CytroCell: Valued Cellulose from Citrus Processing Waste

Abstract

1. Introduction

2. Results and Discussion

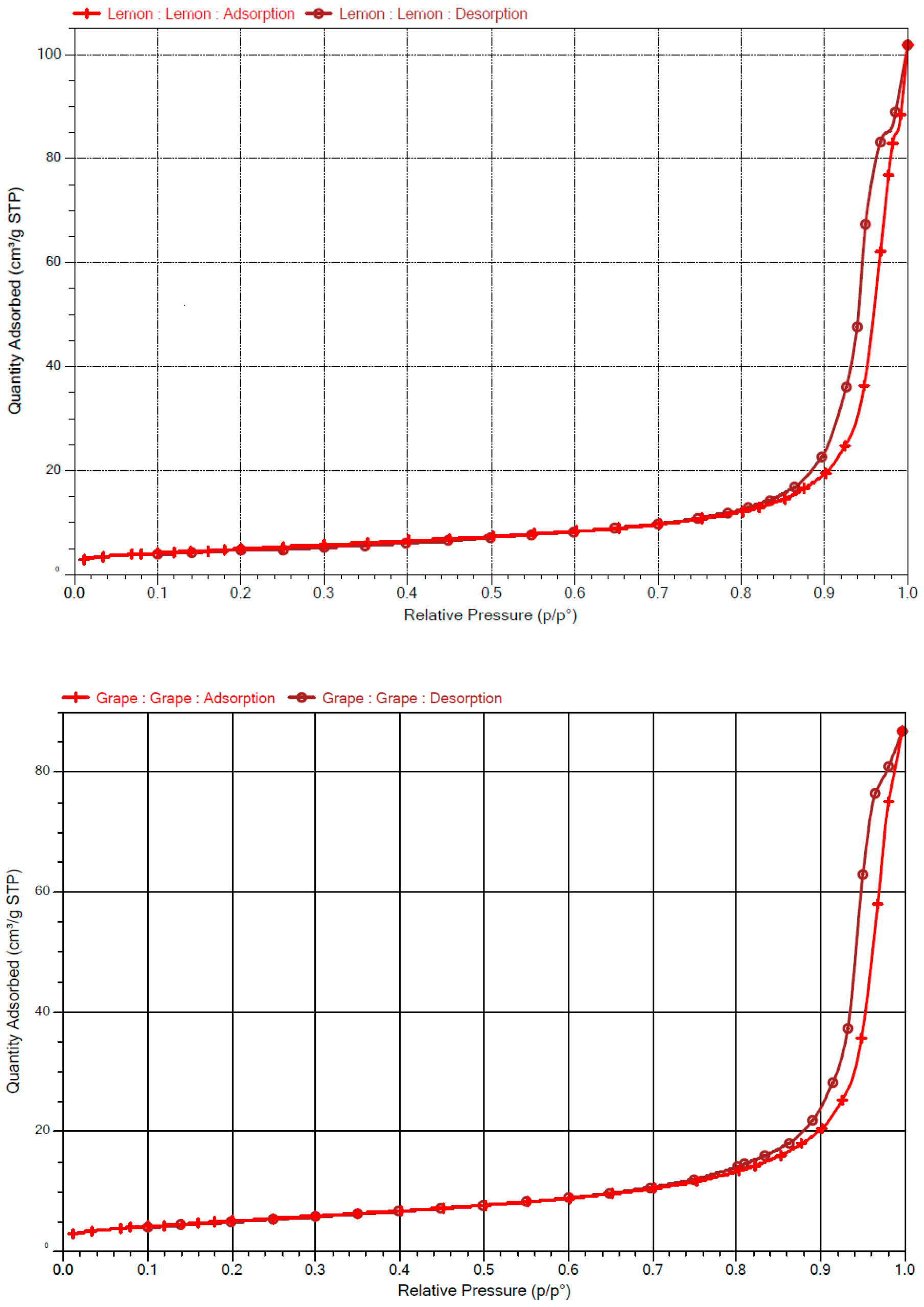

