The Study of HEMs Based on the Mechanically Activated Intermetallic Al12Mg17 Powder

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Al-Mg Material

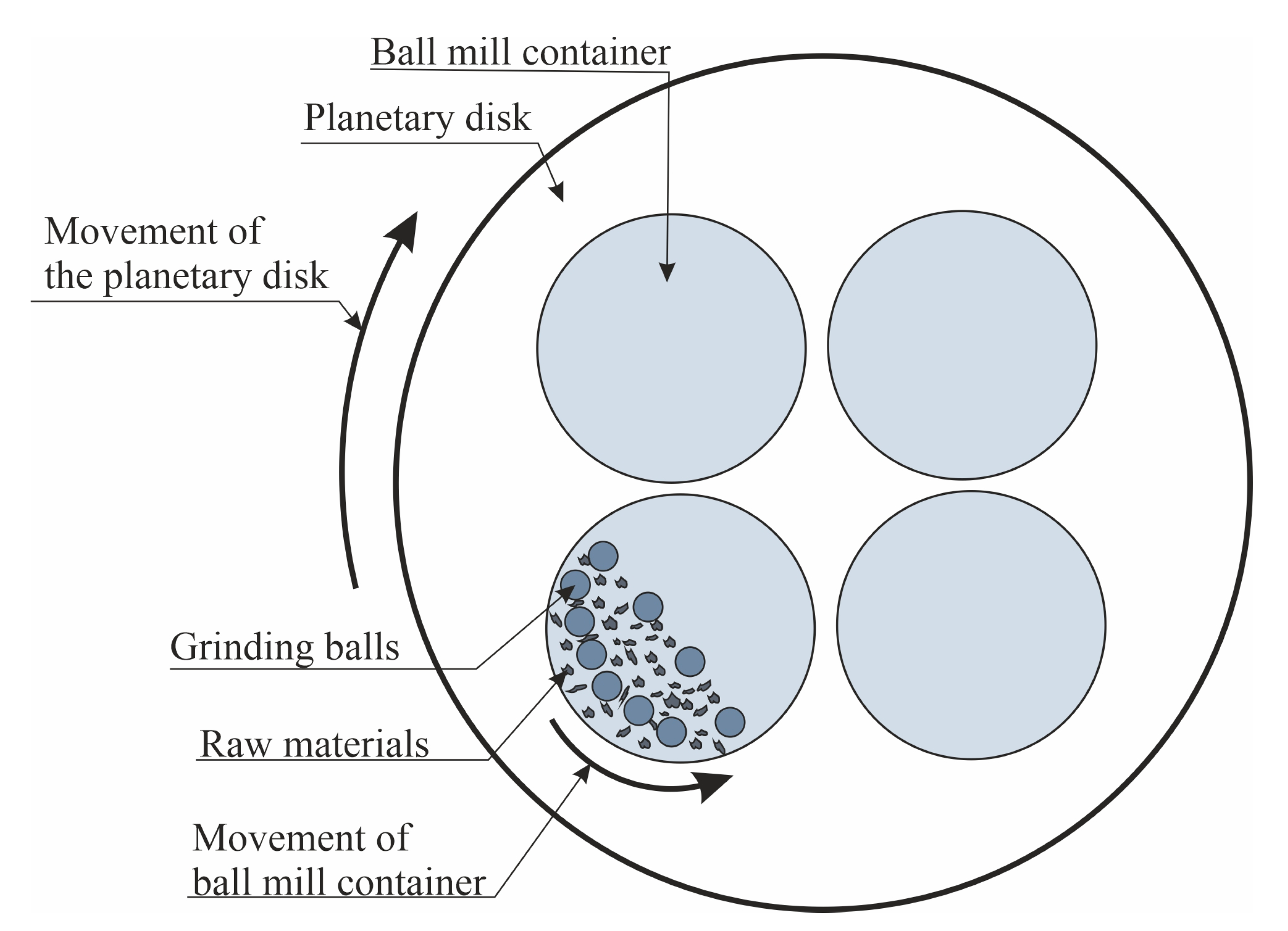

2.2. Mechanical Activation

