Review on the Use of Artificial Intelligence to Predict Fire Performance of Construction Materials and Their Flame Retardancy

Abstract

1. Introduction

2. Brief Description of Machine Learning

2.1. Operation of Machine Learning Models

2.2. Explanation of Descriptors

2.3. Evaluation of the Performance of AI/ML Models

3. Application of AI/ML in Fire Engineering

3.1. Concrete Elements/Structures

3.2. Steel Elements/Structures

3.3. Timber Elements/Structures

3.4. Composite Materials

3.5. Other Types of Elements/Structures

| Type of Structure | Method | Target Output | Descriptors/Input Parameters | Reference |

|---|---|---|---|---|

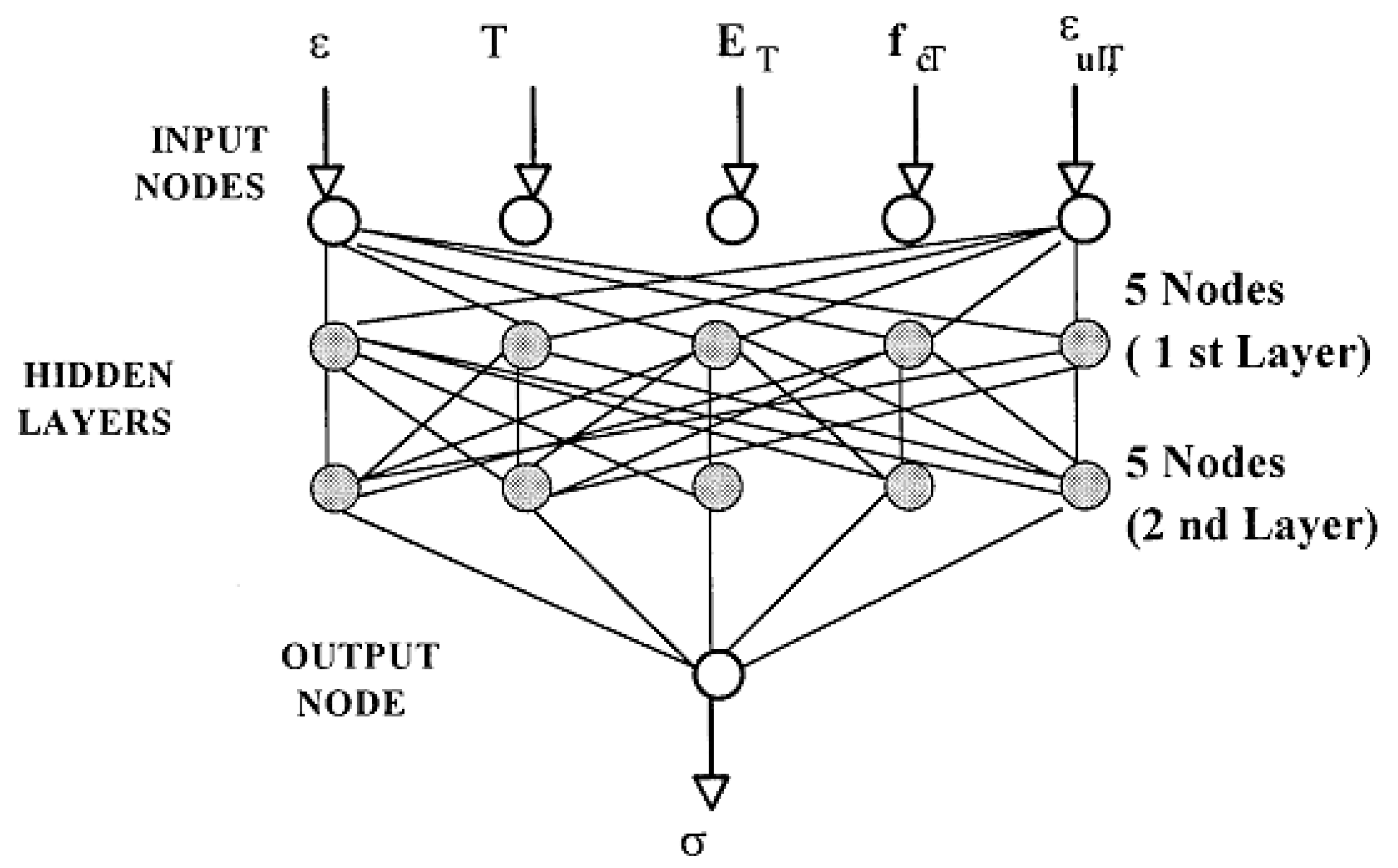

| Concrete material | Artificial neural networks | The stress (σ) | Strain (ε), temperature (T), elastic modulus (ET) at that temperature, compressive strength (fcT), and ultimate strain (εulT) | [32] |

| Concrete material | Artificial neural networks | The strain (ε) | Temperature (T), load level (h), modulus of elasticity (ET), compressive strength (fcT), ultimate strain (εulT), and the coefficient of the thermal expansion (ΩT) | [32] |

| Concrete material | Artificial neural networks | The restrained stress (σ) | Temperature (T), modulus of elasticity (ET), compressive strength (fcT), ultimate strain (εulT), thermal expansion coefficient (ΩT), and heating rate (λ) | [32] |

| Concrete material | Artificial neural networks | The loss of strength | Experimental parameters and environmental factors | [68] |

| Self-compacting concrete | Artificial neural networks | The compressive strength | The amount of cement, fly ash, zeolite, limestone powders, basaltic, marble powders, natural aggregate, group I aggregate, group II aggregate, polypropylene fibers, heating degree | [69] |

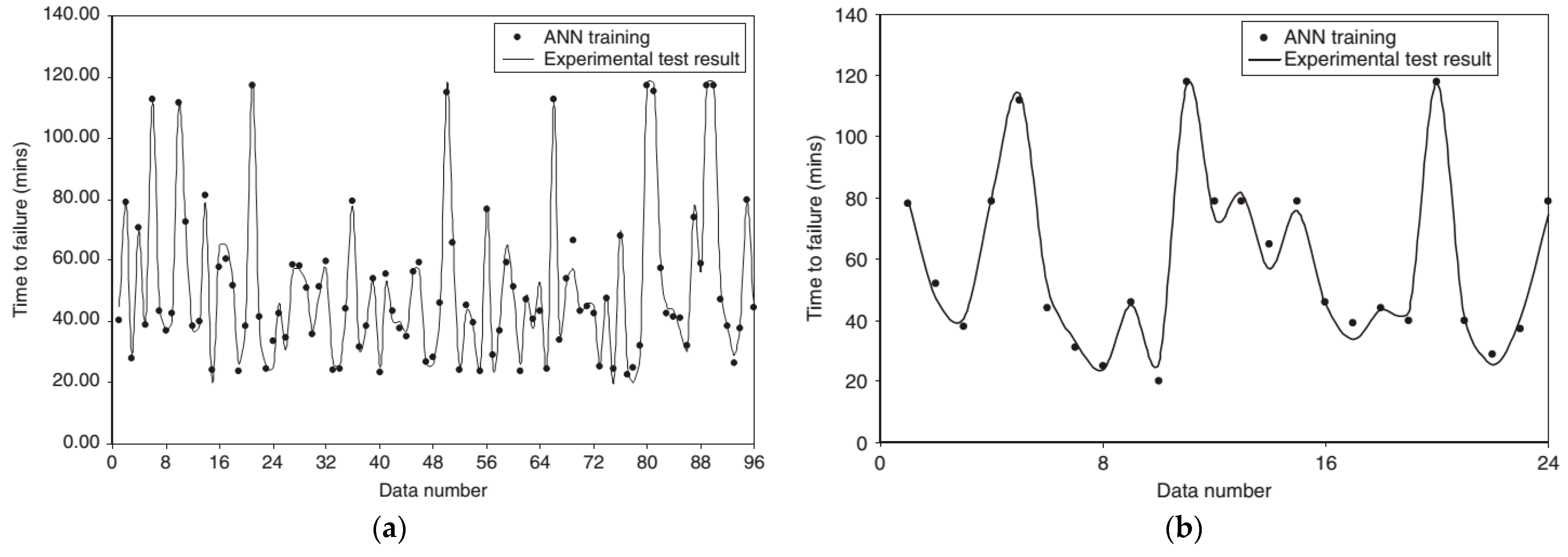

| High-strength concrete columns | Artificial neural networks | The spalling type | Furnace temperature, restraint, loading level, force, spalling degree, failure time, and spalling type | [70] |

| High-strength concrete columns | Artificial neural networks | The failure time | Furnace temperature, restraint, loading level, force, spalling degree, and failure time. | [70] |