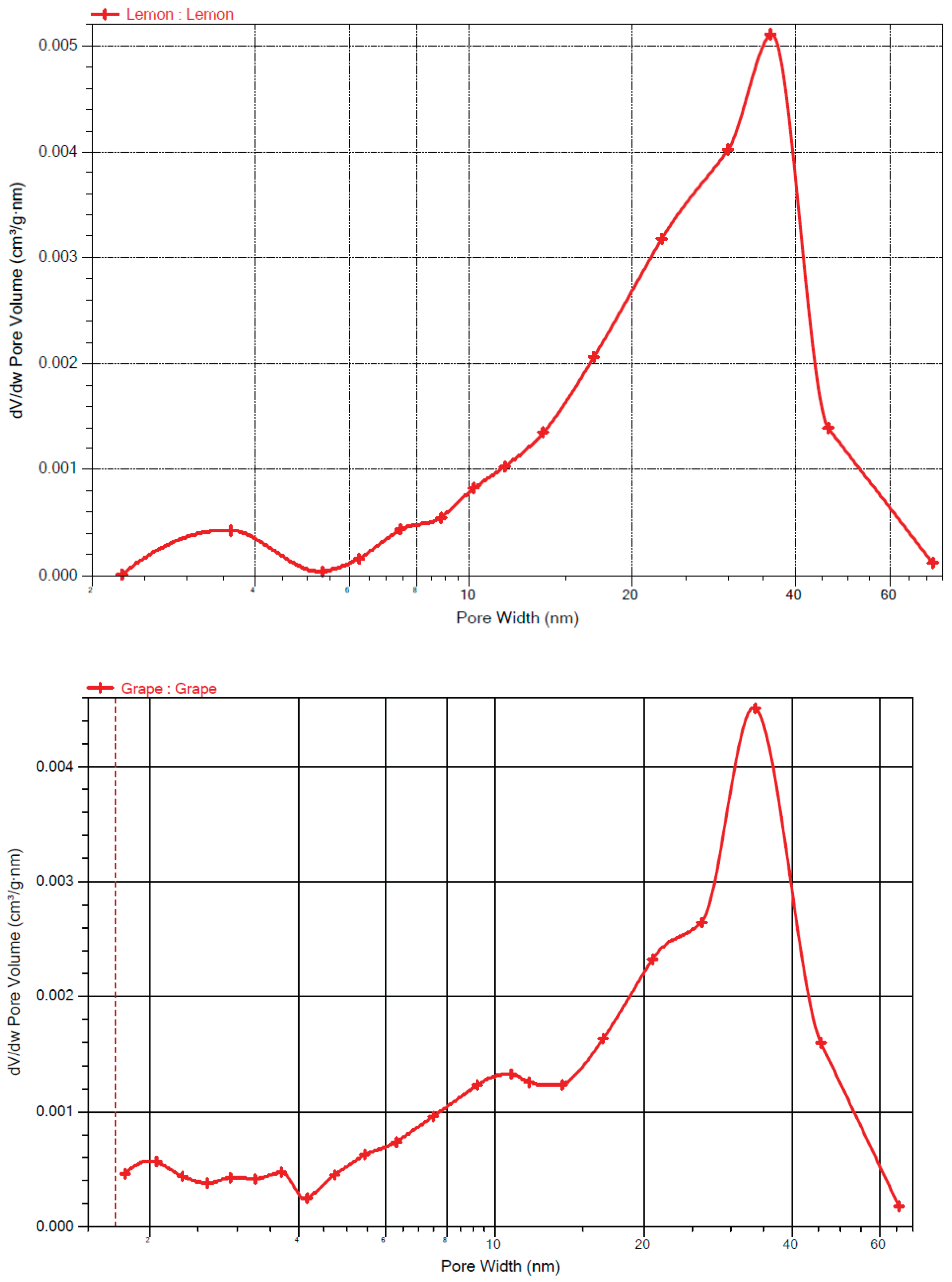

2.1. Textural Properties

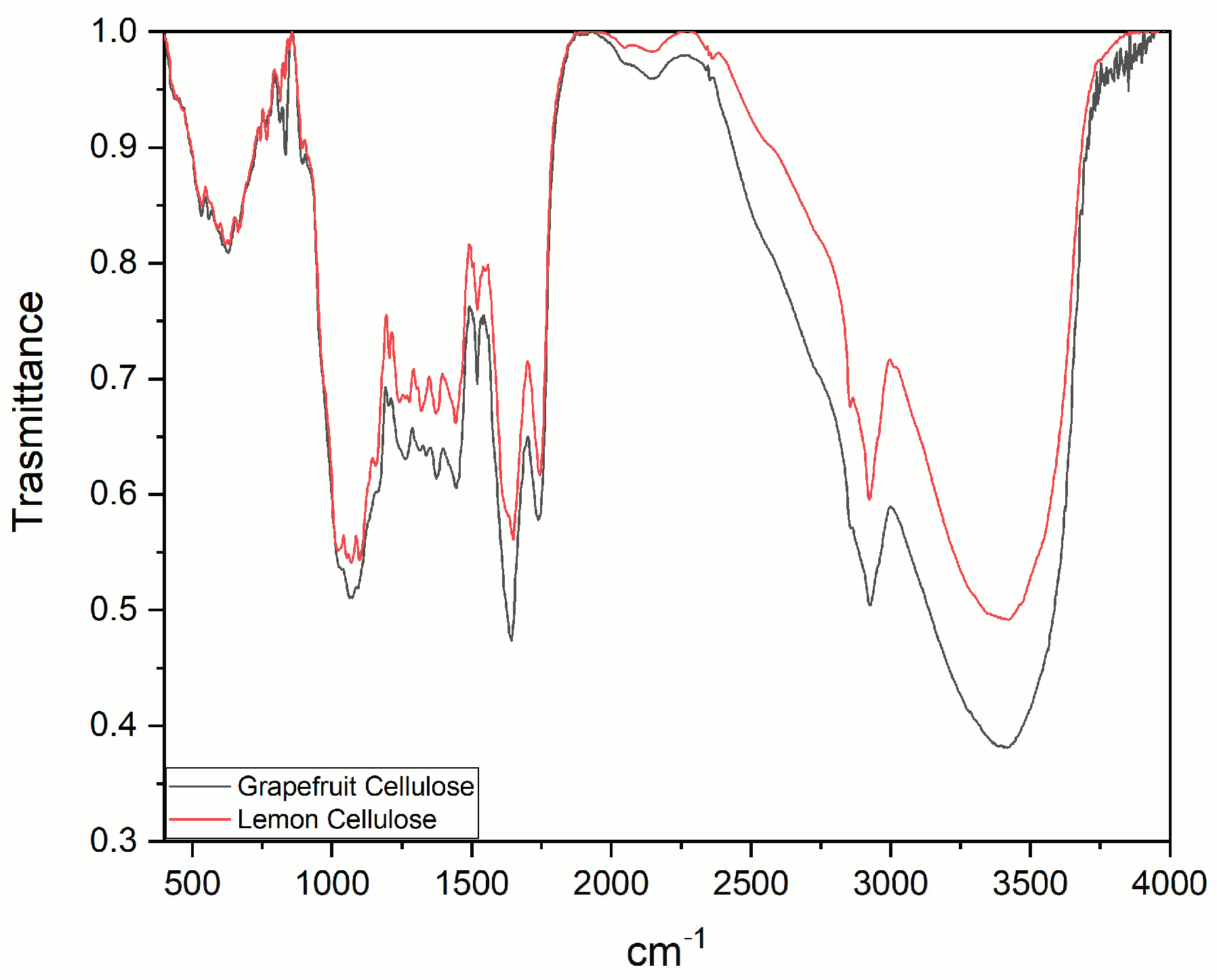

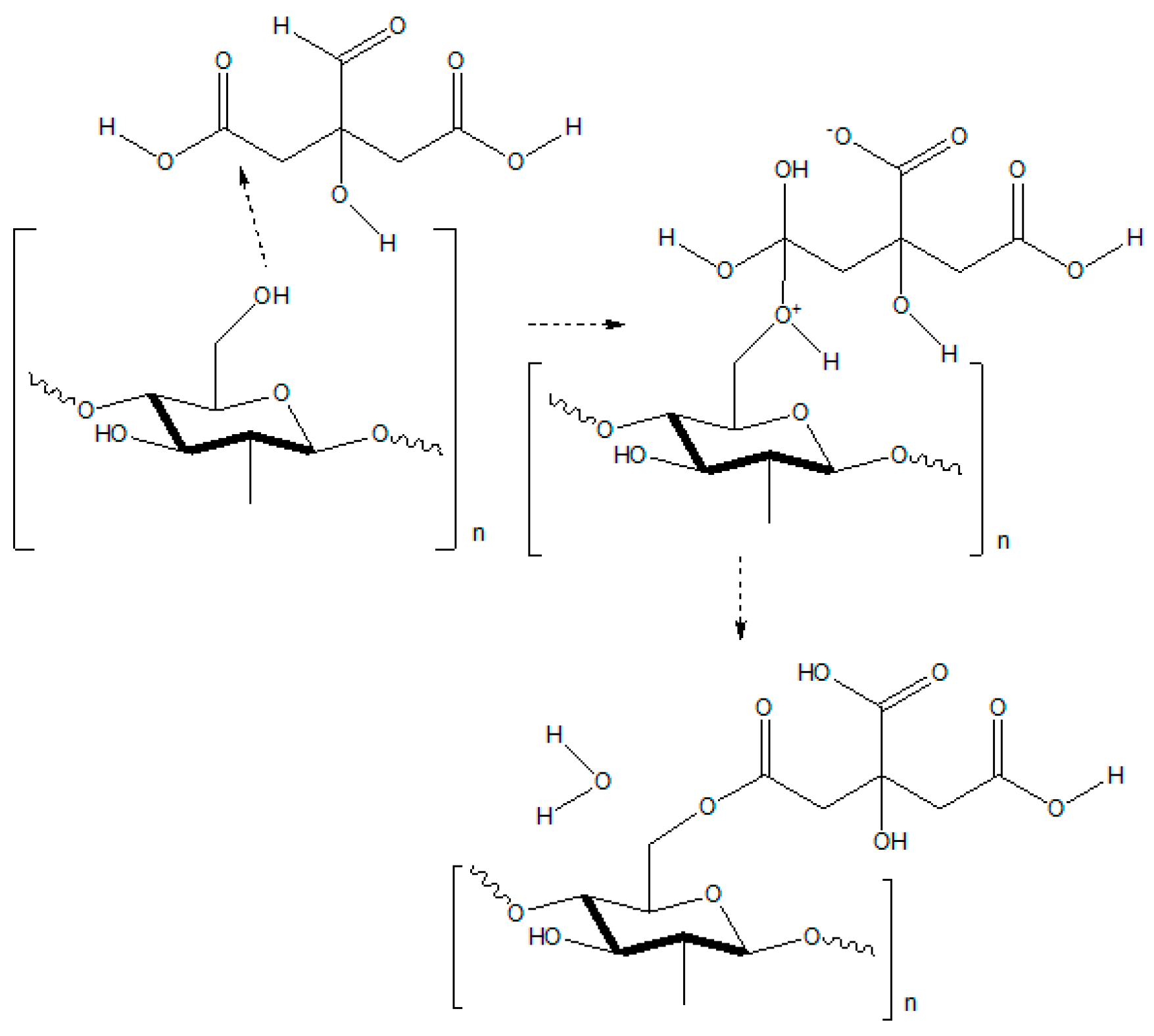

2.2. IR Spectroscopy

