Effect of Power Ultrasound Treatment on Free and Glycosidically-Bound Volatile Compounds and the Sensorial Profile of Red Wines

Abstract

1. Introduction

2. Results and Discussion

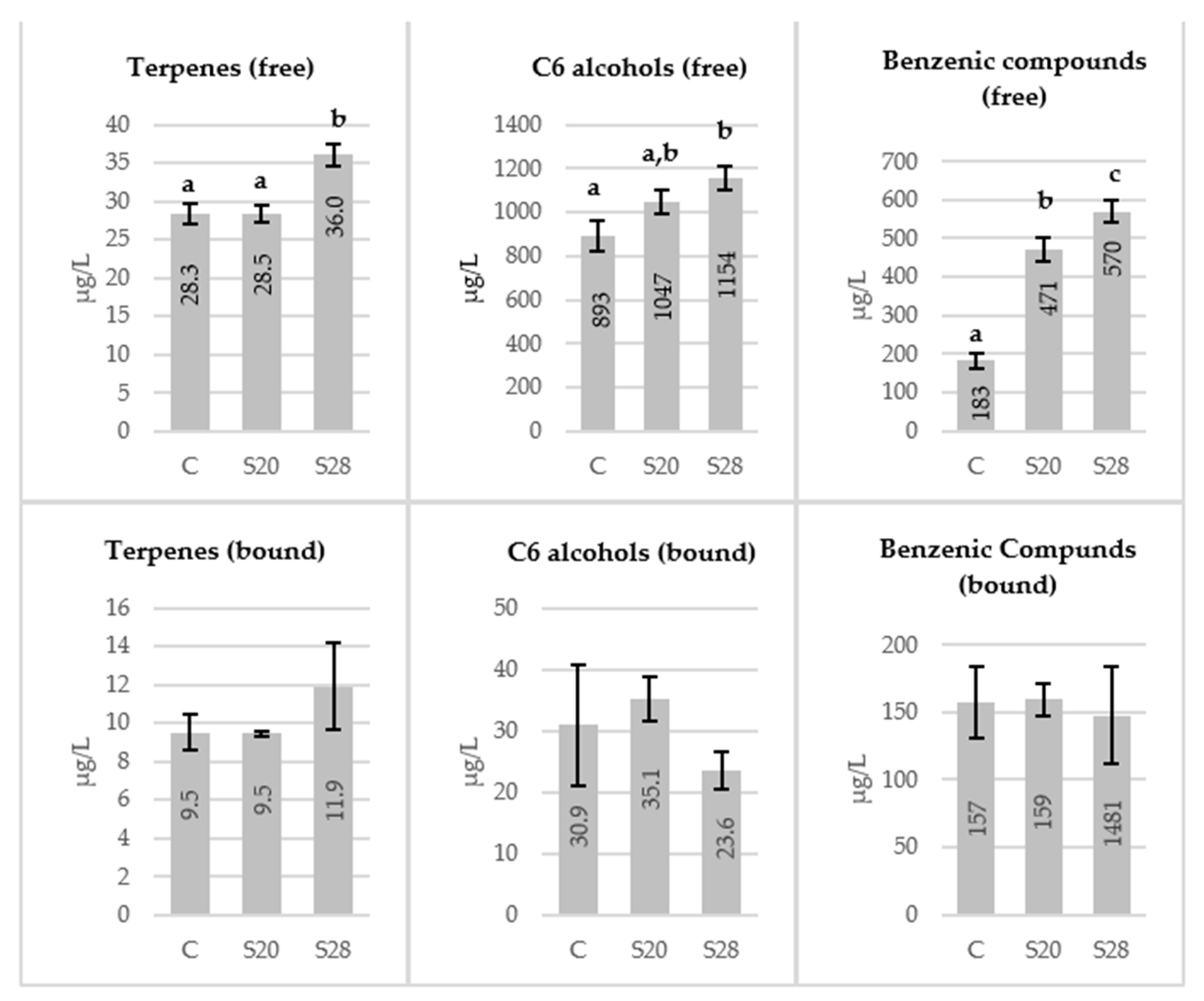

2.1. Effect of Ultrasounds Treatment on Free and Glycosidically Bound Volatile Compounds of Musts

2.2. Effect of Ultrasounds Treatment on Free and Glycosidically Bound Volatile Compounds of Control Wines and Those Made from Sonicated Grapes

2.3. Effect of Ultrasound Treatment on Volatile Compounds Formed during Alcoholic Fermentation of Control and Wines from Sonicated Grapes

