Effect of Alkali-Free Synthesis and Post-Synthetic Treatment on Acid Sites in Beta Zeolites

Abstract

1. Introduction

2. Results

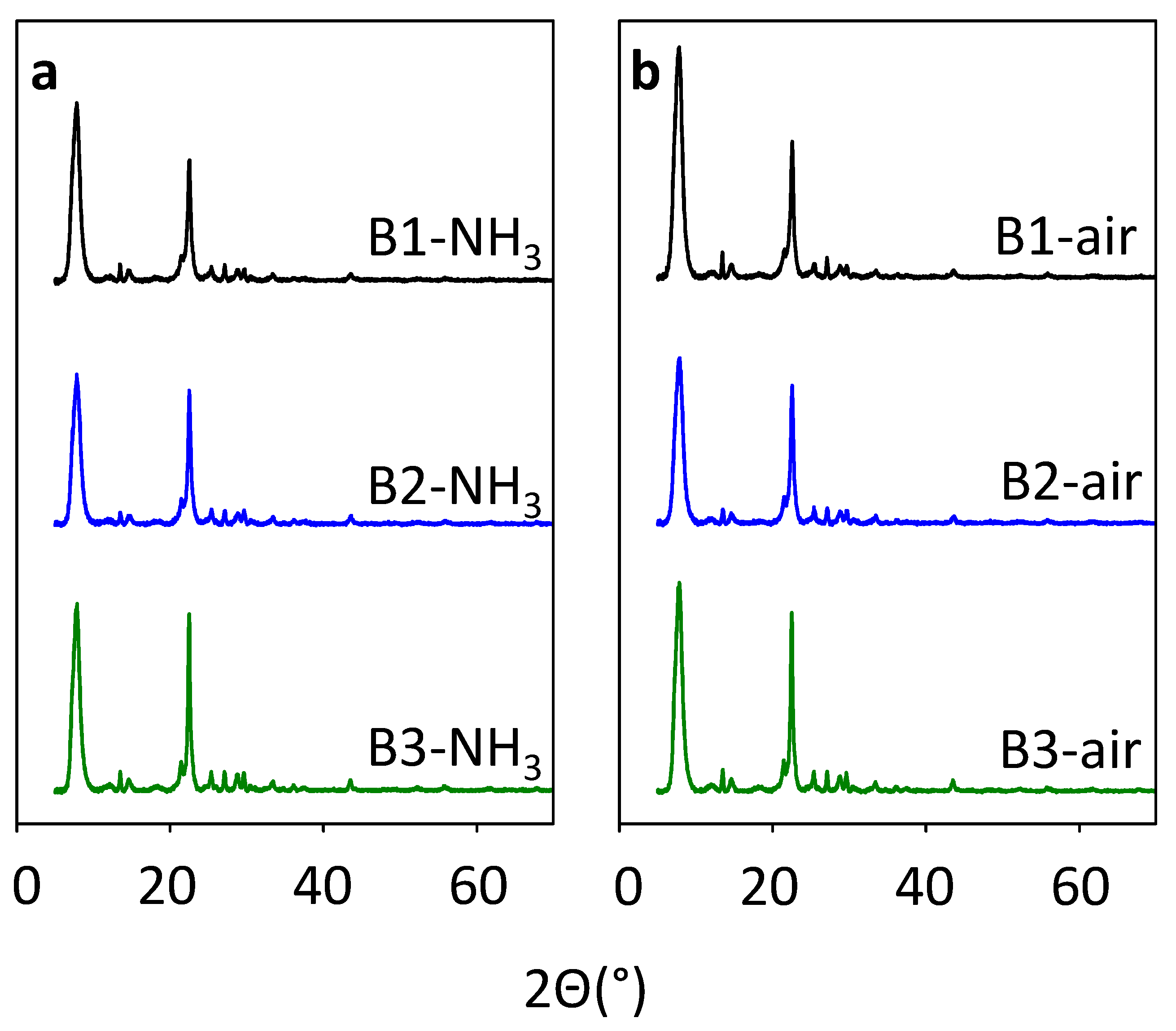

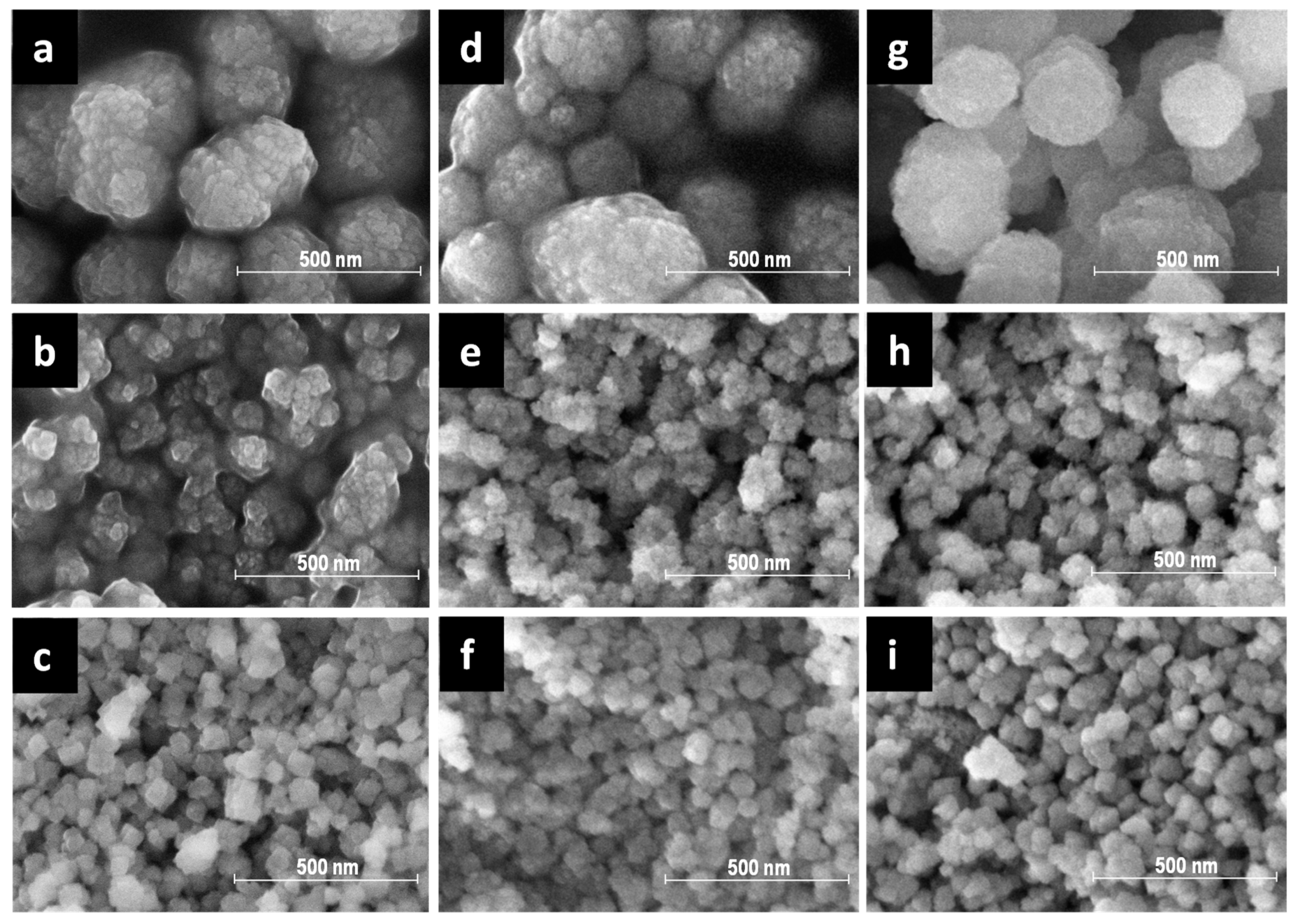

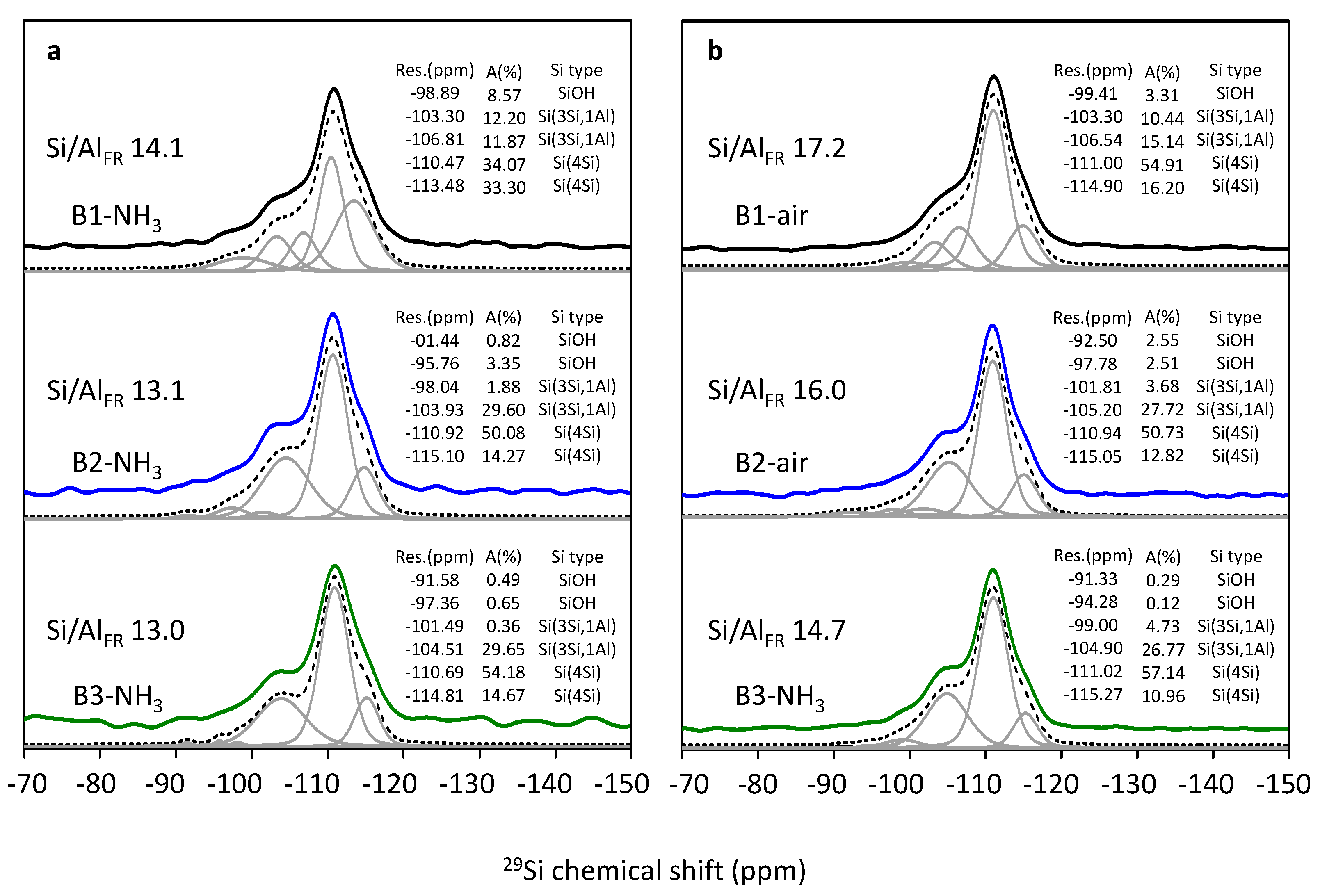

2.1. Alkali-Free Synthesis of Beta Zeolites