| Reinforced-concrete columns | Artificial neural networks | The fire resistance of the column expressed in minutes (t) | Dimensions of the cross-section of the column (b and d), the concrete cover thickness (a), percentage of reinforcement (μ), load coefficient for axial force (η), and load coefficient for the bending moment (β). | [72] |

| Concrete-filled tubular steel columns | Backpropagation neural network | The fire resistance | Structural factors (external dimension, steel thickness, column height), material factors (water–cement ratio, type of aggregate, concrete 28 days cylinder strength, steel yield strength), loading conditions (test load) | [71] |

| Concrete slabs | Artificial neural networks | The ultimate moment capacity (Mu) | The distance from the extreme fiber in tension to the centroid of the steel on the tension side of the slab (d’), the effective depth (d), the ratio of previous parameters (d’/d), the area of reinforcement on the tension face of the slab (As), the fire exposure time (t), the compressive strength of the concrete (fcd), and the yield strength of the reinforcement (fyd) | [79] |

| Prismatic concrete beams | Artificial neural network, fuzzy logic, and fuzzy genetic models | The toughness (Tg) value of the prismatic beams | The fiber type used to prepare the specimen mixtures (Ft), curing period (Cp), temperature (T), volumetric fiber ratios in the mixture (FR), the compressive strength of the cylindrical specimens (fc) | [80] |

| Reinforced-concrete T-beams strengthened with carbon fiber-reinforced polymer (CFRP) plates | Artificial neural networks | The temperature at the interface between the CFRP/concrete | Insulation thicknesses, materials types, and fire curves | [81] |

| Structural steel | Artificial neural networks and genetic algorithms | Temperature-dependent material properties: thermal conductivity, specific heat, reduction factor for yield strength, and reduction factor for modulus of elasticity | Temperature | [84] |

| Steel frames | Artificial neural networks | The stress (σ) | Strain (ε) and temperature (T) | [85] |

| Steel tubular truss | Artificial neural networks | The limiting temperature | Diameter ratio (β), the wall thickness ratio (τ), the diameter–thickness ratio (γ), and the load ratio | [86] |

| Steel columns | Hybrid neural network and genetic algorithm | The failure temperature (T) | The length of the steel columns (L), the radius of Gyration of the cross-section (r), the sectional area (A), the yield strength of the material at room temperature (fy), the applied load (P), and the eccentricity of the load at failure (e) | [87] |

| Timber member | Artificial neural networks | The temperature in timber | The density of timber, the time of fire exposure, and the distance from the exposed surface | [88] |

| Timber material | Artificial neural network together with symbolic regressions and genetic algorithms | Mechanical properties (Reduction factors of density, Young’s modulus, compressive strength, tensile strength, and shear strength), thermal properties (thermal conductivity and specific heat), charring depth | Temperature | [89] |

| Timber floors | Artificial neural network together with symbolic regressions and genetic algorithms | The temperature in the plywood subfloor | Fire exposure duration (t), number of layers in ceiling finish (C), sub-floor thickness (kth), and type of cavity insulation (I) | [89] |

| Timber beams | Artificial neural network together with symbolic regressions and genetic algorithms | Mid-span deflection | Fire exposure time (t), load level (P), height (H), and charring rate (β) | [89] |

| Timber columns | Artificial neural network together with symbolic regressions and genetic algorithms | Fire resistance expressed in minutes | Column depth (D), column breadth (B), compressive strength (fc), specific gravity (SG), and level of applied loading (P) | [89] |

| Finger–joint timber connections | Artificial neural network together with symbolic regressions and genetic algorithms | Fire resistance expressed in minutes | The adhesive type (A), width (W), charring rate (β), and applied loading (P) | [89] |

| Nailed timber connection | Artificial neural network together with symbolic regressions and genetic algorithms | The slip of the connection (d) | Fire exposure time (t) and load level (P) | [89] |

| Redwood and Red Oak | Genetic algorithms and pyrolysis model | Surface temperature and mass loss rate | Thermal conductivity (kv), specific heat (cv), pre-exponential factor (Z), activation energy (EA), and heat of pyrolysis (ΔHp), char thermal conductivity (kc), char specific heat (cc), and char density (𝜌c) | [90] |

| Flexible polyurethane foam (Composite material) | Genetic algorithms | Kinetic and stoichiometric parameters | The reaction mechanism of thermal and oxidative degradation with thermogravimetric data | [91] |

| Polypropylene (Composite material) | Genetic algorithms and pyrolysis model | Surface temperature and mass loss rate | Thermal conductivity (kv), specific heat (cv), pre-exponential factor (Z), activation energy (EA), and heat of pyrolysis (ΔHp), char thermal conductivity (kc), char specific heat (cc), and char density (𝜌c) | [90] |

| Chitosan/graphene oxide layer-by-layer fire retardant coating on flexible polyurethane foam (composite material) | Genetic algorithms and computational fluid dynamics model | Thermal degradation rate, heat release rate, total heat release, smoke production rate, total smoke production, CO production rate, total CO production | Composition (ci), pre-exponential factor (Ai), activation energy (Ei), and exponent (ni) | [93] |

| Semi-rigid beam-to-column joints | Artificial neural network | The rotational capacity of the joint | The applied moment and joint’s temperatures | [94] |

| Semi-rigid composite joints | Artificial neural network: Backpropagation paradigm | The rotational capacity of the joints | The joint geometrical properties (beam depth, beam width, beam flange thickness, beam web thickness, column depth, column width, column flange thickness, column web thickness, number of bolts, bolt diameter, end-plate thickness, end-plate depth, end-plate width), the joint mechanical properties (beam yield strength, column yield strength), the joint’s temperature, and the applied moment | [95] |

| A single compartment fire | General regression neural network and fuzzy adaptive resonance theory | The location of the thermal interface, the height of the thermal interface, and different widths of the opening | The width and height of the sill of the opening, parallel and perpendicular distances from the center of the fire bed to the vertical centerline of the opening, fire strength, and ambient temperature | [96] |

| A single compartment fire | General regression neural network and fuzzy adaptive resonance theory | The velocity and temperature profiles at the center of the doorway | Width of opening, the height of the sill of the opening, fire strength, distance from the vertical centerline of the opening to the center of the fire bed, distance from the vertical centerline of the opening to the center of the fire load, and the ambient temperature | [97] |

4. Application of AI/ML for Flame-Retardant Materials

Existing Studies

5. Advantages and Challenges

6. Recommendation for Future Studies

7. Conclusions

- AI techniques have been extensively applied to evaluate the fire performance of different construction materials consisting of concrete, steel, timber, and composites, with encouraging results. AI-based models have also shown the potential to predict the behavior of a variety of structural components such as beams, columns, slabs, frames, trusses, and connections under fire scenarios.

- Some ML and AI algorithms have commonly been used in the evaluation of the behavior of materials/structural systems exposed to fires, including ANNs, the ANFIS, and the GA. While neural networks have mostly been applied to simulate the nonlinear relationship between various input descriptors and the target output, the GA has been employed to generate the required input parameters for the computational approach.

- ML techniques have brought many advantages compared to conventional approaches, such as saving computing time, providing a high level of accuracy, and implementing with minimal human intervention. However, some drawbacks of these advanced techniques could be noticed, such as requiring database construction with adequate data points for ML-based models or being unable to simulate the essence of the input–output relationship for fire engineering problems.

- For the purpose of constructing AI/ML models, it is suggested that further fire tests should be arranged to generate the fire database. Additionally, reliable finite element models could be constructed and validated to provide additional input data points to be used in AI models. The AI approach should work in conjunction with traditional methods (e.g., experimental tests and numerical simulations) to better understand the fire phenomena and flame retardancy of construction materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Organization for Standardization. ISO 5660-1: Reaction-to-Fire Tests-Heat Release, Smoke Production and Mass Loss Rate-Part 1:(Cone Calorimeter Method); International Organization for Standardization: Geneva, Switzerland, 2002. [Google Scholar]

- Tu, J.; Yeoh, G.H.; Liu, C. Computational Fluid Dynamics: A Practical Approach; Butterworth-Heinemann: Oxford, UK, 2018. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep Residual Learning for Image Recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar] [CrossRef]

- Hinton, G.; Deng, L.; Yu, D.; Dahl, G.E.; Mohamed, A.-R.; Jaitly, N.; Senior, A.; Vanhoucke, V.; Nguyen, P.; Sainath, T.N.; et al. Deep Neural Networks for Acoustic Modeling in Speech Recognition: The Shared Views of Four Research Groups. IEEE Signal Process. Mag. 2012, 29, 82–97. [Google Scholar] [CrossRef]

- Pazzani, M.; Billsus, D. Learning and Revising User Profiles: The Identification of Interesting Web Sites. Mach. Learn. 1997, 27, 313–331. [Google Scholar] [CrossRef]