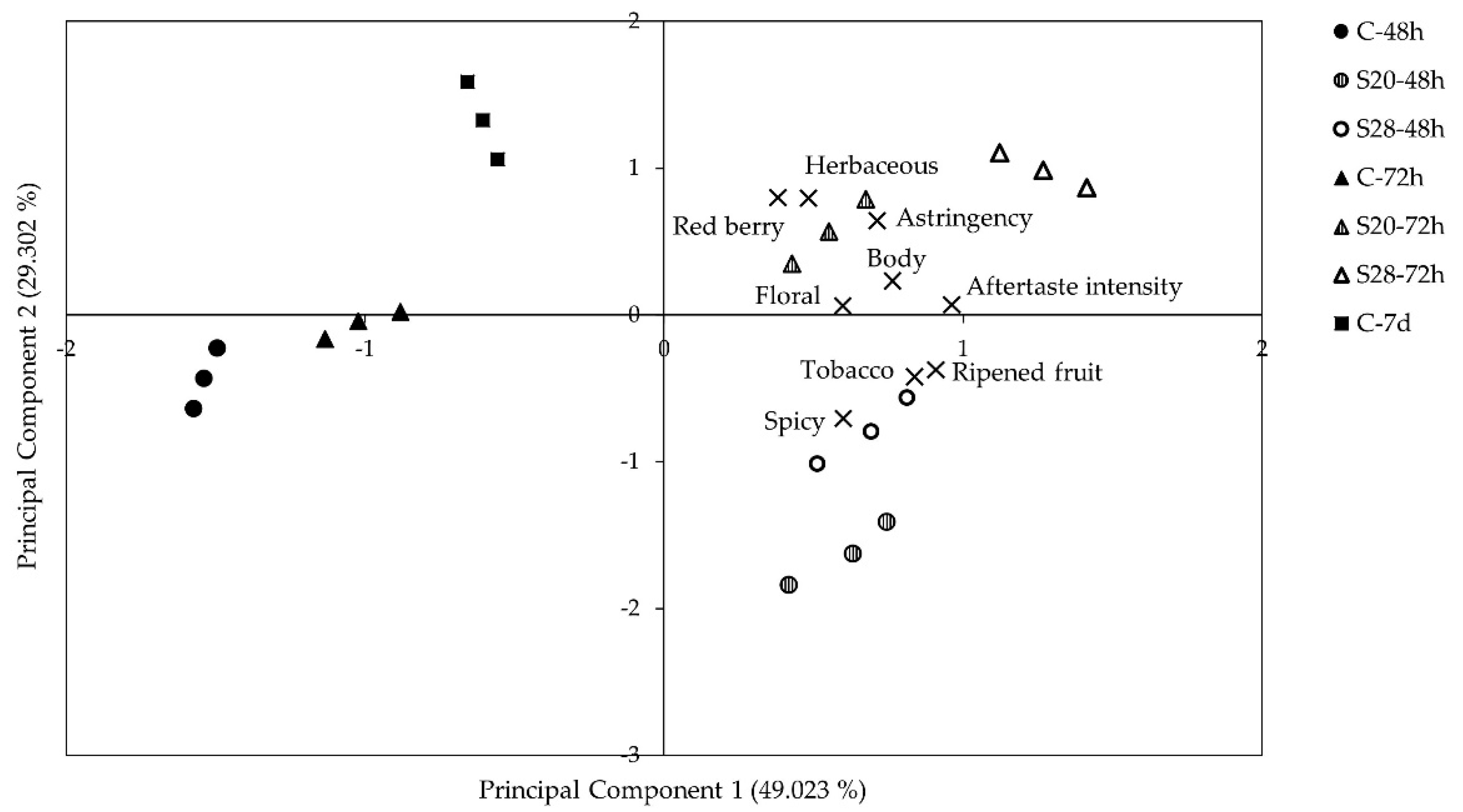

2.4. Sensorial Analysis of Control and Wines from Sonicated Grapes

3. Materials and Methods

3.1. Grape Samples

3.2. Winemaking Process

3.3. Isolation of Free and Glycosidically-Bound Minor Volatile Compounds

3.3.1. Solid Phase Extraction of Free Volatile Compounds

3.3.2. Solid Phase Extraction of Glycosidically-Bound Volatile Compounds

3.4. Gas Chromatography-Mass Spectrometry (GC-MS)

3.5. Sensory Descriptive Analysis

3.6. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baumes, R. Wine aroma precursors. In Wine Chemistry and Biochemistry; Moreno Arribas, M.V., Polo, M.C., Eds.; Springer Science & Business Media LLD.: Berlin, Germany, 2009; pp. 251–274. [Google Scholar] [CrossRef]

- Hjelmeland, A.K.; Ebeler, S.E. Glycosidically Bound Volatile Aroma Compounds in Grapes and Wine: A Review. Am. J. Enol. Vitic. 2015, 66, 1–11. [Google Scholar] [CrossRef]

- Sánchez Palomo, E.; Díaz-Maroto, M.C.; González-Viñas, M.A.; Pérez-Coello, M.S. Aroma enhancement in wines from different grape varieties using exogenous glycosidases. Food Chem. 2005, 95, 627–635. [Google Scholar] [CrossRef]

- Ugliano, M.; Bartowsky, E.J.; Mccarthy, J.; Moio, L.; Henschke, P.A. Hydrolysis and Transformation of Grape Glycosidically Bound Volatile Compounds during Fermentation with Three Saccharomyces Yeast Strains. J. Agric. Food Chem. 2006, 54, 6322–6331. [Google Scholar] [CrossRef]

- Sánchez Palomo, E.; González-Viñas, M.A.; Díaz-Maroto, M.C.; Soriano Pérez, A.; Pérez-Coello, M.S. Aroma potential of Albillo wines and effect of skin-contact treatment. Food Chem. 2007, 103, 631–640. [Google Scholar] [CrossRef]