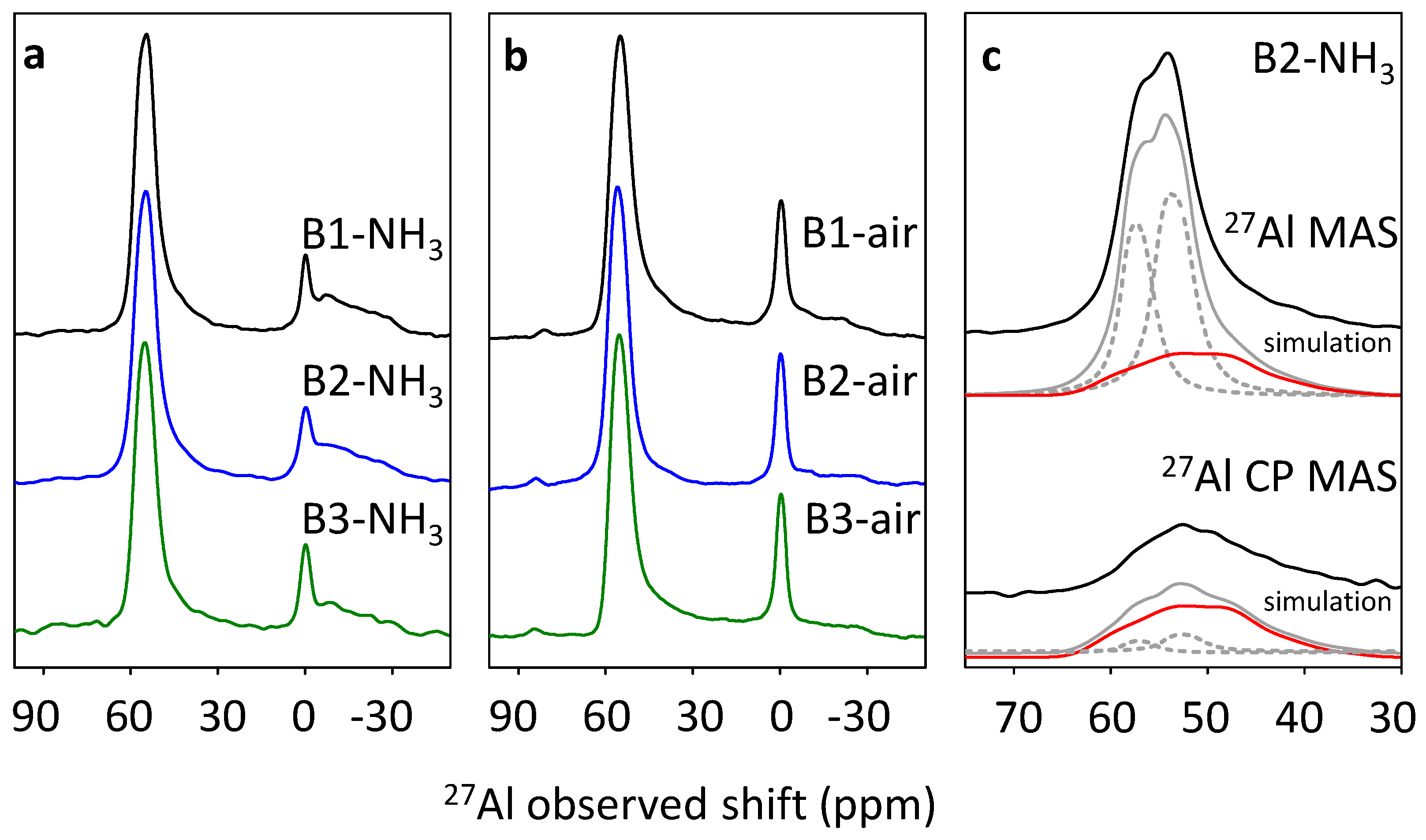

2.2. Post-Synthetic Treatment—Organic SDA Removal

2.3. FTIR Studies

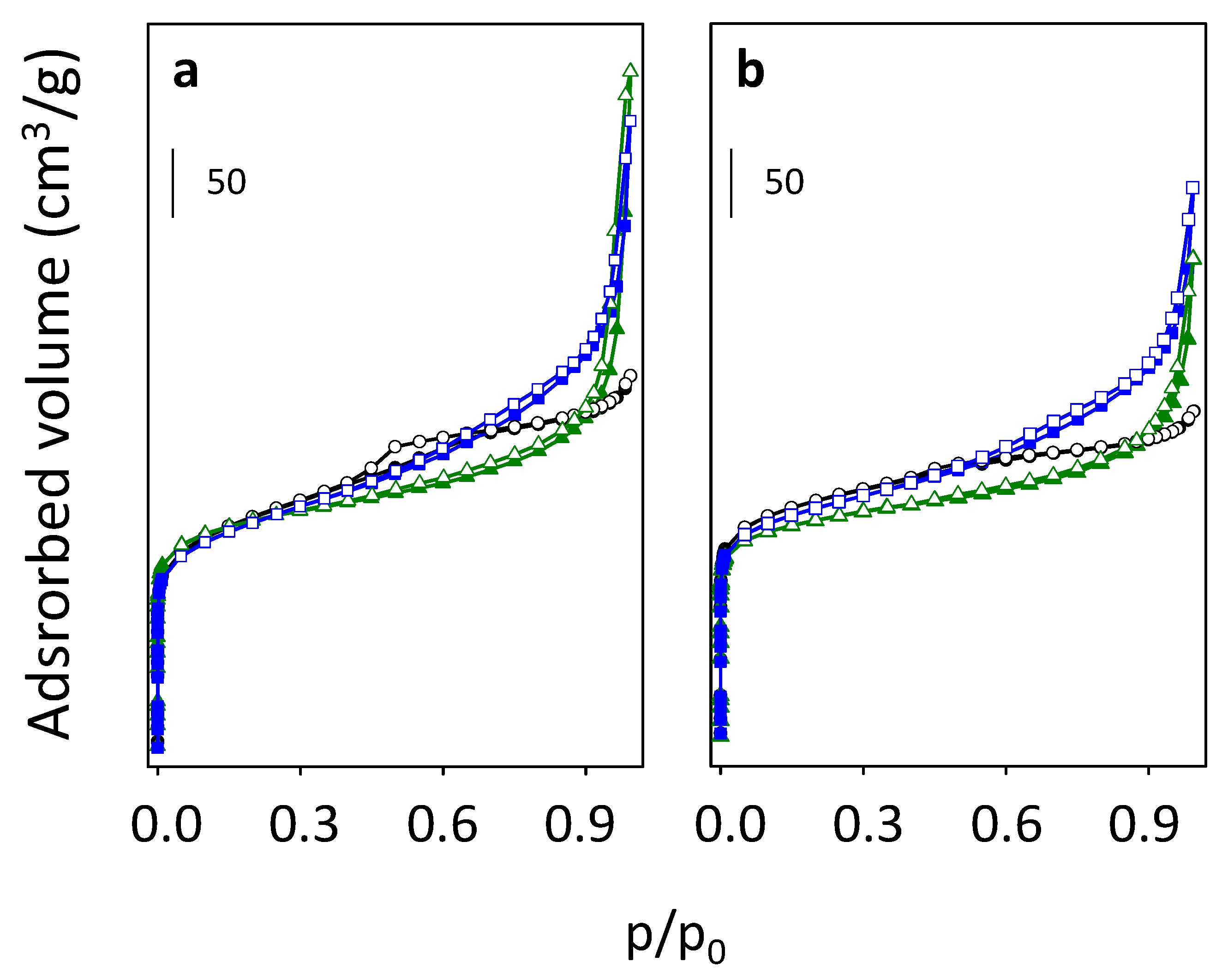

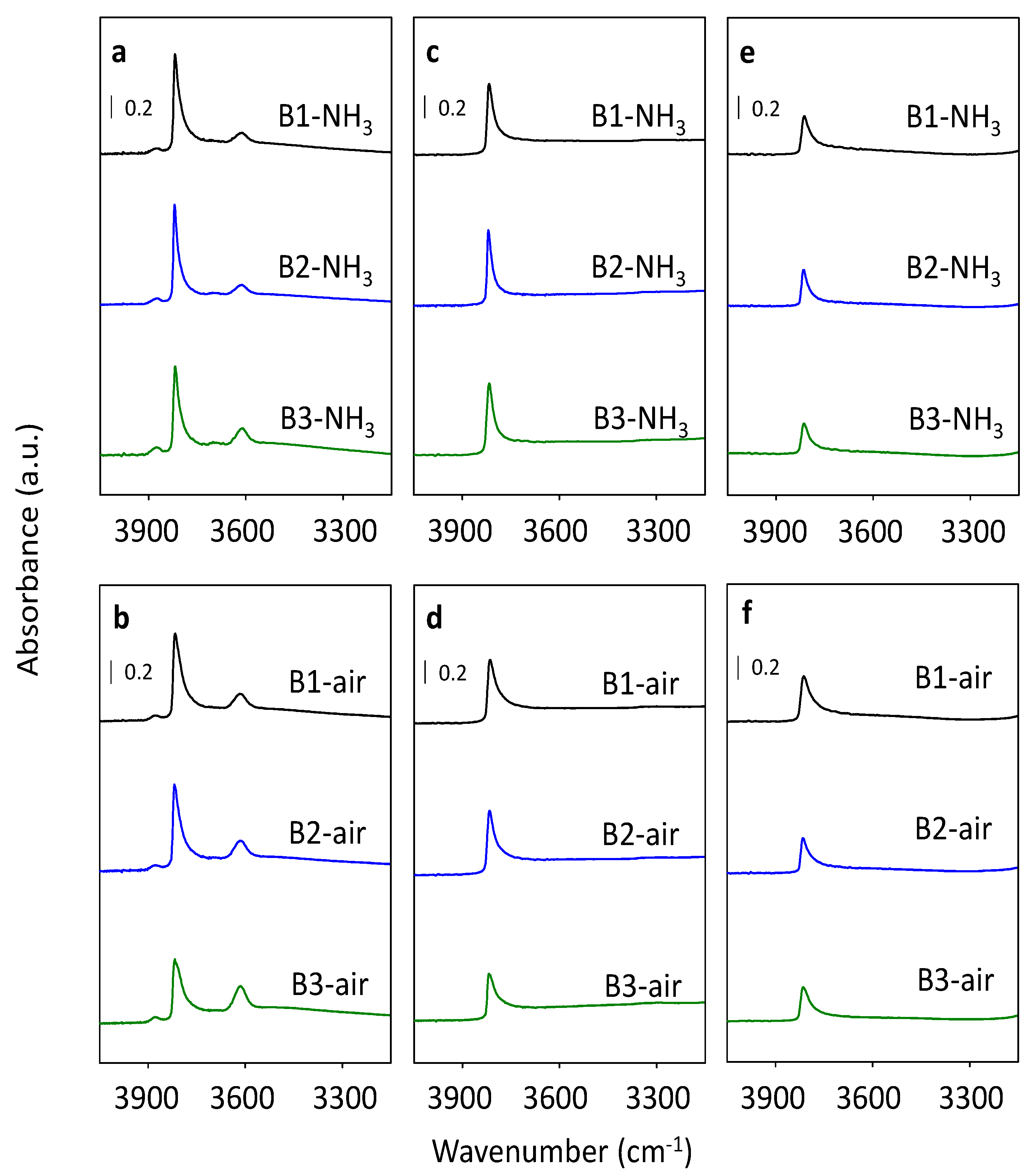

2.3.1. Accessibility of the Channel System

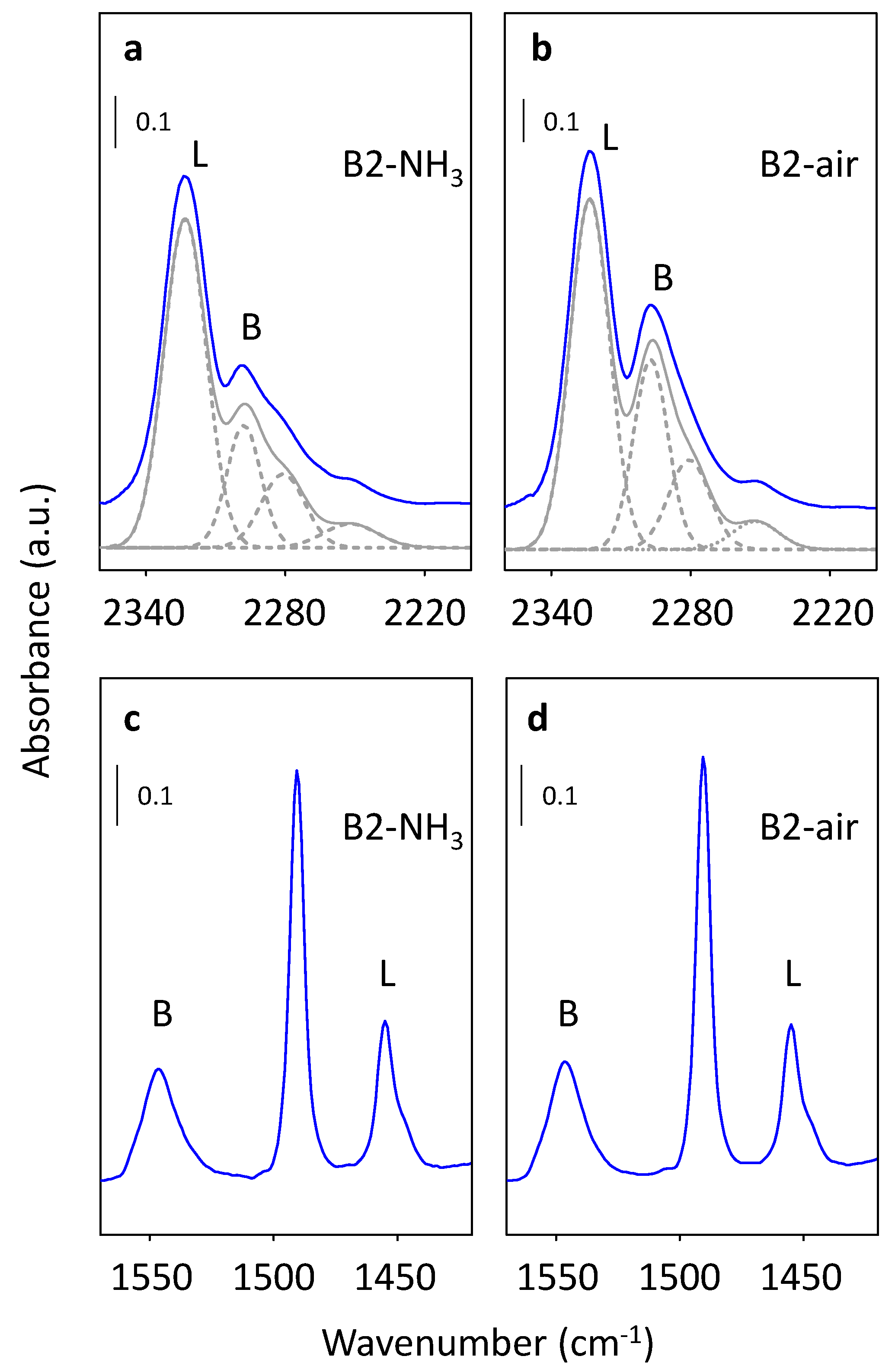

