Functional MgO–Lignin Hybrids and Their Application as Fillers for Polypropylene Composites

Abstract

1. Introduction

2. Results and Discussion

2.1. Characteristics of Inorganic–Organic Hybrid Materials and Pristine Components

2.1.1. Fourier Transform Infrared Spectroscopy (FTIR)

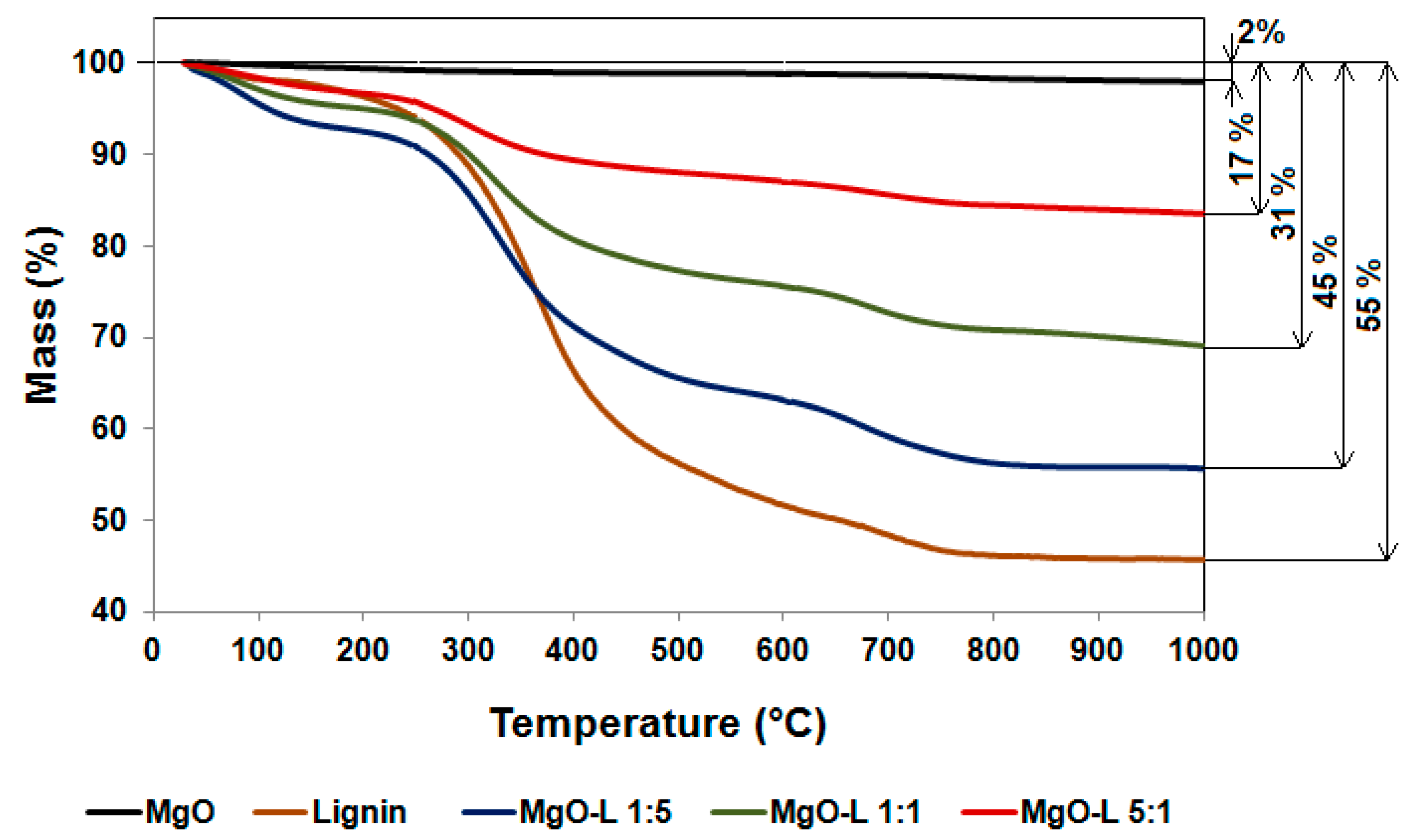

2.1.2. Thermogravimetric Analysis (TGA)

2.1.3. Dispersive-Morphological Properties

2.1.4. Porous Structure Parameters

2.2. Characteristics of Polypropylene (PP)/MgO–Lignin Composites

2.2.1. Wide-Angle X-ray Scattering (WAXS)

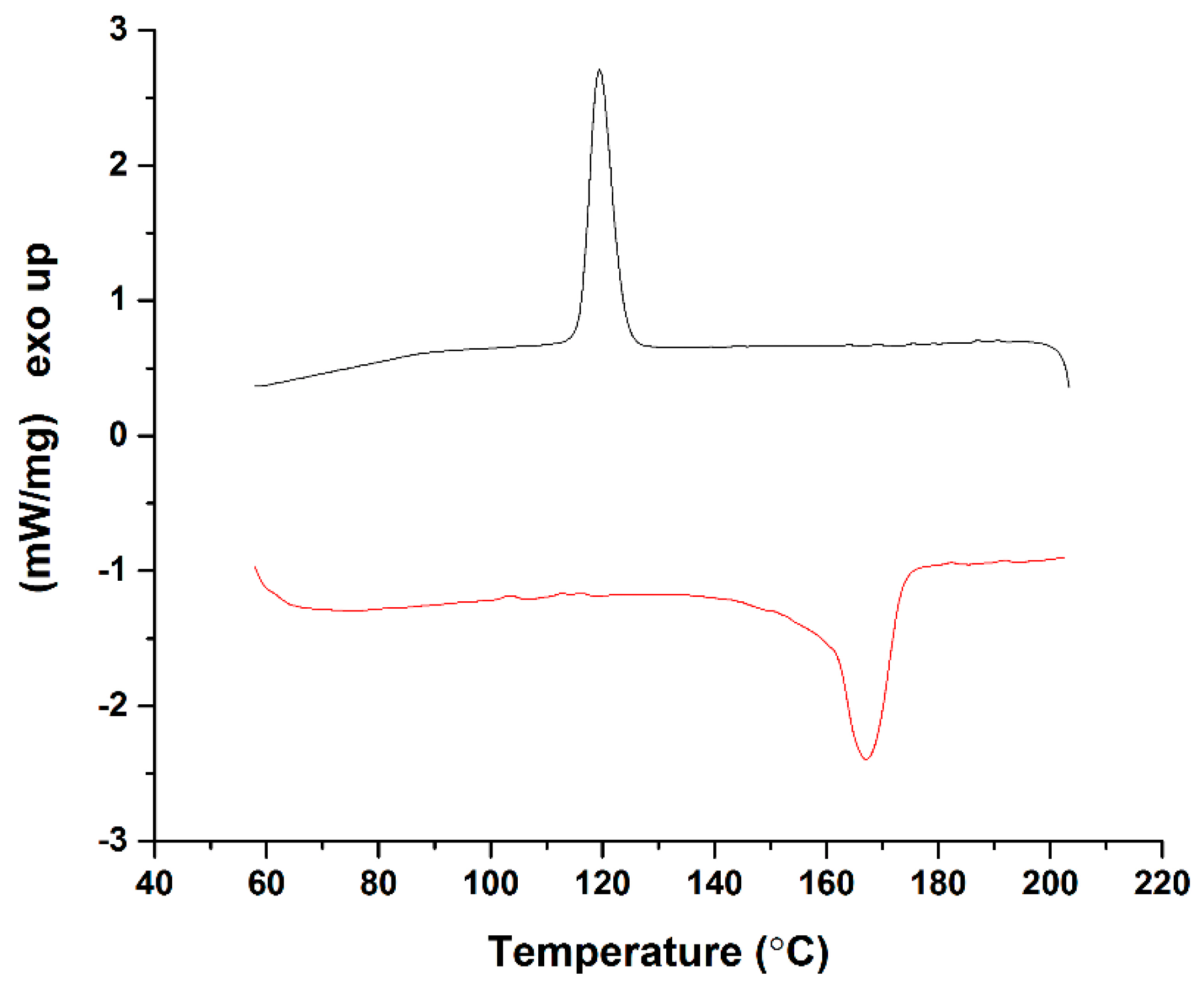

2.2.2. Differential Scanning Calorimetry (DSC)

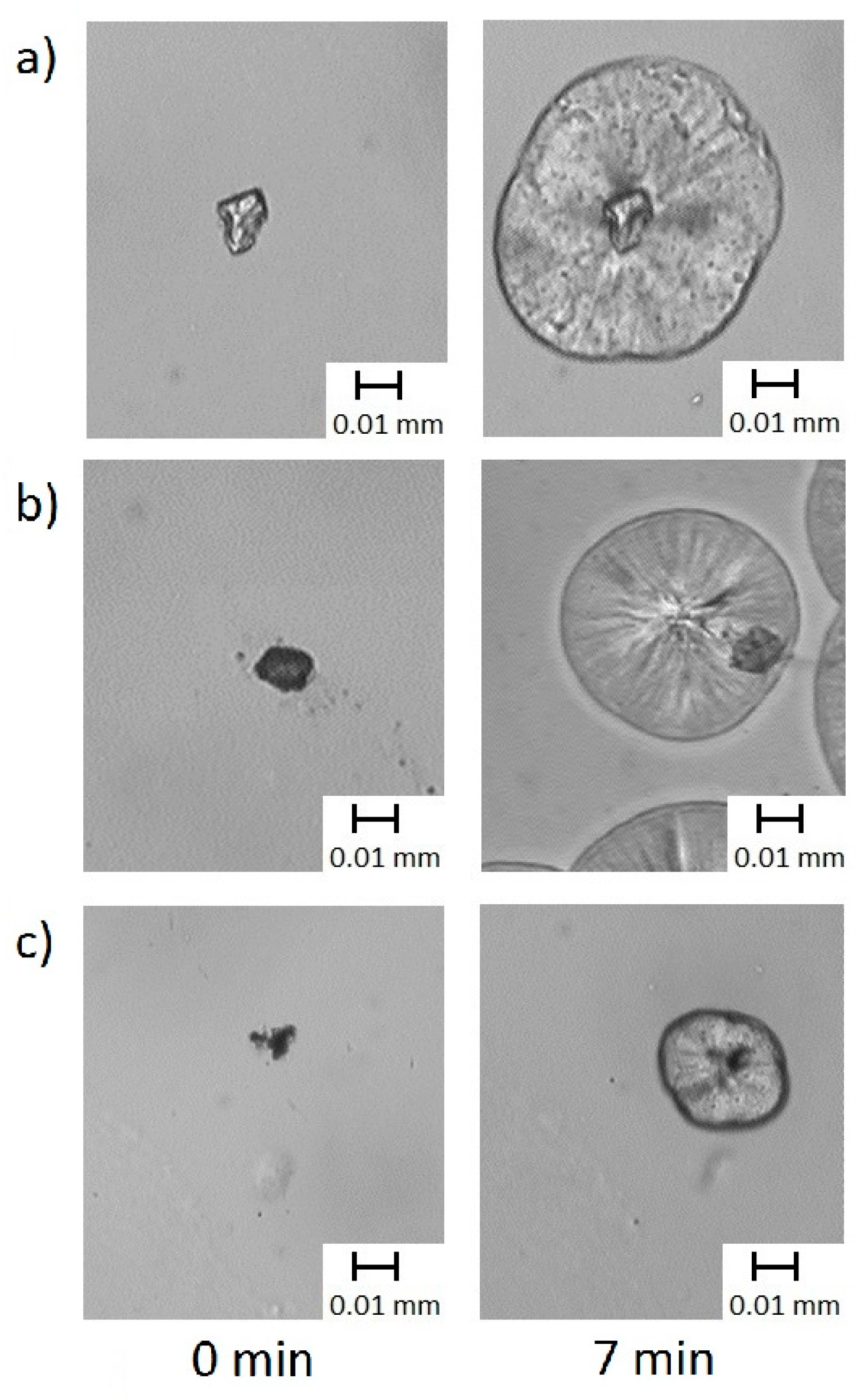

2.2.3. Polarized Light Microscopy (PLM)

2.2.4. Mechanical Properties

3. Materials and Methods

3.1. Materials

3.2. Preparation of MgO–Lignin Hybrid Materials

3.3. Characterization of Inorganic–Organic Hybrid Materials

3.4. Preparation of Polypropylene Composites