- Sachi, K.L.; Bisson, L.F.; Adams, D.O. A review of the effect of winemaking techniques on phenolic extraction in red wines. Am. J. Enol. Vitic. 2005, 56, 197–206. [Google Scholar] [CrossRef]

- Atanackovic, M.; Petrovic, A.; Jovic, S.; Gojkovic-Bukarica, L.; Bursac, M.; Cvejic, J. Influence of winemaking techniques on the resveratrol content, total phenolic content and antioxidant potential of red wines. Food Chem. 2012, 131, 513–518. [Google Scholar] [CrossRef]

- Parenti, A.; Spugnoli, P.; Calamai, L.; Ferrari, S.; Gori, C. Effects of cold maceration on red wine quality from Tuscan Sangiovese grape. Eur. Food Res. Techn. 2004, 218, 360–366. [Google Scholar] [CrossRef]

- Tartian, A.C.; Cotea, V.V.; Niculaua, M.; Zamfir, C.I.; Colibaba, C.L.; Moros, A.M. The influence of the different techniques of maceration on the aromatic and phenolic profile of the Busuioaca de Bohotin wine. In Proceedings of the BIO Web of Conferences. 40th World Congress of Vine and Wine, Sofia, Bulgaria, 29 May–2 June 2017; Volume 9, p. 02032. [Google Scholar] [CrossRef]

- Geffroy, O.; Lopez, R.; Serrano, E.; Dufourcq, T.; Gracia-Moreno, E.; Cacho, J.; Ferreira, V. Changes in analytical and volatile compositions of red wines induced by pre-fermentation heat treatment of grapes. Food Chem. 2015, 187, 243–253. [Google Scholar] [CrossRef] [PubMed]

- Geffroy, O.; Lopez, R.; Feilhes, C.; Violleau, F.; Kleiber, D.; Favarel, J.L.; Ferreira, V. Modulating analytical characteristics of thermovinified Carignan musts and the volatile composition of the resulting wines through the heating temperature. Food Chem. 2018, 257, 7–14. [Google Scholar] [CrossRef]

- Carew, A.L.; Gill, W.; Close, D.C.; Dambergs, R.G. Microwave maceration with early pressing improves phenolics and fermentation kinetics in Pinot noir. Am. J. Enol. Vitic. 2014, 65, 401–406. [Google Scholar] [CrossRef]

- Comuzzo, P.; Marconi, M.; Zanella, G.; Querzè, M. Pulsed electric field processing of white grapes (cv. Garganega): Effects on wine composition and volatile compounds. Food Chem. 2018, 264, 16–23. [Google Scholar] [CrossRef]

- OIV. Treatment of Crushed Grapes with Ultrasound to Promote the Extraction of Their Compounds; Resolution OIV-OENO 616-2019; OIV: Paris, France, 2019. [Google Scholar]

- Tao, Y.; Zhang, Z.; Sun, D.W. Experimental and modeling studies of ultrasound assisted release of phenolics from oak chips into model wine. Ultrason. Sonochem. 2014, 21, 1839–1848. [Google Scholar] [CrossRef]

- Paniwnyk, L. Applications of ultrasound in processing of liquid foods: A review. Ultrason. Sonochem. 2017, 38, 794–806. [Google Scholar] [CrossRef] [PubMed]

- Morata, A.; Loira, I.; Vejarano, R.; Gonzalez, C.; Callejo, M.J.; Suarez-Lepe, J.A. Emerging preservation technologies in grapes for winemaking. Trends Food Sci. Technol. 2017, 67, 36–43. [Google Scholar] [CrossRef]

- Hasan, M.H.; Yun, H.K.; Kwak, E.J.; Baek, K.H. Preparation of resveratrol-enriched grape juice from ultrasonication treated grape fruits. Ultrason. Sonochem. 2014, 21, 729–734. [Google Scholar] [CrossRef]

- Ojha, K.S.; Mason, T.J.; O’Donnell, C.P.; Kerry, J.P.; Tiwari, B.K. Ultrasound technology for food fermentation applications. Ultrason. Sonochem. 2017, 34, 410–417. [Google Scholar] [CrossRef] [PubMed]

- Jiranek, V.; Grbin, P.; Yap, A.; Barnes, M.; Bates, D. High power ultrasonics as a novel tool offering new opportunities for managing wine microbiology. Biotechnol. Lett. 2008, 30, 1–6. [Google Scholar] [CrossRef]

- Luo, H.; Schmid, F.; Grabin, P.R.; Jiranek, V. Viability of common wine spoilage organisms after exposure to high power ultrasonics. Ultrason. Sonochem. 2012, 19, 415–420. [Google Scholar] [CrossRef] [PubMed]

- García Martín, J.F.; Sun, D.W. Ultrasound and electric fields as novel techniques for assisting the wine ageing process: The state-of-the-art research. Trends Food Sci. Technol. 2013, 33, 40–53. [Google Scholar] [CrossRef]