- Burrell, J. How the machine ‘thinks’: Understanding opacity in machine learning algorithms. Big Data Soc. 2016, 3, 1–12. [Google Scholar] [CrossRef]

- Guzella, T.S.; Caminhas, W. A review of machine learning approaches to Spam filtering. Expert Syst. Appl. 2009, 36, 10206–10222. [Google Scholar] [CrossRef]

- Carrasquilla, J.; Melko, R.G. Machine learning phases of matter. Nat. Phys. 2017, 13, 431–434. [Google Scholar] [CrossRef]

- Sanchez-Lengeling, B.; Aspuru-Guzik, A. Inverse molecular design using machine learning: Generative models for matter engineering. Science 2018, 361, 360–365. [Google Scholar] [CrossRef]

- He, J.; Baxter, S.L.; Xu, J.; Xu, J.; Zhou, X.; Zhang, K. The practical implementation of artificial intelligence technologies in medicine. Nat. Med. 2019, 25, 30–36. [Google Scholar] [CrossRef]

- Reker, D.; Bernardes, G.J.L.; Rodrigues, T. Computational advances in combating colloidal aggregation in drug discovery. Nat. Chem. 2019, 11, 402–418. [Google Scholar] [CrossRef] [PubMed]

- Camacho, D.M.; Collins, K.M.; Powers, R.K.; Costello, J.C.; Collins, J.J. Next-Generation Machine Learning for Biological Networks. Cell 2018, 173, 1581–1592. [Google Scholar] [CrossRef] [PubMed]

- Neftci, E.O.; Averbeck, B.B. Reinforcement learning in artificial and biological systems. Nat. Mach. Intell. 2019, 1, 133–143. [Google Scholar] [CrossRef]

- Gómez-Bombarelli, R.; Aguilera-Iparraguirre, J.; Hirzel, T.D.; Duvenaud, D.; Maclaurin, D.; Blood-Forsythe, M.A.; Chae, H.S.; Einzinger, M.; Ha, D.-G.; Wu, T.; et al. Design of efficient molecular organic light-emitting diodes by a high-throughput virtual screening and experimental approach. Nat. Mater. 2016, 15, 1120–1127. [Google Scholar] [CrossRef]

- Ramprasad, R.; Batra, R.; Pilania, G.; Mannodi-Kanakkithodi, A.; Kim, C. Machine learning in materials informatics: Recent applications and prospects. npj Comput. Mater. 2017, 3. [Google Scholar] [CrossRef]

- Gu, G.X.; Chen, C.-T.; Richmond, D.J.; Buehler, M.J. Bioinspired hierarchical composite design using machine learning: Simulation, additive manufacturing, and experiment. Mater. Horiz. 2018, 5, 939–945. [Google Scholar] [CrossRef]

- Himanen, L.; Geurts, A.; Foster, A.S.; Rinke, P. Data-Driven Materials Science: Status, Challenges, and Perspectives. Adv. Sci. 2019, 6, 1900808. [Google Scholar] [CrossRef]

- Gu, G.H.; Noh, J.; Kim, I.; Jung, Y. Machine learning for renewable energy materials. J. Mater. Chem. A 2019, 7, 17096–17117. [Google Scholar] [CrossRef]

- Wan, X.; Feng, W.; Wang, Y.; Wang, H.; Zhang, X.; Deng, C.; Yang, N. Materials Discovery and Properties Prediction in Thermal Transport via Materials Informatics: A Mini Review. Nano Lett. 2019, 19, 3387–3395. [Google Scholar] [CrossRef]

- Toyao, T.; Maeno, Z.; Takakusagi, S.; Kamachi, T.; Takigawa, I.; Shimizu, K.-I. Machine Learning for Catalysis Informatics: Recent Applications and Prospects. ACS Catal. 2019, 10, 2260–2297. [Google Scholar] [CrossRef]

- Chen, C.; Zuo, Y.; Ye, W.; Li, X.; Deng, Z.; Ong, S.P. A Critical Review of Machine Learning of Energy Materials. Adv. Energy Mater. 2020, 10, 1903242. [Google Scholar] [CrossRef]

- Ghahramani, Z. Probabilistic machine learning and artificial intelligence. Nature 2015, 521, 452–459. [Google Scholar] [CrossRef]

- Jordan, M.I.; Mitchell, T.M. Machine learning: Trends, perspectives, and prospects. Science 2015, 349, 255–260. [Google Scholar] [CrossRef]

- Naser, M.Z. Mechanistically Informed Machine Learning and Artificial Intelligence in Fire Engineering and Sciences. Fire Technol. 2021, 1–44. [Google Scholar] [CrossRef]

- Zhang, Z.; Friedrich, K. Artificial neural networks applied to polymer composites: A review. Compos. Sci. Technol. 2003, 63, 2029–2044. [Google Scholar] [CrossRef]

- McGrattan, K.B.; Baum, H.R.; Rehm, R.G.; Hamins, A.; Forney, G.P. Fire Dynamics Simulator—Technical Reference Guide; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2000. [CrossRef]

- Butler, K.T.; Davies, D.W.; Cartwright, H.; Isayev, O.; Walsh, A. Machine learning for molecular and materials science. Nature 2018, 559, 547–555. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Ling, C. A strategy to apply machine learning to small datasets in materials science. npj Comput. Mater. 2018, 4, 25. [Google Scholar] [CrossRef]

- Bishop, C.M. Pattern Recognition and Machine Learning; Springer: New York, NY, USA, 2006. [Google Scholar]

- Katritzky, A.R.; Kuanar, M.; Slavov, S.; Hall, C.D.; Karelson, M.; Kahn, I.; Dobchev, D.A. Quantitative Correlation of Physical and Chemical Properties with Chemical Structure: Utility for Prediction. Chem. Rev. 2010, 110, 5714–5789. [Google Scholar] [CrossRef]

- Faber, F.A.; Hutchison, L.; Huang, B.; Gilmer, J.; Schoenholz, S.S.; Dahl, G.E.; Vinyals, O.; Kearnes, S.; Riley, P.F.; Von Lilienfeld, O.A. Prediction Errors of Molecular Machine Learning Models Lower than Hybrid DFT Error. J. Chem. Theory Comput. 2017, 13, 5255–5264. [Google Scholar] [CrossRef]

- Mukherjee, A.; Biswas, S.N. Artificial neural networks in prediction of mechanical behavior of concrete at high temperature. Nucl. Eng. Des. 1997, 178, 1–11. [Google Scholar] [CrossRef]

- Hawkins, D.M. The Problem of Overfitting. J. Chem. Inf. Comput. Sci. 2004, 44, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Le, T.; Epa, V.C.; Burden, F.R.; Winkler, D.A. Quantitative Structure–Property Relationship Modeling of Diverse Materials Properties. Chem. Rev. 2012, 112, 2889–2919. [Google Scholar] [CrossRef]

- Golbraikh, A.; Tropsha, A. Beware of q2! J. Mol. Graph. Model. 2002, 20, 269–276. [Google Scholar] [CrossRef]

- Alexander, D.L.J.; Tropsha, A.; Winkler, D.A. Beware of R2: Simple, Unambiguous Assessment of the Prediction Accuracy of QSAR and QSPR Models. J. Chem. Inf. Model. 2015, 55, 1316–1322. [Google Scholar] [CrossRef]

- Arlot, S.; Celisse, A. A survey of cross-validation procedures for model selection. Stat. Surv. 2010, 4, 40–79. [Google Scholar] [CrossRef]

- Baduge, S.K.; Mendis, P.; Nicolas, R.S.; Nguyen, K.; Hajimohammadi, A. Performance of lightweight hemp concrete with alkali-activated cenosphere binders exposed to elevated temperature. Constr. Build. Mater. 2019, 224, 158–172. [Google Scholar] [CrossRef]

- Huang, Z.-F.; Tan, K.-H.; Phng, G.-H. Axial restraint effects on the fire resistance of composite columns encasing I-section steel. J. Constr. Steel Res. 2007, 63, 437–447. [Google Scholar] [CrossRef]

- Li, Y.; Pimienta, P.; Pinoteau, N.; Tan, K.H. Effect of aggregate size and inclusion of polypropylene and steel fibers on explosive spalling and pore pressure in ultra-high-performance concrete (UHPC) at elevated temperature. Cem. Concr. Compos. 2019, 99, 62–71. [Google Scholar] [CrossRef]

- Li, Y.; Tan, K.H.; Yang, E.-H. Synergistic effects of hybrid polypropylene and steel fibers on explosive spalling prevention of ultra-high performance concrete at elevated temperature. Cem. Concr. Compos. 2019, 96, 174–181. [Google Scholar] [CrossRef]

- Liu, J.-C.; Tan, K.H. Fire resistance of strain hardening cementitious composite with hybrid PVA and steel fibers. Constr. Build. Mater. 2017, 135, 600–611. [Google Scholar] [CrossRef]

