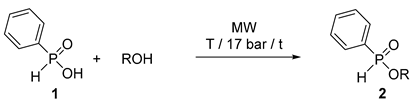

2.1. MW-Assisted Direct Esterification of Phenyl-H-Phosphinic Acid (1)

Before the flow chemical attempts, let us survey the precedents on the batch MW synthesis of alkyl phenyl-

H-phosphinates (

2). In the first round, phosphinic acid

1 was reacted with ethyl and other linear or branched C

3–C

5 and C

8 alcohols applied in a 15-fold quantity at 160–200 °C to afford the esters

2a,

2b,

2d–

i in yields of 73–90% (

Table 1/Entries 1, 3, 7–9, 11, 13, 15, 17 and 19). More developed syntheses were performed in the presence of 10% of [bmim][PF

6] at a lower temperature of 140–160 °C providing the products

2a,

2b,

2d–

I after a short reaction time of 30 min in somewhat higher yields of 82–94% (

Table 1/Entries 2, 4, 10, 12, 14, 16, 18 and 20). It was found earlier that a catalytic amount (5–10%) of the IL is beneficial in the direct esterifications. A few ILs were tested as additives. Although all tested ILs enhanced the esterifications, [bmim][PF

6] was the best one [

24]. In the small-scale reactions it was appropriate to apply 10% of the IL. The basic role of the IL additive may be to enhance the absorption of MWs due to its polar nature. The results with

i-propanol referred to steric hindrance, as an almost complete conversion could only be attained at 180 °C in the presence of the IL (

Table 1/Entries 5 and 6). Most of the results were reported earlier [

20,

26] that were completed by a few new data (

Table 1/Entries 4, 6, 8, 9, 15, 16, 19 and 20).

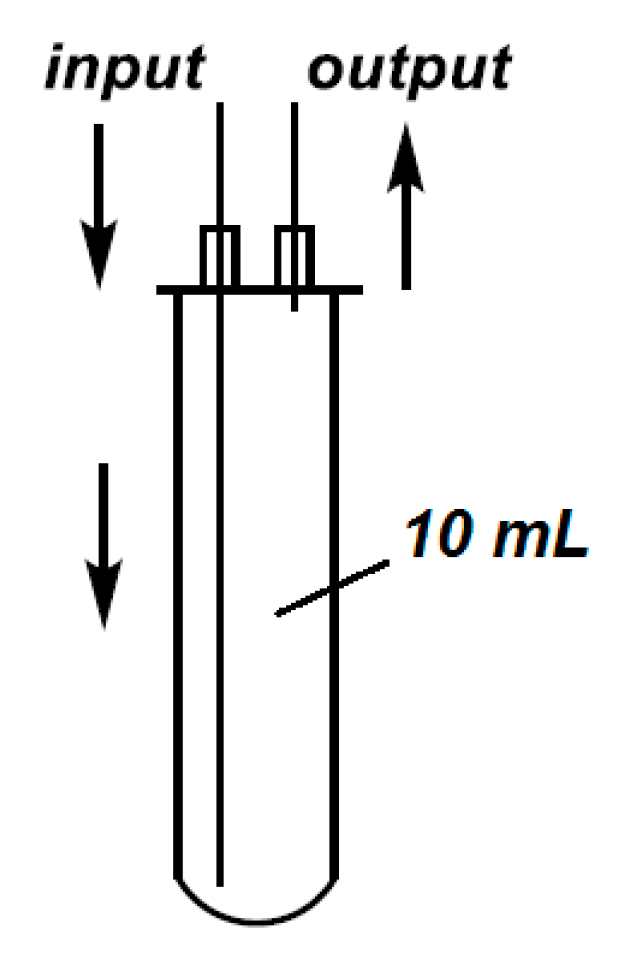

Next, we tried to convert the esterification into a flow method. The sketch of the continuous flow system used in our experiments is shown in

Figure 1. A commercially available flow cell (

Figure 2) was inserted into the CEM reactor, and the transport of the PhP(O)H(OH)/ROH mixture was ensured by a HPLC pump. The pressure was maintained by a back pressure regulator.