2.3. Particle Size, Chemical Analysis, Morphology, and Phase Composition

2.4. Calorimetric Studies

2.5. Process to Obtain Samples of HEMs

2.6. Study of the Combustion Heat and Burning Rate of HEMs

3. Results and Discussion

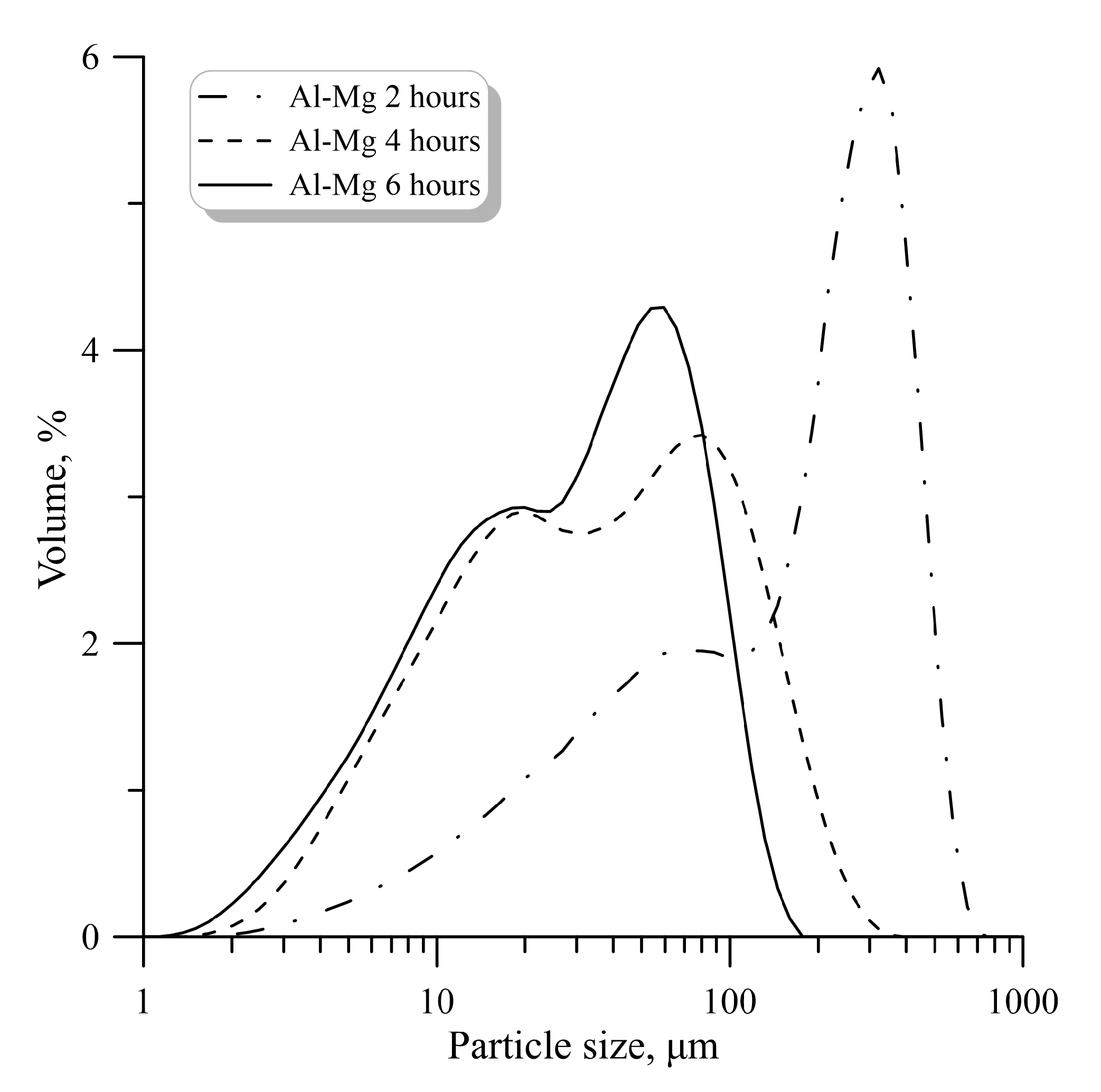

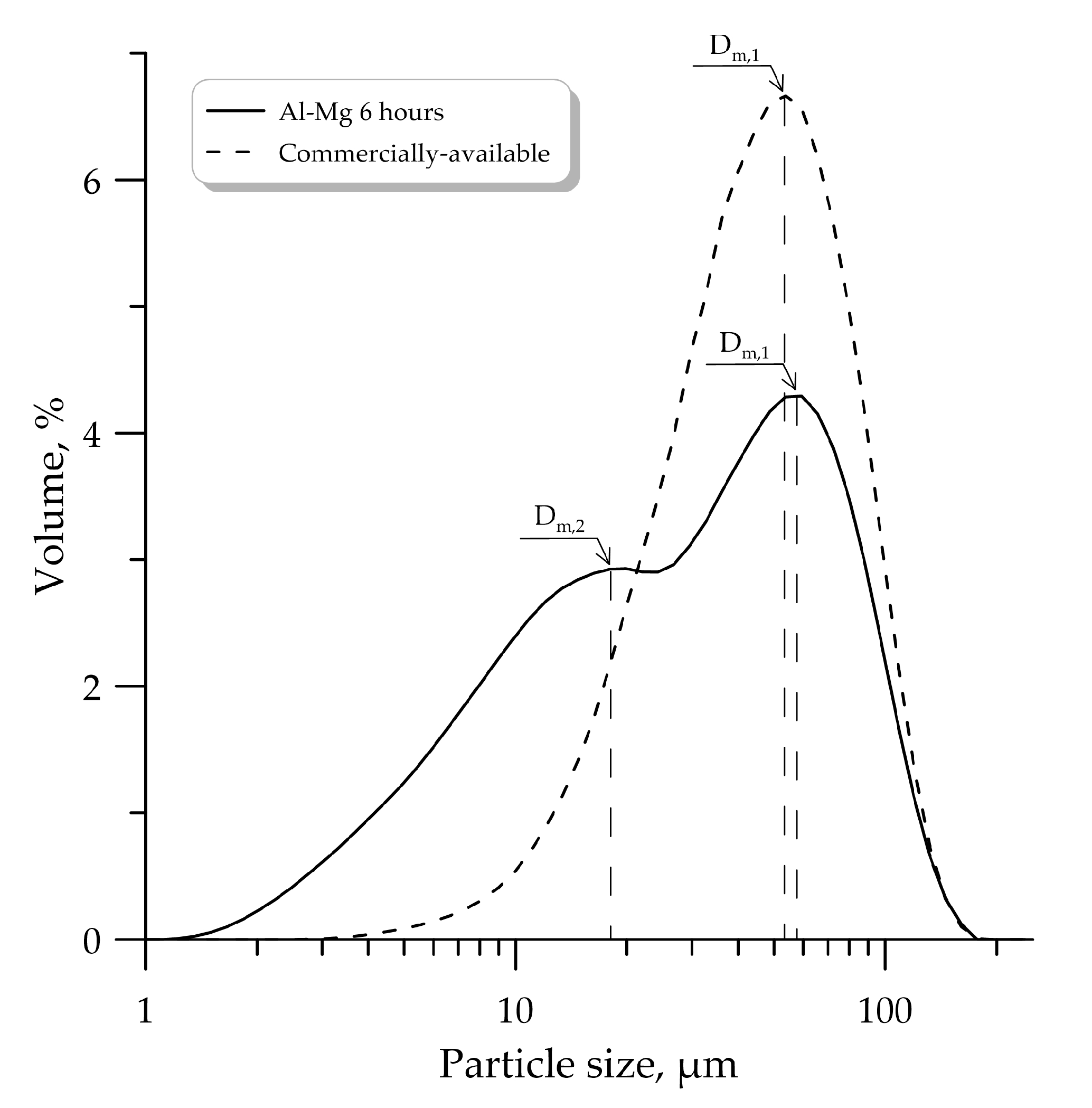

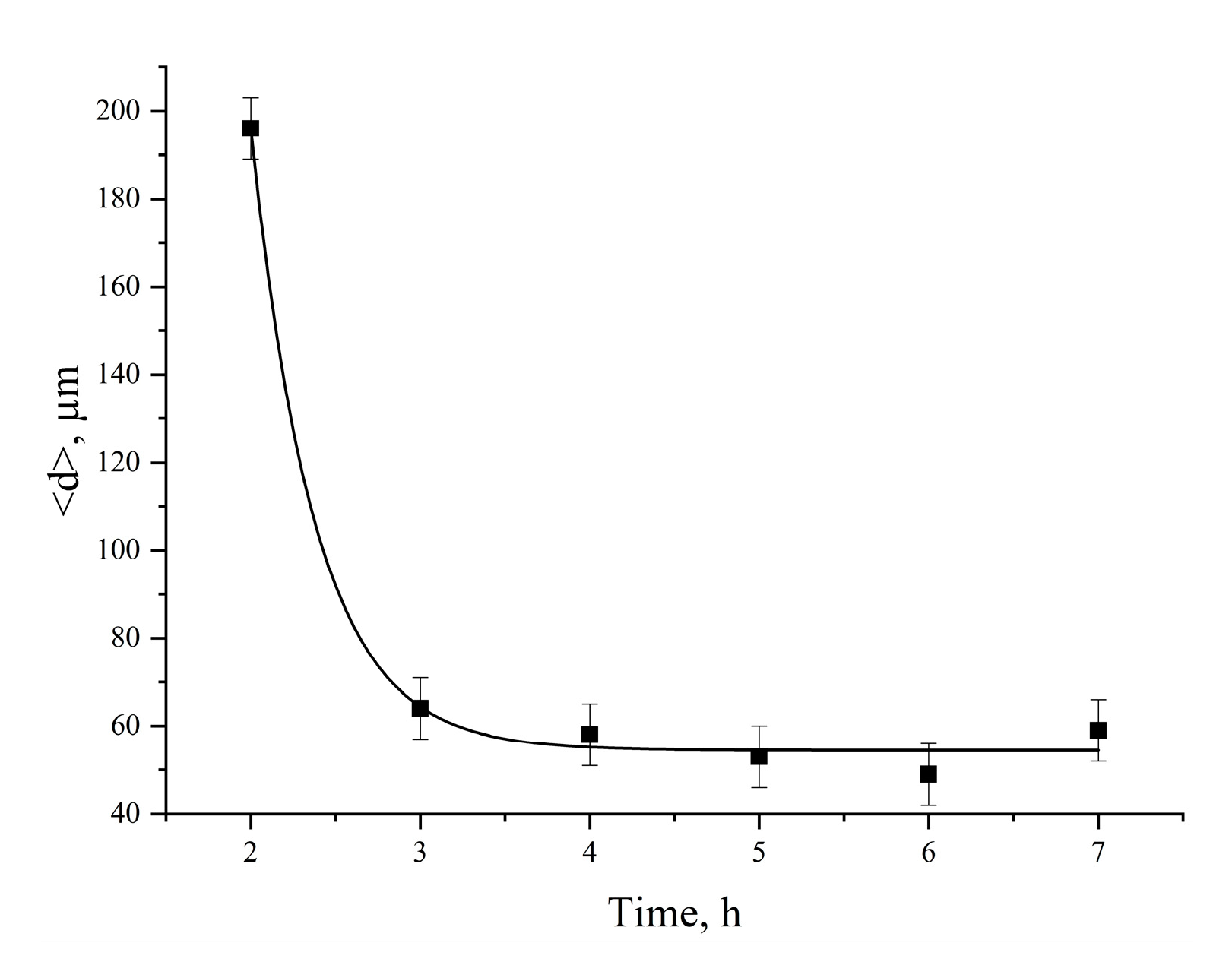

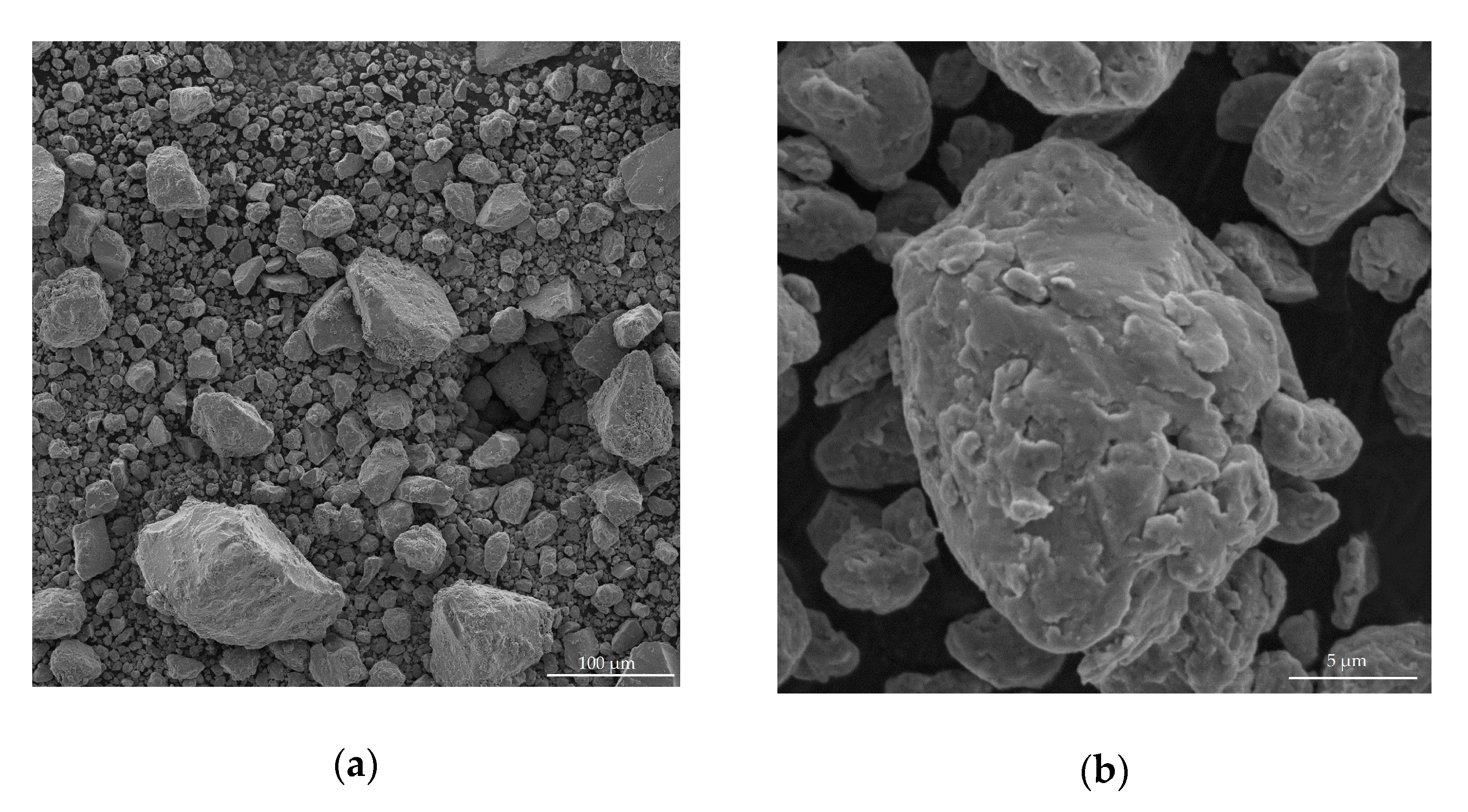