- Liu, J.-C.; Tan, K.H.; Yao, Y. A new perspective on nature of fire-induced spalling in concrete. Constr. Build. Mater. 2018, 184, 581–590. [Google Scholar] [CrossRef]

- Nguyen, Q.; Ngo, T.; Tran, P.; Mendis, P.; Aye, L.; Baduge, S.K. Fire resistance of a prefabricated bushfire bunker using aerated concrete panels. Constr. Build. Mater. 2018, 174, 410–420. [Google Scholar] [CrossRef]

- Weerasinghe, P.; Nguyen, K.; Mendis, P.; Guerrieri, M. Large-scale experiment on the behaviour of concrete flat slabs subjected to standard fire. J. Build. Eng. 2020, 30, 101255. [Google Scholar] [CrossRef]

- Andres, B.; Hoehler, M.S.; Bundy, M.F. Fire resistance of cold-formed steel framed shear walls under various fire scenarios. Fire Mater. 2019, 44, 352–364. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Xingxing, W.; Li, X. Thermal behavior of gypsum-sheathed cold-formed steel composite assemblies under fire conditions. J. Constr. Steel Res. 2018, 149, 165–179. [Google Scholar] [CrossRef]

- Chen, W.; Ye, J.; Zhao, Q. Thermal performance of non-load-bearing cold-formed steel walls under different design fire conditions. Thin-Walled Struct. 2019, 143, 106242. [Google Scholar] [CrossRef]

- Chen, W.; Ye, J.; Zhao, Q.; Jiang, J. Full-scale experiments of gypsum-sheathed cavity-insulated cold-formed steel walls under different fire conditions. J. Constr. Steel Res. 2020, 164, 105809. [Google Scholar] [CrossRef]

- Hoehler, M.S.; Smith, C.M. Influence of Fire on the Lateral Load Capacity of Steel-Sheathed Cold-Formed Steel Shear Walls—Report of Test; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2016. [CrossRef]

- Hoehler, M.S.; Valiente, B.A.; Bundy, M.F. Influence of Fire on the Lateral Resistance of Cold-Formed Steel Shear Walls–Phase 2: Oriented Strand Board, Strap Braced, and Gypsum-Sheet Steel Composite; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2019.

- Kang, L.; Suzuki, M.; Ge, H.; Wu, B. Experiment of ductile fracture performances of HSSS Q690 after a fire. J. Constr. Steel Res. 2018, 146, 109–121. [Google Scholar] [CrossRef]

- Ye, J.; Chen, W.; Wang, Z. Fire-Resistance Behavior of a Newly Developed Cold-Formed Steel Composite Floor. J. Struct. Eng. 2017, 143, 04017018. [Google Scholar] [CrossRef]

- Bartlett, A.I.; Hadden, R.M.; Bisby, L.A. A Review of Factors Affecting the Burning Behaviour of Wood for Application to Tall Timber Construction. Fire Technol. 2018, 55, 1–49. [Google Scholar] [CrossRef]

- Dârmon, R.; Lalu, O. The fire performance of Cross Laminated Timber beams. Proced. Manuf. 2019, 32, 121–128. [Google Scholar] [CrossRef]

- Jessop, D.; Abu, A.K.; Wade, C.; Spearpoint, M.; Gerlich, H. Performance of a light timber-framed compartment in natural fire subjected to lateral load. Fire Mater. 2018, 43, 175–188. [Google Scholar] [CrossRef]

- Klippel, M.; Schmid, J. Design of Cross-Laminated Timber in Fire. Struct. Eng. Int. 2017, 27, 224–230. [Google Scholar] [CrossRef]

- Ostman, B.A. Fire performance of wood products and timber structures. Int. Wood Prod. J. 2017, 8, 74–79. [Google Scholar] [CrossRef]

- Lahoti, M.; Tan, K.H.; Yang, E.-H. A critical review of geopolymer properties for structural fire-resistance applications. Constr. Build. Mater. 2019, 221, 514–526. [Google Scholar] [CrossRef]

- Liu, J.-C.; Tan, K.H. Fire resistance of ultra-high performance strain hardening cementitious composite: Residual mechanical properties and spalling resistance. Cem. Concr. Compos. 2018, 89, 62–75. [Google Scholar] [CrossRef]

- Ngo, T.D.; Nguyen, Q.T.; Tran, P. Heat release and flame propagation in prefabricated modular unit with GFRP composite facades. Build. Simul. 2016, 9, 607–616. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Navaratnam, S.; Mendis, P.; Zhang, K.; Barnett, J.; Wang, H. Fire safety of composites in prefabricated buildings: From fibre reinforced polymer to textile reinforced concrete. Compos. Part B Eng. 2020, 187, 107815. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Weerasinghe, P.; Mendis, P.; Ngo, T. Barnett, J. Performance of modern building façades in fire: A comprehensive review. Electron. J. Struct. Eng. 2016, 16, 69–86. [Google Scholar]

- Nguyen, Q.; Ngo, T.; Tran, P.; Mendis, P.; Zobec, M.; Aye, L. Fire performance of prefabricated modular units using organoclay/glass fibre reinforced polymer composite. Constr. Build. Mater. 2016, 129, 204–215. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Ngo, T.D.; Bai, Y.; Tran, P. Experimental and numerical investigations on the thermal response of multilayer glass fibre/unsaturated polyester/organoclay composite. Fire Mater. 2016, 40, 1047–1069. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Ngo, T.D.; Tran, P.; Mendis, P.; Bhattacharyya, D. Influences of clay and manufacturing on fire resistance of organoclay/thermoset nanocomposites. Compos. Part A Appl. Sci. Manuf. 2015, 74, 26–37. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Tran, P.; Ngo, T.D.; Tran, P.A.; Mendis, P. Experimental and computational investigations on fire resistance of GFRP composite for building façade. Compos. Part B Eng. 2014, 62, 218–229. [Google Scholar] [CrossRef]

- Chan, Y.N.; Jin, P.; Anson, M.; Wang, J.S. Fire resistance of concrete: Prediction using artificial neural networks. Mag. Concr. Res. 1998, 50, 353–358. [Google Scholar] [CrossRef]

- Uysal, M.; Tanyildizi, H. Estimation of compressive strength of self compacting concrete containing polypropylene fiber and mineral additives exposed to high temperature using artificial neural network. Constr. Build. Mater. 2012, 27, 404–414. [Google Scholar] [CrossRef]

- McKinney, J.; Ali, F. Artificial Neural Networks for the Spalling Classification & Failure Prediction Times of High Strength Concrete Columns. J. Struct. Fire Eng. 2014, 5, 203–214. [Google Scholar] [CrossRef]

- Al-Khaleefi, A.M.; Terro, M.J.; Alex, A.P.; Wang, Y. Prediction of fire resistance of concrete filled tubular steel columns using neural networks. Fire Saf. J. 2002, 37, 339–352. [Google Scholar] [CrossRef]

- Lazarevska, M.; Knezevic, M.; Cvetkovska, M.; Trombeva-Gavriloska, A. Application of artificial neural networks in civil engineering. Teh. Vjesn. 2014, 21, 1353–1359. [Google Scholar]

- Naser, M. Heuristic machine cognition to predict fire-induced spalling and fire resistance of concrete structures. Autom. Constr. 2019, 106. [Google Scholar] [CrossRef]

- Naser, M. AI-based cognitive framework for evaluating response of concrete structures in extreme conditions. Eng. Appl. Artif. Intell. 2019, 81, 437–449. [Google Scholar] [CrossRef]

- Naser, M.Z. Autonomous Fire Resistance Evaluation. J. Struct. Eng. 2020, 146, 4020103. [Google Scholar]

- Naser, M.Z. Observational Analysis of Fire-Induced Spalling of Concrete through Ensemble Machine Learning and Surrogate Modeling. J. Mater. Civ. Eng. 2021, 33, 04020428. [Google Scholar] [CrossRef]

- Naser, M.Z.; Seitllari, A. Concrete under fire: An assessment through intelligent pattern recognition. Eng. Comput. 2019, 36, 1915–1928. [Google Scholar] [CrossRef]

- Seitllari, A.; Naser, M. Leveraging artificial intelligence to assess explosive spalling in fire-exposed RC columns. Comput. Concr. 2019, 24, 271–282. [Google Scholar]

- Erdem, H. Prediction of the moment capacity of reinforced concrete slabs in fire using artificial neural networks. Adv. Eng. Softw. 2010, 41, 270–276. [Google Scholar] [CrossRef]

- Altun, F.; Dirikgil, T. The prediction of prismatic beam behaviours with polypropylene fiber addition under high temperature effect through ANN, ANFIS and fuzzy genetic models. Compos. Part B Eng. 2013, 52, 362–371. [Google Scholar] [CrossRef]