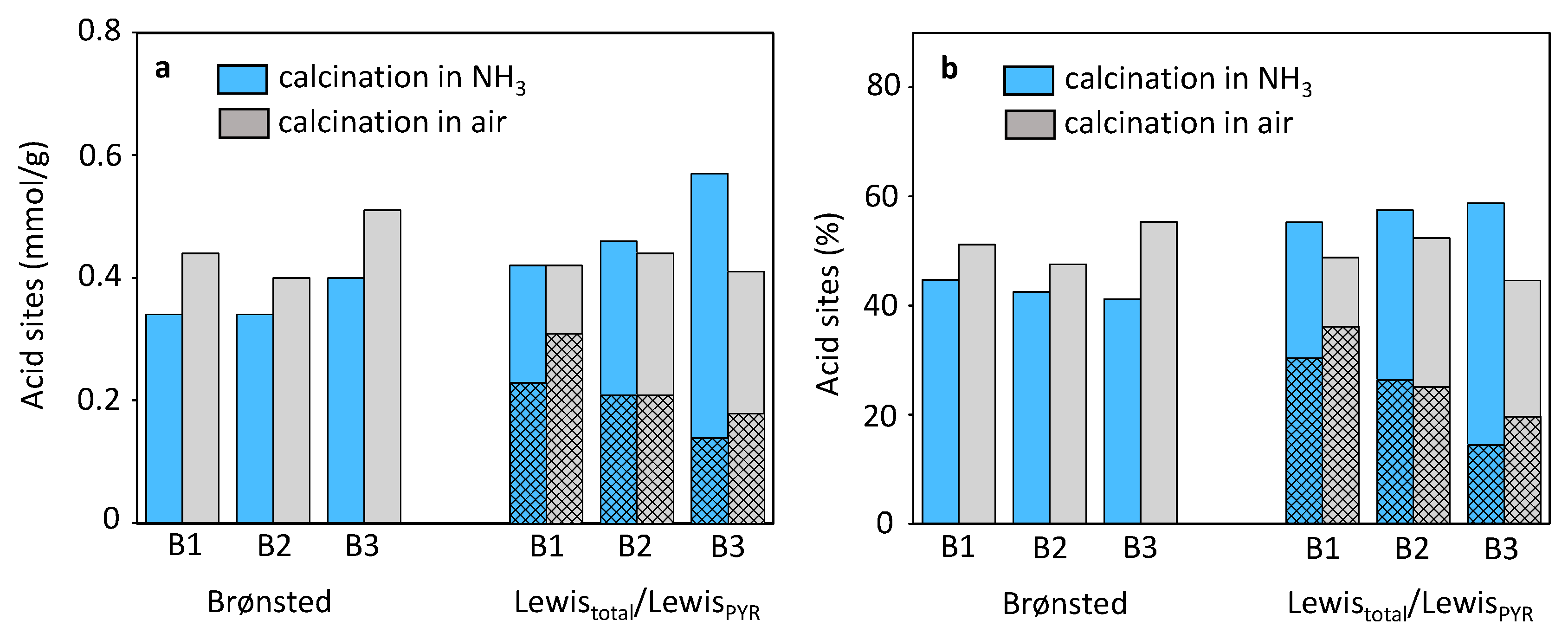

2.3.2. Brønsted and Lewis Acidity

3. Discussion

3.1. Tailored Alkali-Free Synthesis of Beta Zeolite

3.2. Effect of Post-Synthetic Treatment on the Beta Zeolite Structure

3.3. Framework Al Atoms in De-Templated and Rehydrated Beta Zeolite

3.4. Effect of Post-Synthetic Treatment on the Beta Zeolite Acidity

4. Materials and Methods

4.1. Synthesis of the Zeolites

4.1.1. Synthesis of Beta Zeolite B1

4.1.2. Synthesis of Beta Zeolite B2

4.1.3. Synthesis of Beta Zeolite B3

4.2. Organic SDA Removal

4.2.1. Calcination in Ammonia (Samples B1-, B2-, and B3-NH3)

4.2.2. Calcination in the Air (Samples B1-, B2-, and B3-air)

4.3. Characterization Methods

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Primo, A.; Garcia, H. Zeolites as catalysts in oil refining. Chem. Soc. Rev. 2014, 43, 7548–7561. [Google Scholar] [CrossRef]