3.5. Characterization of Polypropylene Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ragauskas, A.J.; Williams, C.K.; Davison, B.H.; Britovsek, G.; Cairney, J.; Eckert, C.A.; Frederick, W.J., Jr.; Hallett, J.P.; Leak, D.J.; Liotta, C.L.; et al. The path forward for biofuels and biomaterials. Science 2006, 311, 484–489. [Google Scholar] [CrossRef] [PubMed]

- Sanchez, C.; Julián, B.; Belleville, P.; Popall, M. Applications of hybrid organic–inorganic nanocomposite. J. Mater. Chem. 2005, 15, 3559–3592. [Google Scholar] [CrossRef]

- Sanchez, C.; Belleville, P.; Popall, M.; Nicole, L. Applications of advanced hybrid organic–inorganic nanomaterials: From laboratory to market. Chem. Soc. Rev. 2011, 40, 696–753. [Google Scholar] [CrossRef] [PubMed]

- Faustini, M.; Nicole, L.; Ruiz-Hitzky, E.; Sanchez, C. History of organic–inorganic hybrid materials: Prehistory, art, science, and advanced applications. Adv. Funct. Mater. 2018, 28, 1704158. [Google Scholar] [CrossRef]

- Duval, A.; Lawoko, M. A review on lignin-based polymeric, micro- and nano-structured materials. React. Funct. Polym. 2014, 85, 78–96. [Google Scholar] [CrossRef]

- Naseem, A.; Tabasum, S.; Zia, K.M.; Zuber, M.; Ali, M.; Noreen, A. Lignin-derivatives based polymers, blends and composites: A review. Int. J. Biol. Macromol. 2016, 93, 296–313. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K.; Raghavan, P.; Kessler, M.R. Progress in green polymer composites from lignin for multifunctional applications: A review. ACS Sustain. Chem. Eng. 2014, 2, 1072–1092. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Jesionowski, T. Novel lignin-based materials as a products for various applications. In Handbook of Composites from Renewable Materials, Volume 6, Polymeric Composites; Thakur, V.K., Thakur, M.K., Kessler, M.R., Eds.; Wiley Scrivener Publishing: Austin, TX, USA, 2017; pp. 519–554. [Google Scholar]

- Johar, N.; Ahmad, I.; Dufresne, A. Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind. Crop. Prod. 2012, 37, 93–99. [Google Scholar] [CrossRef]

- Figueiredo, P.; Lintinen, K.; Hirvonen, J.T.; Kostiainen, M.A.; Santos, H.A. Properties and chemical modifications of lignin: Towards lignin-based nanomaterials for biomedical applications. Prog. Mater. Sci. 2018, 93, 233–269. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Rzemieniecki, T.; Krawczyk, M.; Malina, D.; Norman, M.; Zdarta, J.; Majchrzak, I.; Dobrowolska, A.; Czaczyk, K.; Jesionowski, T. Kraft lignin/silica–AgNPs as a functional material with antibacterial activity. Colloids Surf. B 2015, 134, 220–228. [Google Scholar] [CrossRef]

- Sahoo, S.; Misra, M.; Mohanty, A.K. Effect of compatibilizer and fillers on the properties of injection molded lignin-based hybrid green composites. J. Appl. Polym. Sci. 2013, 127, 4110–4121. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Nowacka, M.; Milczarek, G.; Jesionowski, T. Physicochemical and electrokinetic properties of silica/lignin biocomposites. Carbohydr. Polym. 2013, 94, 345–355. [Google Scholar] [CrossRef] [PubMed]