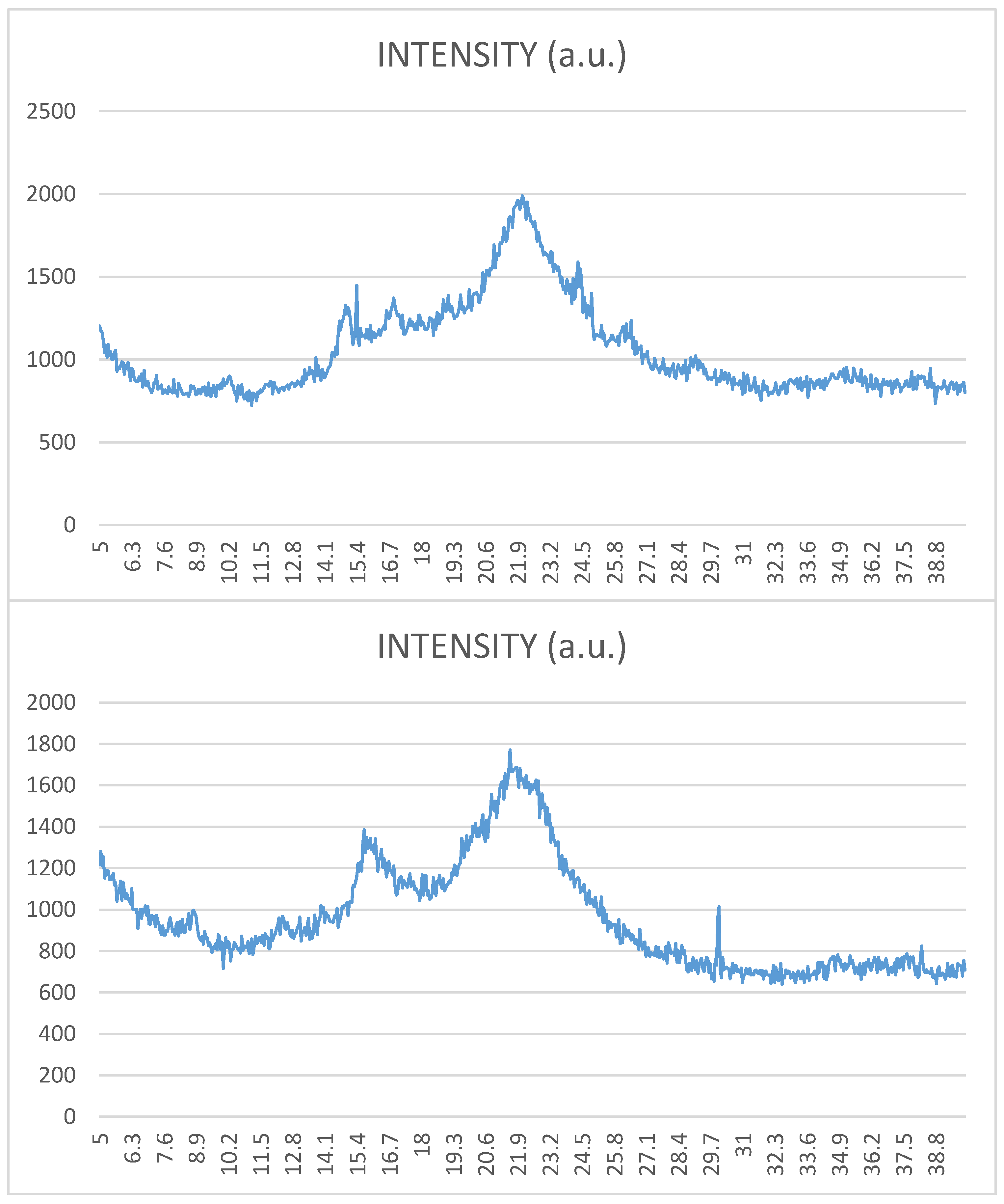

2.3. X-ray Diffraction

2.4. Zeta Potential

2.5. Water Holding Capacity

3. Materials and Methods

3.1. Materials Preparation

3.2. Water Holding Capacity

3.3. FT-IR Analyses

3.4. XRD Analysis

3.5. Nitrogen Physisorption Measurements

3.6. Disc Preparation

3.7. Zeta potential

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- López, J.Á.S.; Li, Q.; Thompson, I.P. Biorefinery of waste orange peel. Crit. Rev. Biotechnol. 2010, 30, 63–69. [Google Scholar] [CrossRef] [PubMed]

