Fabrication and Characterization of Microcellular Polyurethane Sisal Biocomposites

Abstract

:1. Introduction

2. Results and Discussion

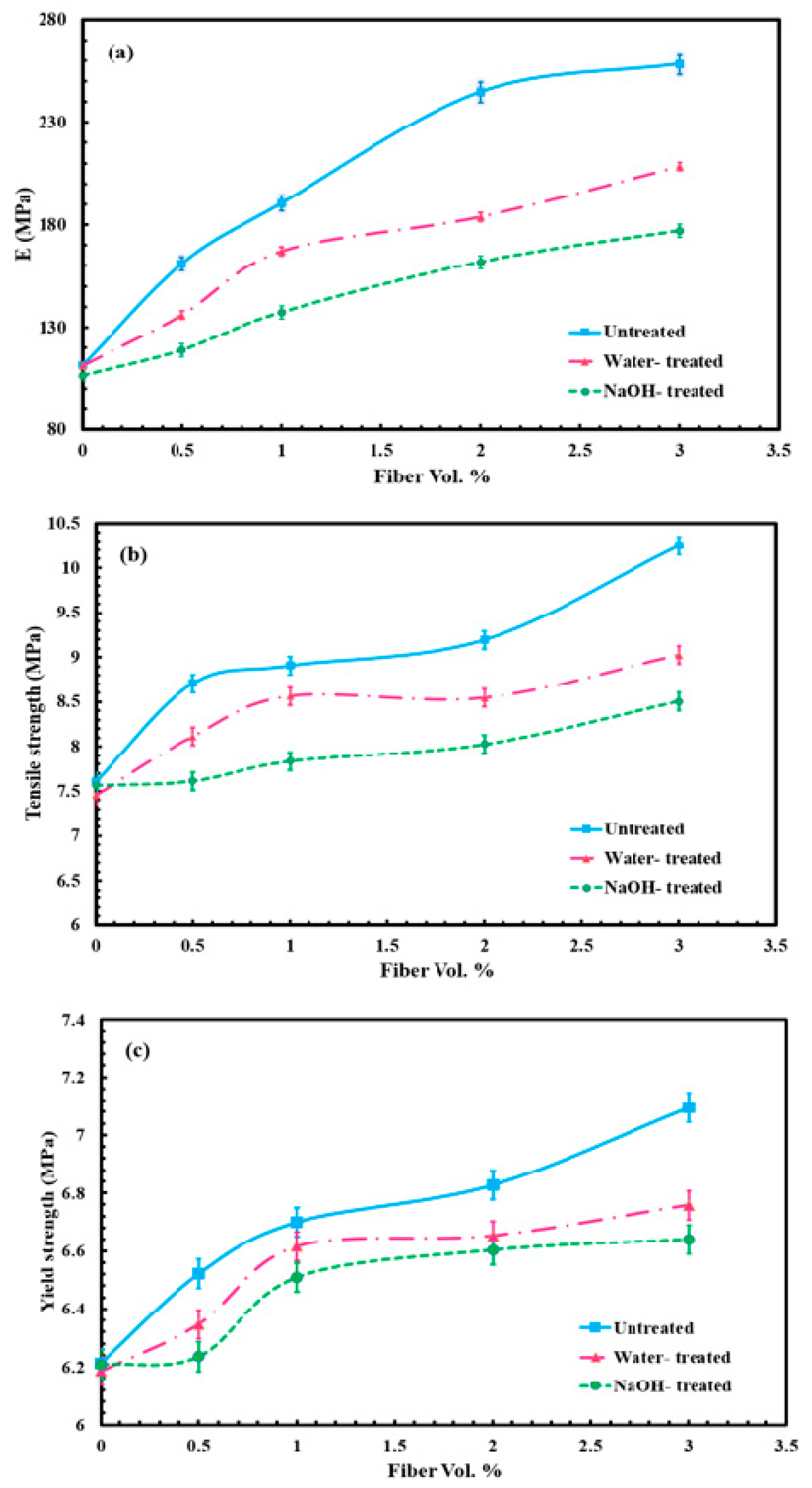

2.1. Tensile Test

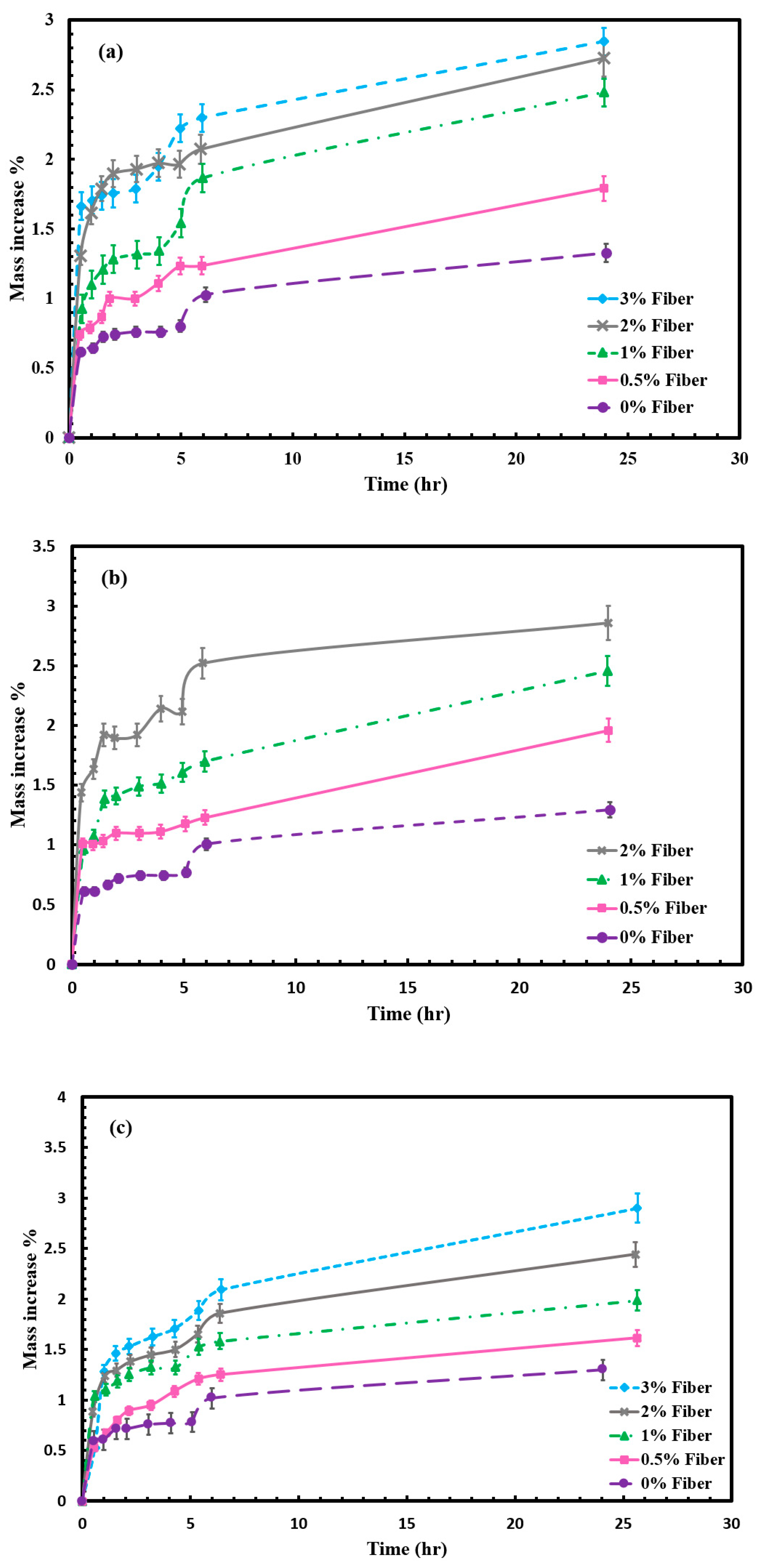

2.2. Water Uptake

2.3. SEM

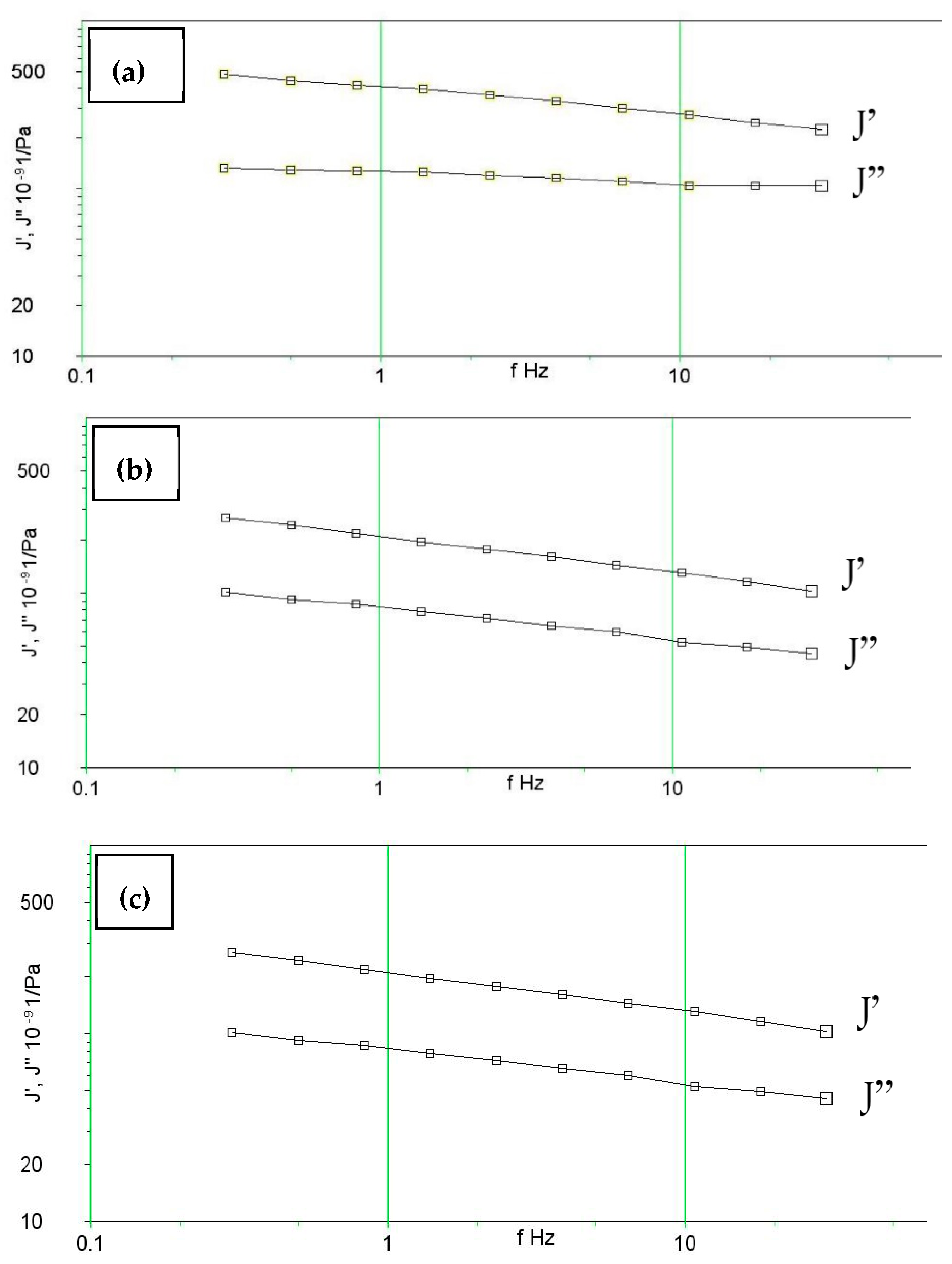

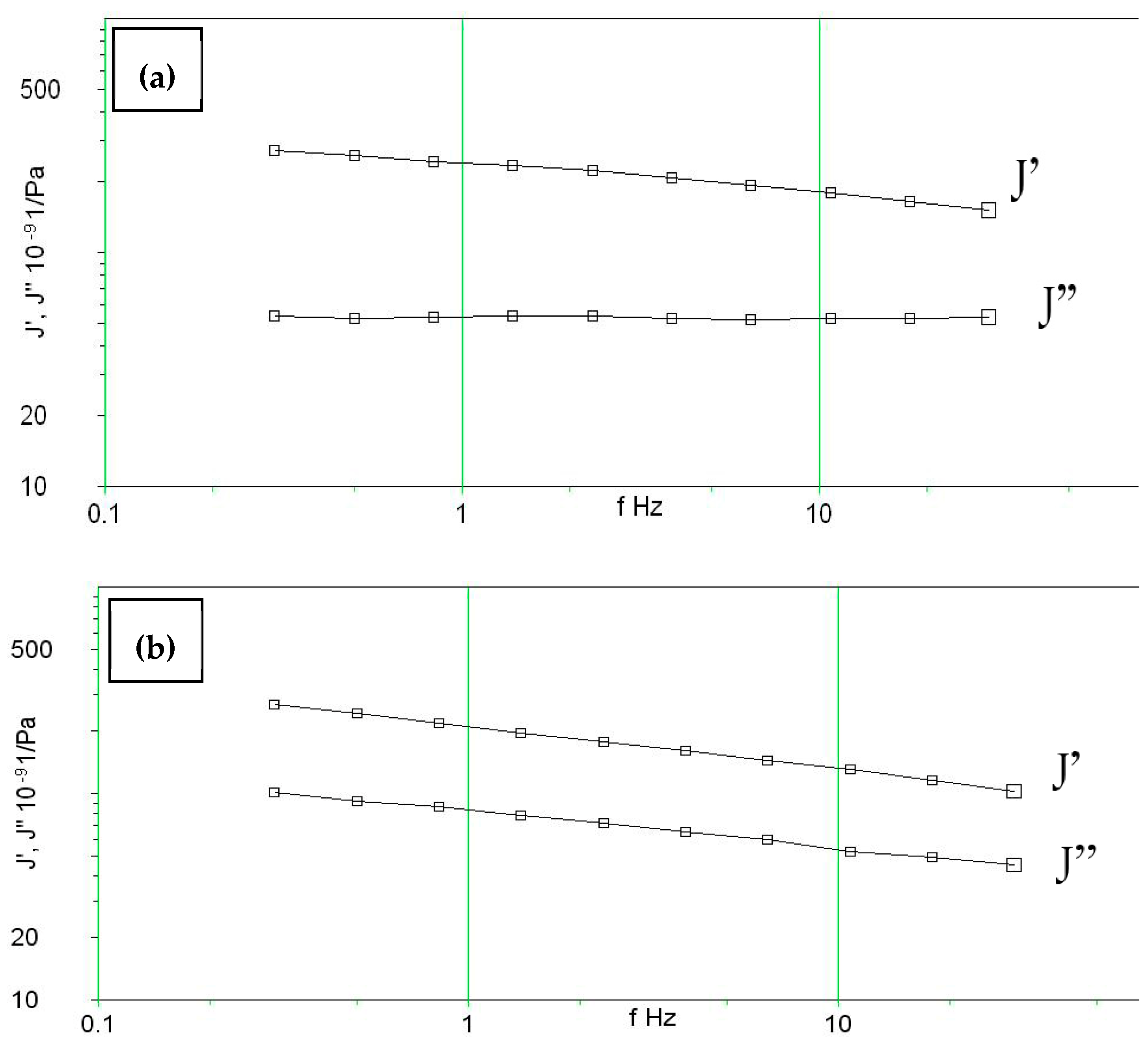

2.4. Viscoleasticity

3. Materials and Methods

3.1. Materials

3.2. Mold Preparation

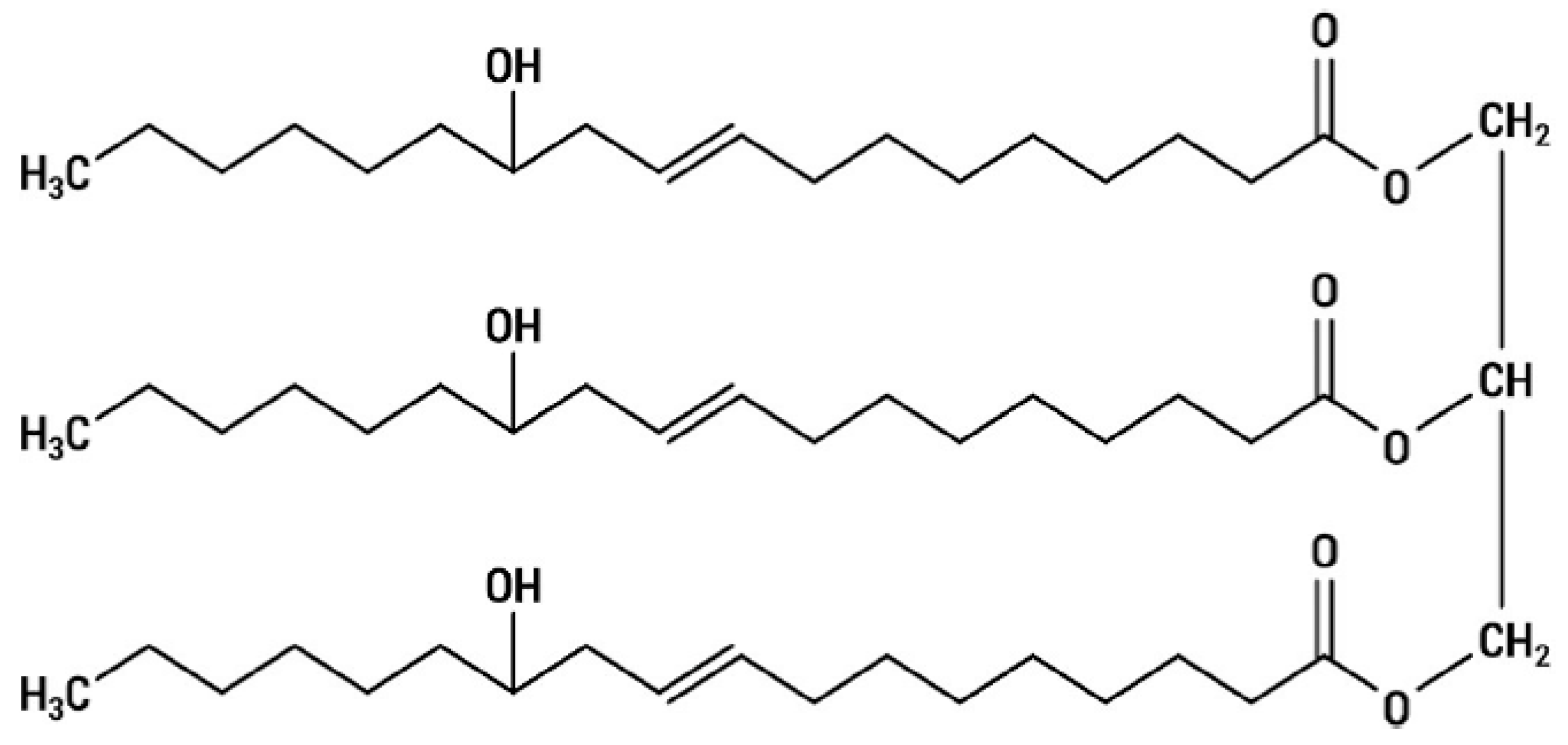

3.3. Castor Oil Treatment

3.4. Sisal Treatment

3.5. Synthesis of Biocomposites

4. Tests

4.1. Tensile Test

4.2. Water Uptake Test

4.3. Viscoelasticity Test