- Klapiszewski, Ł.; Grząbka-Zasadzińska, A.; Borysiak, S.; Jesionowski, T. Preparation and characterization of polypropylene composites reinforced by functional ZnO/lignin hybrid materials. Polym. Testing 2019, 79, 106058. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Bartczak, P.; Wysokowski, M.; Jankowska, M.; Kabat, K.; Jesionowski, T. Silica conjugated with kraft lignin and its use as a novel ‘green’ sorbent for hazardous metal ions removal. Chem. Eng. J. 2015, 260, 684–693. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Siwińska-Stefańska, K.; Kołodyńska, D. Preparation and characterization of novel TiO2/lignin and TiO2-SiO2/lignin hybrids and their use as functional biosorbents for Pb(II). Chem. Eng. J. 2017, 314, 169–181. [Google Scholar] [CrossRef]

- Bula, K.; Klapiszewski, Ł.; Jesionowski, T. A novel functional silica/lignin hybrid material as a potential bio-based polypropylene filler. Polym. Compos. 2015, 36, 913–922. [Google Scholar] [CrossRef]

- Grząbka-Zasadzińska, A.; Klapiszewski, Ł.; Bula, K.; Jesionowski, T.; Borysiak, S. Supermolecular structure and nucleation ability of polylactide-based composites with silica/lignin hybrid fillers. J. Therm. Anal. Calorim. 2016, 126, 263–275. [Google Scholar] [CrossRef]

- Grząbka-Zasadzińska, A.; Klapiszewski, Ł.; Borysiak, S.; Jesionowski, T. Thermal and mechanical properties of silica–lignin/polylactide composites subjected to biodegradation. Materials 2018, 11, 2257. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Szalaty, T.J.; Kurc, B.; Stanisz, M.; Zawadzki, B.; Skrzypczak, A.; Jesionowski, T. Development of new acidic imidazolium ionic liquids for activation of kraft lignin by controlled oxidation. Comprehensive evaluation and practical utility. ChemPlusChem 2018, 83, 361–374. [Google Scholar] [CrossRef]

- Choudhury, B.; Choudhury, A. Microstructural, optical and magnetic properties study of nanocrystalline MgO. Mater. Res. Express 2014, 1, 025026. [Google Scholar] [CrossRef]

- Raveesha, H.R.; Nayana, S.; Vasudha, D.R.; Shabaaz Begum, J.P.; Pratibha, S.; Ravikumara, C.R.; Dhananjay, N. The electrochemical behavior, antifungal and cytotoxic activities of phytofabricated MgO nanoparticles using Withania somnifera leaf extract. J. Sci. Adv. Mater. Dev. 2019, 4, 57–65. [Google Scholar] [CrossRef]

- Kleiman, S.; Chaim, R. Thermal stability of MgO nanoparticles. Mater. Lett. 2007, 61, 4489–4491. [Google Scholar] [CrossRef]

- Pilarska, A.; Klapiszewski, Ł.; Jesionowski, T. Recent development in the synthesis, modification and application of Mg(OH)2 and MgO: A review. Powder Technol. 2017, 319, 373–407. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, S.; Zheng, Y.; Luo, Z.; Cen, K. Mechanism study of wood lignin pyrolysis by using TG-FTIR analysis. J. Anal. Appl. Pyrolysis 2008, 82, 170–177. [Google Scholar] [CrossRef]

- Shen, D.K.; Gu, S.; Luo, K.H.; Wang, S.R.; Fang, M.X. The pyrolytic degradation of wood-derived lignin from pulping process. Bioresour. Technol. 2010, 101, 6136–6146. [Google Scholar] [CrossRef] [PubMed]

- Li, S. Combustion synthesis of porous MgO and its adsorption properties. Int. J. Ind. Chem. 2019, 10, 89–96. [Google Scholar] [CrossRef]

- Tian, P.; Han, X.Y.; Ning, G.-L.; Fang, H.-X.; Ye, J.-W.; Gong, W.-T.; Lin, Y. Synthesis of porous hierarchical MgO and its superb adsorption properties. ACS Appl. Mater. Interfaces 2013, 5, 12411–12418. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Bula, K.; Dobrowolska, A.; Czaczyk, K.; Jesionowski, T. A high-density polyethylene container based on ZnO/lignin dual fillers with potential antimicrobial activity. Polym. Testing 2019, 73, 51–59. [Google Scholar] [CrossRef]