- Beale, A.M.; Gao, F.; Lezcano-Gonzalez, I.; Peden, C.H.F.; Szanyi, J. Recent advances in automotive catalysis for NOx emission control by small-pore microporous materials. Chem. Soc. Rev. 2015, 44, 7371–7405. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Hegde, M.S.; Madras, G. Catalysis for NOx abatement. Appl. Energy 2009, 86, 2283–2297. [Google Scholar] [CrossRef]

- Shan, W.; Song, H. Catalysts for the selective catalytic reduction of NOx with NH3 at low temperature. Catal. Sci. Technol. 2015, 5, 4280–4288. [Google Scholar] [CrossRef]

- Casci, J.L.; Cundy, C.S.; Barrer, R.M. Hydrothermal Chemistry of Zeolites; Academic Press: London, UK; New York, NY, USA, 1982; p. 360. [Google Scholar] [CrossRef]

- van Bekkum, H.; Flanigen, E.M.; Jansen, J.C. Introduction to Zeolite Science and Practice; Elsevier: Amsterdam, The Netherlands, 1991; Volume 58. [Google Scholar]

- Bellussi, G.; Pazzuconi, G.; Perego, C.; Girotti, G.; Terzoni, G. Liquid-Phase Alkylation of Benzene with Light Olefins Catalyzed by β-Zeolites. J. Catal. 1995, 157, 227–234. [Google Scholar] [CrossRef]

- Perego, C.; Amarilli, S.; Carati, A.; Flego, C.; Pazzuconi, G.; Rizzo, C.; Bellussi, G. Mesoporous silica-aluminas as catalysts for the alkylation of aromatic hydrocarbons with olefins. Microporous Mesoporous Mater. 1999, 27, 345–354. [Google Scholar] [CrossRef]

- Perego, C.; Amarilli, S.; Millini, R.; Bellussi, G.; Girotti, G.; Terzoni, G. Experimental and computational study of beta, ZSM-12, Y, mordenite and ERB-1 in cumene synthesis. Microporous Mater. 1996, 6, 395–404. [Google Scholar] [CrossRef]

- Available online: https://europe.iza-structure.org/IZA-SC/framework.php?STC=BEA (accessed on 27 July 2020).

- Beyerlein, R.A.; Choi-Feng, C.; Hall, J.B.; Huggins, B.J.; Ray, G.J. Effect of steaming on the defect structure and acid catalysis of protonated zeolites. Top. Catal. 1997, 4, 27–42. [Google Scholar] [CrossRef]

- Bortnovsky, O.; Sobalik, Z.; Wichterlova, B.; Bastl, Z. Structure of Al-Lewis site in beta zeolite active in the Meerwein-Ponndorf-Verley reduction of ketone to alcohol. J. Catal. 2002, 210, 171–182. [Google Scholar] [CrossRef]

- Kunkeler, P.J.; Zuurdeeg, B.J.; van der Waal, J.C.; van Bokhoven, J.A.; Koningsberger, D.C.; van Bekkum, H. Zeolite Beta: The Relationship between Calcination Procedure, Aluminum Configuration, and Lewis Acidity. J. Catal. 1998, 180, 234–244. [Google Scholar] [CrossRef]

- Pérez-Pariente, J.; Sanz, J.; Fornés, V.; Corma, A. 29Si and 27Al MAS NMR study of zeolite β with different Si/Al Ratios. J. Catal. 1990, 124, 217–223. [Google Scholar] [CrossRef]

- Brown, D.R.; Rhodes, C.N. Brønsted and Lewis acid catalysis with ion- exchanged clays. Catal. Lett. 1997, 45, 35–40. [Google Scholar] [CrossRef]

- Xavier, N.M.; Lucas, S.D.; Rauter, A.P. Zeolites as efficient catalysts for key transformations in carbohydrate chemistry. J. Mol. Catal. A Chem. 2009, 305, 84–89. [Google Scholar] [CrossRef]

- Robson, H.; Lillerud, K.P. Verified Syntheses of Zeolitic Materials; Elsevier Science: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Wadlinger, R.L.; Kerr, G.T.; Rosinski, E.J. Catalytic Composition of a Crystalline Zeolite. U.S. Patent 3308069A, 7 March 1967. [Google Scholar]

- Camblor, M.A.; Corma, A.; Mifsud, A.; Pérez-Pariente, J.; Valencia, S. Synthesis of nanocrystalline zeolite beta in the absence of alkali metal cations. In Studies in Surface Science and Catalysis; Chon, H., Ihm, S.-K., Uh, Y.S., Eds.; Elsevier: Amsterdam, The Netherlands, 1997; Volume 105, pp. 341–348. [Google Scholar]

- Guo Wanping, L.Q. Process for Synthesizing Beta-Zeolite from Non-Alkali-Metal Ion System. CN Patent Application No. 1313244A, 19 September 2001. [Google Scholar]

- Rao, K.; Rao, B.P.; Choudary, B.; Mannepalli, L.; Kondapuram, V. Mannepalli Lakshmi Kantam, Rao Bhavnari Puma Chandra, Rao Kottapalli Koteswara, Process for the Preparation of Nanocrystalline Zeolite Beta. U.S. Patent 20040105814A1, 3 June 2004. [Google Scholar]

- Chaikittisilp, W.; Yokoi, T.; Okubo, T. Crystallization behavior of zeolite beta with balanced incorporation of silicon and aluminum synthesized from alkali metal cation-free mixture. Microporous Mesoporous Mater. 2008, 116, 188–195. [Google Scholar] [CrossRef]