- Naser, M.M.; Abulebdeh, G.; Hawileh, R. Analysis of RC T-beams strengthened with CFRP plates under fire loading using ANN. Constr. Build. Mater. 2012, 37, 301–309. [Google Scholar] [CrossRef]

- Williams, B.; Kodur, V.; Green, M.F.; Bisby, L. Fire Endurance of Fiber-Reinforced Polymer Strengthened Concrete T-Beams. ACI Struct. J. 2008, 105, 60–67. [Google Scholar] [CrossRef]

- Hawileh, R.; Naser, M.Z.; Zaidan, W.; Rasheed, H. Modeling of insulated CFRP-strengthened reinforced concrete T-beam exposed to fire. Eng. Struct. 2009, 31, 3072–3079. [Google Scholar] [CrossRef]

- Naser, M. Deriving temperature-dependent material models for structural steel through artificial intelligence. Constr. Build. Mater. 2018, 191, 56–68. [Google Scholar] [CrossRef]

- Hozjan, T.; Turk, G.; Srpčič, S. Fire analysis of steel frames with the use of artificial neural networks. J. Constr. Steel Res. 2007, 63, 1396–1403. [Google Scholar] [CrossRef]

- Xu, J.; Zhao, J.; Wang, W.; Liu, M. Prediction of temperature of tubular truss under fire using artificial neural networks. Fire Saf. J. 2013, 56, 74–80. [Google Scholar] [CrossRef]

- Zhao, Z. Steel columns under fire—A neural network based strength model. Adv. Eng. Softw. 2006, 37, 97–105. [Google Scholar] [CrossRef]

- Cachim, P. Temperature Prediction in Timber Using Artificial Neural Networks. In Proceedings of the World Conference on Timbre Engineering, Trento, Italy, 20–24 June 2010. [Google Scholar]

- Naser, M. Fire resistance evaluation through artificial intelligence—A case for timber structures. Fire Saf. J. 2019, 105, 1–18. [Google Scholar] [CrossRef]

- Lautenberger, C.; Rein, G.; Fernandez-Pello, C. The application of a genetic algorithm to estimate material properties for fire modeling from bench-scale fire test data. Fire Saf. J. 2006, 41, 204–214. [Google Scholar] [CrossRef]

- Rein, G.; Lautenberger, C.; Fernandezpello, A.; Torero, J.; Urban, D. Application of genetic algorithms and thermogravimetry to determine the kinetics of polyurethane foam in smoldering combustion. Combust. Flame 2006, 146, 95–108. [Google Scholar] [CrossRef]

- Gen, M.; Lin, L. Genetic algorithms. In Wiley Encyclopedia of Computer Science and Engineering; Wiley & Sons: Hoboken, NJ, USA, 2007; pp. 1–15. [Google Scholar]

- Yuen, A.C.Y.; Chen, T.; Wang, C.; Wei, W.; Kabir, I.; Vargas, J.; Chan, Q.; Kook, S.; Yeoh, G. Utilising genetic algorithm to optimise pyrolysis kinetics for fire modelling and characterisation of chitosan/graphene oxide polyurethane composites. Compos. Part B Eng. 2020, 182, 107619. [Google Scholar] [CrossRef]

- Al-Jabri, K.S.; Al-Alawi, S.M. Predicting the behaviour of semi-rigid joints in fire using an artificial neural network. Steel Struct. 2007, 7, 209–217. [Google Scholar]

- Al-Jabri, K.S.; Al-Alawi, S.M. An advanced ANN model for predicting the rotational behaviour of semi-rigid composite joints in fire using the backpropagation paradigm. Int. J. Steel Struct. 2010, 10, 337–347. [Google Scholar] [CrossRef]

- Lee, E.W.M.; Yuen, R.K.K.; Lo, S.; Lam, K.; Yeoh, G.H. A novel artificial neural network fire model for prediction of thermal interface location in single compartment fire. Fire Saf. J. 2004, 39, 67–87. [Google Scholar] [CrossRef]

- Yuen, R.K.; Lee, E.W.; Lo, S.M.; Yeoh, G. Prediction of temperature and velocity profiles in a single compartment fire by an improved neural network analysis. Fire Saf. J. 2006, 41, 478–485. [Google Scholar] [CrossRef]

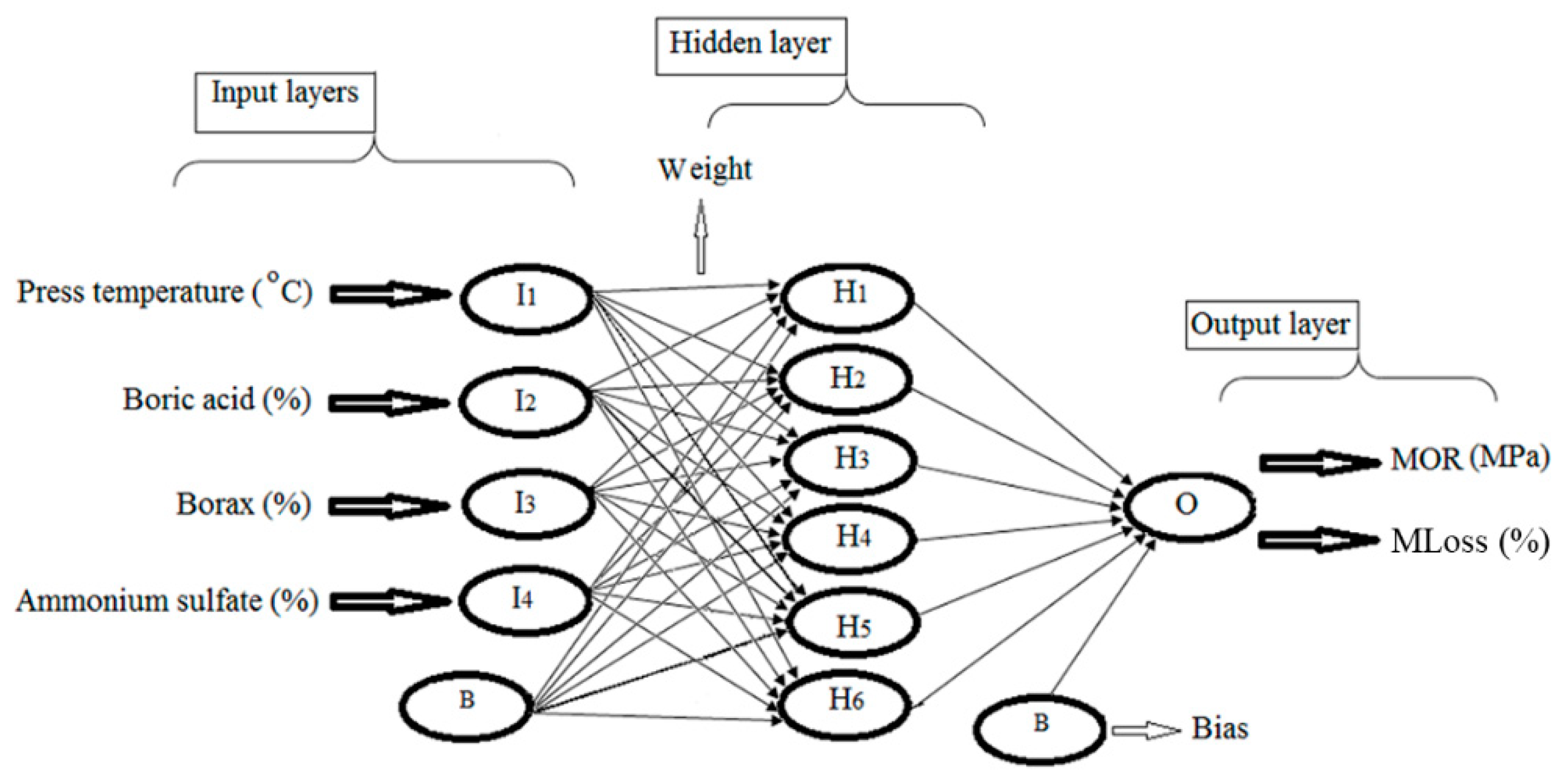

- Nazerian, M.; Shirzaii, S.; Gargarii, R.M.; Vatankhah, E. Evaluation og mechanical and flame retardant properties od medium density fireboard using artificial neural nerwork. Cerne 2020, 26, 279–292. [Google Scholar] [CrossRef]