4.4. Scanning Electron Microscopy (SEM)

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Oushabi, A.; Sair, S.; Hassani, F.O.; Abboud, Y.; Tanane, O.; El Bouari, A. The effect of alkali treatment on mechanical, morphological and thermal properties of date palm fibers (DPFs): Study of the interface of DPF–Polyurethane composite. S. Afr. J. Chem. Eng. 2017, 23, 116–123. [Google Scholar] [CrossRef]

- De Carvalho Bello, C.B.; Boem, I.; Cecchi, A.; Gattesco, N.; Oliveira, D.V. Experimental tests for the characterization of sisal fiber reinforced cementitious matrix for strengthening masonry structures. Constr. Build. Mater. 2019, 219, 44–55. [Google Scholar] [CrossRef] [Green Version]

- Devaraju, A.; Sivasamy, P. Comparative Analysis of Mechanical Characteristics of Sisal Fibre Composite with and without Nano Particles. Mater. Today Proc. 2018, 5, 14362–14366. [Google Scholar] [CrossRef]

- Haldar, P.; Modak, N.; Sutradhar, G. Comparative evaluation of mechanical properties of sisal-epoxy composites with and without addition of aluminium powder. Mater. Today Proc. 2017, 4, 3397–3406. [Google Scholar] [CrossRef]

- Bassyouni, M.; Sherif, S.A.; Sadek, M.; Ashour, F. Synthesis and characterization of polyurethane–treated waste milled light bulbs composites. Compos. Part B Eng. 2012, 43, 1439–1444. [Google Scholar] [CrossRef]

- Milanese, A.C.; Cioffi, M.O.H.; Voorwald, H.J.C. Mechanical behavior of natural fiber composites. Procedia Eng. 2011, 10, 2022–2027. [Google Scholar] [CrossRef] [Green Version]

- Naveen, J.; Jawaid, M.; Amuthakkannan, P.; Chandrasekar, M. Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 427–440. [Google Scholar]

- Otto, G.P.; Moisés, M.P.; Carvalho, G.; Rinaldi, A.W.; Garcia, J.C.; Radovanovic, E.; Fávaro, S.L. Mechanical properties of a polyurethane hybrid composite with natural lignocellulosic fibers. Compos. Part B Eng. 2017, 110, 459–465. [Google Scholar] [CrossRef]