- Varga, J. β-Modification of isotactic polypropylene: Preparation, structure, processing, properties, and application. J. Macromol. Sci. B 2002, 41, 1121–1171. [Google Scholar] [CrossRef]

- Sobczak, R.; Nitkiewicz, Z.; Koszkul, J. Struktura nadcząsteczkowa i własności termiczne kompozytów na osnowie polipropylenu wzmacnianych włóknem szklanym. Kompozyty 2003, 8, 343–349. (In Polish) [Google Scholar]

- Li, S.; Lu, S. The effect of hyperbranched polymer lubricant as a compatibilizer on the structure and properties of lignin/polypropylene composites. Wood Mater. Sci. Eng. 2013, 8, 159–165. [Google Scholar]

- Borysiak, S. Fundamental studies on lignocellulose/polypropylene composites: effects of wood treatment on the transcrystalline morphology and mechanical properties. J. Appl. Polym. Sci. 2013, 127, 1309–1322. [Google Scholar] [CrossRef]

- Felix, J.M.; Gatenholm, P. Effect of transcrystalline morphology on interfacial adhesion in cellulose/polypropylene composites. J. Mater. Sci. 1994, 29, 3043–3049. [Google Scholar] [CrossRef]

- Zhou, Y.; Jinliang, H.; Hu, J.; Dang, B. Surface-modified MgO nanoparticle enhances the mechanical and direct-current electrical characteristics of polypropylene/polyolefin elastomer nanodielectrics. J. Appl. Polym. Sci. 2016, 133, 42863–42873. [Google Scholar] [CrossRef]

- Dörrstein, J.; Scholz, R.; Schwarz, D.; Schieder, D.; Sieber, V.; Walther, F.; Zollfrank, C. Effects of high-lignin-loading on thermal, mechanical, and morphological properties of bioplastic composites. Compos. Struct. 2018, 189, 349–356. [Google Scholar]

- Ouyang, W.; Huang, Y.; Luo, H.; Wang, D. Poly(Lactic Acid) blended with cellulolytic enzyme lignin: Mechanical and thermal properties and morphology evaluation. J. Polym. Environ. 2012, 20, 1–9. [Google Scholar] [CrossRef]

- Chen, F.; Dai, H.; Dong, X.; Yang, J.; Zhong, M. Physical properties of lignin-based polypropylene blends. Polym. Compos. 2011, 32, 1019–1025. [Google Scholar] [CrossRef]

- Morandim-Giannetti, A.A.; Angelli, J.A.M.; Lancas, B.Z.; Magnabosco, R.; Casarin, S.A.; Bettini, S.H.P. Lignin as additive in polypropylene/coir composites: Thermal, mechanical and morphological properties. Carbohydr. Polym. 2012, 87, 2563–2568. [Google Scholar] [CrossRef]

- Zaborski, M.; Kosmalska, A.; Masak, A. Elastomer composites with proecological additives. Przem. Chem. 2017, 96, 163–168. [Google Scholar]

- Mark, J.E. Physical Properties of Polymers Handbook; Springer Nature Switzerland AG: Basel, Switzerland, 2018. [Google Scholar]

Sample Availability: Not available. |

| Sample Name | Dispersive Properties | |||||

|---|---|---|---|---|---|---|

| Particle Size Distribution from Zetasizer Nano ZS (nm) | Polydispersity Index (PDI) from Zetasizer Nano ZS | Particle Diameter from Mastersizer 2000 (μm) | ||||

| d(0.1) 1 | d(0.5) 2 | d(0.9) 3 | D [4.3] 4 | |||

| MgO | 106–2670 | 0.286 | 0.5 | 1.2 | 2.1 | 1.4 |

| Lignin | 91–122, 712–1110, 2670–4800 | 0.691 | 2.1 | 5.2 | 8.3 | 6.5 |

| MgO–lignin (1:5 wt./wt.) | 122–615, 1720–5560 | 0.587 | 1.6 | 3.8 | 4.5 | 4.0 |