- Tao, Y.; Sun, D.W. Enhancement of Food Processes by Ultrasound: A Review. Crit. Rew. Food Sci. Nut. 2015, 55, 570–594. [Google Scholar] [CrossRef] [PubMed]

- Bautista-Ortín, A.B.; Jiménez-Martínez, M.D.; Jurado, R.; Iniesta, J.A.; Terrades, S.; Andrés, A.; Gómez-Plaza, E. Application of high-powder ultrasounds during red wine vinification. Int. J. Food Sci. Technol. 2017, 52, 1314–1323. [Google Scholar] [CrossRef]

- Pérez-Porras, P.; Bautista-Ortín, B.; Jurado, R.; Gómez-Plaza, E. Using high-power ultrasounds in red winemaking: Effect of operating conditions on wine physico-chemical and chromatic characteristics. LWT 2021, 138, 110645–110653. [Google Scholar] [CrossRef]

- Martínez-Pérez, M.P.; Bautista-Ortín, A.B.; Pérez-Porras, P.; Jurado, R.; Gómez-Plaza, E. A New Approach to the Reduction of Alcohol Content in Red Wines: The Use of High-Power Ultrasounds. Foods 2020, 9, 726–742. [Google Scholar] [CrossRef]

- Jambrak, A.R.; Simunek, M.; Petrovic, M.; Bedic, H.; Herceg, Z.; Juretic, H. Aromatic profile and sensory characterisation of ultrasound treated cranberry juice and nectar. Ultrason. Sonochem. 2017, 38, 783–793. [Google Scholar] [CrossRef]

- Chouliara, E.; Georgogianni, K.G.; Kanellopoulou, N.; Kontominas, M.G. Effect of ultrasonication on microbiological, chemical and sensory properties of raw, thermized and pasteurized milk. Int. Dairy J. 2010, 20, 307–313. [Google Scholar] [CrossRef]

- Jahouach-Rabal, W.; Trabelsi, M.; Adams, A.; Verthé, R.; De Kimpe, N.; Frikha, M.H. Influence of bleaching by ultrasound on fatty acids and minor compounds of olive oil. Qualitative and quantitative analysis of volatile compounds (by SPME coupled to GC/MS). Ultrason. Sonochem. 2008, 15, 590–597. [Google Scholar] [CrossRef]

- Zhang, Q.A.; Shen, Y.; Fan, X.H.; García Martín, J.F. Preliminary study of the effect of ultrasound on physicochemical properties of red wine. CyTA J. Food. 2016, 14, 55–64. [Google Scholar] [CrossRef]

- Cui, Y.; Lv, W.; Liu, J.; Wang, B. Effect of different ending fermentation technologies on microbial stability of Italian Riesling low alcohol sweet white wine. Adv. Mat. Res. 2012, 1165, 393–395. [Google Scholar] [CrossRef]

- Ruiz-Rodríguez, A.; Carrera, C.; Palma-Lovillo, M.; García Barroso, C. Ultrasonic treatments during the alcoholic fermentation of red wines: Effects on ‘Syrah’ wines. Vitis 2019, 58, 83–88. [Google Scholar] [CrossRef]

- Roman, T.; Tonidandel, L.; Nicolini, G.; Bellantuono, E.; Barp, L.; Larcher, R.; Celotti, E. Evidence of the Possible Interaction between Ultrasound and Thiol Precursors. Foods 2020, 9, 104–116. [Google Scholar] [CrossRef]

- González-Centeno, M.R.; Knoerzer, K.; Sabarez, H.; Simal, S.; Rossell’o, C.; Femenia, A. Effect of acoustic frequency and power density on the aqueous ultrasonic-assisted extraction of grape pomace (Vitis vinifera L.) a response surface approach. Ultrason. Sonochem. 2014, 21, 2176–2184. [Google Scholar] [CrossRef] [PubMed]

- Celotti, E.; Ferraretto, P. Studies for the ultrasound application in winemaking for a low impact enology. In Proceedings of the 39th World Congress of Vine and Wine, Bento Gonçalves, Brazil, 24–28 October 2016; pp. 104–106. [Google Scholar]

- Wu, Z.; Ondruschka, B.; Stark, A. Ultrasonic cleavage of thioethers. J. Phys. Chem. A 2005, 109, 3762–3766. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Sicaire, A.G.; Meullemiestre, A.; Fabiano-Tixier, A.S.; Abert-Vian, M. Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef]

- Ferreira, V. Volatile aroma compounds and wine sensory attributes. In Managing Wine Quality, Volume II: Oenology and Wine Quality; Andrew, G.R., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2010; pp. 3–28. [Google Scholar] [CrossRef]

- Loscos, N.; Hernández-Orte, P.; Cacho, J.; Ferreira, V. Release and formation of varietal aroma compounds during alcoholic fermentation from nonfloral grape odorless flavor precursors fractions. J. Agric. Food Chem. 2007, 55, 6674–6684. [Google Scholar] [CrossRef] [PubMed]

- Bayonove, C.; Baumes, R.; Crouzet, J.; Günata, Z. Aromas. In Enología: Fundamentos Científicos y Tecnológicos; Flanzy, C., Ed.; AMV Ediciones, Mundi Prensa: Madrid, Spain, 2000; pp. 137–176. [Google Scholar]