- Pappu, A.; Pickering, K.L.; Thakur, V.K. Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as reinforcement of poly (lactic acid) via injection moulding. Ind. Crop. Prod. 2019, 137, 260–269. [Google Scholar] [CrossRef]

- Ramakrishna, G.; Sundararajan, T. Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 211–255. [Google Scholar]

- Ramalingam, S.; Murugasan, R.; Nagabhushana, M. Laboratory performance evaluation of environmentally sustainable sisal fibre reinforced bituminous mixes. Constr. Build. Mater. 2017, 148, 22–29. [Google Scholar] [CrossRef]

- Ramzy, A.; Beermann, D.; Steuernagel, L.; Meiners, D.; Ziegmann, G. Developing a new generation of sisal composite fibres for use in industrial applications. Compos. Part B Eng. 2014, 66, 287–298. [Google Scholar] [CrossRef]

- Rojas, M.F.; Miranda, L.P.; Ramirez, A.M.; Quintero, K.P.; Bernard, F.; Einloft, S.; Díaz, L.A.C. New biocomposites based on castor oil polyurethane foams and ionic liquids for CO2 capture. Fluid Phase Equilibria 2017, 452, 103–112. [Google Scholar] [CrossRef]

- Sair, S.; Oushabi, A.; Kammouni, A.; Tanane, O.; Abboud, Y.; El Bouari, A. Mechanical and thermal conductivity properties of hemp fiber reinforced polyurethane composites. Case Stud. Constr. Mater. 2018, 8, 203–212. [Google Scholar] [CrossRef]

- Bassyouni, M.; Hasan, S.W.U. Biofiber Reinforcements in Composite Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 385–422. [Google Scholar]

- Bassyouni, M.; Gutub, S.A. Materials selection strategy and surface treatment of polymer composites for wind turbine blades fabrication. Polym. Polym. Compos. 2013, 21, 463–472. [Google Scholar] [CrossRef]

- Dominici, F.; García García, D.; Fombuena, V.; Luzi, F.; Puglia, D.; Torre, L.; Balart, R. Bio-Polyethylene-Based Composites Reinforced with Alkali and Palmitoyl Chloride-Treated Coffee Silverskin. Molecules 2019, 24, 3113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fiore, V.; Scalici, T.; Valenza, A. Effect of sodium bicarbonate treatment on mechanical properties of flax-reinforced epoxy composite materials. J. Compos. Mater. 2018, 52, 1061–1072. [Google Scholar] [CrossRef]

- Pierre, F.; Avérous, L. Renewable polyols for advanced polyurethane foams from diverse biomass resources. Polym. Chem. 2018, 9, 4258–4287. [Google Scholar]

- Wang, F.; Lu, M.; Zhou, S.; Lu, Z.; Ran, S. Effect of Fiber Surface Modification on the Interfacial Adhesion and Thermo-Mechanical Performance of Unidirectional Epoxy-Based Composites Reinforced with Bamboo Fibers. Molecules 2019, 24, 2682. [Google Scholar] [CrossRef] [Green Version]

- Mazur, K.; Kuciel, S. Mechanical and Hydrothermal Aging Behaviour of Polyhydroxybutyrate-Co-Valerate (PHBV) Composites Reinforced by Natural Fibres. Molecules 2019, 24, 3538. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Chen, T.; Fei, M.E.; Qiu, R.; Yu, D.; Fu, T.; Qiu, J. Properties of natural fiber-reinforced biobased thermoset biocomposites: Effects of fiber type and resin composition. Compos. Part B Eng. 2019, 171, 87–95. [Google Scholar] [CrossRef]

- Trovati, G.; Suman, M.V.N.; Sanches, E.A.; Campelo, P.H.; Neto, R.B.; Neto, S.C.; Trovati, L.R. Production and characterization of polyurethane castor oil (Ricinus communis) foam for nautical fender. Polym. Test. 2019, 73, 87–93. [Google Scholar] [CrossRef]

- Carriço, C.S.; Fraga, T.; Pasa, V.M. Production and characterization of polyurethane foams from a simple mixture of castor oil, crude glycerol and untreated lignin as bio-based polyols. Eur. Polym. J. 2016, 85, 53–61. [Google Scholar] [CrossRef]

- Cardoso, G.T.; Neto, S.C.; Vecchia, F. Rigid foam polyurethane (PU) derived from castor oil (Ricinus communis) for thermal insulation in roof systems. Front. Archit. Res. 2012, 1, 348–356. [Google Scholar] [CrossRef] [Green Version]

- Członka, S.; Bertino, M.F.; Strzelec, K.; Strąkowska, A.; Masłowski, M. Rigid polyurethane foams reinforced with solid waste generated in leather industry. Polym. Test. 2018, 69, 225–237. [Google Scholar] [CrossRef]

- Agrawal, A.; Kaur, R.; Walia, R. PU foam derived from renewable sources: Perspective on properties enhancement: An overview. Eur. Polym. J. 2017, 95, 255–274. [Google Scholar] [CrossRef]

- Hejna, A.; Kirpluks, M.; Kosmela, P.; Cabulis, U.; Haponiuk, J.; Piszczyk, Ł. The influence of crude glycerol and castor oil-based polyol on the structure and performance of rigid polyurethane-polyisocyanurate foams. Ind. Crop. Prod. 2017, 95, 113–125. [Google Scholar] [CrossRef]