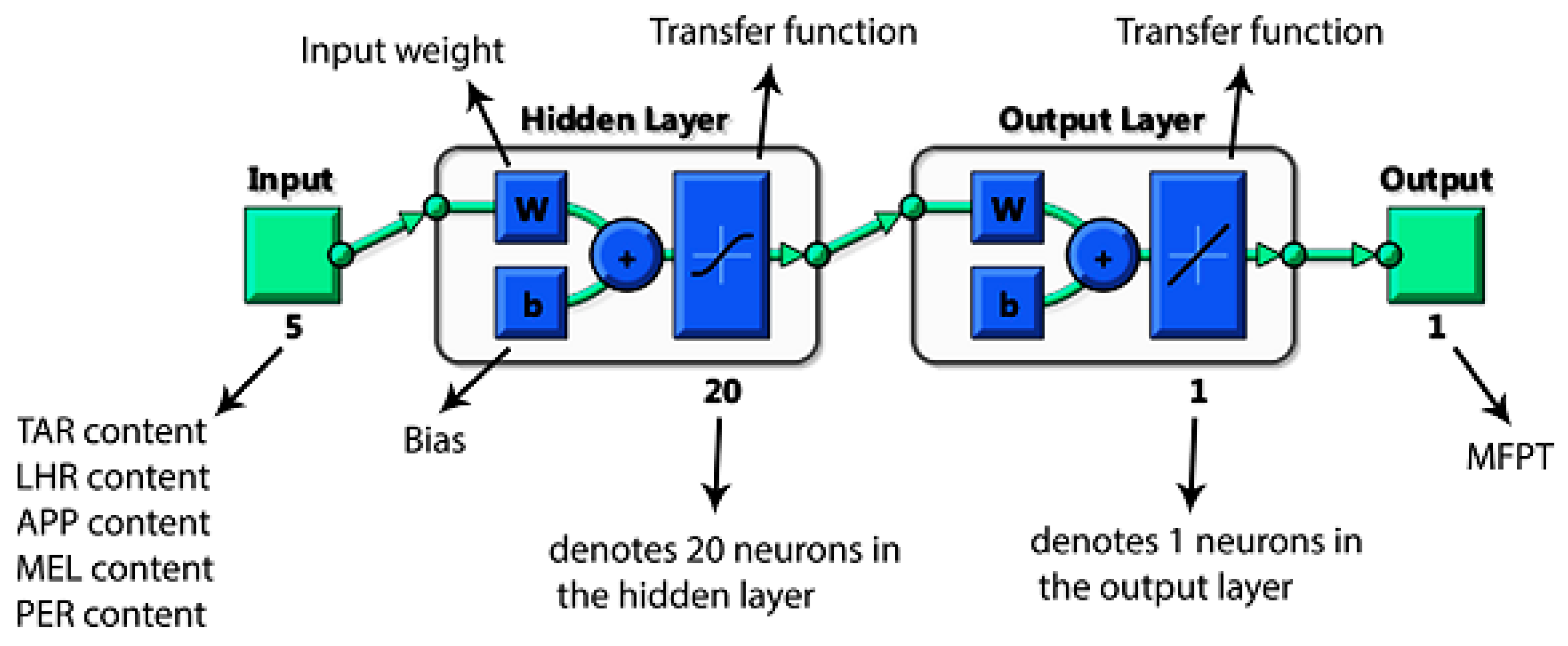

- Arabasadi, Z.; Khorasani, M.; Akhlaghi, S.; Fazilat, H.; Gedde, U.W.; Hedenqvist, M.S.; Shiri, M.E. Prediction and optimization of fireproofing properties of intumescent flame retardant coatings using artificial intelligence techniques. Fire Saf. J. 2013, 61, 193–199. [Google Scholar] [CrossRef]

- Roy, R.K. A Primer on the Taguchi Method; Society of Manufacturing Engineers: Dearborn, MI, USA, 2010. [Google Scholar]

- Xia, J.; Xiao, C.; Wang, J.; Huang, C. The Application of Artificial Neural Network (ANN) Technique to Formulation Design of Flame Retardant Polymers. I. Intumescent Flame Retardant PA-66 Composites. J. Fire Sci. 2001, 19, 3–17. [Google Scholar] [CrossRef]

- Xia, J.; Wang, J.; Huang, C. The Application of Artificial Neural Network (ANN) Technique to Formulation Design of Flame Retardant Polymers—II. Halogen-Free Flame Retardant Polymeric Composites. J. Fire Sci. 2001, 19, 309–328. [Google Scholar] [CrossRef]