- Guth, H. Quantification and sensory studies of character impact odorants of different white varieties. J. Agric. Food Chem. 1997, 45, 3027–3032. [Google Scholar] [CrossRef]

- Ferreira, V.; Lopez, R.; Cacho, J.F. Quantitative determination of the odorants of young red wines from different grape varieties. J. Sci. Food Agric. 2000, 80, 1659–1667. [Google Scholar] [CrossRef]

- Schneider, R.; Razungles, A.; Augier, C.; Baumes, R. Monoterpenic and norisoprenoidic glycoconjugates of Vitis vinífera L. cv. Melon B. as precursors of odorants in Muscadet wines. J. Chromatogr. A 2001, 936, 145–157. [Google Scholar] [CrossRef]

- Campo, E.; Cacho, J.; Ferreira, V. Multidimensional chromatographic approach applied to the identification of novel aroma compounds in wine. Identification of ethyl cyclohexanoate, ethyl 2hydroxy3methylbutyrate and ethyl 2hydroxy4methylpentanoate. J. Chromatogr. A 2006, 1137, 223–230. [Google Scholar] [CrossRef] [PubMed]

- Falcao, L.D.; Lytra, G.; Darriet, P.; Barbe, J.C. Identification of ethyl 2hydroxy4methylpentanoate in red wines, a compound involved in blackberry aroma. Food Chem. 2012, 132, 230–236. [Google Scholar] [CrossRef]

- Pozzatti, M.; Guerra, C.C.; Martins, G.; dos Santos, I.D.; Wagner, R.; Ferrão, M.F.; Manfroi, V. Effects of winemaking on ‘Marselan’ red wines: Volatile compounds and sensory aspects. Ciência Téc. Vitiv. 2020, 35, 63–75. [Google Scholar] [CrossRef]

- Buttery, R.G.; Orts, G.W.J.; Takeoka, G.R.; Nam, Y. Volatile flavor components of rice cakes. J. Agric. Food Chem. 1999, 47, 4353–4356. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, S.; Crowell, E.A.; Ough, C.S.; Totsuka, A. Quantitative analysis of-nonalactone in wines and its threshold determination. J. Food Sci. 1988, 53, 124–244. [Google Scholar] [CrossRef]

- Silva Ferreira, A.C.; Rodrigues, P.; Hogg, T.; Guedes De Pinho, P. Influence of Some Technological Parameters on the Formation of Dimethyl Sulfide, 2-Mercaptoethanol, Methionol, and Dimethyl Sulfone in Port Wines. J. Agric. Food Chem. 2003, 51, 727–732. [Google Scholar] [CrossRef] [PubMed]

- Slaghenaufi, D.; Ugliano, M. Norisoprenoids, Sesquiterpenes and Terpenoids Content of Valpolicella Wines During Aging: Investigating Aroma Potential in Relationship to Evolution of Tobacco and Balsamic Aroma in Aged Wine. Front. Chem. 2018, 6, 66. [Google Scholar] [CrossRef]

- Díaz-Maroto, M.C.; Guchu, M.; Castro-Vázquez, L.; de Torres, M.C.; Pérez-Coello, M.S. Aroma-active compounds of American, French, Hungarian and Russian oak woods, studied by GC–MS and GC–O. Flavour Fragr. J. 2008, 23, 93–98. [Google Scholar] [CrossRef]

- Gracin, L.; Jambrak, A.R.; Juretic, H.; Dobrovic, S.; Barukcic, I.; Grozdanovic, M.; Smoljanic, G. Influence of high power ultrasound on Brettanomyces and lactic acid bacteria in wine in continuous flow treatment. Appl. Acoust. 2016, 103, 143–147. [Google Scholar] [CrossRef]

| Volatile Compounds | C-48 | S20-48 | S28-48 | C-72 | S20-72 | S28-72 | C-7d |

|---|---|---|---|---|---|---|---|

| Mean ± SD | Mean ± SD | Mean ± SD | Mean ± SD | Mean ± SD | Mean ± SD | Mean ± SD | |

| 1-hexanol | 1678 ± 239 a | 2159 ± 9 b,c | 2395 ± 57 c | 2001 ± 133 a,b,c | 1819 ± 88 a,b | 1784 ± 159 a,b | 2003 ± 298 a,b,c |

| cis-3-hexen-1-ol | 65.3 ± 9.1 a | 84.8 ± 0.4 a | 80.7 ± 7.0 a | 75.8 ± 5.8 a | 68.1 ± 2.8 a | 105 ± 5 b | 74.1 ± 15.7 a |

| trans-3-hexen-1-ol | 24.3 ± 1.2 a | 34.0 ± 1.4 b,c | 29.3 ± 3.7 a,b | 21.2 ± 1.0 a | 22.6 ± 2.1 a | 40.8 ± 8.5 c | 22.7 ± 4.6 a |

| cis-2-hexen-1ol | 8.5 ± 0.5 a | 10.5 ± 0.8 b | 8.4 ± 0.6 a | 10.1 ± 0.3 b | 8.0 ± 0.2 a | 10.2 ± 0.4 b | 13.7 ± 0.6 c |