- Zhang, M.; Pan, H.; Zhang, L.; Hu, L.; Zhou, Y. Study of the mechanical, thermal properties and flame retardancy of rigid polyurethane foams prepared from modified castor-oil-based polyols. Ind. Crop. Prod. 2014, 59, 135–143. [Google Scholar] [CrossRef]

- Ionescu, M.; Radojčić, D.; Wan, X.; Shrestha, M.L.; Petrović, Z.S.; Upshaw, T.A. Highly functional polyols from castor oil for rigid polyurethanes. Eur. Polym. J. 2016, 84, 736–749. [Google Scholar] [CrossRef] [Green Version]

- Bassyouni, M. Dynamic mechanical properties and characterization of chemically treated sisal fiber-reinforced polypropylene biocomposites. J. Reinf. Plast. Compos. 2018, 37, 1402–1417. [Google Scholar] [CrossRef]

- Lagazzo, A.; Moliner, C.; Bosio, B.; Botter, R.; Arato, E. Evaluation of the Mechanical and Thermal Properties Decay of PHBV/Sisal and PLA/Sisal Biocomposites at Different Recycle Steps. Polymers 2019, 11, 1477. [Google Scholar] [CrossRef] [Green Version]

- Aliotta, L.; Gigante, V.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A.; Seggiani, M. Thermo-Mechanical Properties of PLA/Short Flax Fiber Biocomposites. Appl. Sci. 2019, 9, 3797. [Google Scholar] [CrossRef] [Green Version]

- Lei, B.; Liang, Y.; Feng, Y.; He, H.; Yang, Z. Preparation and Characteristics of Biocomposites Based on Steam Exploded Sisal Fiber Modified with Amphipathic Epoxidized Soybean Oil Resin. Materials 2018, 11, 1731. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- de Melo, K.M.; dos Santos, T.F.; da Silva Santos, C.M.; da Fonseca, R.T.; de Lucena, N.D.; de Medeiros, J.I.; de Aquino, M.S. Study of the reuse potential of the sisal fibers powder as a particulate material in polymer composites. J. Mater. Res. Technol. 2019, 8, 4019–4025. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Rajini, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S.; Alotman, O.Y. Mechanical properties evaluation of sisal fibre reinforced polymer composites: A review. Constr. Build. Mater. 2018, 174, 713–729. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- da Silva, C.C.B.; Terashima, F.J.H.; Barbieri, N.; de Lima, K.F. Sound absorption coefficient assessment of sisal, coconut husk and sugar cane fibers for low frequencies based on three different methods. Appl. Acoust. 2019, 156, 92–100. [Google Scholar] [CrossRef]

- de Souza Castoldi, R.; de Souza, L.M.S.; de Andrade Silva, F. Comparative study on the mechanical behavior and durability of polypropylene and sisal fiber reinforced concretes. Constr. Build. Mater. 2019, 211, 617–628. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Hariharan, V.; Scalici, T. Effect of NaOH treatment on properties of Phoenix Sp. fiber. J. Nat. Fibers 2016, 13, 702–713. [Google Scholar]

- Girijappa, Y.G.T.; Rangappa, S.M.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Wu, Y.; Xia, C.; Cai, L.; Garcia, A.C.; Shi, S.Q. Development of natural fiber-reinforced composite with comparable mechanical properties and reduced energy consumption and environmental impacts for replacing automotive glass-fiber sheet molding compound. J. Clean. Prod. 2018, 184, 92–100. [Google Scholar] [CrossRef]

- Sood, M.; Dwivedi, G. Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egypt. J. Pet. 2018, 27, 775–783. [Google Scholar] [CrossRef]

- Lin, J.; Yang, Z.; Hu, X.; Hong, G.; Zhang, S.; Song, W. The effect of alkali treatment on properties of dopamine modification of bamboo fiber/polylactic acid composites. Polymers 2018, 10, 403. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, F.; Zhou, S.; Yang, M.; Chen, Z.; Ran, S. Thermo-Mechanical Performance of Polylactide Composites Reinforced with Alkali-Treated Bamboo Fibers. Polymers 2018, 10, 401. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El-Sabbagh, A. Effect of coupling agent on natural fibre in natural fibre/polypropylene composites on mechanical and thermal behaviour. Compos. Part B Eng. 2014, 57, 126–135. [Google Scholar] [CrossRef]

- Bassyouni, M.; Taha, I.; Abdel-Hamid, S.M.S.; Steuernagel, L. Physico-mechanical properties of chemically treated polypropylene rice straw bio-composites. J. Reinf. Plast. Compos. 2012, 31, 303–312. [Google Scholar] [CrossRef] [Green Version]

Sample Availability: Samples of the compounds Microcellular Polyurethane Sisal Biocomposites available from the authors. |