- Sazama, P.; Wichterlova, B.; Sklenak, S.; Parvulescu, V.I.; Candu, N.; Sadovska, G.; Dedecek, J.; Klein, P.; Pashkova, V.; Stastny, P. Acid and redox activity of template-free Al-rich H-BEA* and Fe-BEA* zeolites. J. Catal. 2014, 318, 22–33. [Google Scholar] [CrossRef]

- Sazama, P.; Mokrzycki, L.; Wichterlova, B.; Vondrova, A.; Pilar, R.; Dedecek, J.; Sklenak, S.; Tabor, E. Unprecedented propane-SCR-NOx activity over template-free synthesized Al-rich Co-BEA* zeolite. J. Catal. 2015, 332, 201–211. [Google Scholar] [CrossRef]

- Sazama, P.; Tabor, E.; Klein, P.; Wichterlova, B.; Sklenak, S.; Mokrzycki, L.; Pashkkova, V.; Ogura, M.; Dedecek, J. Al-rich beta zeolites. Distribution of Al atoms in the framework and related protonic and metal-ion species. J. Catal. 2016, 333, 102–114. [Google Scholar] [CrossRef]

- Abraham, A.; Lee, S.-H.; Shin, C.-H.; Bong Hong, S.; Prins, R.; van Bokhoven, J.A. Influence of framework silicon to aluminium ratio on aluminium coordination and distribution in zeolite Beta investigated by 27Al MAS and 27Al MQ MAS NMR. Phys. Chem. Chem. Phys. 2004, 6, 3031–3036. [Google Scholar] [CrossRef]

- Roberge, D.M.; Hausmann, H.; Hölderich, W.F. Dealumination of zeolite beta by acid leaching: A new insight with two-dimensional multi-quantum and cross polarization 27Al MAS NMR. Phys. Chem. Chem. Phys. 2002, 4, 3128–3135. [Google Scholar] [CrossRef]

- Fyfe, C.A.; Feng, Y.; Grondey, H.; Kokotailo, G.T.; Gies, H. One- and two-dimensional high-resolution solid-state NMR studies of zeolite lattice structures. Catal. Rev. Sci. Eng. 1991, 91, 1525–1543. [Google Scholar] [CrossRef]

- Jia, C.; Massiani, P.; Barthomeuf, D. Characterization by infrared and nuclear magnetic resonance spectroscopies of calcined beta zeolite. J. Chem.Soc. Faraday Trans. 1993, 89, 3659–3665. [Google Scholar] [CrossRef]

- Fyfe, C.A.; Thomas, J.M.; Klinowski, J.; Gobbi, G.C. Magic-Angle-Spinning NMR (MAS-NMR) Spectroscopy and the Structure of Zeolites. Angew. Chem. Int. Ed. 1983, 22, 259–275. [Google Scholar] [CrossRef]

- MacKenzie, K.D.J.; Smith, M.E. Multinuclear Solid-State NMR of Inorganic Material; Elsevier: London, UK, 2002. [Google Scholar]

- Newsam, J.M.; Treacy, M.M.J.; Koetsier, W.T.; Gruyter, C.B.D.; Thomas, J.M. Structural characterization of zeolite beta. Proc. R. Soc. Lond. A 1988, 420, 375–405. [Google Scholar] [CrossRef]

- Čapek, L.; Dědeček, J.; Wichterlová, B. Co-beta zeolite highly active in propane–SCR-NOx in the presence of water vapor: Effect of zeolite preparation and Al distribution in the framework. J. Catal. 2004, 227, 352–366. [Google Scholar] [CrossRef]

- Mlekodaj, K.; Dedecek, J.; Pashkova, V.; Tabor, E.; Klein, P.; Urbanova, M.; Karcz, R.; Sazama, P.; Whittleton, S.R.; Thomas, H.M.; et al. Al Organization in the SSZ-13 Zeolite. Al Distribution and Extraframework Sites of Divalent Cations. J. Phys. Chem. C 2019, 123, 7968–7987. [Google Scholar] [CrossRef]

- Brus, J.; Kobera, L.; Schoefberger, W.; Urbanová, M.; Klein, P.; Sazama, P.; Tabor, E.; Sklenak, S.; Fishchuk, A.V.; Dědeček, J. Structure of Framework Aluminum Lewis Sites and Perturbed Aluminum Atoms in Zeolites as Determined by 27Al{1H} REDOR (3Q) MAS NMR Spectroscopy and DFT/Molecular Mechanics. Angew. Chem. Int. Ed. 2015, 54, 541–545. [Google Scholar] [CrossRef]

- Hunger, M.; Kärger, J.; Pfeifer, H.; Caro, J.; Zibrowius, B.; Bülow, M.; Mostowicz, R. Investigation of internal silanol groups as structural defects in ZSM-5-type zeolites. J. Chem. Soc. Faraday Trans. 1 Phys. Chem. Condens. Phases 1987, 83, 3459–3468. [Google Scholar] [CrossRef]

- Emeis, C.A. Determination of Integrated Molar Extinction Coefficients for Infrared Absorption Bands of Pyridine Adsorbed on Solid Acid Catalysts. J. Catal. 1993, 141, 347–354. [Google Scholar] [CrossRef]

- Kubelková, L.; Beran, S.; Malecka, A.; Mastikhin, V.M. Acidity of modified Y zeolites: Effect of nonskeletal Al, formed by hydrothermal treatment, dealumination with SiCl4, and cationic exchange with Al. Zeolites 1989, 9, 12–17. [Google Scholar] [CrossRef]

- Makarova, M.A.; Karim, K.; Dwyer, J. Limitation in the application of pyridine for quantitative studies of brönsted acidity in relatively aluminous zeolites. Microporous Mater. 1995, 4, 243–246. [Google Scholar] [CrossRef]

- Wichterlová, B.; Tvarůžková, Z.; Sobalık, Z.; Sarv, P. Determination and properties of acid sites in H-ferrierite: A comparison of ferrierite and MFI structures. Microporous Mesoporous Mater. 1998, 24, 223–233. [Google Scholar] [CrossRef]

- Tokarova, V.; Stavova, G.; Novakova, J.; Stiborova, S.; Kasparek, A.; Zukal, A. Synthesis of beta zeolite with mesopores from a milk containing precursor and its performance in naphthalene isopropylation. React. Kinetics, Mechanisms Catal. 2017, 122, 343–356. [Google Scholar] [CrossRef]