During the continuous flow esterification of phenyl-

H-phosphinic acid (

1), 0.10 g

1/mL alcohol solutions were prepared, and fed in the reactor at different temperatures (160–200 °C) and flow rates (

Table 2). The unstationary phase that was comparable with the residence time (at

V = 0.15 mL/min and

V =0.25 mL/min t = 67 min and t = 40 min, respectively) was followed by the steady state operation. The esterifications were monitored by

31P-NMR measurements. The reaction of phosphinic acid

1 with

nBuOH was investigated in detail. In this particular case, the 0.1 g/mL concentration means 15-fold quantity of the alcohol. Increasing the temperature from 160 °C to 180 °C, and then to 200 °C, at a flow rate of 0.25 mL/min, the conversions were 50%, 53% and 63%, respectively (

Table 2/Entries 1, 3 and 5). At the same temperatures, but setting a lower flow rate of 0.15 mL/min that allows a longer residence time in the reactor, somewhat higher conversions of 54%, 64% and 72%, respectively, were detected (

Table 2/Entries 2, 4 and 6). The addition of 5% of [bmim][PF

6] to the mixture of the reagents prior to irradiation was helpful to attain higher conversions. It has to be mentioned that 5% of the IL was sufficient. Applying a flow rate of 0.25 mL/min at 160 °C, 180 °C and 200 °C, the conversions were 66%, 83% and 100%, respectively (

Table 2/Entries 7, 9 and 11). At a lower rate of 0.15 mL/min, the conversions were somewhat higher 72% (160 °C) and 95% (180 °C) (

Table 2/Entries 8 and 10) than setting 0.25 mL/min. In the next step, the volatile alcohols EtOH,

nPrOH and

iPrOH were reacted at the possible maximum temperatures of 160–180 °C applying the lower flow rate of 0.15 mL/min. In these cases, the conversions were 65%, 71% and 68%, respectively (

Table 2/Entries 12–14). Recycling the mixture from the esterification with EtOH, and re-reacting it under the same conditions (160 °C/0.15 mL/min), the conversion became quantitative (see footnote “e” of

Table 2). The comparative thermal esterification of phosphinic acid

1 with EtOH at 160 °C applying a flow rate of 0.15 mL/min proceeded until a conversion of 35% (see footnote “d” of

Table 2). Using

iBuOH (160 °C, 0.15 mL/min), the conversion was quantitative (

Table 2/Entry 15).

nPentOH,

iPentOH,

nOctOH and

iOctOH allowed the application of a somewhat higher temperature of 180–200 °C. In these cases, the higher rate of 0.25 mL/min was efficient at 190 °C (and in one case at 200 °C) as the conversions were quantitative (

Table 2/Entries 17, 19, 21 and 23). Applying a lower flow rate of 0.15 mL/min at somewhat lower temperature of 180 °C, the conversion was 100%, or almost quantitative (

Table 2/Entries 16, 18, 20 and 22). The yields of the phosphinates

2a–

i prepared from the best experiments fell in the range of 63–91%. If there is a time frame for the preparation of the esters (

2), it is worth choosing the parameter set of 190 °C/0.25 mL/min against 180 °C/0.15 mL/min.

Comparing the batch and continuous flow preparation of the butyl-(

2d) or pentyl phosphinate (

2f) (

Table 1/Entries 10 and 14 vs.

Table 2/Entries 11 and 17), one can conclude that the flow operation afforded products

2d and

2f in a 4.5-fold and 6.9-fold higher quantity, respectively, as compared to the corresponding batch method. Of course, during the comparison, the operation time of the flow reactor should be equal to the reaction time applied in the batch reactor. It can be said that the batch method provides ca. 0.10 g ester/30 min, while the flow preparation may give ca. 0.75 g product after the same time. It can be concluded that the batch approach is more limited in respect of scale. If more alkyl phenyl-

H-phosphinate is needed, it is worth choosing the flow operation. It is noteworthy that the quantity of the IL (that is the most expensive component) could be halved, as 5% was enough.

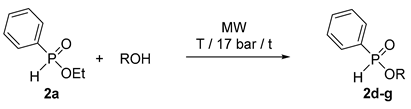

2.2. MW-Assisted Transesterification of Ethyl-Phenyl-H-Phosphinate (2a)

As an alternative method to direct esterification, transesterification (alcoholysis) is another option for the preparation of esters, and seemed to be a suitable model for MW application. For this, we wished to investigate the reaction of ethyl phenyl-

H-phosphinate (

2a) (a commercially available P-ester) with simple alcohols under MWs to prepare other representatives of this family of compound. The C

1, C

3–C

5 alcohols, along with BnOH were applied in a 15-fold quantity, and with the exception of the volatile MeOH, they were used at 160–190 °C. The experimental data are listed in

Table 3. One can see that in reaction with MeOH at 120 °C for 3 h and at 140 °C for 2 h, a conversion average of 91% was attained (

Table 3/Entries 1 and 2). Alcoholysis with

nPrOH and

iPrOH at 180 °C took place in conversions of 97% and 89%, after reaction times of 1 h and 2 h, respectively (

Table 3/Entries 3 and 4). Regarding

nBuOH, quantitative conversions could be observed at parameter sets of 160 °C/2.25 h and 180 °C/40 min (

Table 3/Entries 5 and 6). The transesterifications of ethyl phosphinate

2a with

iBuOH,

nPentOH,

iPentOH, 3-PentOH and BnOH were complete at 160 °C/2.25 h, 180 °C/40 min, 190 °C/40 min, 190 °C/45 min, and 180 °C/1 h, respectively (

Table 3/Entries 7–11). Phosphinates

2b–

g, 2j–

l were obtained in yields of 74–91% after flash column chromatography. One may conclude that the uncatalyzed transesterifications of

H-phosphinate

2a requires harsh conditions, but can be performed efficiently under MW irradiation.