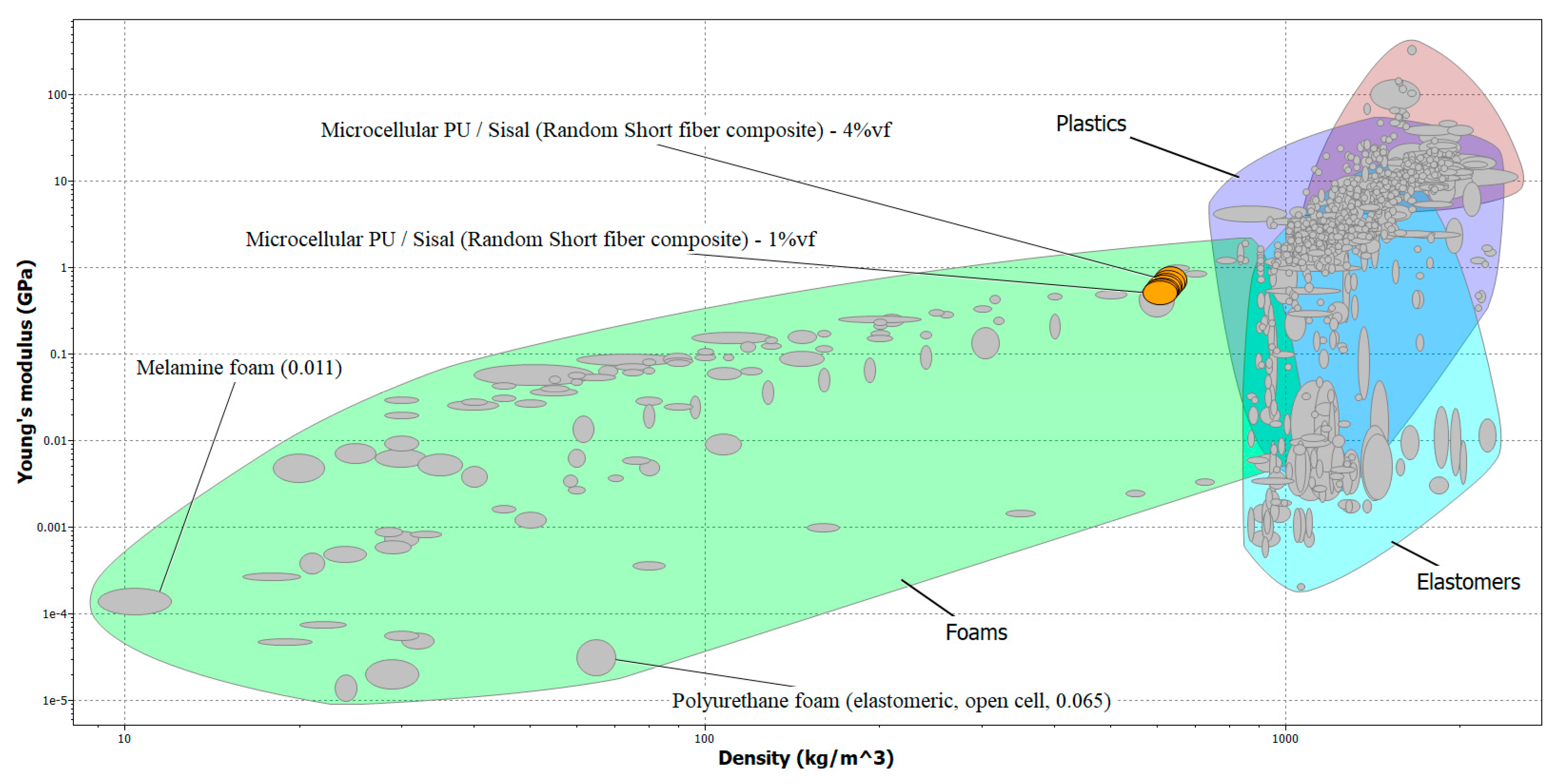

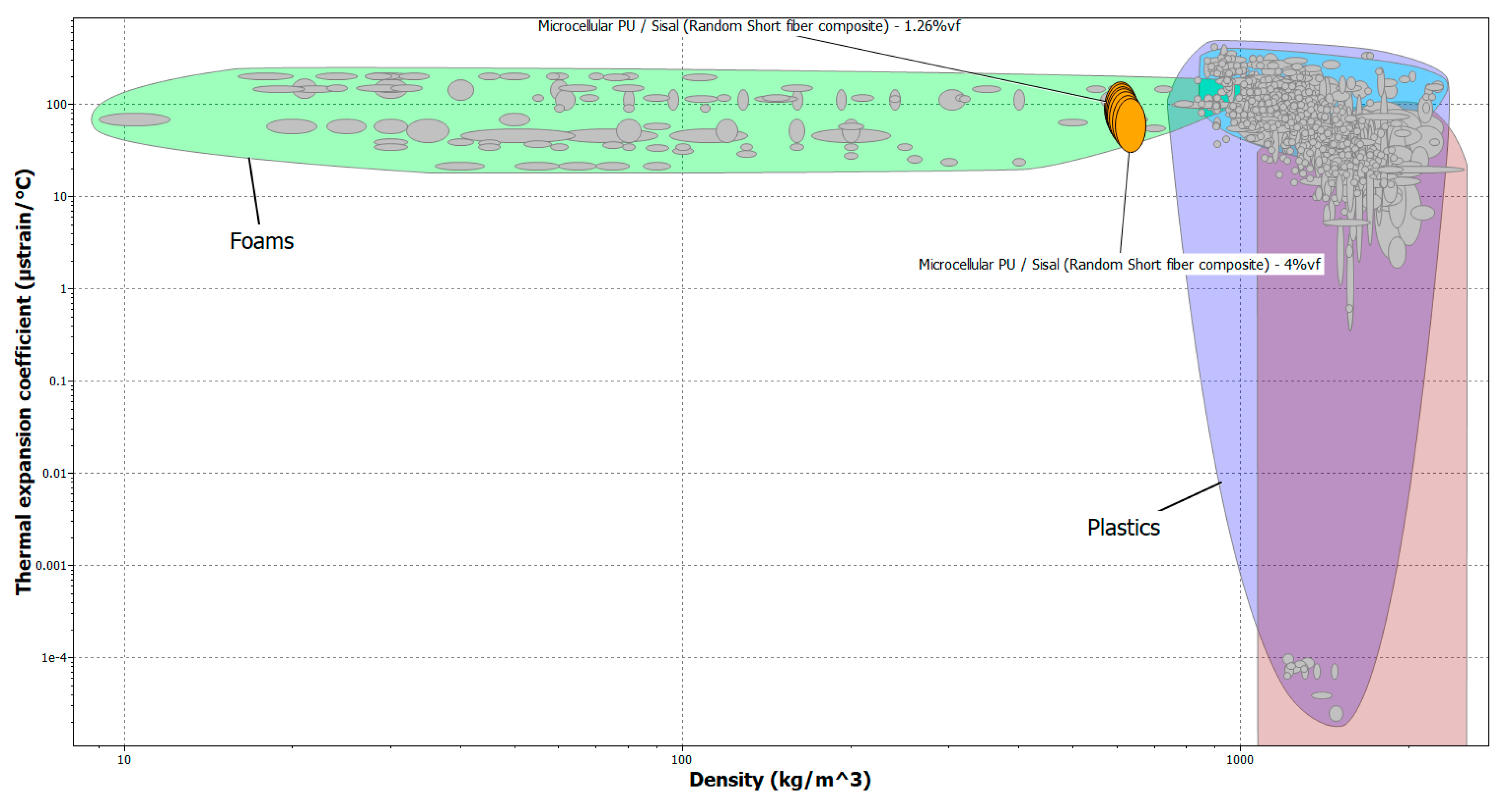

| M-C PU/Sisal (Random Short Fiber Composite) 1%vf | M-C PU/Sisal (Random Short Fiber Composite) 1.26%vf | M-C PU/Sisal (Random Short Fiber Composite) 1.59%vf | M-C PU/Sisal (Random Short Fiber Composite) 2%vf | M-C PU/Sisal (Random Short Fiber Composite) 2.52%vf | M-C PU/Sisal (Random Short Fiber Composite) 3.17%vf | M-C PU/Sisal (Random Short Fiber Composite) 4%vf | M-C PU | |

|---|---|---|---|---|---|---|---|---|

| Density (kg/m3) | 607 | 610 | 613 | 616 | 621 | 626 | 634 | 599 |

| Young’s modulus (GPa) | 0.521 | 0.539 | 0.562 | 0.59 | 0.626 | 0.67 | 0.726 | 0.43 |

| Yield strength (elastic limit) (MPa) | 6.7 | 7.09 | 7.59 | 8.21 | 8.99 | 9.96 | 11.2 | 5.1 |

| Thermal expansion coefficient (µstrain/°C) | 90.5 | 86.1 | 81.4 | 76.3 | 70.9 | 65.4 | 60 | 114 |

| Chemical Composition | |

| Cellulose (%) | 41.6–62.6 |

| Hemi cellulose (%) | 9.2–14.6 |

| Lignin (%) | 11.4–19.5 |

| Mechanical Properties | |

| Young’s modulus (GPa) | 9.4–22 |

| Yield strength (elastic limit) (GPa) | 460–576 |

| Tensile strength (MPa) | 511–640 |

| Elongation strain (%) | 2–7 |

| Flexural modulus (GPa) | 9.4–22 |

| Fatigue strength at 107 cycles (MPa) | 220–316 |

| Mechanical loss coefficient (tan delta) | 0.00407–0.00753 |

| Thermal Properties | |

| Glass temperature (°C) | 380–390 |

| Maximum service temperature (°C) | 400–420 |

| Thermal conductivity (W/m °C) | 0.25–0.35 |

| Specific heat capacity (J/Kg °C) | 1.2 ×10 3- 1.22×103 |