- Zema, D.; Calabrò, P.S.; Folino, A.; Tamburino, V.; Zappia, G.; Zimbone, S. Valorisation of citrus processing waste: A review. Waste Manag. 2018, 80, 252–273. [Google Scholar] [CrossRef] [PubMed]

- Bicu, I.; Mustata, F. Optimization of isolation of cellulose from orange peel using sodium hydroxide and chelating agents. Carbohydr. Polym. 2013, 98, 341–348. [Google Scholar] [CrossRef] [PubMed]

- Santonocito, A.M.; Vismara, E. Production of Textile from Citrus Fruit. U.S. Patent WO2015018711A1, 26 September 2017. [Google Scholar]

- Rivas-Cantu, R.C.; Mills, P.L.; Jones, K.D. A citrus waste-based biorefinery as a source of renewable energy: Technical advances and analysis of engineering challenges. Waste Manag. Res. 2013, 31, 413–420. [Google Scholar] [CrossRef] [PubMed]

- Phanthong, P.; Reubroycharoen, P.; Hao, X.; Xu, G.; Abudula, A.; Guan, G. Nanocellulose: Extraction and application. Carbon Resour. Convers. 2018, 1, 32–43. [Google Scholar] [CrossRef]

- Mariño, M.; Da Silva, L.L.; Durán, N.; Tasic, L. Enhanced Materials from Nature: Nanocellulose from Citrus Waste. Molecules 2015, 20, 5908–5923. [Google Scholar] [CrossRef]

- De Melo, E.M.; Clark, J.H.; Matharu, A.S. The Hy-MASS concept: Hydrothermal microwave assisted selective scissoring of cellulose for in situ production of (meso)porous nanocellulose fibrils and crystals. Green Chem. 2017, 19, 3408–3417. [Google Scholar] [CrossRef]

- Naz, S.; Ahmad, N.; Akhtar, J.; Ahmad, N.M.; Ali, A.; Zia, M. Management of citrus waste by switching in the production of nanocellulose. IET Nanobiotechnol. 2016, 10, 395–399. [Google Scholar] [CrossRef]

- De Nooy, A.E.J.; Besemer, A.C.; Van Bekkum, H. On the Use of Stable Organic Nitroxyl Radicals for the Oxidation of Primary and Secondary Alcohols. Synthesis 1996, 1996, 1153–1176. [Google Scholar] [CrossRef]

- Stora Enso, MFC for Packaging. 2020. Available online: https://www.storaenso.com/en/products/bio-based-materials/mfc-for-packaging (accessed on 7 January 2020).

- Jongaroontaprangsee, S.; Chiewchan, N.; Devahastin, S. Production of nanocellulose from lime residues using chemical-free technology. Mater. Today Proc. 2018, 5, 11095–11100. [Google Scholar] [CrossRef]

- Panda, D.; Manickam, S. Cavitation Technology—The Future of Greener Extraction Method: A Review on the Extraction of Natural Products and Process Intensification Mechanism and Perspectives. Appl. Sci. 2019, 9, 766. [Google Scholar] [CrossRef]

- Meneguzzo, F.; Brunetti, C.; Fidalgo, A.; Ciriminna, R.; DeLisi, R.; Albanese, L.; Zabini, F.; Gori, A.; Nascimento, L.B.D.S.; De Carlo, A.; et al. Real-Scale Integral Valorization of Waste Orange Peel via Hydrodynamic Cavitation. Processes 2019, 7, 581. [Google Scholar] [CrossRef]

- Meneguzzo, F.; Ciriminna, R.; Zabini, F.; Pagliaro, M. Review of Evidence Available on Hesperidin-Rich Products as Potential Tools against COVID-19 and Hydrodynamic Cavitation-Based Extraction as a Method of Increasing Their Production. Processes 2020, 8, 549. [Google Scholar] [CrossRef]

- Nuzzo, D.; Cristaldi, L.; Sciortino, M.; Albanese, L.; Scurria, A.; Zabini, F.; Lino, C.; Pagliaro, M.; Meneguzzo, F.; Di Carlo, M.; et al. Exceptional Antioxidant, Non-Cytotoxic Activity of Integral Lemon Pectin from Hydrodynamic Cavitation. ChemistrySelect 2020, 5, 5066–5071. [Google Scholar] [CrossRef]