| MgO–lignin (1:1 wt./wt.) | 106–615, 1484–4800 | 0.522 | 1.4 | 3.1 | 4.2 | 3.2 |

| MgO–lignin (5:1 wt./wt.) | 106–712, 1110–2670 | 0.461 | 1.4 | 2.9 | 4.1 | 3.0 |

| Sample Name | Porous Structure Properties | ||

|---|---|---|---|

| ABET (m2/g) 1 | Sp (nm) 2 | Vp (cm3/g) 3 | |

| MgO | 99 | 2.20 | 0.037 |

| Lignin | 1 | 9.21 | 0.001 |

| MgO–lignin (1:5 wt./wt.) | 23 | 2.19 | 0.010 |

| MgO–lignin (1:1 wt./wt.) | 54 | 2.19 | 0.021 |

| MgO–lignin (5:1 wt./wt.) | 92 | 2.20 | 0.035 |

| Sample Name | Xc (%) 1 |

|---|---|

| PP | |

| PP + MgO-lignin 5:1 | 58 |

| PP + MgO-lignin 1:5 | 57 |

| PP + MgO-lignin 1:1 | 53 |

| Sample Name | ΔHm (J/g) 1 | Tm (°C) 2 | Tc (°C) 3 | Xc (%) 4 |

|---|---|---|---|---|

| PP | 76 | 164 | 113 | 36 |

| PP + MgO–lignin 5:1 | 78 | 167 | 120 | 37 |

| PP + MgO–lignin 1:5 | 82 | 167 | 121 | 39 |

| PP + MgO–lignin 1:1 | 86 | 167 | 120 | 41 |

| Sample Name | t0.5 (min) 1 |

|---|---|

| PP | 2.65 |

| PP + MgO-lignin 5:1 | 1.90 |

| PP + MgO-lignin 1:5 | 1.70 |

| PP + MgO-lignin 1:1 | 1.77 |

| Sample Name | Growth Rate of Transcrystalline Layer (or Spherulite *) (µm/min) | Induction Time (min) |

|---|---|---|

| PP + MgO–lignin 5:1 | 5.4 | 0.5 |

| PP + MgO–lignin 1:5 | 4.3* | 0.5 |

| PP + MgO–lignin 1:1 | 1.4 | 3.5 |

| YM 1 [MPa] | TS 2 [MPa] | EB 3 [%] | |

|---|---|---|---|

| PP | 1328 ± 22.4 | 33.8 ± 0.40 | 91.8 ± 4.4 |

| PP + MgO-lignin 5:1 | 1382 ± 15.1 | 32.8 ± 0.31 | 8.0 ± 0.4 |

| PP + MgO-lignin 1:5 | 1375 ± 21.8 | 33.2 ± 0.20 | 8.9 ± 0.1 |

| PP + MgO-lignin 1:1 | 1372 ± 4.4 | 33.0 ± 0.17 | 8.2 ± 0.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grząbka-Zasadzińska, A.; Klapiszewski, Ł.; Jesionowski, T.; Borysiak, S. Functional MgO–Lignin Hybrids and Their Application as Fillers for Polypropylene Composites. Molecules 2020, 25, 864. https://doi.org/10.3390/molecules25040864

Grząbka-Zasadzińska A, Klapiszewski Ł, Jesionowski T, Borysiak S. Functional MgO–Lignin Hybrids and Their Application as Fillers for Polypropylene Composites. Molecules. 2020; 25(4):864. https://doi.org/10.3390/molecules25040864

Chicago/Turabian StyleGrząbka-Zasadzińska, Aleksandra, Łukasz Klapiszewski, Teofil Jesionowski, and Sławomir Borysiak. 2020. "Functional MgO–Lignin Hybrids and Their Application as Fillers for Polypropylene Composites" Molecules 25, no. 4: 864. https://doi.org/10.3390/molecules25040864

APA StyleGrząbka-Zasadzińska, A., Klapiszewski, Ł., Jesionowski, T., & Borysiak, S. (2020). Functional MgO–Lignin Hybrids and Their Application as Fillers for Polypropylene Composites. Molecules, 25(4), 864. https://doi.org/10.3390/molecules25040864