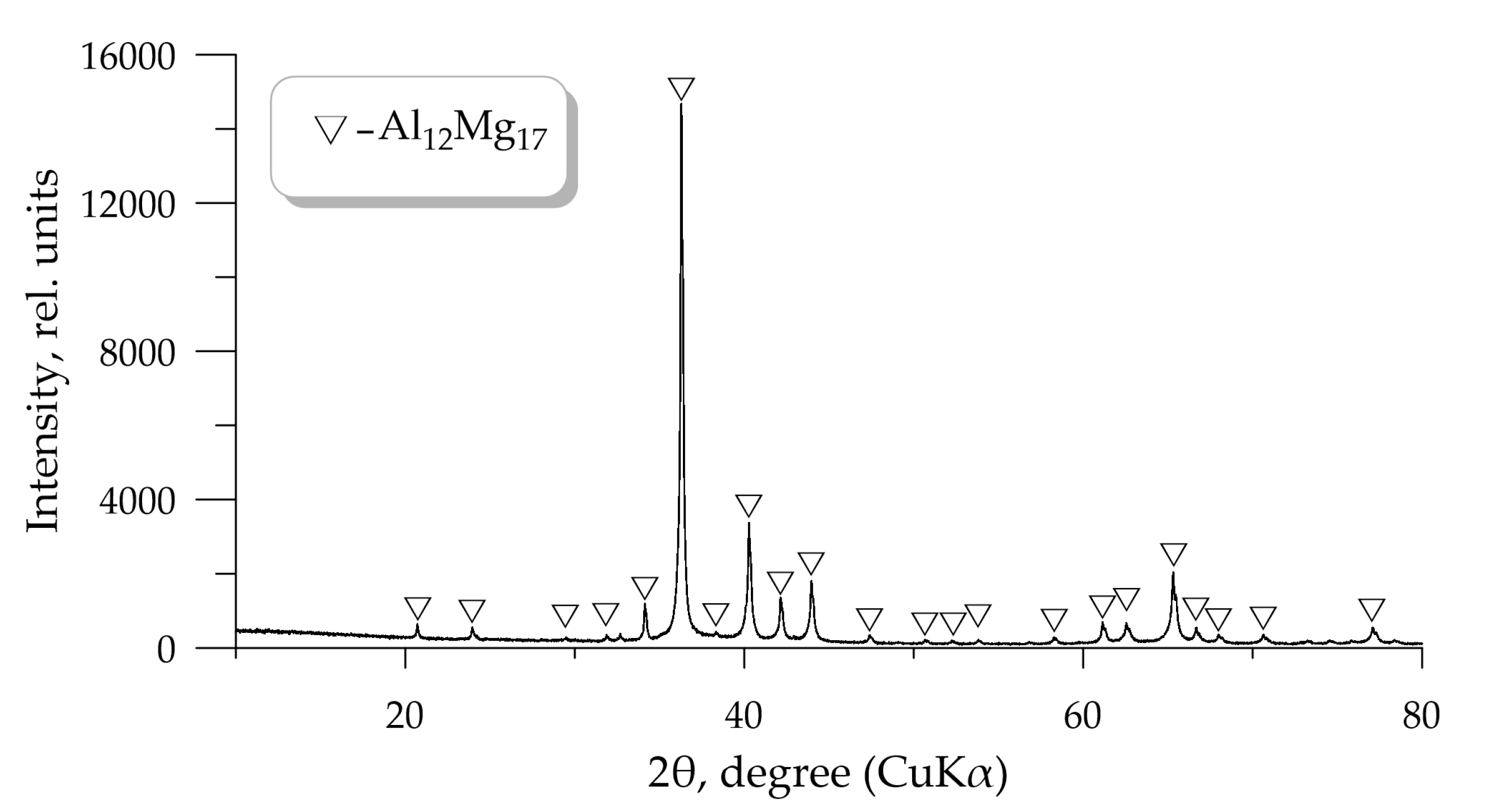

3.1. Particle Size, Chemical Analysis, Morphology, and Phase Composition

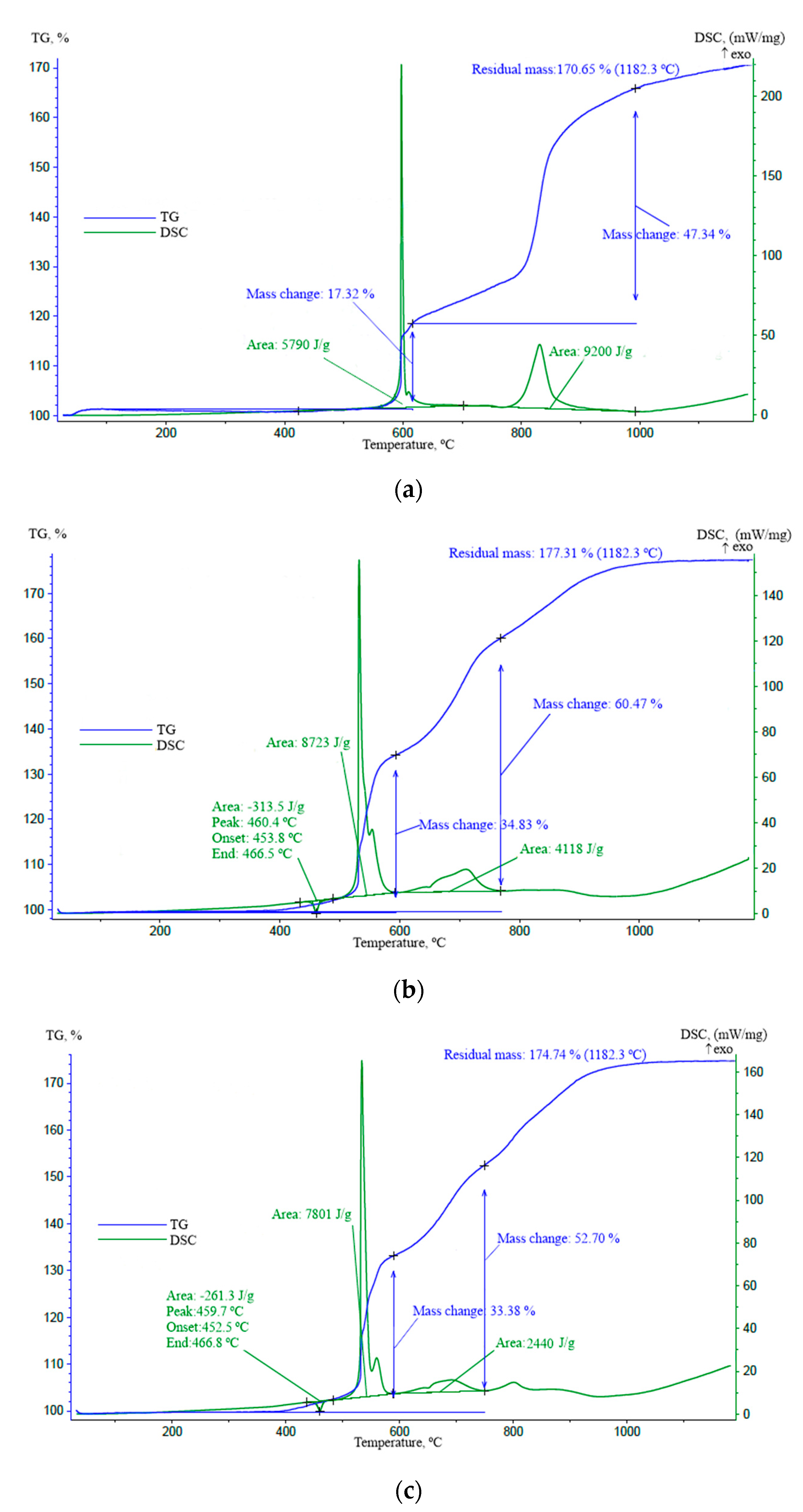

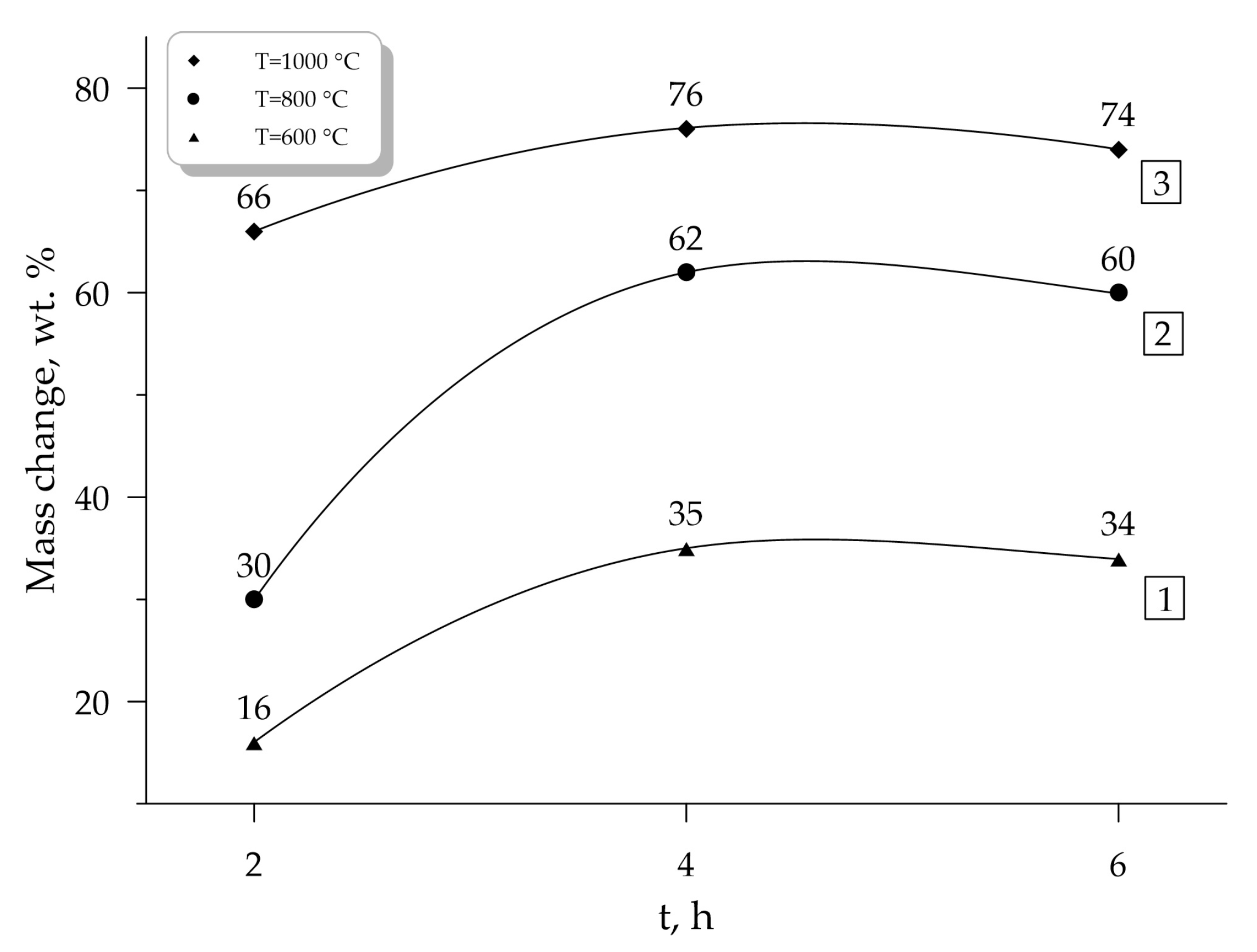

3.2. Calorimetric Studies