| trans-2-hexen-1ol | 13.0 ± 1.5 a | 21.3 ± 0.5 b,c | 23.6 ± 2.7 c | 18.6 ± 3.4 b | 16.1 ± 0.6 a,b | 17.3 ± 2.3 a,b | 18.4 ± 2.7 b |

| Σ C6-alcohols | 1789 ± 248 a | 2310 ± 10 b,c | 2537 ± 71 c | 2127 ± 138 a,b,c | 1934 ± 84 a,b | 1958 ± 164 a,b | 2132 ± 322 a,b,c |

| linalool | 12.4 ± 1.3 b | 13.4 ± 0.6 b,c | 14.8 ± 0.2 c,d | 15.5 ± 1.0 d | 13.0 ± 0.0 b,c | 3.9 ± 0.5 a | 14.4 ± 1.1 c,d |

| 4-terpineol | 13.8 ± 3.2 b | 14.2 ± 0.8 b | 13.8 ± 0.8 b | 20.9 ± 1.8 c | 13.4 ± 1.2 b | 5.3 ± 0.3 a | 15.3 ± 0.3 b |

| α-terpineol | 6.4 ± 1.1 a | 6.3 ± 0.6 a | 6.3 ± 0.7 a | 6.3 ± 0.6 a | 8.6 ± 3.2 a | 6.1 ± 1.3 a | 8.0 ± 1.2 a |

| citronellol | 20.9 ± 5.5 b,c | 23.7 ± 4.4 b,c | 21.8 ± 1.2 b,c | 24.3 ± 1.0 b,c | 29.5 ± 6.7 c | 7.8 ± 0.3 a | 17.5 ± 0.0 b |

| trans-geraniol | 4.9 ± 0.5 a | 5.1 ± 0.2 a | 4.3 ± 0.3 a | 6.8 ± 1.5 b | 4.3 ± 0.4 a | 7.8 ± 0.2 b | 6.5 ± 0.5 b |

| hydroxylinalool | 7.4 ± 1.2 c | 4.7 ± 0.5 b | 5.9 ± 0.4 b,c | 6.4 ± 0.3 b,c | 4.7 ± 0.6 b | 2.8 ± 0.2 a | 5.9 ± 1.0 b,c |

| hydroxycitronellol | 4.0 ± 0.4 b,c | 3.6 ± 0.1 a,b,c | 4.3 ± 0.2 c | 4.5 ± 0.5 c | 2.9 ± 0.6 a,b | 2.7 ± 0.2 a | 4.5 ± 1.1 c |

| geranyl acetate | 19.3 ± 2.7 d | 15.2 ± 0.8 c | 12.7 ± 3.1 b,c | 2.2 ± 0.1 a | 15.7 ± 0.2 c | 10.2 ± 0.0 b | 13.1 ± 1.5 b,c |

| α-ionone | 5.4 ± 0.3 d | 1.0 ± 0.3 a | 1.1 ± 0.0 a | 1.4 ± 0.1 a,b | 2.4 ± 0.3 c | 1.0 ± 0.0 a | 1.6 ± 0.1 b |

| vitispirane | 3.0 ± 1.2 a | 11.1 ± 0.3 c | 5.2 ± 1.0 b | 2.3 ± 0.5 a | 2.4 ± 1.1 a | ND | 0.60 ± 1.06 c |

| β-damascenone | 7.3 ± 0.2 b | 7.1 ± 0.2 b | 7.3 ± 0.1 b | 7.3 ± 1.4 b | 5.6 ± 0.0 b | 2.6 ± 1.3 c | 6.2 ± 0.0 b |

| 3-oxo-α-ionol | 7.3 ± 0.4 a | 20.0 ± 11.5 b,c | 13.0 ± 0.5 a,b | 10.4 ± 0.9 a,b | 8.3 ± 1.0 a,b | 25.1 ± 3.2 c | 15.2 ± 3.2 a,b,c |

| 3-hydroxy-7,8-dihydro β-ionol | 46.6 ± 7.3 b | 69.4 ± 4.0 c | 61.0 ± 0.6 c | 29.5 ± 6.8 a | 29.1 ± 4.6 a | 27.7 ± 0.6 a | 59.7 ± 10.4 c |

| 2,3-dehydro-4-oxo-β-ionol | 1.4 ± 0.4 a | ND | ND | 1.5 ± 0.2 a | 1.5 ± 0.0 a | 1.9 ± 0.2 b | ND |

| Σ Terpenes and norisoprenoids | 160 ± 1 b,c | 195 ± 12 d | 171 ± 8 c | 139 ± 8 b | 141 ± 7 b | 104 ± 5 a | 171 ± 19 c |

| benzaldehyde | 57.2 ± 4.9 b,c | 66.6 ± 0.0 c | 14.2 ± 3.1 a | 38.3 ± 25.1 b | 43.0 ± 6.4b | 8.0 ± 1.3 a | 14.4 ± 0.4 a |

| guaiacol | 236 ± 75 b | 220 ± 1 b | 175 ± 11 a,b | 101 ± 10 a | 462 ± 51 c | 134 ± 10 a | 180 ± 30 a,b |