In the next phase, we tried to elaborate the continuous flow transesterification of ethyl phosphinate

2a with

nBuOH applied in a 15-fold excess quantity. As can be seen from

Table 4, at 180 or 200 °C, the alcoholysis remained incomplete (as characterized by conversions of 53–84%) no matter if the flow rate was 0.25 or 0.15 mL/min (

Table 4/Entries 1–4). At 220 °C, the conversions were 81% (0.25 mL/min) and 94% (0.15 mL/min) (

Table 4/Entries 5 and 6). The optimum parameter set for a quantitative reaction involved a temperature of 225 °C and a flow rate of 0.15 mL/min (

Table 4/Entry 7). In this case, the yield of butyl phosphinate

2d was 85%. Adopting these parameters to the transesterification of phosphinate

2a with

iBuOH,

nPentOH and

iPentOH, the corresponding esters

2e–

g were obtained in complete conversions, and in high yields of 82–89%.

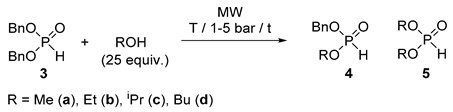

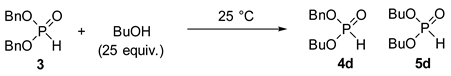

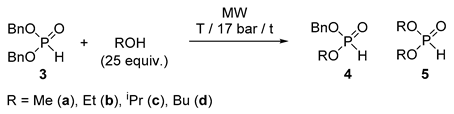

2.3. MW-Assisted Transesterification of Dibenzyl Phosphite (3)

Keglevich and co-workers have investigated the MW-assisted transesterifications (alcoholyses) of dialkyl phosphites [

27,

28]. These kinds of reactions take place in two steps resulting first in a phosphite with two different alkyl groups, and in the second step the fully transesterified dialkyl phosphite. The outcome of the reaction depended on the temperature, and on the molar ratio of the reactants. It was not easy to achieve selectivity. At the same time, it is known that the benzyl phosphonates may undergo easy substitution of the BnO group [

29]. For this, alcoholysis of dibenzyl phosphite (

3) seemed to be an appropriate model. Simple C

1–C

4 alkyl alcohols were used as reactants in 25 equivalent quantities in the temperature range of 80–130 °C under MW irradiation. Experimental data can be found in

Table 5. In reaction with MeOH, irradiation at 80 °C for 3 h or at 120 °C for 0.5 h led to similar results, to a mixture containing 26/26% starting phosphite

3, 57/54% of the intermediate

4a, and 17/20% of the fully transesterified phosphite

5a (

Table 5/Entries 1 and 3). Running the alcoholysis at 100 °C for 2 h or at 120 °C for 1.5 h, dimethyl ester

5a predominated in 56/70% (

Table 5/Entries 2 and 4). After a 2.5 h heating the diester (

5a) was present in a maximum quantity of 87% (

Table 5/Entry 5). Using EtOH, the course of alcoholysis towards diethyl phosphite was somewhat slower than that with MeOH (

Table 5/Entries 6, 9 and 10 vs. 1, 2 and 3, respectively). After an irradiation at 120 °C for 1 h, the ratio of products

3b,

4b and

5b was 9:51:40, that after 4 h was shifted to 0:11:89 (

Table 5/Entries 11 and 12). A comparison was made at 100 °C/0.5 h to see the effect of 20% of [bmim][PF

6] as an additive. In the absence of the IL, the starting dibenzyl phosphite (

3) was the main component (65%), while performing the alcoholysis in the presence of the additive, the diethyl ester (

5) predominated (58%) (

Table 5/Entries 7 and 8). In the presence of

iPrOH as the agent, the consecutive transformation was slower at 100 and 120 °C (

Table 5/Entries 13 and 14). There was need for a 5 h irradiation at 130 °C to compensate the effect of steric hindrance (

Table 5/Entries 15 and 16). In reaction with

nBuOH, almost similar results were obtained as with EtOH (

Table 5/Entries 17, 18 and 20 vs. 9, 10 and 12). A comparative thermal experiment at 100 °C for 2 h took place in a lower conversion of 73% (

Table 5/Entry 17/ footnote “d”). It is recalled that the conversion of the MW variation was 92% (

Table 5/Entry 17). While the relative quantity of the intermediate (

4d) was almost the same (59/61%), that of dibutyl phosphite (

5d) was 14% (Δ) and 31% (MW).