| Data | R2 | RMSE | ||

|---|---|---|---|---|

| MLoss | MOR | MLoss | MOR | |

| All datasets | 0.91882 | 0.92117 | 0.1725 | 1.3033 |

| The training set | 0.96919 | 0.95721 | 0.1545 | 1.2025 |

| The validation set | 0.99899 | 0.92552 | 1.4846 | 1.9196 |

| The test set | 0.93291 | 0.96552 | 0.0836 | 1.9914 |

| Procedure | R2 | RMSE | MSE |

|---|---|---|---|

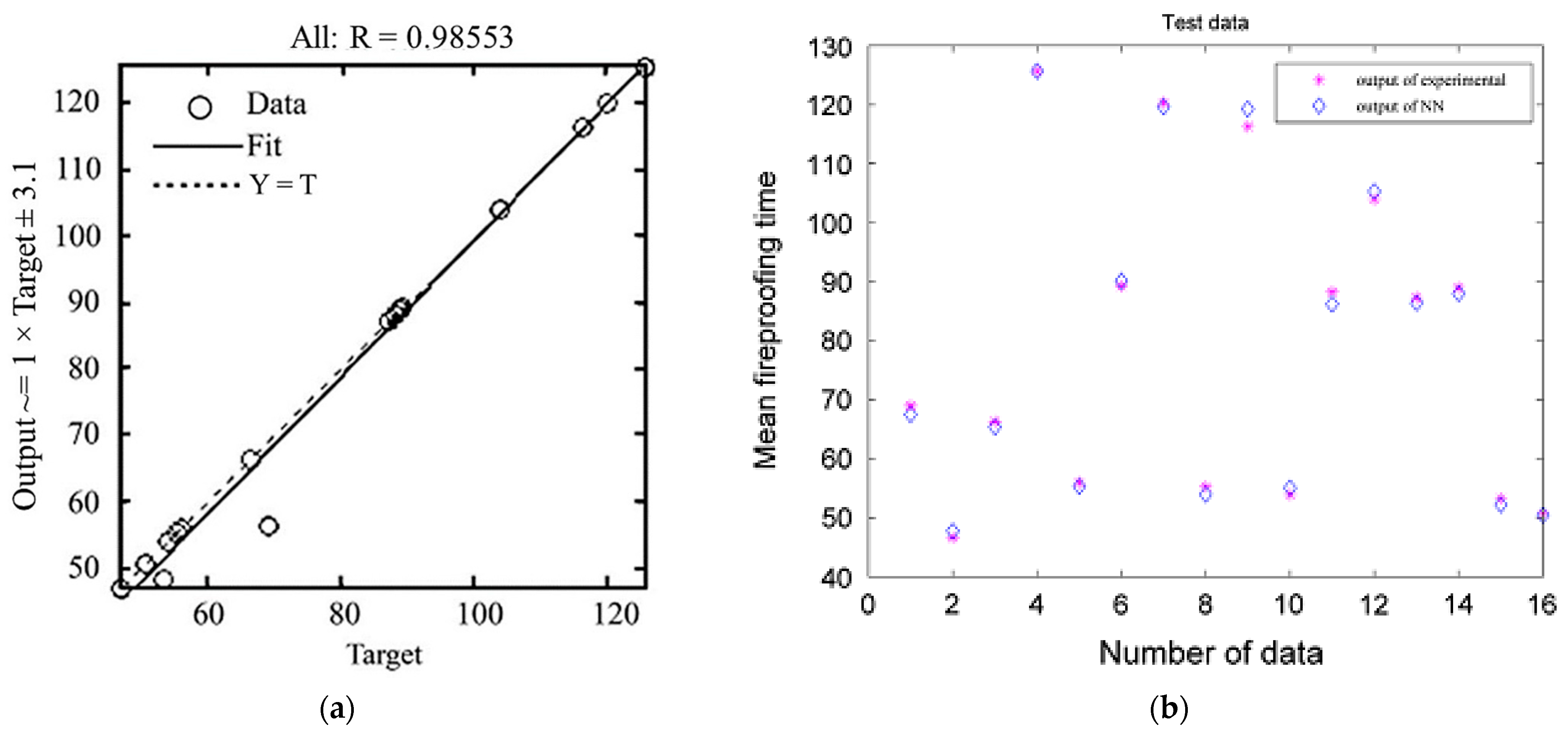

| Training | 1 | 0.01229 | 0.01512 |

| Validating | 0.96120 | 0.02519 | 0.06345 |

| Testing | 0.99562 | 0.01954 | 0.03818 |

| All data | 0.98553 | - | - |

| Methods | TAR (g) | LHR (g) | APP (g) | MEL (g) | PER (g) | MFPT (Min) |

|---|---|---|---|---|---|---|

| Taguchi | 13 | 2.5 | 25 | 10 | 11 | 129.2 |

| GA | 15.85 | 2.8 | 26.7 | 10.01 | 8.4 | 132.8 |

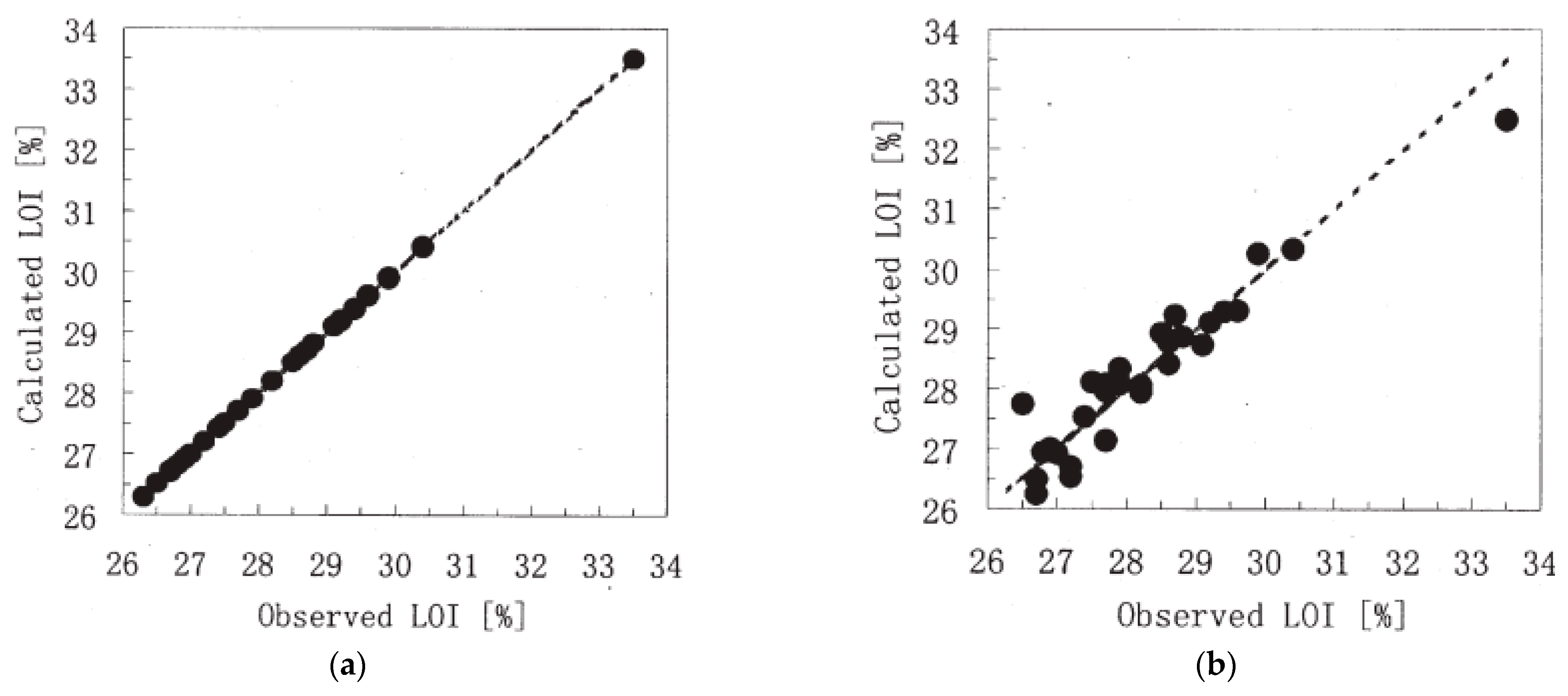

| Methods | Correlation Coefficient | Root-Mean-Square Error |

|---|---|---|

| MNLR model | 0.9474 | 0.4388 |

| ANN model | 1.0000 | 0.0002 |

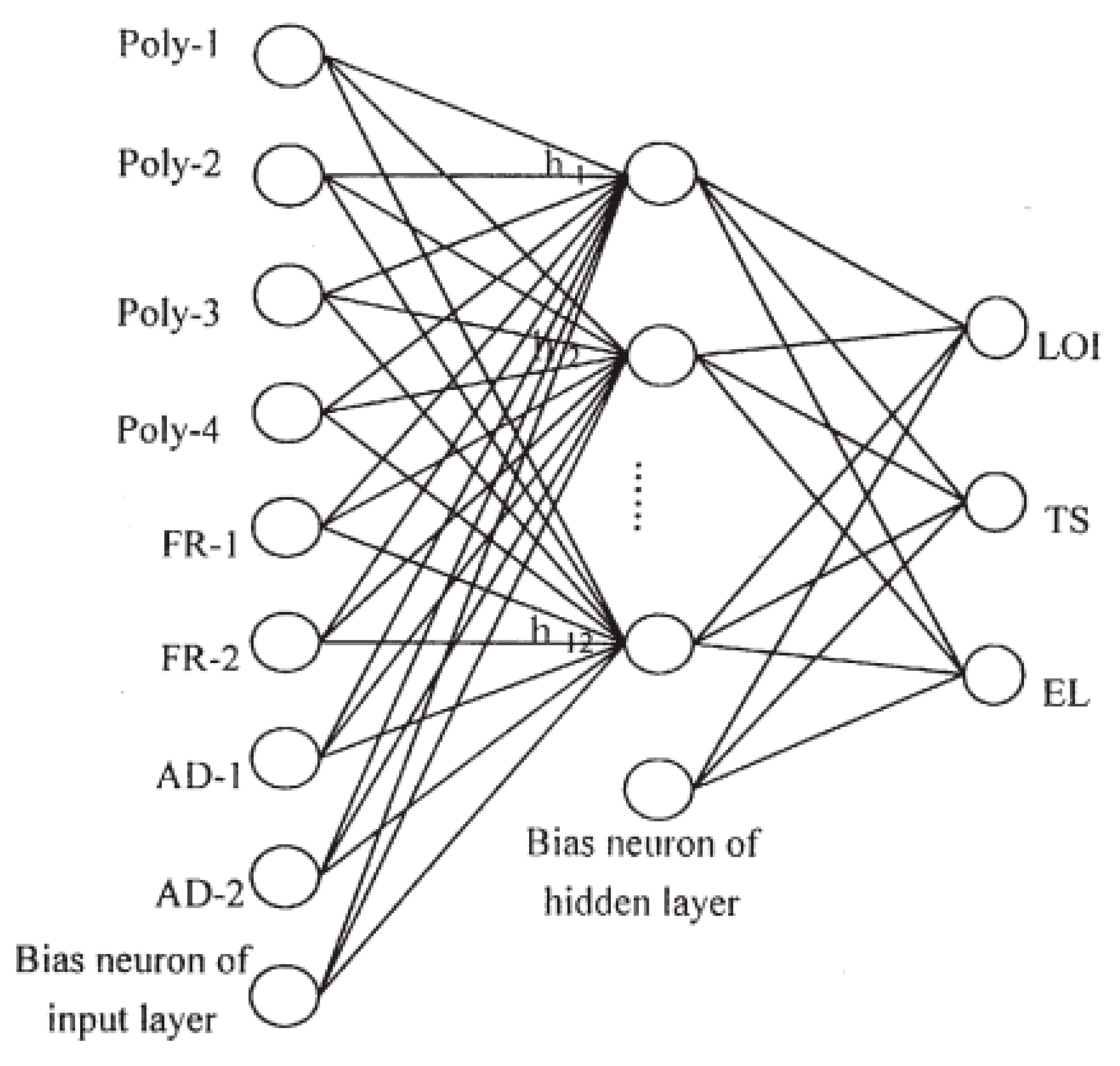

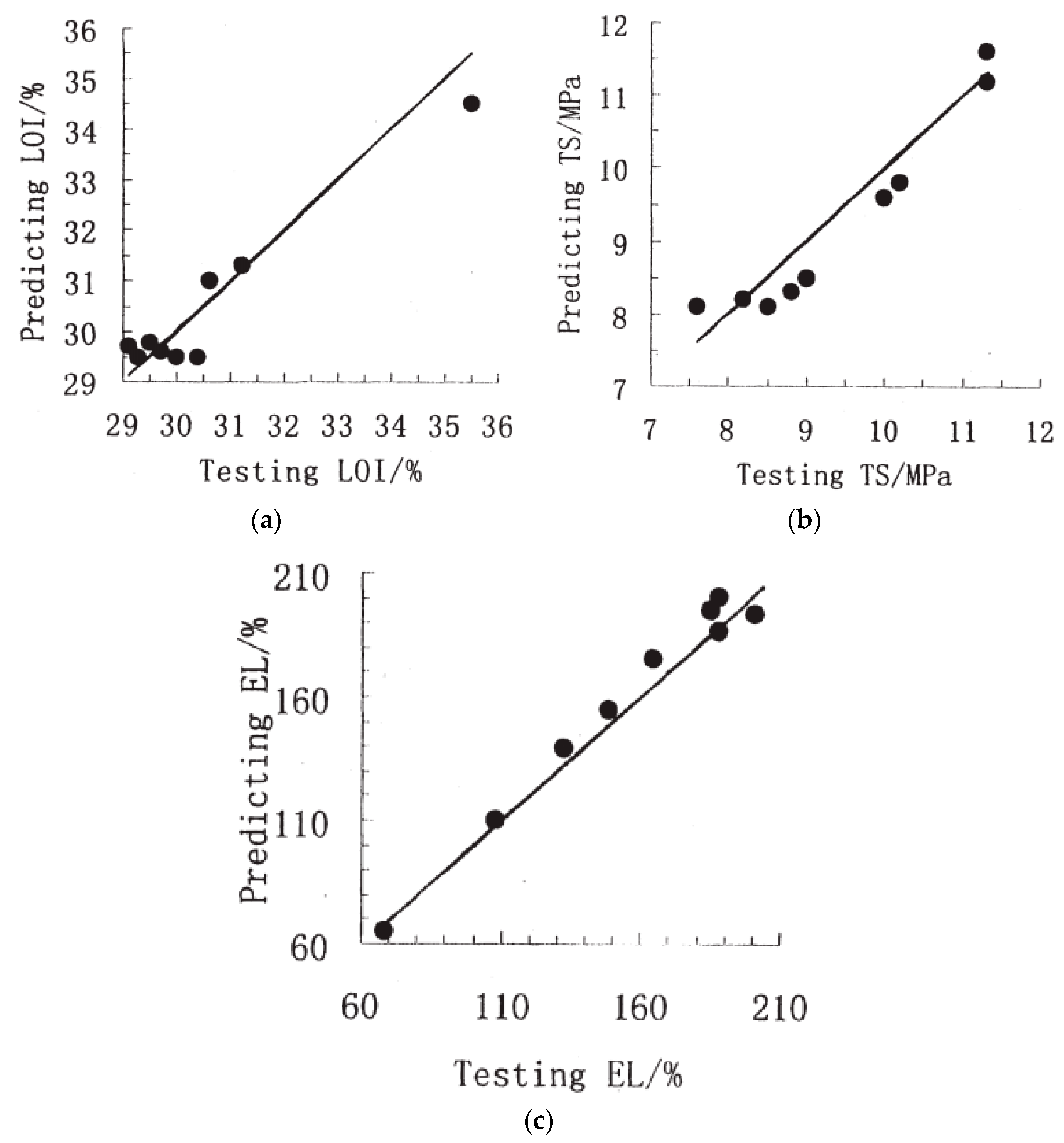

| Output Results | Correlation Coefficient | Root-Mean-Square Error |

|---|---|---|

| LOI (%) | 0.9524 | 0.38 |

| TS (MPa) | 0.9557 | 0.54 |

| EL (%) | 0.9695 | 10.10 |

| Materials | Method | Target Output | Descriptors/Input Parameters | Reference |

|---|---|---|---|---|

| Flame-retardant fiberboards | Artificial neural networks | The modulus of rupture (MOR) and mass loss (ML) | The concentration of boric acid, borax, and ammonium sulfate, and press temperature | [98] |

| Intumescent flame-retardant coatings | Artificial neural networks (ANNs), adaptive neuro-fuzzy-inference-system (ANFIS), and genetic algorithm (GA) | The mean fireproofing time (MFPT) | The compositional concentration of ammonium polyphosphate (APP), pentaerythritol (PER), melamine (MEL), thermoplastic acrylic resin (TAR), and liquid hydrocarbon resin (LHR) | [99] |