| benzyl alcohol | 208 ± 10 a | 322 ± 0 b | 298 ± 38 b | 312 ± 43 b | 275 ± 2 b | 261 ± 27 b | 456 ± 14 c |

| 4-vinylguaiacol | 248 ± 62 a | 385 ± 2 a | 226 ± 168 a | 216 ± 44 a | 204 ± 18 a | 245 ± 31 a | 388 ± 58 a |

| syringol | 613 ± 122 a | 459 ± 25 a | 415 ± 16 a | 171 ± 21 a | 607 ± 326 a | 745 ± 203 a | 464 ± 94 a |

| vanillin | 16.8 ± 4.8 b | 17.8 ± 2.7 b,c | 11.8 ± 3.2 a,b | 23.7 ± 2.4 d | 18.3 ± 0.8 b,c | 7.1 ± 2.8 a | 7.3 ± 1.3 a |

| methyl vanillate | 11.5 ± 1.1 a | 13.0 ± 0.3 a | 12.6 ± 0.0 a | 11.7 ± 1.5 a | 10.0 ± 0.5 a | 10.8 ± 0.1 a | 13.0 ± 2.8 a |

| ethyl vanillate | 154 ± 21 b,c | 164 ± 11 c | 131 ± 10 b,c | 137 ± 25 b,c | 119 ± 1.8 b | 52.2 ± 5.3 a | 162 ± 15 c |

| Σ Benzenic compounds | 1545 ± 263a | 1649 ± 35 a | 1285 ± 229 a | 1238 ± 66a | 1738 ± 406 a | 1464 ± 156 a | 1715 ±3 7 a |

| Volatile Compounds | C-48 | S20-48 | S28-48 | C-72 | S20-72 | S28-72 | C-7d |

|---|---|---|---|---|---|---|---|

| Mean ± SD | Mean ± SD | Mean ± SD | Mean ± SD | Mean ± SD | Mean ± SD | Mean ± SD | |

| 2-hexenal | 1.5 ± 0.2 b | 0.33 ± 0.05 a | ND | 1.0 ± 0.1 b | 2.3 ± 0.6 c | 1.4 ± 0.2 b | ND |

| 1-hexanol | 13.1 ± 1.0 c | 16.7 ± 0.8 a | 4.9 ± 0.6 a | 11.2 ± 2.5 b,c | 9.6 ± 1.4 b | 9.5 ± 1.7 b | 5.2 ± 1.4 a |

| cis-2-hexen-1-ol | 2.6 ± 0.2 c | 0.94 ± 0.03 a | 0.83 ± 0.04 a | 2.2 ± 0.5 b,c | 1.8 ± 0.3 b | 1.6 ± 0.3 b | 1.1 ± 0.3 a |

| Σ C6-alcohols and aldehydes | 17.2 ± 1.3 c,d | 18.0 ± 1.0 d | 5.8 ± 0.6 a | 14.4 ± 2.9 b,c,d | 16.6 ± 2.1 b,c | 12.8 ± 1.1 b | 6.2 ± 1.7 a |

| nerol | 1.4 ± 0.1 b | 0.61 ± 0.00 a | 0.49 ± 0.09 a | 1.6 ± 0.2 b | 1.6 ± 0.3 b | 1.4 ± 0.1 b | 0.62 ± 0.10 a |

| geraniol | 3.4 ± 0.2 a,b | 1.9 ± 0.4 a | 1.8 ± 0.1 a | 5.1 ± 1.6 b | 4.2 ± 0.8 b | 4.2 ± 1.1 b | 1.5 ± 0.1 a |

| hydroxylinalool | 0.98 ± 0.15 a | 0.67 ± 0.06 a | 0.55 ± 0.08 a | 1.1 ± 0.3 a | 0.95 ± 0.08 a | 2.1 ± 1.2 b | 0.72 ± 0.18 a |

| geranic acid | 3.6 ± 0.4 a | 3.0 ± 0.4 a | 5.2 ± 1.9 a | 4.1 ± 0.4 a | 5.2 ± 2.1 a | 11.1 ± 1.5 b | 3.3 ± 0.1 a |

| geranyl acetate | 4.4 ± 0.7 a | 3.7 ± 0.3 a | 5.1 ± 1.2 a | 4.3 ± 0.3 a | 3.8 ± 0.1 a | 7.1 ± 0.7 a | 7.2 ± 1.7 a |

| TDN | ND | 0.30 ± 0.01 b | 0.37 ± 0.06 b | 0.08 ± 0.01 a | 0.03 ± 0.00 a | 0.05 ± 0.05 a | 0.35 ± 0.04 b |

| α-ionone | 1.2 ± 0.0 a | 1.1 ± 0.3 a | 1.2 ± 0.1 a | ND | 1.9 ± 0.3 a | 1.4 ± 0.4 a | 3.7 ± 1.1 b |

| β-damascenone | 0.93 ± 0.05 a,b | 0.84 ± 0.23 a,b | 0.60 ± 0.06 a | 1.07 ± 0.16 b | 0.87 ± 0.24 a,b | 0.77 ± 0.01 a,b | ND |