It is noteworthy that the valuable

H-phosphonates with different alkyl groups could be obtained in a maximum proportion of 57% (

4a), 68% (

4b), 60% (

4c) and 61% (

4d) covered by entries 1, 10, 13 and 17, respectively (

Table 5). Isolated yields of the BnO–RO phosphonates

4a–

d fell in the range of 47–59%.

Regarding the conditions (T and t) needed to reach complete conversions (disappearance of the starting material (

3) from the mixture, and predominant appearance of the fully transesterified product (

5)) (see entries 5, 12, 16 and 20 of

Table 5), the order of reactivity of the alcohols was the following: MeOH > BuOH ~ EtOH >

iPrOH.

It is worth noting that dibenzyl phosphite (

3) is significantly more reactive in transeserifications than ethyl phenyl-

H-phosphinate

2a. The enhanced reactivity of dibenzyl phosphite (

3) in transesterification prompted us to try the reaction with

nBuOH at room temperature. The data summarized in

Table 6 and

Figure 3. showed that the consecutive transesterification took place slowly: after 18 days, there was 54% of the starting phosphite (

3) together with 44% of the “mixed” ester

4d, and 2% of the dibutyl derivative

5d (

Table 6/Entry 7). The final “equilibrium” concentration was attained after 38 days, when the mixture comprised 16% of the starting material (

3), 67% of the Bu-Bn ester (

4d) and only 17% of the dibutyl ester (

5d) (

Table 6/Entry 10). This experiment was found reproducible. It is assumed that the application of a larger excess of BuOH would result in the shift of the equilibrium toward esters

4d and

5d. However, it is worth noting that the composition of the above “equilibrium” mixture with 67% of the benzyl-butyl ester (

4d) is favorable, as it is a valuable intermediate.

The next step was to try the continuous flow method. The transesterification of dibenzyl phosphite (

3) with MeOH at 110 °C applying a flow rate of 0.25 mL/min led to a mixture containing 24% of the starting material (

3), 52% of the “mixed” ester (

4a) and 24% of dimethyl phosphite (

5a) (

Table 7/Entry 1). At 120 °C, the composition was 17% (

3), 44% (

4a) and 39% (

5a) (

Table 7/Entry 2). Operation at a lower rate of 0.15 mL/min and at 135 °C provided the three components (

3a,

4a and

5a) in relative quantities of 5%, 23% and 72%, respectively (

Table 7/Entry 3). EtOH displayed somewhat lower reactivity, and under the previous two sets of parameters, mixtures containing 28% of

3b, 48% of

4b, 24% of

5b, and 7% of

3b, 27% of

4b and 66% of

5b, respectively, were obtained (

Table 7/Entries 4 and 7). The use of parameter sets of 0.15 mL/min at 120 °C and 0.25 mL/min at 135 °C resulted in a comparative outcomes of 20/17% of

3b, 40/36% of

4b and 40/47% of

5b (

Table 7/Entries 5 and 6). In agreement with expectation,

iPrOH was found to be the less reactive alcohol. Setting a flow rate of 0.25 mL/min at 120 °C, the composition of the reaction mixture was 49% of

3c, 48% of

4c and 3% of

5c (

Table 7/Entry 8). In order to achieve a more complete conversion, a temperature of 145 °C and a rate of 0.15 mL/min were applied (

Table 7/Entry 9). The results with

nBuOH were again rather similar to those obtained with EtOH (

Table 7/Entries 10 and 11 vs. entries 4 and 7). The experiments providing the phosphites with different alkoxy groups

4a–

d are of importance, as the “mixed” phosphites may be used as valuable intermediates in the reactions outlined in the Introduction. Optical resolution may lead to enantiomer-enriched forms of the >P(O)H species. The best runs are marked by entries 1, 4, 8 and 10 of

Table 7. The proportions of 47–52% allowed isolated yields of 39–44% for the “mixed” esters

4a–

d. A comparative thermal transesterification of dibenzyl ester

3 with butanol at 120 °C and at a flow rate of 0.25 mL/min led to a composition of 49% of starting material

3, 47% of benzyl-butyl ester

4d, and 4% of dibutyl ester

5d, suggesting that on conventional heating, the efficiency is lower (compare footnote “d” of

Table 7 with Entry 10).

As a novel trial, the pre-reacted mixture of dibenzyl phosphite (3) and BuOH (26 °C, 18 days) comprising 55% of dibenzyl phosphite, 41% of the “mixed” ester (4d) and 4% of dibutyl phosphite (5d) was re-fed into the flow reactor at 120 °C applying 0.25 mL/min. The final mixture contained 8% of the starting material (3), as well as 23% and 69% of esters 4d and 5d, respectively. Hence, the product ratio could be shifted towards the fully transesterified product 5d.