- Presentato, A.; Scurria, A.; Albanese, L.; Lino, C.; Sciortino, M.; Pagliaro, M.; Zabini, F.; Meneguzzo, F.; Alduina, R.; Nuzzo, D.; et al. Superior Antibacterial Activity of Integral Lemon Pectin Extracted via Hydrodynamic Cavitation. ChemistryOpen 2020, 9, 628–630. [Google Scholar] [CrossRef]

- Presentato, A.; Piacenza, E.; Scurria, A.; Albanese, L.; Zabini, F.; Meneguzzo, F.; Nuzzo, D.; Pagliaro, M.; Martino, D.F.C.; Alduina, R.; et al. A New Water-Soluble Bactericidal Agent for the Treatment of Infections Caused by Gram-Positive and Gram-Negative Bacterial Strains. Antibiotics 2020, 9, 586. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Chang, S.-S.; Clair, B.; Ruelle, J.; Beauchêne, J.; Di Renzo, F.; Quignard, F.; Zhao, G.-J.; Yamamoto, H.; Gril, J. Mesoporosity as a new parameter for understanding tension stress generation in trees. J. Exp. Bot. 2009, 60, 3023–3030. [Google Scholar] [CrossRef]

- Groen, J. Critical appraisal of mesopore characterization by adsorption analysis. Appl. Catal. A: Gen. 2004, 268, 121–125. [Google Scholar] [CrossRef]

- Zhbankov, R.G.; Firsov, S.P.; Korolik, E.V.; Petrov, P.T.; Lapkovski, M.P.; Tsarenkov, V.M.; Marchewka, M.K.; Ratajcak, H. Vibrational spectra and the structure of medical biopolymers. J. Mol. Struct. 2000, 555, 85–96. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A. IR Study on Cellulose with the Varied Moisture Contents: Insight into the Supramolecular Structure. Materials 2020, 13, 4573. [Google Scholar] [CrossRef] [PubMed]

- Berezin, K.V.; Shagautdinova, I.T.; Chernavina, M.L.; Novoselova, A.V.; Dvoretskii, K.N.; Likhter, A.M. The experimental vibrational infrared spectrum of lemon peel and simulation of spectral properties of the plant cell wall. Opt. Spectrosc. 2017, 123, 495–500. [Google Scholar] [CrossRef]

- Oh, S.Y.; Yoo, D.I.; Shin, Y.; Seo, G. FTIR analysis of cellulose treated with sodium hydroxide and carbon dioxide. Carbohydr. Res. 2005, 340, 417–428. [Google Scholar] [CrossRef] [PubMed]

- Widsten, P.; Dooley, N.; Parr, R.; Capricho, J.; Suckling, I. Citric acid crosslinking of paper products for improved high-humidity performance. Carbohydr. Polym. 2014, 101, 998–1004. [Google Scholar] [CrossRef] [PubMed]

- Arslanoglu, H.; Altundoğan, H.S.; Tumen, F. Preparation of cation exchanger from lemon and sorption of divalent heavy metals. Bioresour. Technol. 2008, 99, 2699–2705. [Google Scholar] [CrossRef]

- Bondancia, T.J.; De Aguiar, J.; Batista, G.; Cruz, A.J.G.; Marconcini, J.M.; Mattoso, L.H.C.; Farinas, C.S. Production of Nanocellulose Using Citric Acid in a Biorefinery Concept: Effect of the Hydrolysis Reaction Time and Techno-Economic Analysis. Ind. Eng. Chem. Res. 2020, 59, 11505–11516. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.; Martin, A.; Conrad, C. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Scurria, A.; Sciortino, M.; Presentato, A.; Lino, C.; Piacenza, E.; Albanese, L.; Zabini, F.; Meneguzzo, F.; Nuzzo, D.; Pagliaro, M.; et al. Volatile Compounds of Lemon and Grapefruit IntegroPectin. Molecules 2020, 26, 51. [Google Scholar] [CrossRef]