| 3-oxo-α-ionol | 1.8 ± 0.3 c | 1.0 ± 0.2 a,b | 0.63 ± 0.05 a | 1.7 ± 0.4 c | 1.4 ± 0.2 b,c | 4.8 ± 0.3 d | 0.63 ± 0.18 a |

| 6,7-dehydro-7,8-dihydro-3-oxo-α-ionol | 9.0 ± 1.0 c,d | 2.6 ± 0.2 a | 4.7 ± 0.8 a,b,c | 9.8 ± 2.2 d | 7.7 ± 2.3 b,c,d | 22.4 ± 4.3e | 3.8 ± 0.4 a,b |

| Σ Terpenes and norisoprenoids | 26.7 ± 1.7 a | 15.7 ± 0.1 a | 20.6 ± 3.8 a | 28.9 ± 1.2 a | 27.5 ± 4.4 a | 55.2 ± 14.0 b | 21.7 ± 0.3 a |

| benzaldehyde | 1.5 ± 0.2 a | 2.1 ± 0.6 b | 2.8 ± 0.2 c | 1.2 ± 0.2 a | 1.6 ± 0.1 a | 1.3 ± 0.2 a | 1.1 ± 0.2 a |

| guaiacol | 54.0 ± 4.4 c | 10.1 ± 2.4 a | 25.0 ± 4.0 b | 61.6 ± 11.4 c | 78.6 ± 4.7 d | 50.4 ± 0.8 c | 7.6 ± 0.8 a |

| benzyl alcohol | 8.1 ± 0.7 b,c | 5.4 ± 0.1 a | 4.8 ± 0.7 a | 9.2 ± 1.3 c | 7.9 ± 0.2 b,c | 7.6 ± 0.5 b | 7.3 ± 0.3 b |

| 2-phenylethanol | 119 ± 7 b | 65.4 ± 15.1 b,c | 62.8 ± 8.2 b,c | 244 ± 44 d | 83.2 ± 14.9 b,c | 116 ± 31 b | 58.7 ± 6.2 a |

| 4-vinylguaiacol | 55.8 ± 15.5 b | 14.0 ± 0.8 a | 18.6 ± 6.2 a | 53.0 ± 5.1 b | 51.3 ± 1.5 b | 98.7 ± 27.9 c | 11.4 ± 0.3 a |

| syringol | 57.7 ± 9.3 a,b | 44.9 ± 1.4 a | 58.4 ± 32.0 a,b | 168 ± 26 c | 73.5 ± 20.7 a,b | 138 ± 83 b,c | 29.3 ± 4.6 a |

| vanillin | 19.7 ± 0.6 a | 18.7 ± 1.4 a | 10.8 ± 0.9 a | 20.6 ± 3.7 a | 16.6 ± 2.3 a | 47.5 ± 4.2 b | 18.4 ± 8.4 a |

| methyl vanillate | 13.1 ± 2.1 a | 9.7 ± 1.0 a | 10.1 ± 0.4 a | 13.1 ± 3.9 a | 15.8 ± 0.8 a | 33.2 ± 10.6 b | 8.5 ± 2.6 a |

| Σ Benzenic compounds | 329 ± 12 b | 170 ± 9 a | 193 ± 34 a | 572 ± 63 d | 329 ± 26 b | 493 ± 68 c | 142 ± 23 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliver Simancas, R.; Díaz-Maroto, M.C.; Alañón Pardo, M.E.; Pérez Porras, P.; Bautista-Ortín, A.B.; Gómez-Plaza, E.; Pérez-Coello, M.S. Effect of Power Ultrasound Treatment on Free and Glycosidically-Bound Volatile Compounds and the Sensorial Profile of Red Wines. Molecules 2021, 26, 1193. https://doi.org/10.3390/molecules26041193

Oliver Simancas R, Díaz-Maroto MC, Alañón Pardo ME, Pérez Porras P, Bautista-Ortín AB, Gómez-Plaza E, Pérez-Coello MS. Effect of Power Ultrasound Treatment on Free and Glycosidically-Bound Volatile Compounds and the Sensorial Profile of Red Wines. Molecules. 2021; 26(4):1193. https://doi.org/10.3390/molecules26041193

Chicago/Turabian StyleOliver Simancas, Rodrigo, María Consuelo Díaz-Maroto, María Elena Alañón Pardo, Paula Pérez Porras, Ana Belén Bautista-Ortín, Encarna Gómez-Plaza, and María Soledad Pérez-Coello. 2021. "Effect of Power Ultrasound Treatment on Free and Glycosidically-Bound Volatile Compounds and the Sensorial Profile of Red Wines" Molecules 26, no. 4: 1193. https://doi.org/10.3390/molecules26041193

APA StyleOliver Simancas, R., Díaz-Maroto, M. C., Alañón Pardo, M. E., Pérez Porras, P., Bautista-Ortín, A. B., Gómez-Plaza, E., & Pérez-Coello, M. S. (2021). Effect of Power Ultrasound Treatment on Free and Glycosidically-Bound Volatile Compounds and the Sensorial Profile of Red Wines. Molecules, 26(4), 1193. https://doi.org/10.3390/molecules26041193