing and characterization of an Al2O3/TiCN micro-nano-composite graded ceramic tool material. Key Eng. Mater. 2012, 499, 132–137. [Google Scholar] [CrossRef]

- Sadowski, T.; Samborski, S. Modeling of porous ceramics response to compressive loading. J. Am. Ceram. Soc. 2003, 86, 2218–2221. [Google Scholar] [CrossRef]

- Sadowski, T.; Golewski, G. Effect of aggregate kind and graining on modelling of plain concrete under compression. Comput. Mater. Sci. 2008, 43, 119–126. [Google Scholar] [CrossRef]

- Sadowski, T. Gradual degradation in two-phase ceramic composites under compression. Comput. Mater. Sci. 2012, 64, 209–211. [Google Scholar] [CrossRef]

- Sadowski, T.; Pankowski, B. Numerical modelling of two-phase ceramic composite response under uniaxial loading. Compos. Struct. 2016, 143, 388–394. [Google Scholar]

- Marsavina, L.; Sadowski, T. Kinked crack at a bi-material ceramic interface—Numerical determination of fracture parameters. Comput. Mater. Sci. 2009, 44, 941–950. [Google Scholar] [CrossRef]

- Marsavina, L.; Sadowski, T. Stress intensity factors for an interface kinked crack in a Bi-material plate loaded normal to the interface. Int. J. Fract. 2007, 145, 237–243. [Google Scholar] [CrossRef]

- Sadowski, T.; Hardy, S.; Postek, E. Prediction of the mechanical response of polycrystalline ceramics containing metallic intergranular layers under uniaxial tension. Comput. Mat. Sci. 2005, 34, 46–63. [Google Scholar] [CrossRef]

- Sadowski, T.; Hardy, S.; Postek, E. A new model for the time-dependent behaviour of polycrystalline ceramic materials with metallic inter-granular layers under tension. Mater. Sci. Eng. A 2006, 424, 230–238. [Google Scholar] [CrossRef]

- Sadowski, T.; Postek, E.; Denis, C. Stress distribution due to discontinuities in polycrystalline ceramics containing metallic inter-granular layers. Comput. Mater. Sci. 2007, 39, 230–236. [Google Scholar] [CrossRef]

- Postek, E.; Sadowski, T. Assessing the influence of porosity in the deformation of metal–ceramic composites. Compos. Interfaces 2011, 18, 57–76. [Google Scholar] [CrossRef]

- Nakonieczny, K.; Sadowski, T. Modelling of ‘thermal shocks’ in composite materials using a meshfree FEM. Comput. Mater. Sci. 2009, 44, 1307–1311. [Google Scholar] [CrossRef]

- Burlayenko, V.; Altenbach, H.; Sadowski, T.; Dimitrova, S.; Bhaskar, A. Modelling functionally graded materials in heat transfer and thermal stress analysis by means of graded finite elements. Appl. Math. Model. 2017, 45, 422–438. [Google Scholar] [CrossRef]

- Ivanov, I.; Sadowski, T.; Pietras, D. Crack propagation in functionally graded strip under thermal shock. Eur. Phys. J. Spec. Top. 2013, 222, 1587–1595. [Google Scholar] [CrossRef]

| Compounds | Components, wt % | ||||

|---|---|---|---|---|---|

| Al2O3 + MgO | ZrO2(m) | Ti(C0.3,N0.7) | Ti(C0.5,N0.5) | Ti(C0.5,N0.5)n | |

| TICN3 | 68 | 2 | 30 | - | - |

| TICN5 | 68 | 2 | - | 30 | - |

| TICN5n | 68 | 2 | - | 20 | 10 |

| Samples | Sintering Temperature (°C) | Vickers Hardness HV1(GPa) | Apparent Density ρ (g/cm3) | Young’s Modulus E (GPa) | Fracture Toughness KIC (MPa·m1/2) |