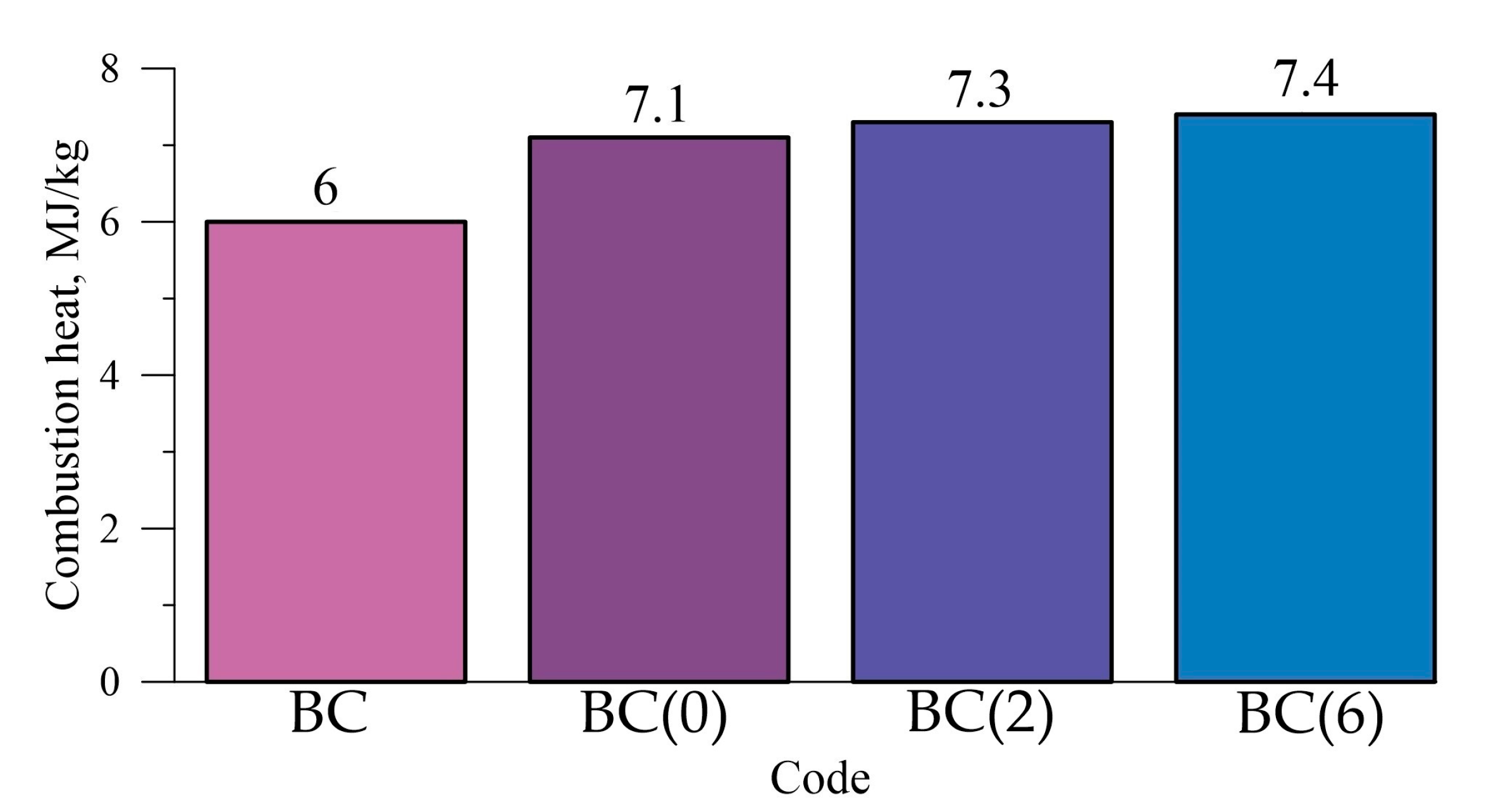

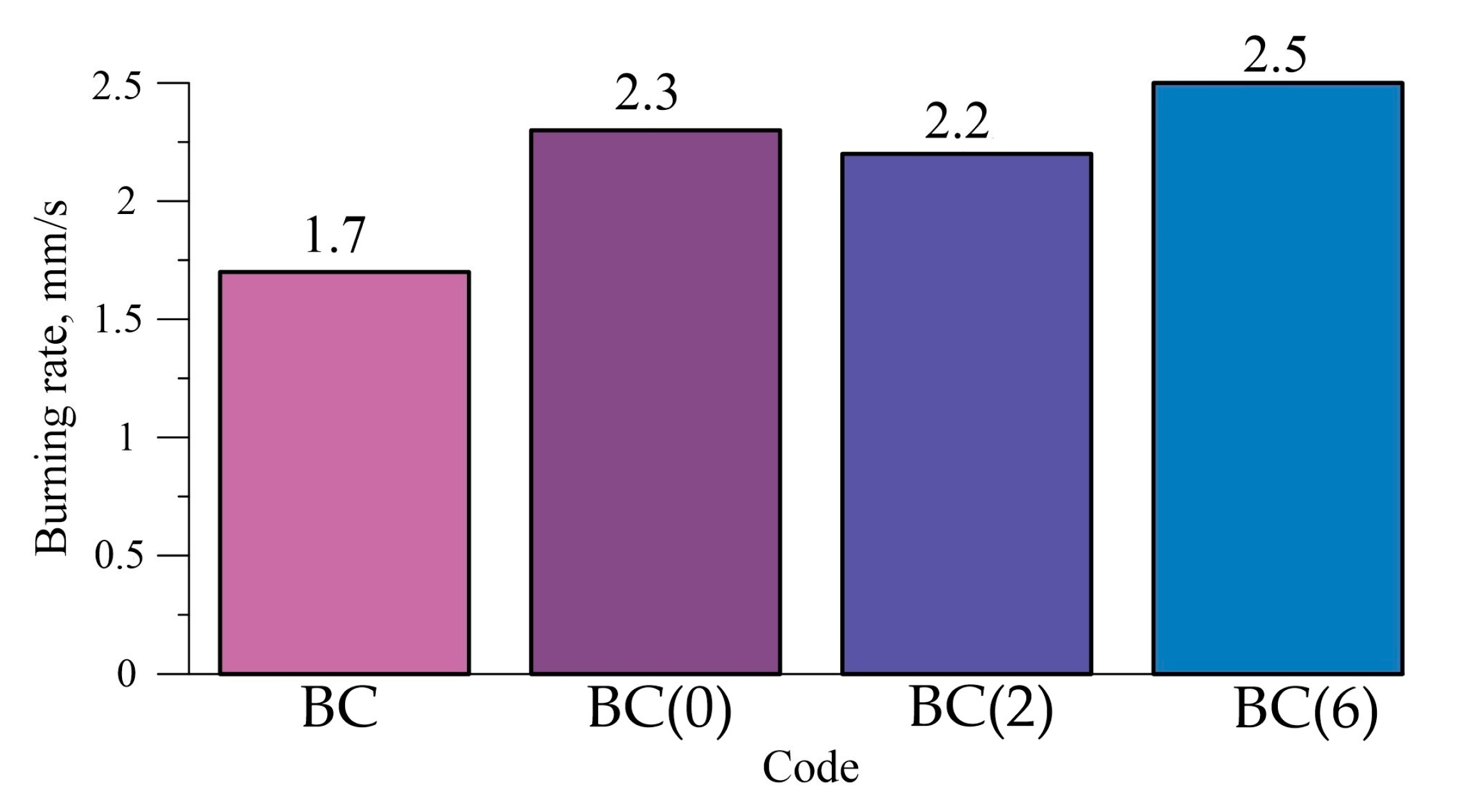

3.3. Combustion Heat and Burning Rate

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tsander, F.A. Flights to other planets: (Theory of interplanetary travels). In Pioneers of Rocket Technology: Kibalchich. Tsiolkovsky. Tsander. Kondratyuk; Selected works; Nauka Pablishers: Moscow, USSR, 1964; pp. 277–359. [Google Scholar]