- Satyamurthy, P.; Jain, P.; Balasubramanya, R.H.; Vigneshwaran, N. Preparation and characterization of cellulose nanowhiskers from cotton fibres by controlled microbial hydrolysis. Carbohydr. Polym. 2011, 83, 122–129. [Google Scholar] [CrossRef]

- Karabourniotis, G.; Horner, H.T.; Bresta, P.; Nikolopoulos, D.; Liakopoulos, G. New insights into the functions of carbon–calcium inclusions in plants. New Phytol. 2020, 228, 845–854. [Google Scholar] [CrossRef]

- Bhattacharjee, S. DLS and zeta potential—What they are and what they are not? J. Control. Release 2016, 235, 337–351. [Google Scholar] [CrossRef] [PubMed]

- Ang, J.F. Water Retention Capacity and Viscosity Effect of Powdered Cellulose. J. Food Sci. 1991, 56, 1682–1684. [Google Scholar] [CrossRef]

- Mahato, N.; Sharma, K.; Sinha, M.; Baral, E.R.; Koteswararao, R.; Dhyani, A.; Cho, M.H.; Cho, S. Bio-sorbents, industrially important chemicals and novel materials from citrus processing waste as a sustainable and renewable bioresource: A review. J. Adv. Res. 2020, 23, 61–82. [Google Scholar] [CrossRef] [PubMed]

- Chemat, F.; Vian, M.A.; Cravotto, G. Green Extraction of Natural Products: Concept and Principles. Int. J. Mol. Sci. 2012, 13, 8615–8627. [Google Scholar] [CrossRef] [PubMed]

| Entry | Sample | Specific Pore Volume (cm³/g) | Pore Size (nm) |

|---|---|---|---|

| 1 | Lemon CytroCell | 0.137 a | 29.49 a |

| 2 | Lemon CytroCell | 0.137 b | 27.34 b |

| 3 | Grapefruit CytroCell | 0.117 a | 23.63 a |

| 4 | Grapefruit CytroCell | 0.125 b | 23.96 b |

| Wavenumber of Absorption Bands (cm−1) | Chemical Group |

|---|---|

| 3300–3400 | νOH covalent bond, hydrogen bonding |

| 2850–2925 | νCH, νCH2 |

| 1641 | absorbed water (hydrogen-bonded) |

| 1428 | δCH2 (symmetric) at C-6; crystalline region |

| 1236 | δCOH in plane at C-6 |

| 1160 | νCOC at β-glycosidic linkage |

| 1104 | ν(C-O-C) in ring |

| 1030 | νCO at C-6 |

| 897 | νCOC at β-glycosidic linkage, amorphous region |

| 662 | δCOH out of plane |

| Material | Zeta Potential (mV) |

|---|---|

| Lemon CytroCell | −29.5 |

| Grapefruit CytroCell | −22.67 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scurria, A.; Albanese, L.; Pagliaro, M.; Zabini, F.; Giordano, F.; Meneguzzo, F.; Ciriminna, R. CytroCell: Valued Cellulose from Citrus Processing Waste. Molecules 2021, 26, 596. https://doi.org/10.3390/molecules26030596

Scurria A, Albanese L, Pagliaro M, Zabini F, Giordano F, Meneguzzo F, Ciriminna R. CytroCell: Valued Cellulose from Citrus Processing Waste. Molecules. 2021; 26(3):596. https://doi.org/10.3390/molecules26030596

Chicago/Turabian StyleScurria, Antonino, Lorenzo Albanese, Mario Pagliaro, Federica Zabini, Francesco Giordano, Francesco Meneguzzo, and Rosaria Ciriminna. 2021. "CytroCell: Valued Cellulose from Citrus Processing Waste" Molecules 26, no. 3: 596. https://doi.org/10.3390/molecules26030596

APA StyleScurria, A., Albanese, L., Pagliaro, M., Zabini, F., Giordano, F., Meneguzzo, F., & Ciriminna, R. (2021). CytroCell: Valued Cellulose from Citrus Processing Waste. Molecules, 26(3), 596. https://doi.org/10.3390/molecules26030596