|---|---|---|---|---|---|

| TICN5.1 | 1600 | 18.5 ± 0.2 | 4.27 ± 0.01 | 400 ± 5.0 | 5.06 ± 0.2 |

| TICN5.2 | 1650 | 18.6 ± 0.3 | 4.27 ± 0.01 | 410 ± 6.0 | 4.69 ± 0.1 |

| TICN5.3 | 1675 | 16.4 ± 0.2 | 4.26 ± 0.01 | 400 ± 5.0 | 5.01 ± 0.2 |

| TICN5.1n | 1600 | 19.5 ± 0.2 | 4.28 ± 0.01 | 400 ± 5.0 | 4.88 ± 0.1 |

| TICN5.2n | 1650 | 19.4 ± 0.2 | 4.29 ± 0.01 | 405 ± 4.0 | 4.87 ± 0.1 |

| TICN5.3n | 1675 | 18.4 ± 0.3 | 4.27 ± 0.01 | 400 ± 5.0 | 4.97 ± 0.2 |

| TICN3.1 | 1600 | 18.5 ± 0.3 | 4.30 ± 0.01 | 410 ± 5.0 | 5.29 ± 0.3 |

| TICN3.2 | 1650 | 18.4 ± 0.2 | 4.29 ± 0.01 | 400 ± 5.0 | 5.07 ± 0.2 |

| TICN3.3 | 1675 | 17.7 ± 0.2 | 4.30 ± 0.01 | 400 ± 5.0 | 5.10 ± 0.2 |

| Samples | Sintering Temperature (°C) | Vickers Hardness HV1 (GPa) | Apparent Density ρ (g/cm3) | Young’s Modulus E (GPa) | Fracture Toughness KIC (MPa·m1/2) |

|---|---|---|---|---|---|

| TICN5.5 | 1720 | 16.8 ± 0.2 | 4.21 ± 0.01 | 390 ± 4.0 | 5.10 ± 0.2 |

| TICN5.5n | 1720 | 17.5 ± 0.2 | 4.21 ± 0.01 | 375 ± 4.0 | 4.32 ± 0.1 |

| TICN3.5 | 1720 | 17.6 ± 0.2 | 4.24 ± 0.01 | 400 ± 5.0 | 4.74 ± 0.2 |

| Content (wt %) | |||||

|---|---|---|---|---|---|

| Composite | Al2O3 | Ti(C0.5,N0.5) | Ti(C0.3,N0.7) | ZrO2(m) | ZrO2(t) |

| TICN5.1 | 68.8 | 29.3 | - | 0.9 | 1.0 |

| TICN5.3 | 68.8 | 30.0 | - | 0.6 | 0.6 |

| TICN5.1n | 70.0 | 28.0 | - | 1.5 | 0.5 |

| TICN5.3n | 69.0 | 29.0 | - | 1.5 | 0.5 |

| TICN3.1 | 74.0 | - | 23.9 | 1.3 | 0.6 |

| TICN3.3 * | 68.7 | - | 29.2 | 1.2 | 0.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szutkowska, M.; Podsiadło, M.; Sadowski, T.; Figiel, P.; Boniecki, M.; Pietras, D.; Polczyk, T. A Novel Approach by Spark Plasma Sintering to the Improvement of Mechanical Properties of Titanium Carbonitride-Reinforced Alumina Ceramics. Molecules 2021, 26, 1344. https://doi.org/10.3390/molecules26051344

Szutkowska M, Podsiadło M, Sadowski T, Figiel P, Boniecki M, Pietras D, Polczyk T. A Novel Approach by Spark Plasma Sintering to the Improvement of Mechanical Properties of Titanium Carbonitride-Reinforced Alumina Ceramics. Molecules. 2021; 26(5):1344. https://doi.org/10.3390/molecules26051344

Chicago/Turabian StyleSzutkowska, Magdalena, Marcin Podsiadło, Tomasz Sadowski, Paweł Figiel, Marek Boniecki, Daniel Pietras, and Tomasz Polczyk. 2021. "A Novel Approach by Spark Plasma Sintering to the Improvement of Mechanical Properties of Titanium Carbonitride-Reinforced Alumina Ceramics" Molecules 26, no. 5: 1344. https://doi.org/10.3390/molecules26051344

APA StyleSzutkowska, M., Podsiadło, M., Sadowski, T., Figiel, P., Boniecki, M., Pietras, D., & Polczyk, T. (2021). A Novel Approach by Spark Plasma Sintering to the Improvement of Mechanical Properties of Titanium Carbonitride-Reinforced Alumina Ceramics. Molecules, 26(5), 1344. https://doi.org/10.3390/molecules26051344