| Absorption & Permeability | |

| Water absorption @ 24 h (%) | 2–2.4 |

| Durability | |

| Water (salt) | Excellent |

| Weak acids | Acceptable |

| Weak alkalis | Acceptable |

| Organic solvents | Acceptable |

| UV radiation (sunlight) | Good |

| Physical Properties | |

| Density (kg/m3) | 1410 |

| Fiber diameter(µm) | 145–440 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdel-Hamid, S.M.S.; Al-Qabandi, O.A.; N.A.S., E.; Bassyouni, M.; Zoromba, M.S.; Abdel-Aziz, M.H.; Mira, H.; Y., E. Fabrication and Characterization of Microcellular Polyurethane Sisal Biocomposites. Molecules 2019, 24, 4585. https://doi.org/10.3390/molecules24244585

Abdel-Hamid SMS, Al-Qabandi OA, N.A.S. E, Bassyouni M, Zoromba MS, Abdel-Aziz MH, Mira H, Y. E. Fabrication and Characterization of Microcellular Polyurethane Sisal Biocomposites. Molecules. 2019; 24(24):4585. https://doi.org/10.3390/molecules24244585

Chicago/Turabian StyleAbdel-Hamid, S.M.S., O.A. Al-Qabandi, Elminshawy. N.A.S., M. Bassyouni, M.S. Zoromba, M.H. Abdel-Aziz, H. Mira, and Elhenawy Y. 2019. "Fabrication and Characterization of Microcellular Polyurethane Sisal Biocomposites" Molecules 24, no. 24: 4585. https://doi.org/10.3390/molecules24244585

APA StyleAbdel-Hamid, S. M. S., Al-Qabandi, O. A., N.A.S., E., Bassyouni, M., Zoromba, M. S., Abdel-Aziz, M. H., Mira, H., & Y., E. (2019). Fabrication and Characterization of Microcellular Polyurethane Sisal Biocomposites. Molecules, 24(24), 4585. https://doi.org/10.3390/molecules24244585