- Dreizin, E.L. Metal-based reactive nanomaterials. Prog. Energy Combust. Sci. 2009, 35, 141–167. [Google Scholar] [CrossRef]

- Young, G.; Wang, H.; Zachariah, M. Application of Nano-Aluminum/Nitrocellulose Mesoparticles in Composite Solid Rocket Propellants. Propellants Explos. Pyrotech. 2015, 40, 413–418. [Google Scholar] [CrossRef]

- De Luca, L.T.; Galfetti, L.; Saverini, F.; Meda, L.; Marra, G.; Vorozhtsov, A.B.; Sedoi, V.S.; Babuk, V.A. Burning of Nano-Aluminized Composite Rocket Propellants. Combust Explos. Shock Waves 2005, 41, 80–94. [Google Scholar] [CrossRef]

- Yankovskiy, S.; Korotkikh, A.; Arkhipov, V. The effect of dispersity of aluminum powder on ignition and specific impulse of thrust HEMs. MATEC Web Conf. 2014, 3, 191–192. [Google Scholar]

- Pang, W.; De Luca, L.; Huixang, X.; Xuezhong, F.; Fengqu, Z.; Fangli, L.; Wuxi, X.; Yonghong, L. Effects of nano-metric aluminum powder on the properties of composite solid propellants. Int. J. Energetic Mater. Chem. Propul. 2015, 14, 265–282. [Google Scholar] [CrossRef]

- Jayaraman, K.; Anand, K.; Chakravarthy, S.; Sarathi, R. Effect of nano-aluminium in plateau-burning and catalyzed composite solid propellant combustion. Combust. Flame 2009, 156, 1662–1673. [Google Scholar] [CrossRef]

- Gany, A.; Caveny, L. Agglomeration and ignition mechanism of aluminum particles in solid propellants. Symp. (Int.) Combust. 1979, 17, 1453–1461. [Google Scholar] [CrossRef]

- Jayaraman, K.; Anand, K.; Bhatt, D.; Chakravarthy, S.; Sarathi, R. Production, characterization, and combustion of nanoaluminum in composite solid propellants. J. Propul. Power. 2009, 25, 471–481. [Google Scholar] [CrossRef]

- Yavor, Y.; Gany, A. Effect of nickel coating on aluminum combustion and agglomeration in solid propellants. In Proceedings of the 44th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Hartford, CT, USA, 21–23 July 2008; p. 5255. [Google Scholar]

- Yagodnikov, D.; Andreev, E.; Vorob’ev, V.; Glotov, O. Ignition, combustion, and agglomeration of encapsulated aluminum particles in a composite solid propellant. I. Theoretical study of the ignition and combustion of aluminum with fluorine-containing coatings. Combust. Explos. Shock Waves 2006, 42, 534–542. [Google Scholar] [CrossRef]

- Reese, D.; Groven, L.; Son, S.; Mukasyan, A. Intermetallic compounds as fuels for composite rocket propellants. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, San Diego, CA, USA, 31 July–3 August 2011; p. 5865. [Google Scholar]

- Sippel, T.; Son, S.; Groven, L.; Zhang, S.; Dreizin, E.L. Exploring mechanisms for agglomerate reduction in composite solid propellants with polyethylene inclusion modified aluminum. Combust. Flame 2015, 162, 846–854. [Google Scholar] [CrossRef]

- Shoshin, Y.L.; Mudryy, R.S.; Dreizin, E.L. Preparation and characterization of energetic Al-Mg mechanical alloy powders. Combust. Flame 2002, 128, 259–269. [Google Scholar] [CrossRef]

- Shoshin, Y.L.; Trunov, M.A.; Zhu, X.; Schoenitz, M.; Dreizin, E.L. Ignition of aluminum-rich Al–Ti mechanical alloys in air. Combust. Flame 2006, 144, 688–697. [Google Scholar] [CrossRef]

- Belal, H.; Han, C.W.; Gunduz, I.E.; Ortalan, V.; Son, S. Ignition and combustion behavior of mechanically activated Al-Mg particles in composite solid propellants. Combust. Flame 2018, 194, 410–418. [Google Scholar] [CrossRef]

- Aly, Y.; Dreizin, E.L. Ignition and combustion of Al-Mg alloy powders prepared by different techniques. Combust. Flame 2015, 162, 1440–1447. [Google Scholar] [CrossRef]

- Cerri, S.; Bohn, M.; Menke, K.; Galfetti, L. Aging of HTPB/Al/AP rocket propellant formulations investigated by DMA measurements. Propellants Explos. Pyrotech. 2013, 38, 190–198. [Google Scholar] [CrossRef]

- Brill, T.B.; Ren, W.; Yang, V. Solid Propellant Chemistry, Combustion, and Motor Interior Ballistics; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2000; pp. 749–776. [Google Scholar]

- Meda, L.; Marra, G.; Galfetti, L.; Severini, F.; De Luca, L. Nano-Aluminum as Energetic Material for Rocket Mater. Sci. Eng. C 2007, 27, 1393–1396. [Google Scholar] [CrossRef]

- Chen, R.H.; Suryanarayana, C.; Chaos, M. Combustion Characteristics of Mechanically Alloyed Ultrafine-Grained Al-Mg Powders. Adv. Eng. Mater. 2006, 8, 563–567. [Google Scholar] [CrossRef]

- Aly, Y.; Schoenitz, M.; Dreizin, E.L. Ignition and combustion of mechanically alloyed Al-Mg powders with customized particle sizes. Combust. Flame 2013, 160, 835–842. [Google Scholar] [CrossRef]

- Gopienko, V.G.; Petrovich, S.Y.; Cherepanov, V.P. Metal Powders of Aluminum, Magnesium, Titanium and Silicon. Consumer Properties and Applications, Kor. RAS prof. AI Rudskogo; Publishing House Polytechnic University: St. Petersburg, Russia, 2012. [Google Scholar]

- Takacs, L. The historical development of mechanochemistry. Chem. Soc. Rev. 2013, 42, 7649–7659. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Matveev, A.; Zhukov, I.; Ziatdinov, M.; Zhukov, A. Planetary Milling and Self-Propagating High-Temperature Synthesis of Al-TiB2 Composites. Materials 2020, 13, 1050. [Google Scholar] [CrossRef] [PubMed]

- Seplyarsky, B.S.; Kochetov, N.A.; Kochetkov, R.A. Influence of mechanical activation on the combustion rate of pressed samples and bulk density samples from a mixture of Ni–Al. Chem. Sustain. Dev. 2012, 20, 377–383. [Google Scholar]