- Sklenak, S.; Dědeček, J.; Li, C.; Wichterlová, B.; Gábová, V.; Sierka, M.; Sauer, J. Aluminum Siting in Silicon-Rich Zeolite Frameworks: A Combined High-Resolution 27Al NMR Spectroscopy and Quantum Mechanics / Molecular Mechanics Study of ZSM-5. Angew. Chem. Int. Ed. 2007, 46, 7286–7289. [Google Scholar] [CrossRef] [PubMed]

- van Bokhoven, J.A.; Koningsberger, D.C.; Kunkeler, P.; van Bekkum, H.; Kentgens, A.P.M. Stepwise Dealumination of Zeolite Βeta at Specific T-Sites Observed with 27Al MAS and 27Al MQ MAS NMR. J. Am. Chem. Soc. 2000, 122, 12842–12847. [Google Scholar] [CrossRef]

- van Bokhoven, J.A.; van der Eerden, A.M.J.; Koningsberger, D.C. Three-Coordinate Aluminum in Zeolites Observed with In situ X-ray Absorption Near-Edge Spectroscopy at the Al K-Edge: Flexibility of Aluminum Coordinations in Zeolites. J. Am. Chem. Soc. 2003, 125, 7435–7442. [Google Scholar] [CrossRef]

- Massiot, D.; Fayon, F.; Capron, M.; King, I.; Le Calvé, S.; Alonso, B.; Durand, J.-O.; Bujoli, B.; Gan, Z.; Hoatson, G. Modelling one- and two-dimensional solid-state NMR spectra. Magn. Reson. Chem. 2002, 40, 70–76. [Google Scholar] [CrossRef]

- Engelhardt, G.; Lohse, U.; Lippmaa, E.; Tarmak, M.; Mägi, M. 29Si-NMR-Untersuchungen zur Verteilung der Silicium-und Aluminiumatome im Alumosilicatgitter von Zeolithen mit Faujasit-Struktur. Z. Anorg. Allg. Chem 1981, 482, 49–64. [Google Scholar] [CrossRef]

- Barzetti, T.; Selli, E.; Moscotti, D.; Forni, L. Pyridine and ammonia as probes for FTIR analysis of solid acid catalysts. J. Chem. Soc. Faraday Trans. 1996, 92, 1401–1407. [Google Scholar] [CrossRef]

Sample Availability: Samples of all compounds are available from the authors. |

| Sample | Si/AlFR | AlXRF (mmol/g) | AlFR (mmol/g) | AlEF (mmol/g) |

|---|---|---|---|---|

| B1-NH3 | 14.1 | 1.00 | 1.00 | 0.00 |

| B2-NH3 | 13.1 | 1.13 | 1.13 | 0.00 |

| B3-NH3 | 13.0 | 1.21 | 1.13 | 0.08 |

| B1-air | 17.2 | 1.00 | 0.87 | 0.13 |

| B2-air | 16.0 | 1.13 | 0.96 | 0.17 |

| B3-air | 14.7 | 1.21 | 1.05 | 0.16 |

| B1-NH3 | B1-Air | B2-NH3 | B2-Air | B3-NH3 | B3-Air | |

|---|---|---|---|---|---|---|

| BET surface area, m2/g | 671 | 739 | 659 | 718 | 690 | 697 |

| total pore volume, cm3/g | 0.45 | 0.41 | 0.74 | 0.66 | 0.80 | 0.58 |

| micropore volume *, cm3/g | 0.17 | 0.23 | 0.17 | 0.21 | 0.23 | 0.24 |

| external surface area *, m2/g | 265 | 176 | 254 | 206 | 136 | 110 |

| d3-Acetonitrile (mmol/g) | Pyridine (mmol/g) | |||

|---|---|---|---|---|

| Sample | Brønsted | Lewis | Brønsted | Lewis |

| B1-NH3 | 0.24 | 0.42 | 0.34 | 0.23 |

| B2-NH3 | 0.25 | 0.46 | 0.34 | 0.21 |

| B3-NH3 | 0.32 | 0.57 | 0.40 | 0.14 |

| B1-air | 0.35 | 0.42 | 0.44 | 0.31 |

| B2-air | 0.37 | 0.44 | 0.40 | 0.21 |

| B3-air | 0.46 | 0.41 | 0.51 | 0.18 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mlekodaj, K.; Olszowka, J.E.; Tokarova, V.; Tabor, E.; Kasparek, A.; Novakova, J.; Stavova, G.; Gonsiorova, O.; Peliskova, L.; Brus, J.; et al. Effect of Alkali-Free Synthesis and Post-Synthetic Treatment on Acid Sites in Beta Zeolites. Molecules 2020, 25, 3434. https://doi.org/10.3390/molecules25153434

Mlekodaj K, Olszowka JE, Tokarova V, Tabor E, Kasparek A, Novakova J, Stavova G, Gonsiorova O, Peliskova L, Brus J, et al. Effect of Alkali-Free Synthesis and Post-Synthetic Treatment on Acid Sites in Beta Zeolites. Molecules. 2020; 25(15):3434. https://doi.org/10.3390/molecules25153434

Chicago/Turabian StyleMlekodaj, Kinga, Joanna E. Olszowka, Venceslava Tokarova, Edyta Tabor, Ales Kasparek, Jana Novakova, Gabriela Stavova, Olga Gonsiorova, Lenka Peliskova, Jiri Brus, and et al. 2020. "Effect of Alkali-Free Synthesis and Post-Synthetic Treatment on Acid Sites in Beta Zeolites" Molecules 25, no. 15: 3434. https://doi.org/10.3390/molecules25153434

APA StyleMlekodaj, K., Olszowka, J. E., Tokarova, V., Tabor, E., Kasparek, A., Novakova, J., Stavova, G., Gonsiorova, O., Peliskova, L., Brus, J., Pilar, R., Klein, P., & Dedecek, J. (2020). Effect of Alkali-Free Synthesis and Post-Synthetic Treatment on Acid Sites in Beta Zeolites. Molecules, 25(15), 3434. https://doi.org/10.3390/molecules25153434