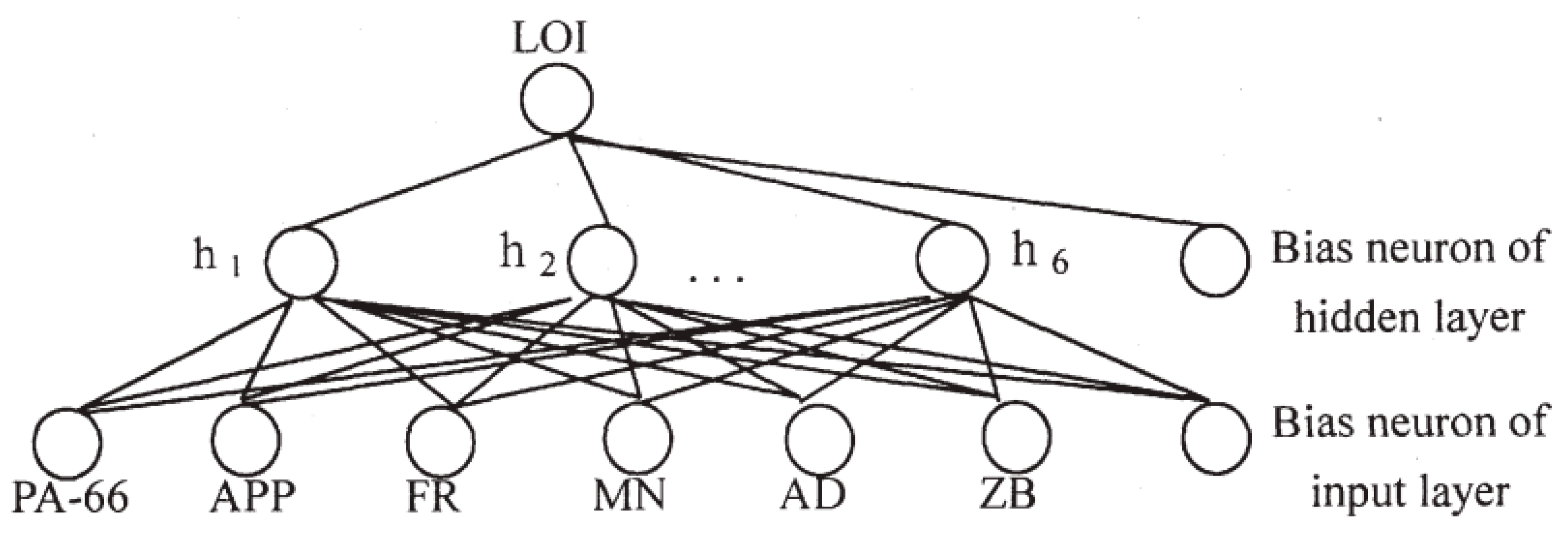

| Polyamide-66 | Artificial neural networks | The limiting oxygen index (LOI) | Constituents of composites: polyamide-66 (PA-66), ammonium polyphosphate (APP), phosphorus-containing flame retardant (FR), melamine (MN), silicon-containing additive (AD), and zinc borate (ZB) | [101] |

| Halogen-free flame-retardant composites | Artificial neural networks | The limiting oxygen index (LOI), tensile strength (TS), and elongation (EL) | Ethylene-vinyl acetate copolymer (Poly-1), ethylene-propylene copolymer (Poly-2), polyethylene (Poly-3), compatibilizer (Poly-4), alumina trihydrate (FR-1), zinc borate (FR-2), silicon-containing additive (AD-1), and phosphorus-containing additive (AD-2) | [102] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, H.T.; Nguyen, K.T.Q.; Le, T.C.; Zhang, G. Review on the Use of Artificial Intelligence to Predict Fire Performance of Construction Materials and Their Flame Retardancy. Molecules 2021, 26, 1022. https://doi.org/10.3390/molecules26041022

Nguyen HT, Nguyen KTQ, Le TC, Zhang G. Review on the Use of Artificial Intelligence to Predict Fire Performance of Construction Materials and Their Flame Retardancy. Molecules. 2021; 26(4):1022. https://doi.org/10.3390/molecules26041022

Chicago/Turabian StyleNguyen, Hoang T., Kate T. Q. Nguyen, Tu C. Le, and Guomin Zhang. 2021. "Review on the Use of Artificial Intelligence to Predict Fire Performance of Construction Materials and Their Flame Retardancy" Molecules 26, no. 4: 1022. https://doi.org/10.3390/molecules26041022

APA StyleNguyen, H. T., Nguyen, K. T. Q., Le, T. C., & Zhang, G. (2021). Review on the Use of Artificial Intelligence to Predict Fire Performance of Construction Materials and Their Flame Retardancy. Molecules, 26(4), 1022. https://doi.org/10.3390/molecules26041022

_Zhang.png)