- Tsapalo, L.I.; Naiborodenko, Y.S.; Kasatskiy, N.G.; Arkatova, L.A. Influence of mechanical activation on high-temperature synthesis of Fe3Al and its catalytic properties during carbon dioxide conversion of natural gas. Chem. Sustain. Dev. 2012, 20, 377–383. [Google Scholar]

- Vorozhtsov, S.; Minkov, L.; Dammer, V.; Khrustalyov, A.; Zhukov, I.; Promakhov, V.; Khmeleva, M. Ex situ introduction and distribution of nonmetallic particles in aluminum melt: Modeling and experiment. JOM 2017, 69, 2653–2657. [Google Scholar] [CrossRef]

- Dubkova, Y.; Zhukov, A. The analysis of combustion heat of the metallized solid fuel compositions. MATEC Web Conf. 2017, 92, 1068. [Google Scholar] [CrossRef]

- Dubkova, Y.; Zhukov, A.; Zhukov, I.; Promakhov, V. Experimental study of the boron-containing mixtures burning rate. MATEC Web Conf. 2017, 110, 1022. [Google Scholar] [CrossRef]

- Monakhov, V.T. Methods for Studying the Flammability of Substances; AmerindPublishingCo.: NewDelhi, India, 1985; p. 436. [Google Scholar]

- Xu, C.; Gao, W. Pilling-Bedworth ratio for oxidation of alloys. Mater. Res. Innov. 2000, 3, 231–235. [Google Scholar] [CrossRef]

- Breiter, A.L.; Kashporov, L.; Mal’tsev, V.; Pokhil, P.; Popov, E.; Pepekin, V.; Stasenko, A. Combustion of individual aluminum-magnesium alloy particles in the flame of an oxidizer-fuel mixture. Combust. Explos. Shock Waves. 1971, 7, 186–190. [Google Scholar] [CrossRef]

- Murray, J.L. Phase Diagrams of Binary Magnesium Alloys; ASM International Metals Park: Ohio, OH, USA, 1988; pp. 17–34. [Google Scholar]

- Boldyrev, V.V.; Avvakumov, E.G. Fundamentals of Mechanical Activation, Mechanosynthesis and Mechanochemical Technologies; Pb. SB RAS: Novosibirsk, Russia, 2009; pp. 15–26. [Google Scholar]

| Code | Components of HEMs, wt % | |||||

|---|---|---|---|---|---|---|

| AP | Boron | SKDM-80 | Commercially-Available Al-Mg | Al-Mg 2 h | Al-Mg 6 h | |

| BC | 74 | 15 | 11 | - | - | - |

| BC(0) | 70.5 | 14.3 | 10.5 | 4.7 | - | - |

| BC(2) | 70.5 | 14.3 | 10.5 | - | 4.7 | - |

| BC(6) | 70.5 | 14.3 | 10.5 | - | - | 4.7 |

| Element | Result, at. % | |

|---|---|---|

| Al-Mg Alloy | Commercially–Available Al-Mg Alloy | |

| Al | 50.4121 | 44.4907 |

| Mg | 48.6949 | 51.8649 |

| Si | 0.5359 | 0.0473 |

| Fe | 0.2229 | 0.0275 |

| Cr | 0.0595 | 0.0284 |

| Ti | 0.0250 | - |

| C | 0.0249 | - |

| Zn | 0.0094 | 0.0052 |

| Ni | 0.0076 | 0.0111 |

| Ga | 0.0076 | 0.0075 |

| O | 0.0001 | 3.5126 |

| Cu | - | 0.0040 |

| Mo | - | 0.0007 |

| Nb | - | 0.0001 |

| Metal | Si | Ti | Zr | Al | Mg | Ca | Li |

|---|---|---|---|---|---|---|---|

| PBC | 2.04 | 1.73 | 1.45 | 1.45 | 0.81 | 0.64 | 0.58 |

| 2 h | 4 h | 6 h | |

|---|---|---|---|

| Endothermic peak, °C | - | 460.4 | 459.7 |

| Endothermic peak area, J/g | - | −313.5 | −261.3 |

| Exothermic peak 1, °C | 600 | 520 | 520 |

| Exothermic peak 2, °C | 820 | 710 | 690 |

| Exothermic peak area 1, J/g | 5790 | 8723 | 7801 |

| Exothermic peak area 2, J/g | 9200 | 4118 | 2440 |

| Mass change (600 °C), wt % | 16 | 35 | 34 |

| Mass change (800 °C), wt % | 30 | 62 | 60 |

| Mass change (1000 °C), wt % | 66 | 76 | 74 |

| Residual mass (1182.3 °C), wt % | 70.65 | 77.31 | 74.74 |

| Code | d43, μm | Dm,1, μm | Dm,2, μm | Q, MJ/kg | ΔQ, % | U, mm/s | ΔU, % |

|---|---|---|---|---|---|---|---|

| BC | - | - | - | 6.0 ± 0.2 | - | 1.7 ± 0.08 | - |

| BC(0) | 50 | 54 | - | 7.1 ± 0.2 | 19 | 2.3 ± 0.08 | 36 |

| BC(2) | 196 | 322 | 80 | 7.3 ± 0.2 | 22 | 2.2 ± 0.08 | 27 |

| BC(6) | 49 | 58 | 18 | 7.4 ± 0.2 | 23 | 2.5 ± 0.08 | 47 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sokolov, S.; Vorozhtsov, A.; Arkhipov, V.; Zhukov, I. The Study of HEMs Based on the Mechanically Activated Intermetallic Al12Mg17 Powder. Molecules 2020, 25, 3561. https://doi.org/10.3390/molecules25163561

Sokolov S, Vorozhtsov A, Arkhipov V, Zhukov I. The Study of HEMs Based on the Mechanically Activated Intermetallic Al12Mg17 Powder. Molecules. 2020; 25(16):3561. https://doi.org/10.3390/molecules25163561

Chicago/Turabian StyleSokolov, Sergei, Alexander Vorozhtsov, Vladimir Arkhipov, and Ilya Zhukov. 2020. "The Study of HEMs Based on the Mechanically Activated Intermetallic Al12Mg17 Powder" Molecules 25, no. 16: 3561. https://doi.org/10.3390/molecules25163561

APA StyleSokolov, S., Vorozhtsov, A., Arkhipov, V., & Zhukov, I. (2020). The Study of HEMs Based on the Mechanically Activated Intermetallic Al12Mg17 Powder. Molecules, 25(16), 3561. https://doi.org/10.3390/molecules25163561